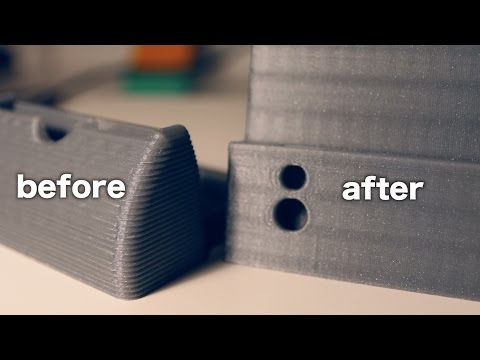

3D printing retraction problems

How to Avoid 3D Printing Issues Using Retraction Settings

3D Insider is ad supported and earns money from clicks, commissions from sales, and other ways.

Retraction is one of the built-in functions of FDM printers that can help address several 3D printing issues, particularly those related to over-extrusion. The great thing about retraction is that it can be tweaked very easily via your slicer.

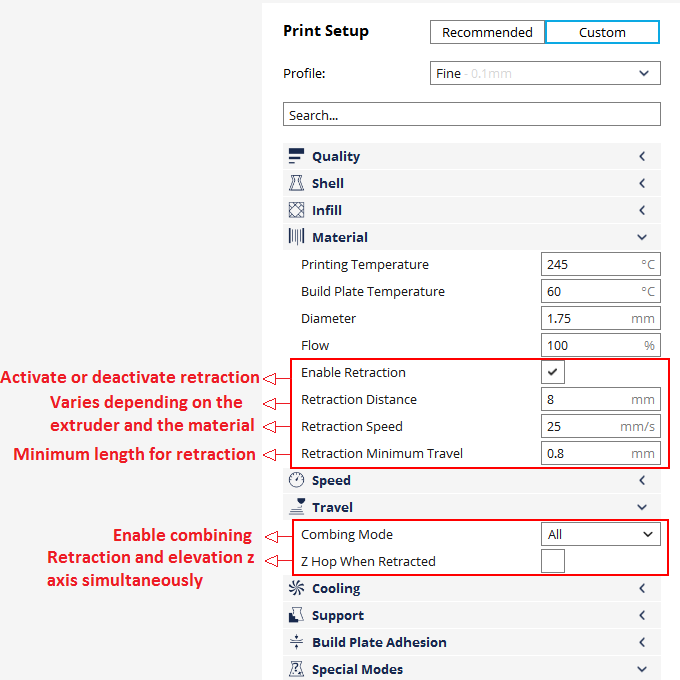

The basic parameters of retraction are distance, speed, and minimum travel distance. Other 3D printers may offer more advanced settings such as enabling “combing mode.” The optimal retraction settings can vary based on the filament you are using or the model you are printing.

Fine-tuning your retraction settings may take a bit of trial and error, but there are good starting points we can recommend so that you’ll get there faster.

How does retraction work?

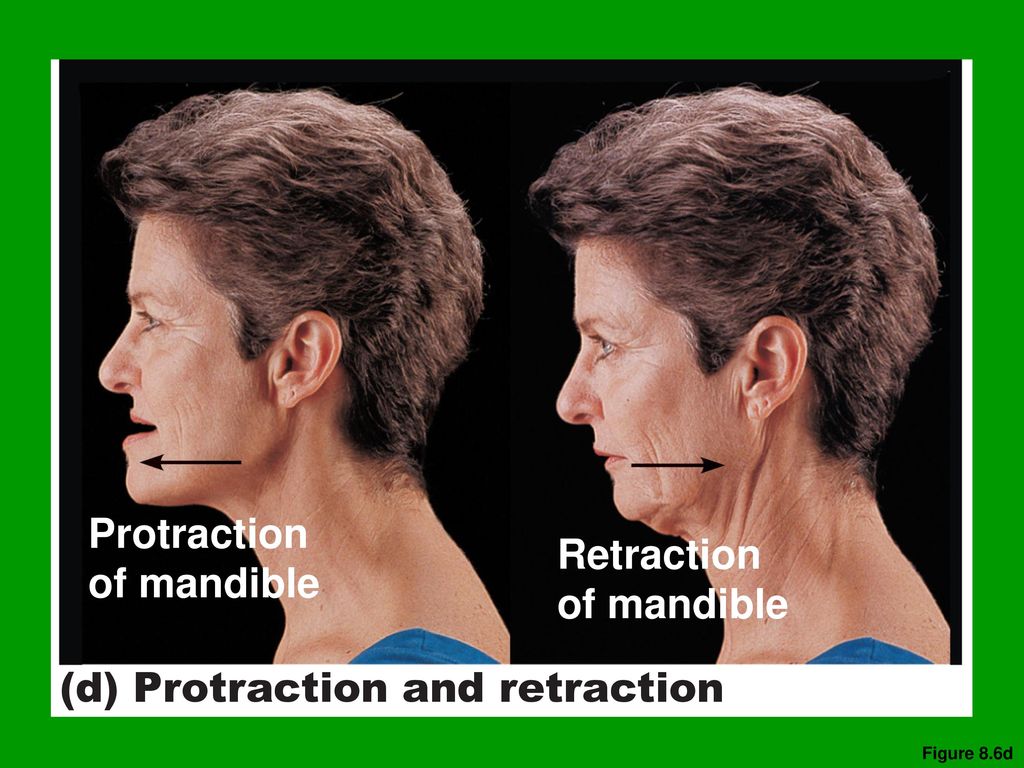

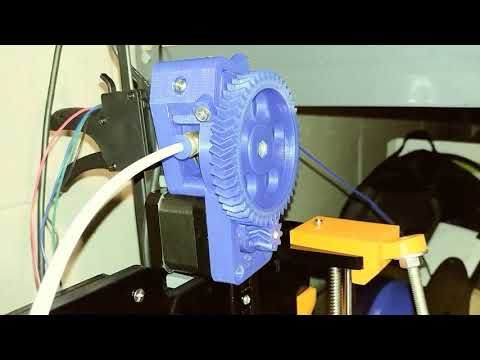

Retraction is a mechanism that allows the extruder to “pull back” a short segment of the filament. This happens via a reverse rotation of the extruder gears. By pulling back some of the filament, pressure on the hot end nozzle is relieved. This makes it less likely for molten filament to ooze out of the nozzle.

Enabling retraction is one of the more widely used solutions to stringing. This is a common 3D printing problem characterized by having very thing strands of filament or “strings” that ruin the aesthetics of the final print. Other symptoms of over-extrusion are blob in the final print or frequent jamming of the nozzle.

Some filaments are more prone to stringing than others. Good examples are flexible filaments such as TPU or TPE and filaments that print at very high temperatures such as Nylon. When working with these filaments, you can already expect to enable retraction to help avoid extrusion-related issues.

The standard settings for retraction are distance, speed, and minimum travel distance. Just about every 3D printer or slicer has these options. You can also choose to enable or disable retractions. Some slicers offer finer control over retraction performance via more advanced settings. Although retraction is generally beneficial, setting the parameters to very high values can also lead to other problems.

Some slicers offer finer control over retraction performance via more advanced settings. Although retraction is generally beneficial, setting the parameters to very high values can also lead to other problems.

Retraction distance

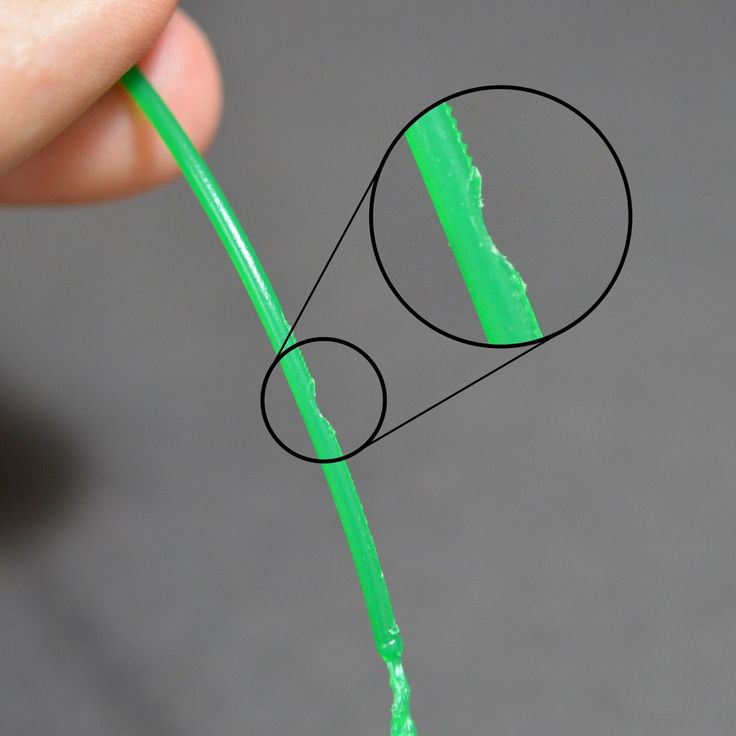

The most basic setting in retraction is the retraction distance. This refers to the length of the filament that is pulled back by the extruder during retraction. Retracting a greater length of filament generally causes better pressure relief in the melt zone. However, excessive retraction can also damage the filament and cause other extrusion issues.

The standard recommendation is to set the retraction distance at 5 mm at the start and adjust as necessary. If stringing is still observed, then increasing the retraction distance by 1-mm increments can be done. Only increase this until no more stringing is observed. It is rarely necessary to set a retraction distance higher than 7 mm.

Another rule of thumb is that printers with Bowden extruders will typically require a higher retraction distance compared to those with direct extruders. This is because of how far the extruder gears are from the nozzle – a unique characteristic of the Bowden extruder design. The difference isn’t a huge value – an additional 2 mm can give good results.

This is because of how far the extruder gears are from the nozzle – a unique characteristic of the Bowden extruder design. The difference isn’t a huge value – an additional 2 mm can give good results.

Retracting very long segments of filament can make filament damage more likely. This is more specifically known as “filament grinding” and happens because a segment of the filament goes through the extruder gears too many times. For this reason, setting retraction distance too high is generally not a good idea.

Retraction speed

The retraction speed refers to the speed at which the filament is pulled back by the extruder gears. Retracting at a high speed makes oozing or stringing less likely, but it can also significantly increase the likelihood of filament damage.

The rule of thumb is to use the fastest retraction speed setting that does not damage your filament. An easy way to tell this is to check for any filament dust around the extruder during retraction. This is a certain sign that some filament grinding is taking place. If this is observed, then reduce the retraction speed by 10 mm/s increments.

This is a certain sign that some filament grinding is taking place. If this is observed, then reduce the retraction speed by 10 mm/s increments.

Setting a faster retraction time should more readily resolve stringing and reduce your total printing time. We recommend limiting retraction speed settings to within the range of 40 to 70 mm/s.

Minimum travel distance

The minimum travel distance determines the distance that the print head will travel before the retraction mechanism activates. The setting in the slicer is the minimum value. Controlling the minimum travel distance avoids repeated retraction, especially if the print head is just crossing over very short gaps.

The goal of setting a minimum travel distance is to retract the filament only when necessary. By now, we already know that excessive retractions can result in filament damage.

The common default value for the minimum travel distance is 2 mm. You can try increasing this by 1-mm increments as long as oozing or stringing issues are not observed. A higher value for this setting is preferable, as it means that you do not retract the filament unnecessarily. This makes filament damage less likely and reduces the total printing time.

A higher value for this setting is preferable, as it means that you do not retract the filament unnecessarily. This makes filament damage less likely and reduces the total printing time.

Combing mode

This is one of the more advanced retraction options that are popularly available in Cura. Combing is a feature that attempts to reduce retraction by directing the print head to move only along a path that has already been filled or will be filled later on. Along this Combing path, there will be no retraction. Ultimately, it does not matter because any stringing effects will be hidden in the final print.

Enabling combing has the advantage of massively reducing printing time by disabling retraction in sections where it is not necessary. However, it can also compromise the appearance of the final print when used inappropriately.

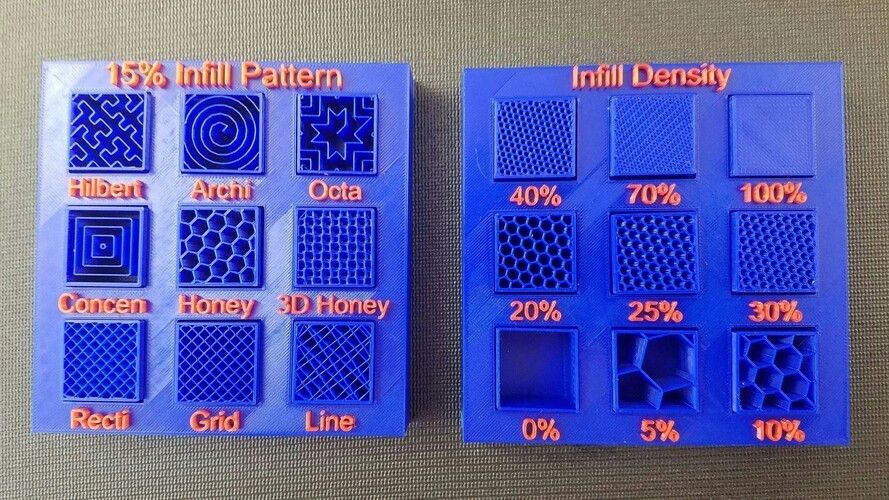

The standard practice is to enable Combing Mode but set it to only “Only Infill” or “Not in skin.” With this setting, combing will only happen when printing the infill pattern of your print. This retains the pristine appearance of your final print while reducing printing time and avoiding filament damage.

This retains the pristine appearance of your final print while reducing printing time and avoiding filament damage.

Maximum retraction count

The maximum retraction count is a more refined means of controlling the number of times that retraction can happen over the same segment of filament. Although this parameter can be indirectly controlled via the retraction distance setting, the maximum retraction count puts a hard limit on the number of retractions.

Should the slicer reach the maximum retraction count, it will disable retraction for that particular length of the filament. The goal of this is to avoid filament damage caused by excessive retraction.

In setting the maximum retraction count, you want to strike a balance between the possibility of filament damage and that of issues like stringing or oozing. Ideally, the slicer would never have to implement the cap on the number of retractions. A setting of 10 retractions is typically enough to attain this state.

If you are having problems with filament damage despite the settings we have recommended above, then limiting the maximum retraction count to a lower number can be an option. Try to be conservative when making this move – reducing by 1 at a time seems just right. We do not recommend going below 5.

Limit support retractions

This is simply a toggle-box available in some slicers. When ‘limit support retractions’ is enabled, the slicer will no longer instruct the extruder to do a retraction when printing support structures. Since these supports will just be removed anyway, this can be a huge help in reducing print time. There are typically no issues when enabling this option, so keeping the box checked is generally recommended.

Looking outside retraction

If you’re having problems with stringing or oozing, then retraction should not be your only solution. It’s more sensible to deal with the fundamentals first. Are you sure that you are printing with dry filament? Is your temperature within the recommended temperature range? Either one of these factors can also contribute to stringing.

Keep in mind that retraction does come with considerable drawbacks. If you can minimize retraction by fine-tuning your other slicer settings, you can save a lot of time and potential headaches.

Testing your retraction settings

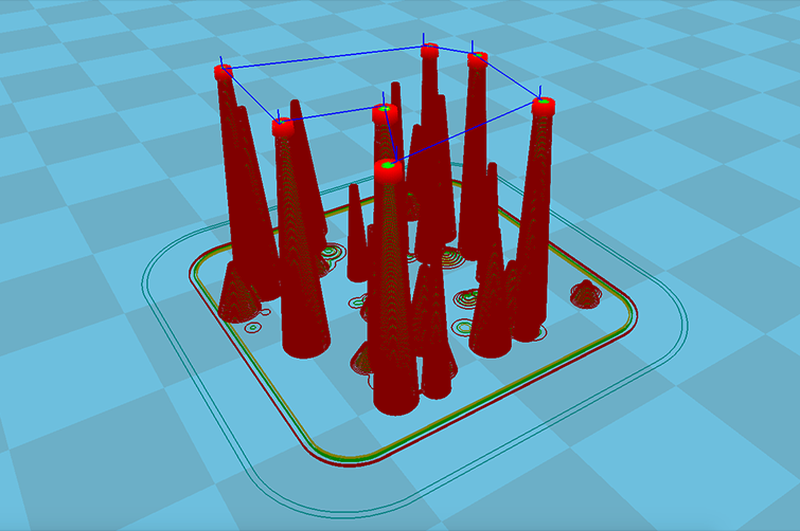

Getting the best retraction settings can be tough, especially if you have to work with a new filament. We often recommend doing a test print just after you have dialed in new settings for your slicer.

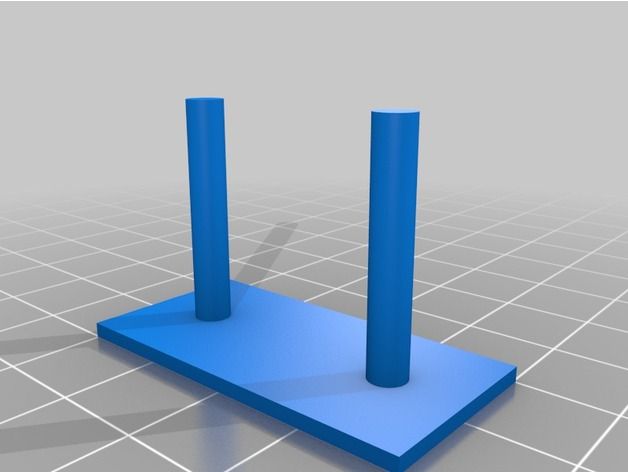

For retraction, we recommend either one of these two models – the four triangular pillars or the two circular columns. Both are free to download and are fairly small models that will allow you to test the stringing performance of your printer with minimal filament usage.

Final thoughts

Retraction can be a very powerful tool in 3D printing if you can learn how to use it optimally. The key thing to remember is that it’s not a magic pill that will solve all your over-extrusion problems. Not only does it have a few drawbacks, but it’s still better to focus on your fundamentals first before relying on retraction.

Most slicers will offer options for adjusting the retraction speed, distance, and minimum travel distance. These are usually enough to get the retraction mechanic to work just right for your project. Other slicers offer more advanced options. These are similarly useful, but not always necessary.

Warning; 3D printers should never be left unattended. They can pose a firesafety hazard.

The Insidious Problem of 3D Print Retraction « Fabbaloo

By Kerry Stevenson on October 10th, 2015 in learning

Tags: printing, simplify3d, tips

A common problem encountered with plastic extrusion 3D printers is stripped filament. We explain how this happens.

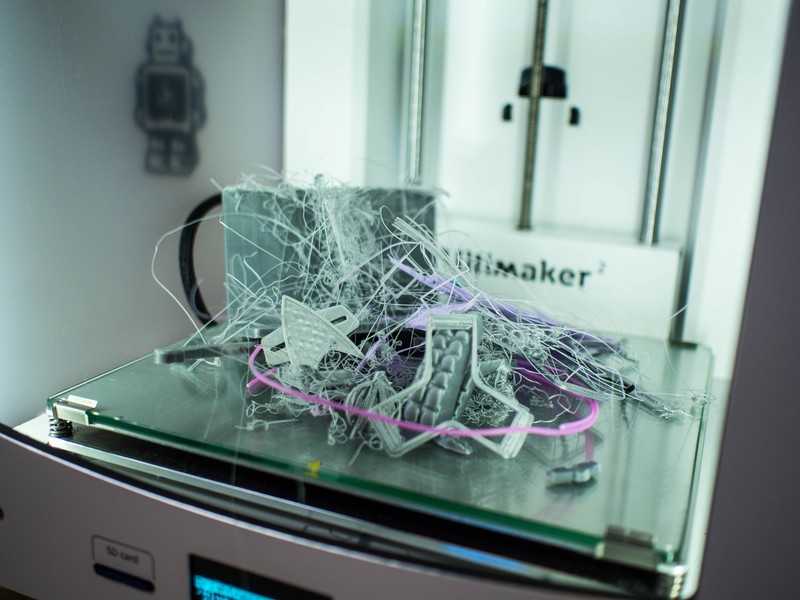

If you’re new to 3D printing and using a machine with the plastic extrusion process, you may find some 3D models very challenging to print. In some cases, they may seem impossible to print, because you keep stripping the filament and printing fails.

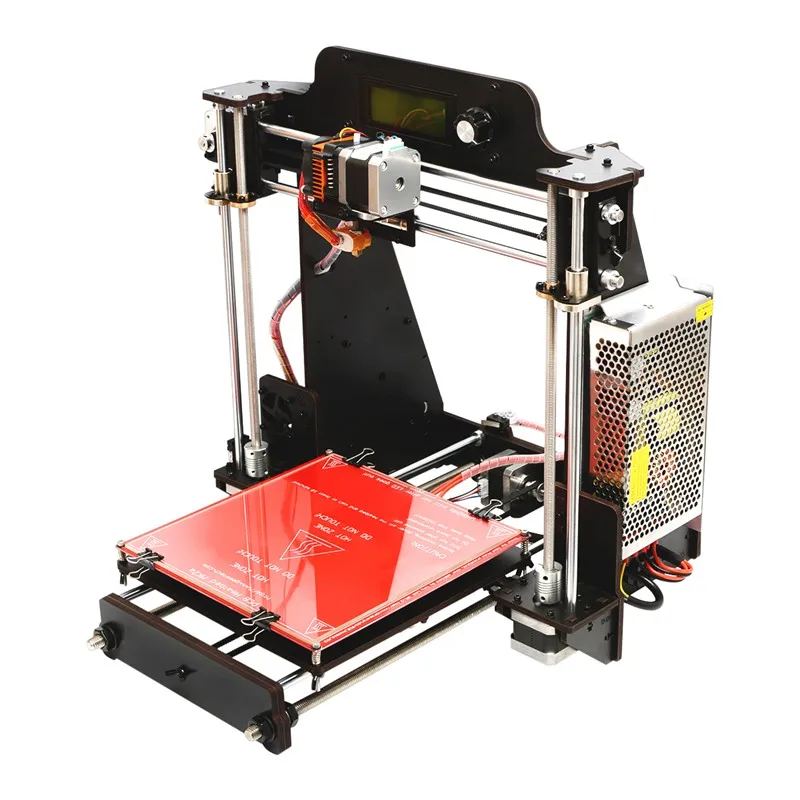

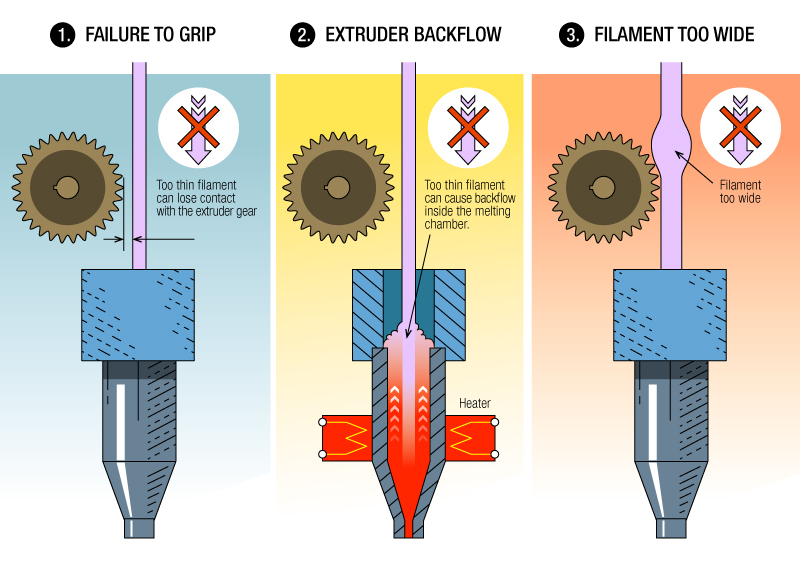

What’s a stripped filament? That plastic wire that feeds into your 3D printer is usually powered by a small toothed wheel that grips the side of the filament and pulls it off the spool and pushes it towards the hot end. Normally this process works quite well, as the tension between the wheel and the filament ensures a “good grip”. You can see how this works in the graphic at top: the extruder wheel grabs the filament with its teeth.

Normally this process works quite well, as the tension between the wheel and the filament ensures a “good grip”. You can see how this works in the graphic at top: the extruder wheel grabs the filament with its teeth.

During printing, the extruder wheel may change speeds during printing, or even stop pushing if the hot end must jump from one spot to another.

It’s this jumping that can cause problems. By moving from one spot to another without extruding, you’d think nothing comes out of the hot end. But that’s usually not the case, as the heat of the hot end may result in a very small drip of fluid plastic. This drip becomes a “stringy” when the extruder jumps from point to point. Prints having many jumps will often be covered in thin, stringy plastic like cobwebs. Removing them is quite tedious and depending on the geometry, sometimes impossible, such as you can see in our stringy Eiffel Tower model here:

There is a very common technique to avoid “stringy” prints: retraction. In this method, the extruder motor is put in reverse for a brief moment to “suck up” the drip before it falls out of the hot end. This can, if properly tuned, eliminate stringy prints entirely.

In this method, the extruder motor is put in reverse for a brief moment to “suck up” the drip before it falls out of the hot end. This can, if properly tuned, eliminate stringy prints entirely.

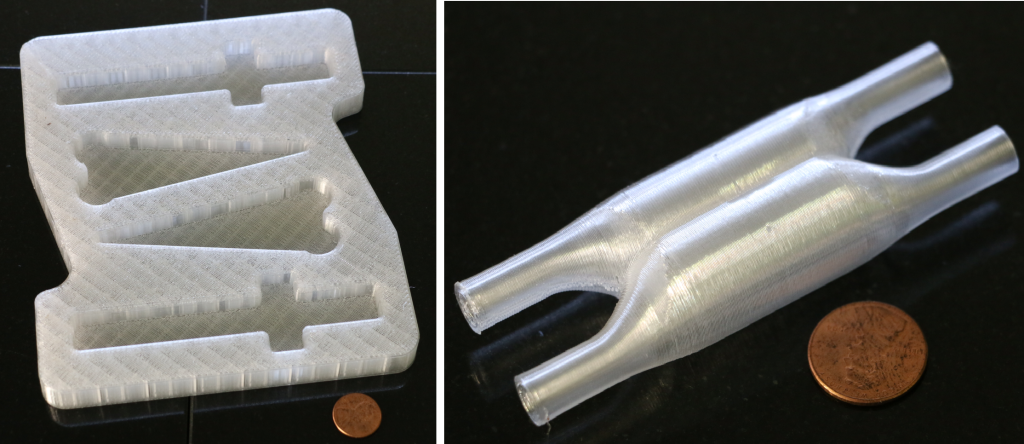

But there can be a problem if there are repeated retractions, which can happen if you have a great deal of non-printing movements in rapid succession, such as would happen if printing this 3D model above. (It’s a pathological support structure for demonstration only; Don’t EVER DO THIS!)

As you might imagine, there would be countless retractions occurring during the printing of the lower portions of this pathological 3D model.

During these endless retractions, it’s possible that the gearing on the extruder wheel may become slightly out-of-line with its previous indentations in the filament. If so, it can squash the remaining filament and thus lose its ability to grip the filament.

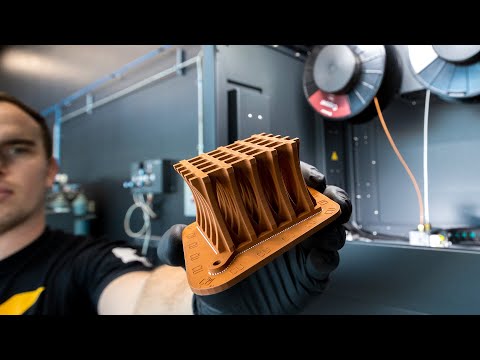

Once grip is lost, subsequent retractions will simply polish the dead spot on the filament, resulting in a complete stoppage of printing, since the filament can no longer move. Your print might look like the image above: abruptly ended on a random layer, usually one with a lot of jumps, as is clearly the case in this Eiffel Tower print. Below we see an example of a filament stripped.

Your print might look like the image above: abruptly ended on a random layer, usually one with a lot of jumps, as is clearly the case in this Eiffel Tower print. Below we see an example of a filament stripped.

What can you do at this point? Well, nothing; your print has failed. You’ve wasted any material used up to that stage of the print and you must restart the print job.

What can you do in the future? It’s possible to turn of retraction in most slicing programs, which can avoid this scenario completely. But it comes at a cost: stringy prints. Another approach is to set a retraction limit, which indicates the minimum amount of printing that must occur before a second retraction can occur.

Depending on the geometry of your 3D model, you might need to play around with these settings to achieve the optimum successful print. Another option that’s possible in some slicing programs, such as Simplify3D, is to assign two different printing configurations: one without retraction for the lower portion in our pathological example above, and another for the upper portion that includes retraction to ensure the model prints clean.

As you can see, 3D printing is not always a matter of “pressing the print button”. For all but the most simple geometries, you likely have to do some analysis and parameter tweaking to ensure print success.

TwitterKerry Stevenson, aka "General Fabb" has written over 8,000 stories on 3D printing at Fabbaloo since he launched the venture in 2007, with an intention to promote and grow the incredible technology of 3D printing across the world. So far, it seems to be working!

View all of Kerry Stevenson's posts.

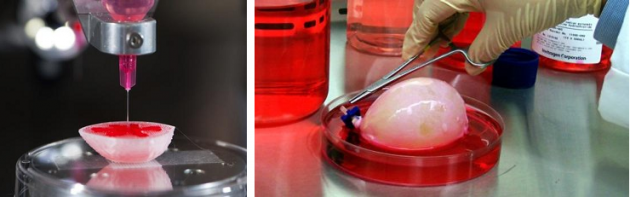

3D printing defects - Let's try to introduce classification

Good afternoon, dear visitors of the portal.

Today I decided not to go into the artistic part of our work, but again into the scientific one.

By coincidence, I graduated from the university with a degree in foundry engineering. Why am I mentioning this: firstly, for the last 10 years, the foundry has been threatened that it will die due to stamping and 3D printing. Secondly, foundry uses a lot of its own terminology. Today I want to try to describe the main defects in 3D printing, possible names and ways to deal with them (defects, not names). Of course, within the framework of one article on one portal, we will not introduce our own terminology, but at least there will be something to discuss. I invite you to read and adequately comment. nine0003

Secondly, foundry uses a lot of its own terminology. Today I want to try to describe the main defects in 3D printing, possible names and ways to deal with them (defects, not names). Of course, within the framework of one article on one portal, we will not introduce our own terminology, but at least there will be something to discuss. I invite you to read and adequately comment. nine0003

Defect : Warp

Commonly used description: Peel off platform, bend

Description : Geometry distortion. Due to the transition of plastic from one state to another (liquid - solid-liquid - solid) and temperature changes, the plastic begins to decrease in volume. This process is uneven - first the edges cool down, and then only the central part. Because of this, internal stresses arise that tear off the edges or break the part. nine0003

Now some physics and explanation. It is IMPOSSIBLE to get rid of thermal shrinkage or shrinkage. This is a physical process - you can only compensate for it. In addition, remember - shrinkage of 0.5 -0.9% is mentioned everywhere. But this is only linear, which means you will have more volume.

This is a physical process - you can only compensate for it. In addition, remember - shrinkage of 0.5 -0.9% is mentioned everywhere. But this is only linear, which means you will have more volume.

How to fight:

- Reduce fill - less plastic, less to shrink - less tear force.

- Use a hot table - you heat up the lower layers, which gives an even distribution of stresses inside the part. nine0028

- Outline - You can print an outer layer around the part. This creates a kind of thermal barrier around the part, thereby maintaining the temperature throughout the volume, resulting in an even distribution of stresses throughout the part. An alternative is a closed build chamber, serving in the same way

- Use structural elements - First, check that your part is lying well on the table - if your flat side of the part is not flat at all (in art it's easy - to move a couple of polygons or vertices to the wrong place on a couple of mm), then it will easily come off.

Secondly, if you understand the physics of the process, you can either add material somewhere, or make a hole in the part, etc. In this way, you will artificially cause stress redistribution in the part, however, this method is extremely complicated. nine0028

Secondly, if you understand the physics of the process, you can either add material somewhere, or make a hole in the part, etc. In this way, you will artificially cause stress redistribution in the part, however, this method is extremely complicated. nine0028 - Increase grip strength - you don't have to fight stress, just provide the required grip strength. However, this option does not seem very good to me - these stresses will remain and your part can then be easily broken in this place.

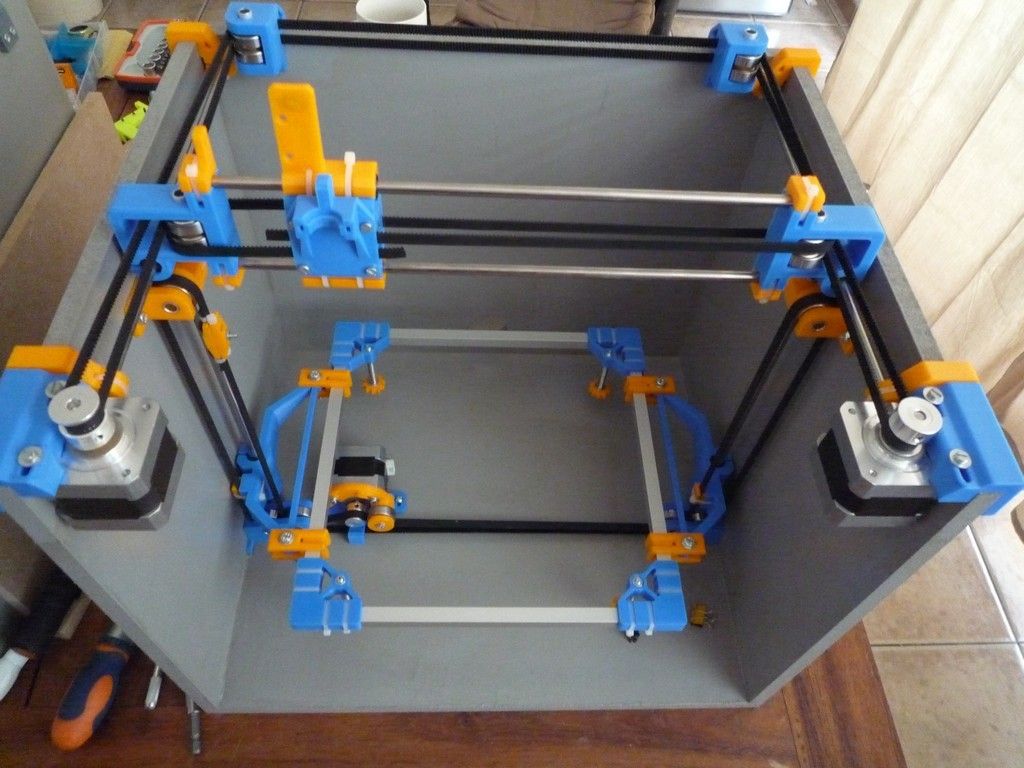

Defect : Skewed

Frequently used description: Layers floated, the vertical is not respected, the layers do not lie exactly on top of each other

Description: Several variants of this defect are possible. Either the layers just lie unevenly, or the model is printed somehow in pieces, or just a slight skew. This defect is usually associated with the mechanical part of the printer. Due to friction, the actual path of the print head does not match the one that was loaded into the machine. nine0003

nine0003

How to fight:

- Check the belts. Since there are many designs, it is difficult to give a universal answer here. Check that they lie normally at the points of contact and are not frayed anywhere. Look at the printer's instructions or some tips on the Internet - it is quite possible that the problem has already been sorted out before you.

- If the printer simply shifts the layers relative to each other, then it is possible that the pulleys are not fixed properly. With a black marker, you can mark the position, and after printing, compare and tweak this place if necessary. nine0028

- Move the print head without power - it should move without significant problems. If this is not so, then maybe it is worth finally lubricating the shafts?

- Squareness not ensured - again, due to poor mounting, the X and Y axes may not be perpendicular. This can lead to this defect, which means it's time to climb into the printer again and twist.

- Check the print platform - the glass may start to slide on your printer.

And just like that, in the same direction. In this case, it is necessary to ensure its fixation in some way. nine0028

And just like that, in the same direction. In this case, it is necessary to ensure its fixation in some way. nine0028 - Electronic problem. Rare case, but possible.

Defect : Boiling, Puffiness (?)

Common Description: Holes in top layer, problem with outer layer.

Description : Protrusions on the upper layer of the part - can be either open or closed. In fact, this is due to the sagging of the plastic, which does not have time to cool when printed in the air without supports. Considering that there can be several such layers and all of them are of poor quality, we get this defect. nine0003

How to fight:

- Provide cooling - your plastic should cool well on the top layer. According to the recommendations, at this stage, cooling should go as much as possible.

- Ensure sufficient layer and wall thickness - In addition to sufficient cooling, you must have the required number of layers.

Again, according to the recommendations, your wall should consist of at least 6 layers of your thickness. Thus, when printing with a layer of 0.1 mm, you want your wall to be at least 0.6 mm. But remember - too thin base layers will not work either - they simply will not hold themselves and other layers. nine0028

Again, according to the recommendations, your wall should consist of at least 6 layers of your thickness. Thus, when printing with a layer of 0.1 mm, you want your wall to be at least 0.6 mm. But remember - too thin base layers will not work either - they simply will not hold themselves and other layers. nine0028 - Try changing the occupancy - some slicers change the occupancy configuration at a certain percentage of infill, so the difference can be even between 24% and 25%. In addition, with a larger fill, the distance that is printed in the air is smaller, which can also remove this defect.

Defect : Lack of layers (?)

Commonly used description: Round things do not come out round, parallel straight things do not come out parallel

Description : Sometimes the geometry of the layers is not observed - this can manifest itself in circles, when the circle is not perfect, as well as in parallel lines. For example, parallel lines first diverge a little, and then, on the contrary, slightly overlap. This is due to the belts going to the stepper motors - most likely they are not fastened tightly enough.

For example, parallel lines first diverge a little, and then, on the contrary, slightly overlap. This is due to the belts going to the stepper motors - most likely they are not fastened tightly enough.

How to deal:

- Tighten the straps near the print head - how to do this is best to look at the 3dtoday portal or ask your 3d printer supplier. nine0028

- Check that all fasteners are tight - use the tool that most likely came with your kit to do this

- Lubricate the guides - literally add one drop of light lubricant to your guides.

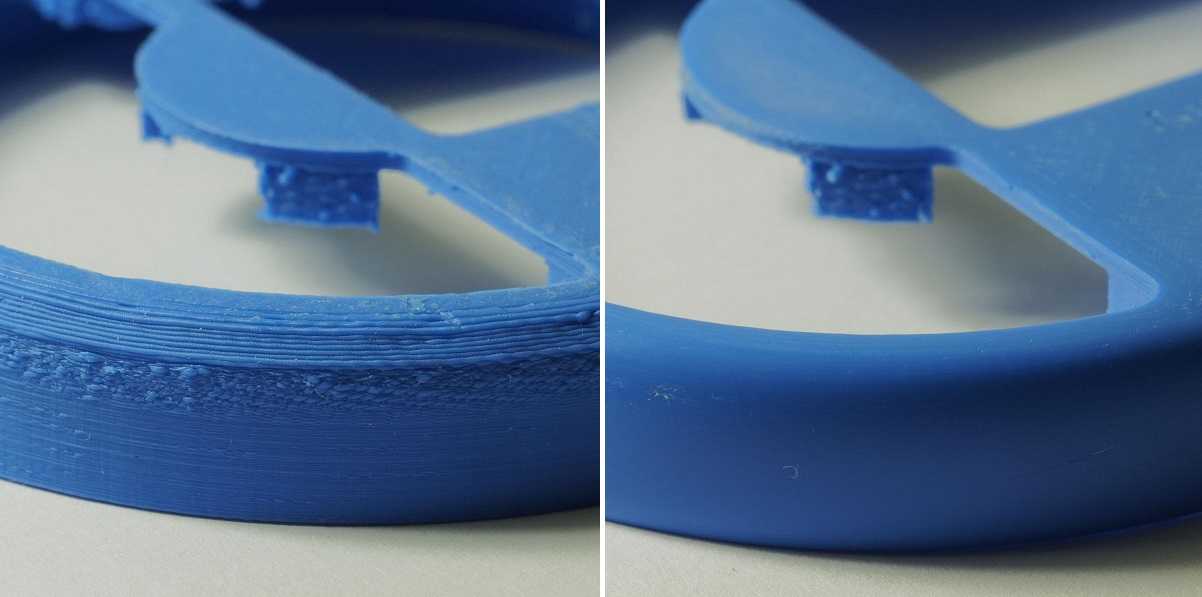

Defect : Elephant Leg

Commonly Used Description: Thick bottom layers, uneven layers at base.

Description : The effect when the bottom layers of your part are larger in area than they should be. Due to the fact that the nozzle at the beginning of printing is firmly pressed against the printing table at the beginning of printing, the layer begins to smear a little, thereby decreasing in thickness, but increasing in area. Then the print is evened out, because there is no longer a tight pressure

Then the print is evened out, because there is no longer a tight pressure

How to fight:

- Adjust the table - your nozzle should not rest against the print platform - there should be a slight, but still gap.

- Reduce the table temperature - a slight decrease in the table temperature can also reduce this defect. Do not get carried away with these methods too much - this may degrade the overall print quality.

- Structural model improvements - add small chamfers or fillets. You will have to play around with the settings a bit, but thanks to such a design improvement in the model, your model will be smooth and beautiful. However, it is impossible to say for sure which chamfer to make. Start with a 0.5 x 45 bevel, and then empirically find the best option. nine0028

Defect : External slack (?)

Common description: Snot, plastic between two parts part to another, a long, thin layer of plastic is created that spoils the outer shape of the part(s). This is due to the fact that the plastic that remains at the tip of the nozzle under the influence of gravity and friction is caught on one part and begins to drag through the air. Depending on the fluidity parameter and the hardening time, different plastics exhibit this defect in different ways. nine0003

This is due to the fact that the plastic that remains at the tip of the nozzle under the influence of gravity and friction is caught on one part and begins to drag through the air. Depending on the fluidity parameter and the hardening time, different plastics exhibit this defect in different ways. nine0003

How to fight:

- Use the retract function - thanks to it, the print head will slightly return the plastic, thus removing it from the tip of the nozzle. This setting is activated directly in the slicer (if it supports it). In the Cura slicer, the retract is drawn with thin blue lines and you can check this moment at the level of the finished task.

- Increase your print speed - the physics is simple - by increasing your print speed, you reduce the amount of time the plastic can catch on your part. However, increasing the print speed is not always possible and may cause other defects. nine0028

- Change the print temperature - print temperature has a direct effect on fluidity, especially with PLA.

Reducing the temperature even by 10 degrees significantly reduces the effect of external sagging.

Reducing the temperature even by 10 degrees significantly reduces the effect of external sagging.

Defect : Waviness

Commonly used description: Discoloration at the edges of the part, defects along the edges

Description : This defect appears as darkening and slight waviness around the sharp ends. If you start typing the text, it will look like a slight shadow effect on it. This is due to the inertia that is imparted to the liquid plastic during printing. Regarding plastic, the print head has a large mass and during a sharp change in direction, liquid plastic is not able to sharply repeat the trajectory, which causes slight waviness in the corners. nine0003

How to deal with:

- Decrease print speed - Decreases print speed, reduces sharpness at corners, thereby smoothing the effect.

- Decrease print head acceleration - these settings are not available in all slicers, however, this will get rid of the defect without reducing the print speed.

- Change the print temperature - as we mentioned earlier, temperature affects fluidity, so lowering the print temperature can help get rid of the defect. nine0028

Defect : Looseness, Sagging (?)

Frequently used description: Snot on the part, sagging plastic on the part

Description: One of the most common and basic defects in plastic is due to printing in the air sags instead of getting a flat horizontal surface. This is due to the fact that the plastic does not have time to cool down and is printed without support where they are needed. Sagging can occur for many reasons, although the physical nature of the defect is practically unchanged. Because of this, the elimination of this defect may not be obvious. nine0003

How to fight:

- Cooling - Depending on the plastic, you may or may not need cooling. If it is necessary - provide it as much as possible.

- Print more than one part - for small parts, printing more than one part will help a lot. This will remove the heat source and give your part time to cool.

- Work with the thickness of the layer - it is not possible to make a recommendation whether it is better to increase the layer or reduce it. Each situation must be decided, however, changing the thickness of the layer can improve or worsen the effect of sagging. nine0028

- Reduce print speed - very often reducing print speed can improve the quality of your part.

- Reduce temperature - if you decrease the temperature, the plastic will cool faster to a solid state. However, do not lower the temperature too low, otherwise the print quality may drop.

- Reposition the part - if possible without loss of quality, try to position the part differently. Stop, think, or use auto-positioning (like Meshmixer). Instead of fighting a defect, you can often simply eliminate it. nine0028

Defect : Layering of the bottom layer

Commonly used description: Clearly defined bottom layer, thick lines of the bottom layer

Description : Printing the bottom layer is one of the most important moments in printing. If we print too close, we will get an elephant leg defect. In the case of a large gap, we can get excessive layering of the lower layer.

If we print too close, we will get an elephant leg defect. In the case of a large gap, we can get excessive layering of the lower layer.

How to deal with:

- Decrease the thickness of the first layer - many slicers have the ability to change the first layers of printing. Try to make it smaller to achieve a result that suits you. nine0028

- Recalibration - many problems with the bottom layers can be solved by recalibrating the table. Set the distance a little less and you might get the desired result.

Defect : Underextrusion

Common Description: Holes in Print, Layer Problems, Surface Defects

Description : Underextrusion is a defect worthy of its own article with a description. It can occur as a result of a huge number of factors, both related to the printer and plastic. It is very easy to observe it - the surface of the part comes out not even, but with all sorts of inclusions, or vice versa, the absence of plastic where it is needed. To eliminate this defect, an integrated approach may be required. nine0003

To eliminate this defect, an integrated approach may be required. nine0003

How to deal with:

- Change the speed - your printer may not technically be able to print at this speed. You may need to lubricate it or change the plastic, but first try printing at a slower speed. In addition, not all parts and not all plastics, the printer can print at maximum speed

- Change the temperature - all plastics have recommended temperatures for printing. If you print at the wrong temperature, then you do not provide the required fluidity parameters for working with this plastic and you will not print correctly with it. nine0028

- Check plastic - plastic may be damp, dirty or of poor quality. All this can lead to under extrusion, or that you will not print at all. In addition, plastic can break due to the feed mechanism and its strength properties. You may not be able to print with this plastic. Or maybe his diameter is walking .. As you understand, changing the plastic to another will allow you to quickly understand the problem in the printer or consumable.

- Check the paper feed mechanism - if you are working with soft plastic, the plastic may creased too much, which will prevent you from printing properly. Then, most likely, it will be necessary to loosen the grip of the bar, however, this should be done only after contacting those. support if you are doing this for the first time. nine0028

- Check the bar - during printing, sometimes your bar may become knotted or something is preventing it from entering the extruder. Be sure to check it out right now.

- Change or clean the nozzle - your nozzle will not last forever. In the course of work, it will become dirty - both from the soot of plastic, and from the dust that you allowed. Always have a pair of replacement nozzles available to help you understand this problem. In addition, when you refill plastic with a lower printing temperature, print at a high temperature so that the remnants of the old plastic completely come out and do not interfere with work. nine0028

- Check slicer settings - some slicers may use nozzle retraction and nozzle cleaning to get rid of external slack.

Because of this, when you return the print head, you do not immediately start feeding plastic. This can lead to underextrusion in some parts of the model.

Because of this, when you return the print head, you do not immediately start feeding plastic. This can lead to underextrusion in some parts of the model. - Check the Teflon tube - due to dirt allowed in the printing area, the Teflon tube may become contaminated. Because of this, the rod will experience friction, which will lead to underextrusion.

- Check the gears - if the gears that grip the bar do not work properly, then it will be problematic to exit the nozzle. If simpler measures do not suit you, check that this mechanism works correctly.

Defect : Notches (?)

Common description: Walls do not fuse together. Hollows in the walls.

Description: Mechanical problem. Due to the limited path of the printing part, there are voids and inconsistencies between the walls. Contact may be partial or absent entirely. nine0003

How to deal:

- Tighten the straps near the print head - how to do this is best to look at the 3dtoday portal or ask your 3d printer supplier.

This option is best used in case of partial contact.

This option is best used in case of partial contact. - Reduce the print speed - plastic may not fit well at this speed. A slight increase in temperature may also help.

- Change the wall settings - this problem may arise due to the principle of laying this very wall. If you have a 0.3 nozzle, then it is impossible to lay a 1 mm wall in ideal layers of 0.3 mm. So the program can either represent the wall as 0.9mm and lay 3 layers, or somehow compensate for this. Try changing the wall thickness and maybe you can get rid of the defect.

Defect : Scratches

Commonly used description: Surface scratches and color unevenness

Description : During the movement of the surface, the print head leaves a mark on the plastic due to close contact with the plastic. This can be either grazing old plastic or smearing new plastic that flows out of the nozzle due to contact. nine0003

How to deal with:

- Increasing speed and decreasing temperature - as in other similar defects, when plastic leaves a mark, increasing speed and decreasing temperature can reduce the effect of this problem.

- Slicer setting change - To a large extent, this defect can be controlled by the slicer. Using Cura as an example, you can use the z-hop function (raises the nozzle). In addition, you can work on the retract.

- Change in geometry - this defect can still appear on complex surfaces. Try adding an even layer to your model or simplifying the geometry altogether if you're having this problem and it's making your life worse. nine0028

Defect : Underfill

Common Description: Part prints strangely. Incorrect entry of the part. Print supports where they shouldn't be

Description : The type of defects associated with the electronic model - can be associated with many things. If the polygons have incorrectly directed normals, if the model is not fully stitched (there are holes) or consists of several elements - all this can lead to this type of defects, when the slicer will misunderstand what they want from it. nine0003

nine0003

How to fight:

- Check the model in Netfabb/Meshmixer - with the help of specialized products you can check the model and see what errors it has. These programs eliminate many of the problems that were made before printing. However, these programs may distort your geometry.

- Fix the electronic model - if you have the skills and the ability to use the functionality of 3d programs to fix the mesh. Sew the meshes, close the gaps, reverse the normals, then check the resulting g-code. In it you will see how your model will be printed and whether everything suits you. nine0028

Defect : Fluffiness

Commonly used description: Model as in hair. Snot. Sagging.

Description : Reduced external sag. Small hairs stick out on the model, which remain from the printing nozzle. The physics of the phenomenon is the same, but the amount of plastic is much less. However, this defect can occur even if the nozzle does not move from one object to another.

How to fight:

- Check the plastic - your plastic may be dirty or poorly made. Try a different plastic and you may be able to get rid of the

- Check the nozzle - this fluffiness may be the first sign that something is wrong with the nozzle. Check the outside of the nozzle to make sure nothing is sticking out or try a different nozzle

- Remove the defect after work - this is the rare type of defect that is quite easy to get rid of by post-processing. Use a sandpaper, needle file or other handy tool. nine0028

Defect: Skipped layer

Common description: The layer is different from the other layers in the model. The model is flaking into pieces

Description: The case when one or more layers differ from the others. Then comes stable printing and the defect may recur. May be due to underextrusion or machine problems.

How to deal with:

- Familiarize yourself with underextrusion - it is possible that you will see more similar defects and you will know how to proceed.

nine0028

nine0028 - Lubricate the Z-track - since the table moves in the Z direction, it is possible that in some areas you have accumulated dirt or lack of lubrication. Lubricate the guide as recommended by the manufacturer and check operation.

- Bearing problem - it is possible that the problem is not in the guide, but in another element of the lifting mechanism. In this case, you need to check the bearing adjustment or return the printer for service. Look for more information on the portal 3dtoday

- Too much lubrication - too much lubricant - does not mean better. It can start to easily accumulate dirt and again begin to cause this effect. Wipe the shafts and lubricate with the necessary amount of material.

- Electronic problem - it is possible that the problem is not with the mechanical, but with the electronic part of the movement. If other methods do not help, then most likely the printer may need to be returned for repair.

- Defective parts - unfortunately this happens.

It is possible that everything is done well, but some part of the mechanism is out of order. Again, this cannot be solved without disassembling the printer. nine0028

It is possible that everything is done well, but some part of the mechanism is out of order. Again, this cannot be solved without disassembling the printer. nine0028

Defect: Misalignment of axes

Commonly used description: No right angle.

Description: Cases where the mating parts of the mechanism do not fit into the grooves due to misalignment. Another way to identify a problem is that the printer head moves with force.

How to fight:

- Editing axes - the defect is eliminated only mechanically. Ask the supplier or manufacturer for information on how to correct the axes and then reconfigure the printer. nine0028

I do not claim to be the final authority. For my part, I would like an adequate discussion and proposals in order to supplement and develop this article and formulate it into a finished version. Icons? mean that I still do not consider this name final and I expect other proposals for names from you. Only the names should be sensible so that a person imagines what it is and uses a short word to define it. It is better to mark grammatical and lexical errors in my personal - I hope we will agree with the editors so that they give the opportunity to correct the article. The material is based on this source. I did not specifically add some defects that are not related to the plastic, the printer and the printing mechanism (such as the detachment of the part from the table and the poor performance of the electronics), although you may say that it is more logical to add. In short, ready for discussion. nine0003

Only the names should be sensible so that a person imagines what it is and uses a short word to define it. It is better to mark grammatical and lexical errors in my personal - I hope we will agree with the editors so that they give the opportunity to correct the article. The material is based on this source. I did not specifically add some defects that are not related to the plastic, the printer and the printing mechanism (such as the detachment of the part from the table and the poor performance of the electronics), although you may say that it is more logical to add. In short, ready for discussion. nine0003

Sincerely, Sergey Panin

Problems, defects, 3D printing errors and solutions

Often during the operation of a 3D printer, problems may arise due to which defects appear on the finished model. Or instead of a neat product, plastic noodles suddenly appear on the table.

In fact, the causes of defects can be conditionally divided into 2 types - these are physical and software.

Physical ones are those that arise due to problems with the mechanics or any other causes that can be eliminated physically. These include problems with printer mechanisms (belt tension, backlash), clogged or deformed nozzle, incorrect table geometry, etc. nine0003

Software - these are defects that occur due to incorrect slicer settings or, less often, errors in the printer firmware. For example, incorrectly selected print speed, retract settings, incorrectly selected temperature for plastic, etc.

Very rarely, the problem may lie in the wrong or “flying” printer firmware (although usually the printer simply will not start then), overheating of some boards during printing, etc. These are rather special cases, so we will not consider them. nine0003

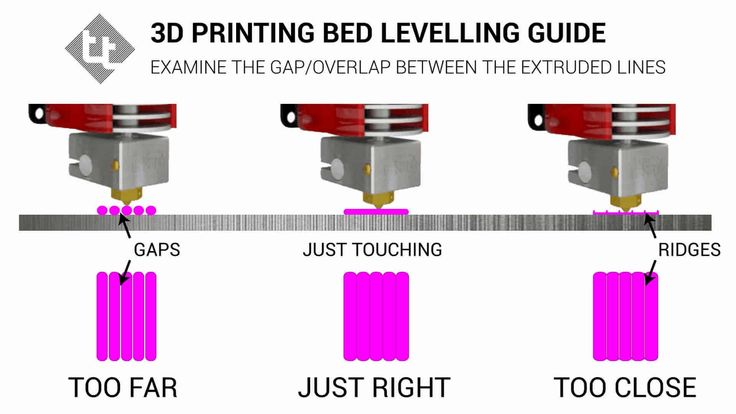

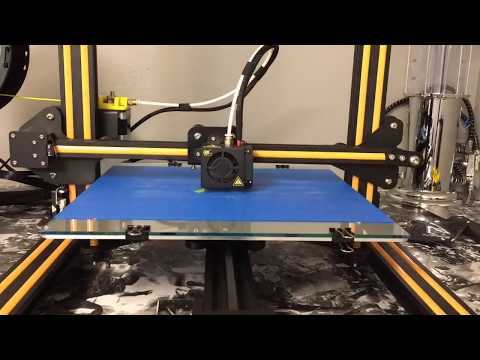

Model peels off or does not stick to platen

This is the most common 3D printing problem. Every 3D printer has had a case when the first layer treacherously rolls, clinging to the extruder, or the most offensive - when it tears off a partially printed model from the table. The first layer must stick tightly otherwise nothing will be printed.

The first layer must stick tightly otherwise nothing will be printed.

Gap between table and nozzle 9 too large0010

This is the most common reason. You just need to set the correct gap between the table and the nozzle.

Modern printers often use an auto-calibration (auto-leveling) table system or an auxiliary table leveling program. To calibrate such printers, use the instructions. If there is no manual, it can be downloaded from the manufacturer's website.

If you have a simple printer without auto-calibration, a self-assembly or KIT kit, use a probe or a piece of paper folded in half to calibrate. The probe should be slightly pressed against the table by the nozzle. Before calibration, the table and extruder must be heated. Align the table surface over each adjustment screw (there may be 3 or 4) in turn, and only then check the center point. nine0003

If you're having trouble getting your table surface perfectly level, try raft printing.

Raft is a thick substrate in several layers that is printed under the model. It will help smooth out the slight curvature of the table.

A small cheat sheet to determine the correct gap on the first layer

Plastic with poor adhesion

Some types of plastic, due to various reasons, such as large shrinkage, do not adhere well to the surface of the printing platform. In this case, try using stickers or special 3D adhesives to improve adhesion between the table and the first layer of plastic. nine0003

In the early days of 3D printing, there were experiments with different homemade 3D adhesive recipes. ABS diluted in acetone, BF glue, sugar syrup and even beer. Some experiments have been successful. Until now, some enthusiasts use some types of hairspray or glue sticks as 3D glue. But still they are inferior in their properties to industrial 3D adhesives.

Some types of high temperature plastics with a high percentage of shrinkage (ABS, Nylon, etc. ) may peel off the table during printing. This is due to uneven cooling and “compression” of the model (the lower layers have already cooled down, but the upper ones have not yet). For such plastics, it is imperative to use a 3D printer with a heated table and a closed case. nine0003

) may peel off the table during printing. This is due to uneven cooling and “compression” of the model (the lower layers have already cooled down, but the upper ones have not yet). For such plastics, it is imperative to use a 3D printer with a heated table and a closed case. nine0003

Plastic temperature too low

The hotter the plastic is when it exits the nozzle, the better it will adhere to the print bed. It is better to print the first 5-10 layers at a higher temperature (+ 5-10 degrees) and turn off the blower fan.

Wrong first layer settings (speed and thickness)

A thicker layer sticks easier, so the standard first layer is 0.3mm thick. With an increase in print speed, the heating block may simply not have time to heat the plastic to the desired temperature and it will stick to the table worse. Before printing, check the speed and thickness settings of the first layer in the slicer. nine0003

A lot depends on how the 3D printer prints the first layer.

Try to control the printing of the first layer and only then leave the printer to work alone.

Plastic does not choke from nozzle

The printer has already begun to print, but the print table remains empty. Or part of the model did not print.

Clogged nozzle

In 3D printing, a nozzle is a consumable. The nozzles are clogged or worn out (frequency depends on the type of plastic). The simplest thing is to replace the nozzle. But if there was no spare at hand, you can try to clean the old one. To do this, there is a whole set of thin needles. Or you can heat a clogged nozzle above the melting point of the plastic and “burn out” the blockage. But later it is still better to replace the nozzle. nine0003

Low temperature nozzle

You need to increase the temperature of the extruder in the slicer settings or check the thermistor and heating block. Sometimes the thermistor may not read the temperature correctly due to a malfunction or incorrect 3D printer firmware settings.

If the problem occurs after replacing the thermistor - contact the manufacturer or read articles about PID tuning.

Empty extruder

As the extruder heats up, plastic begins to ooze out of the nozzle. Because of this, the extruder may start printing half empty. Because of this, part of the first layer is not printed. You can push the plastic manually by simply pushing the bar into the nozzle. Or solve this problem programmatically - in the slicer, add a contour print around the model (one line).

Some manufacturers and 3D enthusiasts add a line print on the edge of the table at the beginning of each GCode. This is done so that there is plastic in the nozzle by the time the model is printed. nine0003

Feed mechanism does not push through plastic

The plastic pushes the feed mechanism to the extruder - a motor with a special pulley put on the shaft. If for some reason the plastic is not pushed through (nozzle clogged, extruder temperature low, etc. ), then the pulley “gnaws” through the bar. You need to push the plastic bar with your hands or cut off the damaged piece.

), then the pulley “gnaws” through the bar. You need to push the plastic bar with your hands or cut off the damaged piece.

Elephant foot

The first layers of the model are wider and protrude beyond the boundaries of the model. This is due to the fact that the upper layers put pressure on the first ones that have not yet cooled down and flatten them. nine0003

High table temperature

Due to the too high temperature of the table, the lower layers remain soft for a long time. Try lowering the table temperature. It is better to reduce gradually (in increments of 5 degrees). You can try to turn on the blower when printing the first layers.

Small gap between nozzle and platen

If, when printing the first layer, the nozzle is too close to the table, then excess plastic will be forced out. After a few coats, this will not be as noticeable, but can lead to the effect of an “elephant's foot”. nine0003

nine0003

Plastic re-extrusion

When too much material is squeezed out of the nozzle, the walls of the model are not smooth, but bumpy, with sagging.

The solution is software - in the settings of the slicer, you need to set the material feed rate (fluidity) to a lower value. The average value is 95-98%.

It is worth checking the diameter of the rod. If its size is greater than 1.75, then the plastic will be squeezed out more than necessary. nine0003

Plastic underextrusion

The plastic is squeezed out too little, because of this, gaps may appear between the layer. The finished model will be fragile and fragile.

Wrong thread diameter

Check the filament diameter in the slicer settings. Sometimes, instead of the popular 1.75, the default is 2.85.

Incorrect feed rate settings nine0003

Check the fluidity settings in the slicer. The average should be 95-98%.

The average should be 95-98%.

Clogged nozzle

Something could get into the nozzle and partially block the exit of the plastic. Visually, the plastic will choke from the nozzle, but in a smaller amount than necessary for printing.

Hairiness or cobwebs on finished model

Thin threads of plastic protrude from the outer wall of the model (most often on one side). The defect appears due to the flow of plastic from the nozzle during idle movement. nine0003

Insufficient retract

A retract is a slight pull of a plastic filament from an extruder. Due to the retract when the extruder is idle (from layer to layer or from model to model), heated plastic does not drip from the nozzle. For some flowable plastics (eg PETG) the speed and amount of retraction must be increased.

"Hairiness" can be easily removed by grinding or cutting off the threads with a sharp scalpel. nine0003

nine0003

High temperature extruder

The higher the extruder temperature, the more fluid the plastic becomes. It is important to find a balance so that the plastic is not too liquid and sticks well in layers.

In the selection of the optimal extruder temperature, a test model - a tower - helps a lot. It clearly shows how plastic behaves when printed at different temperatures.

.

Temperature test nine0003

Perforated or uneven top

The top of the model is bumpy or with holes. The problem may arise if the top of the model is flat. For example, like a cube.

Insufficient airflow

When printing the top plane (cover), the plastic does not have time to cool down and remains too liquid. Because of this, the threads are torn and holes are formed. Increase the fan speed on the last layers. nine0003

Few top layers

The top of the print may be too thin and deform as a result. Check slicer settings. The number of upper layers is not recommended to be set less than 6.

Check slicer settings. The number of upper layers is not recommended to be set less than 6.

Fill percentage low

If the infill percentage is too low, then the top layer will simply have nothing to rely on. Increase the fill percentage in the slicer settings.

Model deformation

Some parts of the model seem to have melted in some places or on one side. The problem most often occurs when printing with PLA plastic. The defect appears due to the fact that the plastic does not have time to cool and deforms.

Insufficient airflow model

Turn the fans on to maximum. If their power is not enough (in some printers, the fan is located only on one side), you can put a regular desktop fan and direct it to the 3D printer table. nine0003

Small model

Small models are difficult to blow well. Try to print small items alongside larger ones, or place several identical models in different corners of the table. So the plastic will have more time to cool.

So the plastic will have more time to cool.

Layer offset

Layers shift along the x or y axis during printing.

Print head jam

Turn off the printer and try to move the extruder along the x and y axes with your hands. The extruder must move freely. If there are jams, check the mechanics of the printer. Bearing wear or the curvature of the shafts may be to blame. nine0003

Electronics overheating

Sometimes electronics problems can be to blame for misaligned layers. The most common cause is overheating of the drivers or too low current exposed to them.

Table top is loose

This is most often seen in 3D printers with glass. During printing, the nozzle may hit the model and move the glass slightly. Before printing, check if the glass or other printing surface is well fixed on the heating table. nine0003

Skip layers

Small holes are visible on the print, or the shell of the model is not continuous.

Teflon tube deformed

There are 2 types of thermal barriers - all-metal and with a Teflon tube. If overheated, the Teflon tube may deform. Plastic will pass through it, but in a smaller amount.

Low extruder temperature or high print speed

If the extruder is not heated enough, then the plastic will not be liquid enough and simply will not have time to be forced through the nozzle. The higher the print speed, the higher the extruder temperature should be.

Sometimes the outer walls print well, but the infill is “torn”. In this case, slow down the infill print speed in the slicer.

Model bundle

Cracks form on the surface of the printout during or after printing. Cracks can be large or very small. Most often, this problem occurs with plastics with a high percentage of shrinkage - ABS or Nylon. nine0003

Sudden temperature difference (if model delaminates during printing)

With a sharp temperature difference (for example, a draft), part of the model cools down faster. This leads to uneven shrinkage and incorrect distribution of internal stress. For plastics with low shrinkage, this is not critical. But if the shrinkage percentage is more than a few percent, the model may burst in layers.

This leads to uneven shrinkage and incorrect distribution of internal stress. For plastics with low shrinkage, this is not critical. But if the shrinkage percentage is more than a few percent, the model may burst in layers.

For printing with such plastics, it is recommended to use a printer with a closed housing. If this is not possible, try to avoid drafts and sudden temperature changes in the room where the 3D printer prints as much as possible. nine0003

Print temperature

Due to too low printing temperatures, the layers may not “stick” well to each other. Raise the print temperature in the slicer settings.

Hardening (if the model cracks after printing)

Sometimes cracks appear on the model a few days after printing. This is due to uneven distribution of internal stress after cooling. You can try to “harden” the finished product. nine0003

For hardening, the model is placed, for example, in an oven, and heated to the softening temperature of the plastic. After that, the heating is turned off and the oven is left to cool slowly with the model inside. Due to this, the stress inside the print is distributed more evenly. But accuracy is very important in this method - if you make a little mistake with the temperature, the finished product can “float”.

After that, the heating is turned off and the oven is left to cool slowly with the model inside. Due to this, the stress inside the print is distributed more evenly. But accuracy is very important in this method - if you make a little mistake with the temperature, the finished product can “float”.

Ringing

In places where the extruder changed direction, ripples are visible. Most often it looks like a shadow around the “sharp” protruding elements of the model. nine0003

Mechanical problems

Sometimes the problem occurs due to extruder play. Check if the extruder mount to the rails is loose. Be sure to check the tension of all belts.

High print speed or high accelerations

Moving the extruder too fast can cause vibrations that cause ripples on the wall of the model. The lighter the weight of the extruder, the less noticeable the ripples will be. To get rid of ringing, simply reduce the print speed in the slicer settings. nine0003

nine0003

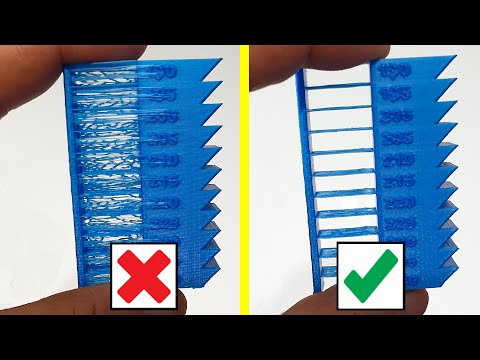

Slits for thin-walled models (not solid shell)

The thin wall of the model is not solid, but consists of two thin walls with a narrow gap between them. This problem is often faced by fans of printing "cutting" for baking.

Left model with wall defect, right without

Wall thickness and nozzle diameter mismatch

If the wall thickness is 1 mm, and the nozzle diameter is 0.4, it turns out that for a solid wall, 2 nozzle passes are few, and 3 are already many. The result will depend on the slicer algorithm, but most often you will get 2 walls with a thin slot in the middle (the slicer cannot change the wall thickness). The solution to the problem may be a slight refinement of the 3D model or the use of a different slicer. nine0003

Algorithms for calculating 3D models are constantly being improved and refined, and now this problem is less common.

When modeling, take into account not only the thickness of the nozzle, but also the percentage of “overlapping” of lines on each other.

If you have a nozzle with a diameter of 0.4 - make the wall in your model not 0.8, but 0.7 - 0.75.

Wrong model geometry

When instead of a circle you get an oval, and instead of a square you get a semblance of a rhombus. nine0003

The main reason is malfunctions in the mechanics of the printer. Be sure to check:

Belts

Check belt tension in x and y. Belts stretch over time and may need to be tightened or replaced. Each 3D printer has its own way of tightening the belt. If the belts are slightly stretched, you can tighten them with the help of a "spring".

Loose pulleys, etc.

Check if all bolts and nuts are tight. Are there backlashes. Pay special attention to tightening the pulleys located on the motors along the x and y axes.

Sagging of some parts of the model

Some parts are not printed, broken, or instead of a neat surface, a swollen plastic snot is obtained.

No support for overhangs

A 3D printer cannot print in the air, so if there are overhanging elements in the model, you need to set supports - supports. The slicer can set the necessary support itself, you need to check the appropriate box in the settings. nine0003

When printing with soluble support, you can set the gap between the model and support - 0. This will make the surface smoother. If the support material and the model are the same, you need to add a small gap. Otherwise, it will be difficult to separate the support from the model.

Divide model

Sometimes the supports can take more plastic than the model. In this case, to save material and time, it will be more convenient to cut the model. If you have more than one 3D printer, then the model will print several times faster. nine0003

When cutting the model, you can leave grooves or mortgages so that the pieces of the model are connected without displacement.