3D printed thruster

Thruster best STL files for 3D printing・Cults

Drone Jet pack evo2

€1.25

Drone Jet pack evo1

€1

SURF DAGGERBOARD FCS2 - THRUSTER

€0.50

jetpack smoke

€0.50

Stellar Engine- Caplan Thruster

Free

90mm 4bl. kort nozzle propeller for m5 thread

€5

Diving Buddy Underwater Sea Scooter

€2.35

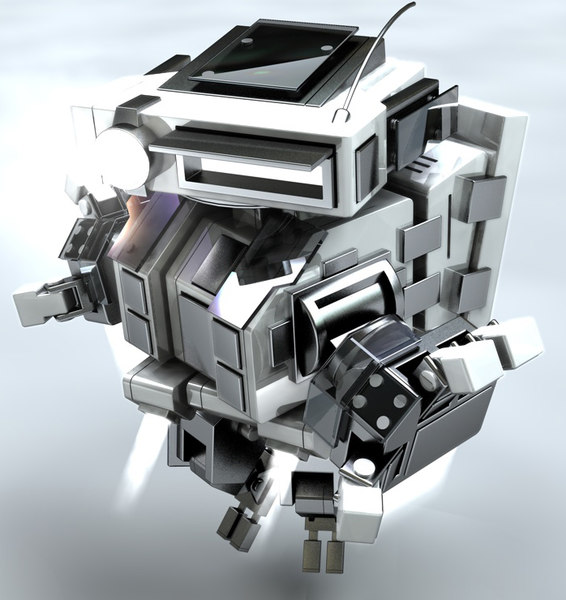

Spacecraft Thruster

€1.65

Hexagonal thruster

€1.45

Engine / Thruster 2

€1.65

Aerospike Engine/Thruster Cubical

Free

Aerospike Engine/Thruster

€1. 45

Reactive Control System (RCS thrusters)

Free

Rocket Enigne/Thruster

€1.24

Engine / Thruster with Hexagonal Grid

€1.20

Engine / Thruster

€1.68

water thruster for paddle board STL 3D Digital File 3D Printer Printable

€1.83

Micro Motor Thrust Stand V1

Free

3d printed thurster

Free

Catamaran propeller support 1G

€3

SUP fin for Bluerobotics T200 electrical thruster

€7

Sleek Single Pod MRF Engines (Gaslands)

Free

Anatec catamaran hoses 1st 90MM for propeller

€5

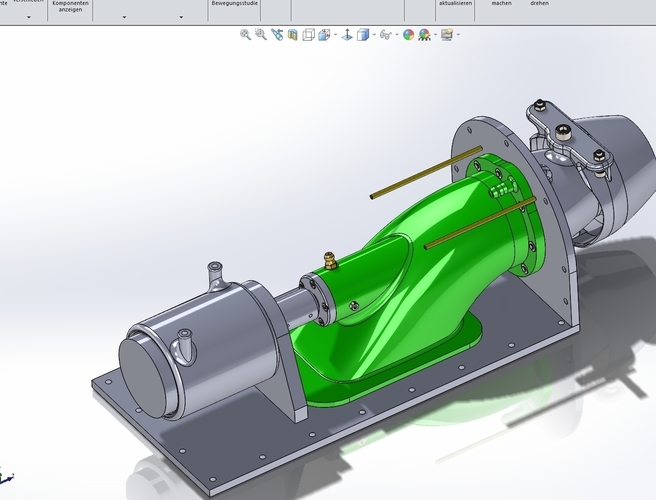

mjs2008 Bow Thruster 30-50mm 3D print model

€16

Kerbal Space Program - RV-105 RCS Thruster Block

Free

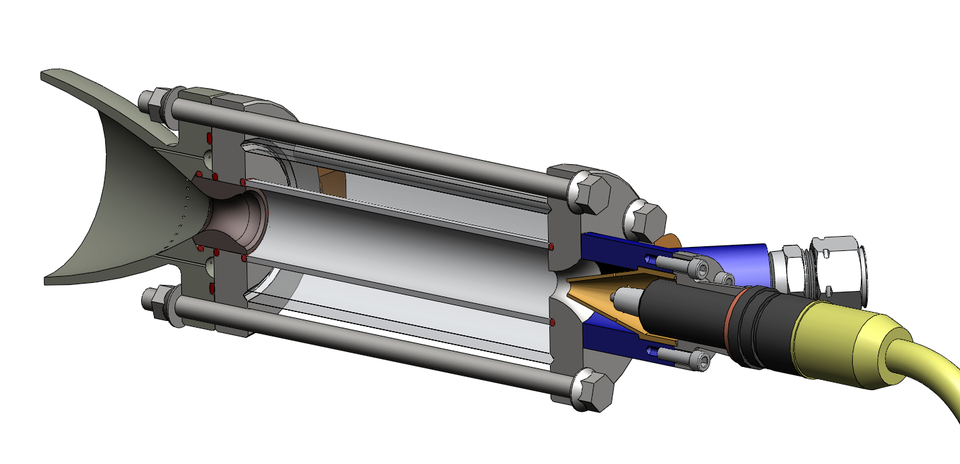

WATER JET PROPULSION UNIT SMALLER MAIN HOUSING 80MM- FOR ENDER 3

€4. 70

70

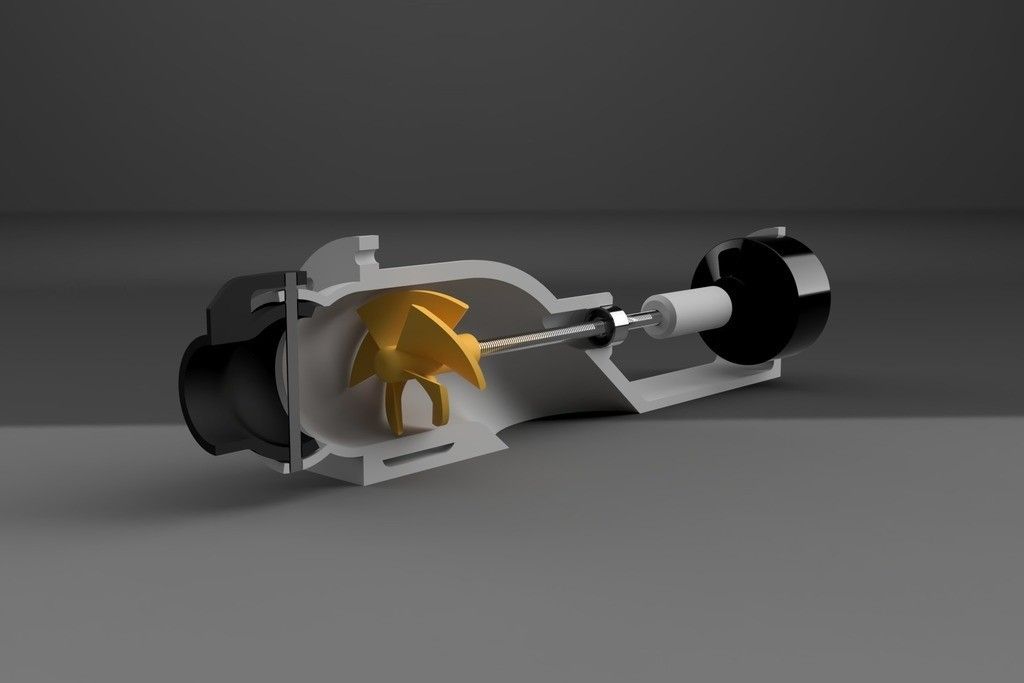

Water Jet Propulsion Pump Unit Hamilton Water Jet Thruster 50mm

€8.70

WATER JET PUMP PROPULSION UNIT 80MM

€10.50

thruster

€4

mjs2002-17 Bow Thruster 17mm for scale model boats

€8

mjs2002-23 Bow Thruster 23mm for scale model boats

€8

mjs2002-21 Bow Thruster 21mm for scale model boats

€8

Thruster Fin

Free

Ball channel

€2.10

multi-shot ball launcher

€4.48

ball thrower

€3.69

mjs1701BG v2 Bow Thruster for Bernhard Gruben DGzRS or SAR boat 3D print model

€11. 15

15

mjs1812 Veth Jet 360 thruster for Smit Bronco tug

€11.77

ROV Kort Nozzle for Bilge Pump Thruster w/Integrated Mount.

Free

ROV Kort Nozzle for Bilge Pump Thruster

Free

Rocket Thruster

Free

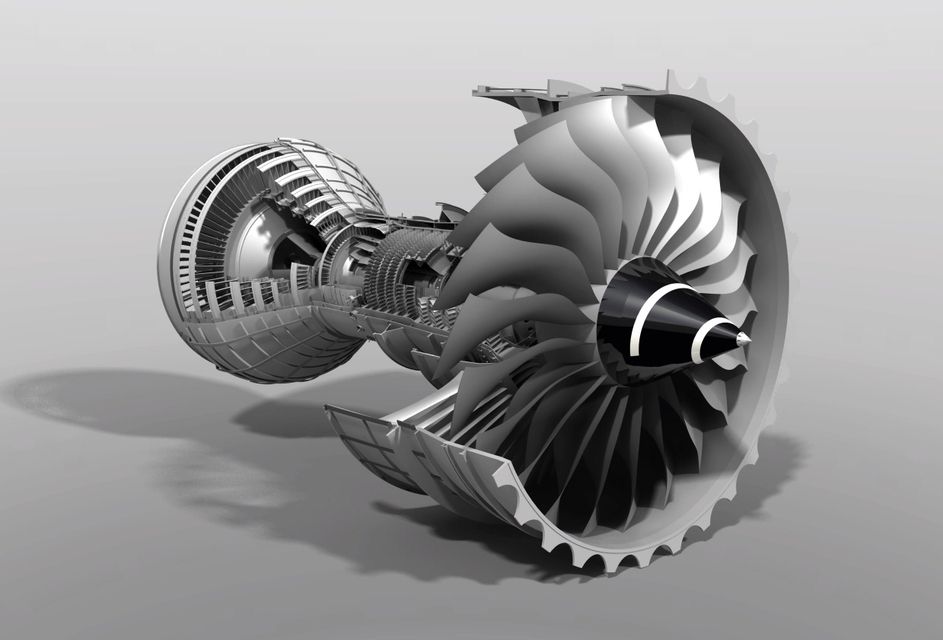

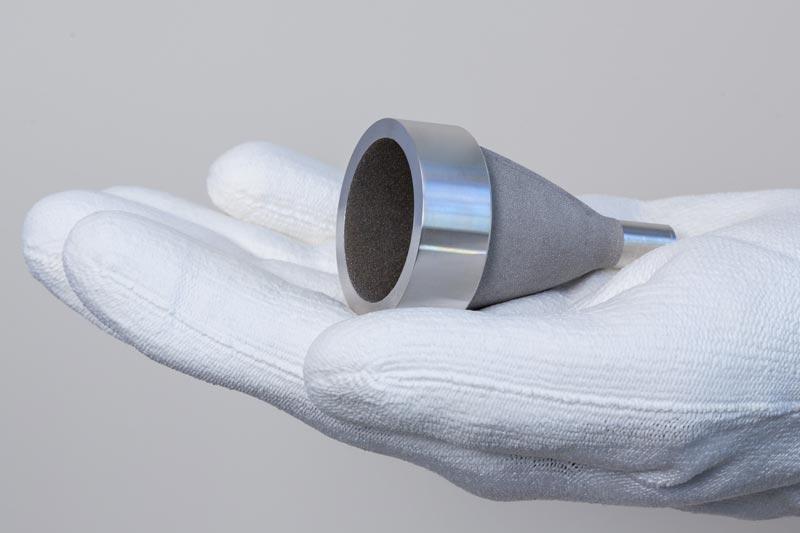

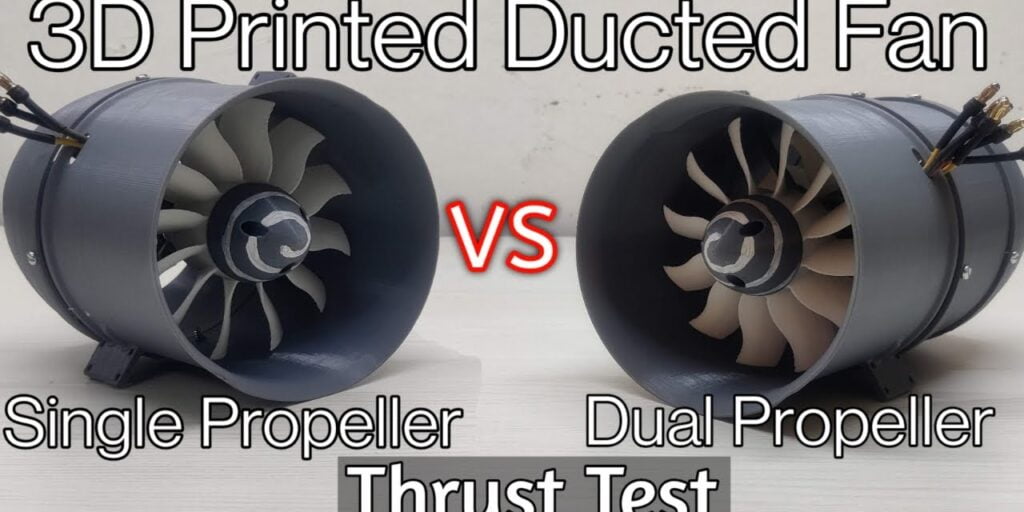

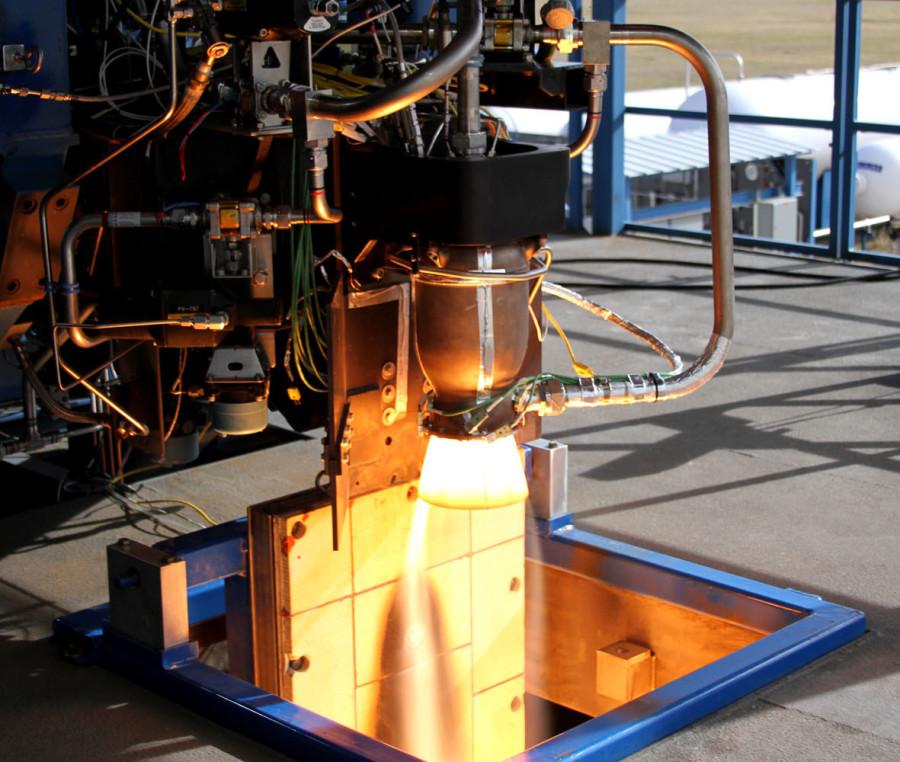

3D-Printed Thruster Boosts Range of CubeSat Applications

A new 3-D printed electric thruster could one day help make advanced miniature satellites significantly easier and more affordable to build, a new study finds.

Conventional rockets use chemical reactions to generate propulsion. In contrast, electric thrusters produce thrust by using electric fields to accelerate electrically charged propellants away from a spacecraft.

The main weakness of electric propulsion is that it generates much less thrust than chemical rockets, making it too weak to launch a spacecraft from Earth’s surface. On the other hand, electric thrusters are extremely efficient at generating thrust, given the small amount of propellant they carry. This makes them very useful where every bit of weight matters, as in the case of a satellite that’s already in orbit.

On the other hand, electric thrusters are extremely efficient at generating thrust, given the small amount of propellant they carry. This makes them very useful where every bit of weight matters, as in the case of a satellite that’s already in orbit.

Electric thrusters have propelled spacecraft for decades, but these have often relied on compressed gases stored in bulky pressurized tanks, as well as pipes, valves and pumps to shuttle those gases around. A new kind of electric rocket, known as an electrospray thruster, instead relies on salty fluid propellants known as ionic liquids.

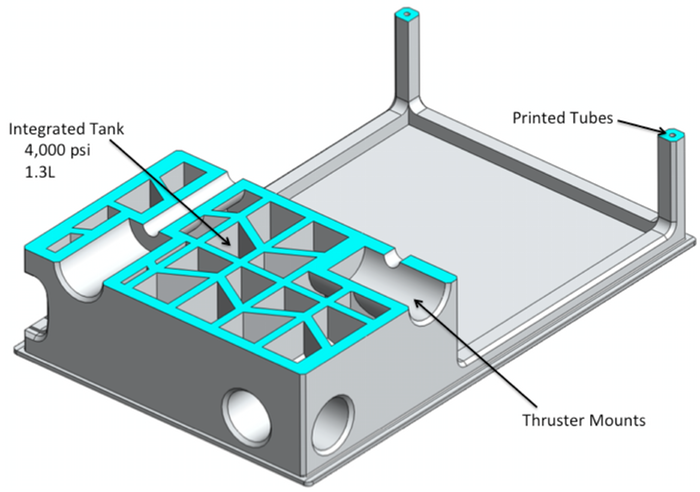

The new 3D-printed electrospray thruster is roughly the size of a dime. Inside the device is an array of miniature cones that are each covered with a forest of zinc oxide nanowires. These nanowires act like candlewicks, drawing liquid from a reservoir onto the cones. When the cones generate electric fields, they spray ions out microscopic nozzles.

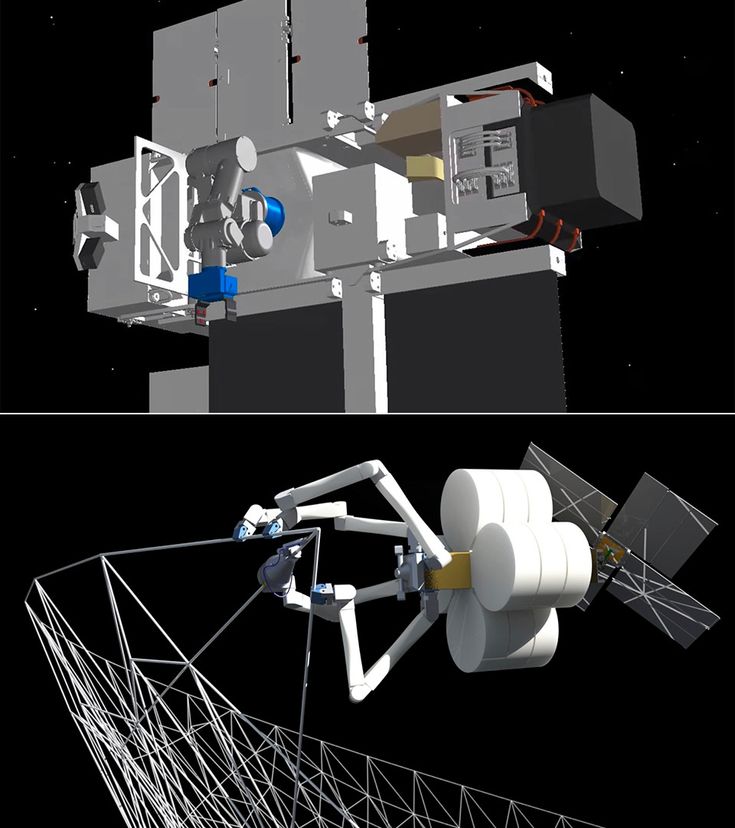

The amount of force the new thruster generates is a few dozen micronewtons, roughly equal to half the weight of a sesame seed. Still, in the absence of air friction in outer space, even such a minuscule amount of force could help a miniature spacecraft maneuver in orbit. CubeSats are each just the size of a Rubik's Cube and weigh about 1 kilogram. Envisioned CubeSat applications include one day providing satellite-based Internet or Earth-observing networks, says study senior author Luis Fernando Velásquez-García, principal research scientist at MIT’s Microsystems Technology Laboratories.

Still, in the absence of air friction in outer space, even such a minuscule amount of force could help a miniature spacecraft maneuver in orbit. CubeSats are each just the size of a Rubik's Cube and weigh about 1 kilogram. Envisioned CubeSat applications include one day providing satellite-based Internet or Earth-observing networks, says study senior author Luis Fernando Velásquez-García, principal research scientist at MIT’s Microsystems Technology Laboratories.

The new device is the first electrospray thruster produced entirely using additive manufacturing techniques: Its body was made using 3-D printing, whereas the zinc oxide nanowires were grown in reactors. As such, the researchers say it could prove far cheaper and faster to make than other electrospray thrusters made using subtractive manufacturing techniques such as laser machining.

“Making the devices via 3D printing is 1 percent of the cost and time it takes making them in the cleanroom,” says Velásquez-García. “There’s this idea that space is for the best and wealthiest, and our work could help change that. Space is for everyone.”

Space is for everyone.”

The researchers note their new invention is also the first electrospray thruster to emit a stream of pure ions, instead of ions mixed in with electrically neutrally charged molecules as other electrospray thrusters do. This means it can use its electrical fields on more of its spray than other electrospray thrusters, giving it more thrust per unit of spray and operating more efficiently overall. Such efficiency is key for objects in orbit, since refueling satellites is rarely an option.

Velásquez-García says these new engines could help prolong the lifespan of satellites around Earth by keeping their orbits from decaying, or prove useful for probes on deep-space missions.

“A key advantage of 3-D printing is that it allows you to aggressively iterate designs,” Velásquez-García adds. “In 3-D printing, it’s okay to make mistakes. You learn from your mistakes, and you have the time and resources to make better devices.”

More research is needed before these 3D-printed thrusters can reach the market, Velásquez-García says, including understanding whether the devices degrade after long-term operation, and building thrusters with larger, denser emitter arrays.

Velásquez-García and study lead author Dulce Viridiana Melo Máximo detailed their findings in the December issue of the journal Additive Manufacturing.

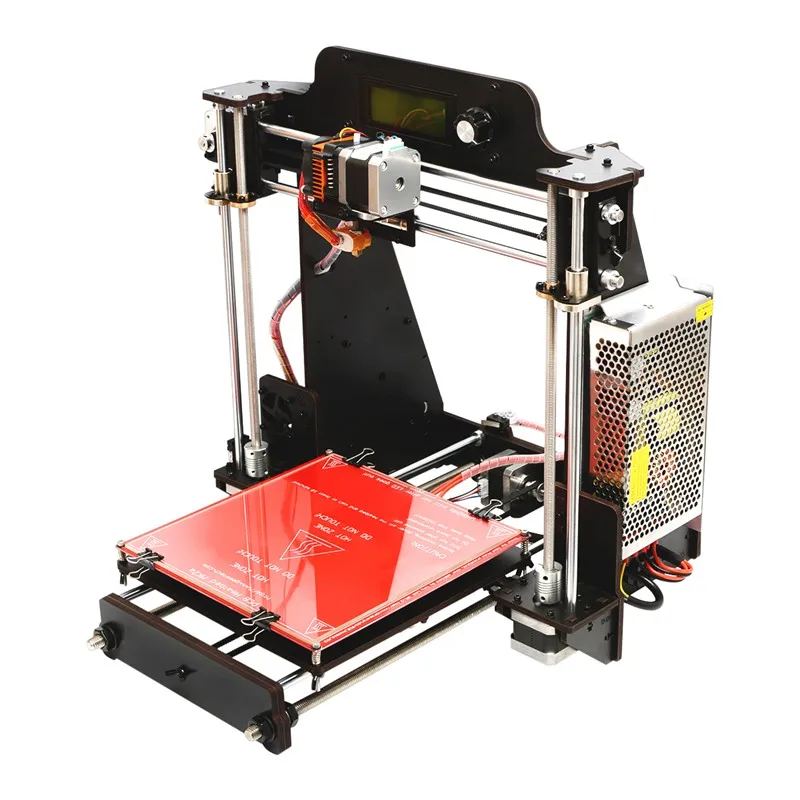

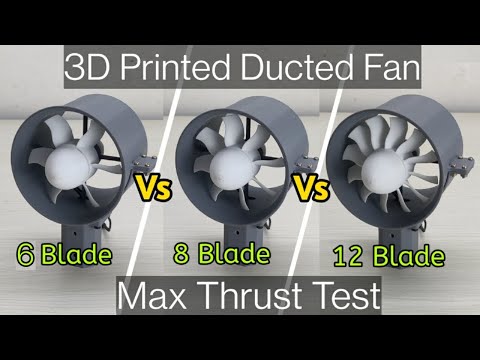

3D printing engine (5 best models for 3D printing)

3DPrintStory 3D printing process How to 3D Print an Engine (Top 5 Models for 3D Printing)

3D printing at home has come a long way. To date, there are a huge number of 3D printers in various price ranges, there are plenty to choose from. And as there are more and more happy owners of 3D printers, the community is growing, there is a huge number of 3D models that people share. But the static figures downloaded from Thingiverse are gradually getting bored and I want new challenges and experiments. Well, you've come to the right place. How about printing a running electric motor? nine0005

Well, you've come to the right place. How about printing a running electric motor? nine0005

If you're interested, then wellcome to the rest of the article, because here we have collected for you the best options for engine designs that you can print on your 3D printer.

Brushless motor

This motor, designed and manufactured by Christophe Laimar, has impressive power. The 3D printed motor uses a 3D printed rotor and stator and delivers 600W of power with an efficiency of 80%. The complexity of 3D printing rightly allows it to be used as a demonstration of technical prowess as well as knowledge of 3D printing. nine0005

Where to find : You can download the part files from the developer's website for a fairly small $10 license fee. Also included is an approved list of 3D printing hardware and engine components.

How to make : Christophe provides very detailed information on how to print and assemble this impressive brushless motor project. You can find the full instructions for 3D printing and assembling this model on Instructables. nine0005

You can find the full instructions for 3D printing and assembling this model on Instructables. nine0005

In the video below you can see how this engine works.

Simple DC Motor

This motor is amazingly simple: it was designed for training purposes by user Thingiverse for MakerEd Challenge 2.0.

Where to find : Thingiverse has all the parts you need to 3D print this DC motor. In addition, there are detailed instructions for assembling the model, as well as materials with examples of its use. nine0005

How to make : Follow instructions on Thingiverse where the author recommends printing at a high resolution of 0.1mm. In addition, it provides a complete list of required parts for a complete build so that even before starting this project, you can be fully prepared and armed with everything you need.

A short video demonstrating the operation of this 3D printed motor is shown below.

Mendocino small solar motor

As stated by the creator, "The Mendocino engine is a solar-powered electric motor with magnetic levitation." Watching a video of his work will definitely make you wonder and realize how interesting this design really is. The assembled model is practically a work of art, with a stylish floating design.

Where to find : This unusual engine model can be found on Thingiverse.

How to make : The author used a 0.5 mm nozzle with a layer height of 0.2 mm for the stator components. Detailed instructions are also provided on the Thingiverse page. nine0005

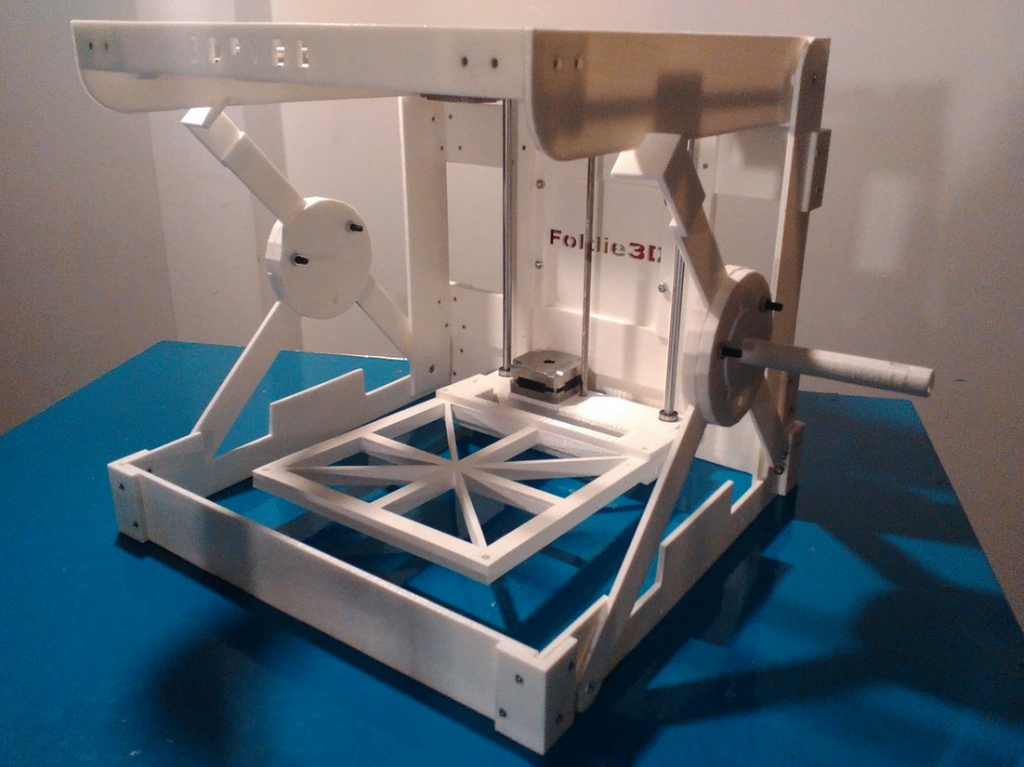

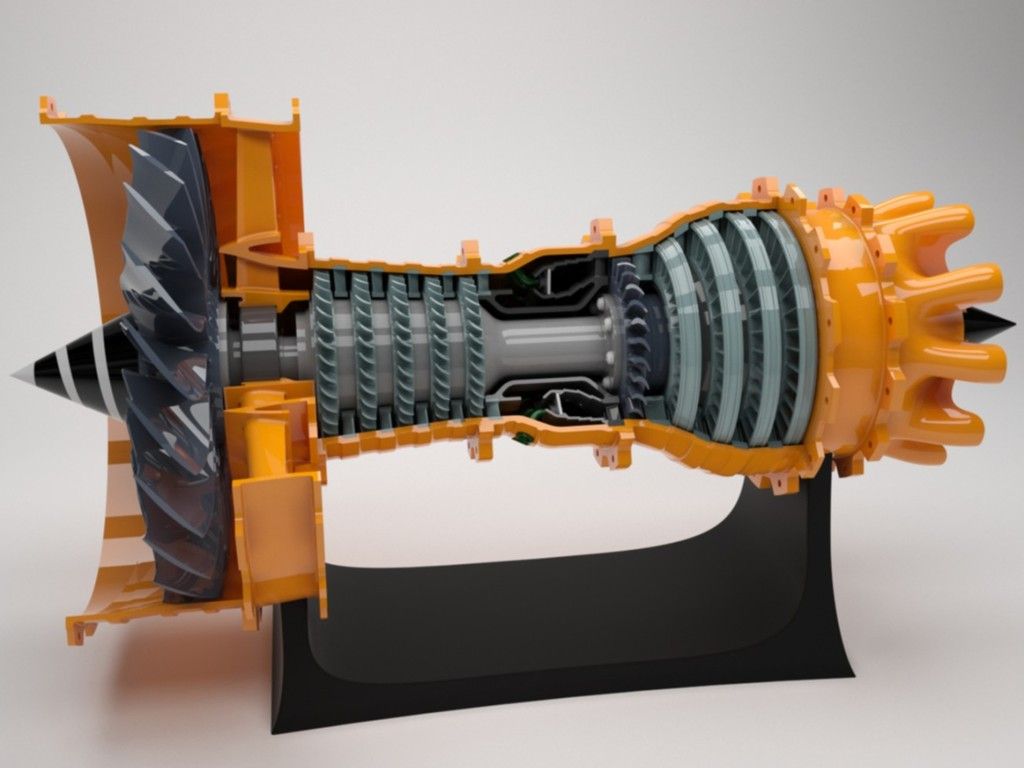

Tesla Turbine

The model was originally designed and manufactured by the Portuguese manufacturer and engineer Integza. This 3D printed engine is based on a Tesla turbine. It is propelled by the use of high-pressure air, acting in a vortex through thin, 3D printed plates. The original design used a few 3D printed components, but the current second iteration is almost entirely 3D printed.0005

It is propelled by the use of high-pressure air, acting in a vortex through thin, 3D printed plates. The original design used a few 3D printed components, but the current second iteration is almost entirely 3D printed.0005

Where to find : The author has posted 3D printing files and instructions on her Thingiverse page.

How to make : unfortunately the author does not offer any technical documentation. But the author has a video where he reveals some background of this project, and also describes the build process.

Spring Motor

Designed and printed by Greg Zumwalt, this powerful 3D printed spring motor demonstrates the unique properties of PLA plastic. And it's especially impressive that Greg has created many other models based on the lessons learned in this project. nine0005

Where to find : Greg Zumwalt posted all his part files on MyMiniFactory.

How to make : Greg has posted instructions on MyMiniFactory that explains in detail how to print and assemble each of the parts. The most important tip is to print with 100% coverage. In addition, he recommends using light machine oil for lubrication.

Here are just a few options to make your 3D printed projects even more colorful and impressive. As you can see, 3D printing is about more than just static miniatures. Implement at least a couple of the above projects, and your knowledge in the field of 3D printing (and not only) will expand significantly. Well, if the above electric motor designs are too easy for you, then why not create your own? nine0005

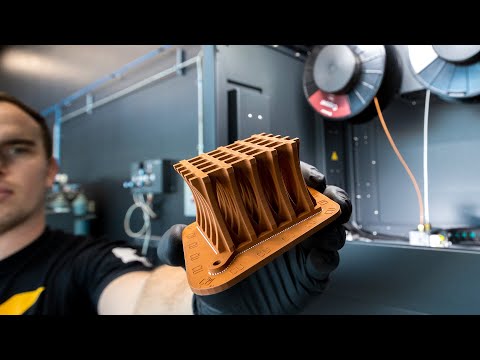

VIAM manufactured the first Russian 3D printed jet engine

Specialists of the All-Russian Research Institute of Aviation Materials (VIAM) completed the first domestic project for the production of a gas turbine engine using additive technologies. The manufactured functional prototype is a promising development of a small-sized engine for unmanned aerial vehicles. According to VIAM CEO Evgeny Kablov, some unique characteristics, including the design of the combustion chamber with a wall thickness of only 0.3 mm, were achieved only through the use of 3D printing. Recall that earlier VIAM produced 3D-printed swirlers for combustion chamber front-end devices for PD-14 engines designed for operation on promising MS-21 long-haul airliners and currently undergoing flight tests. nine0005

According to VIAM CEO Evgeny Kablov, some unique characteristics, including the design of the combustion chamber with a wall thickness of only 0.3 mm, were achieved only through the use of 3D printing. Recall that earlier VIAM produced 3D-printed swirlers for combustion chamber front-end devices for PD-14 engines designed for operation on promising MS-21 long-haul airliners and currently undergoing flight tests. nine0005

3D printing can even be used to print engines.

Content

- 1 3D printer Pollen PAM

- 2 Table 3D-printing with metals

- 3 Budgetary educational 3D printer

- 4 Tomsk Polytechnic will be prepared by 3D printers

- 5 SECTIPIRIGE CENTERIGE

- 50103 50103 6 Printing houses on a 3D printer

- 7 The first domestic 3D printer for metal printing

- 8 A group of 3D printers

- 9 First Russian festival Maker Faire

Pollen Pam 3D printer

The device uses a scheme borrowed from delta robots.

The French company Pollen has introduced a desktop 3D printer that can not only print colored products, but also use granular plastics as consumables. The massive print head is capable of mixing four materials of different types and colors at once, including both conventional thermoplastics and carbon fiber and mineral composites. In order for the bulky head not to interfere with fast printing, the assembly is fixed, and a light worktable is set in motion along all three axes. According to 3Dtoday, the use of granulated plastic instead of filament will theoretically allow not only to reduce the cost of consumables, but also to recycle plastic waste shredded with a shredder. nine0005

Desktop Metal 3D Printing

A 1/2 pound spool of copper or bronze composite is $85.

One of the most cherished areas in 3D printing is the printing of metal products. Unfortunately, this area is almost exclusively represented by industrial installations, whose cost ranges from a few hundred thousand to a couple of million dollars. Available additive technologies are tailored for printing with thermoplastics and photopolymer resins, but there is a possibility to circumvent fundamental limitations. The method consists in 3D printing with composites consisting of polymers filled with metal powder. Such materials are not only outwardly similar to metals, but can also be fired with sintering of metal particles. A series of specialized bars "Filamet" was presented by Virtual Foundry: composites based on PLA and ABS are 88% composed of metal particles. Although a sufficiently high shrinkage is unavoidable during firing, the final products can safely be called all-metal. nine0005

Available additive technologies are tailored for printing with thermoplastics and photopolymer resins, but there is a possibility to circumvent fundamental limitations. The method consists in 3D printing with composites consisting of polymers filled with metal powder. Such materials are not only outwardly similar to metals, but can also be fired with sintering of metal particles. A series of specialized bars "Filamet" was presented by Virtual Foundry: composites based on PLA and ABS are 88% composed of metal particles. Although a sufficiently high shrinkage is unavoidable during firing, the final products can safely be called all-metal. nine0005

Budget Educational 3D Printer

Printer operation is simplified to the maximum with features such as automatic calibration, and specially designed filaments that do not contain toxic substances will be used as consumables.

Taiwanese company XYZ Printing offers a dedicated da Vinci miniMaker printer for teaching basic 3D printing skills. The device is intended primarily for educational institutions, and its main advantage is its low price, which is only 229dollars. The printer was developed on the basis of the popular da Vinci line, which has found fame as inexpensive, but very high-quality and capable 3D printing devices. Users will also have access to the XYZmaker entry-level 3D editor and the XYZprinting STEAM educational project.

The device is intended primarily for educational institutions, and its main advantage is its low price, which is only 229dollars. The printer was developed on the basis of the popular da Vinci line, which has found fame as inexpensive, but very high-quality and capable 3D printing devices. Users will also have access to the XYZmaker entry-level 3D editor and the XYZprinting STEAM educational project.

Tomsk Polytechnic University will train developers of 3D printers

Ten state-funded places were allocated for the program, and the first admission to the master's program will take place this fall.

Tomsk Polytechnic University (TPU) announced its intention to train specialists in the field of additive technologies. As Vitaly Drobchik, secretary of the selection committee, explained, the emphasis will be placed not so much on training technicians to service 3D printing equipment, but on engineers capable of developing new technologies and devices. As 3Dtoday notes, the university has the necessary groundwork: TPU is known for the successful development of technologies in the field of production of fine powders, the manufacture of experimental 3D-printed implants from titanium alloys and participation in the project of the first Russian satellite with 3D-printed structural elements "Tomsk-TPU 120", currently awaiting launch from the International Space Station. nine0005

nine0005

St. Petersburg Prototyping Center

A new prototyping center has opened in St. Petersburg to help small businesses and innovative companies develop and mass-produce new products. The center offers a wide range of tools, including six 3D printers, 3D scanners, measurement instruments and electronic circuit debugging equipment. According to director Sergey Varlamov, the center has already implemented thirteen projects of varying complexity, including 3D printing of a ship power plant model for a large industrial enterprise. The doors of the center are open to companies of any profile. nine0005

3D printed houses

3D printed houses? Easy!

Spanish architects are considering the idea of 3D building printing, but refuse to keep up with the rest of the developers. The fact is that Catalan researchers are interested in the possibility of building high-rise buildings, where popular stationary 3D printers will not be applicable due to size restrictions. Instead of fencing skyscraper-tall 3D printers, researchers at the Institute of Contemporary Architecture of Catalonia (IAAC) suggest entrusting the task to teams of small 3D-printing robots that can navigate the walls being erected. In the current version, the tasks are distributed among three groups of machines: the first lays the foundation and prints the first layers of the walls, the second increases the walls in height, moving along the upper layers, and the third crawls directly along the surfaces of the walls, holding with the help of vacuum pumps and strengthening the structure with additional layers of the mixture. Although full-fledged construction with the help of such devices seems to be a matter of the distant future, construction robots may soon find application in the construction of especially dangerous sections of high-rise buildings. nine0005

Instead of fencing skyscraper-tall 3D printers, researchers at the Institute of Contemporary Architecture of Catalonia (IAAC) suggest entrusting the task to teams of small 3D-printing robots that can navigate the walls being erected. In the current version, the tasks are distributed among three groups of machines: the first lays the foundation and prints the first layers of the walls, the second increases the walls in height, moving along the upper layers, and the third crawls directly along the surfaces of the walls, holding with the help of vacuum pumps and strengthening the structure with additional layers of the mixture. Although full-fledged construction with the help of such devices seems to be a matter of the distant future, construction robots may soon find application in the construction of especially dangerous sections of high-rise buildings. nine0005

The first domestic 3D printer for metal printing

Why use only plastic when you can use metal?

Ural Federal University (UrFU) intends to demonstrate its own industrial 3D printer for printing metals using the selective laser deposition method (SLM) at the upcoming INNOPROM 2016 exhibition. According to the First Vice-Rector Sergei Kortov, "the machines do not require the purchase of imported components, in addition, domestic software is used." According to 3Dtoday sources, the share of domestic components and software can reach 80%. The development of an experimental device is carried out for about six months, and similar devices manufactured by the German company EOS were used in its manufacture. nine0005

According to the First Vice-Rector Sergei Kortov, "the machines do not require the purchase of imported components, in addition, domestic software is used." According to 3Dtoday sources, the share of domestic components and software can reach 80%. The development of an experimental device is carried out for about six months, and similar devices manufactured by the German company EOS were used in its manufacture. nine0005

If the project is successful, it will be possible to eliminate the critical dependence of the domestic additive industry on the supply of foreign industrial equipment for metal 3D printing. The exhibition is scheduled for July 11-14.

If you are interested in science and technology news, subscribe to us on Google News and Yandex.Zen so as not to miss new materials!

3D Printer Group

The software controls the robotic arm that maintains the 3D farm offline. nine0005

It is generally accepted that 3D printing is limited to rapid prototyping, but at least small-scale production is possible and economically justified using 3D printing farms. However, the simultaneous operation of ten or more desktop printers requires the constant attention of the operator, monitoring for possible failures, removing and cleaning finished models, and reloading 3D printers with consumables. Startup Tend.ai came up with a slightly intimidating idea to make the task easier: instead of monitoring ten machines, why not entrust the task to one more machine? To this end, the team is developing a control system with elements of artificial intelligence. nine0005

However, the simultaneous operation of ten or more desktop printers requires the constant attention of the operator, monitoring for possible failures, removing and cleaning finished models, and reloading 3D printers with consumables. Startup Tend.ai came up with a slightly intimidating idea to make the task easier: instead of monitoring ten machines, why not entrust the task to one more machine? To this end, the team is developing a control system with elements of artificial intelligence. nine0005

The high flexibility of the system makes it easy to retrain robots to work with different models of 3D printers, and the number of simultaneously serviced devices in the current version reaches 30 pieces. The commercial premiere of the Tend.ai system is scheduled for 2018.

The first Russian festival Maker Faire

There is no more famous holiday in the world community of do-it-yourselfers than Maker Faire festivals.

These events have been held all over the world for about ten years and attract enthusiasts with the most crazy and ingenious ideas.