Used 3d printer marketplace

How to Sell Your 3D Printer (Used & New) – Where to Sell It – 3D Printerly

Selling your 3D printer can be tough but there are some strategies that you can use to sell your used 3D printer. This article will help you figure out the places where you can sell your 3D printer as well as how to sell it.

To sell your 3D printer, you can try to sell it locally to places such as a community college, an engineering organization, or try and pitch it to another hobbyist. Many people choose to sell their 3D printers online in general marketplaces like eBay and Gumtree, as well as Facebook and even forums.

There is more information that you’ll want to know about selling your 3D printer so keep on reading to find out.

Where to Sell Your 3D Printer

Selling your used 3D printer can be an easy thing to do if you check out the right places both online and in physical stores. Here is a list of places where you can sell your used 3D printer which I have compiled for you.

1. General Market Place Websites

You can check out general marketplace sites such as eBay, Gumtree, and Craigslist (choose your location). This is a great platform to sell your old 3D printer as you get the opportunity to display your printer to a vast audience.

You would still have to ship the printer depending on the arrangement. They can either pick it up in person if they are willing to travel or you pack it up and send it out to them.

However, you should get enough information about the terms and conditions of the platform you choose as they have different policies. Some of them take commissions off sales and you should factor that in.

For instance, you will not be able to sell on eBay if you don’t have a verified address or if your country or region is not among the listed countries.

Another thing is, once you make a sale, you pay eBay about 9% of the selling price and you also pay a fee for listing your item which is a fixed-price listing fee.

Unlike eBay, you can list your used 3D printer for free on Gumtree so you can keep the full sale price. If you choose to, they offer paid options that let you increase your visibility to potential buyers.

Craigslist gives the chance of keeping the full sale price as there are no extra charges either for listing or making a sale. You can just make a post with the 3D printer details and wait for engagement or responses.

The general marketplace websites are proven and effective places to sell your items as many users are known to have successfully sold their old 3D printers there.

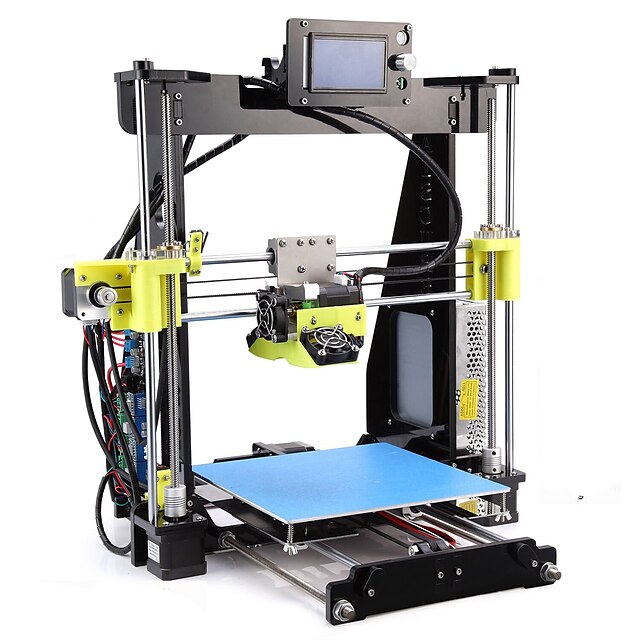

Do keep in mind that people will try to make you offers so have a price range in mind when you go to sell your machine. Maybe you can throw in some accessories like filament and spare nozzles for negotiating power.

Remember to keep safe when using these online marketplaces if you are meeting people in person.

2. 3D Printing Forums

Even though 3D printing forums are commonly used as platforms where users connect and share their 3D printing experiences, you can also sell your 3D printer on these platforms.

Here, you can get your old 3D printers right in front of the right community that may need it. You have a higher chance of selling it off since this is a gathering of actual users who are more involved in 3D printing and creation.

However, you may not be able to upload photos or post ads on some 3D printing forums as these actions may be restricted. You may also have to message people on the forum by sending them a direct message which may be time-consuming.

You can take advantage of the forums to both connect and cart off your used 3D printer.

3. Facebook Market Place

The Facebook marketplace is another platform where you can sell your used 3D printer. A user mentioned how they sold their Prusa 3D printer without hassle on a Prusa Facebook group.

You can also contact local businesses on Facebook that rent out used 3D printers to sell yours since they are always looking for units to buy. Another user recalled how they sold a PrintrBot 3D printer in no time by simply pinging them up.

You can have immediate results on Facebook as you have access to an unlimited number of users and 3D printers available for sale.

A Facebook group by Vincent Puthoff with about 11,000 members called 3D Printers Buy Sell Trade connects 3D printer buyers and sellers. All you have to do is join the group and post your 3D printer with a price and description and wait for responses.

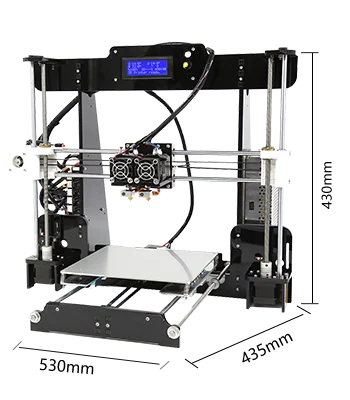

How to Sell Your 3D Printer

Your used 3D printer may not look so new or may be a bit worn out but there are certain procedures that are needed if you want to sell your used 3D printer. The first thing you want to do is to get your printer in a good shape since it is fairly used.

You also want to make sure that it is well functioning as buyers may want to test it out before offering to buy it.

After ensuring that it is in a good state, you can try to box it up either in a new unlabeled box or the box or package that came with the printer if it is still in a good and presentable state. This is so it can be easily sent out for delivery if your buyer is not in your region or country.

This is so it can be easily sent out for delivery if your buyer is not in your region or country.

This is also where you ensure that you pack all the parts that came with your printer if they are still available or in a good shape. There are some 3D printers that come with extra screws and parts so may want to pack up all of that too.

Then find a good platform from one of the marketplaces listed above where you can easily list your printer for sale. As mentioned earlier, you should ensure to check out the policies and terms of the marketplace before making your choice.

A user suggested returning your 3D printer to the place you bought it from and that way you can have your money back for the printer. Most companies also have warranties and you may be able to take it back if you are still within the given timeframe if there are issues.

You can also decide to join various 3D printing groups on social media where you can put up your printer for sale.

Is Owning a 3D Printer Illegal?

No, it is absolutely legal to own a 3D printer. There are no laws against owning a 3D printer in all countries of the world including countries like China, Iran, North, South Korea, and many others where one can be tempted to think that it is illegal.

There are no laws against owning a 3D printer in all countries of the world including countries like China, Iran, North, South Korea, and many others where one can be tempted to think that it is illegal.

3D printers have proven to be very useful to society and even in the medical space as they are used in printing prosthetics so they may not be easily written off.

It is also not voluntary to get a license to own or use a 3D printer.

You may only have to be careful with the models you 3D print as there are laws surrounding this especially when they are models that are owned by a licensed 3D printing company or registered works of private individuals.

Used 3D Printer Marketplace 3DPrinterBoom.com is Now Live - 3DPrint.com

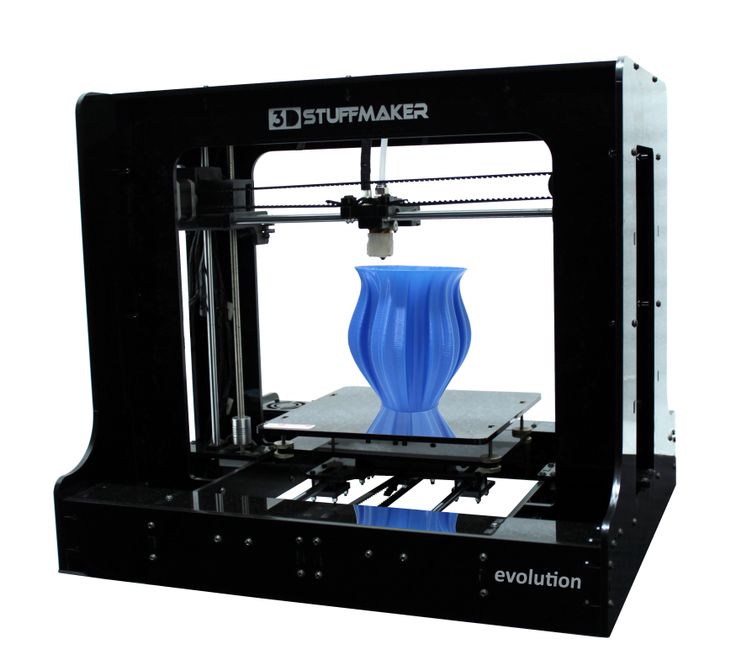

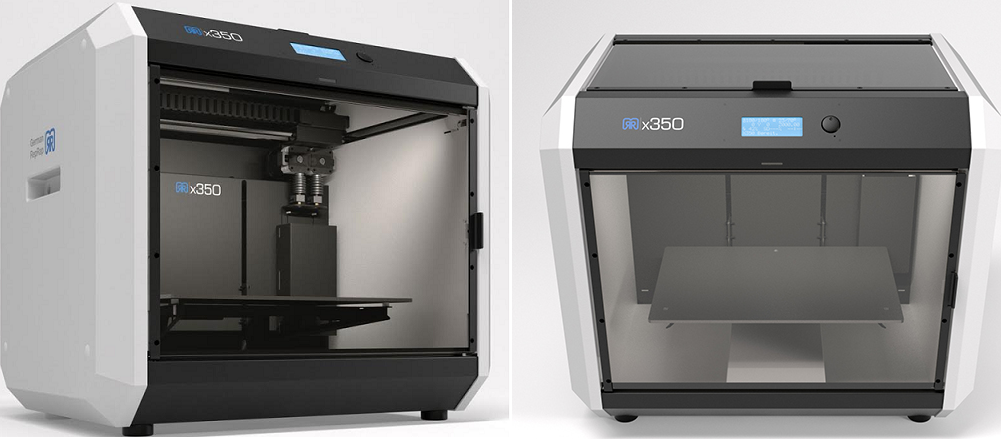

Do you have a used 3D printer that you’re not using? Perhaps an old model that’s gathering dust in your den? Maybe you’ve recently upgraded and have a perfectly good machine on your desk next to your new one? Perhaps you’ve moved from FDM to SLA or the other way around? Or your company has traded up to an industrial 3D printer? 3DPrinterBoom. com is the place where you can sell your old 3D printer, for free.

com is the place where you can sell your old 3D printer, for free.

This is how you publish a new advert.

There are no listing fees, and the 3DPrinterBoom.com used 3D printer marketplace created just so you can sell your old 3D printers. 3DPrinterBoom.com connects you with people looking for used 3D printers all over the world. Listings are categorized per country should you only wish to buy local. You can post any 3D printer to 3DPrinterBoom.com, and when they are sold, there is no transaction fee like you have with eBay. 3DPrinterBoom.com is completely free for both buyers and sellers.

You can send messages via the platform.

You can directly arrange for shipment, delivery, terms, and payment via an internal messaging system. The website, app and communications tools link buyers and sellers from all over the world directly with each other. There is no need for either of you to post addresses or phone numbers publically online. You don’t have to disclose your business name publicly or give an exact address publicly which is ideal for companies needing a discrete sale. You can also view stats for your advert to see if your free advertisement is getting views. Ads are free for 90 days on the site, and you can upload multiple images of your printer.

You can also view stats for your advert to see if your free advertisement is getting views. Ads are free for 90 days on the site, and you can upload multiple images of your printer.

You can see your own ad stats.

3DPrinterBoom.com is the only dedicated preowned 3D printer website. Even though there are over 500,000 3D printers sold each year, there is not another site that specially caters to second-hand 3D printer sales. We are a specialized place for you to find the exact printer you are looking for. No matter if you’re a handy student willing to give some TLC to a down on its luck printer or a company looking to offload older machines from its balance sheet. If you have buyers remorse on a brand new system or have some industrial SLA machine from the mid-nineties that still powers through the day, come to us. Have an old DTM machine? We’d love to have your free listing. We cater to enterprise, home or educational customers. Worldwide. 3DPrinterBoom.com wants to be your one-stop pre-owned 3D printing shop. Boom or bust there will be a lot of second-hand 3D printers available worldwide, but right now there’s no way to find them all, help give your 3D printer a second life by listing with us.

Boom or bust there will be a lot of second-hand 3D printers available worldwide, but right now there’s no way to find them all, help give your 3D printer a second life by listing with us.

Want to get started?

- Go to 3DPrinterBoom.com to sign up for free.

- Post an advert.

- Add a detailed description of the precise make and model of the printer.

- Include a fair assessment of the state of the 3D printer.

Boom, you’re done.

Head over to 3DPrinterBoom.com now to sign up.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: ecommerce • old 3D printers • online sales • preowned 3D printers • preowned printers • second hand printers • used 3d printers

Please enable JavaScript to view the comments powered by Disqus.

Overview of the 3D printing market in 2020

Analytics and business

Experts recommend

Author: Andrey Kombarov

Author: Andrey Kombarov

Additive Manufacturing Trends | Application of 3D printing | A look at additive technologies | Business Strategies for 3D Printing | Overview of the 3D printing industry over the past 6 years | Key Findings

The future of additive manufacturing starts with understanding the goals and expectations of 3D printing users around the world. This was the reason for the launch of an ambitious research project by the French company Sculpteo - the annual State of 3D Printing report. Today it is one of the most authoritative and comprehensive sources of information about the real situation and prospects of the industry. nine0003

This was the reason for the launch of an ambitious research project by the French company Sculpteo - the annual State of 3D Printing report. Today it is one of the most authoritative and comprehensive sources of information about the real situation and prospects of the industry. nine0003

This year, 1,600 respondents from 71 countries took part in the Sculpteo survey. According to the report, a growing number of companies are realizing the possibilities of additive manufacturing, increasing investments and demonstrating undeniable confidence in the future of professional use of 3D printing.

This material offers a complete overview of the world of additive manufacturing and will help you develop the right business strategy.

In the blog , the State of the 3D Printing Market 2020 is published in abbreviated form. You can download the full version for free in our virtual library:

Additive Manufacturing Trends

Materials

- New and available materials.

- Improving the quality and stability of budget additive technologies. nine0035 Improving post-processing technologies to obtain parts with the highest quality surface.

- 3D printing from multiple materials at once.

Environmental sustainability

- Biodegradable materials and materials of biological origin.

- Manufactured on demand and on site to reduce transport and environmental costs.

- Application of 3D printing to meet the challenges of renewable energy and energy efficiency. nine0036

Technology Development

- Improved usability of software and printers

- Mass Production: Printing and 3D Scanning Speed

- Generative design

Availability

- Reducing the cost of 3D printers and materials (metals, photopolymers).

- Low post-processing costs.

- Sharing projects and tools. nine0036

iQB Technologies experts recommend articles:

3D printing as a full-fledged manufacturing technology in the context of the COVID-19 pandemic

2020 results and forecasts: the 3D printing market will grow by 25% annually

Application of 3D printing

The possibilities of 3D printing are growing every day, and with them the scope of its application is expanding. Gradually, companies begin to feel more confident in relation to 3D technologies. nine0082 68% of respondents are looking to use additive manufacturing to solve more problems, and 44% of are going to introduce new 3D printing technologies. Most professionals outsource SLS and Jet Fusion printing, as well as metal 3D printing, so they do not need to maintain their own equipment, and this will encourage them to test new technologies.

Gradually, companies begin to feel more confident in relation to 3D technologies. nine0082 68% of respondents are looking to use additive manufacturing to solve more problems, and 44% of are going to introduce new 3D printing technologies. Most professionals outsource SLS and Jet Fusion printing, as well as metal 3D printing, so they do not need to maintain their own equipment, and this will encourage them to test new technologies.

So what are the most popular 3D printing and post-processing technologies? Let's find out! nine0003

We emphasize once again that production volumes using 3D printing continue to grow. We are seeing this growth in research and development and education, which is in line with the increased demand for new materials and technologies in the market.

Click image to enlarge

The use of photopolymers is increasing through both internal and external services, while for metal 3D printing, most users outsource. nine0003

nine0003

Design, testing and prototyping remain the main tasks solved with the help of 3D printing.

Stability and quality control remain a major concern for users seeking to scale up the use of 3D printing.

Most users use SLS, Jet Fusion and metal 3D printing technologies through outsourcing without purchasing equipment.

nine0002 3D printing users are interested in exploring new applications, technologies and materials.Typically, 3D printing is used in conjunction with traditional manufacturing methods such as laser cutting, CNC machining, and injection molding.

A look at additive technologies

What do respondents think about 3D printing technologies? In this section, we will look at the main benefits of 3D printing for users and their companies. How exactly does it optimize production processes? nine0003

66% of respondents use 3D printing to create parts with complex geometries. Survey participants cite the reduction in iterations, lead times and costs as the most important benefits of this technology.

Survey participants cite the reduction in iterations, lead times and costs as the most important benefits of this technology.

In this section, we will also look at the future of the additive industry and the factors driving its growth and business adoption. What needs to be done to accelerate the adoption of 3D technologies? Now we will find out.

nine0002 As technology and materials become more accessible, the cost savings of 3D printing become clear to more and more users. Many also cite time savings due to reduced iterations and lead times as a benefit.Set-up costs and lack of knowledge are seen as the main limiting factors for the adoption of 3D printing.

nine0002 The role of 3D printing in business and manufacturing continues to grow.New materials and reliable technologies are in demand for more than 55% industries.

Business Strategies for 3D Printing

Additive manufacturing is a huge competitive advantage. With some significant benefits of 3D printing, such as reduced lead times and speed of innovation, the vast majority of respondents view 3D printing as a significant improvement for their business. nine0003

With some significant benefits of 3D printing, such as reduced lead times and speed of innovation, the vast majority of respondents view 3D printing as a significant improvement for their business. nine0003

As for money, investment in additive technologies is growing every year. Most of these users will increase their investments in 2020! It can also be seen that the vast majority of those surveyed have been using 3D printing for several years and plan to invest more in this technology in the near future. The business world believes in the promise of additive manufacturing.

Let's watch how 3D printing becomes a real asset for companies, helping them develop their business strategy! nine0003

63% of see a significant or dramatic impact on sales. Reduced lead times and speed of innovation are the most important success metrics for 3D printing.

Nearly 60% of consider 3D printing one of their strengths compared to the competition.

65% of companies plan to increase their investment in 3D printing in 2020.

nine0002 The integration of 3D printing into manufacturing processes continues to increase: 74% of actively use 3D printing in their companies.Overview of the 3D printing industry over the past 6 years

The Sculpteo report offers a look at the analysis of the state of the 3D printing industry for each year since 2015. How has the use of 3D printing evolved over the period 2015-2020? Let's look at the answers of the latest polls.

nine0002 Large-scale production using 3D printing continues to spread, becoming as commonplace as prototyping and testing.Accelerating development and offering customized products and limited editions remains a major challenge for companies using 3D printing.

The market share of photopolymers continues to increase, showing significant growth over the past two years. nine0003

Key Findings

1.

Lack of stability is the Achilles' heel of 3D printing

Lack of stability is the Achilles' heel of 3D printing In order for additive technologies to become an integral part of any production, it is necessary to develop equipment and materials that ensure high stability.

- 51% claims to use 3D printing mostly for quality control purposes.

- 62% of believe the 3D printing industry needs more robust technology to grow.

2. 3D printing is gaining ground in certain industries

Many industries are beginning to increase their use of 3D printing as its role in their manufacturing processes becomes more significant. Users are constantly deepening their knowledge and experience in the application of additive technologies.

- 80% of have been using 3D printing in their companies for over 2 years.

- 33% expect up to 50% increase in investment this year, which is a more conservative estimate than in previous years.

3.

3D printing may not be profitable

3D printing may not be profitable For wider use of additive technologies, the cost of manufactured parts must be reduced - this will attract more industries and sectors. nine0003

- More than 50% of outsource SLS, Jet Fusion, SLM/DMLS and Binder Jetting to offset equipment and service costs.

- 59% indicate that the cost of organizing production is a limiting factor for the adoption of 3D printing.

4. Changing Perceptions: From Prototyping to Full Manufacturing Technology

Despite the increasing use of 3D printing in manufacturing, its benefits are so far only apparent for prototyping and small-scale production. Businesses need to be shown the real benefits of 3D printing for industrial production. nine0003

- 60% report a significant reduction in part cost when using 3D printing.

- 52% of use 3D printing for manufacturing, while 68% of use 3D printing for prototyping.

This article is an abridged version of the Sculpteo report. The full version is available at link .

© 2020 Sculpteo. The material was translated by iQB Technologies exclusively for the 3D experts' blog blog.iqb.ru. nine0020

Download material

Article published on 08/20/2020 , updated on 06/11/2021

How to make money from 3D printing: an overview of promising niches

3D printing is a growing market all over the world. The grandiose ambitions of the first wave of projects have come to naught, and now is the time to look at the real prospects of this direction.

Roman Koposov, Head of Technological Consulting, Leading Analyst of the Training Institute - ARB Pro Group of Companies, talks about the most promising (and so far free) niches in this market. nine0003

The heyday of 3D printing was in 2010-2015. Additive technologies have rapidly burst into the market, making possibilities that previously existed only in science fiction films a reality. Even the most pessimistic critics had no doubts that very soon approaches to the production and customization of goods will change dramatically.

Even the most pessimistic critics had no doubts that very soon approaches to the production and customization of goods will change dramatically.

However, the revolution did not happen. Mass-produced products are still mass-produced without the use of 3D printing, and the idea of moving production closer to the consumer has not been realized, despite billions in investments and the active participation of the world's largest players from various industries. What's the matter? nine0003

Global failure

In 2015, Amazon applied for a patent for using 3D printers installed in cars to print ordered items at a nearby pickup location. A patent was obtained, but the idea was never implemented.

In the same period, the transport operator UPS placed one hundred 3D printers belonging to the startup CloudDDM (now Fast Radius) in one of the logistics hubs in the United States to create a full-cycle automated production. nine0003

The site could operate 24/7 under the control of just one operator. UPS resources made it possible to deliver manufactured goods to another continent the very next day. All conditions were created for the success of the project, but it also did not receive development.

UPS resources made it possible to deliver manufactured goods to another continent the very next day. All conditions were created for the success of the project, but it also did not receive development.

Global retailers Tesco, Walmart and Carrefour tried to introduce 3D printing as a service, but they also stopped at the testing stage. Just like toy manufacturers Mattel, Lego and Toys "R" Us - with 3D printing projects. nine0003

New strategy

The lack of fast and large-scale results excluded 3D printing from the list of hype topics, but did not kill the idea itself. The market got rid of the excess of those who want to change the world and become famous, clearing the way for those who really want to work.

Over the past five years, favorable conditions have developed in the industry for the development of projects in the field of additive technologies.

To take advantage of the situation, the new wave of businessmen should abandon large-scale ideas and focus on narrow niches and specific customers.

Of course, it does not sound as incendiary as the presentations of Amazon and Google, but it can bring real money. nine0003

This is the path followed by the founders of Align Technology (USA), who created and patented the Invisalign teeth alignment system using caps, having previously received FDA approval and $140 million in investments. In 2015, the company shipped 583.2 million 3D printed caps to customers and generated a net profit of $144 million at a 17% margin.

The success of the American startup was repeated by the Russian company 3D Smile, which, using three-dimensional printing, produces removable transparent mouth guards for bite correction. In terms of cost, they are comparable to braces, but much more convenient to use. In August 2014, 3D Smile was certified by Roszdravnadzor, launched sales in October, and reached operating profit in December. nine0003

SOLS (USA) raised $23.7 million in investments and implemented 3D printing technology for custom-made orthopedic insoles. The service was tested in partnership with 50 orthopedists, from whose patients up to a hundred orders were received per week. At the launch stage in 2014, the cost of a pair of personal insoles was 300-500 dollars (for analogues in pharmacies, you had to pay 500-1000 dollars). Two years later, they managed to reduce the price to $ 99 per pair and increase the flow of orders many times over. nine0003

The service was tested in partnership with 50 orthopedists, from whose patients up to a hundred orders were received per week. At the launch stage in 2014, the cost of a pair of personal insoles was 300-500 dollars (for analogues in pharmacies, you had to pay 500-1000 dollars). Two years later, they managed to reduce the price to $ 99 per pair and increase the flow of orders many times over. nine0003

Several Russian projects have been successfully launched in a similar niche. The most famous of them is the Motorika children's traction prostheses, which have now evolved into bioelectric prostheses with built-in gadgets. The company's turnover for 2018 is about one million dollars.

The Zdravprint service can also be noted - 3D printing of individual orthoses that replace plaster and its alternatives, as well as used in complex fractures after plaster removal. They are printed on a custom printer. At the product creation stage, the founders invested $50,000 in the project, and then raised another $100,000 from Maxfield Capital venture fund. nine0003

nine0003

Not a single seal

In the wake of the popularity of 3D printers, not only manufacturers of goods, but also equipment sellers earn money.

After the expiration of the first patents, the price of the printer dropped from $20,000 to $2,000. This was taken advantage of by several Russian companies, which now make up the main pool of sellers of such equipment.

Each manufacturer has developed its own technological solution with unique elements, which helped to divide niches and not create heat in the competitive field. nine0003

One of the first manufacturers in the Russian Federation was PICASO 3D, ApisCOR created the first really working construction 3D printer, 3D SLA is responsible for printing metal products.

There are also desktop 3D printer vendors on the market (TOP 3DSHOP, 3D REP) that have focused on import and distribution. In addition, they are engaged in 3D modeling and custom printing, and offer CNC machines and robotic systems.

For new players, the entrance to a clearly segmented business that operates in each of the listed niches is still open. At the same time, to start, it is not necessary to have a unique technology or idea, it is enough to identify your client and focus on demand. nine0003

In addition, there are a sufficient number of empty niches in the market that you can enter and work in.

Open niches

Jewelry

The jewelry market is stagnating, buyers are increasingly trying to save money and get an interesting design, so they choose jewelry not from gold, but from silver, as well as costume jewelry.

In response, manufacturers reduce the weight of precious metal products and introduce cheaper substitutes into the range. nine0003

3D printing gives the market the missing element - the personalization of jewelry.

This allows you to "drop" the cost of production under the order, reduce the time and meet real demand. There is no need to invent technology, any jewelry shape can be easily found on the Internet and adapted in a 3D editor.

There is no need to invent technology, any jewelry shape can be easily found on the Internet and adapted in a 3D editor.

Characters and artifacts for gamers

3D printing of artifacts or game characters (Warcraft, DotA, GTA) is an interesting and promising niche, and not just printing children's toys. nine0003

In the US, there are examples of cases with large sales turnovers. For example, the WhiteClouds company offers fans and lovers of computer games to create a personalized figure of their favorite game character.

Demand from gamers for such products is stable and will grow. According to Newzoo forecasts, this solvent audience will reach 28.2 million people by the end of 2019. And most of them like the idea of printing out their sword, armor, or an entire character from the game. nine0003

Orthopedics

In Russia, this niche is practically not occupied. Individual players are engaged in insoles and orthoses, however, this market is much wider and includes everything that is made of plastic, rubber, requires a certain level of rigidity and individual settings.

Today, the main sellers of such goods buy them in bulk in China. The use of 3D printing will help to abandon this in favor of small-scale production on site on demand. The result is cost savings, simplification of logistics, and an increase in turnover. For the client, this is an opportunity to quickly, right at the medical center, get what the doctor has prescribed. No need to search, order and wait. nine0003

There are successful cases on this market, they can be studied and “tried on” for other groups of orthopedic products.

Auto parts

3D printing of automotive parts is an idea that has been successfully implemented by a number of companies in the US. Moreover, we are not talking about the nodes of running systems, but about simple spare parts that constantly break down.

Door handles, sun visors and blinds, disk plugs are all products of steady demand. They can be printed on a 3D printer, make a markup of 400-500%, and at the same time successfully compete with official dealers who are not interested in selling "trifle".nine0268

Owners of used cars often look for such parts at disassemblies, since it is not possible to order a new one or the price is not acceptable. The range can be expanded with plastic elements for tuning and car customization.

Also, 3D printing can be used in auto tuning and more globally. For example, the RingBrothers company is engaged in the creation of unique "custom" cars. At some point, the team decided that it was too expensive to constantly make metal parts, figure out how they would look on the car, and then make a new version. Therefore, I began to use 3D printers to create cheaper prototypes. nine0003

Another example is the collaboration between MINI (BMW) and the Belgian company Twikit, a personalization software provider. The automaker has brought in Twikit so that car buyers can use the platform to create their own interior and exterior elements using 3D modeling. These models were sent to BMW's additive manufacturing center, where customer-designed parts are 3D printed and then integrated into the ordered car.

Learn more