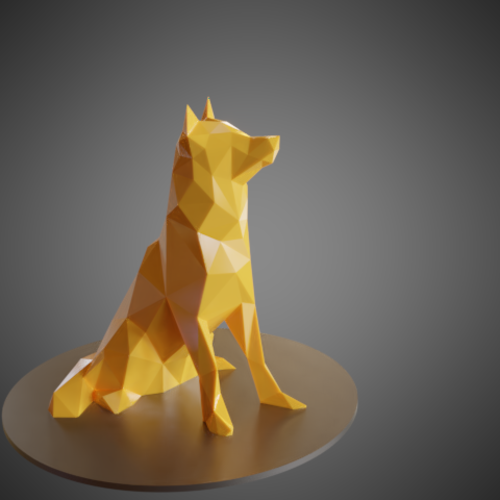

Husky 3d printed legs

Pet Prosthetics Get a Boost From 3D Printing

Boone Ashworth

Gear

New modeling software is helping animal health experts develop more customizable prosthetics for pets with missing limbs. Still, not all legs are created equal.

Photograph: Dive Design

Consider the three-legged dog. Maybe you own one, or have seen them in the park or in any of the billions of Dodo videos about them. Lopsided yet resilient, they evoke a kind of fawning sympathy from us humans that’s unmatched by the typical quadruped canine.

“People are drawn to specially abled pets,” says Rene Agredano, a cofounder of the pet-amputation support website Tripawds. “I think the attraction is that we just want to help them. We just want to make sure that they are given an equal chance at having a happy life. ”

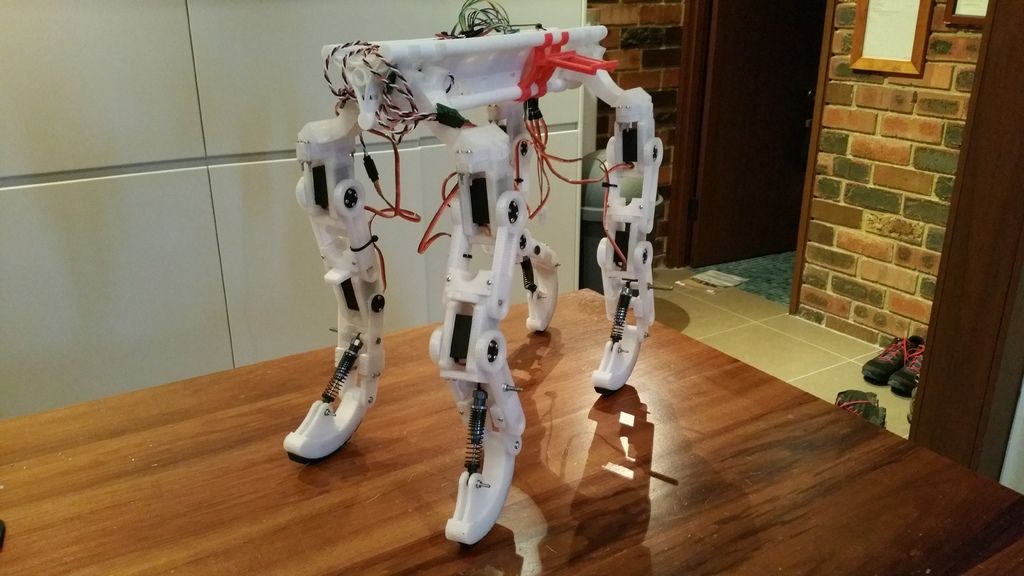

More and more, that desire to help manifests as prosthetics, especially in cases where the animal has lost more than one limb. Pets with artificial limbs have become a whole genre of feel-good videos of their own. A cat with bionic hind legs. A tortoise with wheels. The clips make the rounds on Facebook, where they add a smidge of feel-good optimism to the otherwise dour deluge that is your newsfeed. 3D printing has propelled the industry forward. Printed prosthetics can be lightweight, affordable-ish, and infinitely customizable. Doctors craft beaks for birds. High school students build artificial dog legs in their free time.

But not all pet prosthetics are created equal. And some veterinarians and people in the tripod community worry that the proliferation of easily craftable attachments could lead to unintended consequences for the critters that wear them.

Walking Distance

Dogs can lose a limb for a variety of reasons. Maybe they were born with an abnormal limb, or were hit by a car, or developed a cancerous growth that necessitated an amputation. A common quip among tripod lovers is that “dogs have three legs and a spare.” It’s true, to a point. Dogs adapt remarkably well to losing a limb, says Theresa Wendland, who specializes in animal sports medicine and rehabilitation at the Colorado Veterinary Specialist Group. But complications can arise as the animal compensates for what’s missing. In older dogs and dogs with arthritis or other mobility issues, putting extra weight on the remaining limbs can be a big problem.

A common quip among tripod lovers is that “dogs have three legs and a spare.” It’s true, to a point. Dogs adapt remarkably well to losing a limb, says Theresa Wendland, who specializes in animal sports medicine and rehabilitation at the Colorado Veterinary Specialist Group. But complications can arise as the animal compensates for what’s missing. In older dogs and dogs with arthritis or other mobility issues, putting extra weight on the remaining limbs can be a big problem.

Photograph: Dive Design

Photograph: Dive Design

“It really impacts their spinal mobility,” Wendland says. “They have to change the range of motion in their other limbs. They have to pull themselves forward in ways that are very unnatural.”

Prosthetics, if made right, can restore that range of motion. But as heart melting as it is to see a three-legged dog return to running on four legs, it’s not easy to build a proper puppy peg leg. Wendland, who works with the orthopedic and prosthetic company OrthoPets to help dogs adapt to their new limbs, says that it’s an involved process that takes time and technical know-how.

As with human prosthetics, an animal prosthetic has to be individually tailored to the build of the wearer. That means factoring in the animal's size, weight, height, stance, and gait. (A kit for a doberman won’t fit on a dachshund.) To do that, orthopedists have to study the animal’s movements and try to mold a limb that will sync up with the others. While techniques vary, a standard process is to make a plaster cast, design the prosthetic based on photos and video, then build it out with durable thermoplastics and metal. From there, they tweak the finer details by hand until it works with the animal. The process can take weeks.

Most Popular

There’s also the matter of the amount of the limb that needs replacing. The ideal spot to put a prosthetic, Wendland says, is as low on the limb as you can go. But if the whole limb is gone and there’s no obvious point to attach a prosthetic, it gets much trickier.

A Leg Up

3D printing has long been hailed as a manufacturing revolution in many industries, prosthetics among them. And now, a New Jersey–based design firm called Dive Design thinks it’s the solution to full-limb replacement. It has partnered with a company called Bionic Pets that builds exactly what its name implies: accessibility tech for pets. Derrick Campana, who runs Bionic Pets, has long built pet prosthetics by hand. (He’s even got a show about it called The Wizard of Paws, which airs on Brigham Young University's television channel.) About a year ago, he invited Dive Design heads Alex Tholl and Adam Hecht to his lab in Virginia to look at how he could improve the process.

And now, a New Jersey–based design firm called Dive Design thinks it’s the solution to full-limb replacement. It has partnered with a company called Bionic Pets that builds exactly what its name implies: accessibility tech for pets. Derrick Campana, who runs Bionic Pets, has long built pet prosthetics by hand. (He’s even got a show about it called The Wizard of Paws, which airs on Brigham Young University's television channel.) About a year ago, he invited Dive Design heads Alex Tholl and Adam Hecht to his lab in Virginia to look at how he could improve the process.

“Something that kept coming up was the need for full limb prosthesis development,” Tholl says. The limbs that Campana had been building used too many resources and required too much labor to be manageable. Plus, Tholl says, “With the waste that was involved, it just didn’t make financial sense. For us, that’s when the wheels started turning.”

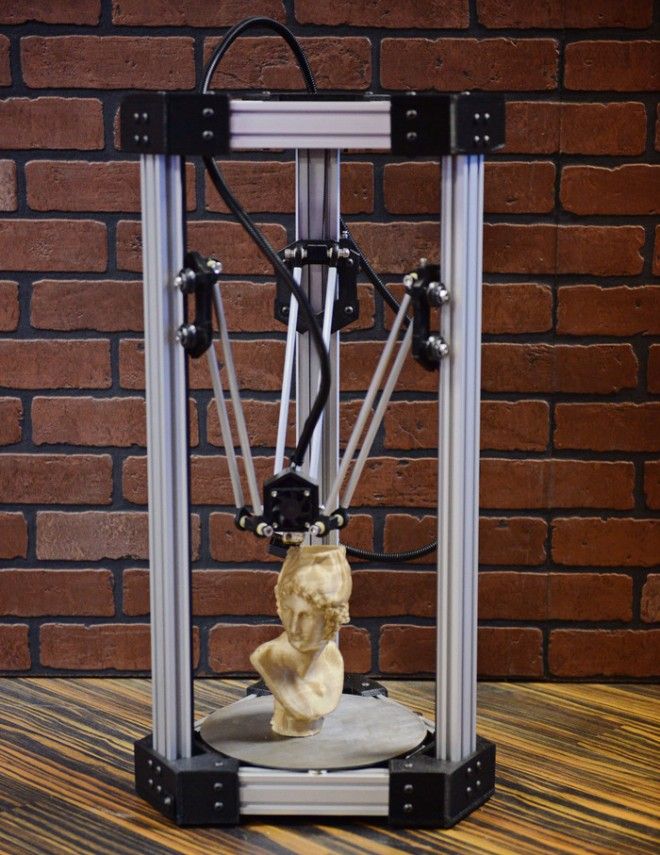

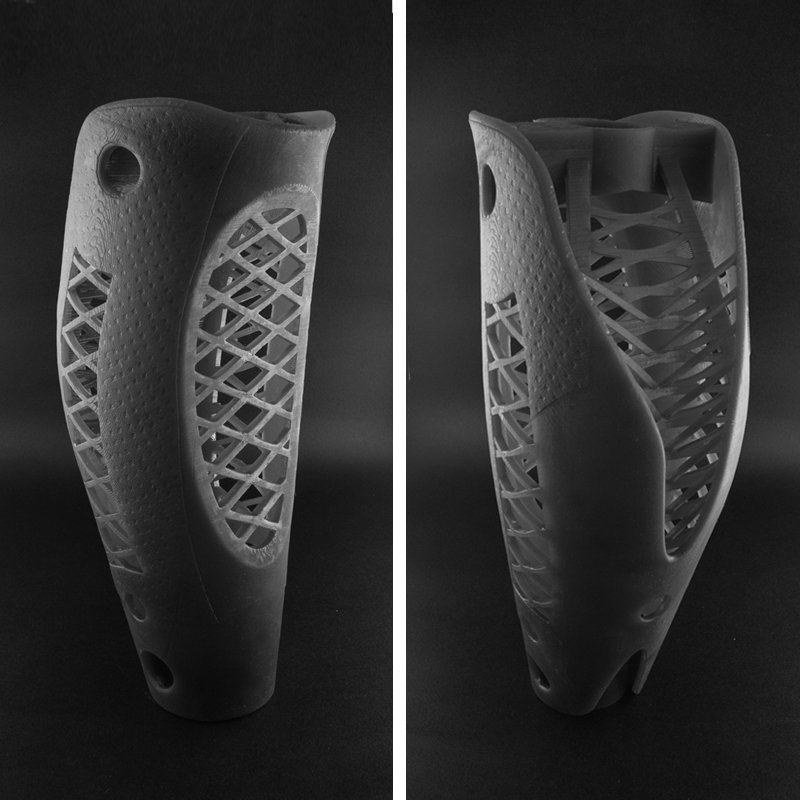

The first step was to find the right software to build the 3D models. Dive Design's intern, Julio Aira IV, a mechanical and biomedical engineering student at Penn State, had a student license to a modeling program developed by a company called nTopology. The others at Dive Design piggybacked off that pseudo-bootlegged software and went to work. (Their software licenses are now up to date.) The nTop Platform lets users build 3D models and simulate how they might function in the real world. That means designers can stress test and map movements of the limb before ever printing it out. The software is not limited to cute animal projects; the government defense contractor Lockheed Martin is an investor, and nTopology has designed optical components for defense tech companies like Raytheon as well. (The intricate jackets that fit the prosthetic to the dog's body were designed and customized with another 3D design company called Landau Design+Technology.)

Dive Design's intern, Julio Aira IV, a mechanical and biomedical engineering student at Penn State, had a student license to a modeling program developed by a company called nTopology. The others at Dive Design piggybacked off that pseudo-bootlegged software and went to work. (Their software licenses are now up to date.) The nTop Platform lets users build 3D models and simulate how they might function in the real world. That means designers can stress test and map movements of the limb before ever printing it out. The software is not limited to cute animal projects; the government defense contractor Lockheed Martin is an investor, and nTopology has designed optical components for defense tech companies like Raytheon as well. (The intricate jackets that fit the prosthetic to the dog's body were designed and customized with another 3D design company called Landau Design+Technology.)

Photograph: Dive Design

Most Popular

“The biggest thing is iterating,” Hecht says. “When you're doing something new, you never have the perfect idea immediately. It's always a lot of trial and error. So the faster we can go through the process of creating things and testing things in the real world, the better solution we’re going to have.”

“When you're doing something new, you never have the perfect idea immediately. It's always a lot of trial and error. So the faster we can go through the process of creating things and testing things in the real world, the better solution we’re going to have.”

Dive Design’s process is similar to building standard orthopedics: Study the dog, take measurements, model it out, and then build from there. But 3D printing lets the engineers quickly adapt and change the physical product in ways that are far less feasible with traditional prosthetics. If a particular joint or lattice that makes up a support isn’t working, they can rework it in a matter of hours.

Bionic Pets' Campana says the rapid iteration afforded by 3D printing is especially beneficial for younger animals, since the patient may need many devices as its body grows. "A new device may be needed, but we do not need to make a cast or redesign," he says in an email. "We can just resize the file and reprint."

“I’m kind of borderline obsessed with this kind of work,” Aira, who works on modeling and developing the prosthetics, says. “We’re really just scratching the surface of how we think about 3D printing and how we think about everything around us. It’s really amazing what we’re going to be able to do and how we’re going to be able to take advantage of these technologies.”

“We’re really just scratching the surface of how we think about 3D printing and how we think about everything around us. It’s really amazing what we’re going to be able to do and how we’re going to be able to take advantage of these technologies.”

Hit a Stride

While that enthusiasm may be in high supply, labor and expertise doesn’t come cheap. Wendland says the prosthetics on which she’s consulted typically fall somewhere between $1,800 to $2,000. Bionic Pets’ prices are still expensive, but more reasonable: $850 for a partial limb and $1,750 for a full limb. These hefty price tags may be familiar to pet owners who have experienced the sticker shock of an astronomical vet bill. So the ability to make inexpensive prosthetics is no doubt appealing.

Photograph: Dive Design

Most Popular

Wendland says she’s had people reach out to her who want to 3D print DIY prosthetics for their own dog, or for a school project. But the kind of materials people are able to utilize in their home printer likely aren’t going to meet the same standards as something that is professionally made.

But the kind of materials people are able to utilize in their home printer likely aren’t going to meet the same standards as something that is professionally made.

“What makes me a little nervous about 3D printing is that people start to get this idea that anybody can make a prosthetic,” Wendland says. “I just see potential for harm with something like that. I love that people are excited about it and that they want to help, but there’s a lot that has gone into the training and the people who are actually doing this for a living and making this happen in a functional way.”

Photograph: Dive Design

An animal might look cute with its artificial limb in an Instagram video, but if that prosthetic hasn’t been carefully crafted by people with the orthopedic knowledge to properly customize it, there’s a risk of it causing more harm than if there was no prosthetic at all. Let’s say a dog moves with the assistance of a wheeled cart. If the wheels are placed too far back, it can create excess stress on the spine. Place them too far forward, and the dog’s constantly tipping over onto its face. A leg prosthetic that doesn’t fit properly can cause sores and ulcerations where the bone meets the skin, sometimes resulting in internal damage in the leg.

Place them too far forward, and the dog’s constantly tipping over onto its face. A leg prosthetic that doesn’t fit properly can cause sores and ulcerations where the bone meets the skin, sometimes resulting in internal damage in the leg.

Prosthetic builders like Dive Design, Bionic Pets, and Ortho Pets have to work in close consultation with orthopedic veterinarians to ensure that their creations aren’t actively detrimental to the animal. Pet prosthetics are a new enough phenomenon that there isn’t a lot of research to definitively show what works and what doesn’t. For now, orthopedic surgeons and builders just have to rely on clinical experience.

Regardless of the type of prosthetic, one thing the animal can't avoid is the need for rehabilitation. It can take weeks or months of physical rehab for a dog to become comfortable with a prosthetic. That means more vet visits, more investment and expenses.

Wendland hasn’t worked with Dive Design’s models specifically, but she says these types of full-limb assistive devices have their place. But it’s important for every pet owner who finds themselves considering one to know their options.

But it’s important for every pet owner who finds themselves considering one to know their options.

“Depending on the situation, I almost wonder if that money wouldn't be a little bit better spent towards good rehabilitation,” Wendland says. “Maybe acupuncture for secondary muscle soreness, things like that, to keep a dog mobile. But I would absolutely consider these for a dog where they have problems with the other leg. I think this is a great use of 3D printing.”

Correction Dec. 21, 9:00 a.m: Updated language to clarify the difference between nTopology and its software. The company is nTopology and the software is nTop Platform. Also clarified the role of Landau Design+Technology, who worked to design and customize the prosthetic jackets.

More Great WIRED Stories

📩 Want the latest on tech, science, and more? Sign up for our newsletters!

Get rich selling used fashion online—or cry trying

The 8 best books about artificial intelligence to read now

Hold everything: Stormtroopers have discovered tactics

I tested positive for Covid-19.

What does that really mean?

What does that really mean?Gift ideas for people who just need a good night’s sleep

🎮 WIRED Games: Get the latest tips, reviews, and more

🏃🏽♀️ Want the best tools to get healthy? Check out our Gear team’s picks for the best fitness trackers, running gear (including shoes and socks), and best headphones

Boone Ashworth is a staff writer on the WIRED Gear desk, where he also produces the weekly Gadget Lab podcast. He graduated from San Francisco State University and still lives in the city. Currently, he has opened too many browser tabs.

Topics3-D printingdogsrobotics

More from WIRED3D Printed Prosthetic Legs Give Derby the Dog Full Mobility & New Lease on Life - 3DPrint.com

3D printing is such an amazing technology. In the past 2-3 years we have really seen the technology make its way into all fields of study and all walks of life. It has gone on to impact the lives of millions of people in one way or another, and has enabled many individuals to do things they never would have thought possible previously.

It’s not just humans that have been reaping the benefits of 3D printing. Our four-legged friends have also been seeing the many advantages that 3D printing provides. In the past, we’ve covered stories of different ways in which animals have been the benefactors of the technology. This includes TurbooRoo, a dog that had a wheelchair 3D printed for him, as well as other animals such as ducks, penguins, cats and more, that in some way, shape or form have benefited greatly from this relatively new technology.

Now, comes a story that may just blow all of these others out of the water. It is of a dog named Derby, who was born with two deformed legs.

It all started back in October when 3D Systems’ Director of CJP Product Management, Tara Anderson adopted Derby as a foster mom from Peace and Paws Dog Rescue, after his owners could no long care for him. Peace and Paws provided Derby with a home, preventing him from ultimately being euthanized.

Derby, sans prostheses

“I kept looking at his photo, and hearing his story, and I cried literally every time,” explained Tara Anderson.

“I had to try and help this dog.”

A cast made of Derby’s left leg

Anderson first decided to get Derby a cart, which he actually could use quite well. However, she felt as though it was inhibiting him from playing with other dogs, and could not provide Derby with the full motion of running. So, with the help of 3D Systems, their Freeform Product Manager, Kevin Atkins, and ABC Certified Orthotist at Animal Ortho Care, Derrick Campana, the team was able to come up with a design for two prosthetic legs, after creating several different iterations.

Using a plethora of different 3D technologies, including 3D scanners, as well as highly sophisticated 3D modeling software, the team was able to create very unique prostheses for Derby, which fit him to a tee.

“The great thing about using 3D technology in Derby’s case, is having these images on file on a computer, and being able to print them. [It] is a lot quicker than having to hand sculpt every single mold and rebuild these braces five to ten times,” explained Kevin Atkins.

At first, they created Derby a “running man” like prothetic, but Anderson was concerned that they would too easily dig into the ground. So, she came up with more of a looped design, which the team created and then printed on a 3D Systems’ ProJet 5500 MultiJet 3D printer. This printer allows for the printing of dual materials, creating rigid as well as flexible parts on the same object.

One of the original iterations — a “running man” device.

Derby’s adopted parents, Sherry and Dom Portanova were extremely impressed by the results that were provided by Anderson, 3D Systems and Campana, in the creation of the dog’s prosthetic legs.

“When I saw him sprinting, it was amazing,” exclaimed Dom Portanova. “I couldn’t believe it! He runs with Sherry and myself every day, at least 2-3 miles.

He runs faster than both of us, he never really tires out [and] he’s just so happy to [run].”

The very first time the prosthetic legs were fitted to Derby, he immediately started running, as if it was totally natural for him. As you can see in the video provided, it was almost as if Derby was born for these legs, and the legs born for him.

“This is what 3D printing is about,” said Anderson. “To be able to help anybody; a dog, person, whoever, to have a better life, there is no better thing to be involved in.”

Derby, Anderson, and the Portanova’s are very pleased with the results. While it originally took some time for Derby to get used to his new prosthetic legs, and the development team a while to get just the right fit and iteration, in the end they turned out perfect.

This goes to show you that when you combine 3D printing with people who care, almost anything is possible. Thanks to the volunteers at 3D Systems, the love shown by Anderson and the Portanova family, and the expertise of Derrick Campana, this is yet another example of a heartwarming 3D printing story.

What do you think about this design? Will 3D printing lead to an easy way of creating prostheses on a one-to-one basis for both humans and animals of all walks of life, in the near future? Discuss in the 3D printed dog prostheses forum thread on 3DPB.com.

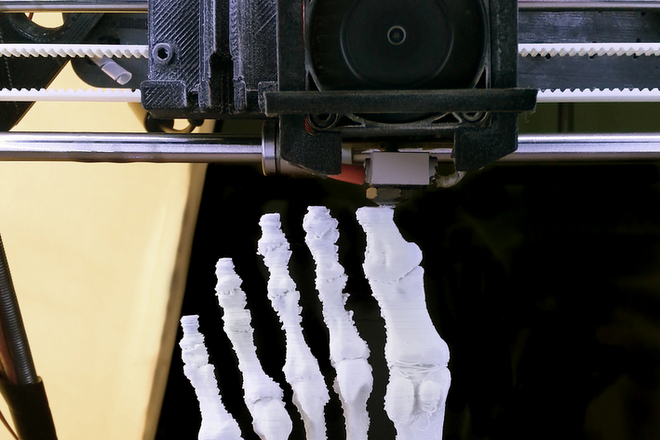

The legs being 3D printed

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printed legs • 3d printed prosthesis • 3d systems • derby the dog • dogs • peace and paws • prosthesis • prosthetics

Please enable JavaScript to view the comments powered by Disqus.

Animals whose lives were saved using a 3D printer

3D printing is a unique technology that allows you to create almost any detail or figure quickly, accurately and from a wide variety of materials: plastic, metal, wax, and so on. As a result, manufacturers do not need to reconfigure machines or "cut" prototypes manually - it is enough to entrust this task to the printer. You can print a variety of things: superhero figures for children, pizza for astronauts, special shoes for a hacker, as well as medical prostheses for people and even animals.

You can print a variety of things: superhero figures for children, pizza for astronauts, special shoes for a hacker, as well as medical prostheses for people and even animals.

In the 3D printing market, helping our little brothers is not only an act of charity, but also a great way to showcase what new technologies can do. For animals, 3D printers create not only prostheses, but also special splints, splints and other medical devices. When the patient recovers, they can be removed and reused.

New legs for the dog

The front paws of the dog named Derby were underdeveloped from birth, so the dog did not run all his life, but crawled. He would have ended up in a shelter if Tara Anderson, director of 3D Systems, had not adopted him and made this dog the face of an advertising campaign for 3D printing technologies. Finally standing on all fours, Derby quickly learned to run. He liked this activity so much that now he goes on a daily five-kilometer jog with his new owner, Tara's husband.

3D Systems has tried more than one type of prosthesis. The first models did not allow the dog to keep his back straight, which increased the load on the spine and could lead to injury in the future. A simple increase in the size of the prosthesis did not solve the problem - such legs interfered with walking more than helped. The developers had to change the design, pick up a new material and create a kind of functional semblance of a knee. The result is prostheses that don't look like dog paws, but that doesn't stop Derby from happily running around with his tongue hanging out.

Titanium-jawed turtle

Most species of sea turtles are in danger of extinction, so scientists are trying to save every affected animal. In 2014, an adult male sea turtle met the propeller blades of a motor boat, and the meeting ended tragically: the upper and lower jaws of the animal were partially crushed, which made it unable to feed on its own.

In 2014, an adult male sea turtle met the propeller blades of a motor boat, and the meeting ended tragically: the upper and lower jaws of the animal were partially crushed, which made it unable to feed on its own.

Feeding the turtle in the laboratory was also not easy: the animal could hardly swallow small fish and was on the verge of exhaustion. Therefore, specialists from the Center for the Study, Rescue and Rehabilitation of Turtles at the University of Pamukkale in Turkey modeled and 3D printed a titanium prosthesis, which completely replaced the turtle's lost jaw.

By the way, it is worth noting that metal 3D printing is now considered one of the most promising technologies. Most used to associate 3D printing with plastic products, mainly ABS plastic. Fusion-printed parts made of such plastic are cheap, but not very strong, and most importantly, this method does not allow creating complex products with sufficient accuracy. Plastic is not suitable for creating a turtle jaw.

Fusion-printed parts made of such plastic are cheap, but not very strong, and most importantly, this method does not allow creating complex products with sufficient accuracy. Plastic is not suitable for creating a turtle jaw.

Metal 3D printing, on the other hand, allows you to create stronger and more precise parts with small elements. Developers have worked long and hard to create a 3D printer capable of printing metal of the proper quality. Now metal clay is used for this, consisting of a mixture of metal shavings, an organic binder and water (the last two components burn out during firing, due to which, in fact, a solid metal object is obtained).

Two in one: a masterpiece of architecture and an artificial house for a hermit crab

Hermit crabs use the empty shells of various mollusks as shelter and regularly change them - either when they grow out of an old shell, or when a stronger and more aggressive competitor kicks the occupant out of the house he occupied. The population of these animals directly depends on the availability of a sufficient number of shells of suitable shapes and sizes nearby. Some hermit crabs don't even molt until they find a new home.

The population of these animals directly depends on the availability of a sufficient number of shells of suitable shapes and sizes nearby. Some hermit crabs don't even molt until they find a new home.

Japanese designer Aki Inomata decided to combine art and caring for hermit crabs. Having carefully studied the structure of their favorite shells, Inomata began to print unique houses, identical to the clam shell from the inside. Well, from the outside they look like crystal buildings: cities, mills, churches and famous masterpieces of architecture. Cancers seem to appreciate her concern.

Toucan beak

A group of teenagers in Costa Rica attacked a young toucan. The bird survived the attack but lost the top of its beak. Unfortunately, the injury meant only a slow, painful death for her: without a beak, toucans are not able to forage and eat. The beak is also involved in heat exchange processes. In addition, the female toucan chooses her mate based on the color of her partner's beak, so this injury would prevent the victim of child aggression from reproducing.

The beak is also involved in heat exchange processes. In addition, the female toucan chooses her mate based on the color of her partner's beak, so this injury would prevent the victim of child aggression from reproducing.

Activists launched a fundraising campaign to help the bird and made a new beak with the money raised. The required amount - about $ 5,000 - was collected in less than 48 hours.

A similar story happened to another toucan named Tieta. The bird was rescued from an illegal poultry market in Brazil. The female toucan has lost the top of her beak. Most likely, she was injured by smugglers. Experts from three Brazilian universities worked together for three months to design and 3D print a special prosthesis for Tieta. Now the toucan can eat on its own.

Drake's foot

A duckling named Buttercup was born and lived with a defective foot turned backwards. The situation changed for the better when a young drake ended up in a shelter for abandoned geese and ducks Feathered Angels. Here, veterinarians advised to remove the flawed foot, and the founder of the shelter turned to NovaCopy, a 3D printing company, for help.

The situation changed for the better when a young drake ended up in a shelter for abandoned geese and ducks Feathered Angels. Here, veterinarians advised to remove the flawed foot, and the founder of the shelter turned to NovaCopy, a 3D printing company, for help.

After scanning the left paw of Buttercup's friend, Minnie the duck, NovaCopy specialists made a prosthesis for a drake, followed by several more copies, including a festive New Year's version and a special prosthesis for swimming. By the way, Dandelion has now become a Facebook star and a symbol of the Feathered Angels shelter.

Tibia for a cat

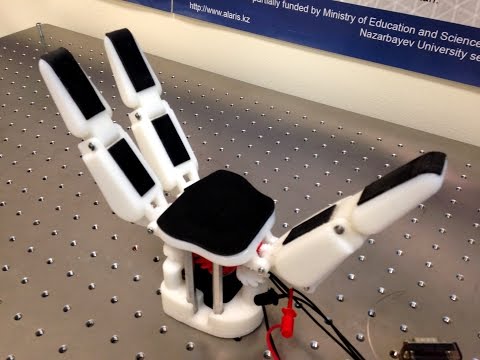

Vincent the cat was born without tibia, that is, he could not walk. He got new "bionic" paws thanks to Dr. Merry Berg, an employee of the State University of Iowa.

Merry couldn't figure out how to help Vincent for a long time until she got colleagues from Biomedtrix involved in the project. As a result of the joint work, titanium prostheses were created and printed. Conventional prostheses are extensions of a limb, but Vincent had no hind legs at all, so the printed parts were implanted directly into the cat's bones so that the bone could later grow around the metal base. According to the treatment plan, gradually the prostheses will be made longer and longer until they are equal to the front paws. Now the cat is more than three years old, and he is doing well.

Vincent's experiment with titanium prostheses is considered unique, and the experience will be very useful in the treatment of animals suffering from similar diseases.

Wheels for disabled dogs

Chihuahua TurboRu's touching story changed the life of not one dog, but many animals at once. Like many other dogs, this puppy was born with underdeveloped front paws. The owners did not dare to euthanize the baby: they made several home-made devices on wheels that support his chest and help the puppy move around. They posted their research on the Web, and the TurboRu story caused a great resonance.

Among the sympathizers were representatives of the 3dyn company, who made a special gift for the dog - a special cart on wheels. TurboRu quickly got used to the new device and now runs along the street on a par with his peers.

TurboRu was one of the first puppies to get 3D printed wheels, but not the last. Similar devices are now being created for many disabled dogs. One such lucky person was Narcissus, who was found as a puppy in a box in the middle of the street. The owners wanted to get rid of the dog with underdeveloped forepaws and simply threw it away.

Similar devices are now being created for many disabled dogs. One such lucky person was Narcissus, who was found as a puppy in a box in the middle of the street. The owners wanted to get rid of the dog with underdeveloped forepaws and simply threw it away.

A passer-by took pity and adopted the puppy, and then turned to the SFSPCA charity organization, where specialists made special wheels for little Narcissus. In the video below, you can see how the first acquaintance of the puppy with this device went.

Every year 3D printing becomes more and more accessible, and although 3D printers are unlikely to appear in every home, we do not have to go far to print a toy or even a paw for a pet - it will be enough just to download model from the Internet and walk to the nearest workshop. By then, these technologies will become even more interesting, gain even more possibilities - and who knows what else we will be able to print on such printers.

By then, these technologies will become even more interesting, gain even more possibilities - and who knows what else we will be able to print on such printers.

A 3D printer has created unique prostheses for a disabled dog that take into account the individual features of the structure of the paws - FEA.RU | CompMechLab

A new publication on the website of the leading company in the 3D printing market 3 D Systems (USA) tells the story of a Derby dog whose life was changed thanks to additive technologies. The dog was born with a disability - because of the severely deformed front paws, she could not walk.

Specially for Derby in 3 D Systems were developed and printed on the industrial machine ProJet 5500X individual prostheses with which the animal can run and play with other dogs.

“If it wasn't for additive manufacturing, all of this would have been out of reach for Derby. Products such as her prostheses can today be created with an extremely high degree of precision and without additional processing, and it will take only a few hours, ”says the website 3 D Systems .

“A three-dimensional model of the prosthesis, taking into account the structural features of the paws of the dog, was built using computed tomography. It took much less time than working with casts, when the model has to be remade several times,” commented animal prosthesis specialist Derrick Campana .

|

|

|

The unusual curved shape of the prostheses was chosen from several options. They decided to abandon the model imitating ordinary paws due to safety reasons: when the dog moves on soft surfaces, for example, on the lawn, “straight” artificial paws, unlike rounded prostheses, could get stuck.

They decided to abandon the model imitating ordinary paws due to safety reasons: when the dog moves on soft surfaces, for example, on the lawn, “straight” artificial paws, unlike rounded prostheses, could get stuck.

This is not the first time additive technologies have helped animals, according to the 3D Printer World website. Using a 3D printer, the beak of Beauty, a female bald eagle rescued by biologist Jane Fink Cantwell (USA), was restored.

Among the most famous projects for 3D printing of polyamide prostheses can be noted Robohand by Richard van As (South Africa). The project has already helped hundreds of people, including children born with amniotic constriction syndrome (absence of fingers), as well as Van As himself. In 2011, he lost the fingers on his right hand while working on the machine, after which, after learning about the cost of the prosthesis, he decided to try to make it himself. On the Web, Richard found a video demonstrating a functioning mechanical arm created by engineer Ivan Owen (USA). Van As and Ivan Owen began a collaboration, and as a result of joint work, Robohand and Robofinger are functional and inexpensive mechanical prostheses, the parts for which are quickly printed on 3D printers. The authors of the project post drawings and instructions for manufacturing on the Internet.

Van As and Ivan Owen began a collaboration, and as a result of joint work, Robohand and Robofinger are functional and inexpensive mechanical prostheses, the parts for which are quickly printed on 3D printers. The authors of the project post drawings and instructions for manufacturing on the Internet.

Example Robohand inspired the team of the Russian company Can Touch , which specializes in industrial 3D printing. In collaboration with engineers W . E . A . S . Robotics (Russia) they started to create inexpensive prostheses for children.

Photo: can-touch.ru

According to the measurements taken from the child's hand, a model is made, then on an industrial printer 3 D -printer EOS Formiga P 100 Selective laser sintering (SLS) technology prints all the necessary details. The final assembly of the prosthesis takes place on the arm using medical thermoplastic.

The material was prepared on the basis of publications on the sites: 3dsystems.com, makerbot.com, can-touch.ru, robohand.net, 3D Printer World.

The latest materials on additive technologies on the website FEA.ru:

2014.12.19. A 3D printer has created unique prostheses for a disabled dog that take into account the individual features of the structure of the paws

whose life has changed thanks to additive technologies. The dog was born with a disability - because of the severely deformed front paws, she cannot walk on her own. Special for Derby at 3D Systems custom prostheses have been designed and printed on an industrial 3D printer that allow the dog to run and play.

Special for Derby at 3D Systems custom prostheses have been designed and printed on an industrial 3D printer that allow the dog to run and play.

2014.12.09. 3D Systems Demonstrates New High-Speed, Fab-Grade 3D Printer

Leading Additive Technology Company - 3D Systems is preparing to release a new system Continuous High-Speed, Fab-Grade 3D Printer , which will allow you to create products approximately 50 times faster than other industrial inkjet 3D printers.

2014.12.08.

Frankfurt EuroMold 2014 Showcases Advances in Additive Manufacturing

Frankfurt hosted the EuroMold 2014 Industrial Show, one of the world's largest annual events showcasing modern manufacturing technologies, both traditional and additive (3D printing technologies) . The forum brought together leading representatives of the automotive, machine-building, electronic, medical, aerospace, telecommunications industries, as well as companies developing software systems for computer engineering.

2014.11.30.

Altair Engineering , Inc ., and its subsidiary SOLIDTHINKING , Inc ., presented solutions for innovative design and additive manufacturing at the international industrial exhibition EuroMold-2014 . The use of additive technologies makes it possible to create highly complex structures, the production of which was previously impossible by traditional methods or required huge efforts and significant financial costs.

2014.10.11. The potential for the development of advanced manufacturing technologies (Advanced Manufacturing Technology) was discussed at SPbPU by the heads of OBORONPROM, the United Engine Corporation (UEC) and the Center for Strategic Research "North-West"

Seminar "Prospects for the development of advanced manufacturing technologies at SPbPU and the feasibility of creating an Institute / School of Advanced Manufacturing Technologies (PPT, Advanced Manufacturing Technologies)" -Zapad”, and SPbPU became its organizer.

Learn more