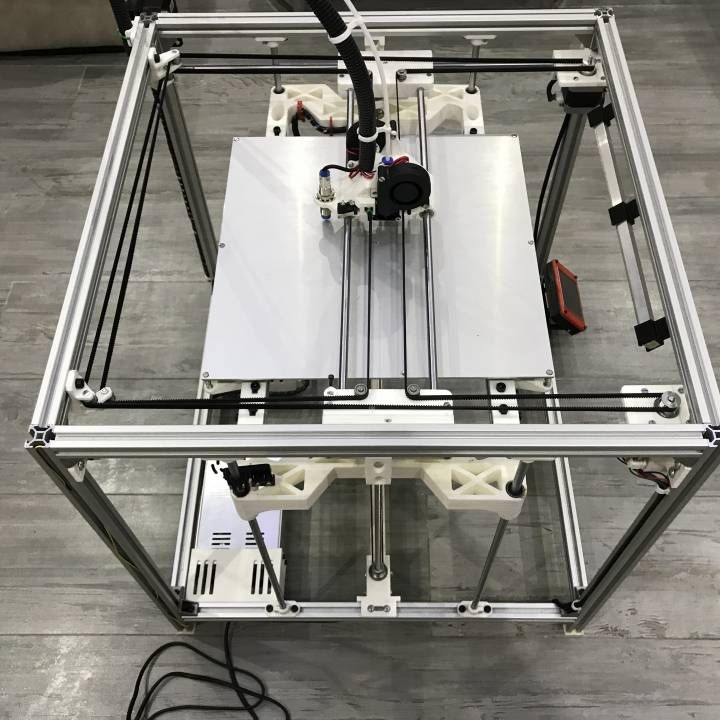

Originator i1 3d printer

3D MAKERJET LAUNCHES A NEW INTERACTIVE WEBSITE.

3D MakerJet Inc. has launched a new interactive website complete with social media integration and daily live chat product support.

3D MakerJet Inc. develops premier, industrial-grade premium desktop printers; sized and aggressively priced, for the consumer, professional, and business markets.

The company, who recently launched their corporate headquarters and showroom in Orlando, Florida, is supplied by ZBOT, one of the world's largest and most successful 3D developers and manufacturers of the latest 3D printers and technology.

www.3DMakerJet.com has introduced the company's first line of

affordable desktop plastic printers (Originator Series models i1, i2,

20, and 35) and a wide selection of multi- color ABS and PLA filaments,

spare beds and nozzles. Upcoming products will include a 6-foot tall

Human Body Scanner, a self-cooling candy printer, and the world's

first Powderless metal printer, currently in co- development with

ZBOT/Guangzhou DNSPOWER Design CO. LTD.

We launched the website with social channel integration and live chat product support because we simply want to be connected with our customers on a daily basis, says John Crippen, President of 3D MakerJet. We use two platforms currently; Facebook and Twitter, because it gives us the opportunity to share in the excitement and joy our customers are feeling when their ideas are made real. The same goes for support, so our customers get the most out of their 3D printing experience.

3DMakerJet's support is powered by Zopim Live Chat (www.zopim.com) for daily live chat customer service during 9:00am-5:00pm EST Monday - Friday. Customers can also call directly into the 3DMakerJet corporate headquarters support line using 407.930.0811, or can simply email questions directly from the SUPPORT page on the www.3DMakerJet.com website.

About 3D MakerJet

3D MakerJet, Inc. the Orlando-based 3D printing company, is

committed to supplying the best plastic, medical, culinary, and

powderless metal 3D printers in the industry, and is supplied by one of

the largest and most experienced 3D printing Research, Development and

Manufacturing entities in the world. 3D MakerJet's Research &

Development Partner and Manufacturer, ZBOT / Guangzhou DNSPOWER Design

Co. LTD, was founded in 2000, and is a leader in the 3D printing

industry. A cutting-edge developer in the plastics and manufacturing

sector, ZBOT won the coveted CDA National Design Award for its ZBOT 3D

Printer, which is the platform of the 3D MakerJet printer line, making

their 3D printer the only CDA winner at the Civilian level, re?ecting

the product's superior quality, as well as the manufacturer's

comprehensive strength, commitment and capabilities. Additional offices

in the ZBOT Industrial Design Center in Guangzhou, China.

3D MakerJet's Research &

Development Partner and Manufacturer, ZBOT / Guangzhou DNSPOWER Design

Co. LTD, was founded in 2000, and is a leader in the 3D printing

industry. A cutting-edge developer in the plastics and manufacturing

sector, ZBOT won the coveted CDA National Design Award for its ZBOT 3D

Printer, which is the platform of the 3D MakerJet printer line, making

their 3D printer the only CDA winner at the Civilian level, re?ecting

the product's superior quality, as well as the manufacturer's

comprehensive strength, commitment and capabilities. Additional offices

in the ZBOT Industrial Design Center in Guangzhou, China.

For more information, visit www.3DMakerJet.com or call 647/762-7962.

Which 3D printer should I buy?

Which 3D Printer Should I Buy?

Overview of 3D printer options

In this section I'll give you a brief overview of your options for 3D printers. This list is certainly going to change quickly now that the market has opened up for lower end systems so be sure to send us a note with a link to information if you know of a system that should be included on this page. I'll review the information you send and I'll do my best to keep this page up to date.

This list is certainly going to change quickly now that the market has opened up for lower end systems so be sure to send us a note with a link to information if you know of a system that should be included on this page. I'll review the information you send and I'll do my best to keep this page up to date.

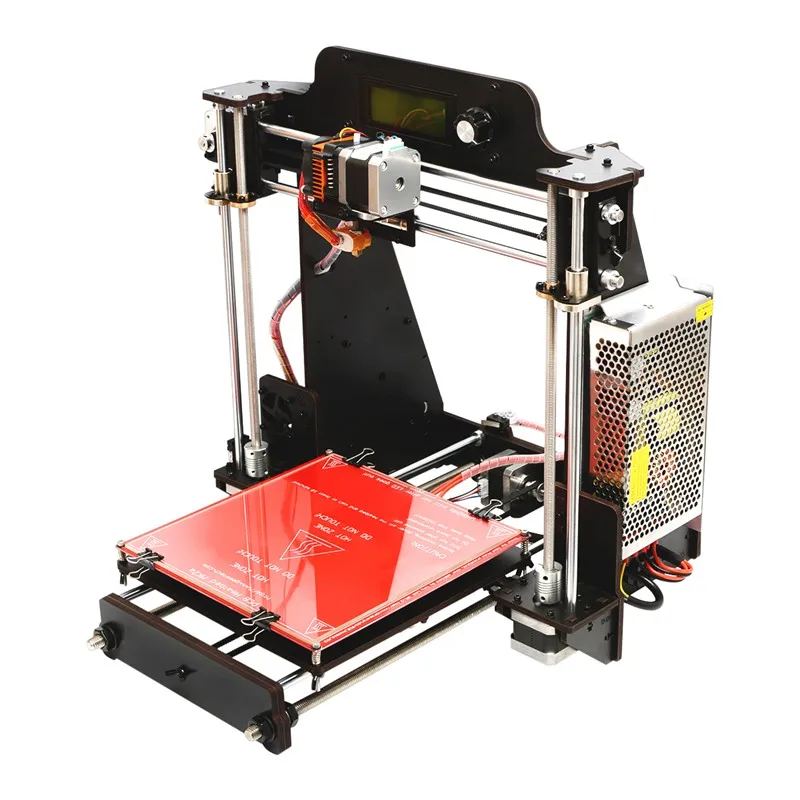

There are two categories of 3D printers sold to the general public. FDM (Fused Deposition Modeling) and SLA (stereolithography apparatus). FDM printers and filaments are much cheaper than SLA printers and materials.

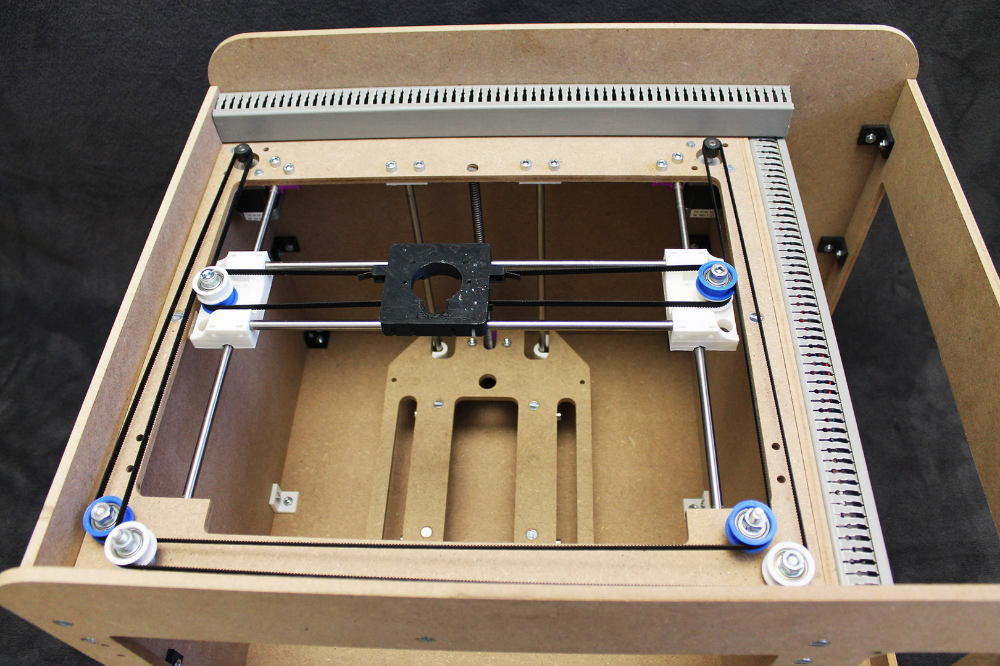

FDM PrintersOverview

FDM stands for fused deposition modeling. Picture a hot glue gun attached to a CNC gantry. It lays down one layer of plastic at a time which creates a 3D shape. The plastic used is called filament and it typically costs from $20/kg to $50/kg. Some brands or specialty filaments cost less and some cost much more.

Popular Choices

- Ender - very low cost with decent quality

- Creality series - (open source design) low cost with a large print area.

Some models have good quality. Check reviews before choosing.

Some models have good quality. Check reviews before choosing. - Zortrax - (proprietary hardware, firmware and software) Easiest to use and most reliable FDM printer. Doesn't require the user to learn a maze of print settings. It does require printing with a raft which is sometimes difficult to remove. Best option for user's who want an easy to use printer and don't want to have to become an expert at using printing software.

- Prusa - ( open source design)Originator of open source 3D printing. Solid design and cult following. Great support community.

- Lulzbot - (open source design) Several models to choose from. Very established vendor. Prices are much higher than other open source designs.

- Many, many others...

FDM Feature Options

- Bowden extruders - allow lighter extruder which allows faster printing at the expense of slightly less precision

- Direct drive extruders - can feed flexible filaments using direct drive.

Highest precision possible with proper design.

Highest precision possible with proper design. - Multi material - feed multiple materials into one extruder and the system switches between filaments automatically

- Multi extruder - each extruder is fed a different material

- Materials - ABS and PLA are the most popular but there are hundreds of types and brands with more coming out every day. ABS can be vapor polished for a smooth finish but it will warp if used for large prints with long straight sides. ABS will withstand outside use and temperatures up to about 150F without becoming soft or warping under light load. PLA warps much less during printing and can offer a slightly better stock finish than ABS but will sag under light loading if exposed to temperatures over 120F, UV light (sunlight), or water. There are literally scores more types of materials with properties to fit every project.

Overview

SLA printers generally offer much higher resolution prints with smoother surfaces and are often the best choice if you need to print fine details such as jewelry or very small parts. It is common for SLA materials to cost over $100/kg and FDM filament is closer to $20/kg. This is a major factor to consider when selecting an printer since material costs will be higher than the cost of the printer over time.

It is common for SLA materials to cost over $100/kg and FDM filament is closer to $20/kg. This is a major factor to consider when selecting an printer since material costs will be higher than the cost of the printer over time.

Popular Choices

- Form2

- Peopoly Moai Laser SLA 3D Printer - Kit

- There are several others but not nearly as many choices as there are for FDM printers.

Laser

Projection

Materials

I have just barely scratched the surface here. I suggest going to the 3D Printing Resources and Links page to check out videos and information from some of my favorite content creators in this area.

Formlabs Form 1+ 3D Printer (SLA)

Form 1 + Printer from Formlabs, which uses laser stereolithography instead of extrusion - the layering of molten plastic - the object is formed by the thinnest layers of resin, photopolymerized under the action of a laser, which ensures the highest printing accuracy at 25 microns. Projects are very smooth with little need for post-processing, and thanks to the high print quality, you can create a model that matches the digital sample down to the smallest detail. nine0003

Projects are very smooth with little need for post-processing, and thanks to the high print quality, you can create a model that matches the digital sample down to the smallest detail. nine0003

Technical features:

Another feature of the Form 1+ is the ability to print parts with so-called "hanging parts" that extruder (FDM) printers rarely offer. (Printing without support)

Changes in Formlabs Form 1+ compared to the first version of the 3D printer:

- Print speed increased by 2 times

- 2nd generation laser, laser power increased by 4 times

- Print quality improved nine0014

Installation:

The Form 1+ printer is the simplest device in the world in terms of setup and connection complexity. You connect it via USB to a computer, select the desired file in the program and then send it for printing. The file is being downloaded to the printer, at this time the cable must not be pulled out, otherwise printing will not start. In 5-10 minutes, the file goes to the printer, and then you can turn off your computer, remove the wire, this will not affect printing in any way.

In 5-10 minutes, the file goes to the printer, and then you can turn off your computer, remove the wire, this will not affect printing in any way.

Usage details:

The printer indicator shows the progress of printing, which layer is in operation and the remaining time.

Large objects are sometimes easier to break off, but small ones should only be removed with a scraper. Remove the item - and immediately place it in isopropyl alcohol for about 10 minutes. A second wash is not necessary.

Printer dimensions 300 x 280 x 450 mm

Frame Metal + Glass

Color Orange

Maximum print size 125 x 125 x 165 mm

Platform no

Press material-photopolymer

layer thickness 25 μm

Type of assembly Fully Assembled

SD Card Net

Power 100-240 V, 50-60 Hz, 60W

Type of extruder no

according PreForm Software

Manufacturer Formlabs

Manufacturer's Warranty 12 months

9062 3 power cable0003 Printer

1 piece

1 piece

USB-Cabble

1 piece

Complex for part of the part:

1 Carpot

- Wash tubes

- Absorbent pads

- Tweezers

- Scraper

- Bottle

- Gloves

Source: Ink-Market.ru.

Please note that the approximate cost and delivery time are indicated. The exact calculation takes place at the time of ordering.

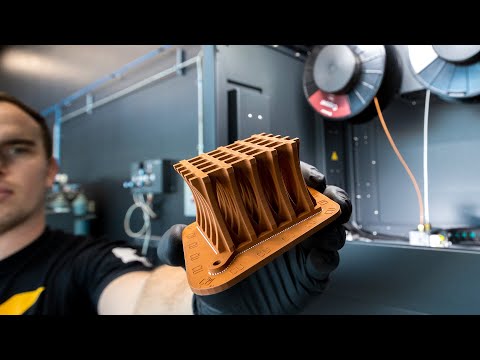

Video review of Fuse 1 - the first affordable SLS 3D printer / Sudo Null IT News Jack_K

Top 3D Shop Blog

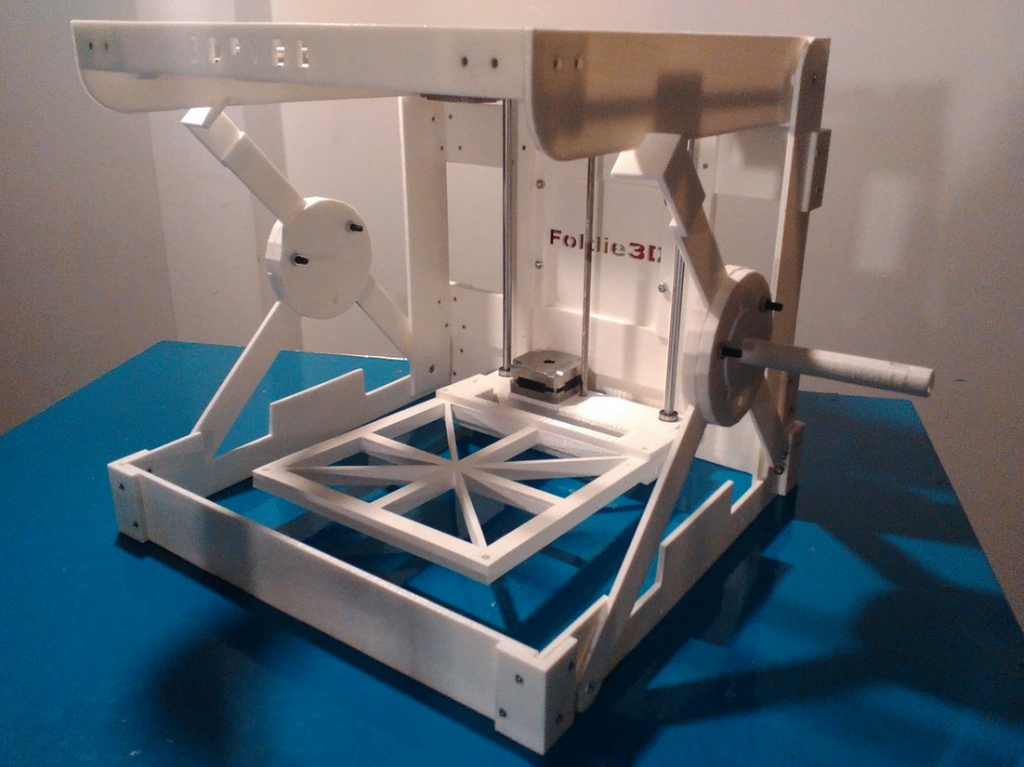

This is the first personal SLS 3D printer - previously this technology was only used in industrial printers for hundreds of thousands of dollars.

Original video released by Adam Savage's YouTube channel Adam Savage's TESTED.

What kind of printer

Formlabs Fuse 1

- Technology: SLS

- Printable area: 165 x 165 x 320 mm

- Print material: nylon

- Manufacturer's price, in the USA from: 9 999 usd

The price for Russia is not yet known, but you can pre-order for and receive information about the price as soon as it becomes available.

Video

What's interesting about Fuse 1

SLS (selective laser sintering) 3D printing technology was previously used only in industrial 3D printers. Such printers took up much more space and cost from a few hundred thousand dollars to a million. Fuse 1 is the first personal SLS printer, the price of which is ten times less, and the print quality is not inferior to expensive colleagues. nine0003

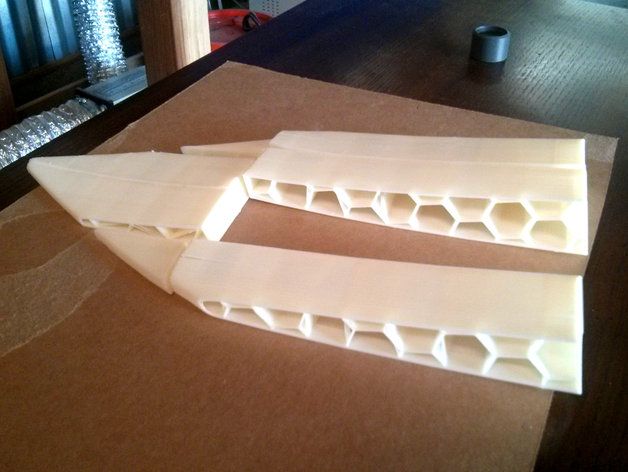

SLS technology fills the entire printable area, resulting in significant performance gains. Supports are not needed, which means that you can add as many details to the print as will fit in the workspace.

The print bed is a removable container to avoid downtime - simply replace the container when printing is complete and continue working. The printer can be used 24/7.

What prints

Fuse 1 prints with nylon, a material that compares favorably with common FDM plastics for its mechanical properties such as flexural and impact strength, wear resistance, heat and UV resistance.