3D printer for peek

2022 Guide to PEEK 3D printers (and PEKK, ULTEM/PEI)

Introduction

PEEK, like PEI (ULTEM) and PEKK, is a high-performance polymer (a.k.a. “ultra polymer” and sometimes “super polymer”) that is able to maintain its mechanical properties in challenging environments. Its continuous use temperature (CUT) can go over 250°C, and it is resistant to almost all chemicals except for nitric and sulphuric acids. For decades, this high-performance thermoplastic has been used in demanding industries such as aerospace, oil and gas, and more.

The 3D printing of high-performance polymers like PEEK is, however, a challenge. It requires a high-temperature extruder and a heated chamber – among other tightly monitored elements – above and beyond what standard FFF 3D printers offer. And whereas the PEEK 3D printer market used to be a niche with very few players, today, many manufacturers claim that their printers are suitable for PEEK and PEI 3D printing. Aniwaa’s 3D printer catalog lists over 90 high-temperature 3D printers!

But boasting high-temperature extruders and heated chambers is often not enough. Thus, our goal here is to select high-temperature 3D printers that stand out from the rest, and not only in terms of hardware. We also take into account a range of factors such as manufacturer maturity, feedback from our network, availability, and distribution.

Of course, this doesn’t mean they’re the only ones out there, but they are some of the most reliable solutions for high-performance polymer AM (additive manufacturing). We mention a few cost-effective options and industry-specific machines in separate sections so as to provide a comprehensive overview nonetheless.

We work with a large number of distributors and brands worldwide– contact us for a personalized recommendation based on your project and location.

High-temperature 3D printers 2022: our selection

The table below recaps our selection of some of the best PEEK 3D printer options. The goal is to provide a quick, visual overview of the market; there are of course numerous other factors to take into account (certifications, software, customer service, …) to get the full picture for each solution and eventually make the right choice.

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| INTAMSYS | FUNMAT PRO 410 | 305 × 305 × 406 mm12.01 × 12.01 × 15.98 in | China | $ 25,00025 412 €22,176 £3,726,400 ¥ | Quote |

| Apium | P220 | 220 × 175 × 160 mm8.66 × 6. 89 × 6.3 in 89 × 6.3 in | Germany | $ 29,00025 000 €25,724 £4,322,624 ¥ | Quote |

| 3DGence | INDUSTRY F421 | 380 × 380 × 420 mm14.96 × 14.96 × 16.54 in | Poland | $ 50,00050 000 €44,352 £7,452,800 ¥ | Quote |

| AON3D This brand is a certified partner from our network. | AON M2+ This product has been reviewed by our team. | 450 × 450 × 565 mm17.72 × 17.72 × 22.24 in | Canada | $ 59,40060 380 €52,690 £8,853,926 ¥ | Quote |

| miniFactory | Ultra | 330 × 180 × 180 mm12.99 × 7.09 × 7.09 in | Finland | $ 65,00065 000 €57,658 £9,688,640 ¥ | Quote |

| 3ntr | Spectral 30 | 300 × 300 × 300 mm11.81 × 11.81 × 11.81 in | – | $ 110,000111 814 €97,574 £16,396,160 ¥ | Quote |

| Stratasys | Fortus 450mc | 406 × 355 × 406 mm15.98 × 13.98 × 15.98 in | – | $ 149,000116 000 €132,169 £22,209,344 ¥ | Quote |

| Roboze | ARGO 500 | 500 × 500 × 500 mm19. 69 × 19.69 × 19.69 in 69 × 19.69 × 19.69 in | Italy | upon request | Quote |

Expand to see more specs

Note: There are over 90 printers that are supposedly capable of 3D printing PEEK and other high-performance materials. This is a shortlist of what we believe to be some of the best PEEK 3D printers on the market.

The products in the table are ranked by price (low to high).

| Brand | Product | Build size | Build volume | Extruder temp. | Build plate temp. | Build chamber temp. | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|---|---|---|---|

| INTAMSYS | FUNMAT PRO 410 | 305 × 305 × 406 mm12.01 × 12.01 × 15.98 in | 37.77 L | 500°C | 160°C | 90°C | China | $ 25,00025 412 €22,176 £3,726,400 ¥ | Get a quote |

| Apium | P220 | 220 × 175 × 160 mm8. 66 × 6.89 × 6.3 in 66 × 6.89 × 6.3 in | 4.77 L | 540°C | 160°C | 180°C | Germany | $ 29,00025 000 €25,724 £4,322,624 ¥ | Get a quote |

| 3DGence | INDUSTRY F421 | 380 × 380 × 420 mm14.96 × 14.96 × 16.54 in | 60.65 L | 500°C | 180°C | 180°C | Poland | $ 50,00050 000 €44,352 £7,452,800 ¥ | Get a quote |

| AON3D This brand is a certified partner from our network. | AON M2+ This product has been reviewed by our team. | 450 × 450 × 565 mm17.72 × 17.72 × 22.24 in | 114.41 L | 500°C | 200°C | 135°C | Canada | $ 59,40060 380 €52,690 £8,853,926 ¥ | Get a quote |

| miniFactory | Ultra | 330 × 180 × 180 mm12.99 × 7.09 × 7.09 in | 10.69 L | 480°C | 250°C | 250°C | Finland | $ 65,00065 000 €57,658 £9,688,640 ¥ | Get a quote |

| 3ntr | Spectral 30 | 300 × 300 × 300 mm11. 81 × 11.81 × 11.81 in 81 × 11.81 × 11.81 in | 27 L | 500°C | 300°C | 250°C | – | $ 110,000111 814 €97,574 £16,396,160 ¥ | Get a quote |

| Stratasys | Fortus 450mc | 406 × 355 × 406 mm15.98 × 13.98 × 15.98 in | 58.52 L | 450°C | 350°C | 350°C | – | $ 149,000116 000 €132,169 £22,209,344 ¥ | Get a quote |

| Roboze | ARGO 500 | 500 × 500 × 500 mm19.69 × 19.69 × 19.69 in | 125 L | 550°C | – | 180°C | Italy | upon request | Get a quote |

Below, we mapped these PEEK 3D printers by price and chamber temperature. Again, there are other factors to take into account (manufacturer maturity, customer service, warranties, material choice, certifications, etc.) – this is just a preliminary, simplistic view of the high-temperature 3D printer market.

An overview of our 2022 PEEK 3D printer selection

In this section, we give some more context and information about each high-temp 3D printer from our selection.

INTAMSYS has been producing high-temperature 3D printers for several years. The FUNMAT PRO 410 is one of the company’s most affordable solutions along with the FUNMAT HT.

This entry-level solution for high-performance polymer 3D printing features a large build volume, a dual extruder, and sensor-assisted bed leveling.

Contact manufacturer Get a quote Add to comparison

This German 3D printer provides a smaller build volume than others on our list, but its adaptive heating system is an uncommon characteristic that is essential for compliance with very tight tolerances.

Repeatability is definitely one of the Apium P220’s main advantages, and makes it one of the best PEEK 3D printers on the market.

Contact manufacturer Get a quote Add to comparison

AON3D is a Montreal-based AM hardware, software, and material company that aims to make industrial 3D printing accessible to businesses. Its AON M2+ printer offers a precision-controlled 3D printing environment for high-performance polymers.

The AONM2+ is one of the only high-temperature 3D printers to offer independent dual extrusion. In addition, it offers one of the largest build volumes in its category. This 3D printer has been used to produce parts with ultra polymers for the Peregrine moon lander.

Contact manufacturer Get a quote Add to comparison

3DGence’s Industry F420 is an enlarged, upgraded version of the Industry F340, a 3D printer for PEEK that we’ve featured before.

It boasts even higher temperatures, as well as a new filament chamber that can hold up to four spools and keep them heated at 50°C.

Contact manufacturer Get a quote Add to comparison

Paired with miniFactory’s AARNI process monitoring system, the Ultra is able to deliver certifiable 3D printed parts.

It’s equipped with an annealing system as well, making it possible to enhance part quality and dimensional stability. The printer’s heated filament chamber keeps materials prepped at 120°C.

Contact manufacturer Get a quote Add to comparison

Italian manufacturer 3ntr has been producing high-temperature 3D printers for several years, but the Spectral 30 is their first printer to be officially dedicated to PEEK and PEI.

With its quadruple 500°C extruders, 300°C build plate, 250°C build chamber, and 110°C filament bay, the Spectral 30 is hard to match. This 3D printer also features a door safety feature: the door is locked until the temperature has descended to 55°C.

Contact manufacturer Get a quote Add to comparison

Stratasys produces some of the best professional and industrial printers on the market. While their systems used to be limited to Stratasys-branded materials, they’re now (h3 2022) compatible with Stratasys-validated materials from other brands. Materials that have not been validated by Stratasys can also be used, but with an annual Open Material License subscription.

The material choice for the Fortus 450mc includes ULTEM 1010 and ULTEM 9085, and a range of ABS, PC, ST, PEKK and PA-based filaments. Stratasys markets the Fortus 450mc as a reliable machine that doesn’t require particular skills or advanced knowledge of 3D printing.

Contact manufacturer Get a quote Add to comparison

The Roboze ARGO 500 is an industrial-grade solution from Roboze, an Italian manufacturer that has dedicated itself to the high-temp 3D printer sector since 2014. The ARGO 500 sits at the middle of the company’s ARGO production series, in between the smaller ARGO 350 and larger ARGO 1000.

The ARGO 500 sits at the middle of the company’s ARGO production series, in between the smaller ARGO 350 and larger ARGO 1000.

Roboze’s high-temperature 3D printer controls, analyzes and stores all of the information and parameters from each print in its onboard, industrial B&R computer. This means that each part can be certified.

Contact manufacturer Get a quote Add to comparison

There are a few other brands that produce good quality PEEK and PEI printers, which almost made it to the main list. However, we didn’t include them for different reasons (e.g. product not yet released, limited distribution network, and/or technical specs or features not up to par with the rest of the list, etc.).

Tip: Use our 3D printer catalog to see the full list of high-performance polymer 3D printers!

Alternative PEEK 3D printers for specific needs

While the high-temperature 3D printers from our selection are excellent options for most applications, some use cases require more specific solutions. Here are a few examples.

Medical PEEK 3D printing

PEEK is a great contender for medical applications. It is namely used for long-term medical implants, as medical-grade PEEK is biocompatible and highly resistant. With certified materials and certified AM systems, it is possible to produce certified medical parts.

Another notable benefit is that PEEK implants, in contrast to metal implants, don’t interfere with scanning machines (MRI, CT, x-rays, …).

The three main medical PEEK 3D printer brands are Apium, VeraShape, and Kumovis.

- Apium M220

- VeraShape VSHAPER MED

- Kumovis R1

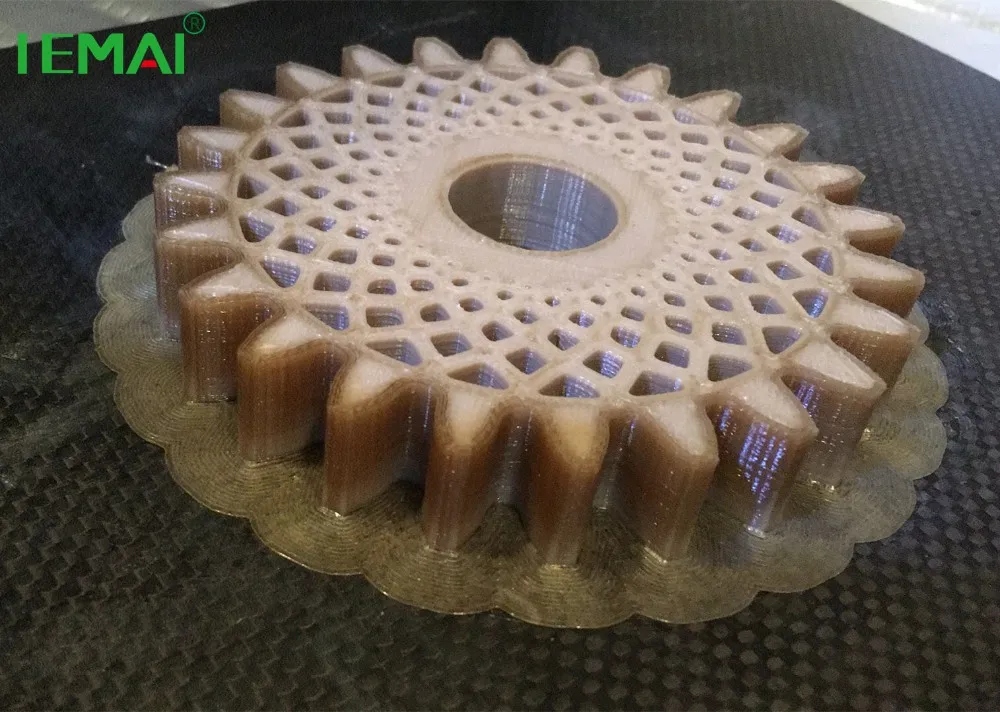

Cost-effective PEEK printers

If you have a smaller budget but you’re willing to spend more time on tweaking and adjusting, there are more affordable options out there such as:

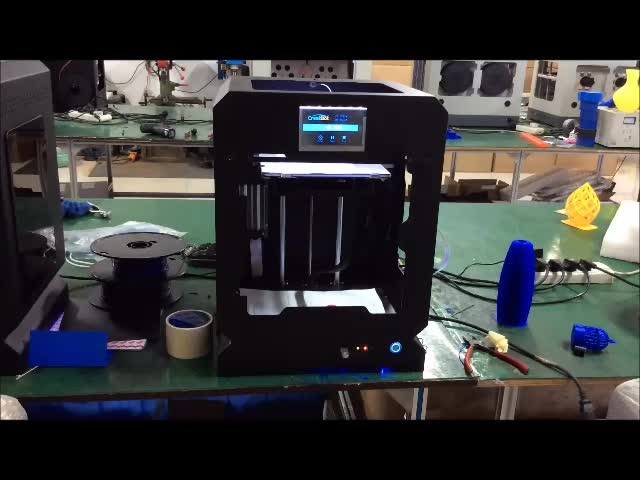

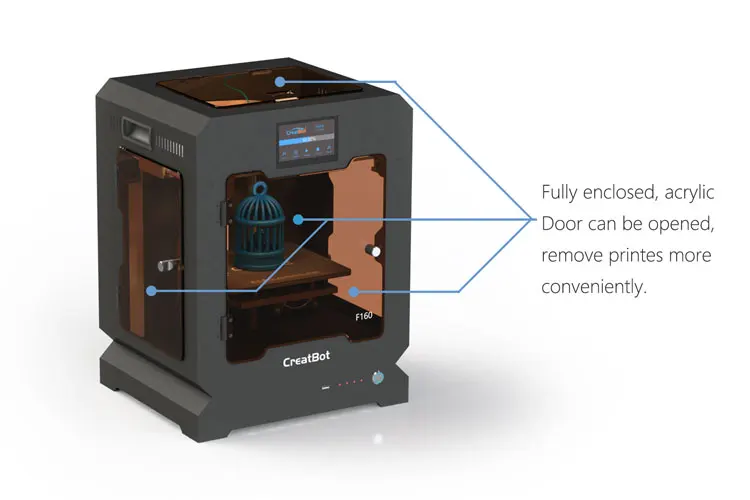

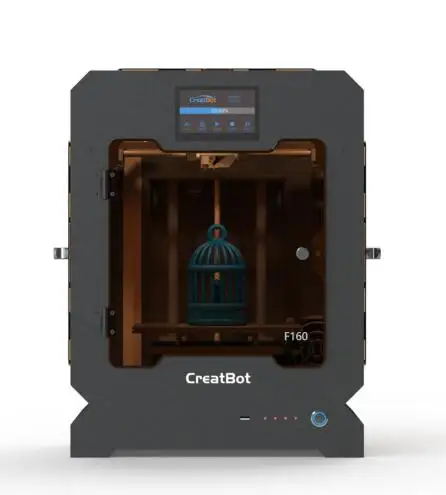

- CreatBot PEEK-300

- IEMAI MAGIC HT PRO

- INTAMSYS FUNMAT HT

Affordable PEEK printer prices can start from around $5,000. They are able to print PEEK, but the resulting quality may not meet your standards, especially in terms of repeatability. These machines are however more than capable of printing other engineering-grade materials.

They are able to print PEEK, but the resulting quality may not meet your standards, especially in terms of repeatability. These machines are however more than capable of printing other engineering-grade materials.

Custom PEEK 3D printers

Some brands like Tobeca, Qualup (SpiderBot), or Hyrel 3D aren’t widespread but offer interesting, tailored solutions for PEEK 3D printing.

Their custom PEI/PEEK 3D printers can be suitable for R&D applications or any case where specific sizes and components are needed.

Large, industrial PEEK 3D printing systems

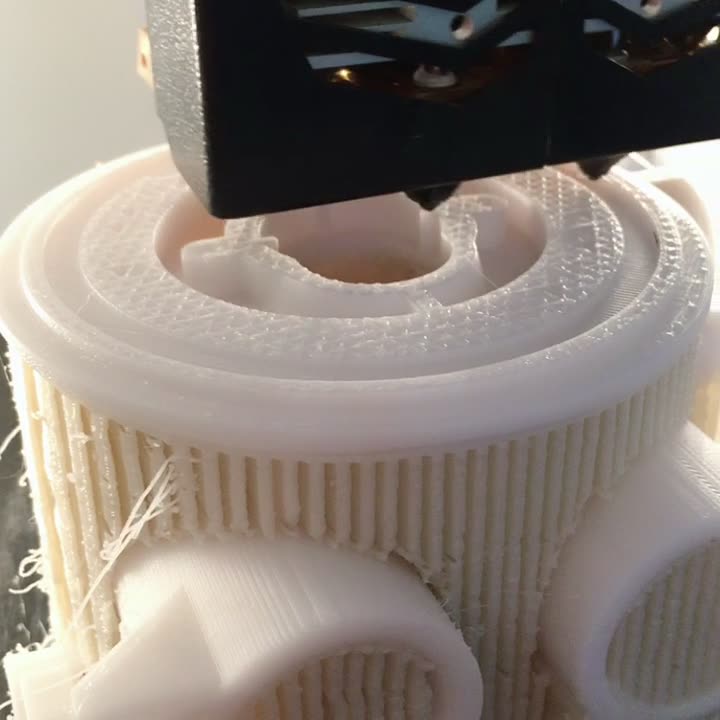

Warpage is often an issue when 3D printing large parts. Hence, 3D printing large parts with a thermoplastic as challenging as PEEK is double the risk.

Some manufacturers that are specialized in large-scale 3D printers claim that they are also able to print PEEK (e.g. Cincinnati, BigRep, CEAD, Cosine Additive, etc.).

We know the PEEK printer market like the back of our hands. Contact us now to save time and receive expert advice based on your needs and budget. We’ll put you in touch with the right manufacturer or PEEK 3D printer distributor near you.

Contact us now to save time and receive expert advice based on your needs and budget. We’ll put you in touch with the right manufacturer or PEEK 3D printer distributor near you.

Key characteristics and properties of PEEK

Pros of PEEK filament

PEEK is a dimensionally stable, semi-crystalline thermoplastic. It can tolerate significant changes in temperature, humidity, and other conditions.

Here are some of the main benefits of PEEK:

- Useful operating temperature (a.k.a. continuous use temperature) of up to 250°C-260°C

- Low flammability and low levels of toxic emissions during combustion

- High mechanical strength

- Low moisture absorption; water and steam resistant

- Chemical resistance (with exceptions)

- Biocompatible

- Lightweight

PEEK drawbacks

This material also has a few limits:

- Complex to 3D print

- PEEK is expensive

- Low impact strength

- Non-resistant to UV light

Alternative high-performance materials

PEEK isn’t the ultimate “one size fits all” material. In many cases, other engineering materials or fiber-filled materials (composites) can substitute the need for PEEK. Here are a few examples.

In many cases, other engineering materials or fiber-filled materials (composites) can substitute the need for PEEK. Here are a few examples.

PEKK (Poly Ether Ketone Ketone): a good alternative to PEEK

PEKK and PEEK are both part of the same polymer family called PAEK (Poly Aryl Ether Ketone). They boast similar properties in terms of strength, chemical resistance, and more. However, PEKK can be easier to 3D print than PEEK.

It is possible for filament manufacturers to tweak its melting point, and therefore generally requires lower temperatures. PEKK can also have a slightly higher glass transition temperature (Tg) than PEEK.

PEEK vs. ULTEM (PEI)

PEEK and ULTEM® (PEI) are quite similar, but have their differences:

- Cost: ULTEM® is more cost-effective than PEEK.

- Impact strength: PEI has lower impact strength than PEEK.

- Tensile strength: PEEK has higher tensile strength than PEI.

- Certifications: ULTEM® (especially the ULTEM® 9085 blend) has received numerous aerospace certifications and is easier to 3D print.

- Temperature resistance: PEEK features higher temperature resistance than PEI.

- Printability: ULTEM® is generally easier to 3D print than PEEK is.

What’s the difference between PEI and ULTEM?

ULTEM® is actually a family of PEI products that was patented and developed at General Electric in the 1980s. SABIC, a company based in Saudi Arabia, acquired GE’s Plastics Division several decades later and now manufactures ULTEM® in the form of resins or foam. 3D printing material providers then transform it into granulates, filament, etc.

Continuous fiber reinforcement

It is also possible to reinforce PEEK or PEKK parts with a continuous strand of carbon fiber. This makes it possible to benefit from high-performance material properties (e.g. chemical resistance) while bringing a drastic increase in part strength.

This makes it possible to benefit from high-performance material properties (e.g. chemical resistance) while bringing a drastic increase in part strength.

Chopped fiber reinforcement (“filled” materials)

There are a number of “filled” material options. A filled material is a material that has been reinforced with, for example, chopped fibers such as carbon fiber or glass fiber. These materials are considered composites and can be good alternatives in some cases (learn more about composites here).

Common examples of filled materials include PEEK-CF (a carbon-fiber-enforced PEEK) and PA-CF (carbon-fiber-enforced Nylon).

Main requirements for 3D printing PEEK and PEI high-performance polymers

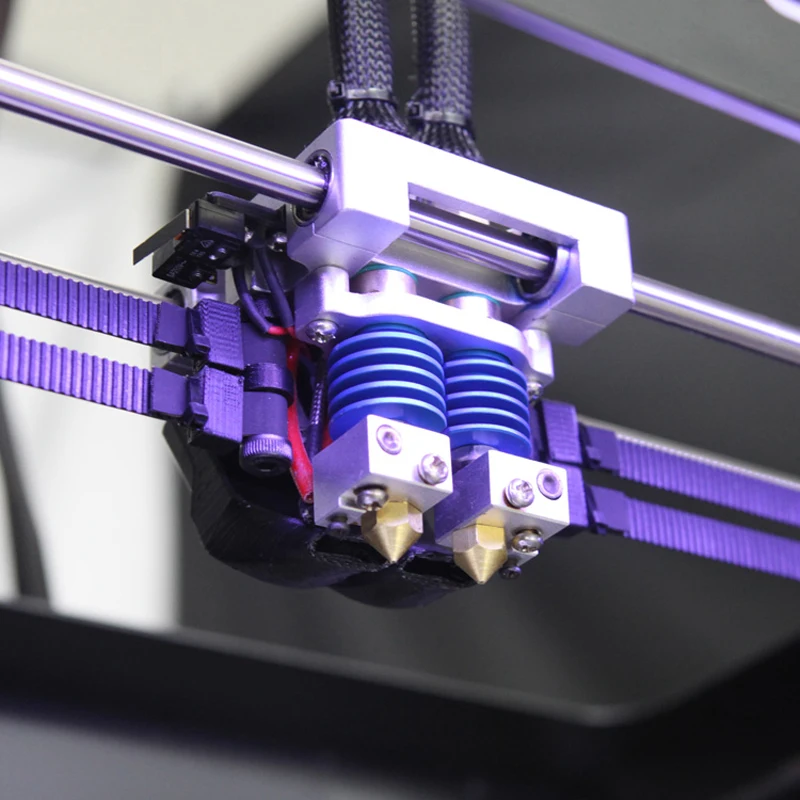

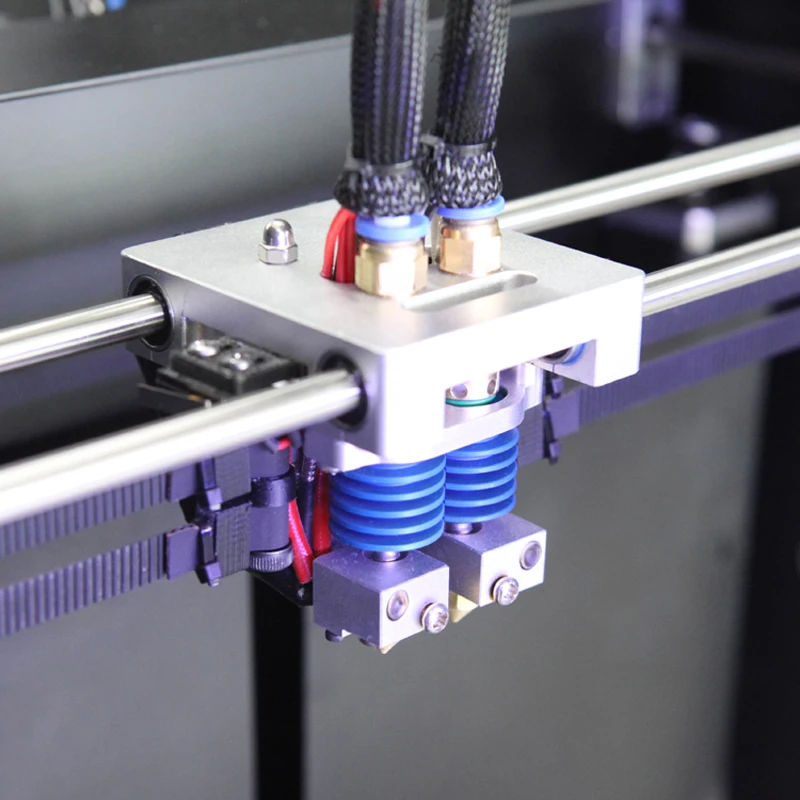

High-temperature extruder

The melting point for PEEK materials is 343°C. This means that the extruder needs to be able to reach that temperature or higher. The hotend extruder must also be all-metal and be resistant to abrasion.

This means that the extruder needs to be able to reach that temperature or higher. The hotend extruder must also be all-metal and be resistant to abrasion.

Heated print bed

To print PAEK high-performance polymers, a heated bed is mandatory, and it must be able to reach temperatures of 120°C at the very least. This ensures correct adhesion and overall 3D print quality.

Closed, heated chamber

PEEK is highly prone to shrinkage and warpage (sometimes called warping). Ideally (and this is especially important for larger parts), the chamber temperature should be able to go up to or over 143°C, which is PEEK’s glass transition temperature (Tg).

The team at Vision Miner explains heated chambers very well in the video below:

It is extremely important to be in control of these temperatures and to keep them constant, as fluctuations can easily affect print quality. However, these aren’t the only conditions for printing high-quality PEEK parts; post-treatment also plays a major role.

However, these aren’t the only conditions for printing high-quality PEEK parts; post-treatment also plays a major role.

In order for PEEK to crystallize as well as possible – and thus for the printed parts to be as strong and stable as possible – the material must be cooled gradually.

Unlike PLA parts, which can be removed from the tray almost as soon as they are printed, waiting several hours for the temperature of a PEEK or ULTEM part to drop to room temperature is necessary. This avoids disturbing the material’s crystallization process.

Some PEEK printers provide precise control over the chamber’s cooling rate.

Applications for high-performance polymer 3D printing

PEEK and ULTEM® 3D printing is mostly useful for manufacturers requiring strong prototypes and/or end parts that can withstand extreme conditions, in a variety of industries.

Some manufacturers even present PEEK 3D printing as an alternative to 3D printing metal parts.

Aerospace, automotive and military

Being lightweight yet strong and resistant, PEEK and ULTEM® 3D printed end parts are increasingly popular in aerospace, automotive and military fields.

ULTEM® has actually been used in the aerospace industry for decades and is heavily certified for related applications (e.g. airplane interiors).

Oil and gas

Thanks to PEEK’s chemical resistance and impermeability, oil and gas manufacturers can use the material to 3D print air valves and other parts.

Medical implants

PEEK and PEI are biocompatible, and can therefore be used for implants or other medical use cases.

Semiconductors

With PEEK’s electrical integrity it is possible to 3D print flexible circuit boards, as well as wire and cable insulation.

Cost of PEEK and ULTEM (PEI) 3D printing

PEEK 3D printers and ULTEM 3D printer prices

Most PEEK-ready 3D printers are available at prices ranging from $25K to $150K, and can even go up to $250K. It might seem like a hefty price tag, but these professional additive manufacturing systems feature specific technology that is difficult to integrate into a machine.

It might seem like a hefty price tag, but these professional additive manufacturing systems feature specific technology that is difficult to integrate into a machine.

However, some PEEK 3D printers under $10,000 do exist.

PEEK and ULTEM filament price

PEEK filament price

Polyetheretherketone (PEEK) material is among the most expensive plastics on the market: its price can range from about $400 to $700 per kilo.

ULTEM filament price

PEI, or ULTEM®, is a cheaper alternative to high-performance PEEK material. The cost per kilogram can vary from $150 to around $280.

PEEK 3D printer FAQ

What kind of material is ULTEM®?

ULTEM® is a kind of thermoplastic used for professional and industrial applications.

What is ULTEM® plastic?

ULTEM® plastic is Polyetherimide (PEI), a strong, resistant thermoplastic that boasts similar characteristics to PEEK while being easier to 3D print.

What is PEI 3D printing?

Professionals and industrials use PEI to produce strong prototypes or end-use parts.

What material is PEI?

PEI stands for Polyetherimide and is also known as ULTEM®, which is actually a brand manufactured by SABIC. This engineering thermoplastic is strong and resistant to extreme conditions, though less than PEEK.

What is PEEK plastic?

PEEK stands for Polyetheretherketone. It is a highly resistant material (extreme temperatures, chemicals, etc.).

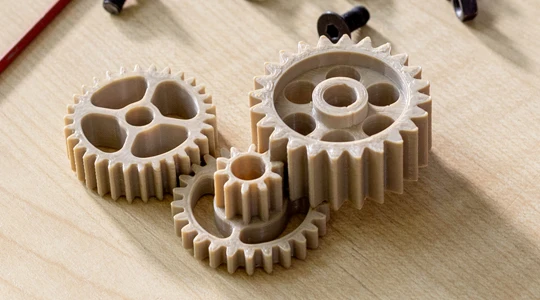

The Best PEEK 3D Printers on the Market

Published on September 15, 2022 by Alexandrea P.

3D printing materials have continued to develop in recent years, meeting the demand of professionals looking for solutions that can meet industrial, mechanical and chemical constraints. The additive manufacturing market has therefore begun to welcome more high-performance materials, that are high performance and, above all, resistant to high temperatures. Mainly marketed in filament form, today PAEK (polyaryletherketones) is available – a family that includes PEEK, PEKK, and PEI (which you probably know under the trade name ULTEM), developed by General Electric in the 1980s. However, as they are such complex materials, only certain 3D printers are capable of working with materials like PEEK and ULTEM.

Mainly marketed in filament form, today PAEK (polyaryletherketones) is available – a family that includes PEEK, PEKK, and PEI (which you probably know under the trade name ULTEM), developed by General Electric in the 1980s. However, as they are such complex materials, only certain 3D printers are capable of working with materials like PEEK and ULTEM.

Today, we will be looking at PEEK and ULTEM FDM/FFF machines – though you should know that powder-based solutions are also available on the market, if less popular. These two high performance thermoplastics require more complex printing parameters, particularly an extrusion temperature of more than 350°C, a heated chamber and a build plate capable of reaching at least 100°C. These technical constraints explain the relatively low number of 3D printers compatible with these materials on the market. To help you in your search, 3Dnatives has brought together the some of the best ULTEM and PEEK 3D printers, based on FDM technology, and listed in alphabetical order.

AON-M2+

Canadian manufacturer AON3D has developed the AON M2+, the company’s fifth generation of high-temperature 3D printers. Like the other solutions on the list, the machine allows for the use of high-performance materials such as PEEK or ULTEM. The printer is equipped with two independent extruders that can heat up to 500°C. These are made of stainless steel and are compatible with glass and carbon fiber. The printing plate can go up to 200°C. Finally, the printing chamber can reach 135°C. The properties of the AON M2+ make the final parts impact, heat, chemical and wear resistant. The largest manufacturing volume in its class is 450 x 450 x 640 mm. The highest layer thickness is up to 0.05 mm and the travel speed is up to 500 mm/s.

Photo Credits: AON3D

Apium P220

Apium is a German manufacturer specialising in the development of PEEK 3D printers, one of which has been developed specifically for the medical sector. The one we are interested in here is the P220, an industrial 3D printer capable of creating parts measuring 205 x 155 x 150 mm. Its extruder can heat up to 540°C and its build plate can reach 160°C. Above all, it is equipped with an adaptive heating system: the manufacturer has installed a device that rises to 180°C, just above the printing area, and forms a film of hot air. This allows the printer to improve layer adhesion and surface quality. Energy consumption is thus optimised as well as machine preparation. The Apium P220 is also compatible with carbon fiber reinforced PEEK and ULTEM.

Its extruder can heat up to 540°C and its build plate can reach 160°C. Above all, it is equipped with an adaptive heating system: the manufacturer has installed a device that rises to 180°C, just above the printing area, and forms a film of hot air. This allows the printer to improve layer adhesion and surface quality. Energy consumption is thus optimised as well as machine preparation. The Apium P220 is also compatible with carbon fiber reinforced PEEK and ULTEM.

Creabot PEEK-300

The Chinese manufacturer Creatbot has developed a 3D printer capable of making parts out of PEEK. It is particularly unique because it integrates a “Direct Annealing System”, i.e. an annealing process during printing in order to give the parts the best possible quality, without deformation or cracking. This technology avoids time-consuming post-processing steps. The Creabot PEEK-300 is a dual extrusion machine, capable of heating up to 500°C. Its printing plate can heat up to 200 °C while its chamber reaches 120 °C. It offers a printing volume of 300 x 300 x 400 mm in single extrusion (240 x 300 x 400 mm in double). Finally, it is a relatively compact machine that integrates a number of features to facilitate the printing process.

It offers a printing volume of 300 x 300 x 400 mm in single extrusion (240 x 300 x 400 mm in double). Finally, it is a relatively compact machine that integrates a number of features to facilitate the printing process.

Fortus 450mc

The American giant Stratasys has developed the Fortus 450mc to enable manufacturers to print high-performance materials of large size. Its print volume is indeed quite generous at 406 x 355 x 406 mm. It is an ideal machine for all specialized sectors such as automotive, medicine or aeronautics that are looking to create solid components, resistant prototypes and production tools of all kinds.

FUNMAT Pro 610HT

Intamsys, based in Shanghai, specializes in high performance materials 3D printing solutions. The company manufactures the FUNMAT HT and FUNMAT PRO HT series. The FUNMAT Pro 610HT is one of their latest releases, it is capable of handling high performance materials such as PEEK, PEKK, ULTEM, and also comes with a dual nozzle that can reach 500°C and a heated chamber of 300°C. Compared to other models, this is a larger solution, boasting a build volume of 610 x 508 x 508mm. Parts made with this machine are perfect for automotive, aerospace, Oil & Gas, and more. The manufacturer also explains that the build chamber has been optimized to avoid warpage by achieving a constant temperature throughout the building process, resulting in parts with higher mechanical strength.

The FUNMAT Pro 610HT is one of their latest releases, it is capable of handling high performance materials such as PEEK, PEKK, ULTEM, and also comes with a dual nozzle that can reach 500°C and a heated chamber of 300°C. Compared to other models, this is a larger solution, boasting a build volume of 610 x 508 x 508mm. Parts made with this machine are perfect for automotive, aerospace, Oil & Gas, and more. The manufacturer also explains that the build chamber has been optimized to avoid warpage by achieving a constant temperature throughout the building process, resulting in parts with higher mechanical strength.

Essentium HSE 280i HT

Essentium is known for its industrial 3D printing solutions, ranging from AM machines to high-performance materials. This company was born in 2013 with the goal of creating a new generation of extrusion materials with strength flexibility and speed that would drive the future of additive manufacturing. In 2018, it was launched as a comprehensive solution to the market proposing solutions in both technology and machines. Now, it has launched it considers to be to the first printer whose dual extruders are independent (IDEX) from both the X and Y axis and capable of printing with PEEK and other high-performance materials. The Essentium HSE 280i HT is capable of solving problems of speed, durability and scalability. It also has an open ecosystem, demanded by 96% of manufacturers as it allows them to have greater control. As for the specifications of this printer, it has two printheads, a Gen 5 Hoozle heated nozzle with a diameter of 0.4 to 0.8 that reaches 550º C. It has a size of 1590 x 1350 x 2490 mm and a weight of 850Kg. Check out the video below for you to learn more about the Essentium HSE 280i HT.

Now, it has launched it considers to be to the first printer whose dual extruders are independent (IDEX) from both the X and Y axis and capable of printing with PEEK and other high-performance materials. The Essentium HSE 280i HT is capable of solving problems of speed, durability and scalability. It also has an open ecosystem, demanded by 96% of manufacturers as it allows them to have greater control. As for the specifications of this printer, it has two printheads, a Gen 5 Hoozle heated nozzle with a diameter of 0.4 to 0.8 that reaches 550º C. It has a size of 1590 x 1350 x 2490 mm and a weight of 850Kg. Check out the video below for you to learn more about the Essentium HSE 280i HT.

INDUSTRY F421 From 3DGence

The INDUSTRY F421 from 3DGence is an industrial 3D printer designed to print high performance polymers such as ULTEM, PEEK and PEKK. According to the manufacturer, this machine guarantees the best quality, dimensional accuracy and reproducible results and impresses with its printing speed of up to 400 mm/s and 1 meter per second. This makes the INDUSTRY F421 a great tool for rapid prototyping. The large print volume of 380 x 380 x 420 mm allows for the printing of large models in one run. The 3D printer also allows printing of high-performance materials that are additionally reinforced to make the resulting final parts even more durable. Each 3DGence INDUSTRY F421 can be equipped with hardware that enables the safe printing of reinforced materials. The INDUSTRY F421’s filtration system also provides extremely good filtration performance, which is not often found in printers powered by FFF technology. The advanced three-stage filtration unit retains macro particles, nanoparticles (VOC, UFP), solvent vapors or harmful gases, enabling user safety and continuity of the technological process.

According to the manufacturer, this machine guarantees the best quality, dimensional accuracy and reproducible results and impresses with its printing speed of up to 400 mm/s and 1 meter per second. This makes the INDUSTRY F421 a great tool for rapid prototyping. The large print volume of 380 x 380 x 420 mm allows for the printing of large models in one run. The 3D printer also allows printing of high-performance materials that are additionally reinforced to make the resulting final parts even more durable. Each 3DGence INDUSTRY F421 can be equipped with hardware that enables the safe printing of reinforced materials. The INDUSTRY F421’s filtration system also provides extremely good filtration performance, which is not often found in printers powered by FFF technology. The advanced three-stage filtration unit retains macro particles, nanoparticles (VOC, UFP), solvent vapors or harmful gases, enabling user safety and continuity of the technological process.

MAGIC-HT-MAX

Introduced earlier this year, the MAGIC-HT-MAX follows the line of solutions offered by the Asian manufacturer IEMAI 3D. Capable of manufacturing high performance parts, the machine uses FDM technology to manufacture with more than 16 different materials (PEEK, PEKK, ULTEM,…). It has a printing volume of 500 x 500 x 700mm and a heated tray that reaches 180°C. In addition, it integrates a liquid cooling system, an end of filament sensor and the ability to recover and resume printing in case of power failure. Despite being an industrial machine, the manufacturer specializes in providing affordable solutions for players in the additive manufacturing industry.

miniFactory Ultra

The Finnish manufacturer miniFactory is especially known for its high temperature 3D printers. The miniFactory Ultra has a build volume of 330 x 180 x 180 mm. Its extruder can reach a temperature of up to 470°C to work with materials such as ULTEM, PEEK, PAEK, PPS and PA. The latest model has two of these extruders. What is special with regard to temperature is that the miniFactory Ultra has a particularly good insulation of the installation space, which is why it can use lower temperatures than other printers to process high-performance materials. In addition, the printer is equipped with a large touch screen, which makes control particularly easy.

The latest model has two of these extruders. What is special with regard to temperature is that the miniFactory Ultra has a particularly good insulation of the installation space, which is why it can use lower temperatures than other printers to process high-performance materials. In addition, the printer is equipped with a large touch screen, which makes control particularly easy.

A150 Series

Orion AM is a company dedicated to industrial additive manufacturing for advanced applications using aerospace-grade polymers. As such, it should come as no surprise that their A150 Series is compatible with high-temperature, high-performance polymers including PEEK and PEKK. This advanced industrial additive manufacturing system allows for the 3D using Thermal Radiation Heating, a process using thermal radiation in all directions to efficiently heat the printed object up to 300°C, allowing the resulting parts to have superior strength properties. The printing bed has a max temperature of 300°C and the extruder has a max temperature of 500°C. Additionally, thanks to TRH the chamber temperature can reach 315°C while the layer heater temperature goes up to 370°C. The solutions are compatible with PEEK, PAEK, PEKK, PEI, ULTEM1010, ULTEM9085, ABS, PC, PA6, PA12 and PPSF/PPSU.

Additionally, thanks to TRH the chamber temperature can reach 315°C while the layer heater temperature goes up to 370°C. The solutions are compatible with PEEK, PAEK, PEKK, PEI, ULTEM1010, ULTEM9085, ABS, PC, PA6, PA12 and PPSF/PPSU.

Photo Credits: Orion AM

Roboze ONE +400 Xtreme

Italian 3D printing manufacturer Roboze specializes in the production of large parts as well as custom batches with its solutions, including the ARGO 500. Introduced in 2017, the maximum extruder temperature for this printer is 550 degrees, with 180 degrees for the build chamber. Manufactured for professional use, the 3D printer has a print bed size of 500 x 500 x 500 mm, in addition to a total weight of 1700 kg. A specific feature of the ARGO 500 is definitely the fully automatically regulated process variables: from the leveling of the build plate to the calibration of the extruder or even the automatic change of the filament: everything is automated and does not require human assistance. Moreover, this 3D printer is equipped with remote maintenance modules that reduce downtime and thus increase productivity.

Moreover, this 3D printer is equipped with remote maintenance modules that reduce downtime and thus increase productivity.

Spectral 30

The Italian manufacturer 3ntr has developed a machine compatible with PEEK, ULTEM but also PPS. It is equipped with a powerful electronic system to control the temperature in an optimal way and thus allow the creation of complex parts with high mechanical properties. It has a volume of 300 x 300 x 300 mm, four extruders with a temperature range up to 500°C, a chamber up to 250°C, and comes with a heated compartment for storing high-performance thermoplastics. The build plate can be heated up to 300°C.

T850 P

The Dutch company Tractus 3D has specialised in the development of Delta printers. The company’s self-proclaimed goal is to develop the most affordable printers possible for industrial applications. With its second 3D printer in the DESK series, the company has succeeded in developing a printer that is based on FDM and, with its dimensions of 550 x 476 x 1140 mm, also fits into an office. It can process materials such as PLA, PEEK and ULTEM. The extruder of the T850 can be heated up to 300°C, making it capable of melting materials such as PEEK. According to the manufacturer, the extruder needs less than 90 seconds to reach this temperature. In terms of printing speed, the T850 P is capable of printing up to 450 mm per second at a resolution of 10 microns.

With its second 3D printer in the DESK series, the company has succeeded in developing a printer that is based on FDM and, with its dimensions of 550 x 476 x 1140 mm, also fits into an office. It can process materials such as PLA, PEEK and ULTEM. The extruder of the T850 can be heated up to 300°C, making it capable of melting materials such as PEEK. According to the manufacturer, the extruder needs less than 90 seconds to reach this temperature. In terms of printing speed, the T850 P is capable of printing up to 450 mm per second at a resolution of 10 microns.

Zortrax Endureal

Last year, Polish manufacturer Zortrax presented its new machine called Zortrax Endureal. With a print volume of 400 x 300 x 300 mm and a maximum precision of 100 µm on the Z-axis, it is equipped with a dual extruder and an aluminium build plate to improve the adhesion of high-performance thermoplastics. Among its features is an advanced thermal management system that makes it easier to control the temperature of the chamber as well as the extrusion temperature. There are also 17 sensors so that the user can monitor the print job in real time and be alerted in the event of a machine failure. Zortrax offers its own range of materials including Z-PEEK, which is wear and abrasion resistant; Z-PEI 9085 for aerospace, Z-ESD, and Z-ULTRAT Plus. According to the manufacturer, the Zortrax Endureal is an ideal industrial machine for designing aerospace and medical applications.

There are also 17 sensors so that the user can monitor the print job in real time and be alerted in the event of a machine failure. Zortrax offers its own range of materials including Z-PEEK, which is wear and abrasion resistant; Z-PEI 9085 for aerospace, Z-ESD, and Z-ULTRAT Plus. According to the manufacturer, the Zortrax Endureal is an ideal industrial machine for designing aerospace and medical applications.

Did we miss any PEEK or ULTEM 3D printers in our ranking? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!

Top 20 Free 3D Printing & 3D Printing Software

Looking for 3D printing software? We've rounded up the top 20 software tools for beginners and professionals alike. Most slicers are free.

What is a slicer? This is a program for preparing a digital model for printing. Models for 3D printing are usually distributed in STL files. To turn an STL file into G-code (a language that a 3D printer understands), a slicer program is required. It is called a slicer because it cuts (to slice - English) a 3D model into many flat two-dimensional layers, from which a 3D printer will add a physical object.

Models for 3D printing are usually distributed in STL files. To turn an STL file into G-code (a language that a 3D printer understands), a slicer program is required. It is called a slicer because it cuts (to slice - English) a 3D model into many flat two-dimensional layers, from which a 3D printer will add a physical object.

Which slicer should I choose? In this article, we will tell you which slicer is best for 3D printing for each stage of your work. Which one is better for preparing a 3D model for printing? But what if you need to create a 3D model from scratch? And if you are only taking the first steps in 3D?

Don't be afraid: we've answered all of these questions, including the required skill level for each program and where you can download it. The great thing is that most of these programs are completely free and open source.

- Cura

- CraftWare

- 123D Catch

- 3D Slash

- TinkerCAD

- 3DTin

- Sculptris

- ViewSTL

- Netfabb Basic

- Repetier

- FreeCAD

- SketchUp

- 3D Tool

- Meshfix

- Simplify3D

- Slic3r

- Blender

- MeshLab

- Meshmixer

- OctoPrint

#1: Cura

For beginners who need a slicer to prepare STL files for 3D printing

Cura is the default slicer software for all Ultimaker 3D printers, but can be used with most others , including RepRap, Makerbot, Printrbot, Lulzbot and Witbox. The program is completely open source, its capabilities can be extended using plugins.

The program is completely open source, its capabilities can be extended using plugins.

This program is very easy to use and allows you to manage the most important 3D printing settings through a clear interface. Start in Basic mode to quickly get up to speed and change print quality settings. If finer control is required, switch to Expert mode.

Cura can also be used to directly control the printer, but then the printer and computer must be connected to each other.

Download: Cura

Price: Free

Systems: PC, Mac, Linux

#2: CraftWare

3D printers by the Hungarian startup CraftUnique to support their CraftBot crowdfunding machine. However, the program works with other printers.

Like Cura, CraftWare allows you to switch from "Easy" to "Expert" mode, depending on how confident you feel. It's a colorful app that features a visual G-code visualization with each function represented by a different color. But the most outstanding feature is the individual support service. As far as we know, only the paid program Simplify3D has this.

As far as we know, only the paid program Simplify3D has this.

Please note, however, that this program is still in beta, so bugs may occur.

Download: CraftWare

Price: Free

Systems: PC, Mac

#3: 123D Catch

-systems, smartphones and tablets, which allows you to convert images of objects into a 3D model. Pictures can be taken with a smartphone/tablet or digital camera.

You need many photos of an object from different angles - the more the better - after which they will be compiled into a 3D model.

123D Catch is more of a fun app than a professional 3D printing tool, but after some tambourine dancing, you can get good results, especially when paired with an STL editor like MeshLab or Meshmixer.

Price: Free

Systems: PC, Android, iOS, Windows Phone

#4: 3D Slash

and surprisingly simple, and refreshingly new. With 3D Slash, you can design 3D models using your dice skills.

You can start with a large block and, like a virtual sculptor, remove small cups from it with tools such as a hammer or drill, or start from empty space and build a model from cubes and other shapes. You can paint with flowers or use template pictures.

Other features worth mentioning are tools for creating logos and 3D text. The Logo Wizard imports an image and creates a 3D model, while the Text Wizard allows you to enter and format text, and then turn it into 3D.

Recommended!

Download: 3dslash.net

Price: Free

Systems: PC, Mac, Linux, Browser

#5: TinkerCAD

- A computer-aided design (CAD) system for 3D printing, which is a good starting point for beginners. Since its capabilities are limited compared to Blender, FreeCAD and SketchUp, many users switch to more powerful tools after some time.

As in 3D Slash, here you can build models from basic shapes. At the same time, unlike 3D Slash, TinkerCAD allows you to create vector shapes in 2D and convert them into three-dimensional models.

Come in: Autodesk TinkerCAD

Price: Free

Systems: Browser

#6: 3DTin

For beginners who want to create 3D printable models

another easy and intuitive online tool choice for beginners in 3D modeling. All you need is a Chrome or Firefox browser with WebGL enabled.

Choose from a huge library of 3D shapes and add them to your sketch. All sketches are stored in the cloud, access to them is free if you honor the Creative Commons license. Everything can be exported to STL or OBJ formats.

Enter: 3DTin

Price: Free

Systems: Browser

#7: Sculptris

For beginners who want to create 3D printable models

clay. This is a fantastic 3D modeling program if figurines are your main task. For example, you can make a bust of your favorite video game or comic book character. Sculptris is completely free and bills itself as a stepping stone to the more complex (and expensive) ZBrush tool.

Download: Pixologic Sculptris

Price: Free

Systems: PC, Mac

#8: ViewSTL

For beginners who want to view STL files

ViewSTL is the easiest way to view STL files . Simply open a web page and drag the STL onto the dotted box.

The STL online viewer allows you to display the model in one of three views: flat shading (for a quick view), smooth shading (for a high-quality image), and wireframe.

Enter: ViewSTL

Price: Free

Systems: Browser

#9: Netfabb Basic

some nice features that allow you to analyze, "repair" and edit STL files before moving on to the model cutting stage.

A good choice if you need more than just a slicer and want to be able to quickly fix STL files without having to learn programs like MeshLab or Meshmixer.

Don't let the 'Basic' in the title fool you, Netfabb Basic is actually a very powerful 3D printing tool. It's "basic" only in the sense that it doesn't cost €1,500 like Netfabb Professional!

Download: netfabb. de

de

Price: Free

Systems: PC, Mac, Linux

No. 10: Repetier

For advanced to prepare STL files for 3D printing

9002 the next level of 3D printer slicer software, but if you want to stay open source, you should look into Repetier. It is the great grandfather of 3D printing software and a favorite of the RepRap community.To date, the program is moving by leaps and bounds from the level for beginners to advanced users. Packaged in an all-in-one configuration, it supports up to 16 extruders, multi-slicing via plug-ins, and virtually every fusing 3D printer on the market. Get ready to tinker!

What's more, Repetier Host works remotely via Repetier Server, so that the 3D printer can be controlled via a browser, tablet or smartphone.

Download: Repetier

Price: Free

Systems: PC, Mac, Linux

#11: FreeCAD

The program is a great option for developing your design skills. More technically, this parametric 3D modeling program allows you to easily change the project by rolling back through the history of the model and editing the parameters.

Download: freecadweb.org

Price: Free

Systems: PC, Mac, Linux

#12: SketchUp

For beginners who want to create 3D printable models

SketchUp is the perfect combination of simplicity and the perfect combination functionality, with a user-friendly interface and a relatively flat learning curve (i.e., as experience grows with the time spent), the ideal program for developing three-dimensional models.

The Make SketchUp version is free and will include everything you need for 3D modeling if you also download and install the free STL exporter. There is also a professional edition for architects, interior designers and engineers.

Download: sketchup.com

Price: Free (SketchUp Make), $695 (SketchUp Pro)

Systems: PC, Mac, Linux

#13: 3D-Tool Free Viewer

view and validate STL files

3D-Tool Free Viewer is a sophisticated tool that, among other things, allows you to check the structural integrity and printability of your file. With the Cross-Section function, for example, you can look at the model from the inside and check the wall thickness. Very useful if you want to check your STL file for killer errors before printing.

With the Cross-Section function, for example, you can look at the model from the inside and check the wall thickness. Very useful if you want to check your STL file for killer errors before printing.

Download: 3D-Tool

Price: Free

Systems: PC

#14: Meshfix

your model for errors.

Price: Free

Systems: Browser

#15: Simplify3D

For professionals to prepare STL files for 3D printing print. A flexible algorithm checks the model for problems, fixes them, shows a preview of the printing process (ideal for identifying potential problems), and then slices it.

This slicer offers the best infill pattern options in the competition. For models that require supports, Simplify3D will create the appropriate structures on its own and give you full control over their placement. For printers with a dual extruder, when printing with different materials, the Dual Extrusion wizard will help, as a result of which, for example, it will be easier to remove the dissolving filament.

Simplify3D supports 90% of today's commercially available desktop 3D printers and is compatible with Marlin, Sprinter, Repetier, XYZprinting, FlashForge, Sailfish and MakerBot firmware. Simplify3D can also be used to directly control the printer, but then the printer and computer must be connected to each other.

Download: simplify3d.com

Price: $149

Systems: PC, Mac, Linux

#16: Slic3r

source code, which has a reputation as a carrier of super new functionality, which you will not find anywhere else. The current version of the program is able to show the model from multiple angles, so that the user gets a better preview experience.

There's also an incredible 3D honeycomb infill, the first of its kind that can extend over multiple layers rather than repeating itself like a stamp. This significantly increases the strength of the internal filling of the model and the final printout.

Another option is direct integration with Octoprint. Once the files on the user's desktop are sliced, they can be directly uploaded to Octoprint with one click.

Once the files on the user's desktop are sliced, they can be directly uploaded to Octoprint with one click.

Download: Slic3r

Price: Free

Systems: PC, Mac, Linux

#17: Blender

For professionals who want to create 3D printable models

Blender is a popular computer-aided design (CAD) system with a steep learning curve. Not at all the best choice for beginners, but what you need if you are quite experienced and need something more complex for modeling and printing.

In short, Blender is one of the most powerful tools out there. Its community is always ready to help, there are a lot of educational materials. It's also open source, so enthusiasts often write extensions to make it even better and more powerful.

Download: blender.org

Price: Free

Systems: PC, Mac, Linux

#18: MeshLab

For professionals to prepare STL files for 3D printing

MeshLab - advanced editor. It allows you to remove parts of a 3D model, merge two models into one, patch holes. If you need a program to modify models for 3D printing or some kind of "repair" work, MeshLab is the right choice.

It allows you to remove parts of a 3D model, merge two models into one, patch holes. If you need a program to modify models for 3D printing or some kind of "repair" work, MeshLab is the right choice.

Price: Free

Systems: PC, Mac, Linux

#19: Meshmixer

For professionals to prepare STL files for 3D printing files. It's especially good for identifying potential problems and fixing them automatically. For example, it will show paper-thin walls that can lead to problems with 3D printing. Meshmixer is part of the Autodesk family of 3D printer software, so it should work well with tools like TinkerCAD.

Price: Free

Systems: PC, Mac

#20: OctoPrint

start, pause or interrupt 3D print jobs. Combined with Wi-Fi capable devices, it makes for a great monitor for remotely monitoring the 3D printing process.

Octoprint understands the G-codes of almost all 3D printers and slicers and includes a gCodeVisualizer to visualize this code before or during printing.

If you want to work away from your 3D printer and control it remotely, Octoprint is the best you can find.

Download: octoprint.org

Price: Free

Systems: PC, Mac, Linux

Source

Top Free 3D Printing Software in 2021 zero? What software is best for beginners? All these questions can be answered in our article. The applications presented in the review are completely free or have free versions for students, teachers and open source projects.

Why did we put this section before all the others? The answer is very simple. By knowing the whole 3D printing process, you can better understand how each software is involved in the preparation and printing of 3D parts.

If you have become a happy owner of a 3D printer, but have absolutely no idea what to do with it and how to get started, then this part of the article is for you.

Different programs are used to print 3D models:

- 3D modeling/design/CAD software;

- Software for editing, viewing and restoring STL files;

- Slicing software;

- 3D printer host.

Before starting work, you need to create a 3D model. To do this, you can use different programs for modeling. We wrote in detail about free versions of software for 3D modeling here.

A small life hack for beginners. If you are not ready to create a model on your own, you can choose and download the right one from the marketplaces. There are also free download links in the maker communities - sometimes the proposed 3D models can be not only interesting, but also useful.

Once a 3D model has been created, it must be converted to a printable format. For desktop 3D printers, this is the STL format. Some created or downloaded files have defects that lead to failures during printing. It is for editing STL files that there is special software that helps prepare the model for playback on the printer.

Slicer software helps to convert STL file into printer friendly G-code. The functionality of such programs allows you to split a 3D model into thousands of flat 2D layers, which will be sequentially reproduced on a printer.

Finally, the 3D printer host provides communication between the computer and the printer. It allows you to receive information for printing, as well as change the parameters of the device in real time via a PC. Often the Slicer and host are combined into one 3D printing software that is supplied by the printer manufacturer.

Dear readers of the 3DToday portal, we want to inform you that a new section "Knowledge Base" has been opened on our website of the LIDER-3D online store. In this section, we share owls, experience, settings and secrets of the world of additive technologies, go to the section at this link.

Examples of some already posted articles in the Knowledge Base section: Post-processing of models after 3D printing, 10 calibration models for your 3D printer, How and what 3D printers print, Printing with HIPS plastic, ABS printing settings, Recommendations for Resin Post-Processing HARZ Labs, Best Free 3D Modeling Software for Beginners.

Cura

One of the popular slicer software that comes with all Ultimaker printers. However, its functionality is suitable for use in conjunction with other 3D printers. Since this software is one of the most popular among makers, you can not waste time on profile settings - for most printers they can be found in the program itself.

The software is designed to change important print settings. Start with the “Recommended” mode to select improved quality settings for your printer and easily adapt to the program.

More precise control of all parameters is possible in the “Custom” user mode. By switching to this mode, you can manage more than 400 different settings.

Cura is not only a simple and intuitive slicer for home users. The software can be used as the main software for your printer, as well as integrated with CAD systems such as SolidWorks or Siemens NX.

The program is constantly updated and supplemented, which allows you to make 3D printing on your printer better.

►►►Link to office. site Cura

PrusaSlicer

This software is based on Slic3r and, unlike the prototype, has gained great popularity among users. The main difference is a large list of customizable parameters and additional features that make the work more convenient.

An easy-to-use user interface, built-in support for Prusa printers, and multi-plastic settings make it easy to get started with your 3D printer. The slicer also allows you to place additional supports, work with different materials and use smooth features with variable layer height.

The PrusaSlicer can be used with both FDM and resin printers. Settings panels for users with different experience in 3D printing help to significantly improve the quality of finished models.

A great bonus for those who have worked with Slic3r before - PrusaSlicer supports most of the original features and accepts Slic3r configuration packages when importing profiles.

►►►Link to office. website PrusaSlicer

website PrusaSlicer

MatterControl 2.0

MatterControl is a CAD modeling software, slicer and simultaneous host for a 3D printer. With host functions, you can directly control printing by connecting the printer via USB. The program also allows you to cut STL files for export to an SD card for offline printing and, of course, create projects in a separate section of the CAD software.

Structured interface makes it easy to create models and prepare them for printing. A file browser and a library of geometric primitives make it easy to import data into print. Geometric figures can be used as supports, which helps to achieve high quality printing of complex details.

Advanced print settings and a user-friendly viewer make this software one of the best for comprehensive control of the 3D printing process. In addition to the host and slicer functions, MatterControl has design tools that allow you to design parts. The resulting 3D models are easy to export to a slicer and print.:quality(80)/images.vogel.de/vogelonline/bdb/1612700/1612740/original.jpg) Thus, the program allows you to control the entire process - from creating a model to cutting it and sending it to print.

Thus, the program allows you to control the entire process - from creating a model to cutting it and sending it to print.

►►►Link to office. PrusaSlicer 9 website0005

3DPinterOS

3DPrinterOS is a cloud-based 3D printer management software. It combines the functions of a slicer, a host, and an STL file editor. The program can create a print queue, manage the printer and plug-in system based on STL data analysis and recovery applications, and perform cloud slicing.

The free Starter package allows users to download G-codes and send them to print, remotely control the printing process, and get support on a like-minded forum. For a modest fee, you can access additional features, including the ability to collaborate on a project.

In fact, this program is a universal tool for converting files for printing in the STL format. That is why 3DPrinterOS is suitable for small businesses, education, production and design.

►►►Link to office. website 3DPinterOS

KISSlicer

The abbreviation of this application “Keep It Simple Slicer” can confuse inexperienced users. It's actually quite a complex 3D printing tool. Conflicting user reviews, however, allow us to conclude that the program is popular and has sufficient functionality to work with 3D printers.

It's actually quite a complex 3D printing tool. Conflicting user reviews, however, allow us to conclude that the program is popular and has sufficient functionality to work with 3D printers.

The free version of the program is suitable for most users who work with printers with a single extruder. KISSlicer helps simplify certain aspects of slicing with Profile Wizards for printer-specific settings and Tuning Wizards for optimizing materials. The paid version of the program allows you to work with printers with 2 extruders.

Although the application settings are quite complex, it's worth the effort - the slicer allows you to have full control over the entire printing process.

►►►Link to office. KISSlicer website

Slic3r

This software is for open source slicers. Its main difference is advanced features that are not found in any other application.

Despite the fact that Slic3r releases almost no updates to its program, it is the base for many other open source software. For example, many programs use 3D honeycomb cavity filling, which is a special merit of the Slic3r developers.

For example, many programs use 3D honeycomb cavity filling, which is a special merit of the Slic3r developers.

In 2018, a new version of the software was released with new integrated functions. So, this version has new fill patterns, experimental support for SLA and DLP printers, 3MF format, and USB printing.

On the software website you can find a detailed manual that gives you an idea of all the functions of Slic3r. A great bonus of the program is the direct integration with OctoPrint for printing at the touch of a button.

►►►Link to office. website Slic3r

SliceCrafter

Browser-based slicer from IceSL developers. Using the program, you can quickly load STL files, cut them, and then prepare the G-code for printing. In the browser program, you can use almost all the options that IceSL offers.

Although many users find this version less powerful, it is suitable for beginners who do not want to set up more complex 3D printing programs.

►►►Link to office. website SliceCrafter

IceSL

IceSL is an excellent tool for 3D modeling and printing. Several working windows allow you to edit the model directly through a Lua script, select different settings for slicing the model, and view the result in real time. Despite the apparent complexity of working with the software, IceSL allows for elegant parametric modeling.

Slicer settings menu allows beginners to easily and quickly prepare a 3D model for printing. In the latest version of the program, it became possible to specify different values for print settings at a certain layer height. All this allows you to make smooth transitions from dense to light filling and gradation of the thickness of the layers from fine to coarse.

►►►Link to office. site IceSL

OctoPrint

This program is a host for 3D printers that allows you to control printing and change settings. The software also allows you to remotely control the printer using a Wi-Fi module connected to the device.

OctoPrint accepts G-code from almost any slicer, while the host allows you to visualize the received files before and during printing. In addition, cutting files can be done directly in the program, using it as a slicer.

OctoPrint offers not only a wide range of tools for remote print management, but also several ways to keep track of your tasks. You can set up push notifications or send alerts through different messengers.

The software is open source and has an active user community that offers many plug-ins to extend the program's functionality. On the community page, you can find many add-ons that will be useful when printing.

►►►Link to office. site OctoPrint

Repetier-Host

Rep-Rap developers favorite host - Repetier is a high performance print management and file preparation software.

Repetier-Host is positioned as a universal software that helps manage printers with a large number of extruders (up to 16 extruders), and also supports almost any 3D printer on the market.

The program has remote access functions through the Repetier Server, which allows you to control your printer through a browser on a PC, tablet or smartphone.

►►►Link to office. Website Repetier-Host

AstroPrint

Like 3DPrinterOS, this program is a cloud-based solution for controlling and managing your 3D printers. Also, using AstroPrint, you can change slicer settings, manage printer and material profiles. A free account allows you to save print information and access all settings through a browser or the AstroPrint mobile app.

This software is unique in that it is compatible with Thingiverse and MyMiniFactory as well as free versions of CAD programs such as 3D Slash and Leopoly. The application also has tools for cutting 3D models with the ability to send files for printing from a smartphone.

The software will be useful for those who work in large scale networks such as 3D farms, enterprises and universities.

►►►Link to office. website AstroPrint

website AstroPrint

3D-Tool Free Viewer

3D-Tool Free Viewer is designed to check the structural integrity of STL files and the ability to print a document on your printer. Additional functions, such as "Cross Section" also allow you to look inside the 3D model and evaluate some parameters.

This program can be useful if you want to check your STL file for errors. The user-friendly interface of the software allows you to measure the size, surface area and volume of all parts of the figure, as well as change the distance, angles and radius at the touch of a button.

For those who do not have sufficient knowledge and experience in CAD, the program offers a quick way to check the STL file and prepare it for 3D printing.

►►►Link to office. website 3D-Tool Free Viewer

MakePrintable

This useful web service allows you to check STL files for errors and correct critical values that may affect printing. Unlike other free programs, MakePrintable gives you complete control over the process. You can choose the level of print quality, make the mesh hollow, fix the polygon count, and even merge multiple targets into one.

You can choose the level of print quality, make the mesh hollow, fix the polygon count, and even merge multiple targets into one.

Although the program no longer offers a free version with limited functionality, users may find several ways to use the program. The program has different payment options - for a single file download (about $ 2 per file) or a "Maker" package with the ability to upload up to 30 files per month (monthly price about $ 15).

The advantage of the program is the compatibility of plug-ins with Blender and SketchUp.

►►►Link to office. MakePrintable 9 website0005

Meshmixer

Meshmixer is a super modern and free software from the Autodesk 3D printing family for viewing, checking, editing and repairing STL files. This program helps you identify potential problems and fix them automatically. For example, the program identifies insufficient wall thickness.

The program is positioned as a universal tool for 3D meshes, offering a variety of tools for working with mesh, 3D modeling, surface embossing and others.

Whether you're trying to fix an STL file, prepare a model for printing, or design multiple objects, Meshmixer is ideal for all of these purposes.

►►►Link to office. website Meshmixer

MeshLab

MeshLab is an open source application that allows you to edit STL files and also has tools for working with 3D triangular meshes. The software's capabilities help you check, render, repair, and transform meshes, and even solidify models and close holes.

The application is great for editing 3D models created in CAD. Despite the fact that the latest version was released in 2016, the program is still popular with makers.

►►►Link to office. website MeshLab

NetFabb

NetFabb is a slicing software that includes advanced analysis and recovery of STL files. One of the most powerful tools, NetFabb aims to streamline the user experience by offering support creation, mesh repair, and a wide range of generative design tools.

The program is free for students, as part of an Autodesk subscription. The 3-year student license allows you to choose one of the following versions:

The 3-year student license allows you to choose one of the following versions:

- NetFabb Standard allows you to quickly prepare a model for printing;

- NetFabb Premium with advanced options for creating grids, supports and automatic packaging of parts;

- NetFabb Ultimate allows you to calculate assembly failures, provides modeling tools, customizable toolpath strategies, and helps automate the process of preparing a model for 3D printing;

- NetFabb Simulation helps you simulate certain metal printing technologies prior to production.

►►►Link to office. NetFabb site

About programs for 3D modeling, which even a beginner will understand, we wrote in this article. Here are equally useful, easy-to-use, and most importantly, free programs for three-dimensional modeling and 3D printing.

3D Builder

3D Builder application offers its users to quickly visualize and edit 3D models. The software helps to create and import files in 3D printing formats. Using simple editing tools, even entry-level users can create 3D images.

Using simple editing tools, even entry-level users can create 3D images.

The application has its own extensive library of 3D models. You can also upload an external file or use the Kinect V2 sensor to scan and import a new 3D image. By joining the 3D Builder community and downloading the 3D Printing SDK, you can expand the capabilities of this free program.

►►►Link to office. website 3D Builder

Figuro

This browser-based modeling software combines the accessibility of TinkerCAD with the power of more advanced 3D modeling tools. The program is suitable for those who want to improve their design skills without going too deep into details.

The creation of objects in Figuro is based on the principle of polygonal modeling - you generate polygons by modifying them and combining them with each other. If you are using the program for the first time, we recommend using additional tools for checking and repairing STL files.

The program has a simple and pleasant user interface. An extensive gallery allows you to evaluate the capabilities of the software and get inspiration for creating new objects.

An extensive gallery allows you to evaluate the capabilities of the software and get inspiration for creating new objects.

►►►Link to office. Figuro 9 website0005

Fusion 360

Fusion 360 is a professional 3D modeling CAD program. Unlike other software, the software allows you to cover the entire process of planning, testing and 3D design.

The program has powerful tools for solving industrial design problems. Fusion 360 allows you to simulate the design of objects under design as well as the loads that they will face after commissioning.

Design collaboration, cloud file sharing, and import/export of various CAD file types make the application easy to use.

Fusion 360 is free for students, startups and hobbyists. At the same time, amateur projects must not be commercial, startup income must not exceed $ 100,000 per year, and the student license of the program is limited to three years.

►►►Link to office. site Fusion 360

FreeCAD

Multifunctional CAD software allows you to perfectly develop design skills. Parametric modeling software creates models according to the given parameters. The big advantage is the ability to drag and control objects directly with the mouse.

Parametric modeling software creates models according to the given parameters. The big advantage is the ability to drag and control objects directly with the mouse.

A feature of this program is the ability to return to the history of the creation of an object and edit its parameters. Despite the fact that the software is free, it has all the necessary tools for full-fledged work.

FreeCAD allows users to draw 2D shapes as a basis for creating additional objects. The program is suitable for product design, mechanical engineering, architecture and other areas.

►►►Link to office. FreeCAD website

OpenSCAD

Unlike the other programs presented, OpenSCAD focuses more on the CAD aspect of 3D modeling. The software works as a 3D camillator that reads a script file describing a 3D model and then converts the object into a 3D model.

The open source program is constantly updated with new features. For example, the latest update has a new Customiser panel. Get support and advice on using the application and working with updates in the user community.

Get support and advice on using the application and working with updates in the user community.

The software does not have interactive components, but it helps to better control the modeling process and manage the design parameters settings. OpenSCAD is considered to be the ideal tool for students.

►►►Link to office. OpenSCAD website

Blender

A popular CAD program with a steep learning curve. This software is not the best choice for a beginner, but is ideal for those who are familiar with 3D modeling concepts and want to create more complex models.

The latest version of the program is more accessible. So the user interface has become more convenient, and a three-dimensional viewing window has also appeared. Eevee's advanced add-ons, real-time renderer, and Grease Pencil for 2D drawing and animation greatly enhance the program's capabilities.

The open source program is constantly updated with new functional solutions for comfortable work.