3D printer tool box

Toolbox best 3D printing files・Cults

brass knuckles box

€5

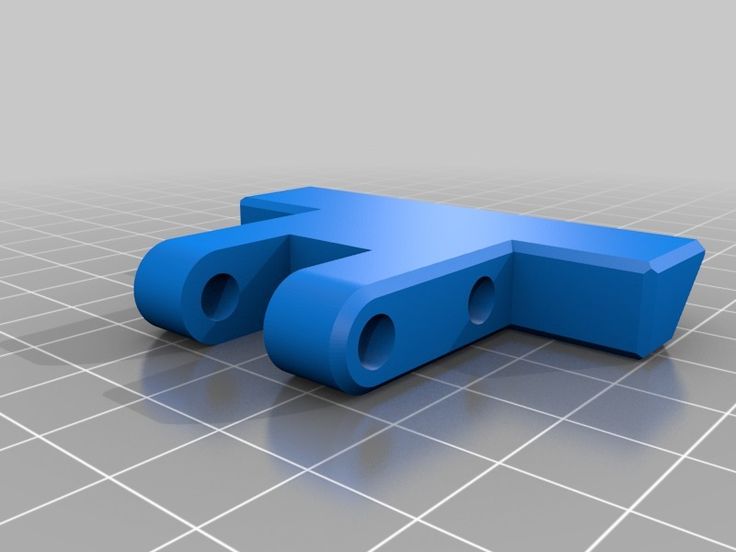

Kobalt Toolbox Latch Thing

Free

soccer ball pen holder

Free

Toolbox Wrench Rack

Free

Nintendo switch cartridge holder (Nes)

€6.50

1/10 TOOL CHEST

€5.53

House Storage toolbox organizer

€3.76

Ender 6 toolbox V.3

€2.14

Box for Robox cleaning tools

Free

Label Storage box action

Free

Toolbox

Free

Truck step toolbox

€10

Tool Case

Free

1/10 scale rc truck tool box.

€4.12

Tetrapod pen holder

Free

TOOL TROLLEY

€3.20

Stuffing Gland spanner (25mm and 20mm)

€0.69

Pill Bottle

€0.94

C clamp

€0.94

Drill Holder

€0.94

Trailer Tongue Box

€1.04

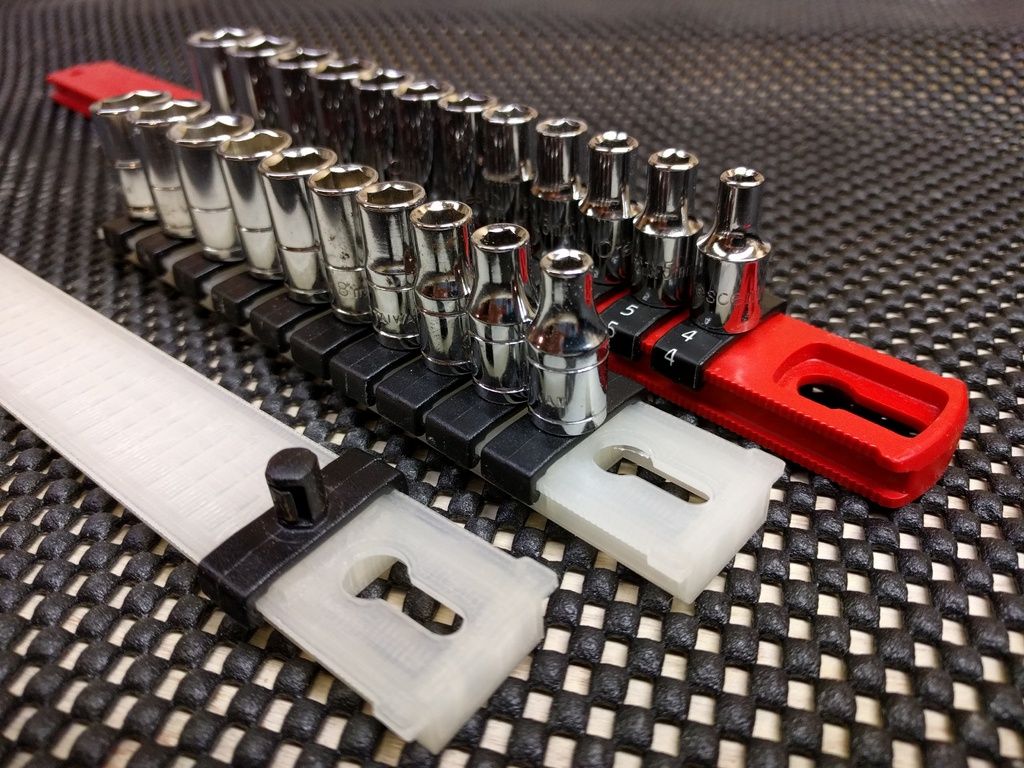

Metric - Drill, Tap, and Thread Tool Holder

Free

Slotted Groove Trays (Toolbox Drawer Organizer)

Free

TAPPING TAPS BOX

€1

Petromax Toolset box

Free

Simson S51 S50 tool compartment / tool box / box / storage compartment / storage space / drawer

€4. 99

99

Facom inlay - hinged socket wrench 66a.1

Free

Tamiya 1850l chassis accessories

Free

Toolbox system for systainer and wallmount

Free

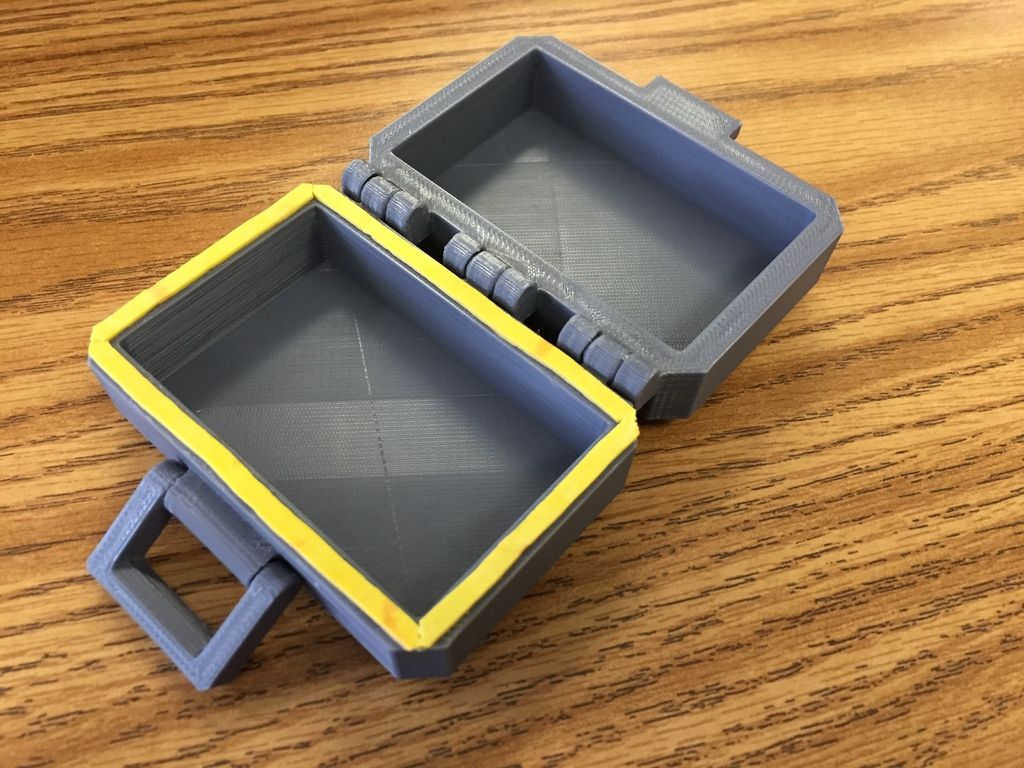

Box for components

Free

Cerniere e chiusura per cassetta degli attrezzi (Hinges and latches to toolbox)

Free

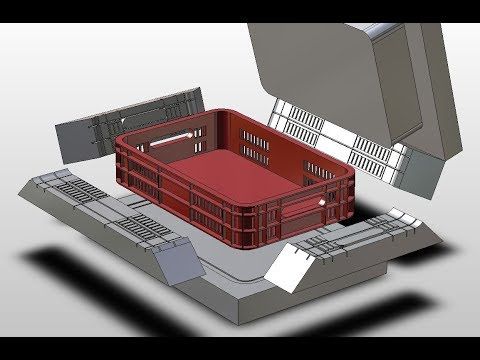

Plastic crate

€0.57

Saint Bernard dog head tools box

Free

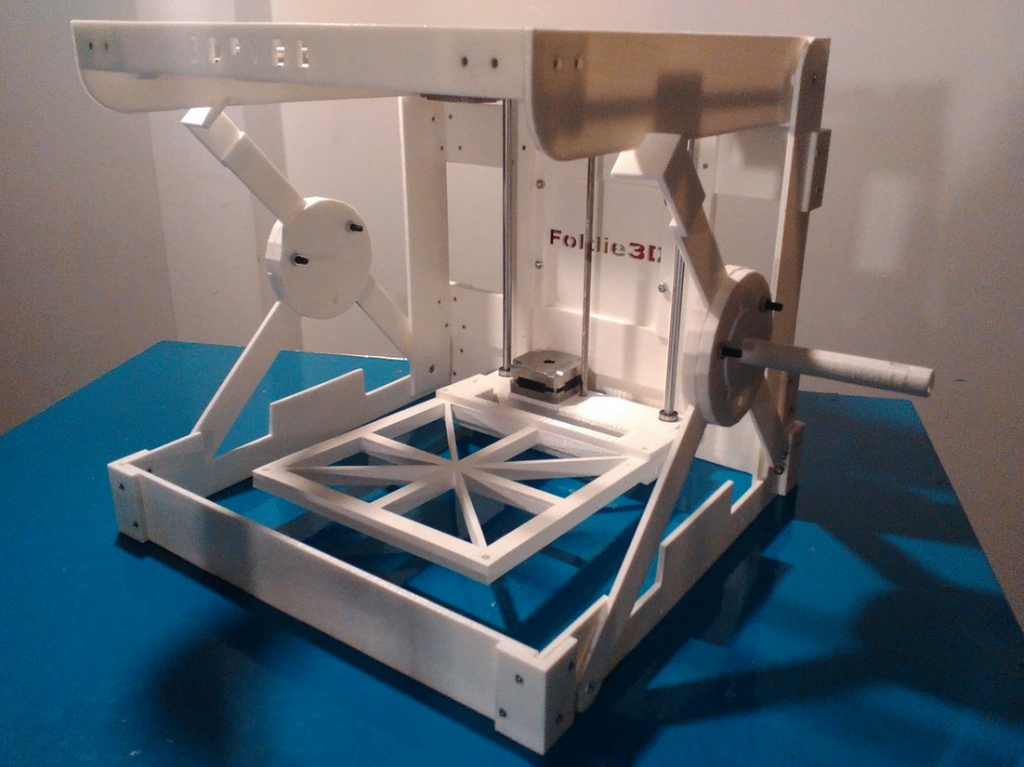

Multi config 3D printer toolbox

Free

screwdriver bit holder

€1

Ultimate Toolbox

Free

Toolbox Print in Place

€1. 20

20

Stackable Toolbox and organizer for switches and keyboard parts

€4.71

Toolbox

€1

Battery Box - AA LR6 & AAA LR3 - 6 Versions

Free

Objects 13 pieces: crate, wall, fuel barrel, first aid kit, toxic puddle, gas cylinders, teleporter, toolbox, trees, swamp monster, rocks, rock.

Free

Toolbox For Kids!

€1.34

Screwdriver bit holder 10 holes

Free

Tool box

Free

LED CONTROLLER Stand

Free

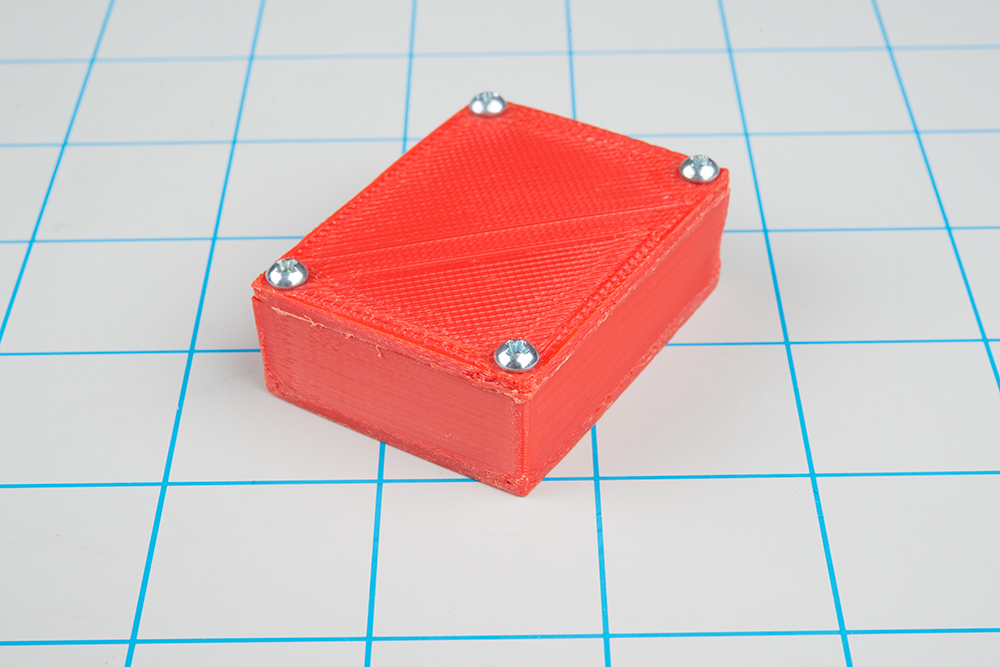

3D Printing toolbox

€1.90

CR10 smart / smart pro Caja Organizadora de Herramientas

€1. 08

08

DeWalt battery caddy

€1.41

3D Print Toolbox — Blender Manual

Reference

- Category

Mesh

- Description

Utilities for 3D printing.

- Location

3D Viewport ‣ Sidebar

- File

object_print3d_utils folder

- Author

Campbell Barton

Installation

This add-on is bundled with Blender.

Open Blender and go to Preferences, then the Add-ons tab.

Click Mesh then 3D Print Toolbox to enable the script.

Description

Blender can be used to created meshes for 3D printing. Meshes exported from Blender are usually imported into a piece of software takes the mesh and “slices” it into paths that the 3D printer can execute. An example of such Slicer software is Cura.

In order to correctly slice a mesh, it needs to be “watertight”, meaning that the surface is closed everywhere. Additionally, there should be no edges or faces sticking out. 3D Print Toolbox helps you analyze problems in your mesh that could cause slicing issues.

Additionally, there should be no edges or faces sticking out. 3D Print Toolbox helps you analyze problems in your mesh that could cause slicing issues.

It can be found in 3D Viewport ‣ Sidebar ‣ 3D-Print, when a mesh is selected.

Analyze

Statistics

By clicking either Volume or Area, the volume or area of the mesh is calculated and shown.

Checks

The Checks panel.

A number of different checks can be performed to analyze in which ways your mesh might be invalid for use with a Slicer.

Upon execution of one of the checks, the Result field shows which, if any, parts of your mesh are invalid.

When in Edit Mode, clicking these results selects these parts of your mesh. You can use View Selected Backslash to focus on these parts.

Although Slicers are becoming increasingly tolerant when it comes to “tidiness” of meshes, it is always worth trying to provide as clean a mesh as possible.

- Solid

Checks for Non-Manifold edges and Bad Contiguous edges.

Edges should connect to exactly 2 faces. In it connects to only one, it means there’s a hole in the mesh. More is also not allowed. These edges are considered Non-manifold. If one of the faces’ normals is pointing in a different direction than its neighbors, its edges are marked as “Bad Contiguous”.

In this screenshot, the left shape has a hole, and the right shape has one of its faces flipped.

Left, marked in blue: Non-manifold edges. Right, marked in red: Bad contiguous edges.

- Intersections

These two cubes have intersecting faces. A Boolean modifier would help in this example. It’s worth noting that some slicer applications can deal with this, so it’s not always required to resolve this issue.

- Degenerate

Faces and edges which have 0 area or length, are considered degenerate. In this example, the top face of a cube has been scaled down to 0, but have not been merged.

A Merge ‣ By Distance would resolve this issue.

A Merge ‣ By Distance would resolve this issue.There’s a hidden face here.

- Distorted

The vertices of a quad or ngon can be folded in such a way that the face is not flat. In practice, quads are rarely ever flat. When exporting, these faces are converted to triangles. If the surface is excessively deformed, this can result in unexpected shapes.

In this example, a quad has been folded into a saddle-like shape. This triggers the Distorted check. It would be best to triangulate by hand here.

This quad can triangulate in unexpected ways.

- Thickness

Faces that form very thin geometry might be missed entirely by the slicer. Such faces are marked as Thin.

- Edge Sharp

Similar to Thickness, sharp edges can thin pieces of geometry which might be missed by the slicer

- Overhang

As 3D printers can’t print in mid-air, parts of the model which overhang will not print correctly.

In practice, slicers can add additional material, support, to anticipate for overhanging layers.

In practice, slicers can add additional material, support, to anticipate for overhanging layers.- Check All

Performs all of the above checks at once. In this example, Suzanne shows quite a few problems. This is because the eyes are separate parts, and the sockets have holes. This makes the mesh not Solid and Intersecting. Some of the faces are Distorted.

Clean Up

- Distorted

Triangulates the faces which are considered Distorted, as explained above.

- Make Manifold

Attempts to fix various problems which might make a mesh non-manifold, such as by fixing bad normals, filling holes, and removing empty edges and faces.

Transform

Scale To

- Volume

Scales the model to an exact given volume.

- Bounds

Scales the model so that the biggest axis of the objects bounds (or dimensions) match the given value.

Export

Provides quick access to Blender’s object exporting operators found in File ‣ Export.

STL file 3D printer toolbox・3D printed design for download・Cults

Vase with twisted star

1.18 €

Mini Shovels For Toy Trucks

0.61 €

AliShanMao's Ultimate 3D Printed Toothpaste dispenser and Holder

1.88 €

Tea Time Candle Romantic Light Shade

0.94 €

Landing skid for AR Wing FPV flying wings

1.18 €

Insta360 Go Angle Adjustable Mount for BetaFPV 95X V2 CineWhoop

1.87 €

PS4 Controller Holder

0.61 €

Rambler RS Hand Launch Assist Finger supports

1. 18 €

18 €

The best files for 3D printers in the Tools category

Gardena 330 mower plug

Free

Star Trek: The Next Generation inspired Enhancement module

Free

Crazy Proxxon CNC

Free

nine0003 PCB HOLDER EvoFree

Clamp with low-poly inlay \ dual extruder

Free

SMOKE TRAP(MASON JAR BONG)

Free

COVID-19 Mask Cap, Animal Crossing Apollo Edition

Free

Nerf Blaster Flintlock Musket (Files only, V2-2)

13.51 €

Bestsellers in the Tools category

Quick Print Paint Bottle Rack (6 sizes)

2. 87 €

87 €

Ender 3 Briss fang Gen2, red lizard, spider, nf crazy, dragonfly, etc.

1.73 €

Ender 3 S1 pro fan duct 5015 4020

1.30 €

ENDER 3 S1, S1 PRO, SPRITE, HOT END DUCT 4020 OR 5015 FAN, PROBE NO Y OFFSET

€2.29 -twenty% 1.83 €

ENDER 3 S1/S1 PRO COIL HOLDER AND DEPORTED COIL

€2.13 -twenty% 1.71€

Quick print stackable parts containers / storage boxes

2.87 €

UNIVERSAL BED LEVELING INDICATOR FOR VERY ALL PRINTERS

2,81 €

Display holder FLSUN v400

€9. -fifty% 4.99 €  99

99

3D printed wave transmission (harmonic drive)

4.99 €

Trailer hitch with steel helmet

10 €

Cooling system Minimus Hotend

2.33 €

Tool holder for 3D printer V3.0

1.04 €

nine0003 well designed: Hemera fan duct2.50 €

Business card embossing system

3 €

ARTEMIS -> Shop for Alligator 2 || 6.5" arrows || Repeating crossbow

6.25 €

INDICATOR FOR BETTER BED LEVELING FOR ENDER 3 V2

2.81 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy. Here are 4 solutions available to everyone:

Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads. nine0006

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

Helpful tips for 3D printing at home

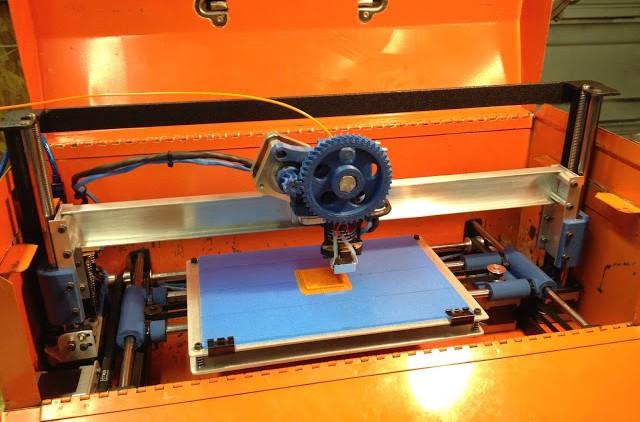

You, like many people around the world, may have had to quickly change from working in a workshop or office with many tools at hand to working at home where resources are more limited. During this difficult period, the ability to adapt to new circumstances and challenges helps to reduce production disruptions and avoid disruptions in the organization of the development cycle.

Formlabs desktop stereolithography (SLA) 3D printers are compact in size and can be used from home or outside the office environment. In addition, the ability to use over 30 different materials that mimic everything from silicone and polypropylene to ABS and more increases flexibility, expands the scope and makes it easy to adapt to new tasks as they arise. nine0006

In addition, the ability to use over 30 different materials that mimic everything from silicone and polypropylene to ABS and more increases flexibility, expands the scope and makes it easy to adapt to new tasks as they arise. nine0006

Introducing 3D printing technology in-house will help you cut costs and keep your feet on the ground during times of uncertainty, especially if you have previously used or currently use third-party 3D printed models. Our customers are using home 3D printing to reduce costs, improve manufacturing process efficiency, continue developing critical products, and help overcome the COVID-19 crisis..

Dan Kirchgessner, Communications Specialist, and Jake Kapusta, Senior Maintenance Specialist share practical tips for printing at home.

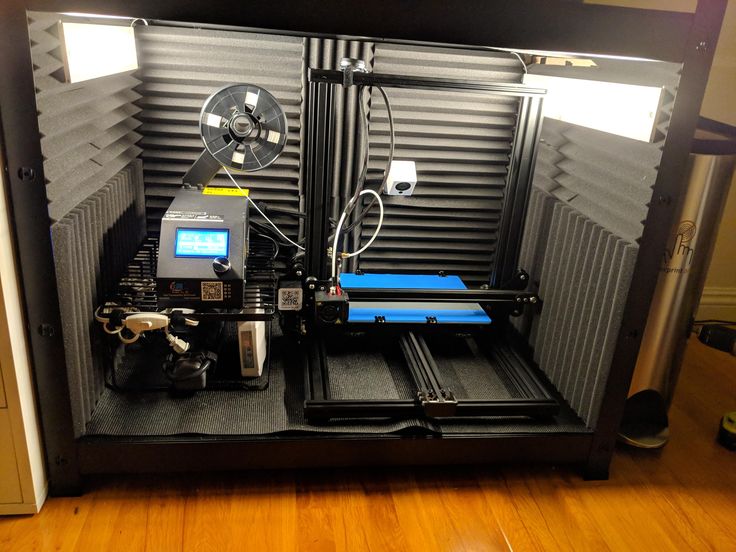

Before the 3D printer is delivered to your home, you need to organize your space and workspace so that you can print, post-process, and finish everything you need. You will need space to house the printer(s), post-processing stations such as Form Wash and Form Cure, workspace to separate and finish parts, and short-term storage space for items such as spare wash solvent, resin reservoirs, cartridges for resins, gloves, post-processing tools, etc.

Alexis Hope, designer and researcher at MIT's Media Lab and MIT's Center for Social Interaction Tools, says that in setting up her home workshop, “getting the printer home was a great incentive to reorganize the workplace. Space is required for flushing and curing systems, as well as space for storing models, so proper organization of space is necessary for productive work. ”

Alexis Hope's home workshop. nine0181

Some of the most frequently asked questions about 3D printing at home have to do with environmental factors such as sounds and smells. To account for sensitivity to odors, we advise placing the post-processing station in a well-ventilated area or near an open window. Although the Form 3 is relatively quiet - it produces a noise comparable to that of a microwave oven - you may prefer to place it away from those areas of your home where you don't want to disturb the silence. nine0006

Woody Hedberg, Formlabs Print Process Engineer, recently hosted a Form 3L in his apartment for material testing purposes. “As a protective measure, I installed thick cardboard on the floor and walls of the room,” says Hedberg. In addition, for the workplace, he chose a space near an open window and behind a closed door to reduce the penetration of potential smells and sounds.

“As a protective measure, I installed thick cardboard on the floor and walls of the room,” says Hedberg. In addition, for the workplace, he chose a space near an open window and behind a closed door to reduce the penetration of potential smells and sounds.

After preparing the workspace, lay out the items needed for 3D printing, such as rinsing containers, baskets and bottles, tweezers, spatula, detach tool, wire cutters, disposable nitrile gloves, and any additional tools that you may need during the work 3D printing process. nine0006

If you already have a 3D printer, the first thing you should consider is transporting it from your office or workplace to your home. When preparing your Formlabs 3D printer for shipping, first remove the resin cartridge, then remove and clean the platform, and finally remove the resin reservoir and close the lid before placing it in its storage case. Ensure that all accessories containing polymers are securely closed before transport.

Before shipping the Form 3 printer, secure the Light Processing Unit (LPU) with thumbscrews and latch. Failure to lock the LPU may damage the printer. Contact us if you can't find the screws. nine0006

Failure to lock the LPU may damage the printer. Contact us if you can't find the screws. nine0006

Carefully wrap the printer in protective material and, if possible, place it in the original packaging. Be sure to pack all the accessories you may need for 3D printing and post-processing: Form Wash and Form Cure or post-processing kit and an alternative curing solution and consumables such as resin reservoirs and cartridges, gloves, tools for post-processing, isopropyl alcohol, etc.

After unpacking 3D printing supplies at home and before printing, be sure to check that the printer is level and stable in the new location. nine0006

Now that your printer is ready to use at home, there are several ways to improve and streamline your workflow.

Schedule the start and end times for printing to fit your work schedule. This way you can load the printer to the maximum. You can schedule the start of your next print using PreForm's Estimated Print Duration feature. Print time-consuming models while you're away from your workspace so you can print while you're away so you can start the next one when you get back. nine0006

nine0006

Kevin Gauthier, Business Development Specialist at Formlabs, found that when working remotely, his team sent models to each other more often: "Never forget to print an instance of an object for yourself so you can refer to it later."

Kevin Gauthier's home workspace.

Continuing the same line, Hedberg suggests documenting and photographing every 3D printed model in detail, especially if your storage space is limited. “Now that we are working remotely, we need a proper documentation system. This does not mean that every 3D printed model should be saved, but carefully documenting the printed models and keeping records for my colleagues, yes,” he says. nine0006

Use the Dashboard to monitor your print progress in real time, as well as tank usage and resin consumption. You'll also be able to track quality prints and scrap rates so you know which designs are the best and use them for future iterations.

“Do all the design work you can and prioritize critical physical prototyping tasks for different teams,” says Zach Frew, Formlabs Technical Specialist. Frew says you need to prioritize these tasks, especially when work resources are limited, and share them with your team members. nine0006

Frew says you need to prioritize these tasks, especially when work resources are limited, and share them with your team members. nine0006

Follow safety guidelines when using Formlabs products. Handle IPS with nitrile gloves in a well-ventilated area. Keep the IPS away from heat, sparks and open flames. Isopropyl alcohol evaporates quickly, so keep containers covered if possible. For detailed safety information, contact the manufacturer or supplier of this chemical.

As Formlabs Materials Expert Zak Zguris says, “You have to practice good chemical hygiene. Keep everything clean. Wipe up any drops or spilled liquids immediately. To avoid sticky residue, use acetone or isopropyl alcohol. When washing in the IRS, ventilation of the working space with fresh air should be provided. The cabinet is not at all suitable for the active use of a 3D printer or a washing station in an IRS.” nine0006

Always wear gloves to protect your skin when handling resin cartridges and containers.