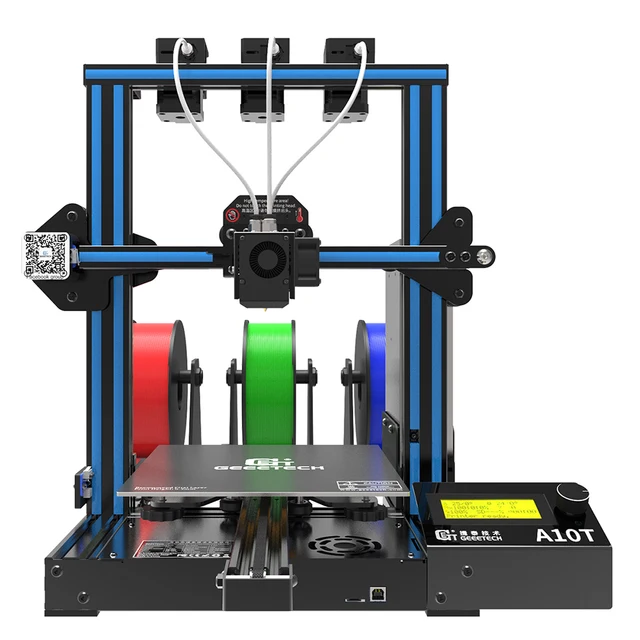

Tempered glass 3d printer

Borosilicate Glass VS Tempered Glass for 3D Printing – 3D Printerly

The conditions for a good print start, quite literally, from the ground up. A good build plate is fundamental to ensuring your 3D model comes out looking great.

It serves several functions like making sure there’s a level surface for printing and enhancing print adhesion.

There are many materials for fabricating build plates, depending on the print requirements.

A popular option among 3D printing enthusiasts is glass. Its high resistance to warping, thermal stability, and conductivity make it a prime choice for printing.

The two main types of glass that people use for 3D printing are borosilicate glass and tempered glass, but many people don’t know which to buy.

This article is going to aim to help you identify the differences and key comparisons to help you move forward and get the right type.

Let’s quickly look at both options before we compare them.

What Is Borosilicate Glass in 3D Printing?

Borosilicate glass is a type of glass made with silica and at least 13% Boron trioxide. This combination gives it some properties that make it useful in 3D printing applications.

Let’s examine these properties.

Thermal Stability

Borosilicate glass has a very low coefficient of thermal expansion. That is, it expands very little with changing temperatures. This means that it will not crack or shatter under extreme temperatures.

Its thermals stability is one of its most important properties, as this makes it possible to use it with a heated bed. It also makes printing with high-temperature materials like ABS very easy.

Durability

Borosilicate glass is strong. It is shatter-proof, which means when it’s dropped, it won’t break. Also, its durability means it lasts longer and is less susceptible to surface degradation from scratches and nicks.

Chemical Resistant

Borosilicate glass has a very stable chemical structure that doesn’t degrade when attacked by outside elements. This is very helpful when printing with reactive filaments.

It’s nice to know your build plate won’t leak dangerous chemicals into the print or the air.

Thermal Shock Resistant

Thermal shock resistance is a property of borosilicate glass that makes it resistant to rapid changes in temperatures. Most materials exposed to rapid changes in temperature lose their strength and may even fail. But, Borosilicate glass stands up well to these thermal shocks.

Some people wonder whether borosilicate glass warps, and most people’s experience show that it doesn’t warp over time due to its physical characteristics.

What Is Tempered Glass in 3D Printing?Tempered glass is any form of glass that has gone through thermal and mechanical processes (tempering) to increase its strength. Tempered glass finds applications in car windshields and things like screen protectors.

All these are made possible due to the properties given to it by tempering. Let’s take a look at some of those properties below:

Strength

Tempered glass is strong and durable by nature. It can withstand impact shocks far better than regular glass. Its strength comes from tempering, which pre-stresses the glass’s structure to make it stronger.

It can withstand impact shocks far better than regular glass. Its strength comes from tempering, which pre-stresses the glass’s structure to make it stronger.

Thermal Stability

Tempered glass is also heat-resistant. The thermal tempering treatment makes it able to withstand temperatures up to 300℃ without failure. Tempered glass can also withstand thermal shock, just not as well as Borosilicate glass.

Scratch Resistant

Tempering gives the surface of the glass a scratch-resistant finish.

It hardens the surface making it more resistant to penetration from an external object. This quality makes tempered glass retain its surface quality for a long time.

The video below shows how easy installation is, and gives a nice review on a tempered glass bed.

Borosilicate Glass Vs Tempered Glass: Which One is Best for You?

When buying a glass build plate, the odds are you are going to get either one made from borosilicate glass or tempered glass. So, how do you decide between them? Let’s take you through some things that can influence your decisions.

So, how do you decide between them? Let’s take you through some things that can influence your decisions.

Quality

Both borosilicate glass and tempered glass have excellent qualities that set them apart from regular glass. Let’s go through those qualities one by one and see how they stack against each other:

- Thermal Stability: Both tempered and borosilicate glass perform well at high temperatures. You can print high-temperature filaments on them with no problem. However, when it comes to thermal shock resistance, Borosilicate glass is the better option.

Due to the pre-stressed nature of tempered glass, it cannot withstand large temperature variations. Prolonged exposure to these temperatures can cause warping, or in extreme cases, total failure.

- Scratch Resistance: The scratch resistance of a material is a function of its hardness and resistance to penetration. Both Borosilicate and tempered glass are harder than regular glass.

On the Mohs hardness scale, tempered glass is rated slightly higher than borosilicate glass.

On the Mohs hardness scale, tempered glass is rated slightly higher than borosilicate glass.

The higher rating means Tempered glass is a slightly harder material. As such, it will be more resistant to chipping and flaking. This will make it retain its surface quality longer.

Ease Of Use

For ease of use, we’ll be rating both glasses on how user-friendly they are. Both provide good quality bottom finishes, are easy to clean, and are flat. We’ll be using different criteria.

We’ll be comparing them based on safety and ease of print removal.

Let’s look at these criteria:

- Safety: Tempered glass is a safer material. It is highly durable and can resist impact shocks better. Even if it breaks, it breaks into cube-like pieces that aren’t harmful.

- Ease of Print Removal: Print removal generally depends on a lot more things than the build plate, but prints are easier to remove from borosilicate glass. Due to its low coefficient of thermal expansion, it won’t expand when heated.

So as it cools, the stresses from the shrinking model make it easier to remove.

So as it cools, the stresses from the shrinking model make it easier to remove.

For more stubborn prints, you can put the build plate in a freezer to cool it faster. Borosilicate glass can survive this swing in temperature because of its resistance to thermal shocks.

Price

The price difference is not so significant, so you can really choose either and be good on price, but let’s look at which one actually comes up as cheaper.

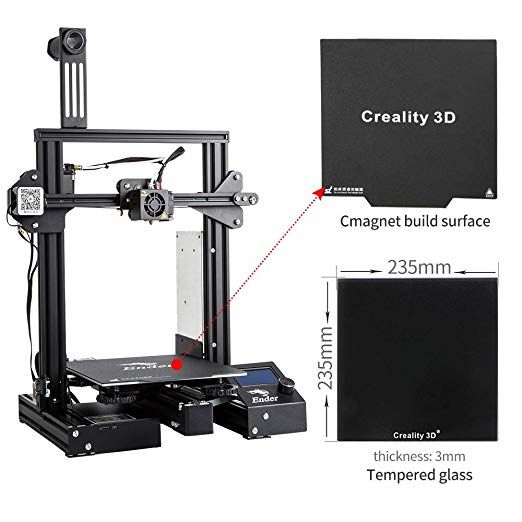

A standard borosilicate glass bed for an Ender 3 on Amazon comes to around $15, with the Dcreate 235 x 235 x 3.8mm Borosilicate Glass Bed.

A standard tempered glass bed for an Ender 3 on Amazon comes to around $20 on Amazon, with the Creality Authentic Tempered Glass Bed, though these prices can fluctuate depending on the brand and the seller.

The prices of 3D printer beds have been getting cheaper over time, which is great for 3D printer hobbyists out there!

Overall, I’d recommend going with the Dcreate Borosilicate Glass Bed from Amazon.

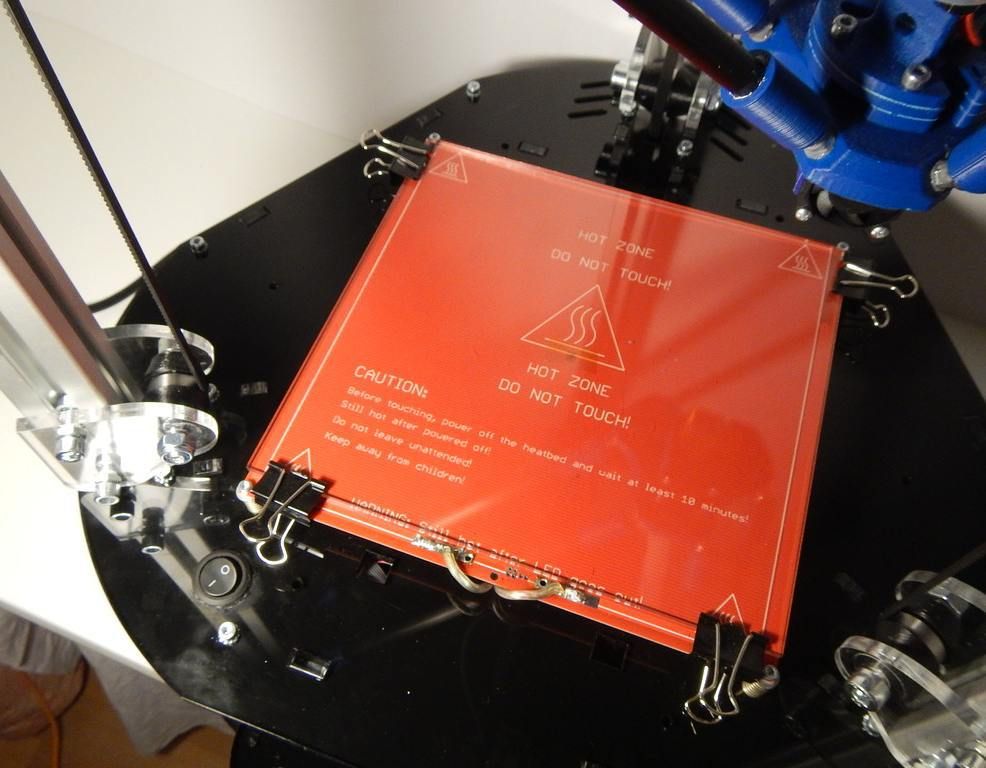

You can also get yourself some professional 3D printer clamps to add onto your 3D printer to hold the glass bed into place. When I tried using the binder clips that came with my Ender 3, it was just too small for the glass bed addition.

The 4-Pack Ender 3 Stainless Steel Clamps from Amazon are a good product to keep your bed in place. They are fairly pricey but they get the job done very well.

Another option which gives you more bang for your buck is the 40 Pcs Extra Large Binder Clips from Amazon. They have a 2-inch width and has multiple practical uses outside of holding your bed in place.

3D Printer Tempered Glass Plate, Ender 3, Ender 3 Pro Glass Bed — Kingroon 3D

$18.00

210*210mm (for Kingroon KP3S Pro) / No need / CN Warehouse - $18.00 180*180mm (for Kingroon KP3S) / No need / US Warehouse - $17.00 180*180mm (for Kingroon KP3S) / No need / EU Warehouse - $17. 00 180*180mm (for Kingroon KP3S) / No need / Australia Warehouse - $17.00 180*180mm (for Kingroon KP3S) / No need / Brazil Warehouse - $25.00 180*180mm (for Kingroon KP3S) / + 4PCS / CN Warehouse - $18.00 180*180mm (for Kingroon KP3S) / + 4PCS / US Warehouse - translation missing: en.products.status.sold_out 180*180mm (for Kingroon KP3S) / + 4PCS / EU Warehouse - translation missing: en.products.status.sold_out 180*180mm (for Kingroon KP3S) / + 4PCS / Australia Warehouse - translation missing: en.products.status.sold_out 180*180mm (for Kingroon KP3S) / + 4PCS / Brazil Warehouse - translation missing: en.products.status.sold_out 220*220mm / No need / CN Warehouse - $22.00 220*220mm / No need / US Warehouse - $22.00 220*220mm / No need / EU Warehouse - $22.00 220*220mm / No need / Australia Warehouse - translation missing: en.

00 180*180mm (for Kingroon KP3S) / No need / Australia Warehouse - $17.00 180*180mm (for Kingroon KP3S) / No need / Brazil Warehouse - $25.00 180*180mm (for Kingroon KP3S) / + 4PCS / CN Warehouse - $18.00 180*180mm (for Kingroon KP3S) / + 4PCS / US Warehouse - translation missing: en.products.status.sold_out 180*180mm (for Kingroon KP3S) / + 4PCS / EU Warehouse - translation missing: en.products.status.sold_out 180*180mm (for Kingroon KP3S) / + 4PCS / Australia Warehouse - translation missing: en.products.status.sold_out 180*180mm (for Kingroon KP3S) / + 4PCS / Brazil Warehouse - translation missing: en.products.status.sold_out 220*220mm / No need / CN Warehouse - $22.00 220*220mm / No need / US Warehouse - $22.00 220*220mm / No need / EU Warehouse - $22.00 220*220mm / No need / Australia Warehouse - translation missing: en. products.status.sold_out 220*220mm / No need / Brazil Warehouse - translation missing: en.products.status.sold_out 220*220mm / + 4PCS / CN Warehouse - $23.00 220*220mm / + 4PCS / US Warehouse - translation missing: en.products.status.sold_out 220*220mm / + 4PCS / EU Warehouse - translation missing: en.products.status.sold_out 220*220mm / + 4PCS / Australia Warehouse - translation missing: en.products.status.sold_out 220*220mm / + 4PCS / Brazil Warehouse - translation missing: en.products.status.sold_out 235*235mm (for Ender 3 (Pro)/Ender 3 V2) / No need / CN Warehouse - $25.00 235*235mm (for Ender 3 (Pro)/Ender 3 V2) / No need / US Warehouse - $25.00 235*235mm (for Ender 3 (Pro)/Ender 3 V2) / No need / EU Warehouse - $25.00 235*235mm (for Ender 3 (Pro)/Ender 3 V2) / No need / Australia Warehouse - translation missing: en.products.status.sold_out 235*235mm (for Ender 3 (Pro)/Ender 3 V2) / No need / Brazil Warehouse - translation missing: en.

products.status.sold_out 220*220mm / No need / Brazil Warehouse - translation missing: en.products.status.sold_out 220*220mm / + 4PCS / CN Warehouse - $23.00 220*220mm / + 4PCS / US Warehouse - translation missing: en.products.status.sold_out 220*220mm / + 4PCS / EU Warehouse - translation missing: en.products.status.sold_out 220*220mm / + 4PCS / Australia Warehouse - translation missing: en.products.status.sold_out 220*220mm / + 4PCS / Brazil Warehouse - translation missing: en.products.status.sold_out 235*235mm (for Ender 3 (Pro)/Ender 3 V2) / No need / CN Warehouse - $25.00 235*235mm (for Ender 3 (Pro)/Ender 3 V2) / No need / US Warehouse - $25.00 235*235mm (for Ender 3 (Pro)/Ender 3 V2) / No need / EU Warehouse - $25.00 235*235mm (for Ender 3 (Pro)/Ender 3 V2) / No need / Australia Warehouse - translation missing: en.products.status.sold_out 235*235mm (for Ender 3 (Pro)/Ender 3 V2) / No need / Brazil Warehouse - translation missing: en. products.status.sold_out 235*235mm (for Ender 3 (Pro)/Ender 3 V2) / + 4PCS / CN Warehouse - $26.00 235*235mm (for Ender 3 (Pro)/Ender 3 V2) / + 4PCS / US Warehouse - translation missing: en.products.status.sold_out 235*235mm (for Ender 3 (Pro)/Ender 3 V2) / + 4PCS / EU Warehouse - translation missing: en.products.status.sold_out 235*235mm (for Ender 3 (Pro)/Ender 3 V2) / + 4PCS / Australia Warehouse - translation missing: en.products.status.sold_out 235*235mm (for Ender 3 (Pro)/Ender 3 V2) / + 4PCS / Brazil Warehouse - translation missing: en.products.status.sold_out 250*250mm / No need / CN Warehouse - $27.00 250*250mm / No need / US Warehouse - translation missing: en.products.status.sold_out 250*250mm / No need / EU Warehouse - $27.00 250*250mm / No need / Australia Warehouse - translation missing: en.products.status.sold_out 250*250mm / No need / Brazil Warehouse - translation missing: en.

products.status.sold_out 235*235mm (for Ender 3 (Pro)/Ender 3 V2) / + 4PCS / CN Warehouse - $26.00 235*235mm (for Ender 3 (Pro)/Ender 3 V2) / + 4PCS / US Warehouse - translation missing: en.products.status.sold_out 235*235mm (for Ender 3 (Pro)/Ender 3 V2) / + 4PCS / EU Warehouse - translation missing: en.products.status.sold_out 235*235mm (for Ender 3 (Pro)/Ender 3 V2) / + 4PCS / Australia Warehouse - translation missing: en.products.status.sold_out 235*235mm (for Ender 3 (Pro)/Ender 3 V2) / + 4PCS / Brazil Warehouse - translation missing: en.products.status.sold_out 250*250mm / No need / CN Warehouse - $27.00 250*250mm / No need / US Warehouse - translation missing: en.products.status.sold_out 250*250mm / No need / EU Warehouse - $27.00 250*250mm / No need / Australia Warehouse - translation missing: en.products.status.sold_out 250*250mm / No need / Brazil Warehouse - translation missing: en. products.status.sold_out 250*250mm / + 4PCS / CN Warehouse - $27.00 250*250mm / + 4PCS / US Warehouse - translation missing: en.products.status.sold_out 250*250mm / + 4PCS / EU Warehouse - translation missing: en.products.status.sold_out 250*250mm / + 4PCS / Australia Warehouse - translation missing: en.products.status.sold_out 250*250mm / + 4PCS / Brazil Warehouse - translation missing: en.products.status.sold_out 310*310mm / No need / CN Warehouse - $35.00 310*310mm / No need / US Warehouse - translation missing: en.products.status.sold_out 310*310mm / No need / EU Warehouse - translation missing: en.products.status.sold_out 310*310mm / No need / Australia Warehouse - translation missing: en.products.status.sold_out 310*310mm / No need / Brazil Warehouse - translation missing: en.products.status.sold_out 310*310mm / + 4PCS / CN Warehouse - $36.

products.status.sold_out 250*250mm / + 4PCS / CN Warehouse - $27.00 250*250mm / + 4PCS / US Warehouse - translation missing: en.products.status.sold_out 250*250mm / + 4PCS / EU Warehouse - translation missing: en.products.status.sold_out 250*250mm / + 4PCS / Australia Warehouse - translation missing: en.products.status.sold_out 250*250mm / + 4PCS / Brazil Warehouse - translation missing: en.products.status.sold_out 310*310mm / No need / CN Warehouse - $35.00 310*310mm / No need / US Warehouse - translation missing: en.products.status.sold_out 310*310mm / No need / EU Warehouse - translation missing: en.products.status.sold_out 310*310mm / No need / Australia Warehouse - translation missing: en.products.status.sold_out 310*310mm / No need / Brazil Warehouse - translation missing: en.products.status.sold_out 310*310mm / + 4PCS / CN Warehouse - $36. 00 310*310mm / + 4PCS / US Warehouse - translation missing: en.products.status.sold_out 310*310mm / + 4PCS / EU Warehouse - translation missing: en.products.status.sold_out 310*310mm / + 4PCS / Australia Warehouse - translation missing: en.products.status.sold_out 310*310mm / + 4PCS / Brazil Warehouse - translation missing: en.products.status.sold_out 310*320mm (for Kingroon KP5L) / No need / CN Warehouse - $35.00 310*320mm (for Kingroon KP5L) / No need / US Warehouse - translation missing: en.products.status.sold_out 310*320mm (for Kingroon KP5L) / No need / EU Warehouse - translation missing: en.products.status.sold_out 310*320mm (for Kingroon KP5L) / No need / Australia Warehouse - translation missing: en.products.status.sold_out 310*320mm (for Kingroon KP5L) / No need / Brazil Warehouse - translation missing: en.products.status.sold_out 310*320mm (for Kingroon KP5L) / + 4PCS / CN Warehouse - $36.

00 310*310mm / + 4PCS / US Warehouse - translation missing: en.products.status.sold_out 310*310mm / + 4PCS / EU Warehouse - translation missing: en.products.status.sold_out 310*310mm / + 4PCS / Australia Warehouse - translation missing: en.products.status.sold_out 310*310mm / + 4PCS / Brazil Warehouse - translation missing: en.products.status.sold_out 310*320mm (for Kingroon KP5L) / No need / CN Warehouse - $35.00 310*320mm (for Kingroon KP5L) / No need / US Warehouse - translation missing: en.products.status.sold_out 310*320mm (for Kingroon KP5L) / No need / EU Warehouse - translation missing: en.products.status.sold_out 310*320mm (for Kingroon KP5L) / No need / Australia Warehouse - translation missing: en.products.status.sold_out 310*320mm (for Kingroon KP5L) / No need / Brazil Warehouse - translation missing: en.products.status.sold_out 310*320mm (for Kingroon KP5L) / + 4PCS / CN Warehouse - $36. 00 310*320mm (for Kingroon KP5L) / + 4PCS / US Warehouse - translation missing: en.products.status.sold_out 310*320mm (for Kingroon KP5L) / + 4PCS / EU Warehouse - translation missing: en.products.status.sold_out 310*320mm (for Kingroon KP5L) / + 4PCS / Australia Warehouse - translation missing: en.products.status.sold_out 310*320mm (for Kingroon KP5L) / + 4PCS / Brazil Warehouse - translation missing: en.products.status.sold_out 210*210mm (for Kingroon KP3S Pro) / + 4PCS / CN Warehouse - $19.00

00 310*320mm (for Kingroon KP5L) / + 4PCS / US Warehouse - translation missing: en.products.status.sold_out 310*320mm (for Kingroon KP5L) / + 4PCS / EU Warehouse - translation missing: en.products.status.sold_out 310*320mm (for Kingroon KP5L) / + 4PCS / Australia Warehouse - translation missing: en.products.status.sold_out 310*320mm (for Kingroon KP5L) / + 4PCS / Brazil Warehouse - translation missing: en.products.status.sold_out 210*210mm (for Kingroon KP3S Pro) / + 4PCS / CN Warehouse - $19.00

210*210mm (for Kingroon KP3S Pro)

180*180mm (for Kingroon KP3S)

220*220mm

235*235mm (for Ender 3 (Pro)/Ender 3 V2)

250*250mm

310*310mm

310*320mm (for Kingroon KP5L)

No need

+ 4PCS

CN Warehouse

US Warehouse

EU Warehouse

Australia Warehouse

Brazil Warehouse

1 2 3 4 5 6 7 8 9 10+ Quantity

Quantity

Share this:Tempered glass plate is solid, super durable, easy to use and to clean. Amazing bed adhension due to the special coating. Printing in Nylon filament, you need a real high-temperature heatbed, which can't be done on PEI heatbed platform surface.

Amazing bed adhension due to the special coating. Printing in Nylon filament, you need a real high-temperature heatbed, which can't be done on PEI heatbed platform surface.

Product specifications:

180*180mm size suitable for Kingroon KP3S 3D printer.

235*235mm (9.25" x 9.25") size suitable for Creality Ender 3, Ender 3 Pro glass bed.

310*320mm size suitable for Kingroon KP5L, Creality CR-10 3D printers.

Package includes:

Tempered Glass Plate * 1PCS

Free shipping from our Chinese warehouse.

The picture is for reference only. Please adhere to the original products in case of any mistake

- Save $5.

00

00 - Save $3.00

glass-ceramic, borosilicate and perforated do-it-yourself

3D printers are very popular in many areas. Today, such devices are widely used in dentistry, jewelry, architecture and business. But in order for any printer to print quality parts, you should take care of choosing a surface for your desktop, taking into account the material used. Next, we will tell you how to do it right.

What types of glasses are available for a 3D printer table?

All 3D printers have one thing in common: the desktop. It is on it that a three-dimensional product is created, the quality of which will depend on adhesion with the platform. Usually the desktop is covered with glass, but there may be other options.

Sitall glass

Sitall glass is one of the most popular adhesion methods to avoid product sticking to the desktop and ensure its reliable retention on the surface. The only drawback is the rather high cost of such material. nine0003

For reference. Sitall is a crystalline material with properties such as transparency, wear resistance, chemical and thermal stability. It was first developed in the Soviet Union for use in the aviation industry.

The use of glass-ceramic glass in 3D printing allows solving a number of the following problems:

- the ability to print with different types of plastic;

- solid surface mounting;

- no deformation when printing samples even when exposed to high temperatures;

- production of quality parts;

- does not require the use of glue or other adhesive materials.

All you have to do is calibrate the height between the nozzle and the build plate and start printing your first 3D products.

Borosilicate glass

Borosilicate glass has a low coefficient of thermal expansion, making it more resistant to heat than ordinary glass. When printing 3D models on a platform equipped with a similar surface, high-quality products are obtained. This is achieved by tightly attaching the first layer to the site and ensuring good adhesion. nine0003

Borosilicate glass is made from tempered materials and is used in medicine, energy and everyday life. It is resistant to temperature extremes and chemical attack. The secret is simple - in the production of borosilicate glass, boron oxide is added to the composition and the content of air bubbles is excluded.

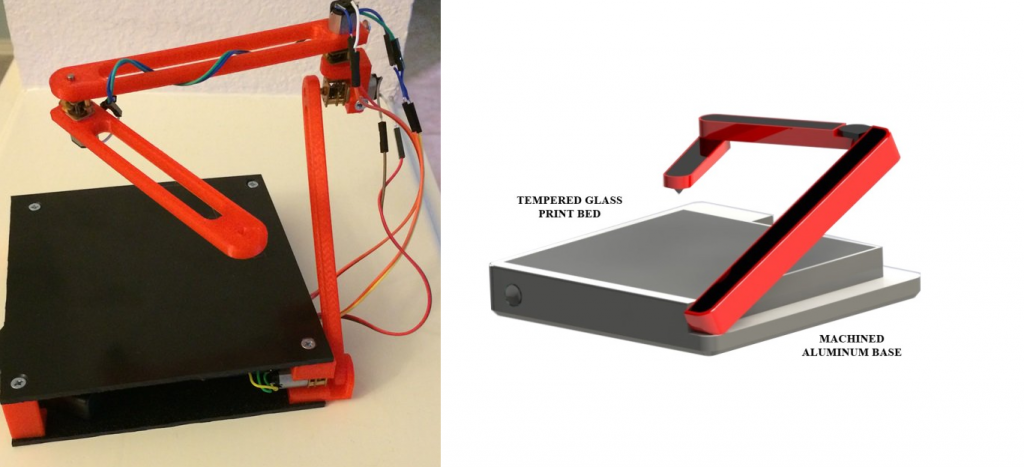

Even a beginner will have no problems installing the glass - it is attached to the desktop of the 3D printer with clerical clips or bolts.

Perforated glass

Special tempered glass with a perforated coating ensures that the future 3D part is firmly attached to the work platform. Another plus is that such material provides easy separation of finished products from the table after they have cooled. Perforated glass is used in a range of heated desktop 3D printers. On such devices it is easy to work with any kind of plastic.

Another plus is that such material provides easy separation of finished products from the table after they have cooled. Perforated glass is used in a range of heated desktop 3D printers. On such devices it is easy to work with any kind of plastic.

What should I do if the glass comes off the 3D printer table?

Many buyers and beginners in 3D printing are faced with the problem of keeping the model on the desktop or dealing with surface irregularities. In these cases, glass comes to the rescue. It provides a dense fastening of the product with the surface and allows you to produce high-quality three-dimensional models. But in words, everything is easy, but in practice, a beginner may have problems not only with printing, but also with such a problem as glass peeling off the desktop. In this case, you should not panic - it is better to carefully study the possible causes, watch videos on the Internet and take possible measures:0003

- Check table calibration settings - we recommend doing this with the bed and extruder preheated to operating temperature.

- Reduce print speed.

- Eliminate poor adhesion - glue or hairspray is suitable for this purpose, as well as alcohol, which is recommended to degrease the surface.

- Fix the glass with special clamps or screws.

How to work with glass?

If you have recently bought a 3D printer and do not yet know about all the features of this device, then most likely you will have many questions during the first and subsequent use. One of the possible options is what kind of surface to choose for the desktop and how to work with glass correctly. Here are a few helpful tips to get your 3D printing process up and running and produce quality products:

- Remove the protective film from the glass surface.

- Before placing the glass on the workbench, preheat the platform to facilitate easy removal of the protective film from the surface with minimal adhesive residue.

- Remove the sticker carefully.

- If adhesive remains on the platform, remove with acetone or thinner.

- Mount the glass on the work table using the clips.

note . Before you start printing, adjust the table height for your glass thickness and calibrate the platform.

Done right, 3D printed pieces will bring maximum comfort without the risk of them sticking to the platform. You can easily get high-quality models and avoid the risk of platform deformation when heated to high temperatures.

How to make glass with your own hands?

If you decide to save on buying glass, there is another way out - to make it yourself. This method may well become an alternative if there is not enough money to buy or there is no time to wait. We list several options for making glass with our own hands:

- Use blue tape or masking tape. One of the most effective and inexpensive ways to get the product to grip the work surface. Opt for wide rolls for quick surface coverage, and optionally use adhesive to avoid using extra heat when printing.

- Make a table with duct tape and hairspray . This method is suitable for printing with ABS plastic - spray regular hairspray on the surface of the desktop and place Kapton on top. nine0024

- Use window glass or a mirror and a sanding disc with grit 53 for the surface. This will create excellent adhesion when working with any plastic. You can fix the structure with ordinary clerical clips.

Mistakes and how to avoid them

Many beginners in 3D printing have problems, in particular with incorrect glass selection or installation. Follow these simple guidelines to avoid common mistakes:

- Select glass according to the plastic you are going to print with. It is best to give preference to glass-ceramic or borosilicate material - this option is not the most budgetary, but the most reliable.

- Before printing 3D models, make sure the desktop is properly calibrated.

- If the product sticks to the desktop surface, use additional methods of adhesion - glue or varnish.

- When making your own desktop surface, use tempered glass if possible and attach it tightly to the platform. nine0024

We hope that the first experience of 3D printing and our advice will help you to produce high-quality three-dimensional products with minimal losses!

- April 19, 2021

- 5891

Get expert advice

Glass blog, interesting facts about glass, opinions from the leaders of the glass industry, important terms and latest news about glass

How much glass do you print? nine0142

The future has come, there is no need to hide, relax!

New GLASS TODAY services: 3D printing of glass partitions, furniture, doors and houses. Applications are being accepted today.

Glass production: an overview from Galileo

We present you a review of "Galileo" on the topic of glass production. Evening video on Sunday GLASS TODAY! nine0156

Evening video on Sunday GLASS TODAY! nine0156

ABC of the glass market: Z

Tempered glass is usually sheet glass obtained by heating to a tempering temperature (650-680°C) and then rapidly uniformly cooling with cold air on both sides. As a result of such treatment, residual compressive stresses are formed in the surface layers of the glass, providing its increased mechanical strength, heat resistance and safety in case of destruction. When broken, such glass breaks into many small fragments with blunt edges that are not capable of causing serious injury. This effect is proof of the high impact strength of this glass. Evenly distributed impact energy for a relatively long time forms very small microcracks in the glass and allows you to get small fragments. Thus, tempered glass has three main useful properties, each of which has its own purpose in the industry. nine0003

Thus, tempered glass has three main useful properties, each of which has its own purpose in the industry. nine0003

The safety and mechanical strength of toughened glass is used in construction, glassware, psychiatry, shop windows, hockey rink fencing, furniture, automotive and railway industries. Such a property as heat resistance makes it possible to glaze buildings without the risk of thermal shock, especially for glass tinted in mass. The only weak point of such sheet glass is the vulnerability to impacts in the end, since in this place the residual stresses can easily be released and break the glass as a whole. A similar effect is often used in design (example: three-layer countertops or doors with the effect of "broken glass"). Tempered glass cannot be cut, drilled or otherwise machined. nine0003

In the automotive industry, tempered glass is used to make side or rear windows. The use of tempered glass as a windshield is prohibited (small, though not sharp, fragments can damage the eyes of the driver or passengers). For the production of windshields, silicate glass triplex is used. Although tempered glass triplexes are much stronger, they have the disadvantage of rapid and complete loss of transparency from strong impacts. However, this does not prevent their use in architecture. Tempered automotive glass is marked with the English word "Tempered" - "tempered glass" or the letter "T". nine0003

For the production of windshields, silicate glass triplex is used. Although tempered glass triplexes are much stronger, they have the disadvantage of rapid and complete loss of transparency from strong impacts. However, this does not prevent their use in architecture. Tempered automotive glass is marked with the English word "Tempered" - "tempered glass" or the letter "T". nine0003

In the USSR it was known as "Stalinite" (in honor of Stalin).

Offices with glass: QIWI

Qiwi is headquartered in Moscow at Chertanovskaya metro station. All the main departments work here: IT, marketing, legal department, investor relations department, HR, accounting. We offer you to feel the atmosphere of the office with the use of glass partitions and glass of various processing. nine0003

Offices with glass: MacPaw

We present to your attention a project from the design studio "Drum +", which completed a project for the MacPaw IT company in a business center in Toronto. As is customary in IT, the atmosphere is conducive to relaxation and friendly communication, the room is filled with the most modern technology and even a barbecue on the terrace. Congratulations to the company with the new office! nine0003

As is customary in IT, the atmosphere is conducive to relaxation and friendly communication, the room is filled with the most modern technology and even a barbecue on the terrace. Congratulations to the company with the new office! nine0003

ABC of the glass market: EN, E, EI, EW

Today, get acquainted with the abbreviations from the English language:

- EN - the designation of European standards.

- E - fire resistance limit for loss of integrity. The fire-resistant design, which has a fire resistance class E, is able to provide integrity for a given time, thereby preventing the spread of fire, smoke and combustion products. nine0024

- EI - fire resistance limit for loss of integrity and heat-insulating ability. A fire-resistant structure with a fire resistance class of EI is able to provide integrity and thermal insulation for a given time, thereby preventing the spread of fire and thermal radiation, smoke and combustion products.

- EW - fire resistance limit for loss of integrity and heat-insulating ability. A fire-resistant structure with a fire resistance class of EW is able to provide integrity and partial thermal insulation for a given time, thereby preventing the spread of fire and thermal radiation, smoke and combustion products. nine0024

Instagram - what is it?

Instaglass - a new photo section from GLASS TODAY dedicated to glass and glass products. A photo stream from all over the world will inspire you to change the space around, suggest an idea or generate a discovery that no one has realized before! View photos and send your solutions to us by mail or social networks

Age of glass: evolution and victory

We present to your attention the popular science film "Science 2. 0. Glass [Complicated things]". Knowledge that will be useful to everyone on Sunday GLASS TODAY!

0. Glass [Complicated things]". Knowledge that will be useful to everyone on Sunday GLASS TODAY!

Offices with glass: Montreal company TUANGO

TUANGO, one of the Canadian stock market leaders, has created a unique business space based on the company logo in the form of a cube of all-glass partitions. A three-meter cube is located in the center of the office and serves as a conference room, perfectly visible from all points of the room. The color schemes of the office are also designed in the colors of the company's brand book.

GLASS TODAY on GOOGLE PLUS nine0142

We inform you that now our page is on the GOOGLE PLUS channel!

Subscribe to the page and stay up to date with the news of the company and the glass industry - https://plus.