3D printed airsoft parts

🔫 Best STL files 3D printed for airsoft・Cults

🔫 Best STL files 3D printed for airsoft

Download 3D models of accessory for Airsoft

Discover a selection of the best 3D files to make with a 3D printer to improve your Airsoft experience. There are many elements related to your weapon or equipment that can be 3D printed, take advantage of it and stand out during your next confrontation.

Print-in-place target spinners

Free

Mini RONI (Carbine conversion for most GBB Airsoft Pistols)

Free

AEG airsoft ar15 pistol (motor) grip #1

Free

Airsoft Prototype

Free

Jumping Target for Toy Shooting

Free

JTW HCC-2A (An Open-Source Hi-CAPA Carbine Kit)

Free

MINI & LARGE PDW (Airsoft Carbine Conversion Kit)

Free

Customizable Picatinny Rail Mount Fusion 360

Free

Humiliator - Airsoft Gun

Free

Quick release Picatinny Rail Mount

Free

Airsoft Magazine Racks (M4, G3, VSS, and SR25)

Free

peq box airsoft

Free

Replica Stielhandgranate

Free

Customizable Mounting Rings for Picatinny Rails

Free

Hyrr, the airsoft pistol shotgun

Free

Micro PDW (Airsoft Conversion)

Free

Airsoft Mk 23 Short silencer

Free

MP5K style foregrip

Free

Karambit with blade mold

Free

"STEALTH" STOCK ADAPTERS

Free

Medium RONI (Carbine Conversion)

Free

MINI & LARGE PDW (Airsoft Carbine Conversion Kit)

Free

3DTAC / Airsoft Helmet Rail Flashlight Adapter

Free

AK74 UltraLight Front End

Free

ICS XFG / Rhino rail compensator (airsoft)

Free

Skammr - Airsoft Sawed off Shotgun

Free

airsoft m4 funnel

Free

KAR 22 (CLOSED BOLT)

Free

Sight Covers (Plexiglass inserts)

Free

Baofeng Volume Cover & Molle Mount

Free

AUG Suppressed Front End

Free

3DTAC / TBR1 Dummy Knife

€1. 99

Lil Fella - Airsoft Pocket Grenade Launcher

Free

MP5 top picatinny rail mount

Free

RIS Rail for round handguard

Free

B&T Style PDW kit (WE-G17-Airsoft ONLY)

Free

Airsoft Micro Claymore

Free

Ymir - Airsoft Shotgun/grenade launcher

Free

Airsoft AK74 Stock (Folding & Fixed)

Free

Airsoft AK74 Stock (Folding & Fixed)

Free

BEAR style Flash hider - (Airsoft)

Free

Hoenir - Airsoft Ballistic Knife

Free

magazine lip replacement for Beretta ASG M9 Gas Blow Back Full Metal airsoft gun

Free

Handgun Tri-Rail Mount

Free

Handleggr - Airsoft 40mm blunderbuss

Free

Functional Smoke/Gas Mask Respirator

Free

Mini Assassin Derringer (TOY 1 & 2 shots versions)

Free

Airsoft Bizon Front End

Free

Here is our selection of the best STL files for Airsoft, all these accessories are from the 3D file library Cults and are perfectly 3D printable.

This collection includes free and paid 3D files of accessories for Airsoft. The many 3D models can be adapted to your Airsoft pistols and rifles to make your gaming experience easier and more enjoyable. There are elements like grips, silencers but also badges and decorations to make your rifle more realistic and personalized.

The main brands of the sector are represented, so you can improve your weapons CYMA, CYBERGUN, UMAREX, APS, Tokyo Marui, Classic Army, ICS, G&G,n etc. The 3D designers have competed in inventiveness to create truly ingenious models for both your guns and your equipment. There are decorative elements but also caches and very useful parts to complete your Airsoft kit.

We remind you of course that we support all playful practices and believe that 3D printing has its place in the world of Airsoft, but that we are fervent opponents to the 3D printing of firearms and guns.

Airsoft Parts best 3D printing models・Cults

ASG BREN 805 Stock Spare Parts

Free

AIRSOFT TM Glock 17 - repair part for krash slider

Free

Airsoft BREN 2 MAGAZINE - 7.62x39

Free

Airsoft AK Hopup Block

Free

Airsoft zenitco JOKER handguard set

€6.78

Muzzle brake LAF ak 14ccw

€7

Airsoft Zenitco RK9 AR GRIP

€7.50

AIRSOFT AK 74 BASE

Free

Airsoft ERGO 2 GRIP

€7.23

AIRSOFT L7 GPMG Sight mount

€28.65

AIRSOFT Bolt charging handle L7

Free

AIRSOFT carrying handle L7 GPMG

€19. 89

89

AIRSOFT Pistol grip cap for L85

Free

AIRSOFT SVD-S gas-block RIS-rail

Free

AIRSOFT Bolt charging handle L85А2

€10.35

AIRSOFT AR15 Short Magazine

€7.50

Airsoft ADAR 2/15 Furniture - AEG

€12.50

VZ61 STOCK ADAPTER

Free

Airsoft AK 19 GRIP

€7.10

AIRSOFT GLOCK SAI BARREL - WE

€3.49

Airsoft glock threaded barrel - WE

Free

Airsoft AK 19 Stock

€9.13

Airsoft L119A2 Charging Handle Latch

Free

AIRSOFT RPK 16 CONVERSION KIT

€13. 29

29

Glock 17 Magplate

Free

SVD LONG AIRSOFT MAGAZINE

€5.20

Vector_Rainbow Six Siege

Free

AIRSOFT FOLDING SKELETON VISOR STOCK

€6.18

Airsoft C8 Handguard

€7.36

Airsoft L119A2 Handguard

€7.38

Airsoft AK 200 Conversion Kit

€9.96

AIRSOFT Cheek Riser For AK12 Stock

Free

AIRSOFT AK 12 Conversion Kit - GEN.1

€13.99

AIRSOFT Folding Skeleton Stock

€7.25

Airsoft Helmet Ear Protection

Free

AIRSOFT AK 12 GRIP - NEW

Free

Cyma AK 74 stock battery cover

Free

Airsoft AK 200 Muzzle device

Free

AIRSOFT AK 200 handguard

Free

AIRSOFT AK 12 Stock

Free

AIRSOFT MP5 motor base plate

Free

AK stock adapter

Free

M4 Charging handle extension

Free

Airsoft bomb

Free

Taclight (X300 Style) dummy for airsoft

Free

Specna Hopup Arm - Original and Flat

Free

Cyma CM.

030 Hopup Arm for R-Hop

030 Hopup Arm for R-HopFree

Umarex Morph 3x bipod scope mount softair airsoft

Free

how I typed "drive" / Sudo Null IT News

Hello everyone! I will try to tell a little about how I tried to make an airsoft drive using a 3D printer, what came of it and what difficulties I had to face. The article may be of interest to those who love airsoft, DIY or 3D printing. For those who are not familiar with airsoft but want to read about an interesting and challenging 3D printing project, there is a brief explanation of what it is about and why it is not easy to build an airsoft drive.

TLDR:

A working airsoft gun can be 3D printed, including the gearbox body. A couple of relevant models are published in the public domain. The article describes how they were developed.

Legal note

An electro-pneumatic weapon with a muzzle energy of less than 3 joules is a toy according to Russian law. This article is not related to the manufacture of firearms or any other weapons using 3D printing methods.

This article is not related to the manufacture of firearms or any other weapons using 3D printing methods.

Likbez

Having written the article, I realized that many of the readers are basically not familiar with what airsoft is and what a drive is for. I will try to tell in a couple of paragraphs with an emphasis on the technical side of the issue.

Airsoft (in the post-Soviet space it is better known as airsoft) is a team tactical game, a competitor to paintball or laser tag. It differs from paintball in greater distances with less need for protection. From laser tag - by the fact that bullets are transmitted from participant to participant, not information. The alternative is "a bunch of grown men firing at each other with toy guns."

Electro-pneumatic guns (commonly referred to as "drives") for 6mm plastic balls are the most widely used for the game. How it works:

- The motor cocks the piston through a system of gears.

- A special rod pushes the ball into the barrel.

- When released, the piston moves forward under the action of the main spring, air pressure is created in the cylinder.

- An additional module at the beginning of the barrel - hop-up provides twisting of the ball. (Twisting the ball along the horizontal axis allows you to increase the flatness of the ball's flight path due to the Bernoulli effect)

- Air pressure pushes the ball out of the barrel.

- With a single fire, the cycle stops, with a burst of fire, it starts anew.

Animated picture from Wikipedia:

The ball flying out of the barrel has a small mass (0.2-0.4 grams) and a fairly high speed (100-170 m / s). The energy source is a battery, currently it is usually a high current li-po. When fired, a 11.1V battery delivers a current of around 30A. The efficiency of the system is low - ~ 300VA per second at the input turn into ~ 20 Joules at the output (16-18 balls per second with an energy slightly higher than 1J each or 10 balls with an energy of 2 J each). These measurements were carried out for the last of the drives described in the article, but they are quite typical for most analogues.

These measurements were carried out for the last of the drives described in the article, but they are quite typical for most analogues.

In case of any serious problems (loss of tightness, misalignment of parts, contamination or mechanical damage), the shot speed drops or gets a large spread, which fatally affects accuracy. It is widely believed among enthusiasts that good repeatability results can only be obtained using the highest quality components, mounted in a cast or milled metal case made with minimal tolerances. This housing is called the gearbox (gearbox) and is the heart of the entire system. The loads on the gear box increase rapidly with the growth of the power of the main spring and with the increase in the rate of fire.

Later in the article I will tell you how I tried to build a compressor housing from plastic and what results I achieved.

A bit of history

I became interested in tuning soft pneumatics about 20 years ago. At first, these were external and internal modifications of Chinese toys, with the advent of widely available Japanese electro-pneumatics, I switched to it. It was possible to repair or tune, probably, about one and a half thousand drives. For a while I monetized this hobby, but I like to work slowly and for myself more.

At first, these were external and internal modifications of Chinese toys, with the advent of widely available Japanese electro-pneumatics, I switched to it. It was possible to repair or tune, probably, about one and a half thousand drives. For a while I monetized this hobby, but I like to work slowly and for myself more.

In 2007 I tried to make my first milled gearbox. It worked if you put it in a vise and hold it in some places;) Several things became clear from the amount of work:

- You can make a gearbox case yourself.

- The volume of efforts, attempts and errors is so great that it is worth doing this only for custom ones, into which an ordinary gearbox cannot be stuffed in any way.

When I got a 3D printer, I decided to remake the milled gearbox. Being able to prototype parts and see how they work together should eliminate a number of pitfalls.

First 3D printer

First 3D printer - Prusa Mendel. Shaky, loud, under a 3mm bar. The parts were printed from some kind of ABS plastic (at that time I was not particularly interested in specific manufacturers). Layers - 0.3 mm. I got this printer in 2012.

After printing and assembling the first prototype, it turned out that the printed gearbox does not fall apart immediately. Seeing a working gear box that didn't have to be behind a milling machine was cool. The work was accelerated many times, it was possible to draw a drawing, put a seal on the night and collect the details the next day.

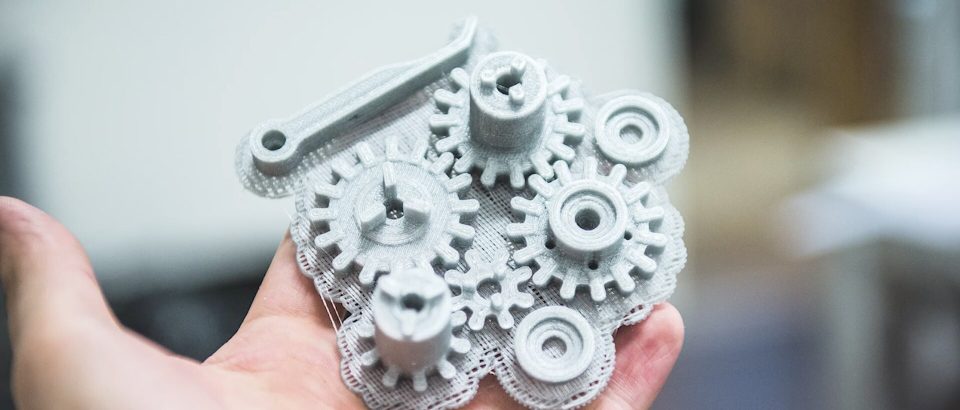

View of an early version of the gearbox top assembly.

First version

I decided to make a plastic gearbox, which will be reinforced with aluminum plates in difficult places. It was assumed: plates for fastening gear bushings, plates with milled grooves for guiding the piston and, if necessary, ties on the outside of the box. Of course, the prototypes of these records were first made of plastic. As a result, the parts remained plastic - it turned out that they themselves are quite strong.

As a result, the parts remained plastic - it turned out that they themselves are quite strong.

It was also planned to make the cylinder head on its own, make it more massive to ensure strength in the place experiencing maximum shock loads. In general, the idea did not justify itself - in the following drives, I used a standard cylinder head and a massive hop-up body, the mount of which acts as ties for the gearbox.

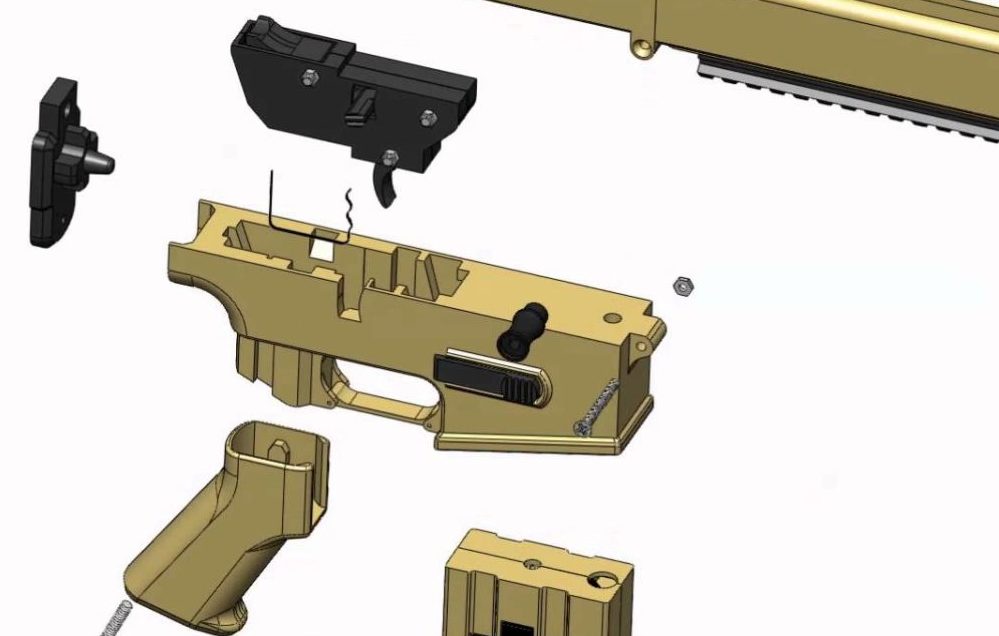

A case was developed for the created gearbox.

In 2013, the airsoft scorpion evo3 was not yet made, which seemed to me very beautiful. However, I did not set myself the task of exact copying - I wanted to make a similar compact submachine gun, light, narrow, but with a full-fledged gearbox.

Scorpion EVO3 S1. Image source - Wikipedia.

The work turned out to be much more painstaking than planned - to assemble printed parts, very often the parts had to be finished with a file. But holding the world's first printed airsoft gun in your hands warmed your soul. Cool achievement, in my opinion =) I should say special thanks to my wife, who supported my experiments and was engaged in the final painting of the finished project. Probably, with less understanding and support, the project would have been abandoned.

Cool achievement, in my opinion =) I should say special thanks to my wife, who supported my experiments and was engaged in the final painting of the finished project. Probably, with less understanding and support, the project would have been abandoned.

The disassembled drive shows how other modules are joined to the upper receiver

STL files for those who want to repeat the design were published on Thingiverse. Thus, the first print drive became an open source product. I don't know if anyone has been able to print it for themselves and get it to work. The source code was published in 2014. There were more than 50,000 views, almost 5,000 downloads, so maybe someone was stubborn. For those interested, the STL can be found at https://www.thingiverse.com/thing:461896.

Ready and painted drive

After the first drive was ready, I wanted to do more - bigger, more perfect and more interesting. A bullpup was designed, leaving only bad photos and a bunch of details in one of the “projects” boxes. For the first time, the concept of strengthening the body with an aluminum channel was tested on it - it practically does not add excess mass and makes the body resistant to bending. Actually, factory-made drives in plastic cases also suffer from this problem, so the problem is caused by not using 3D printing.

For the first time, the concept of strengthening the body with an aluminum channel was tested on it - it practically does not add excess mass and makes the body resistant to bending. Actually, factory-made drives in plastic cases also suffer from this problem, so the problem is caused by not using 3D printing.

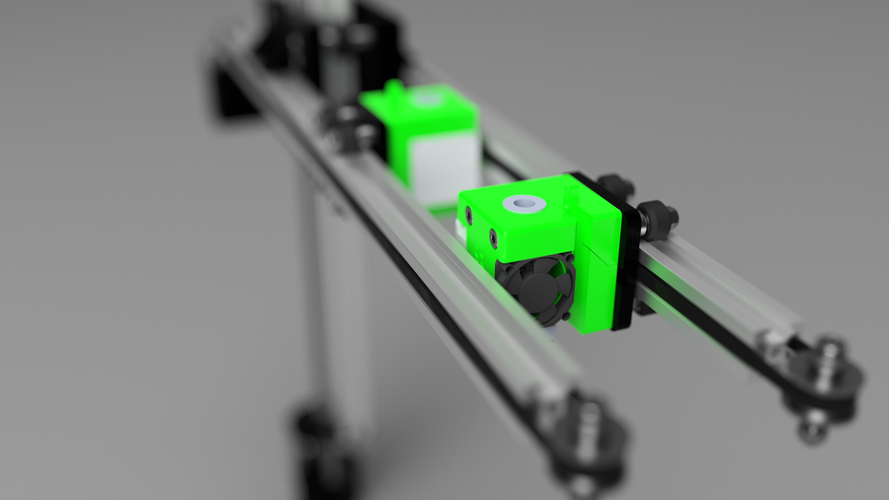

Printer replacement

At the end of 2016, I designed and built a new 3D printer, with a strong frame, machine guides (MGN-12), core-XY layout and an enlarged hot bed. The new printer supports higher speeds, is much quieter, has a water-cooled extruder and a number of experimental developments (24v electrics, quiet drivers, a hot table for 220v). Unfortunately, it has not been completed, although it works and all the following drives were printed on it. On a good note, the carriage needs to be reworked, the hot box is not assembled, it is necessary to make flexible cable channels. Imperfections of the printer and settings will be perfectly visible in some of the following photos, I apologize in advance to perfectionist printers.

All further actuators were printed from FD-plast ABS rod, layer 0.2 mm. I have not experimented with other plastics for printing gearboxes, it seems tedious to me if ABS works well.

Second version

All the time that I played airsoft, I tried to find the most convenient drive for myself. I changed, probably, more than a hundred options, from widespread to very exotic, but I never found a uniquely suitable one. So the idea arose to make the drive as modular as possible - let each user be able to print a set of parts that he likes as much as possible.

Actually the idea is not new, attempts to make modular firearms for various tasks are being undertaken by gunsmiths around the world. An example is the Stoner 63 weapon system, which, depending on the build, can change from a carbine to machine guns.

Photo of various Stoner 63 builds taken from forgottenweapons.com

The second version of the open source 3D-printed drive was a rather thick-walled upper receiver with a frame of aluminum channels, to which the lower receiver with gears was attached and a motor (usually in a pistol grip), a magazine receiver and external body panels. Several variants of cases were printed, however, by the time when it would be possible to start publication, I was already captured by another idea.

Several variants of cases were printed, however, by the time when it would be possible to start publication, I was already captured by another idea.

Two versions of the second version. They differ in the finish of the upper receiver and the front set.

Third version

In the third version, the thickness of the body of the upper part of the gear box is reduced. This was supposed to make the outer walls of the hull thicker and allow more room for design work without overthickening the hull. It turned out that the walls of reduced thickness cope even with powerful (140) springs. Moreover, the walls around the cylinder can be additionally relieved by openings. This result was achieved due to the thickening of the walls "inside". Additional flows of plastic around the cylinder and piston create a kind of “corner”, which is more difficult to bend than the plate.

View of the open top of the gearbox

In general, this frame can also be used to assemble a submachine gun, similar to those presented earlier. But I wanted to make a beautiful and most effective solution - to place the most productive option in a compact size. For the length base, a thin barrel 455 mm long was taken (such a barrel for Kalashnikov airsoft guns). Gearbox internals - any tm-compatible version for gearbox 3. For compactness, the bullpup form factor was chosen (the location of the magazine behind the pistol grip). Stores used from M16 - chosen for the wide distribution and location of the ball feeder in front of the store. This, in turn, allows you to maintain an ergonomic distance from the butt to the trigger with a sufficiently large gap between the handle and the magazine (sounds easy, but this is one of the most critical points for criticizing a real weapon in this form factor). The battery compartment must have enough space.

But I wanted to make a beautiful and most effective solution - to place the most productive option in a compact size. For the length base, a thin barrel 455 mm long was taken (such a barrel for Kalashnikov airsoft guns). Gearbox internals - any tm-compatible version for gearbox 3. For compactness, the bullpup form factor was chosen (the location of the magazine behind the pistol grip). Stores used from M16 - chosen for the wide distribution and location of the ball feeder in front of the store. This, in turn, allows you to maintain an ergonomic distance from the butt to the trigger with a sufficiently large gap between the handle and the magazine (sounds easy, but this is one of the most critical points for criticizing a real weapon in this form factor). The battery compartment must have enough space.

Open bottom of the gearbox

Severe additional restriction - any part must fit on the hot plate of a budget printer (200x200 mm). It took a lot of brainstorming to make parts printable on compact tables.

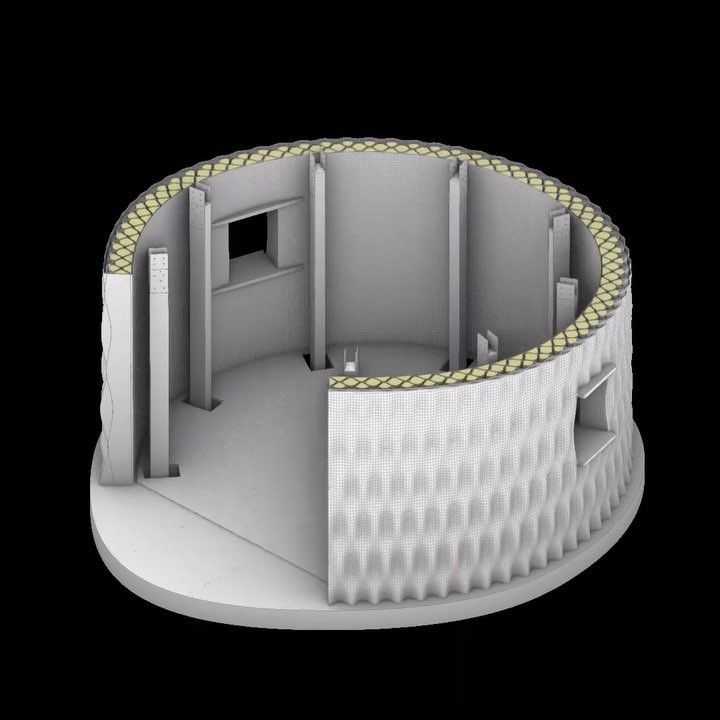

The concept for the outer housing was chosen deliberately futuristic - we wanted to make a drive that would be recognizable at first sight. The design was very difficult for me - I had to look at thousands of reference pictures of fantastic weapons, look for the best solutions, and then understand how a working mechanism and human ergonomics can fit into it.

This is how the hull design looked like

As part of the gearbox reliability tests, it was tested with M100 Systema and M130 Guarder springs. The muzzle speed given is consistent with fairly high quality builds for factory drives (unfortunately I don't have 0.20 balls, had to chrono .28 and recalculate). The approximate speed is 100m/s for the m100 spring and 148m/s for the 130 spring. It's not the best performance, but not below average either. It should be noted that the base parts used are left over from tuning other drives, so there is no doubt that the printed gearbox does not have chronic defects that affect efficiency. The gear box withstands a long burst of blanks (guarder m130 spring, about 200 shots) and after that no hardening is formed on the plastic.

The gear box withstands a long burst of blanks (guarder m130 spring, about 200 shots) and after that no hardening is formed on the plastic.

Gearbox assembly during tests

At a speed of 100 m/s, the hop-up successfully spins the balls, the flight distance of 0.28 balls, although slow, exceeds 50 m (shot in an open sports range, real meters). In the current assembly, accuracy is lame, but most likely this is due to the fact that the hop-up rubber bands that I have are already quite old (the last 8 years I have not bought new parts, there are so many of them at home).

It should be noted that this time not only STL-files, but also solidworks sources are available for public access. I tried to follow certain standards for naming elements of drawings and make the details as clear as possible. In addition, I selected the tolerances of the parts so that they fit together without painstaking file work. I had to print 10 gearboxes until the quality began to suit me.

Some parts I printed in colored plastic to highlight the controls and overall aesthetic. As a result, the drive began to look like this:

View of the finished drive

Sources published on thingiverse.

The model was uploaded from the middle to the end of 2018. At the moment, the root node of the model has more than 25 thousand views and 4.5 thousand downloads, I hope it will be useful for enthusiasts to repeat or upgrade.

When I have time for a hobby, I plan to add more detailed assembly instructions, maybe try to assemble the drive from parts in front of the camera. The basic version assumes the presence of an electronic key and only automatic fire. There is a functional prototype of the electronic cut-off of a single fire by current strength and operating time by the battery condition monitoring system. However, for this you will have to make a new case, a little more. There is an idea to try to create a Patreon account and post alternative options for the external case and electronics for subscribers. I will be glad to advice on the organization of Patreon in the comments.

I will be glad to advice on the organization of Patreon in the comments.

Thank you!

UPD. The project was completed over a year ago. It was great to see other enthusiasts print versions of my drive, I know of at least three completed projects.

I was able to play a few big games with the drive, run some tests. About 15 thousand shots were fired without any breakdowns. Recently I compared the latest version with the classic "AK" produced by CYMA (here is https://airsoft-rus.ru/catalog/1025/14175/, taken from the link). When using similar components and the same springs, my drive shows a slightly lower initial speed (it turned out by rearranging the spring guarder m100 103 for my drive and 107 for CYMA-AK) and noticeably worse accuracy. However, the weight of my drive is significantly lighter, and the overall length is less than that of an AK with a folded stock (having run through the forest with a machine gun at night, you begin to appreciate these indicators very much).

Now I'm starting a new project, which should eliminate the shortcomings of the previous version, the tests of the updated hop-up have successfully passed. I hope the following comparisons will be in favor of my drive.

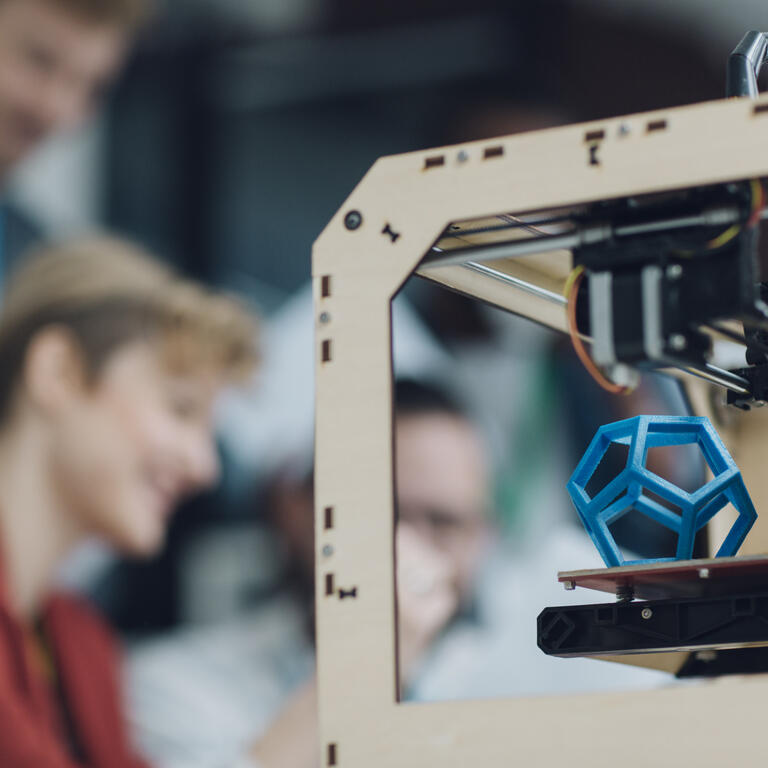

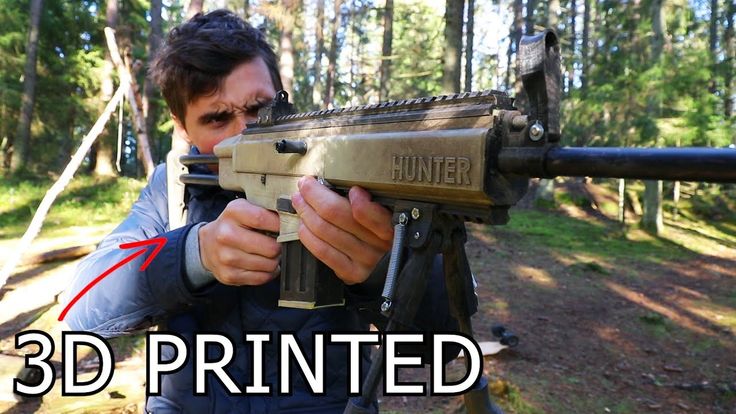

Printing an airsoft gun. Instruction inside.

Hello, dear readers of 3D Today!

Do you like cool guns? Do you love cosplay and role playing? TODAY I have prepared something interesting for you! ;)

One fine day, a friend wrote to me. To be honest, I did not immediately understand what was at stake, but acting on the principle: 'We'll break in, and we'll figure it out on the spot', I agreed.

So, attention, the question is:

What happens if you put a gun in the printer? No, not like that.

What happens if a gun is crossed with a printer? Hmm, wrong again.

What happens if you take a couple of talented guys with straight arms, an airsoft gun and a 3D printer?

(Look for the answer under the picture).

Somehow lovers gathered to drive through the forests with guns, driving away various monsters and thought: 'Let's arrange a real apocalypse?'. No sooner said than done. In the city of NN, on June 11, a live action role-playing game with the use of airsoft guns will take place on the theme of the popular game FALLOUT. [Poke]

What about the entourage and various paraphernalia? The guys approached this event very thoroughly. What is the most important item in any game? Of course, a cool gun!

In order to get a unique perk and be remembered for the game, the comrades took advantage of advanced technology and ... in other words, let's go in order.

1. Model.

We coordinated all actions with the guys via the Internet.

So, they send me a pistol model like this:

And they say:

- We want it to be like this:

What are the options? Where to find models?

1 Option: Estimate the pistol model from the photo, and pull the laser pistol out of the game.

Option 2: Search for finished models on the World Wide Web.

Whether the day is successful, or I'm lucky, both models were found on the Internet and we went for the second option.

What do we have?

Walter p99 model in 3dmax format, and Laser Pistol stl file (found on thingiverse).

Open 3D max and see, the scales don't match:

After playing around with the scaling, we get:

Everything looks good on the render, the models do not overlap, there is enough space for mounting. What will the printed model look like? Do the drawn sizes in 3D max match the real ones? Read on!

2. Print.

To my delight, in the archive with the model there were separate parts of the pistol, ready for printing. After scaling the details, I generated a task in KISSlicer, sent it to the printer and forgot about it for a day.

Print parameters:

Speed - 80mm/s,

Layer 0.25mm,

Material - PLA + PVA.

Print time ~ 30 hours.

I didn't have time to take a picture of the parts on the table after printing. I was in a hurry to ship the same day. I asked the guys to send photos.

Fitting and the moment of truth:

The calculation turned out to be so accurate that there was simply no place for a gap:

Hooray! You can proceed to the most entertaining part of the work - gluing, finishing and painting.

3. Painting.

After gluing, grouting the joints with self-hardening polymer clay, we proceeded to painting. The painting stage was carried out in three stages.

1. Painted with acrylics. Green background, then metallic was applied with a sponge.

2. Applying silver metallic and other colors. A piece of an old USB cable from a printer was used as a tube, ideally suited for the diameter of the holes:

0003

It took 3 days to 'finish' and paint.

I can already smell the pervasive smell of radiation! And you? :D

Feedback:

4.

Learn more