Markforged 3d metal printer

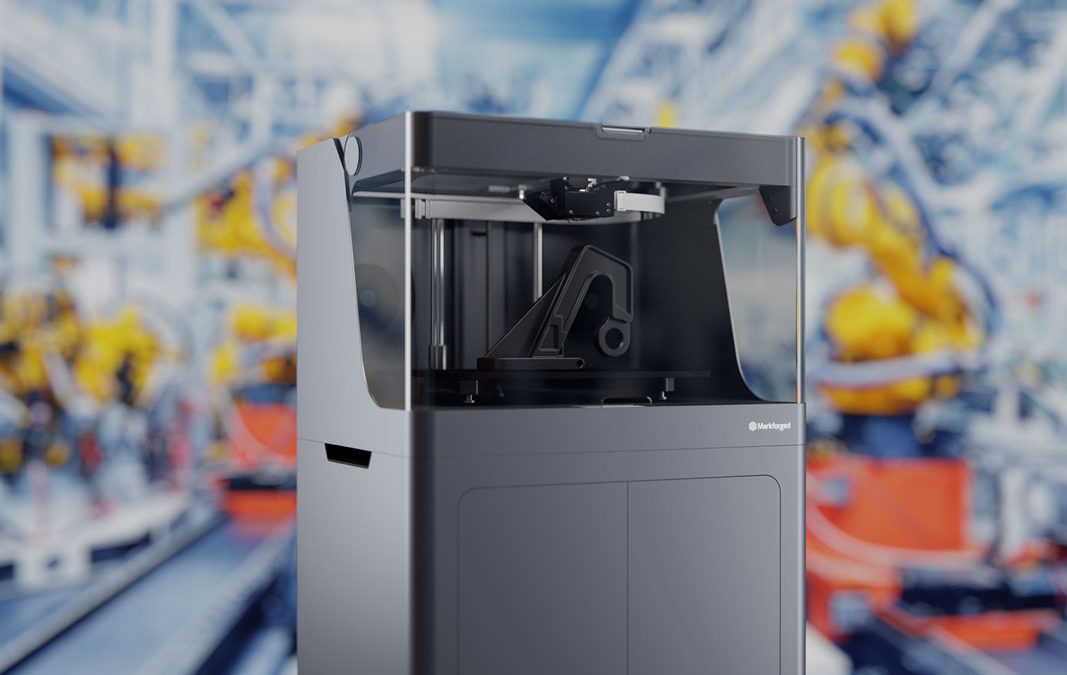

The Metal X 3D Printing System

An accessible end-to-end metal 3D printing solution for functional metal parts, next-day.

Request a Quote

The Metal X System is an accessible way to fabricate complex metal parts in a wide variety of advanced metals.

Simple, Yet Powerful

The Metal X is one of the most intuitive metal 3D printers available today. Print a wide range of materials from stainless steels to copper with minimal training on a closed workflow. Scaling up capacity is easy; just add printers.

Safe and Affordable

The Metal X is designed to be safe to use and accessible for all fabricators. It costs several times less than DMLS metal 3D printing systems and requires no dedicated operator, no powder management system, and minimal PPE.

Quality Parts, Fast

The Metal X is purpose-built for consistent part quality and a seamless user experience. Markforged combines superb software, materials research, and an advanced motion system to deliver industrial-grade parts quickly and reliably.

Specs

From design to fully functional

metal parts in as few as 28 hours.

Physical Dimensions

| Width | 575 mm |

| Depth | 467 mm |

| Height | 1120 mm |

| Weight | 75 kg / 165 lbs |

Build Volume

| Width | 300 mm |

| Depth | 220 mm |

| Height | 180 mm |

Printer primary Specs

- Printing Process

- Metal FFF

- Z Layer Resolution

- 50 μm - 125 μm (Post-Sinter)

- Printing Media

- Bound Powder Filament

- Internal Part Geometry

- Closed Cell Infill (Triangular) or Solid Parts

- Print Bed

- Heated, Auto Leveling, Replaceable Print Sheets

Wash & Sinter

Wash-1

- External Dimensions:

- 609 x 685 x 1,067 mm

- Weight:

- 136 kg (300 lbs)

- Washing Time:

- 12-72 hrs typical

- Solvent:

- Opteon SF-79

- Working Volume:

- 356 x 254 x 203 mm

Sinter-2

- External Dimensions:

- 1,200 x 700 x 1,500 mm

- Weight:

- 350 kg (772 lbs)

- Run Time:

- 17-31 hours

- Sintering Volume:

- 18,356 cu cm

- Peak Internal Temp.

:

: - 1,300° C / 2,372° F

Materials

Compatible Materials

- Release Material

- Ceramic — Becomes Powder During Sintering Process

- Media (Spools)

- Bound Powder Metal Filament

System Details

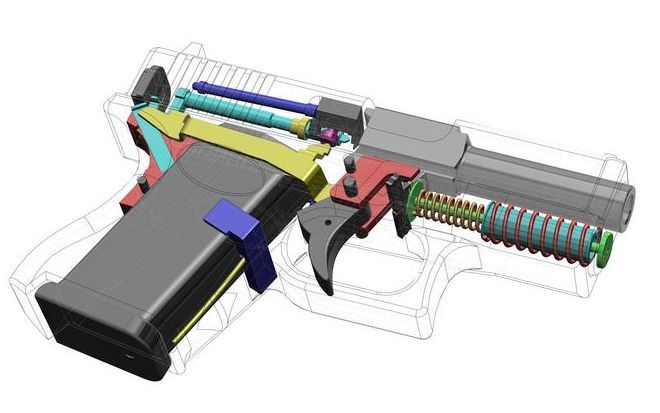

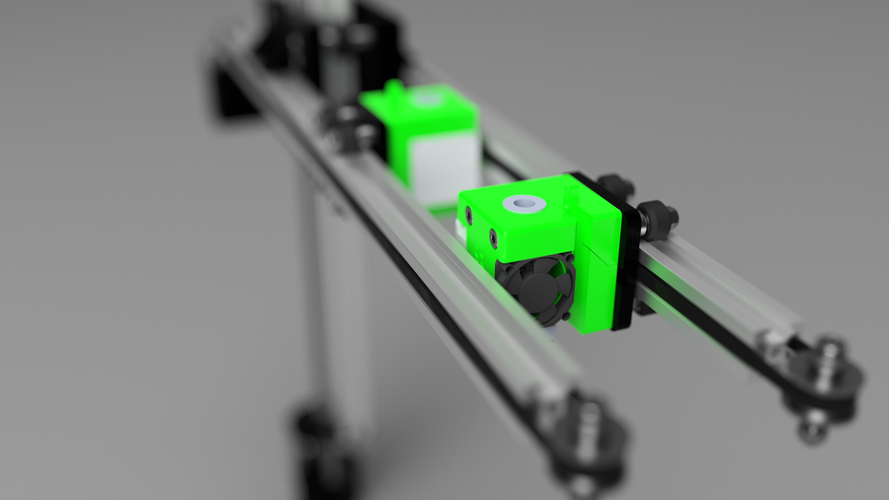

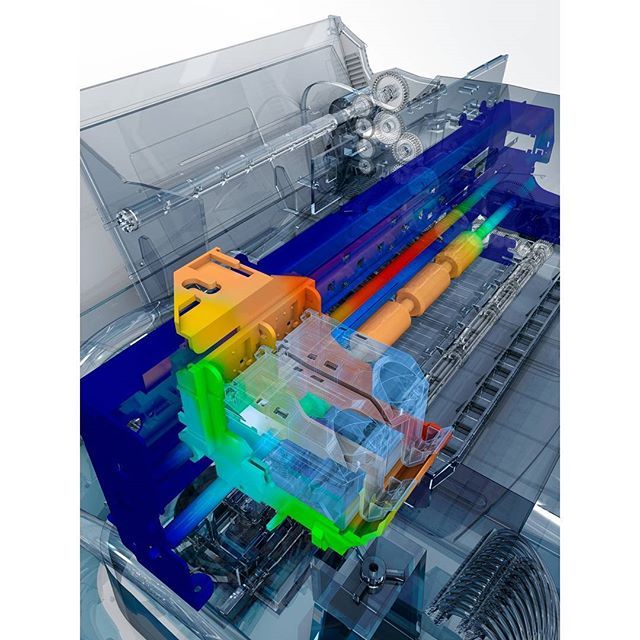

Metal X PrinterThe Markforged Metal X is a new kind of metal printer. By printing metal powder bound in a plastic matrix, Markforged has eliminated many of the safety risks associated with traditional metal 3D printers. That means no loose powder, no lasers, and none of the traditional safety precautions. It’s safe to use in a shop environment with minimal facility upgrades.

In practice, the Metal X is essentially a very advanced FFF 3D printer. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the Metal X is equipped to reliably print you durable parts. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and brushes — accessible and trivial to swap.

Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the Metal X is equipped to reliably print you durable parts. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and brushes — accessible and trivial to swap.

The Wash-1 is a solvent-based debinding system. It primarily uses Opteon SF-79, a high-performance fluid designed to offer superior cleaning power, higher efficiency, and safety in an environmentally sustainable way — Opteon SF-80 or Tergo Metal Cleaning Fluid can be substituted if needed.

The Wash-1 operates with simple ventilation and features an extremely simple user experience. It’s been tested and verified as a shop-safe system.

Sinter-2 and Sinter-1The Markforged Sinter-2 and Sinter-1 are highly optimized tube furnaces used for sintering 3D printed metal parts. They provide leading edge sintering reliability and run times and are equipped with advanced safety features. The Sinter-2 is more advanced than the Sinter-1 — featuring a larger working volume, more precise temperature control, and a mechanical door interlock.

The Sinter-2 is more advanced than the Sinter-1 — featuring a larger working volume, more precise temperature control, and a mechanical door interlock.

The Sinter-1 and Sinter-2 typically have run times between 26 and 31 hours. However, the Sinter-2 can process small parts in express mode, where it can sinter up to 250g of parts in just 17 hours.

Download Datasheet

Materials

From stainless steel to copper,

choose from a wide range of strong,

durable, and capable materials.

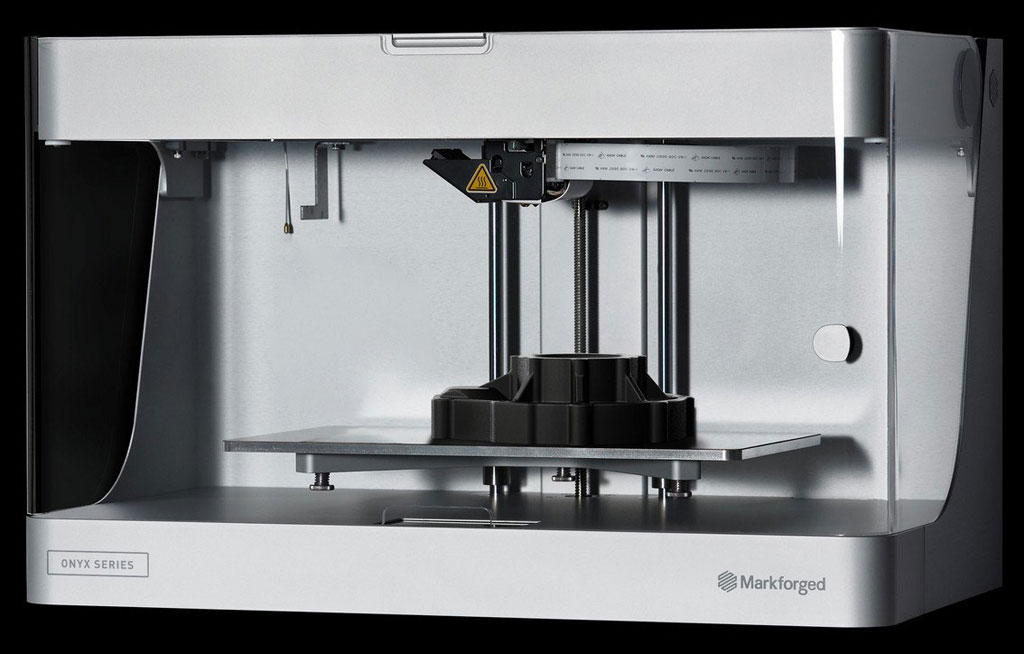

Desktop 3D Printers Designed for Professionals

Desktop 3D Printer Series

Professional desktop 3D printers built with the versatility to test design concepts and build strong end use parts. Our platform covers a wide range of applications - varying from flexible and elastic to strong and rigid.

Compare 3D Printers Talk to an Expert

Drive innovation. Right from your desktop.

Right from your desktop.

Compare Our Desktop 3D Printer Models.

Onyx One™

Our core desktop printer for functional plastic parts with stunning surface finish.

Materials

Plastic

Onyx™

Specs

+320 x 132 x 154 mm build volume

+100 µm - 200 µm layer height

+Precision ground composite print bed

MSRP

$4,990

Talk to an Expert

Onyx Pro™

Our enhanced desktop printer for stunning prototypes, tools, and production parts.

Materials

Plastic

Onyx™

Precise PLA

Smooth TPU

Continuous Fiber

Fiberglass™

Specs

+320 x 132 x 154 mm build volume

+100 µm - 200 µm layer height

+Precision ground composite print bed

MSRP

$9,600

Talk to an Expert

Mark Two™

The best desktop printer for stunning prototypes, tools, high performance end-use parts, and replacement parts.

Materials

Plastic

Onyx™

Nylon White™

Precise PLA

Smooth TPU

Continuous Fiber

Continuous Carbon Fiber™

Aramid Fiber (Kevlar®)*

Fiberglass™

HSHT Fiberglass™

Specs

+320 x 132 x 154 mm build volume

+100 µm - 200 µm layer height

+Precision ground composite print bed

MSRP

$19,900

Talk to an Expert

Dupont™ and Kevlar® are trademarks and registered trademarks of E. I. du Pont de Nemours and Company

I. du Pont de Nemours and Company

What can I build on a desktop 3D printer?

Micro carbon fiber filled nylon offers excellent heat resistance, surface finish, and chemical resistance

APPLICATIONS

- Functional Protos

- Production Covers

- Fit checks

- Job Aids

Learn more

Stiff, strong, and extremely light, carbon fiber reinforcement yields parts capable of replacing machined aluminum.

APPLICATIONS

- Custom production

- Bridge production

- High performance end-use parts

- High-strength tooling

Learn more

HSHT Fiberglass delivers the highest impact resistance and heat deflection temperature of our continuous fibers, and can be used for low-temp molds.

APPLICATIONS

- Welding fixtures

- Ruggedized enclosures

- Low-temp molds

- Forming tools

Learn more

Inexpensive and 11 times stiffer than ABS, this is the perfect entry level continuous fiber for 3D printing functional parts.

APPLICATIONS

- Workholding tools

- Functional Prototypes

- Moderate strength end-use parts

Learn more

Extremely durable and extremely resistant to catastrophic damage, Kevlar is an excellent choice for harsh environments.

APPLICATIONS

- Workholding tools

- Ruggedized enclosures

- Flexures

Learn more

Rubber-like material for high quality, flexible, impact-absorbent parts on demand.

APPLICATIONS

- Seals and gaskets

- Shock absorbers

- Wheels and treads

- Belts

Learn more

Colorful, cost-effective, and easy to print thermoplastic for design validation

APPLICATIONS

- Concept models

- Fit Checks

- Color-coded indicators

Learn more

Unmatched versatility

Our Desktop Series printers unlock production-grade performance and affordable prototypes, all on the same platform. Our most popular printing plastic, Onyx™, gives you a great start in material properties with excellent surface finish. Our selection of continuous fibers take our parts far beyond the mechanical and thermal properties of everyday FFF printing plastics, Smooth TPU 95A provides an efficient way to make high quality flexible parts in low-to-medium volumes, while Precise PLA delivers effective, reliable prototypes at an affordable price. No matter what properties you’re looking for, our desktop 3D printers have the right material for the job.

Our selection of continuous fibers take our parts far beyond the mechanical and thermal properties of everyday FFF printing plastics, Smooth TPU 95A provides an efficient way to make high quality flexible parts in low-to-medium volumes, while Precise PLA delivers effective, reliable prototypes at an affordable price. No matter what properties you’re looking for, our desktop 3D printers have the right material for the job.

How does CFR 3D printing work?

Talk with a

Desktop expert

Let us put together an additive manufacturing solution to suit your needs.

How metal printing works on a 3D printer

Contents:

- Metal printing on a 3D printer

- How 3D technologies work

- Two main methods

- Video

Metal printing on a 3D printer (two main technologies)

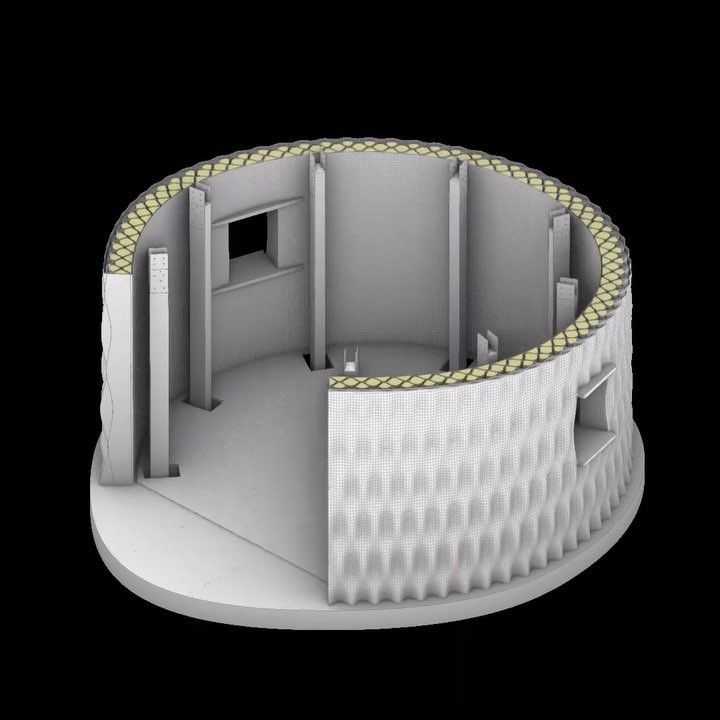

The introduction of innovative technologies opens up new opportunities in various fields of human activity. A modern 3D printer for printing on metal allows you to print high-precision structural elements that are in demand in the space, engineering, and aviation industries.

A modern 3D printer for printing on metal allows you to print high-precision structural elements that are in demand in the space, engineering, and aviation industries.

How 3D technologies work

The production of 3D parts is made using different methods of melting metal powder (using a laser). But the basic principle of operation remains unchanged, so any 3D printer prints with metal in several stages, these are:

- filling the build chamber with an inert gas to minimize the oxidation of the source material;

- heating to the temperature required for the production process.

- powder distribution on the surface of the build platform;

- 3D scanning of the cross section of the starting material with a laser beam;

- melting and sintering of particles, which makes it possible to obtain a hard layer;

- shift of the platform by the amount of the obtained layer for applying the next one (until the object formation is completed).

The moment the metal laser 3D printer completes the process, the product is completely covered in powder. Therefore, until the chamber cools down completely (to avoid deformations), the object on the platform is fixed by the support area.

Two main methods

A modern metal 3D printer can use one of the two most common technologies - selective laser beam melting (SLM) or direct laser sintering (DMLS). Among the main differences between the methods, the principle of gluing the component should be mentioned:

- SLM - occurs as a result of complete melting of the powder;

- DMLS - individual particles are sintered (at lower temperatures compared to SLM) without passing into a liquid substance.

Unlike traditional casting or stamping, DMLS allows objects to be printed without internal stress. This ensures good technical characteristics of the parts. Today, manufacturers offer models that can use several melting options at once.

Among other techniques for bonding powder particles, mention should be made of the UAM (additive ultrasonic) or EBM (electron beam) melting process. Modern equipment - an industrial 3D metal printer is produced by Markforged, ExOne, AurLabs, HP Metal Jet, Stratasys, MX3D, Digital Metal, 3DSLA.RU (the principle of operation of the equipment can be understood by watching the video reviews). Often, the manufactured part requires additional processing: grinding, joining, shaping. Fitting can be done both manually and using automated technologies, one of which is milling on CNC machines, which can significantly reduce the cost of producing serial parts.

Video

Copper 3D Printing - Complete Guide

Copper is one of the newest and most promising areas of metal 3D printing for everything from electric motors to heat sinks.

Previously, copper 3D printing was a challenge due to the metal's reflectivity and high thermal conductivity, but advances in printers and materials have largely resolved these early problems. Today, 3D printed copper propulsion systems send rockets into space, 3D printed copper heatsinks cool processors, and 3D printed copper coils boost the performance of electric motors.

3D printed copper parts (Source: Trumpf)

Why 3D print copper?

Copper has always been a very useful metal due to its ability to conduct heat and electricity, resist corrosion and even kill bacteria and viruses. Demand for complex copper parts is on the rise as 3D printing opens up even more uses and possibilities for this metal.

3D printing (also known as additive manufacturing) allows the creation of exceptionally complex shapes, fine details, internal structures and lattice inserts that are not possible with any other form of metal fabrication. These capabilities reduce weight, increase efficiency, and reduce fabrication and assembly times, as multi-component assemblies can be 3D printed as a single unit.

These capabilities reduce weight, increase efficiency, and reduce fabrication and assembly times, as multi-component assemblies can be 3D printed as a single unit.

Additive Metallurgy

3D printing also makes it possible to produce this relatively expensive metal more efficiently, reducing waste because only the amount of material needed is used to make each part. For companies interested in copper 3D printing, reducing raw material costs is critical.

If you already produce custom copper parts, 3D printing can significantly reduce your production costs while optimizing part performance.

Markforged 3D printed copper heatsink (Source: Markforged)

Although there aren't many 3D printers that can print copper, there is still a wide variety of printing technologies and prices.

FDM printers using copper-filled plastic filament can produce copper jewelry, decorative items, and other parts that are almost 100% copper. While for more advanced production, 3D printers using copper powder, rods or copper polymer slurry produce industrial parts with excellent mechanical and conductive properties, which can meet international standards such as IACS (International Annealed Copper Standard).

While for more advanced production, 3D printers using copper powder, rods or copper polymer slurry produce industrial parts with excellent mechanical and conductive properties, which can meet international standards such as IACS (International Annealed Copper Standard).

Let's look at what types of printers can work with copper today. Trumpf TruPrint 1000 Green Edition 3D Printer several equipment manufacturers have recently included copper in their material list. Since copper is highly reflective, laser processing of the powder has been a hurdle for manufacturers. However, this technology and materials have evolved to solve this problem.

3D printer manufacturer Trumpf, for example, has developed an industrial green laser that can 3D print materials such as copper, copper alloys, and precious metals that are difficult to process with infrared waves.

Two powder layer technologies for metal 3D printing, DMLS (Direct Metal Laser Sintering) and EBM (Electron Beam Melting), work by depositing a thin layer of copper powder onto a platform inside the printer. The powder heats up while lasers or electron beams draw the first layer of the part. When the particles in the layer fuse, the platform is lowered slightly into the assembly chamber, and fresh powder is poured on top, and the process is repeated. Some of the copper powder left over from the process can be recycled for use in the next print.

The powder heats up while lasers or electron beams draw the first layer of the part. When the particles in the layer fuse, the platform is lowered slightly into the assembly chamber, and fresh powder is poured on top, and the process is repeated. Some of the copper powder left over from the process can be recycled for use in the next print.

Copper additive manufacturing powder from GNK Powder Metallurgy (Source: GNK)

Copper-bonded 3D inkjet printers

Copper powder bonded with a liquid binder and sintered in a furnace is a 3D printing technique known as binder inkjet printing that allows parts to be obtained without the use of an auxiliary material. Bond jetting is a no-heat process in which a bonding layer is sprayed between each layer of metal; the binder is then removed during the sintering process.

Binder blasting is a popular additive manufacturing method for high volume metal parts.

Featured image of

Copper Parts Printed by Markforged0 Metal X The most economical approach to 3D printing copper parts is to use machines that extrude the filament. Virtually any Fused Deposition Modeling (FDM) printer can print near-solid metal parts using a polymer filament filled with copper powder. Currently, there is only one option on the market - from the manufacturer of threads The Virtual Foundry. The company claims that its copper filament is suitable for printing on any filament 3D printer with a hardened nozzle and a hot end that can reach temperatures of up to 225ºC. However, the parts do not become metal immediately after printing and require additional post-printing steps to melt the resin binder and leave only the metal. Other types of copper thread contain enough real copper particles to be polished and given a metal-like weight, but are for decorative purposes. A company in Chile called Copper3D produces a copper-filled filament that produces parts that do not have metal parts, but parts that have the antibacterial and antimicrobial properties of copper. NASA is even testing the filament for use in "interplanetary microbial contamination," according to the company. In addition to the mainstream FDM printers, two other filament-extruding printers also offer copper, but they use their own proprietary materials. Desktop Metal uses a bonded metal filament, while Markforged uses a similar metal powder bonded into a plastic matrix. The printers from these manufacturers produce all-metal parts designed for industrial use, such as machine tools, induction coils, heat sinks, and functional prototypes. Cold spray and DED copper 3D printers WarpSpee3D cold spray 3D printer (Source: Spee3D) Although these two metal 3D printing methods are not usually combined together, we are combining them here due to their general application for coating metal parts with another metal and for layering metal parts with metal powder. Directional Energy Deposition (DED) is a system developed by Optomec of New Mexico to create, improve and repair metal parts. Similar to SLS, in DED, high-power lasers build up 3D structures in layers, creating parts with high density and strength, ideal for mechanical applications. In 2019Optomec developed a new copper DED process to produce heat exchangers for use in the aerospace, chemical and other industries. Spee3D's WarpSpee3D process is unique in its use of supersonic 3D deposition to produce parts from a range of metal powder materials, including copper and aluminum. Cold spray is an additive manufacturing technique in which metal powder is injected into a supersonic pressurized gas stream. Instead of melting the metal, cold spraying holds it together in a process called plastic deformation. Companies such as Spee3D are using cold spray technology to apply an antimicrobial copper coating to doors, handrails and touch panels intended for use in hospitals, schools and other public places. Cold spray is also the fastest metal 3D printing method. Spee3D printed a 17.9kg (17.9kg) pure copper aerospace rocket nozzle lining (pictured below) on WarpSpee3D in about three hours at a cost of just $716, according to the company. Parts like this are usually made from solid forged copper, which takes weeks and costs tens of thousands of dollars. One of the disadvantages of DED and cold spray is that they are limited in the production of complex geometries. Rocket nozzle copper plating, engineer spark-free copper hammer and copper cable clip, 3D printed by Spee3D (Source: Spee3D) Photopolymerization Holo) Metal DLP 3D printing is similar to resin 3D printing in that it uses UV light projected onto a photosensitive slurry to cure layer by layer. Instead of resin, metal DLP printers use a liquid polymer filled with metal powder and a small amount of binder. After the parts are printed, they have to go through several more stages before they become the final metal parts. Metal filament for printing metal parts consists of a plastic base with metal particles evenly interspersed in it. Copper interspersed filament for copper parts is a unique type of composite filament that, when used correctly, produces strong, chemically resistant, and near-solid metal parts.

Metal filament for printing metal parts consists of a plastic base with metal particles evenly interspersed in it. Copper interspersed filament for copper parts is a unique type of composite filament that, when used correctly, produces strong, chemically resistant, and near-solid metal parts.

Learn more