Ifun 3d printer

IFUN3D: LCD 3Dprinter&3Dresin Supplier

High accuracy and Higher accuracy

Giant 8K is on sale. Get the power of Giant 8K to take your 3D printing business to the new level

Learn moreGet a Quote!

3D Resin Materials

All for Amazing finished products.

IFUN’s UV resin materials specialize in dentistry, jewelry, and industry application. These liquid 3D resins are compatible with DLP/LCD-type resin 3D printers. All with high quality and good service of IFUN.

View all resins

LCD 3D Printer

Mini Giant Pro

Mini sized. Powerful 3D printing.

It is a chairside Dental 3D printer. Provide a one-stop solution for dentistry.

Learn moreGet a Quote!

Applications

Bring your awesome 3D Printing Ideas into reality.

Dental Application

Bring production in-house or improve existing workflows with industry-leading IFUN LCD 3D printers. Our Dental Resins empower dental labs and practices to rapidly manufacture biocompatible surgical guides, splints, fixed patterns and models, clear aligner models, and full dentures.

Jewelry Application

Whether it's 3D printing a test piece for a client, casting a custom piece of jewelry, or creating a master mold for a reusable jewelry mold, IFUN LCD 3D printers and Jewelry resins can do good for your needs. Reliably reproduce crisp settings, sharp prongs, smooth shanks, and fine surface detail.

Engineering Application

Our library of versatile, reliable Engineering Resins is formulated to help you reduce costs, iterate faster,and bring better experiences to market.

Request a quote?

We’re here to help you find the best, most cost‑effective solution for you.

Country (for shipping use)

Select CountryAfghanistanAland IslandsAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelauBelgiumBelizeBeninBermudaBhutanBoliviaBonaire, Saint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBritish Virgin IslandsBruneiBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape VerdeCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongo (Brazzaville)Congo (Kinshasa)Cook IslandsCosta RicaCroatiaCubaCuraçaoCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHondurasHong KongHungaryIcelandIndiaIndonesiaIranIraqIrelandIsle of ManIsraelItalyIvory CoastJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKosovoKuwaitKyrgyzstanLaosLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacao S. A.R., ChinaMacedoniaMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth KoreaNorthern Mariana IslandsNorwayOmanPakistanPalestinian TerritoryPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarReunionRomaniaRussiaRwandaSão Tomé and PríncipeSaint BarthélemySaint HelenaSaint Kitts and NevisSaint LuciaSaint Martin (Dutch part)Saint Martin (French part)Saint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia/Sandwich IslandsSouth KoreaSouth SudanSpainSri LankaSudanSurinameSvalbard and Jan MayenSwazilandSwedenSwitzerlandSyriaTaiwanTajikistanTanzaniaThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUgandaUkraineUnited Arab EmiratesUnited Kingdom (UK)United States (US)United States (US) Minor Outlying IslandsUnited States (US) Virgin IslandsUruguayUzbekistanVanuatuVaticanVenezuelaVietnamWallis and FutunaWestern SaharaYemenZambiaZimbabwe

A.R., ChinaMacedoniaMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth KoreaNorthern Mariana IslandsNorwayOmanPakistanPalestinian TerritoryPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarReunionRomaniaRussiaRwandaSão Tomé and PríncipeSaint BarthélemySaint HelenaSaint Kitts and NevisSaint LuciaSaint Martin (Dutch part)Saint Martin (French part)Saint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia/Sandwich IslandsSouth KoreaSouth SudanSpainSri LankaSudanSurinameSvalbard and Jan MayenSwazilandSwedenSwitzerlandSyriaTaiwanTajikistanTanzaniaThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUgandaUkraineUnited Arab EmiratesUnited Kingdom (UK)United States (US)United States (US) Minor Outlying IslandsUnited States (US) Virgin IslandsUruguayUzbekistanVanuatuVaticanVenezuelaVietnamWallis and FutunaWestern SaharaYemenZambiaZimbabwe

WhatsApp (contact directly)

Company

Partnership

- Select -DealerProfessional

How can we help you?

LCD 3D printers

Giant 8k

Mini Giant Pro

Jewelry Resin

311C Jewelry casting resin

3122 Jewelry casting resin

3123 Pressure Casting Resin

Dental Resin

3160 Dental Mould Resin

3161 Gingiva Mask Resin

3162 Dental Occlusal Splint Resin

3163 Dental Casting Resin

3164 Temporary Crown Resin

3165 Surgical Guide Resin

3166 Denture Base Resin

3167 Dental Tray Resin

Engineering Resin

3120 Rigid Resin

3121 High Toughness Resin

3124 High Clear Resin

3125 Water Washable Resin

3129 ABS-like resin

3130 Elastic Resin

iFun 3D printer resin review - Is it a lot of fun!?

Table of Contents

I was allowed to try some iFun 3D printer resin, so here is my review.

About iFun

iFun are a french company manufacturing 3D printer resins as well as accessories. They provide a vast range of different types of resins for various applications. For example, rigid resin, ABS resins and clear resins. They also manufacture a resin printer, known as the LCD001 Printer iFun.

Packaging

The iFun 3D printer resin was packaged well. Surrounded by some thick foam, wrapped in bubble wrap and the resin bottles vacuum-packed too.

As a bonus, they also included a handwritten note to check out their site and two small packs of Haribo…how sweet of them! (See what I did there!?)

The bottles are 250g each and I was sent some Blue Rigid Resin and some Grey Toughness Resin. The labels appear to be informative and have the relevant warnings on. However, they are in French, of which I cannot read. The names seem to be printed on an inkjet printer rather than being professionally printed. They have screw caps on which are sealed with a bit of foil, which I did find difficult to try and grab hold of to rip off. Once I had got hold of it though, it didn’t come off in 1 piece, but pieces!

Once I had got hold of it though, it didn’t come off in 1 piece, but pieces!

Smell and consistency

I found that the iFun 3D printer resin had a slightly stronger odour than the other resins I have, however, not too overpowering. Besides, the consistency of the resin is right and as expected. The blue resin had a lovely dark and deep blue to it. The grey resin was a dark looking grey.

Price and where to buy iFun 3D printer resin

The prices of the iFun 3d printer resin are reasonably competitive. For 250g of the Toughness resin, it is €29.90, and for 250g of the Rigid resin, it is €19.90. Other prices vary for the different resin types. These can be purchased directly from iFuns website

Specifications

Rigid Resin

- A low withdrawal rate of 2.5%.

- High precision and beautiful details.

- The hardness of the fully hardened resin is 80 shore D.

- Excellent tensile strength and flexibility.

- Low odour.

Toughness Resin

- High strength and flexibility.

- 350J / m highly shock resistant.Very resistant to shocks.

- Low shrinkage rate 2%, high precision, performance similar to ABS.

- Low odour.

Let’s get printing!

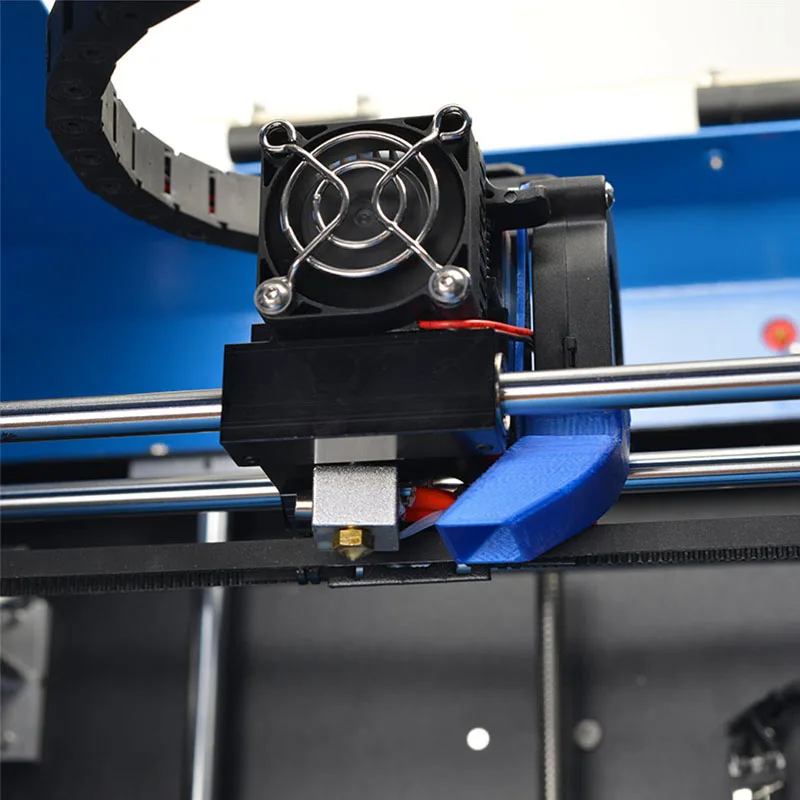

I first started with the Rigid iFun 3D printer resin. I believe this is just your standard resin; however, it is labelled as rigid. A favourite print of mine is the Zombie Hunter Head, so I printed this first to see if the stock settings on my Longer 3D Orange 10 would work – and it did!

Before cleaning After cleaning After curingI do love the blue colour it gives and is delighted with the outcome of this.

Strong Flex door Carabiner

I did attempt the Strong Flex door Carabiner on Thingiverse however even though it printed well. It broke when I was putting together…its just too rigid for it.

Woody

Let’s try another model…This is the Sackboy from LBP in a Woody costume created by Daniel Thredson. The print came out great, however, with the 2nd picture, the light brings out every nook and cranny so doesn’t look as good, but in real life, it is a fantastic print! This was printed on a miniature scale using the stock settings of the Longer 3D Orange 10 resin 3D printer.

The print came out great, however, with the 2nd picture, the light brings out every nook and cranny so doesn’t look as good, but in real life, it is a fantastic print! This was printed on a miniature scale using the stock settings of the Longer 3D Orange 10 resin 3D printer.

Toughness Resin

For the toughness resin, again, I printed the Strong Flex door Carabiner on Thingiverse to see how different it would be compared to the rigid resin. I thought this model would have been perfect for the toughness resin. However, it is not. This resin is flexible! It makes the carabiner clip useless really as it needs rigidity for it to function correctly.

I also found that this needed a longer curing time under the UV light after printing.

I thought why not print some springs, or perhaps some spacers to replace the springs of my FDM print bed as this is a kind of flexible resin. The Toughness resin has a max temp of 95°c so ideal for this type of application. I amended the recipe settings as to what was suggested by iFun 3d on their site

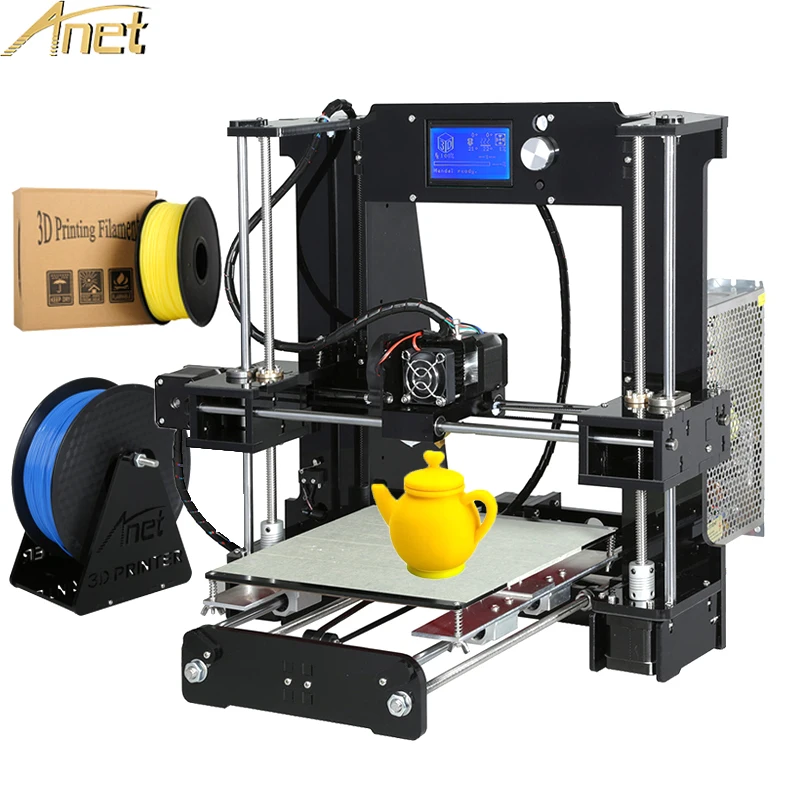

Firstly I printed these Ender 3 Solid Bed Mounts. They printed exceptionally well and appeared to be working well on the Ender 3 without issue! No warping or molten resin I can see so far. (There are remnants of blue resin from the Isopropol Alcohol bath!)

They printed exceptionally well and appeared to be working well on the Ender 3 without issue! No warping or molten resin I can see so far. (There are remnants of blue resin from the Isopropol Alcohol bath!)

Secondly, I printed these Ender 3 Feet Noise Dampers. Again, fantastic prints and I suspect they could well be up to the job…

You can see the flex with the iFun 3D printer toughness resin when I apply pressure to this damper. Unfortunately, the weight is too much on my Ender 3, so it compresses it too much.

You can view a video below from iFun 3D on the best application and what it can achieve with the Tougher resin. The resin itself is pretty tough as you can flex this quite a bit without it breaking.

Overall

To sum up, iFun 3D produce some fantastic resins for many different applications. They have a multitude of colours you can choose from, and they even have a Natural resin set with four colourants of which you can mix your colours! Additionally, if I were to improve anything, it would most likely be the packaging. A professionally printed label, a stopper for the bottle and that would be it; however, the resin itself is perfectly suitable for printing with whatever the application. I would happily experiment more with their resins; however, having a budget resin printer, it may not be doing the justice it deserves!

They have a multitude of colours you can choose from, and they even have a Natural resin set with four colourants of which you can mix your colours! Additionally, if I were to improve anything, it would most likely be the packaging. A professionally printed label, a stopper for the bottle and that would be it; however, the resin itself is perfectly suitable for printing with whatever the application. I would happily experiment more with their resins; however, having a budget resin printer, it may not be doing the justice it deserves!

Where can I find out more?

You can check them out on Facebook or visit their website if you want to purchase.

We have secured an exclusive discount for Inov3D readers! Spent €50 or more and receive 10% off your purchase using the code INOV3D

I hope you enjoyed this review of the iFun 3D Printer resin…why not check out eSun Resin review – A pour performance?? or Dragon Resin Review – Is It Different? We Shall See for more resin reviews!

90,000 programs for modeling and printing on a 3D printerContent

-

- Program programs

- File types for 3D printing

- Free programs

- Paid programs for 3D modeling

- Programs for cutting 3D models (slicers)

- Free slicers

- Paid slicers

- To summarize

The whole cycle of creating a part on a 3D printer can be fit into three stages: Creating / finding a model, cutting a model in a slicer, printing on a 3D printer. Each stage is tied to its own program. Models are created in special programs, then in the slicer the model is “cut” into steps that the printer will sequentially execute. The resulting list of steps (commands) is either placed on a memory card and run from the printer itself, or sent to the printer via a wired/wireless connection. As a result of all these actions, we get the product. Therefore, looking for a “3D printer program” is wrong: you need to look for a modeling program and a slicer.

Each stage is tied to its own program. Models are created in special programs, then in the slicer the model is “cut” into steps that the printer will sequentially execute. The resulting list of steps (commands) is either placed on a memory card and run from the printer itself, or sent to the printer via a wired/wireless connection. As a result of all these actions, we get the product. Therefore, looking for a “3D printer program” is wrong: you need to look for a modeling program and a slicer.

3D modeling software

Programs for 3D modeling are divided into two large groups:

Obviously, when creating a drawing, an engineer needs precise tools: a ruler, pencil, compass, etc. But the artist needs more free tools: brushes, pastels, palettes and others. Programs are divided according to the same principle: in engineering programs, there are all the tools that allow you to accurately specify the characteristics of each element of the part, and in art programs, tools are created to give smoother forms so that the model looks as natural as possible. Of course, in art programs it is possible to model technical products, but this is comparable to drawing a drawing with pastel: it is inconvenient, difficult and inaccurate. Therefore, it is very important to determine why you need a simulation program.

Of course, in art programs it is possible to model technical products, but this is comparable to drawing a drawing with pastel: it is inconvenient, difficult and inaccurate. Therefore, it is very important to determine why you need a simulation program.

Tip: It is best to learn one or two programs at a professional level, as this will allow you to create complex models. But you should also know the basics in other programs, since a large circle of knowledge allows you to more flexibly choose the approach to creating models.

File types for 3D printing

To begin with, it is worth understanding what types of files are involved in the manufacturing process of the part. The first step is to create a model. It can be saved in the format of the program itself (for example, KOMPAS-3D files have the .m3d extension, while 3ds Max has the .MAX file extension). Such files can only be opened in the programs in which they were created. But we need a universal format - STL. All programs can save models in this format. It stores the polygons that create the model.

But we need a universal format - STL. All programs can save models in this format. It stores the polygons that create the model.

All files are divided into 3 categories:

-

Files that store polygonal information (STL, OBJ, etc.). They are analogues of a raster image. It is possible to increase the quality of 3D models in this format only by smoothing, but in this case small details will be lost, and the file weight will increase greatly.

-

Files that store the steps for creating a part (STEP, STP, etc.). Here you can draw an analogy with vector images. Each element is specified either using simple dot connections (for example, as in a cube or pyramid), or using formulas (any curved, rounded objects). Models in this format can be scaled without loss of quality, while maintaining a relatively small file size.

-

Utility files that store steps for a 3D printer (GCODE, GCOD). These files store the commands that the printer executes and, in some cases, comments (for example, with what settings the model was cut).

Some slicers can simulate the movements of the printer, thereby rendering the model, but it is impossible to convert a file from this format to a full-fledged model.

Some slicers can simulate the movements of the printer, thereby rendering the model, but it is impossible to convert a file from this format to a full-fledged model.

Be careful! If you are not sure that the GCODE file is intended for your printer, then you should not print it, because the print area for each printer is different. On third-party firmware there is no limit on the maximum travel distance, some third-party software commands may lead to incorrect operation of the control board. If the printer tries to move the print head out of the printable area many times, then it can harm itself!

If the files are in the same category, then they can be easily converted from one format to another with almost no data loss. The formats indicated in brackets are a kind of “transits”. For example, Inventor has its own file format - itp, and Fusion 360 has its own - f3d. But if you save the file in Inventor in the generic STEP format, you can open it in any engineering program and then save it in that program's format.

But if you save the file in Inventor in the generic STEP format, you can open it in any engineering program and then save it in that program's format.

Free programs

Usually, free programs are either limited in functionality or created by enthusiasts, which is why they have a very crooked interface and a lot of errors. But their functionality is enough to create simple models, and in some cases, such programs can completely replace paid software.

Tinkercad

In essence, this is not even a program, but a website, that is, it does not need to be installed on a computer and it opens from any device that has Internet access. But this is its main disadvantage - without Internet access, you will not be able to download any model for yourself, because each project is initially saved in the cloud. You also need to register to use this site. Initially, the site was created for children, so each tool is intuitive. The program is suitable for modeling simple products: gaskets, bushings, adapters, covers, boxes, etc.

Pros:

Cons:

-

Inability to work without the Internet

-

Each individual project needs to be downloaded

-

Limited number of tools

FreeCAD

This program is designed to create technical products: fasteners, bushings, hinges and more. Since this is an open source project, it is distributed free of charge. At the same time, it has all the necessary functionality for opening and editing files with the .step extension - a universal format for all engineering programs. It is also worth noting the ability to add addons - special subroutines that allow you to perform any actions in a fully automatic mode. For example, there is an addon that makes it easier to create various gears. In this program, you can create more complex products: mechanisms, gearboxes, hinges, etc.

Pros:

Cons:

OpenSCAD

This CAD is closer to programming languages than to modeling: each object or any action is specified as a code. This allows you to create universal models. For example, a coin sorter: once you write the “model code”, you can create a huge number of variants of this model for different countries, changing just a few parameters. This program, like the previous one, is an open source project, as a result of which it is regularly updated.

This allows you to create universal models. For example, a coin sorter: once you write the “model code”, you can create a huge number of variants of this model for different countries, changing just a few parameters. This program, like the previous one, is an open source project, as a result of which it is regularly updated.

Pros:

-

Works on weak PCs

-

Ease of creating universal models

-

Easy to learn if you have programming experience

Cons:

-

No Russian interface

-

Is a programming language

-

Difficult to create curvilinear geometry

Free Shipping

Add to compare

Item added to compare Go

| Manufacturer | Anycubic |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Raise3D |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

Meshmixer

Art program for entry-level 3D modeling. There are simple tools for processing STL files and functions for recovering “broken” files. Using Meshmixer, you can conveniently cut the model into several parts, as it is possible to set the size of the print area of your printer. And one of the most useful tools is the installation of tree supports. This function has already appeared in many slicers, but it is in meshmixer that they can be flexibly configured and installed manually. Despite the many tools, this program is rather auxiliary, as there are more suitable programs for creating a model from scratch.

There are simple tools for processing STL files and functions for recovering “broken” files. Using Meshmixer, you can conveniently cut the model into several parts, as it is possible to set the size of the print area of your printer. And one of the most useful tools is the installation of tree supports. This function has already appeared in many slicers, but it is in meshmixer that they can be flexibly configured and installed manually. Despite the many tools, this program is rather auxiliary, as there are more suitable programs for creating a model from scratch.

Pros:

Cons:

-

Limited functionality for creating 3D models

-

Lack of Russian interface

-

Some operations require a powerful PC

Blender

A completely free program with huge possibilities not only for creating models, but also for animation, rendering, simulations and much more. It is mainly used by multipliers, but due to the large number of extensions, this program covers a huge range of tasks. At first glance, Blender may seem too complicated, but everyone can master the basic functionality. Also worth noting are constant updates that improve performance and add new tools. A large community of people working in this program and developing it will help with the solution of many problems.

It is mainly used by multipliers, but due to the large number of extensions, this program covers a huge range of tasks. At first glance, Blender may seem too complicated, but everyone can master the basic functionality. Also worth noting are constant updates that improve performance and add new tools. A large community of people working in this program and developing it will help with the solution of many problems.

Paid 3D modeling software

This category includes programs for professionals and enterprises, as well as their simplified versions for home use. Many companies have begun releasing a product at a low cost for home use, although initially the designs were intended only for enterprises and were priced accordingly. The common advantage of these programs is great functionality and constant support. For example, Autodesk Inventor was first released back in 1999 and is updated annually. Next, we will look at the most popular of them.

Fusion 360

The new product from Autodesk tried to combine several tasks at once: modeling, simulation and rendering. In many ways, it adopted the functionality of the previously mentioned Inventor, but supplemented it with a simple interface: many tools are similar to those that can be used in the previously mentioned Tinkercad. You can also edit STL files in it, albeit with a limited set of tools.

In many ways, it adopted the functionality of the previously mentioned Inventor, but supplemented it with a simple interface: many tools are similar to those that can be used in the previously mentioned Tinkercad. You can also edit STL files in it, albeit with a limited set of tools.

The main feature of this program is cloud data processing, such as simulations and renders. At the same time, almost all functions can be performed offline using the power of a PC. To process tasks in the cloud, you need to buy additional tokens, but when creating models, they are not necessary. It is worth considering that despite the presence of a native file format (f3d), all files are initially stored on Autodesk servers, and then they can be saved to your computer.

There is a version for schools and universities, but obtaining such a license requires the educational institution to register and issue you a personal license.

Pros:

Cons:

Price: from 7,123₽ to 25,721₽ for 1 year

Netfabb

The program is designed to prepare the model before slicing. In many ways, it is similar to meshmixer, but it does not have the tools to create a model from scratch. Merging several models in STL format can be called a distinctive function, but the most important tool is the “repair” of models. That is why everyone should install this program, even if you have another model editor or model repair built into the slicer. Also in Netfabb it is very convenient to cut the model into several parts for printing separately. At the moment, the Netfabb functionality is built into Fusion 360 and is not officially available separately, but can be found on third-party resources as a separate program.

In many ways, it is similar to meshmixer, but it does not have the tools to create a model from scratch. Merging several models in STL format can be called a distinctive function, but the most important tool is the “repair” of models. That is why everyone should install this program, even if you have another model editor or model repair built into the slicer. Also in Netfabb it is very convenient to cut the model into several parts for printing separately. At the moment, the Netfabb functionality is built into Fusion 360 and is not officially available separately, but can be found on third-party resources as a separate program.

Pros:

-

Great functionality for repairing the model

-

Convenient cutting into pieces

-

Easy to learn all the necessary tools

Cons:

Price: from 18 024₽ for 1 month

KOMPAS-3D

A professional program created by Russian developers for Russian enterprises. It has a huge functionality, but at the same time, each function has a description, and the main tools have explanatory animations, a huge database of standards and GOSTs is built in. The program is free for all students and does not require verification of documents. There is also a paid version of KOMPAS-3D HOME, which, although intended only for home use, retains all the functionality of the “professional” version. Because of this, and also because of the low price, this CAD system is the best choice as the first professional program for creating complex 3D models.

It has a huge functionality, but at the same time, each function has a description, and the main tools have explanatory animations, a huge database of standards and GOSTs is built in. The program is free for all students and does not require verification of documents. There is also a paid version of KOMPAS-3D HOME, which, although intended only for home use, retains all the functionality of the “professional” version. Because of this, and also because of the low price, this CAD system is the best choice as the first professional program for creating complex 3D models.

Pros:

-

Completely Russian interface

-

A large number of tools

-

Availability of a free student version

-

Very low price

Cons:

Price: from 1 490₽ for 1 year

SolidWorks

One of the oldest programs on the market that has become a standard. If you learn how to work in SolidWorks, then you can work in any CAD. It has a relatively simple interface, an average number of tools that are enough even for professionals, but since the program is designed for production, many functions will only interfere with work. It should be noted that this program is available in Russian, and this is one of the reasons for the prevalence of this program in Russia.

If you learn how to work in SolidWorks, then you can work in any CAD. It has a relatively simple interface, an average number of tools that are enough even for professionals, but since the program is designed for production, many functions will only interfere with work. It should be noted that this program is available in Russian, and this is one of the reasons for the prevalence of this program in Russia.

Pros:

-

Easy to learn

-

The presence of the Russian interface

-

Large community of people using SolidWorks

-

Widespread in Russia

Cons:

Price: from 8,431₽ to 292,560₽ for 1 year

Inventor

The main program at many enterprises, but due to the simplicity of the interface and the presence of the Russian language, it is easy to learn. In many ways, it is similar to SolidWorks, both in functionality and in purpose. The main distinguishing feature of this program is a large number of high-quality video tutorials and text courses. It is studied at many universities both around the world and in Russia.

The main distinguishing feature of this program is a large number of high-quality video tutorials and text courses. It is studied at many universities both around the world and in Russia.

Pros:

-

Prevalence among the Russian community

-

Lots of learning materials

-

Intuitive interface

-

Availability of student version

Cons:

Price: from 106 860₽ for 1 year

SelfCAD

It is the simplest program for technical modeling. As easy to learn as Tinkercad, but not for kids, but for professional 3D printing. This program is not CAD, so there is no editing history, which allows, for example, to change sketches without entering edit mode.

You can download this program for free, but this version will have limited functionality. There are also paid versions with monthly payment or a one-time purchase forever. Only paid versions have a simple slicer, but its functionality is extremely limited.

Only paid versions have a simple slicer, but its functionality is extremely limited.

Pros:

Cons:

-

Small functionality

-

Big cost

Price: from 1160₽ ($14.99) for 1 month

3ds Max

The program is designed to create 3D models and render images. It has great functionality, but it is extremely difficult to learn due to the lack of the Russian language and a complex interface. This is due to the fact that 3ds Max was originally developed for 3D animation and video game studios. It was to create a simple and free analogue that the previously mentioned Blender was created. Due to the above reasons, this program is not suitable for creating 3D models for subsequent printing on a 3D printer, but nothing prevents you from doing this.

Pros:

Cons:

Price: from 9 791₽ for 1 month

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

Free Shipping

Add to Compare

Product added to compare Go

| Manufacturer | Anycubic |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | PICASO 3D |

Free Shipping

Add to Compare

Product added to compare Go

| Manufacturer | Phrozen |

3D cutting software (slicers)

Having any model in STL format, you cannot immediately place it in the printer and start printing, because the printer only executes commands, and these commands form a slicer. According to the etymology of the word, one can understand that the program cuts the model into layers, or rather into separate commands. But the number of cutting options for one model is almost endless. In this regard, a large number of programs have appeared that allow you to fully customize the operation of the slicer, or rather, how it will split the model into separate commands. The slicer itself consists of two parts: the core and the shell. The slicer core performs slicing based on the specified parameters, and the shell allows you to set these parameters and visually evaluate the slicing result before sending the model to print. In addition, many slicers have built-in functionality for direct access to the printer, which allows you to manually control the printer and carry out its settings and diagnostics. Next, we will consider the most popular slicers, which have their positive and negative sides.

According to the etymology of the word, one can understand that the program cuts the model into layers, or rather into separate commands. But the number of cutting options for one model is almost endless. In this regard, a large number of programs have appeared that allow you to fully customize the operation of the slicer, or rather, how it will split the model into separate commands. The slicer itself consists of two parts: the core and the shell. The slicer core performs slicing based on the specified parameters, and the shell allows you to set these parameters and visually evaluate the slicing result before sending the model to print. In addition, many slicers have built-in functionality for direct access to the printer, which allows you to manually control the printer and carry out its settings and diagnostics. Next, we will consider the most popular slicers, which have their positive and negative sides.

Free slicers

The availability of free slicers is due to the fact that without them the printer becomes a useless machine that can only heat coffee and play a melody with the help of motors. Therefore, many companies that create 3D printers supply slicers with them, while laying them out in the public domain. Often these are large companies such as Ultimaker, CraftUnique, Prusa, etc.

Therefore, many companies that create 3D printers supply slicers with them, while laying them out in the public domain. Often these are large companies such as Ultimaker, CraftUnique, Prusa, etc.

Ultimaker Cura

It was originally created only for Ultimaker 3D printers, but soon became an open-source project. Now in its library of profiles you can find a huge number of printers from various manufacturers. Uses its own core Cura, which has many settings and functions: tree support, wireframe printing, color printing, etc.

Frequent updates bring innovations and even more profiles for various 3D printers. It is a standard choice for beginners, as it has two control modes: simple and professional. Recently, support for add-ons has appeared that allows you to save backup copies of settings, repair the model directly in the slicer, integrate various programs for 3D modeling, and much more.

It is also possible to control the printer by sending commands directly from the computer. But there is no feedback from the printer, apart from receiving information about the temperature of the nozzle and table.

But there is no feedback from the printer, apart from receiving information about the temperature of the nozzle and table.

Pros:

Cons:

Prusa Slic3r

Sometimes you can find other names: Slic3r Prusa Edition or Slic3r PE. Prusa decided not to reinvent the wheel, and took the open-source Slic3r project, partially reworked it and began to actively develop it. Like Cura, Prusa Slic3r has many printer profiles, but Prusa's printer profiles are the most optimized. The core of the slicer of our own design, while the number of settings is less than that of the same Cura.

A distinctive feature is the flexible adjustment of the layer thickness and the support of a special extruder capable of printing 5 different plastics at once (again, produced by Prusa). The program will be extremely useful for people who have more than one 3D printer: all settings are divided into 3 tabs, each of which can be saved to separate profiles. But the printer control console disappeared completely, only the send button for printing via wire remained. In general, this program will be a reliable and convenient slicer, especially if you have a large number of printers.

But the printer control console disappeared completely, only the send button for printing via wire remained. In general, this program will be a reliable and convenient slicer, especially if you have a large number of printers.

Pros:

Cons:

Repetier

This slicer was created more for remote control of the printer, but it can also cut models. One of the few programs where you can choose the slicing core: Cura, Sic3r, Prusa Slic3r. The number of settings for the slicing itself is extremely small, but they are enough to cut the test cube.

The most important plus of this slicer is the huge functionality for managing and configuring the printer. It is worth noting the convenient interface for sending commands, as well as customizable temperature graphs. This is extremely useful, for example, when tuning the PID or checking the movement of the axes. Even if you choose a different slicer, this program is handy to have in order to 3D print using GCODE from another slicer.

Pros:

Cons:

MatterControl 2.0

One of the few programs that combine functions for editing stl files and a slicer. You won't be able to create any serious model, but you can add text or cut out part of the model. The slicer has not so many settings, but they are enough for a beginner 3D printer. This slicer can be useful if you need to make art products with minor changes. Supports saving to the cloud.

Pros:

Cons:

3DprinterOS

This software is designed to remotely manage printers from anywhere in the world. All that is needed is to connect the printer to the computer and install this program on it. From now on, all printer management occurs through the web interface. In it, you can remotely change the model, cut it and put it on print. It is also possible to connect a camera and observe the printing process. There are very few slicing settings, some will not even be enough to calibrate the printer, not to mention serious printing.

Carefully! It is not recommended to leave the printer unattended, especially if it is no longer new: at any time there may be a risk of fire due to wiring or mechanical problems.

Pros:

-

Simple interface

-

Start printing from anywhere in the world

-

Ability to monitor printing

-

Availability of tools for editing the model

Cons:

IceSL

It is a combination of OpenSCAD with its “modeling language” and slicer. In addition, models can be edited using a “brush”, like the one in Meshmixer. It has many small pluses that are not found in other slicers, but it is not suitable for everyday use due to an inconvenient interface and a small number of slicer functions. This program can be described in one phrase: interesting, but not recommended.

Pros:

Cons:

Octoprint

In many ways it is similar to 3DprinterOS, but is an open source project, as a result of which it has many additions. Designed for home use. It is the most popular way to remotely control a printer, and the user community is constantly growing. Therefore, it will be very easy to transfer your printer to remote control due to the large number of lessons and articles. The program itself does not have a slicer, but direct export of files from Slic3r is supported, which is already good in itself. Just like Repetier, it has an excellent printer management and monitoring console. But, unlike the aforementioned analogue, most of the functions will have to be configured manually.

Designed for home use. It is the most popular way to remotely control a printer, and the user community is constantly growing. Therefore, it will be very easy to transfer your printer to remote control due to the large number of lessons and articles. The program itself does not have a slicer, but direct export of files from Slic3r is supported, which is already good in itself. Just like Repetier, it has an excellent printer management and monitoring console. But, unlike the aforementioned analogue, most of the functions will have to be configured manually.

Pros:

-

Large user base

-

Lots of tutorial articles

-

Ability to create a video broadcast of the printing process

Cons:

Paid Slicers

At the moment, many paid slicers are no longer used, as free ones have either caught up or overtaken them. But some of them are still unique.

Simplify3D

One of the first thundered paid slicers. At the time of its introduction, it was the most advanced due to the ability to change the print settings for one model at different layer heights and the functionality of printing with more than one extruder. But at the moment it has been replaced by Cura and Prusa Slic3r. Nevertheless, the convenience of setting up print settings and their number still remain the main advantage of this slicer. Also worth noting is the excellent printer management interface, second only to Repetier host.

Another difference is the ability to manually install supports and a large number of filling patterns. Viewing models also has several features: changing the way models are displayed, viewing in section, displaying normals to planes.

Pros:

-

Lots of print options

-

Convenient printer management interface

-

Manual installation of supports

-

Changing print settings at different heights

-

Easy print setup with two extruders

Cons:

Price: from 11499₽ ($149)

Read also: A detailed review of 3D printing slicers: Ultimaker Cura, Simplify3D, IdeaMaker, UP Studio, FlashPrint

Astroprint

Many believe that this particular software is a direct competitor to 3DPrinterOS. The most important difference is user friendliness, achieved through a user-friendly interface and easy installation. The program is based on Octoprint, essentially providing only a server, a modified interface and several add-ons that allow you to fully manage the printing process while away from the printer - from finding a model, to cutting and printing. At the same time, the program positions itself as a serious business solution, so the company also provides special PCs and management consoles that make it easy to connect the printer to the system. A trial plan is available where only 2 printers can be connected, but all basic features will be available.

The most important difference is user friendliness, achieved through a user-friendly interface and easy installation. The program is based on Octoprint, essentially providing only a server, a modified interface and several add-ons that allow you to fully manage the printing process while away from the printer - from finding a model, to cutting and printing. At the same time, the program positions itself as a serious business solution, so the company also provides special PCs and management consoles that make it easy to connect the printer to the system. A trial plan is available where only 2 printers can be connected, but all basic features will be available.

Pros:

-

Easy connection and setup

-

Trial Availability

-

Interface specially designed for mobile devices

Cons:

Price: from 765₽ ($9.90) for 1 month

KISSlicer

This slicer is another representative of programs that failed to keep up with the times. Previously, its functionality was a cut above the rest, but now the same Cura has all the same settings as KISSlicer, and also adds its own. Of the useful in this program, we can note the function of joint viewing of GCODE and model.

Previously, its functionality was a cut above the rest, but now the same Cura has all the same settings as KISSlicer, and also adds its own. Of the useful in this program, we can note the function of joint viewing of GCODE and model.

There were two versions: free and PRO. The only significant difference between them is that the paid version has support for printing in multiple colors. At the moment the project is dead, even the main site does not work, but the program can still be found on third-party sources.

Pros:

Cons:

Price: from 3240₽ ($42)

Summing up

After considering all the popular programs, we can highlight the clear favorites:

For beginners in 3D printing, Tinkercad is the best 3D modeling software because it combines simplicity with the necessary functionality. The best programs for professional-level 3D modeling are KOMPAS-3D, Fusion 360 and Blender, due to the huge number of tools and a large community that makes it easy to find lessons and guides. Among the slicers, the Ultimaker Cura and Prusa Slic3r are the best choice for ease of use and flexibility when slicing models. But do not forget about such auxiliary programs as Meshmixer and Netfabb, which allow you to quickly edit or repair the model. You can learn more about some of the programs from this list on our website.

Among the slicers, the Ultimaker Cura and Prusa Slic3r are the best choice for ease of use and flexibility when slicing models. But do not forget about such auxiliary programs as Meshmixer and Netfabb, which allow you to quickly edit or repair the model. You can learn more about some of the programs from this list on our website.

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Achievements in additive manufacturing in 2022.

& Innovation is the norm in additive manufacturing, making it difficult to choose the most innovative companies. Not only is this industry one of the fastest growing and start-up-filled manufacturing technology sectors, but it spans all markets from aerospace and healthcare to construction and consumer products.

Not only is this industry one of the fastest growing and start-up-filled manufacturing technology sectors, but it spans all markets from aerospace and healthcare to construction and consumer products.

The companies we will discuss below have developed innovative approaches to making things. They are disrupting traditional manufacturing markets to help other companies around the world innovate faster, build better and produce more. They innovate on their own, unafraid to destroy previous successes to make them even better. These businesses are forging a new, closer relationship between forward-thinking design and industrial reality, whether it's one-of-a-kind rocket engines or the house next door.

These companies are full of knowledge about how additive manufacturing can have a significant impact on your company, your industry and society as a whole.

10 of the most innovative 3D printing companies 2022

icon/icon

Ecological House Zero from ICON (Source: ICON)

Innovation Innovation in the 3D printer, or then what a 3D printer prints; House Zero debuted in 2022. This Austin, Texas home is what 3D printed construction company Icon hopes will be a whole new genre of homes that celebrate their 3D printed bones and promote sustainability. The house is energy efficient; requires less time, labor and construction costs; and features a wall construction that provides thermal insulation and resistance to extreme weather conditions such as hurricanes. It's also beautiful and comfortable, proving that 3D printed houses are no compromise between design and functionality.

This Austin, Texas home is what 3D printed construction company Icon hopes will be a whole new genre of homes that celebrate their 3D printed bones and promote sustainability. The house is energy efficient; requires less time, labor and construction costs; and features a wall construction that provides thermal insulation and resistance to extreme weather conditions such as hurricanes. It's also beautiful and comfortable, proving that 3D printed houses are no compromise between design and functionality.

Company: Founded in 2017 in Texas, Icon has an audacious mission to revolutionize home building. Using a 3D construction printer called Vulcan and a concrete-like material of its own called Lavacrete, Icon has built houses around the world for the underprivileged, built barracks for the military, designed potential habitats on Mars, and started building basic housing. market to show how our homes can be built faster, safer and greener.

Relativity Space

The new Stargate Factory, still a secret and only visible through visualization, will feature a 3D printer and mission control center (Source: Relativity Space).

Innovation: Future Stargate Factory, announced in 2021 and due to open in 2022, vertically integrates robotics, software and proprietary 3D printing technologies to digitize the production of reusable rockets and engines. In addition to the Stargate 3D printers, which are the largest in the world, the plant will also house a metallurgical laboratory, a machine shop and a mission control center designed to launch 3D printed rockets into space. By co-development of the "Factory of the Future" and rockets, Relativity expands its capabilities to improve design, production, quality and speed.

Company: Relativity Space is a California-based aerospace manufacturing company founded in 2015 to develop additive manufacturing technologies, launch vehicles, and rocket engines for commercial orbital launches. Using a giant patented 3D printer called Stargate, the company produces fully reusable rockets in just 60 days, compared to years for traditional aerospace companies. The first test launch of the Terran 1 rocket is scheduled for 2022.

Axial3D

3D printed anatomical model from Axial3D (Source: Axial3D)

Innovation: Axial3D has created a cloud service that allows surgeons and other healthcare professionals to upload 2D patient scans to a portal with patented technology for automatic segmentation images and creating files for 3D printing. Physicians can then 3D print these models (or send them to a 3D printing service) to create visual aids that improve surgery planning and patient education. Axial3D continues to raise significant growth funds to expand its business beyond surgeons in the nearly 30 countries to which the company currently supplies models.

Company: Axial3D, founded in 2014 in Belfast, aims to improve surgery for everyone around the world through 3D scanning and 3D printing of patient-specific models that make diagnosis and treatment more accurate and personalized. Axial3D offers its portal and 3D printing as a service to medical professionals around the world.

Fluicell

Fluicell's Biopixlar AER is a single cell 3D bioprinter (Source: Fluicell)

Innovation: Launched in early 2022, the Fluicell Biopixlar AER is a single-cell 3D bioprinter that allows users to create detailed biological tissues with high precision. It is the world's first microfluidic high-precision bioprinter compact enough to fit in a standard biosafety cabinet, expanding the technology's reach to new customer segments in the rapidly growing life sciences, pharmacology and medical research sectors. This combination of compactness, ease of use, remote control, proprietary software and portability makes it flexible enough for a wide range of applications from aerospace to deep sea exploration.

It is the world's first microfluidic high-precision bioprinter compact enough to fit in a standard biosafety cabinet, expanding the technology's reach to new customer segments in the rapidly growing life sciences, pharmacology and medical research sectors. This combination of compactness, ease of use, remote control, proprietary software and portability makes it flexible enough for a wide range of applications from aerospace to deep sea exploration.

Company: Fluicell, founded in 2012 as a subsidiary of Chalmers University of Technology in Sweden, is a publicly traded biotech company specializing in high resolution 3D bioprinting and single cell biology. The company is a pioneer in open volume 3D microfluidics for processing and studying the effects of drugs in single cells at a unique level of detail. Fluicell is also developing advanced therapeutics based on transplantable biocomposites printed by Biopixlar. The company operates in three therapeutic areas, where the main cause of the disease is tissue damage.

Velo3D/Velo3D

Sapphire XC by Velo3D (Source: Velo3D)

Innovation: California-based metal 3D printing technology company Velo3D offers a patented Sapphire system that is changing the way products are designed and manufactured in the aerospace, energy, energy and other important industries. In 2022, the company added support for copper 3D printing and expanded its footprint to Europe. More than a metal 3D printer, Sapphire is a complete manufacturing solution that includes software and quality control features that enable companies like SpaceX, Launcher, Honeywell and Honda to reimagine their metal components and break the limits of traditional manufacturing of what can be bring to market.

Company: Velo3D, founded in 2014, offers a metal 3D printing solution that opens up great design possibilities and allows customers to create products that were previously impossible to produce. The end-to-end solution delivers additive manufacturing that can fulfill humanity's space ambitions, realize cost-effective supersonic flight, and bring new levels of efficiency and scalability to the energy and manufacturing sectors.

Nexa3D

Nexa3D NXE 200 SLA 3D printer (Source: Nexa3D)

Innovation: Nexa3D will more than double its hardware portfolio in 2022 with two 3D printers in 2022 QLS 820 with powder coat) is expected later this year. The machines greatly expand the manufacturing sector's access to high-speed 3D printing. The company's patented Lubricant Sublayer Photocuring (LSPc) technology is a key feature of both the NXE 200 3D printer and the XiP desktop resin 3D printer with print speeds up to 18 cm per hour. With these faster machines, designers, engineers and manufacturers have access to accurate and affordable prototyping and manufacturing solutions that enable innovative products.

Company: Nexa3D is a California-based manufacturer of ultra-fast industrial 3D printers that aims to sustainably digitize the global supply chain by making the world's fastest industrial resin 3D printers available to professionals and businesses of all sizes. The company's groundbreaking technology is breaking down traditional 3D printing productivity barriers and opening up opportunities for additive materials to reshape injection molding markets.

Formlabs

Formlabs Form 3+ is now 40% faster than the previous Form 3 (Source: Formlabs)

Innovation: 3D printer, materials and software maker Formlabs continues to push the boundaries of machine efficiency in 2022 by upgrading its already market-leading Form 3 and 3B resin printers. The new Form 3+ and Form 3B+ are up to 40% faster than earlier models thanks to software developments, higher intensity lasers, and new proprietary material settings to optimize laser impact. The company has made innovations backwards applicable so owners of previous models can get the same efficiency without buying a new machine. In 2022, the company also launched ESD Resin, one of the industry's only static electricity dissipative resin materials, which greatly expands the applications of resin 3D printing in electronics.

Massachusetts-based Formlabs was founded in 2011 to expand access to digital manufacturing so that anyone can do anything. Formlabs is the professional 3D printer of choice for engineers, designers, manufacturers and decision makers around the world, giving tomorrow's businesses the flexibility and versatility they need for demanding, evolving industrial applications. Formlabs is also developing its own suite of high performance materials that continue to push the boundaries of 3D printing, as well as best-in-class 3D printing software.

Formlabs is also developing its own suite of high performance materials that continue to push the boundaries of 3D printing, as well as best-in-class 3D printing software.

WAAM3D/BAAM3D

RoboWAAM Metal 3D Printing Systems (Source: WAAM3D)

Innovation: WAAM3D’s launch of the RoboWAAM large-scale industrial 3D printer in 2022 marks a groundbreaking breakthrough in AM technology to make arc welding technology more accessible. and reliable. Driven by proprietary software to control slicing and path strategies with material-specific algorithms, the comprehensive printer operating system provides a monitoring, control, and ease-of-use environment to expand technology coverage in heavy industry, shipbuilding, construction, and mining at a time when these sectors have been severely affected by the supply chain disruption.

Company: The British company WAAM3D was founded in 2018 and grew out of research conducted by Cranfield University. The company aims to provide a cost-effective way to 3D print massive, complex metal structures at entirely new speeds with less waste, challenging traditionally established processes such as subtractive manufacturing and metal casting.

BCN3D/BKN3D

BCN3D Viscous Lithography Manufacturing (VLM) resin 3D printing process (Source: BCN3D)

Innovation: Although not yet commercially available, BCN3D's VLM (Viscous Lithography Manufacturing) technology is considered a significant advance in resin 3D printing. A proprietary lithography-based 3D printing process deposits thin layers of high-viscosity resin on clear transfer film for extremely fast, affordable and scalable production of high-performance parts. The hallmark of VLM is its ability to open up entirely new categories of polymer materials and create parts from multiple materials. VLM gives material engineers the freedom to formulate resins and modifiers to achieve new thermal and mechanical properties.

Company: Spanish company BCN3D Technologies, founded in 2019, started as a division of the Polytechnic University of Catalonia with the aim of changing the traditional status quo of manufacturing by providing reliable, versatile and productive 3D printers and advanced production materials.