Starting your own 3d printing business

How to Start a 3D Printing Business

The 3D printing market value increased on average 25% per year over the last five years. Its increased market value generated a boom of interest in setting up a 3D printing business. The 3D printing industry offers different niches in which to develop a business. While each type of 3D printing business will have specific requirements to start, there is general information that can make setting up any form of 3D printing business easier.

Decide Which Kind of 3D Printer You Want to Be

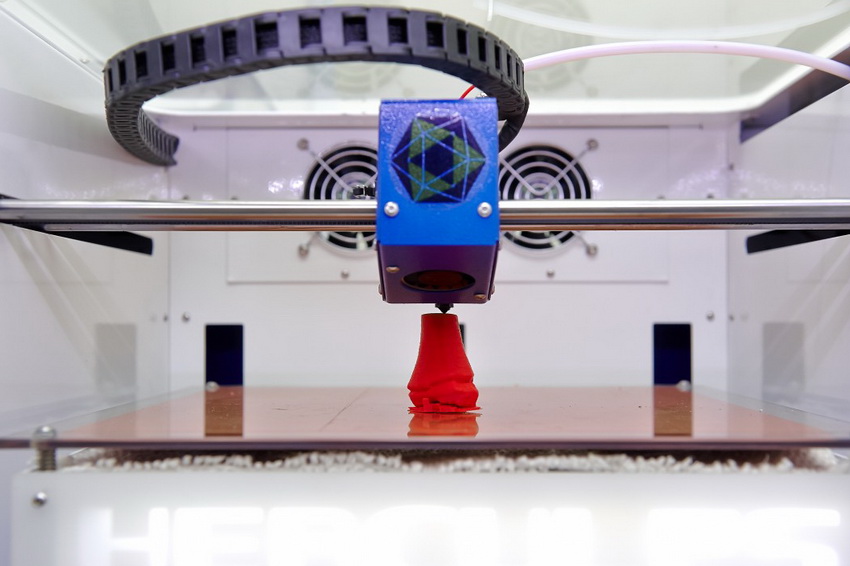

3D printing can be used in a variety of different ways. As such, there are many different niches for profitable 3D printing businesses. Some examples include 3D printing prototypes and manufacturing components, setting up a local 3D printing service, and 3D printing toys.

3D Printing of Prototypes and Models

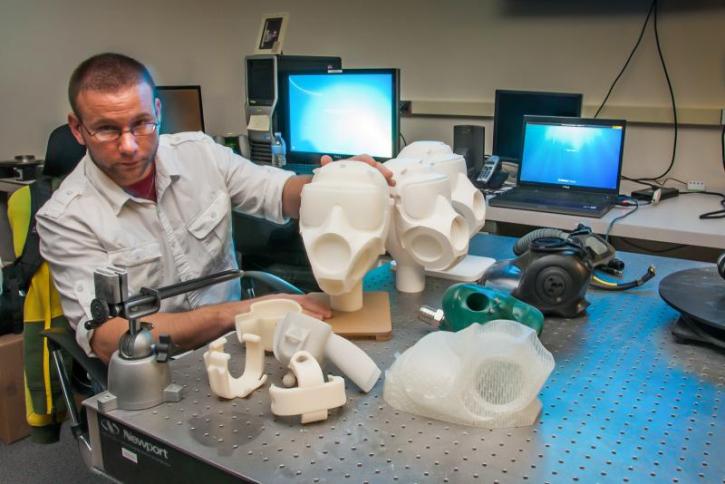

Roughly 65% of the 3D printing demand comes from engineers developing industrial, electrical, or consumer goods. Also, industries such as architecture, engineering, technology, and medicine require models of devices, manufacturing parts, and chemical compounds. These industries also typically have a section of their research and development process dedicated to testing out prototype designs or finding more efficient ways of creating a needed manufacturing part. 3D printed parts and components not only speeds up production time but also lowers cost. Therefore, dedicating a 3D printing business to helping other businesses with these needs can be quite profitable.

Raise 3D recently interviewed 2050.AT, a 3D printer farm to learn how 3D printing assists manufacturing. 2050.AT created 3D printed components and parts. 2050.AT explained that 3D printing is valuable for producing parts that are hard to find or expensive to produce. 3D printers make prototyping more efficient. To learn more about 2050.AT’s range of work with 3D printing, click here.

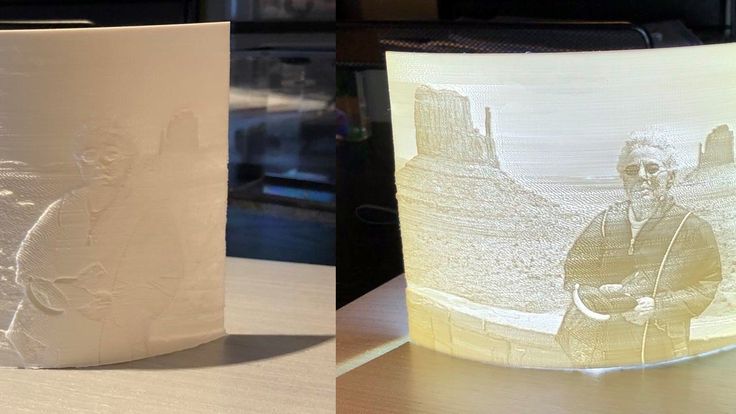

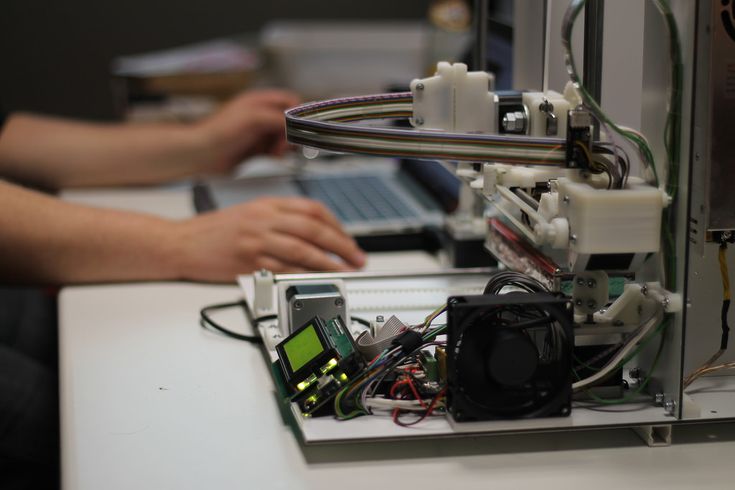

3D Printing Service

A more general idea is to establish a local 3D printing service. As we covered in the previous example, many businesses incorporate 3D printing into their production process. However, not all businesses can afford their 3D printers. In this situation, a local 3D printing service is still more efficient for these businesses than traditional research and manufacturing methods. A 3D printing service also can produce work for individuals that require their own 3d printed products. For example, students may need a 3D printed model for a school project. Or an artist may need 3D printed models or devices for art projects.

As we covered in the previous example, many businesses incorporate 3D printing into their production process. However, not all businesses can afford their 3D printers. In this situation, a local 3D printing service is still more efficient for these businesses than traditional research and manufacturing methods. A 3D printing service also can produce work for individuals that require their own 3d printed products. For example, students may need a 3D printed model for a school project. Or an artist may need 3D printed models or devices for art projects.

3D Printed Toys and Models for Children or Collectors

A third option is to 3D print toys and models of characters or clothing of a character for children, collectors, and cosplayers. For example, a helmet of a well-known character from a tv show or movie will be appealing to all three demographics.

What Kind of 3D Printing Business Can You Set Up?

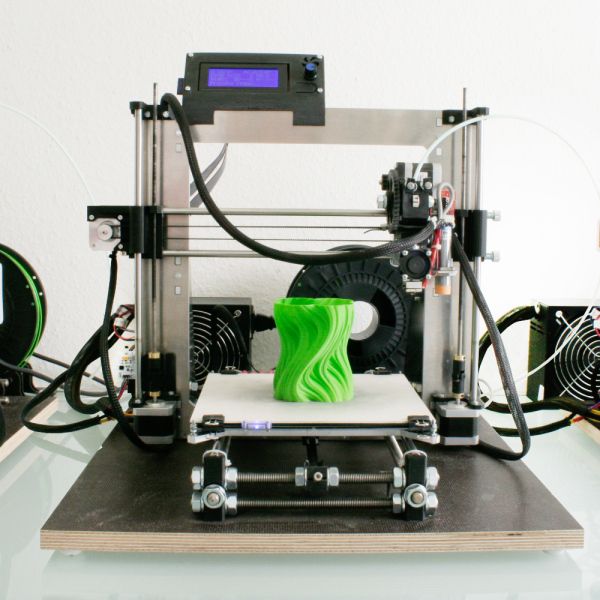

As with any new business, a 3D printing business will take time to get off the ground. Therefore, part of deciding to start a 3D printing business is knowing how much you can handle. This includes knowing your budget, knowing how much physical space you can dedicate to your business, knowing how many people will be working with you, and knowing how much time you can put into each of your projects. Since not every kind of 3D printing business is the same, each niche will have its requirements. For example, 3D printing prototypes and manufacturing parts will require larger printers with more specialized capabilities.

Therefore, part of deciding to start a 3D printing business is knowing how much you can handle. This includes knowing your budget, knowing how much physical space you can dedicate to your business, knowing how many people will be working with you, and knowing how much time you can put into each of your projects. Since not every kind of 3D printing business is the same, each niche will have its requirements. For example, 3D printing prototypes and manufacturing parts will require larger printers with more specialized capabilities.

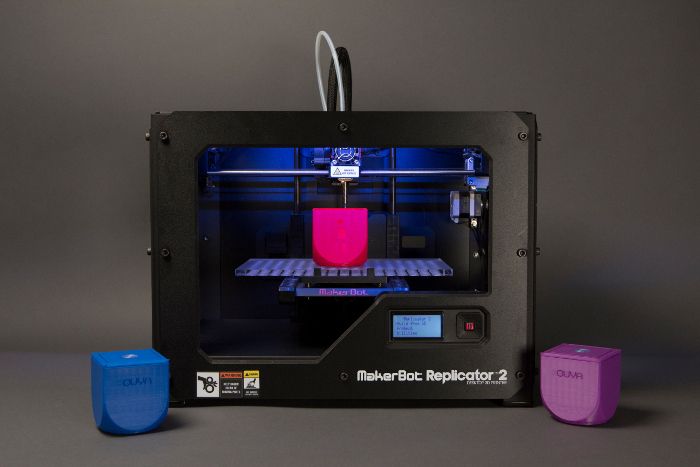

How Much Does Starting a 3D Printing Business Cost?

The actual cost of starting a 3D printing business depends on the type of focus you choose. However, the cost of setting up a 3D printing business ranges from $1,000 to $10,000. This cost will be affected by the type of 3D printer that you choose, utilities, rent (if you choose to not work from home), software, and marketing. The cost of a 3D printer changes based on the size, capabilities, and quality that you wish to produce.

3D Printing Filaments

A crucial aspect of establishing a 3D printing business is in understanding the capabilities, characteristics, and differences of each printing material. The different kinds of 3d printing materials are also known as filaments. The most common filaments for 3D printing are plastics. Each plastic has its strengths which make it suitable for different projects and tasks. Sometimes a 3D printed device has many parts to it, and each part may perform better with a different kind of plastic. For example, TPU/TPE filaments are flexible sometimes to the point of being like rubber. And PLA filament is durable and easy to print.

3D Printing Competitors

Each type of 3D printing business will have its market and competitors. For example, a 3D printing service will have a local market with local competitors. Meanwhile, 3d printed toys and models will rely heavily on online sales and social media. A general suggestion for all 3D printing businesses is to find an focus on making yourself visible on the platforms where other businesses like yours appear.

A general suggestion for all 3D printing businesses is to find an focus on making yourself visible on the platforms where other businesses like yours appear.

Making Your 3D Printing Business Stand Out

All forms of 3d printing businesses are competitive, and it can be hard to know how to stand out from competitors. One way of adding value is to know how to do model design. Model design is a necessary procedure to create a 3D printed product. Many businesses contract out the model design process to another business. However, you can learn how the process of turning an image into a digital model which will be used for 3D printing. This will give you more control over your project and keep your work in-house. Another way to stand out from your competition is through post finish. Post finish means smoothing out the final 3D printed device and adding color. Deciding how far you want to go with post finish can also help you stand out from other 3D printing businesses.

3D printing offers a variety of niches to establish a profitable business. Knowing the exact details for setting up the foundations for each niche will require more specific research. However, there are some common factors for establishing any kind of 3D printing business such as learning about filaments and knowing your competitors. Once these factors are known, a strong foundation can be built for a profitable 3D printing business.

Connect with Raise3D:

Have you had a great experience with Raise3D that you would like to share? Please contact us at [email protected]. We look forward to hearing from you.

For more information about Raise3D printers and services, browse our website, or schedule a demo with one of our 3D printing experts.

Start your own 3D printing business in 2020: Discover 15 ideas

3D Learning Hub

See all categories

Contents:

- Introduction

- 3D printing, a technology helpful for all sectors

- Top 15 of the best 3D printing business ideas

- Improve your manufacturing products using 3D printing

- Start your own company thanks to Additive Manufacturing!

Introduction

Do you know about all the opportunities that 3D printing could offer you? In this blog post, we are going to show you how you could create your own 3D printing business, innovate, iterate, and make your own fantastic success.

You are looking for tips to understand how you could start a 3D printing business? We will share with you the best ideas for 3D printing business and see what are the best examples of profitable 3D printing businesses. Get inspired by all of these 3D printing ideas!

3D printing, a technology helpful for all sectors

At Sculpteo, we see it every day: 3D printing technology is used by more and more businesses, for various applications. It is now quite helpful for the medical industry, the automotive industry, but also for architecture, aeronautics or even agriculture. The printing possibilities are endless.

Did you check our State of 3D printing? This study helps to understand how additive manufacturing technology is used by different businesses. It confirms that this technology is used by more and more different sectors, from aeronautics to consumer goods.

Do you need some help?

Printing products is possible for anybody and any company. If you need a little help to start your 3D printing business – for example, if you want to learn about digital manufacturing and 3D modeling for additive manufacturing – check out our Sculpteo Studio 3D printing consulting service. Our 3D printing experts are going to give you all the tips, training and information you will need to make the most of 3D printing technology!

If you need a little help to start your 3D printing business – for example, if you want to learn about digital manufacturing and 3D modeling for additive manufacturing – check out our Sculpteo Studio 3D printing consulting service. Our 3D printing experts are going to give you all the tips, training and information you will need to make the most of 3D printing technology!

Top 15 of the best 3D printing business ideas

Here is a selection of businesses that are based on Additive Manufacturing, and some others that are using 3D printing technology to develop their opportunities even more. We hope that these examples will inspire you. Indeed, you could find the perfect business opportunity thanks to this cutting-edge technology.

A new phase of product development: rapid prototyping using 3D printing technology

1. The Kupol Project

Gabriel Boutin, a 3D designer, created the Kupol Project using the additive manufacturing technology. It is a bike helmet, 3D printed with the HP Multi Jet Fusion technology, using Sculpteo’s online 3D printing service. This 3D technology helped this innovative designer to develop a relevant and resistant project.

It is a bike helmet, 3D printed with the HP Multi Jet Fusion technology, using Sculpteo’s online 3D printing service. This 3D technology helped this innovative designer to develop a relevant and resistant project.

3D printing can help you with rapid prototyping. Indeed, it is a simple and economical way to produce prototypes. With this technique, you only have to create your 3D design using 3D modeling software, and modify it as much as you want and need.

This way, you only have to change the 3D model and print your 3D file to get your different iterations. This process could help you to save money to develop your project and speed up the production process. Indeed, iterating on your project using additive manufacturing is cheaper than with a traditional prototyping technique.

2. Netlooks

“We are at the moment in the eyewear industry when we have to do something unexpected. We are at a crossroads of technology and craftsmanship”, explains Pierre Andrieu, founder of Netlooks, a custom-made eyewear company and one of our clients.

The goal of Netlooks is to provide their clients with the ultimate made to measure experience. To achieve that, they complement craftsmanship with the latest technologies. Netlooks uses 3D scanning to get the perfect fit for the client’s head, and Additive Manufacturing provided them with time and cost-efficient prototypes before the final product is hand made.

This 3D technology became an essential part of the production process. Manufacturing the prototypes with Additive Manufacturing allowed the company to work faster, speed up the product development time, and to reduce costs. On top of that, thanks to Additive Manufacturing, Netlooks can achieve the ultimate customization and comfort.

Reduce tooling costs

3. Volkswagen Autoeuropa

3D printing can be an asset on different levels, and not only for your products. We saw on our recent blogpost that 3D printing tools could considerably reduce your tooling investment. For example, do you know that Volkswagen Autoeuropa, the car manufacturer, is using 3D printing for manufacturing some of its tools? The company estimates that thanks to 3D printing they saved 250,000€ in 2017. No matter what your sector is, reducing your tooling costs could be a huge asset for your company.

For example, do you know that Volkswagen Autoeuropa, the car manufacturer, is using 3D printing for manufacturing some of its tools? The company estimates that thanks to 3D printing they saved 250,000€ in 2017. No matter what your sector is, reducing your tooling costs could be a huge asset for your company.

Using additive manufacturing to get custom made tools is reducing costs but is also a convenient method that could help you to create a successful business. This way, these tools are totally adapted to their activity, and they are less expensive than produced with another traditional manufacturing technique.

4. P&G

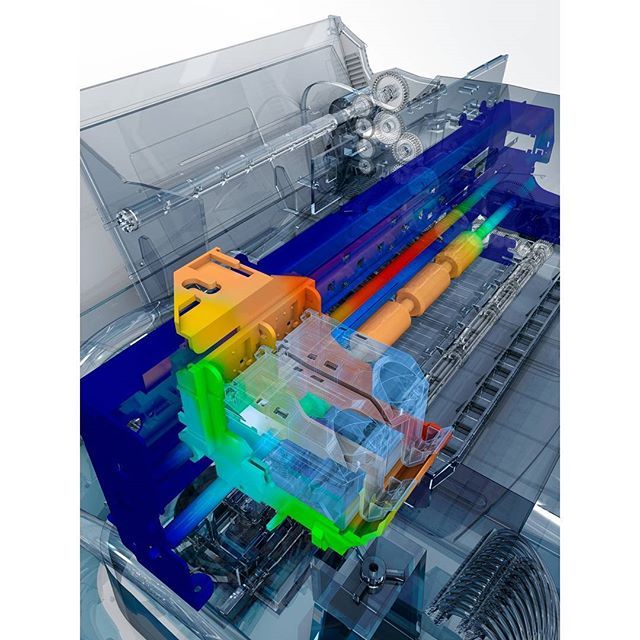

To stay on top of their game, companies like P&G have to chase the latest technology. Where can 3D printing be an asset for Procter & Gamble? In the supply chain innovation sector. Additive Manufacturing brings new solutions to existing problems and improves business strategies.

Peter Hewett, Global Product Supply Platform Leader, explains: “It only took a short investment of time, understanding the technology and services offered by companies like Sculpteo, to realize how we might be able to solve current business manufacturing challenges in a different and smarter way. We’re already bringing the experts together seeking breakthrough solutions which wouldn’t be possible with traditional technologies”.

Achieve the greatest level of detail

5. Gaëtan Le Penhuel

//www.sculpteo.com/blog/2018/10/03/how-using-3d-printing-for-architecture-projects-can-truly-help-your-business/This aspect of the production was crucial for Gaëtan Le Penhuel, an architect company from Paris, which we had the pleasure to partner with. They needed architectural models delivered in a short time, at the same time, achieving a high level of detail.

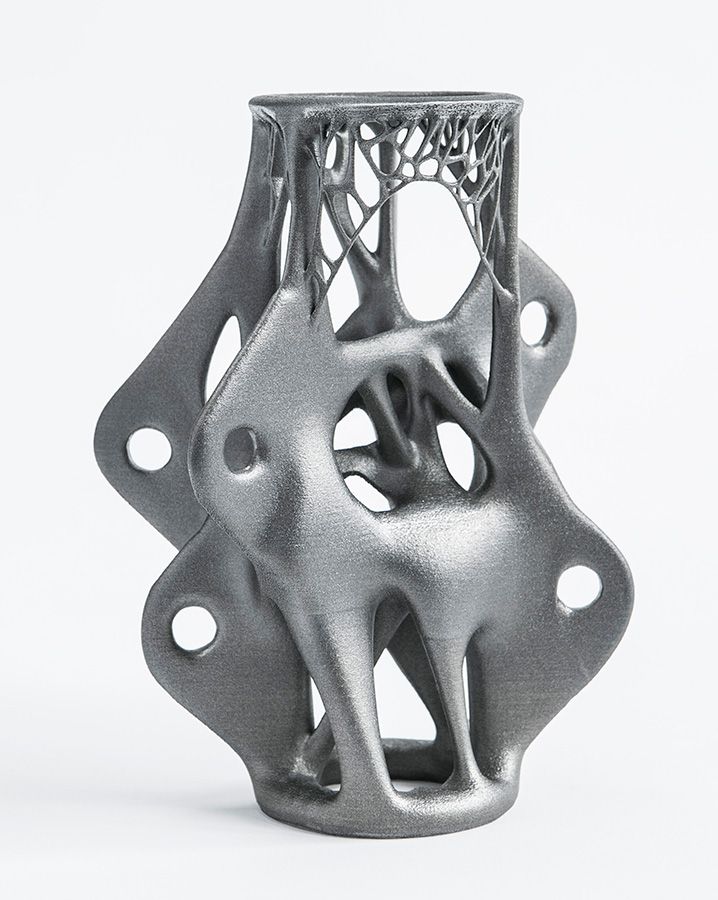

Additive Manufacturing was just the perfect solution Gaëtan Le Penhuel was looking for. They wanted to materialize their architectural proposals, and every aspect of the project had to be shown in solid form. Thanks to SLS technology, they were able to achieve precise openings, thin walls, and sharp edges. Industrial 3D printing such as SLS allows for the production of great quality models, quickly and cost-effectively.

They wanted to materialize their architectural proposals, and every aspect of the project had to be shown in solid form. Thanks to SLS technology, they were able to achieve precise openings, thin walls, and sharp edges. Industrial 3D printing such as SLS allows for the production of great quality models, quickly and cost-effectively.

Create custom-made products easily

6. Octobre71

Mass customization is one of the essential advantages offered by 3D printing technology. Octobre71is a company manufacturing light glasses, and for them, additive manufacturing is terrific to create customizable glasses. For fashion, products often need to be custom made; that is why 3D printing is a great new tool for fashion designers.

3D printing can allow for manufacturing glasses adapted to the morphology but also the style of any person. From jewelry and ornaments to 3D printed shoes, these amazing benefits can be profitable for many other businesses.

7. Endeer

We just saw that 3D printing allows mass-customization. But it could also be the perfect manufacturing technique to turn your product into a service. How? It can lead to amazing 3D printing business ideas.

Claire Chabaud, one of our former colleagues from Sculpteo decided to start her own business, Endeer from this idea. By combining 3D scanning and 3D printing, they are able to create custom-made armatures for women’s bras, and then insert them in their great underwear collection. The armatures are 3D printed in Nylon PA12 through our 3D printing service. The result is simple: a custom-made bra, perfectly shaped to the women, at a reasonable cost.

8. Valoptim

Can 3D printing technology be beneficial for property development companies? Certainly! Valoptim is a perfect example of making the most of 3D technologies.

Thanks to Additive Manufacturing, Valoptim took the customer experience, so crucial in any industry, to the next level. They offer their clients a mini 3D printed version of the property they just purchased!

They offer their clients a mini 3D printed version of the property they just purchased!

Creating one of a kind model of a flat wouldn’t be cost-effective with any other technology but 3D printing. It is also the fastest way to get the model. Valoptim’s clients can already visualize living in the flat before they even get the keys! It is definitely satisfying for the new owners and brings a lot of innovation and pleasantly surprising, unique experience.

Create XL projects

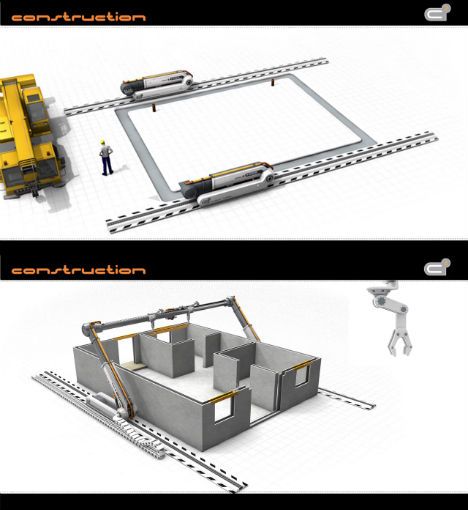

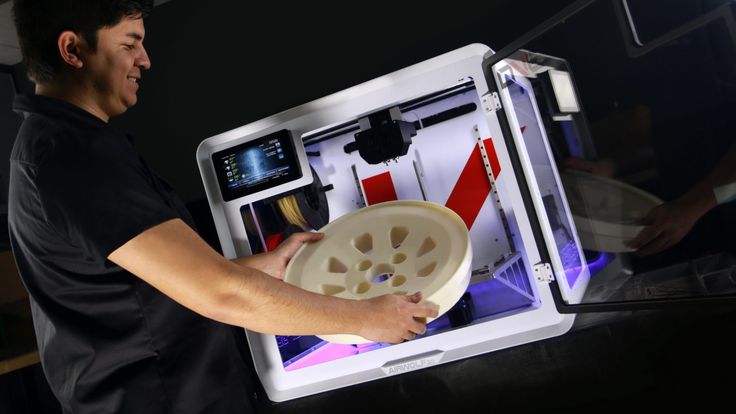

9. Apis Cor

Apis Cor, a San Francisco startup 3D printed an entire house in only 24 hours in Russia. This company is making it possible to innovate in the architecture sector using the 3D printing technology. They are using 3D printing technology and an XL 3D printer to create homes in no time and for a lower cost. 3D printing was actually the only solution for this company to create this amazing project, now that concrete 3D printers are available.

10. MX3D

Olivier De GruijterThe MX3D team created a metal 3D printed bridge in the city of Amsterdam. Indeed, 3D printing is an excellent method to develop urban settings such as bridges. Why? New XL 3D printers are allowing to 3D print at an architectural scale. It is making it possible to 3D print designs for a project as big as bridges. This bridge will be placed right over a canal of Amsterdam, the Oudezijds Achterburgwal! It will be the most massive 3D printed metal structure ever created.

Create eco-friendly projects

11. Simusolar

Simusolar is a company created in 2014, developing and implementing small-scale sustainable solutions to bring solar energy to the rural population of Tanzania. Using our online 3D printing service, they developed solar-charged LED lights for fishermen from Lake Victoria, to replace their petrol lights when they fish at night. You can find more details about this project in this blog post.

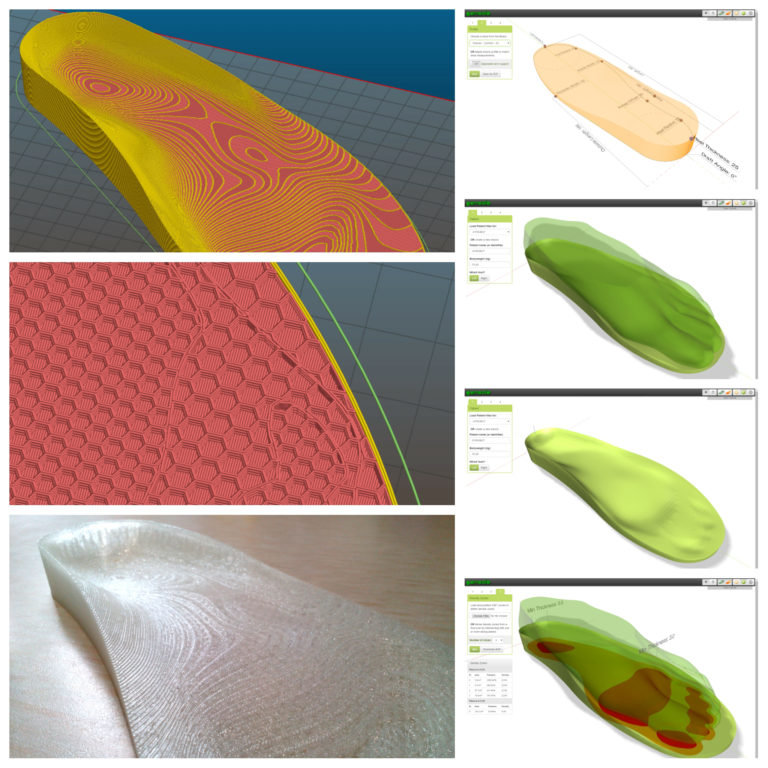

12. Adidas

We already saw on our blog that additive manufacturing is an amazing manufacturing method to create custom-made shoes. Adidas created different 3D printing projects and has been working on sneakers made with plastic found in the ocean. It is actually showing how plastic can be recycled and used by 3D printing businesses. Recycling plastic parts could be more and more important in the 3D printing industry in the upcoming years.

13. Feetz

Feetz is an American startup run by Lucy Beard, specialized in custom-made shoes, comfortable to wear and with a beautiful style. They can be adapted to any feet! Feetz is using 3D printing technology to protect the environment. Indeed, 3D printing also means no material waste! When using this technology to manufacture your products, you only use the amount of material that you need to print your objects, and these 3D printed shoes prove that.

Create spare parts

14. Jaguar

Jaguar, the famous car manufacturer, is using 3D printing to create spare parts for its old vehicles. The company used 3D scanning to recreate the classic XKSS model from 1957. Additive manufacturing is the best way to recreate parts that are no longer manufactured and not available on the market. It is offering new business possibilities, even for big brands such as Jaguar! You have to create 3D files of the unique parts that you need and print them!

Manufacturing in space

15. Made in Space

3D printing is allowing us to go further in any sector. Made in Space is an American company developing solutions to 3D print in space, to help astronauts during their space missions. They form a 3D printer allowing astronauts to print the tools that they need directly in Space. Their goal is to elaborate technologies allowing to 3D print significant structures such as satellites without gravity, outside of the station.

Improve your manufacturing products using 3D printing

Improving your products thanks to a better 3D design

Additive manufacturing can help you to improve your existing products, by making them lighter or even to develop a design that might be too difficult to create with a traditional manufacturing method. For example, you could add lattices to your product, or strengthen your 3D print using jigsaw structures.

It is also really convenient to create objects in just one part. You may know it, but some intricate designs can be challenging to develop in only one part. But additive manufacturing technology allows you to do that.

Improving your products thanks to 3D printing materials

As you can see on our 3D printing material pages, there are a lot of different materials available. Each material has its properties; some of them are better for rapid prototyping; others are better for production. Some are flexible and others more resistant to stress.

For example, you can use Stainless Steel 316L with DMLS technology for mechanical parts, but you could also consider Stainless Steel 316 produced with Binder Jetting. Find the right metal material for your project with our ultimate guide.

You have to find the right material for your project. But once you find it, it can give you the possibility to improve the final properties of the product that you want to manufacture. Indeed, the same product manufactured with a different material can have a lot of different properties: it can be lighter, it can have a higher resistance to heat, etc. The possibilities are endless, just by choosing the right one. You can find a cheaper material with better properties only by using 3D printing technology. Think about it!

Start your own company thanks to Additive Manufacturing!

We hope that you are getting inspired by all of these profitable 3D printing business ideas. Are you ready to create your own 3D printing startup? Keep in mind that everything is 3D printable, and this technology could help you to start a new adventure and grow your business.

Starting your own 3D printing business doesn’t have to be that hard. You need business plans, and with the help of an online 3D printing service, you ‘re good to go! Contact us if you need some help or simply upload your 3D files and start your manufacturing process and today.

If you want to read more about 3D printing applications and 3D printing business ideas, we recommend you to subscribe to our weekly newsletter and follow us on Facebook!

How to start a 3d printing business?

Is it worth starting a 3D printing business?

What are 3d printing business opportunities?

Related Topics

- Return to Top

Get the latest 3D printing news delivered right to your inbox

Subscribe to our weekly newsletter to hear about the latest 3D printing technologies, applications, materials, and software.

7 fresh ideas for starting your own business in the field of 3D printing

3D printing is an absolute technological trend of our time. And since the industry of additive technologies is still quite young, one can easily occupy one of the free market niches. There are a lot of ideas on how to start your own 3D printing business. Especially for you, we have selected the most interesting of them.

7 ideas for starting a successful 3D business

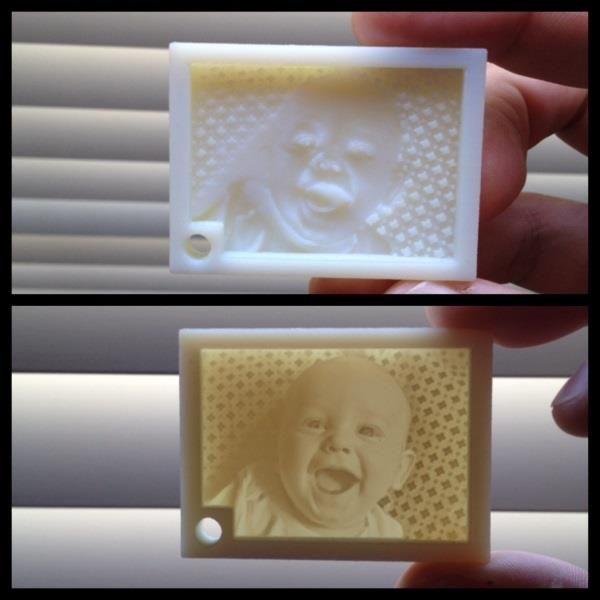

1. Making souvenirs, jewelry, gifts, etc.

With an ordinary custom 3D printer, you can customize the production of absolutely any product. It can be computer game characters, stylish jewelry, interior items, original souvenirs for gifts, small copies of people, etc.

There are many examples of successful implementation: self-taught artist Melissa Ng from Lumecluster, creating 3D printed costumes, founders of LeFabShop, that print home decor items, etc.

2. Print custom prostheses or orthoses

Print custom prostheses or orthoses

The best business projects are those that solve the world's pressing problems. Today, many people are in need of high-quality and inexpensive prostheses, orthoses and additional devices such as 3D-printed denture covers.

One of the most striking examples of such activities is the Motorika company, which creates functional traction prostheses for the upper limbs. So far, there are few such companies, so the niche, consider it free.

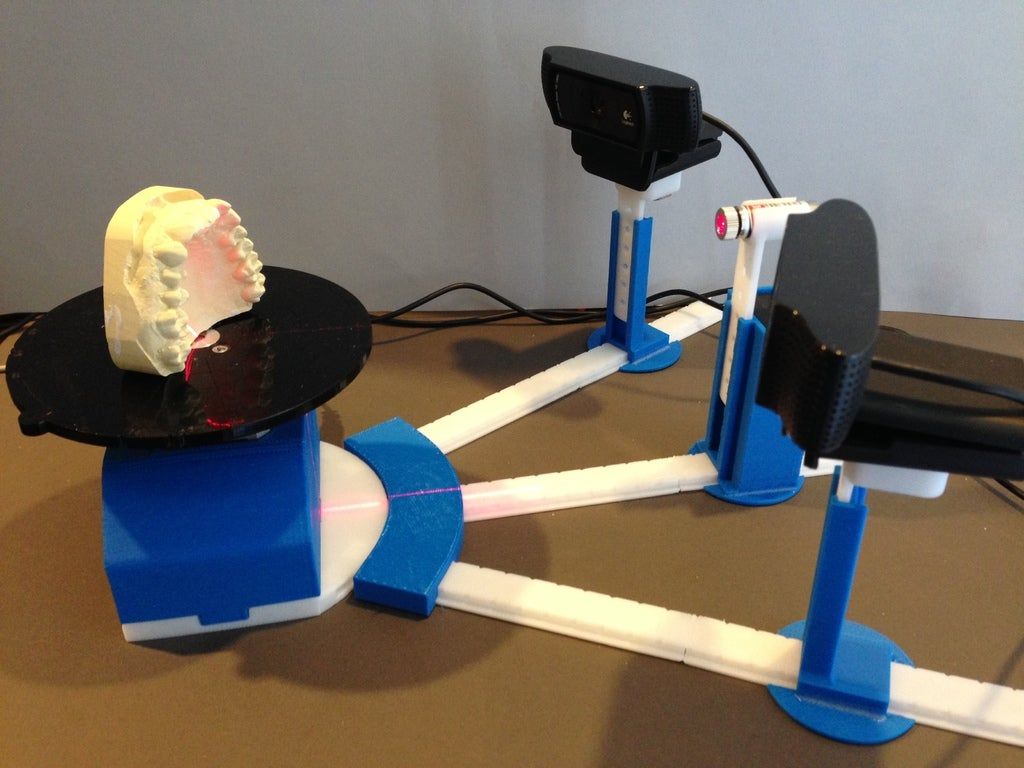

3. Creation of 3D tactile maps

Tactile 3D maps will allow blind and visually impaired people to learn about the features of the landscape, architecture and sights of a particular area. Moreover, you can create not only maps of the Earth, but also of the Moon. 3D maps are also useful for education, design, research, etc.

Versateq, a Finnish company, printed similar additive atlases for the technology startup Slush.

4. Opening a restaurant with 3D printed food

Many experts believe that in the future, 3D food printers will appear in every kitchen. In the meantime, they can become a colorful feature of a cafe or restaurant. The 3D printer can be put on public display so that visitors can watch the exciting process of creating culinary masterpieces. This is exactly what the owners of the famous pop-up restaurant Food Ink do, which opened earlier this year and now travels around the world.

In the meantime, they can become a colorful feature of a cafe or restaurant. The 3D printer can be put on public display so that visitors can watch the exciting process of creating culinary masterpieces. This is exactly what the owners of the famous pop-up restaurant Food Ink do, which opened earlier this year and now travels around the world.

5. Automotive parts printing

With a 3D printer, you can print just one desired part, and it will be much cheaper than ordering a branded part. So why not make a business out of it?

On a 3D printer, you can print wheel caps, headlight washer caps, clips, interior caps, various interior elements, gears, door lock blocks, etc. This service is quite popular in 3D printing workshops.

6. Prototyping services

Many designers, architects, engineers and other professionals need to create a model of a future object. Doing this with 3D printing is much faster, cheaper and more convenient. In addition, the final product is of better quality.

In addition, the final product is of better quality.

There are many examples of workshops providing 3D prototyping services, but it is never too late to enter this market. The main thing is to offer high quality at a reasonable price.

7. 3D Printing Training Services

As additive manufacturing will be our future, companies will need skilled professionals who can work with 3D printers, scanners, modeling software, etc. If you have necessary skills and knowledge, then you can share them and earn good money on it.

How to start your own business: the story of a 3d printer

After the wedding, they decided not to go on a trip and use the donated money for their business. This is how the White Ant company appeared, which offers 3d printing of almost any item, if only there was enough imagination :). In addition to pure creativity in everyday life, the company has also occupied an important social and rehabilitation niche - Nadezhda and her husband print 3D prostheses. How White Ant helps children feel like superheroes, how much money and effort went into creating the company, what are the advantages of 3D printing — says Nadezhda Kovalenko.

How White Ant helps children feel like superheroes, how much money and effort went into creating the company, what are the advantages of 3D printing — says Nadezhda Kovalenko.

Grade

- 4.5 out of 5 possible based on 2 votes

At the age of 20 I wanted to be an editor and work in a glossy magazine, I studied to be a journalist and even wrote articles for my favorite glossy publications.

The idea of to go into business with often crossed my mind. I wanted to make handmade cosmetics, wove bracelets from natural stones, but it was all wrong, I always wanted to be useful and create something special . This is what 3d printing has become.

First, my husband became interested in 3D printing, and then I did too. We started choosing a 3d printer and thinking about opening a 3d printing studio.

There was not much money, there was a choice to buy one small printer with a small print area or a medium one. My mother insisted that there was more, and we, as children, listened to the advice :) And we are grateful for this. Since 3d prostheses became one of our directions, all the details fit easily on the printing table.

My mother insisted that there was more, and we, as children, listened to the advice :) And we are grateful for this. Since 3d prostheses became one of our directions, all the details fit easily on the printing table.

As for the starting capital of , we invested all the wedding money we had. We decided to spend not on travel, but on our business. And we had only $ 3500 and a great desire to create our own.

I'll say even more - we didn't even have money for the next month's rent. We bought materials and made our own furniture, brought home computers, wrote out a plan of actions for a month and got to work.

At first there was a lot of skepticism . This is now being talked about a lot about 3d printers, but earlier, when they only reproduced simple figures, it was perceived as some kind of childish idea. But we were sure that this was the future, and after a while it would be possible to do very useful things.

Really colossal application : prostheses, prototypes, decorations, jewelry, household items…

For about half a year we were engaged in the "White Ant" in parallel with the main work . We sat until night, watched and learned. Everything had to be understood by experience, because about the stages of plastic processing in detail only in the English-speaking communities, where the terminology is also not easy to translate. In addition, information is often presented in experimental conclusions. That is, it will not necessarily work for you with the same inputs. And until you learn yourself...

But time has given its own. Learned a lot.

If earlier the husband was afraid to leave the printer for 20 minutes, now he can calmly leave the printer for at least two hours and go home. He has a camera connected, and he can remotely monitor the process.

We try to keep the printer busy every night to meet deadlines and schedules. The dream of science fiction writers, when you are resting, and the robot is working - it came true (laughs).

The dream of science fiction writers, when you are resting, and the robot is working - it came true (laughs).

My husband and I have clearly divided the duties of . The husband is engaged in the technical part, modeling, mainly (we do very complex orders on outsourcing). I do public relations, brand positioning and customer acquisition.

CUSTOMERS

The most important thing in working with a client is honesty.

Clients appeared quickly . We made a website, advertised, created groups in social networks - and people went to requests. This was a coincidence, as there are still few people who provide such services.

One of the first orders for is to make a prototype. Then they made some designer things, jewelry for acquaintances…

Then we were invited to an exhibition, where the fighter agreed to experiment with our prosthesis. It was a mutual experiment: is the first experience for both us and for him. We saw that it could work and we started to improve it.

It was a mutual experiment: is the first experience for both us and for him. We saw that it could work and we started to improve it.

In general, formed the same customer base as .

ABOUT PROSTHESES

Prostheses as one of the areas of 3d printing service. In our opinion, one of the most effective applications of 3d printing.

In our country prostheses are purchased and manufactured, but they are not functional. They are like a layout. Like a doll's hand. A child with such a prosthesis feels flawed and inferior.

When kids get these colorful themed prostheses, they feel like superheroes. They like it, they perceive it as a game. They are so much easier and more comfortable.

They are perceived differently by their peers, and it is easier for children to adapt. We had a girl who said that the whole kindergarten was already waiting for her "new pen" to see . Such stories, of course, touch to the core.

Such stories, of course, touch to the core.

It is strange why we pay so little attention to this. You will not believe it, but children without arms or legs come to us, and they are all so active! And I wonder why so little effort and time is devoted to making cool good prostheses.

We sell our prostheses mainly through funds . The family turns to the foundations, and they send them to us.

Initially, we made prostheses for fighters. Then the parents of the children contacted us.

There are models of prostheses that are in the public domain. They are created by various international communities and published on the Web. Then, having already these models, we do scanning, measurements and adjustment to the individual parameters of the client . And we make, as a result, a prosthesis.

The main load is carried by the cult receiver, so the most difficult manipulations are in this area of the prosthesis. Here, for example, this prosthesis was made for a girl so that she could ride a bicycle .

Here, for example, this prosthesis was made for a girl so that she could ride a bicycle .

We communicate a lot with prosthetists who are willing to give advice and help.

What's so special about this technology? Detail one is printed 20 minutes. It did not fit - we can instantly fix it for individual parameters.

Now we are developing a robotic prosthesis , which will work on impulses. We have already tested it - it works well.

The material can be recycled - it is bioplastic, which does not pollute the external environment . It is made from either corn pulp or cane. If you leave it in nature for a year, it will simply dissolve.

Plastic is very convenient in this use, because of it can be made both thin plates and dense material , which is quite difficult to damage in everyday life.

We have both Ukrainian and foreign partners.

ABOUT THE BENEFITS OF 3D PRINTING

There are nuances in the amount of here. If you need to make 10 thousand copies, then, of course, it is cheaper to make a master model, and then make everything at once by casting. The cost of such a mold model for casting can start from 2 thousand dollars. When you need to make 10,000 cubes, and let them each cost 2,000 hryvnias, but spend 2,000 dollars, but then you again have 10,000 cubes... That is a question of parties. If 100 cubes, then 3d printing wins tremendously. For small-scale production, and especially for individual orders, is ideal.

If you need to make 10 thousand copies, then, of course, it is cheaper to make a master model, and then make everything at once by casting. The cost of such a mold model for casting can start from 2 thousand dollars. When you need to make 10,000 cubes, and let them each cost 2,000 hryvnias, but spend 2,000 dollars, but then you again have 10,000 cubes... That is a question of parties. If 100 cubes, then 3d printing wins tremendously. For small-scale production, and especially for individual orders, is ideal.

With the help of 3d technology, you can do things that are sometimes simply impossible in other alternative ways. For example, a master who will mill such a ring may make a mistake, which means that he will have to start work again.

Can you imagine, a man sat for a day or two doing, brings to the customer, and he says: “Oh, but here the eyes are not like that.” For 3d printing, this is 40 minutes + you can constantly make adjustments in the process. I made several options, sent them, chose the right "eyes" and that's it.

I made several options, sent them, chose the right "eyes" and that's it.

We often cooperate with schools and make them an anatomical "subject". We did, for example, the puzzle "Shares of the brain." Or here is the heart, which in the context allows students to better understand the structure of the main organ in the human body.

For schools in general, this is all of great interest. For example, the same 3d printer model . Ours is quite inexpensive, 25-300 dollars. We ordered from China, but contrary to our fears, the quality did not disappoint.

Very many order prototypes from us for start-ups . For example, there was a prototype device for washing shoelaces.

ABOUT DEVELOPMENT

The most difficult part of in the first 365 days was, of course, looking for clients and investing the earned money in business. But not because I feel sorry for the money, I just wanted to do it rationally.

Of course, had moments when we didn't know what to do in this or that situation. For example, when you need to expand, hire people ... Then books about business came to the rescue and examples of partners or companies that are exemplary for me. And it worked.

Now we already have 3 printers, foreign partners and 5 people work in the company.

Business became profitable in about six months.

I am convinced that a person should have a goal in life and a dream, from this a person develops and creates, otherwise visualization will not work. This is my motto is .

Our business slogan is "Create the Future".

The year of “our business” was celebrated in in August - this is the period when we left our main job and rented a workshop.

We equal at My mini factory. They started out like us and now they've become a company to follow and are very inspiring.

ABOUT MYSELF

I am inspired by the people we made prostheses for, fighters, children... They are all beautiful souls! And also our parents, because they always support us. My husband inspires me to work with him reliably and calmly. Inspired by friends with whom it's good, when it's good, and when it's hard, they are there. Inspire partners who create, inspire their success.

Everyone asks what we have already done for ourselves at home :) So far the only item is a soap dish (laughs). Strongly wanted lamps, but hands do not reach (laughs). So for the demonstration: everything beautiful and of high quality immediately goes to the customer, and in our office remains ... what is already left :).

For any girl it is important to be able to relieve stress . I do it in the gym. If there is no time for the hall, we lie down with my husband more comfortably, turn on a bright film on the projector (it is important that it be emotional). Our mega-fluffy and kindest cat lies between us, purrs - and I don't need anything else.

Our mega-fluffy and kindest cat lies between us, purrs - and I don't need anything else.

My day starts with coffee , I'm a terrible coffee lover, I can't live without it!

Bad habit that I can't get rid of: I'm too emotional, and I'm struggling with it.

It happens that will flood so despair that it is impossible! I try to capture those moments for myself. How? Yes, it’s very simple: I talk about what worries me with my husband, find out the reason and solve it. A call to my mother is still very stimulating: I unconditionally believe in her “everything will be fine” or “you are fighting off”. And sometimes a client comes, you talk to him and get inspired.

My parents live 600 km from Kyiv and I see them 2-3 times a year. It's sad, but so far there's no other way. I dream and work for my dream in order to buy them a house not far from us and see each other often. But so far it turns out to see her husband's parents, and this pleases us.