3D printer overview

3D Printing | An Overview of 3D Printing Technologies

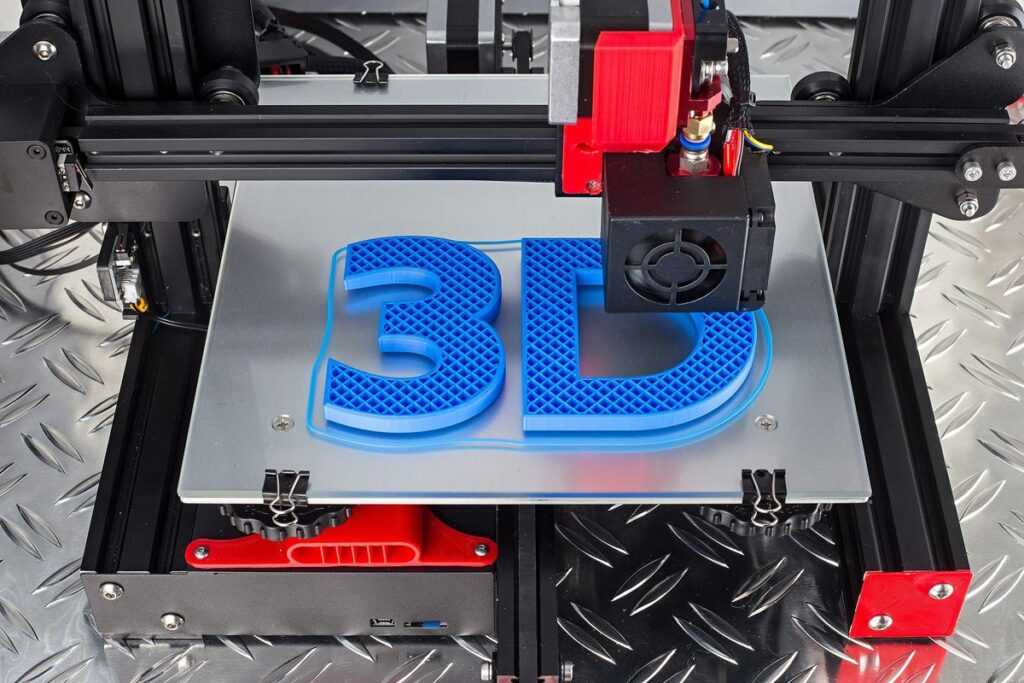

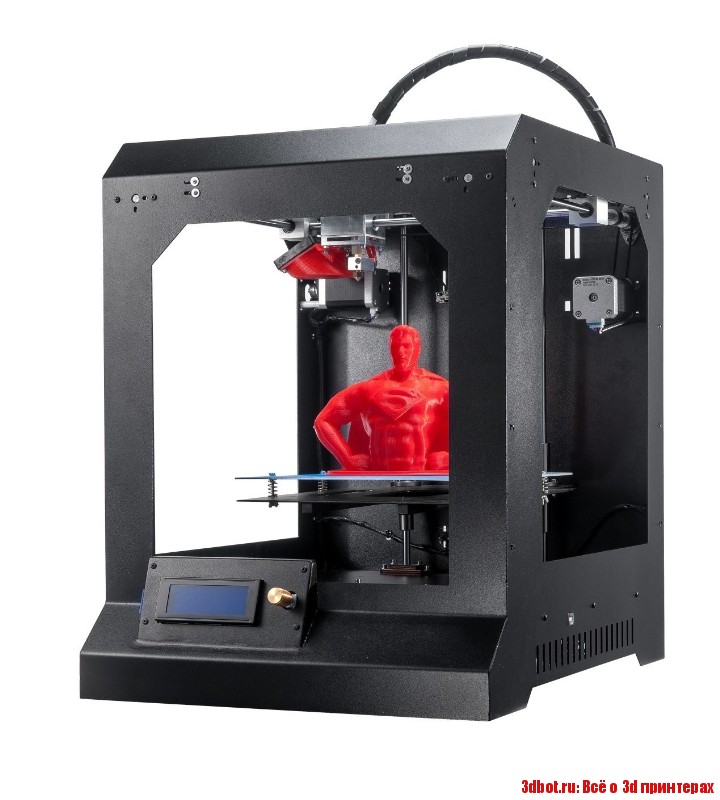

3D printing is sometimes referred to as Additive Manufacturing (AM). In 3D printing, one creates a design of an object using software, and the 3D printer creates the object by adding layer upon layer of material until the shape of the object is formed. The object can be made using a number of printing materials, including plastics, powders, filaments and paper.

There are a number of 3D printing technologies, and this article provides an overview of those technologies.

Stereolithography (SLA)

Stereolithography makes use of a liquid plastic as the source material and this liquid plastic is transformed into a 3D object layer by layer1. Liquid resin is placed in a vat that has a transparent bottom. A UV (UltraViolet) laser traces a pattern on the liquid resin from the bottom of the vat to cure and solidify a layer of the resin. The solidified structure is progressively dragged up by a lifting platform while the laser forms a different pattern for each layer to create the desired shape of the 3D object3.

Schematic representation of Stereolithography: a light-emitting device a) (a laser or DLP) selectively illuminates the transparent bottom c) of a tank b) filled with a liquid photo-polymerizing resin. The solidified resin d) is progressively dragged up by a lifting platform e)

Source: https://en.wikipedia.org/wiki/Stereolithography

Digital Light Processing (DLP)

3D printing DLP technology is very similar to Stereolithography but differs in that it uses a different light source and makes use of a liquid crystal display panel1. This technology makes use of more conventional light sources and the light is controlled using micro mirrors to control the light incident on the surface of the object being printed. The liquid crystal display panel works as a photomask. This mechanism allows for a large amount of light to be projected onto the surface to be cured, thereby allowing the resin to harden quickly1.

Fused Deposition Modeling (FDM)

With this technology, objects can be built with production-grade thermoplastics1. Objects are built by heating a thermoplastic filament to its melting point and extruding the thermoplastic layer by layer. Special techniques can be used to create complex structures. For example, the printer can extrude a second material that will serve as support material for the object being formed during the printing process1. This support material can later be removed or dissolved.

Objects are built by heating a thermoplastic filament to its melting point and extruding the thermoplastic layer by layer. Special techniques can be used to create complex structures. For example, the printer can extrude a second material that will serve as support material for the object being formed during the printing process1. This support material can later be removed or dissolved.

Fused deposition modelling: 1-Nozzle ejecting molten material, 2-Deposited material (modeled part), 3-Controlled movable table

Source: https://en.wikipedia.org/wiki/Fused_deposition_modeling

Selective Laser Sintering (SLS)

SLS has some similarities with Stereolithography. However, SLS makes use of powdered material that is placed in a vat. For each layer, a layer of powdered material is placed on top of the previous layer using a roller and then the powdered material is laser sintered according to a certain pattern for building up the object to be created. Interestingly, the portion of the powdered material that is not sintered can be used to provide the support structure and this material can be removed after the object is formed for re-use1.

Interestingly, the portion of the powdered material that is not sintered can be used to provide the support structure and this material can be removed after the object is formed for re-use1.

Selective Laser Sintering Process

Selective Laser Melting (SLM)

The SLM process is very similar to the SLS process. However, unlike the SLS process where the powdered material is sintered the SLM process involves fully melting the powdered material1.

Electronic Beam Melting (EBM)

This technology is also much like SLM. However, it makes use of an electron beam instead of a high-powered laser1. The electron beam fully melts a metal powder to form the desired object. The process is slower and more expensive than for SLM with a greater limitation on the available materials.

Laminated Object Manufacturing (LOM)

This is a rapid prototyping system. In this process, layers of material coated with adhesive are fused together with heat and pressure and then cut into shape using a laser cutter or knife1,2. More specifically, a foil coated with adhesive is overlaid on the previous layer and a heated roller heats the adhesive for adhesion between the two layers. Layers can be made of paper, plastic or metal laminates1. The process can include post-processing steps that include machining and drilling. This is a fast and inexpensive method of 3D printing1. With the use of an adhesion process, no chemical process is necessary and relatively large parts can be made2.

More specifically, a foil coated with adhesive is overlaid on the previous layer and a heated roller heats the adhesive for adhesion between the two layers. Layers can be made of paper, plastic or metal laminates1. The process can include post-processing steps that include machining and drilling. This is a fast and inexpensive method of 3D printing1. With the use of an adhesion process, no chemical process is necessary and relatively large parts can be made2.

Laminated Object Manufacturing

Source: http://www.livescience.com/40310-laminated-object-manufacturing.html

References Used:

- http://3dprintingfromscratch.com/common/types-of-3d-printers-or-3d-printing-technologies-overview/

- https://en.wikipedia.org/wiki/Laminated_object_manufacturing

- https://en.wikipedia.org/wiki/Stereolithography

What is 3D printing? How does a 3D printer work? Learn 3D printing

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file.

The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the object is created. Each of these layers can be seen as a thinly sliced cross-section of the object.

3D printing is the opposite of subtractive manufacturing which is cutting out / hollowing out a piece of metal or plastic with for instance a milling machine.

3D printing enables you to produce complex shapes using less material than traditional manufacturing methods.

Table of Contents

- How Does 3D Printing Work?

- 3D Printing Industry

- Examples of 3D Printing

- 3D Printing Technologies & Processes

- Materials

- Services

Jump to your field of interest:

- Rapid Prototyping & Manufacturing

- Automotive

- Aviation

- Construction

- Consumer Products

- Healthcare

- Food

- Education

Jump to process:

- All Technologies & Processes

- Vat Photopolymerisation

- Material Jetting

- Binder Jetting

- Material Extrusion

- Powder Bed Fusion

- Sheet Lamination

- Directed Energy Deposition

How Does 3D Printing Work?

It all starts with a 3D model. You can opt to create one from the ground up or download it from a 3D library.

You can opt to create one from the ground up or download it from a 3D library.

3D Software

There are many different software tools available. From industrial grade to open source. We’ve created an overview on our 3D software page.

We often recommend beginners to start with Tinkercad. Tinkercad is free and works in your browser, you don’t have to install it on your computer. Tinkercad offers beginner lessons and has a built-in feature to export your model as a printable file e.g .STL or .OBJ.

Now that you have a printable file, the next step is to prepare it for your 3D printer. This is called slicing.

Slicing: From printable file to 3D Printer

Slicing basically means slicing up a 3D model into hundreds or thousands of layers and is done with slicing software.

When your file is sliced, it’s ready for your 3D printer. Feeding the file to your printer can be done via USB, SD or Wi-Fi. Your sliced file is now ready to be 3D printed layer by layer.

3D Printing Industry

Adoption of 3D printing has reached critical mass as those who have yet to integrate additive manufacturing somewhere in their supply chain are now part of an ever-shrinking minority. Where 3D printing was only suitable for prototyping and one-off manufacturing in the early stages, it is now rapidly transforming into a production technology.

Most of the current demand for 3D printing is industrial in nature. Acumen Research and Consulting forecasts the global 3D printing market to reach $41 billion by 2026.

As it evolves, 3D printing technology is destined to transform almost every major industry and change the way we live, work, and play in the future.

Examples of 3D Printing

3D printing encompasses many forms of technologies and materials as 3D printing is being used in almost all industries you could think of. It’s important to see it as a cluster of diverse industries with a myriad of different applications.

A few examples:

- – consumer products (eyewear, footwear, design, furniture)

- – industrial products (manufacturing tools, prototypes, functional end-use parts)

- – dental products

- – prosthetics

- – architectural scale models & maquettes

- – reconstructing fossils

- – replicating ancient artefacts

- – reconstructing evidence in forensic pathology

- – movie props

Rapid Prototyping & Rapid Manufacturing

Companies have used 3D printers in their design process to create prototypes since the late seventies. Using 3D printers for these purposes is called rapid prototyping.

Using 3D printers for these purposes is called rapid prototyping.

Why use 3D Printers for Rapid Prototyping?

In short: it’s fast and relatively cheap. From idea, to 3D model to holding a prototype in your hands is a matter of days instead of weeks. Iterations are easier and cheaper to make and you don’t need expensive molds or tools.

Besides rapid prototyping, 3D printing is also used for rapid manufacturing. Rapid manufacturing is a new method of manufacturing where businesses use 3D printers for short run / small batch custom manufacturing.

Automotive

Car manufacturers have been utilizing 3D printing for a long time. Automotive companies are printing spare parts, tools, jigs and fixtures but also end-use parts. 3D printing has enabled on-demand manufacturing which has lead to lower stock levels and has shortened design and production cycles.

Automotive enthusiasts all over the world are using 3D printed parts to restore old cars. One such example is when Australian engineers printed parts to bring a Delage Type-C back to life. In doing so, they had to print parts that were out of production for decades.

One such example is when Australian engineers printed parts to bring a Delage Type-C back to life. In doing so, they had to print parts that were out of production for decades.

Aviation

The aviation industry uses 3D printing in many different ways. The following example marks a significant 3D printing manufacturing milestone: GE Aviation has 3D printed 30,000 Cobalt-chrome fuel nozzles for its LEAP aircraft engines. They achieved that milestone in October of 2018, and considering that they produce 600 per week on forty 3D printers, it’s likely much higher than that now.

Around twenty individual parts that previously had to be welded together were consolidated into one 3D printed component that weighs 25% less and is five times stronger. The LEAP engine is the best selling engine in the aerospace industry due to its high level of efficiency and GE saves $3 million per aircraft by 3D printing the fuel nozzles, so this single 3D printed part generates hundreds of millions of dollars of financial benefit.

GE’s fuel nozzles also made their way into the Boeing 787 Dreamliner, but it’s not the only 3D printed part in the 787. The 33-centimeter-long structural fittings that hold the aft kitchen galley to the airframe are 3D printed by a company called Norsk Titanium. Norsk chose to specialize in titanium because it has a very high strength-to-weight ratio and is rather expensive, meaning the reduction in waste enabled by 3D printing has a more significant financial impact than compared to cheaper metals where the costs of material waste are easier to absorb. Rather than sintering metal powder with a laser like most metal 3D printers, the Norsk Merke 4 uses a plasma arc to melt a metal wire in a process called Rapid Plasma Deposition (a form of Directed Energy Deposition) that can deposit up to 10kg of titanium per hour. A 2kg titanium part would generally require a 30kg block of titanium to machine it from, generating 28kg of waste, but 3D printing the same part requires only 6kg of titanium wire.

A 2kg titanium part would generally require a 30kg block of titanium to machine it from, generating 28kg of waste, but 3D printing the same part requires only 6kg of titanium wire.

Construction

Is it possible to print a building? – yes it is. 3D printed houses are already commercially available. Some companies print parts prefab and others do it on-site.

Most of the concrete printing stories we look at on this website are focused on large scale concrete printing systems with fairly large nozzles for a large flow rate. It’s great for laying down concrete layers in a fairly quick and repeatable manner. But for truly intricate concrete work that makes full use of the capabilities of 3D printing requires something a little more nimble, and with a finer touch.

Consumer Products

When we first started blogging about 3D printing back in 2011, 3D printing wasn’t ready to be used as a production method for large volumes. Nowadays there are numerous examples of end-use 3D printed consumer products.

Footwear

Adidas’ 4D range has a fully 3D printed midsole and is being printed in large volumes. We did an article back then, explaining how Adidas were initially releasing just 5,000 pairs of the shoes to the public, and had aimed to sell 100,000 pairs of the AM-infused designs by 2018.

With their latest iterations of the shoe, it seems that they have surpassed that goal, or are on their way to surpassing it. The shoes are available all around the world from local Adidas stores and also from various 3rd party online outlets.

Eyewear

The market of 3D printed eyewear is forecasted to reach $3.4 billion by 2028. A rapidly increasing section is that of end-use frames. 3D printing is a particularly suitable production method for eyewear frames because the measurements of an individual are easy to process in the end product.

But did you know it’s also possible to 3D print lenses? Traditional glass lenses don’t start out thin and light; they’re cut from a much larger block of material called a blank, about 80% of which goes to waste. When we consider how many people wear glasses and how often they need to get a new pair, 80% of those numbers is a lot of waste. On top of that, labs have to keep huge inventories of blanks to meet the custom vision needs of their clients. Finally, however, 3D printing technology has advanced enough to provide high-quality, custom ophthalmic lenses, doing away with the waste and inventory costs of the past. The Luxexcel VisionEngine 3D printer uses a UV-curable acrylate monomer to print two pairs of lenses per hour that require no polishing or post-processing of any kind. The focal areas can also be completely customized so that a certain area of the lens can provide better clarity at a distance while a different area of the lens provides better vision up close.

When we consider how many people wear glasses and how often they need to get a new pair, 80% of those numbers is a lot of waste. On top of that, labs have to keep huge inventories of blanks to meet the custom vision needs of their clients. Finally, however, 3D printing technology has advanced enough to provide high-quality, custom ophthalmic lenses, doing away with the waste and inventory costs of the past. The Luxexcel VisionEngine 3D printer uses a UV-curable acrylate monomer to print two pairs of lenses per hour that require no polishing or post-processing of any kind. The focal areas can also be completely customized so that a certain area of the lens can provide better clarity at a distance while a different area of the lens provides better vision up close.

Jewelry

There are two ways of producing jewelry with a 3D printer. You can either use a direct or indirect production process. Direct refers to the creation of an object straight from the 3D design while indirect manufacturing means that the object (pattern) that is 3D printed eventually is used to create a mold for investment casting.

Healthcare

It’s not uncommon these days to see headlines about 3D printed implants. Often, those cases are experimental, which can make it seem like 3D printing is still a fringe technology in the medical and healthcare sectors, but that’s not the case anymore. Over the last decade, more than 100,000 hip replacements have been 3D printed by GE Additive.

The Delta-TT Cup designed by Dr. Guido Grappiolo and LimaCorporate is made of Trabecular Titanium, which is characterized by a regular, three-dimensional, hexagonal cell structure that imitates trabecular bone morphology. The trabecular structure increases the biocompatibility of the titanium by encouraging bone growth into the implant. Some of the first Delta-TT implants are still running strong over a decade later.

Another 3D printed healthcare component that does a good job of being undetectable is the hearing aid. Nearly every hearing aid in the last 17 years has been 3D printed thanks to a collaboration between Materialise and Phonak. Phonak developed Rapid Shell Modeling (RSM) in 2001. Prior to RSM, making one hearing aid required nine laborious steps involving hand sculpting and mold making, and the results were often ill-fitting. With RSM, a technician uses silicone to take an impression of the ear canal, that impression is 3D scanned, and after some minor tweaking the model is 3D printed with a resin 3D printer. The electronics are added and then it’s shipped to the user. Using this process, hundreds of thousands of hearing aids are 3D printed each year.

Phonak developed Rapid Shell Modeling (RSM) in 2001. Prior to RSM, making one hearing aid required nine laborious steps involving hand sculpting and mold making, and the results were often ill-fitting. With RSM, a technician uses silicone to take an impression of the ear canal, that impression is 3D scanned, and after some minor tweaking the model is 3D printed with a resin 3D printer. The electronics are added and then it’s shipped to the user. Using this process, hundreds of thousands of hearing aids are 3D printed each year.

Dental

In the dental industry, we see molds for clear aligners being possibly the most 3D printed objects in the world. Currently, the molds are 3D printed with both resin and powder based 3D printing processes, but also via material jetting. Crowns and dentures are already directly 3D printed, along with surgical guides.

Bio-printing

As of the early two-thousands 3D printing technology has been studied by biotech firms and academia for possible use in tissue engineering applications where organs and body parts are built using inkjet techniques. Layers of living cells are deposited onto a gel medium and slowly built up to form three dimensional structures. We refer to this field of research with the term: bio-printing.

Layers of living cells are deposited onto a gel medium and slowly built up to form three dimensional structures. We refer to this field of research with the term: bio-printing.

Food

Additive manufacturing invaded the food industry long time ago. Restaurants like Food Ink and Melisse use this as a unique selling point to attract customers from across the world.

Education

Educators and students have long been using 3D printers in the classroom. 3D printing enables students to materialize their ideas in a fast and affordable way.

While additive manufacturing-specific degrees are fairly new, universities have long been using 3D printers in other disciplines. There are many educational courses one can take to engage with 3D printing. Universities offer courses on things that are adjacent to 3D printing like CAD and 3D design, which can be applied to 3D printing at a certain stage.

In terms of prototyping, many university programs are turning to printers. There are specializations in additive manufacturing one can attain through architecture or industrial design degrees. Printed prototypes are also very common in the arts, animation and fashion studies as well.

There are specializations in additive manufacturing one can attain through architecture or industrial design degrees. Printed prototypes are also very common in the arts, animation and fashion studies as well.

Types of 3D Printing Technologies and Processes

The American Society for Testing and Materials (ASTM), developed a set of standards that classify additive manufacturing processes into 7 categories. These are:

- Vat Photopolymerisation

- Stereolithography (SLA)

- Digital Light Processing (DLP)

- Continuous Liquid Interface Production (CLIP)

- Material Jetting

- Binder Jetting

- Material Extrusion

- Fused Deposition Modeling (FDM)

- Fused Filament Fabrication (FFF)

- Powder Bed Fusion

- Multi Jet Fusion (MJF)

- Selective Laser Sintering (SLS)

- Direct Metal Laser Sintering (DMLS)

- Sheet Lamination

- Directed Energy Deposition

Vat Photopolymerisation

A 3D printer based on the Vat Photopolymerisation method has a container filled with photopolymer resin. The resin is hardened with a UV light source.

The resin is hardened with a UV light source.

Stereolithography (SLA)

SLA was invented in 1986 by Charles Hull, who also at the time founded the company, 3D Systems. Stereolithography employs a vat of liquid curable photopolymer resin and an ultraviolet laser to build the object’s layers one at a time. For each layer, the laser beam traces a cross-section of the part pattern on the surface of the liquid resin. Exposure to the ultraviolet laser light cures and solidifies the pattern traced on the resin and fuses it to the layer below.

After the pattern has been traced, the SLA’s elevator platform descends by a distance equal to the thickness of a single layer, typically 0.05 mm to 0.15 mm (0.002″ to 0.006″). Then, a resin-filled blade sweeps across the cross section of the part, re-coating it with fresh material. On this new liquid surface, the subsequent layer pattern is traced, joining the previous layer. Depending on the object & print orientation, SLA often requires the use of support structures.

Digital Light Processing (DLP)

DLP or Digital Light Processing refers to a method of printing that makes use of light and photosensitive polymers. While it is very similar to SLA, the key difference is the light source. DLP utilizes other light sources like arc lamps. DLP is relatively quick compared to other 3D printing technologies.

Continuous Liquid Interface Production (CLIP)

One of the fastest processes using Vat Photopolymerisation is called CLIP, short for Continuous Liquid Interface Production, developed by Carbon.

Digital Light Synthesis

The heart of the CLIP process is Digital Light Synthesis technology. In this technology, light from a custom high performance LED light engine projects a sequence of UV images exposing a cross section of the 3D printed part causing the UV curable resin to partially cure in a precisely controlled way. Oxygen passes through the oxygen permeable window creating a thin liquid interface of uncured resin between the window and the printed part known as the dead zone. The dead zone is as thin as ten of microns. Inside the dead zone, oxygen prohibits light from curing the resin situated closest to the window therefore allowing the continuous flow of liquid beneath the printed part. Just above the dead zone the UV projected light upwards causes a cascade like curing of the part.

Oxygen passes through the oxygen permeable window creating a thin liquid interface of uncured resin between the window and the printed part known as the dead zone. The dead zone is as thin as ten of microns. Inside the dead zone, oxygen prohibits light from curing the resin situated closest to the window therefore allowing the continuous flow of liquid beneath the printed part. Just above the dead zone the UV projected light upwards causes a cascade like curing of the part.

Simply printing with Carbon’s hardware alone does not allow for end use properties with real world applications. Once the light has shaped the part, a second programmable curing process achieves the desired mechanical properties by baking the 3d printed part in a thermal bath or oven. Programmed thermal curing sets the mechanical properties by triggering a secondary chemical reaction causing the material to strengthen achieving the desired final properties.

Components printed with Carbon’s technology are on par with injection molded parts. Digital Light Synthesis produces consistent and predictable mechanical properties, creating parts that are truly isotropic.

Digital Light Synthesis produces consistent and predictable mechanical properties, creating parts that are truly isotropic.

Material Jetting

In this process, material is applied in droplets through a small diameter nozzle, similar to the way a common inkjet paper printer works, but it is applied layer-by-layer to a build platform and then hardened by UV light.

Material Jetting schematics. Image source: custompartnet.comBinder Jetting

With binder jetting two materials are used: powder base material and a liquid binder. In the build chamber, powder is spread in equal layers and binder is applied through jet nozzles that “glue” the powder particles in the required shape. After the print is finished, the remaining powder is cleaned off which often can be re-used printing the next object. This technology was first developed at the Massachusetts Institute of Technology in 1993.

Binder Jetting schematicsMaterial Extrusion

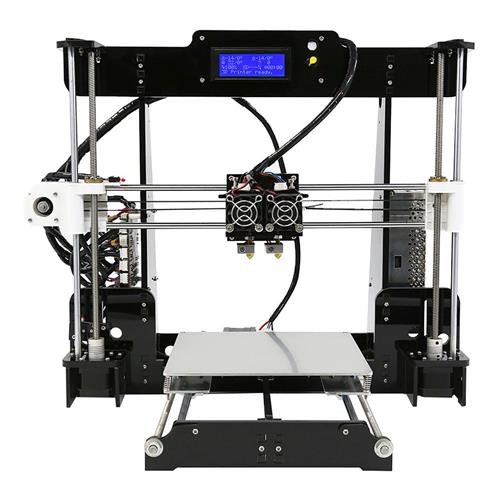

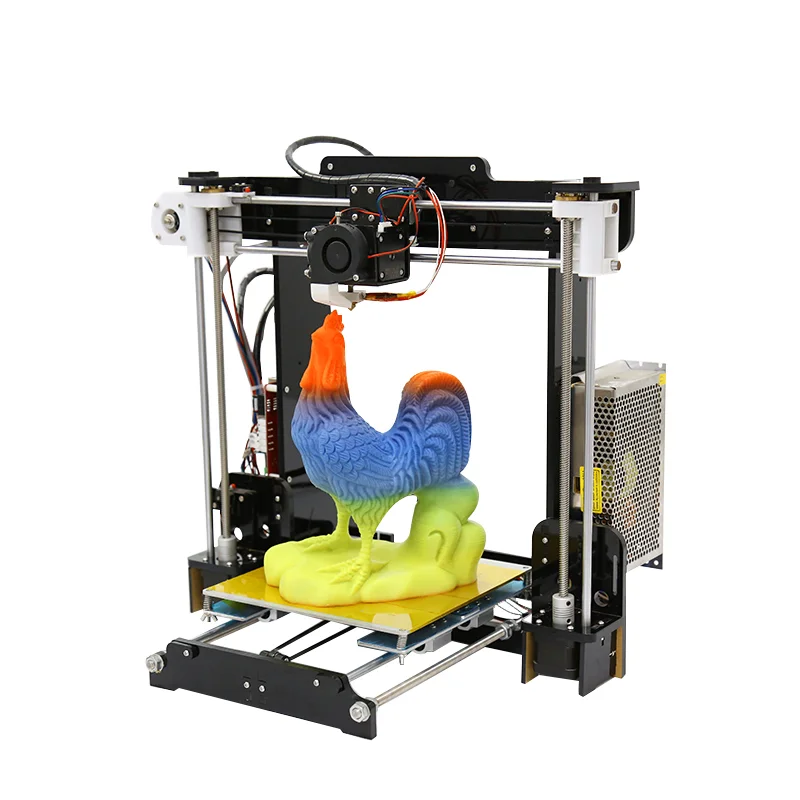

Fused Deposition Modeling (FDM)

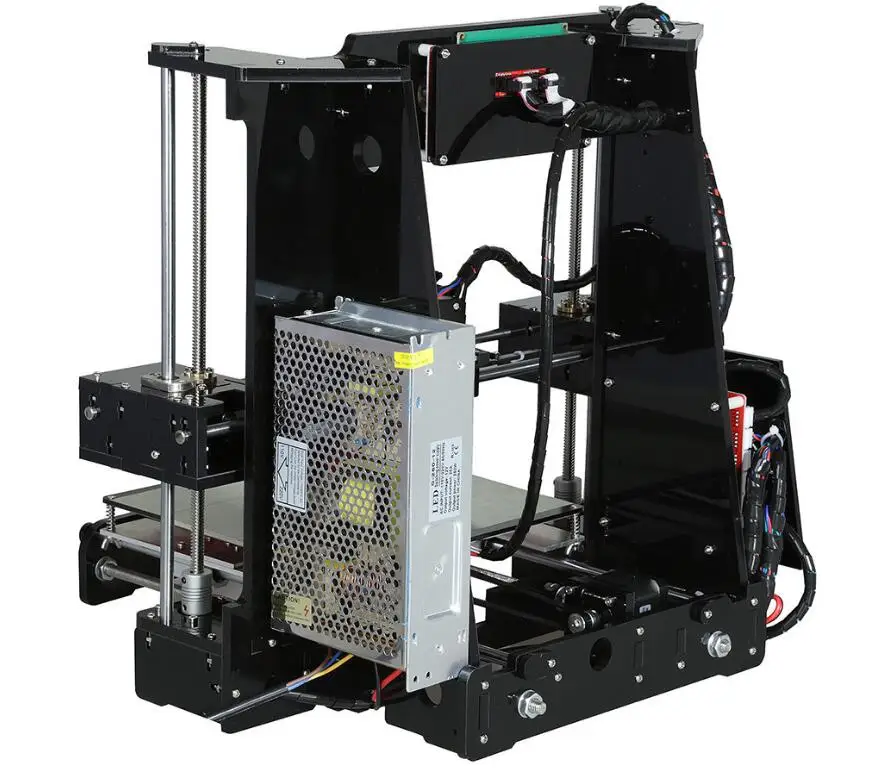

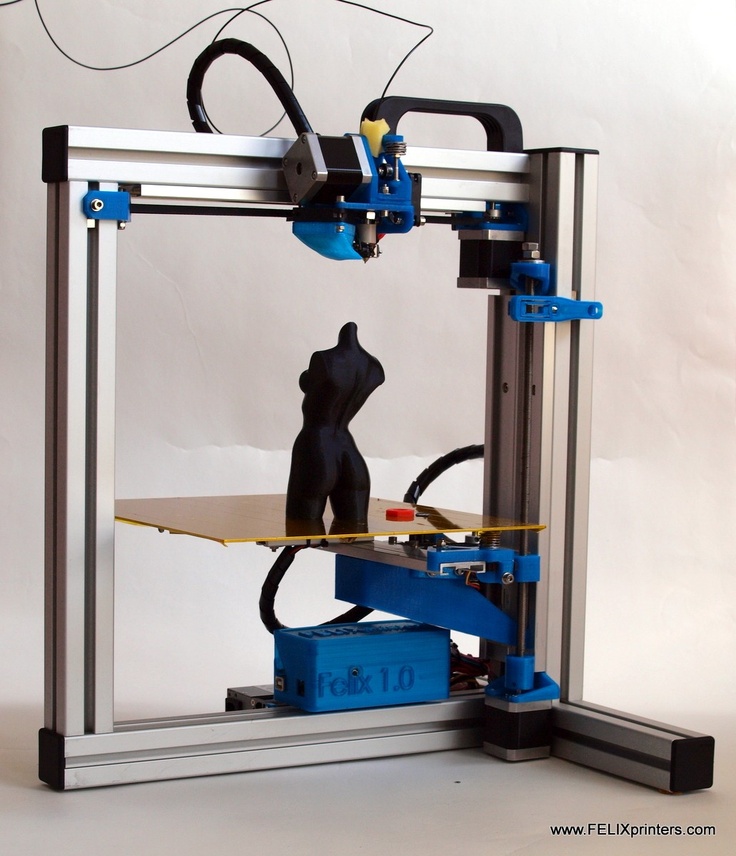

FDM schematics (Image credit: Wikipedia, made by user Zureks)FDM works using a plastic filament which is unwound from a spool and is supplied to an extrusion nozzle which can turn the flow on and off. The nozzle is heated to melt the material and can be moved in both horizontal and vertical directions by a numerically controlled mechanism. The object is produced by extruding melted material to form layers as the material hardens immediately after extrusion from the nozzle.

The nozzle is heated to melt the material and can be moved in both horizontal and vertical directions by a numerically controlled mechanism. The object is produced by extruding melted material to form layers as the material hardens immediately after extrusion from the nozzle.

FDM was invented by Scott Crump in the late 80’s. After patenting this technology he started the company Stratasys in 1988. The term Fused Deposition Modeling and its abbreviation to FDM are trademarked by Stratasys Inc.

Fused Filament Fabrication (FFF)

The exactly equivalent term, Fused Filament Fabrication (FFF), was coined by the members of the RepRap project to give a phrase that would be legally unconstrained in its use.

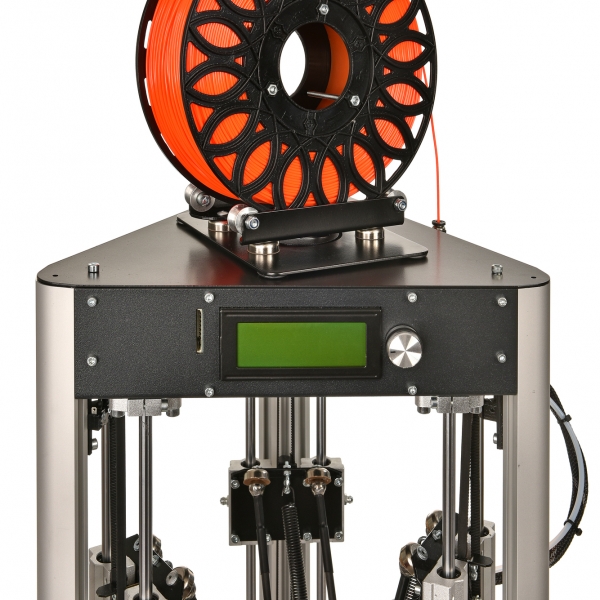

Powder Bed Fusion

Selective Laser Sintering (SLS)

SLS uses a high power laser to fuse small particles of powder into a mass that has the desired three dimensional shape. The laser selectively fuses powder by first scanning the cross-sections (or layers) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness. Then a new layer of material is applied on top and the process is repeated until the object is completed.

After each cross-section is scanned, the powder bed is lowered by one layer thickness. Then a new layer of material is applied on top and the process is repeated until the object is completed.

Multi Jet Fusion (MJF)

Multi Jet Fusion technology was developed by Hewlett Packard and works with a sweeping arm which deposits a layer of powder and then another arm equipped with inkjets which selectively applies a binder agent over the material. The inkjets also deposit a detailing agent around the binder to ensure precise dimensionality and smooth surfaces. Finally, the layer is exposed to a burst of thermal energy that causes the agents to react.

Direct Metal Laser Sintering (DMLS)

DMLS is basically the same as SLS, but uses metal powder instead. All unused powder remains as it is and becomes a support structure for the object. Unused powder can be re-used for the next print.

Due to of increased laser power, DMLS has evolved into a laser melting process. Read more about that and other metal technologies on our metal technologies overview page.

Sheet Lamination

Sheet lamination involves material in sheets which is bound together with external force. Sheets can be metal, paper or a form of polymer. Metal sheets are welded together by ultrasonic welding in layers and then CNC milled into a proper shape. Paper sheets can be used also, but they are glued by adhesive glue and cut in shape by precise blades.

Simplified schematics of ultrasonic sheet metal process (Image credit: Wikipedia from user Mmrjf3)Directed Energy Deposition

This process is mostly used in the metal industry and in rapid manufacturing applications. The 3D printing apparatus is usually attached to a multi-axis robotic arm and consists of a nozzle that deposits metal powder or wire on a surface and an energy source (laser, electron beam or plasma arc) that melts it, forming a solid object.

Materials

Multiple materials can be used in additive manufacturing: plastics, metals, concrete, ceramics, paper and certain edibles (e.g. chocolate). Materials are often produced in wire feedstock a.k.a. filament, powder form or liquid resin. Learn more about our featured materials on our materials page.

Services

Looking to implement 3D printing in your production process? Get a quote for a custom part or order samples on our 3D print service page.

Category "Reviews" - a community of owners of 3D printers 3DToday

Reviews of 3D printers and consumables for them, as well as 3D scanners and programs.

Reviews

2

Subscribe to the author

Subscribe

Don't want

Good afternoon, dear beginners and experienced chpuvods! Yesterday a new worker from China called flying bear ghost 6 came to me. configuration, it is rich enough for the printer, you don’t need to buy anything to start working. The printer is small 377x365x349, perfect for home use, 250 * 210 * 210 print area is completely enough for the fun of a home designer. externally assembled very carefully, wires do not stick out from anywhere,...

configuration, it is rich enough for the printer, you don’t need to buy anything to start working. The printer is small 377x365x349, perfect for home use, 250 * 210 * 210 print area is completely enough for the fun of a home designer. externally assembled very carefully, wires do not stick out from anywhere,...

Read more

Reviews

one

Subscribe to the author

Subscribe

Don't want

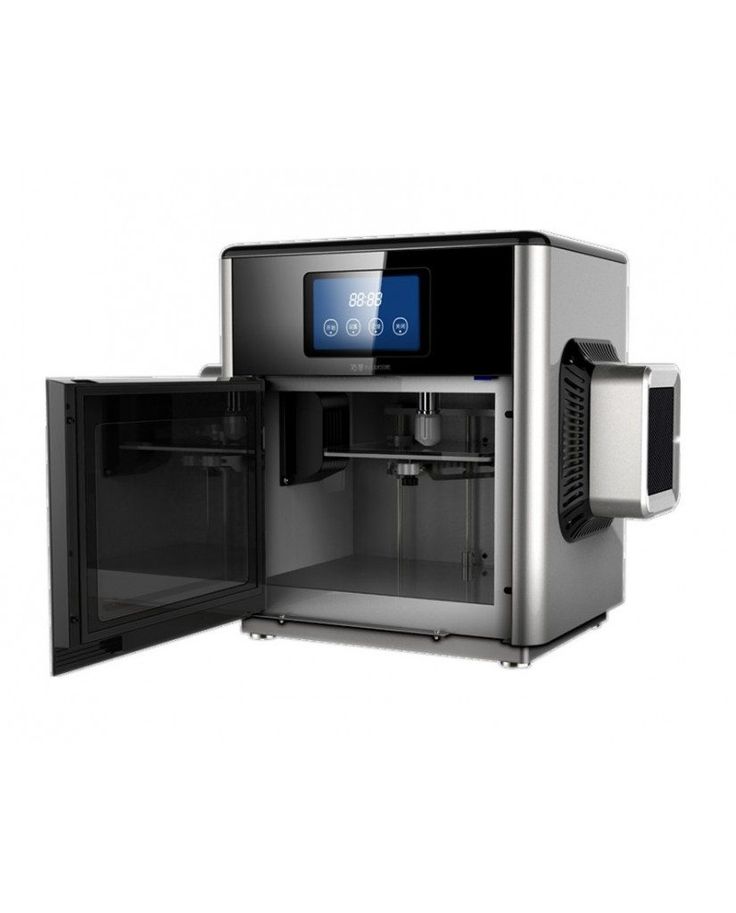

Dreambot 3D printers are reliable high performance devices for professional use. In this article, we will look at the features of Dreambot large-format 3D printers for printing with photopolymer resins and plastics.About the company

Shenzhen Dreambot 3D Technology Co., Ltd is a Chinese high-tech enterprise specialized in the production of industrial 3D printers and large format equipment. The company was founded in 2008 and was first engaged in the production of. ..

..

Read more

Reviews

one

Subscribe to the author

Subscribe

Don't want

Hello, Friends! 3DTool is with you!

The difficult situation in the 3D printing market makes it necessary to select equipment for purchase more carefully, especially when it comes to analogues of devices subject to trade sanctions or discontinued for one reason or another. Speaking of stereolithographic (SLA) 3D printing, we most often remember the unpretentious and high-quality printing Formlabs Form. But what if these devices are no longer available in our market? It's time to look...

Read more

D!al Up

Loading

10/17/2022

3399

Reviews

35

Subscribe to the author

Subscribe

Don't want

Hello everyone. The photo in the header is for those who start talking about the frivolity of my project. I myself know)

The photo in the header is for those who start talking about the frivolity of my project. I myself know)

So, I collected all kinds of different circuit printers, but somehow my hands did not reach the delta. From the experience of reworking the finished delta, there is a Frankenstein, the former Anycubic Kossel in the world, which came out surprisingly well in terms of print quality and accuracy. Of course, after long dances with a tambourine. Here he is, handsome.

If anyone pays attention to the extra engine in the os...

Read more

Reviews

four

Subscribe to the author

Subscribe

Don't want

Good day to all.

Immediately to all readers who want to ask the question: "What does 3d printing have to do with it?". The answer is towards the end of the article. And this is not a banal "because this company produces printers"). Good reading.

Good reading.

In this article, as it has already become clear, we will focus on the Flying Bear Laserman laser engraver. Engraver, from a company well known for making good, quality 3d printers that many people love. I am the owner of Flying Bear Reborn, for which I am...

Read more

Reviews

four

Subscribe to the author

Subscribe

Don't want

This year, Raise3D released the MetalFuse metal 3D printing system, consisting of a Forge1 3D printer, a D200-E catalytic resin removal station, and an S200-C vacuum furnace. We have already published a review of this system, here we would like to share our personal experience of using MetalFuse.

3D printing on a Forge1 printer

Features of the MetalFuse system appear even at the stage of preparing a model for printing. The Forge1 printer works with its own slicer. ..

..

Read more

Reviews

22

Subscribe to the author

Subscribe

Don't want

A long time ago, you can say in another life, I got excited about buying a photopolymer printer. On the one hand, there is a good FDM at home and, in principle, there was no need, but the plane of my interests gradually shifted to printing detailed small things, and the hours of deriving the finished model to perfect smoothness from enthusiasm began to cause nausea, and of course the most offensive is that some small details are simply smoothed out and disappear during processing.

For me, the most “WOW” composition is...

Read more

Reviews

one

Subscribe to the author

Subscribe

Don't want

Hello, Friends! 3DTool is with you!

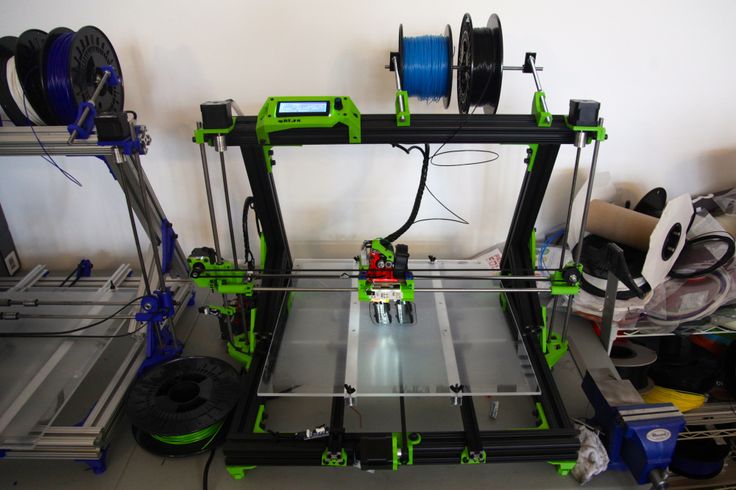

The need for large area 3D printers has been growing in the 3D printing market and consumer demand for years. With an increase in the number of companies using 3D printing in car modifications, the production of large-format blanks for creating master models, the creation of large-scale mock-ups and prototypes, the widespread medium-sized 3D printers no longer cope with the tasks set before them...

With an increase in the number of companies using 3D printing in car modifications, the production of large-format blanks for creating master models, the creation of large-scale mock-ups and prototypes, the widespread medium-sized 3D printers no longer cope with the tasks set before them...

Read more

Reviews

one

Subscribe to the author

Subscribe

Don't want

In this review, we will get acquainted with the new 3D printers of the Chinese manufacturer iFUN, which are designed specifically for dentistry. Read below about what the manufacturer offers to improve print quality and what solutions each of the new products can boast of.About

iFUN entered the 3D printing industry in 2015 and is one of the first additive manufacturing manufacturers. iFUN provides 3D printing solutions to professionals from all over the world in various industries. AT

AT

Read more

Reviews

6

Subscribe author

Subscribe

Don't want

The Anet ET4 Pro is a 3D printer that I definitely wouldn't recommend to beginners. Before he started typing more or less normally, he drank a lot of blood from me (and not figuratively, but really). Table calibration is a pain. Screws loose during printing, firmware failure, limit switches glitch, not very high-quality assembly. All this you get in full, with the purchase of this model. It took me several weeks to get this printer to print more or less tolerably. But I still...

Read more

- 1

- 2

- .

..

.. - 180

What is a 3D printer?

Selpic Star A / 3D printers, machines and accessories / iXBT Live

Today we are going to review a 3D printer from Selpic.

A US based company specializing in the manufacture of various printing devices. At the moment, he has two miniature handheld printers and cartridges for them in his arsenal, as well as the printer that we will talk about today (they are currently running a Kickstarter campaign and pre-order is available for $ 99).

There is a website where you can view and purchase all products. Free international shipping (DHL) is available.

This printer is positioned as the most optimal for beginners due to the ease of assembly and installation, as well as low cost. But it's also open source, allowing advanced users to make modifications.

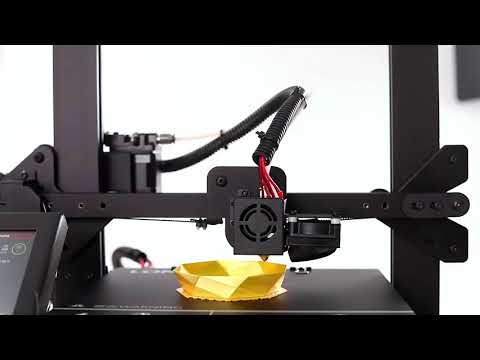

Printer promo video:

The package with the printer is light and small, its weight is just over 3 kilograms.

Packing:

Contents:

Among other things, the kit includes one set of 10 meters of PLA plastic, as well as an 8GB flash drive and a Netac card reader.

To my surprise, there are no instructions in the package, although the main audience of printers is beginners. As it turned out later, the instruction was in electronic form on a USB flash drive, but there is not a word about how to connect and work with the laser head.

Also on the flash drive are drivers, G-codes for two models for printing, and a Cura application installation file for macOS and Windows.

The length of the cable for connecting the printer to the computer is 51 cm, as for me, this is a significant drawback, especially if a person uses a stationary PC and not a laptop.

The length of the power cable is sufficient and is 149cm.

Features:

The features I would also include the presence of a heating platform, a 2.4-inch touch screen and a laser engraving head (1.6 W). It should be noted that these accessories are not included in the basic package and are purchased separately.

It would be nice if the manufacturer provided the ability to choose the power of the laser engraving head. However, it can also be purchased separately on Aliexpress.

However, it can also be purchased separately on Aliexpress.

Comparison with analogues:

Printer assembly steps:

Photos in the assembled state:

Minor manufacturing flaws:

without removing anything).

Bottom view:

The disadvantage is the lack of anti-slip inserts. Not that it slides much on smooth surfaces, but they wouldn't get in the way anyway.

The plastic holder can hold up to 250 grams. The weight of the plastic that comes with the kit is 30 grams. It is worth noting that the holder clings to the printer simply on hooks, that is, without a strong and reliable fixation, and at the slightest movement it walks back and forth and strives to fly off.

After turning on the printer, it must be calibrated, the distance between the nozzle and the desktop in each corner should be minimal (adjustment is done using the wheels in each corner).

Next, load the printing material: you need to click on the “+” and the nozzle will start heating (about 1 minute), after which we push the plastic into the hole until it comes out of the extruder (then click on “+” again to complete the process).

All processes are accompanied by light indicators of control buttons and are described in detail in the instructions.

Printing is set up and started in the Cura application.

Application setting:

Print setting:

Nozzle standby temperature is about 23 degrees. Heating up to 180° occurs in an average of 2.5 minutes.

After the first start of printing, it started to do something like this:

As I understand it, this was due to too small a distance between the nozzle and the working surface. In order for everything to be normal, you need to accurately guess with the optimal distance: so that it is not too tight, but also so that the A4 sheet does not crawl freely.

Noise during operation averages 47dB. The biggest noise comes from the extruder fan.

Printing rocket (height 4 cm) took 1 hour 25 minutes.

The problem was that the bottom of the figurine stuck too strongly to the working surface, so much so that the rocket broke away from it and flew away, and I had to tear it off, melting the plastic with fire and tearing it off with a knife.

Printing of the second figurine (height 5 cm) was made from a memory card (the file must be in the root of the card), it took 3 hours and 35 minutes to print it.

As for the print quality, there are no questions about it, especially the cost of the printer and the fact that it can be used almost immediately from the box.

Print timelapse:

Unfortunately, due to the lack of instructions on how to connect and work with laser engraving, I can not say anything about its operation. If anyone can tell me how to connect it and make it work - I will be grateful!

Results

Summing up, we can say that the idea of a ready-made printer for beginners with advanced features is definitely interesting and promising, but the implementation requires some improvements.

Among the advantages, I would like to note the following: ease of installation and operation, light weight and compact size, large print area and quiet operation, as well as the possibility of various customizations.