Dutch 3d printed house

First tenants move into 3D-printed home in Eindhoven

James Parkes | Leave a comment

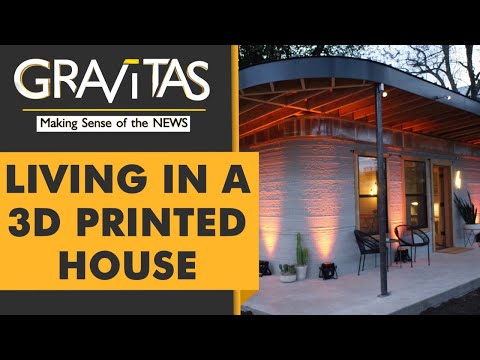

A boulder-shaped concrete house in the Netherlands has become the first lived-in 3D-printed home in the country after its tenants received the key on April 30.

Located in a suburb of Eindhoven, the single-storey home was built as part of a five-home 3D printing scheme named Project Milestone, and is said to be the first 3D-printed home in Europe where people actually live.

Top: the home forms part of a series of 3D-printed homes. Above: it has a boulder-like appearanceThe project was first announced in 2018 with the intention of building the world's first 3D-printed houses to use as rental properties. On April 30, Dutch couple Elize Lutz and Harrie Dekkers received the keys to their home in Project Milestone.

"I saw the drawing of this house and it was exactly like a fairytale garden," Lutz explained to The Guardian. "It is beautiful."

"It has the feel of a bunker – it feels safe," said Dekkers.

Residential real estate investor Vesteda is the owner of the house, which it rents out to private tenants.

It has an open-plan kitchen-dinerThe home was designed by Dutch architects Houben & Van Mierlo and informed by the shape of a boulder.

It has curved, sloped exterior walls and was constructed through printing layers of stacked concrete to form 24 individual components.

These pieces were printed at a nearby printing site and transported to the plot to be assembled, fixed to a foundation and fitted with a roof, windows and doors.

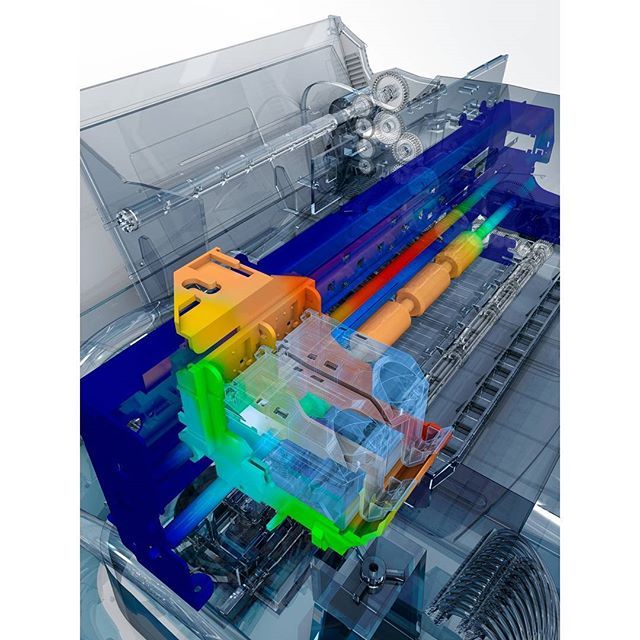

The home was constructed using 24 printed concrete components"With the printing insulated and self-supporting wall elements curved in three planes, we've taken important steps in this project in the further development of 3D concrete printing in construction," said Weber Benelux CEO Bas Huysmans.

The construction company developed the concrete mortar for the project and helped develop the printing technology.

Inside, the home's stacked concrete walls were left exposed to reveal its layered texture. Floor-to-ceiling windows interrupt the concrete layers and are recessed within its thick walls.

The 94-square-metre home includes an open-plan kitchen-diner and living area that occupies over half of the floor plan, while a large double bedroom and bathroom are contained within the remainder of the home.

Eindhoven to build "world's first" 3D-printed houses that people will live inside

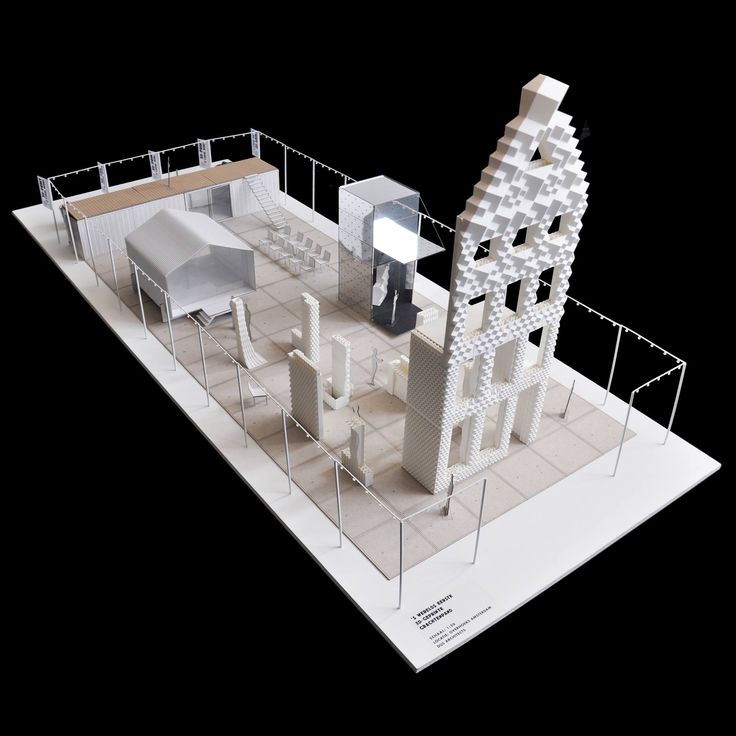

Project Milestone is a collaboration between the Eindhoven University of Technology and a number of construction specialists, and was designed with the aim of learning from it to help broaden the production of 3D-printed homes.

The scheme will build five 3D-printed homes, with each home becoming more complex through the use of different printing techniques and the addition of multiple storeys.

It is the first in a series of 3D-printed rental homesAs the project grows, it is anticipated that other homes in the scheme will be manufactured and printed entirely onsite further reducing costs.

"We're now setting the tone for the future: the rapid realization of affordable homes with control over the shape of your own house," said Eindhoven's alderman for housing, Yasin Torunoglu.

Recently, Mario Cucinella Architects collaborated with 3D printing specialists WASP to create a low-carbon housing prototype that is printed using locally sourced clay.

While Mighty Buildings designed an entire neighbourhood of homes that use 3D-printed panels as its main construction feature.

Photography is by Bart van Overbeeke.

Subscribe to our newsletters

Your email addressDezeen Debate

Our most popular newsletter, formerly known as Dezeen Weekly. Sent every Thursday and featuring a selection of the best reader comments and most talked-about stories. Plus occasional updates on Dezeen’s services and breaking news.

New! Dezeen AgendaSent every Tuesday and containing a selection of the most important news highlights. Plus occasional updates on Dezeen’s services and breaking news.

Plus occasional updates on Dezeen’s services and breaking news.

A daily newsletter containing the latest stories from Dezeen.

Dezeen JobsDaily updates on the latest design and architecture vacancies advertised on Dezeen Jobs. Plus occasional news.

Dezeen AwardsNews about our Dezeen Awards programme, including entry deadlines and announcements. Plus occasional updates.

Dezeen Events GuideNews from Dezeen Events Guide, a listings guide covering the leading design-related events taking place around the world. Plus occasional updates.

We will only use your email address to send you the newsletters you have requested. We will never give your details to anyone else without your consent. You can unsubscribe at any time by clicking on the unsubscribe link at the bottom of every email, or by emailing us at [email protected].

For more details, please see our privacy notice.

Thank you!

You will shortly receive a welcome email so please check your inbox.

You can unsubscribe at any time by clicking the link at the bottom of every newsletter.

The Future Is Now: 3D Printed Houses Start To Be Inhabited in the Netherlands

The Future Is Now: 3D Printed Houses Start To Be Inhabited in the Netherlands

© Bart van Overbeeke- Written by Eduardo Souza

If only a few years ago 3D printing was viewed with a certain suspicion, recent news has shown that it is in fact a viable technology that is here to stay. On April 30, 2021, tenants of the first 3D printed concrete house in the Netherlands received their keys. The house in Eindhoven—the first of five within the 'Milestone Project'—fully complies with all the country's stringent construction requirements.

The single story building has 94 square meters of floor space, including a living room and two bedrooms. It replicates the shape of a large rock, which fits well with the natural site and demonstrates the freedom of form offered by 3D concrete printing. Thanks to extra thick insulation and a connection to the heating network, the house is highly comfortable and energy efficient, with an energy performance coefficient of 0.25.

It replicates the shape of a large rock, which fits well with the natural site and demonstrates the freedom of form offered by 3D concrete printing. Thanks to extra thick insulation and a connection to the heating network, the house is highly comfortable and energy efficient, with an energy performance coefficient of 0.25.

The house consists of 24 printed concrete elements that were printed layer by layer at a factory in Eindhoven. The elements were then transported by truck to the construction site and placed on a foundation. The house was then equipped with a roof and window frames, with finishes applied afterward.

© Bart van Overbeeke© Bart van OverbeekeAccording to the team, it was especially challenging to print the building's inclined walls, but learning from the prototype helped them master the technique in the next 4 buildings planned. Concrete has been the most widely used building material in the world for decades and we are all by now familiar with it; we know how and where it should be used. Traditionally, we pour concrete into wooden or metallic formwork, and end up using much more than necessary for the construction. The more that is used, the worse the building's CO2 emissions and the worse its greenhouse effect. One of the great advantages of 3D printing is that the concrete printer has the ability to place concrete only where it is needed, without overloading the foundations and without wasting materials.

Traditionally, we pour concrete into wooden or metallic formwork, and end up using much more than necessary for the construction. The more that is used, the worse the building's CO2 emissions and the worse its greenhouse effect. One of the great advantages of 3D printing is that the concrete printer has the ability to place concrete only where it is needed, without overloading the foundations and without wasting materials.

In principle, printed houses can be built much more quickly, with more flexibility and potential for custom designs. The ambition of the Milestone Project partners is for 3D concrete printing to become a sustainable construction method that contributes to solving the housing deficit. According to Theo Salet, Professor of Concrete Structures at Eindhoven University of Technology: “With this small building, a first major step has been taken today in the development of construction into a high-quality manufacturing industry. From design to implementation, digitalization leads to sustainable and affordable homes tailored to the wishes of the occupant.”

From design to implementation, digitalization leads to sustainable and affordable homes tailored to the wishes of the occupant.”

The five houses of the Milestone Project are being built one after the other so that each new round of construction can maximize learning opportunities from the previous ones. Soon, the project partners will start working on the design of the next building, which will have several floors and, therefore, require further development of the technique.

Cortesia de Project MilestonePieter Knauff, Investment Director at Vesteda, adds that “3D concrete printing’s freedom of form creates an enormous new scope of possibilities in the design and experience of a home. At the same time, this new technique contributes to the required sustainability in the construction industry, the acceleration of building production and the control of construction costs, which is much needed in order to continue building affordable homes. ”

”

Cite: Souza, Eduardo. "The Future Is Now: 3D Printed Houses Start To Be Inhabited in the Netherlands" [O futuro é agora: casas impressas em 3D começam a ser habitadas na Holanda] 11 May 2021. ArchDaily. Accessed . <https://www.archdaily.com/961135/the-future-is-now-3d-printed-houses-start-to-be-inhabited-in-the-netherlands> ISSN 0719-8884

3D printed house rented out in Holland. Why is he good?

The first fully 3D printed house is rented in Holland. We have previously written about such projects, but all previous structures were only partially printed and no one used them for housing. An elderly couple has settled in the new house and has already shared their impressions. Apparently, there are no special disadvantages in the structure: it was built very quickly, it has high strength and a very unusual shape. If the same house were built by hand, it would take a lot of time, while in the case of the Dutch dwelling, it took the builders only 5 days. Perhaps the future lies behind 3D-printed houses, so let's take a closer look at how the structure was built and why all this is very cool? At the same time, we will see how the house looks from the inside and outside.

Perhaps the future lies behind 3D-printed houses, so let's take a closer look at how the structure was built and why all this is very cool? At the same time, we will see how the house looks from the inside and outside.

The first 3D-printed house and its occupants

To begin with, I would like to note that this dwelling is called “the first in the world” in the media. Apparently, the journalists mean that this house is the first of its kind, which was successfully rented out.

3D printed houses

An unusual house was built by Saint-Gobain Weber Beamix near the Dutch city of Eindhoven. According to the head of the company Bas Huysmans (Bas Huysmans), this house printed on a 3D printer differs from all others in that it is 100% authorized by the authorities and has already been rented out. Construction was supposed to be completed in 2019However, the company noticed problems in the structure of the walls, which caused the event to be postponed indefinitely..jpg) But now the house is completely ready for housing and it was not empty for long.

But now the house is completely ready for housing and it was not empty for long.

It is important to note that there are residential buildings printed on a 3D printer in Russia. The photo shows a house printed in 2017 in Yaroslavl

The house was rented by a married couple, Harry Dekkers, 67, and Eliza Lutz, 70. Instead of a key to the front door, they got access to a mobile application that allows them to enter the house with the touch of a single button. According to Harry Dekkers, the dwelling is somewhat reminiscent of a bunker and inside he feels completely safe. In the photos below you can see the first inhabitants of the house against the backdrop of a very neat interior - it seems that they have nothing to complain about.

Harry Dekkers and Eliza Lutz in their new home

See also: Thieves learned how to print a key from a photo on a 3D printer

How does a 3D printer print a house?

According to The Guardian, a huge robotic arm with a nozzle that extrudes cement was used to construct the building. Layer by layer, a huge 3D printer created 24 components, which were subsequently transported to the current location of the dwelling. The builders had only to connect these parts together, and then install the doors and windows. The use of a 3D printer made it possible to quickly create an oval-shaped dwelling, which is a rather difficult task for builders. With manual construction, this could take a month or even more, but printing technology made it possible to complete the construction in just 5 days.

Layer by layer, a huge 3D printer created 24 components, which were subsequently transported to the current location of the dwelling. The builders had only to connect these parts together, and then install the doors and windows. The use of a 3D printer made it possible to quickly create an oval-shaped dwelling, which is a rather difficult task for builders. With manual construction, this could take a month or even more, but printing technology made it possible to complete the construction in just 5 days.

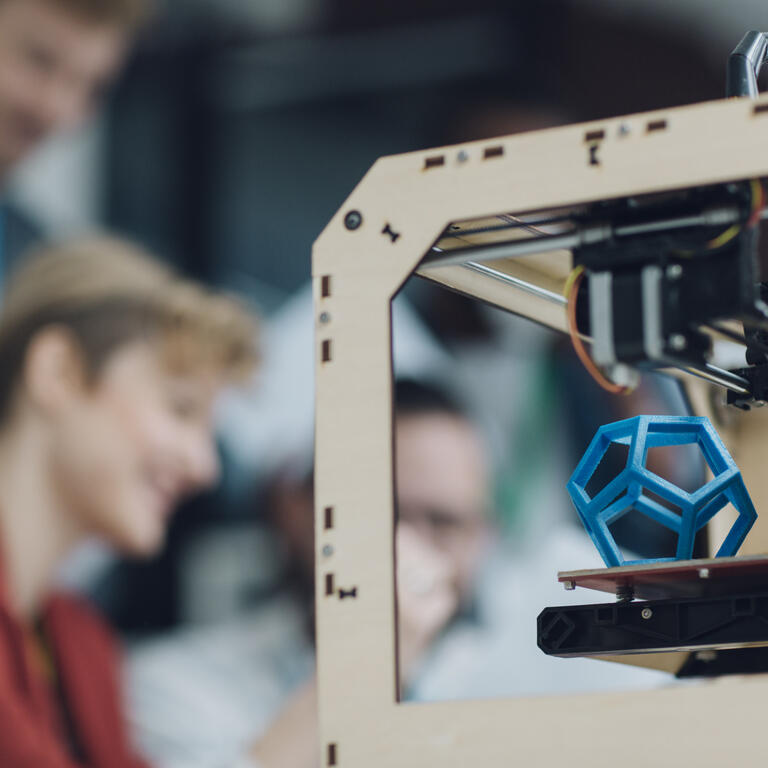

Construction 3D printers look different. Here is one of them

In the photographs, the house looks small, but it is reported that the area of the house is 94 square meters. Stripes are visible on the walls of the structure, which can be used to distinguish each layer of cement applied by a 3D printer. In fact, in the pictures, the construction does not look as solid as it is reported. Hurricanes often rage in Holland and I personally wonder if such a house can withstand strong gusts of wind? In February 2020, Hurricane Ciara raged across the country, which created winds at speeds up to 120 kilometers per hour. Seems to be printed Bungalow could not withstand such a blow.

Seems to be printed Bungalow could not withstand such a blow.

Bungalow is a one-story single-family home with a flat roof and a large veranda. Most often, such structures are found in the US state of California, but, as we have already understood, they are in Holland and other countries.

Advantages of 3D printed houses

At the beginning of the article, I mentioned that 3D printed houses could be the future. Perhaps in the future people will prefer such dwellings, as they will have the following advantages:

- they are built quickly and without expensive materials, that is, they will be cheap;

- for all their cheapness, they are very durable (or so they say) and look good;

- to create such houses do not need manual labor, everything is done by a robot that does not need rest - this should also reduce the cost.

Saint-Gobain Weber Beamix plans to build four more houses in the near future. In the process, she will try to make sure that the components are printed on the spot and do not have to be transported by trucks. It is possible that someday a whole housing complex of such structures will appear in Holland, but this is still only an assumption.

In the process, she will try to make sure that the components are printed on the spot and do not have to be transported by trucks. It is possible that someday a whole housing complex of such structures will appear in Holland, but this is still only an assumption.

The Milestone project will be located almost in the forest, the houses will be sustainably and energy-efficient, comfortable and with modern layouts. Construction is subject to all the usual rules and regulations. The first one-story house will be printed this year, and the housewarming will be next. The remaining four houses are multi-storey. They will be built sequentially, each time improving the technology and applying the lessons learned in the previous stages.

The design is based on chaotic blocks in a green landscape. The irregular and somewhat even futuristic shape in the form of rounded boulders appeared due to the key feature of 3D printing: the ability to build and print any shape.

Residential printed complex will be located in the vicinity of the city of Eindhoven, in the town of Bosrijk, which is developing as a "sculpture garden". There are high-quality and ambitious architectural projects placed like sculptures in a continuous landscape.

There are high-quality and ambitious architectural projects placed like sculptures in a continuous landscape.

By the way, Bosrijk is the first place in Eindhoven that is not connected to the gas network.

The first house - one-storey and with a wooden roof, 3 rooms, area 95 m2. The house will be ready for occupancy in mid-2019.

The long time between the design and implementation of the first house is due to the novelty of the project and unusual construction technologies. Further it will be faster and easier.

Designed by Houben & Van Mierlo Architecten and Eindhoven University of Technology.

Multi-storey buildings will have printed concrete floors and a printed concrete roof. The foundations are ordinary, based on the traditional technology of pouring concrete.

The elements of the first house will be printed by a concrete printer at the workshop of the Eindhoven University of Technology. In the future, the process will gradually be transferred directly to the construction site of the house. The last house will be fully realized on site, including printing works.

The last house will be fully realized on site, including printing works.

Concrete 3D printing is almost any form of construction, precision in design and execution, any color and concrete properties. Easy implementation of the customer's wishes for each specific house.

Less concrete required than conventional construction. Consequently, cement consumption and CO2 emissions from cement production are reduced.

The Eindhoven University of Technology in the Netherlands and the Dutch construction company BAM Infra carried out a joint project in 2017 to print a concrete bridge for cyclists. The 8-meter bridge was printed in sections using 800 layers of reinforced concrete. The bridge can withstand loads up to two tons. Service life 30 years.

The Netherlands also created the world's first 3D printed metal bridge over a canal in Amsterdam. The bridge span is 12.5 meters long and 6.23 meters wide. It took 4.5 tons of steel wire and half a year to create it.

And now - the next experiment in the field of 3D printing in the Netherlands - the residential complex Project Milestone.

These 3D houses are being printed in Dubai, UAE and Beijing, China.

Houses will probably no longer be rectangular…

Printed house by CLS Architetti and Arup, Milano

Concrete houses are ambiguous. Are these printed concrete buildings really good for the 21st century? After all, concrete and steel were the main elements in the architecture of the last century.

Source: houbenvanmierlo.nl, 3dprintedhouse.nl

Tags: 3d, architecture, concrete, printed house, printed bridge, modern technology, building technology

Subscribe

-

Autumn in New York: the return of King Kong, for whom the orange bells and murals ring in Hudson Yards

King Kong is back in New York. The huge monkey, which became famous after the 1933 adventure film, often appears in remakes, .

Learn more