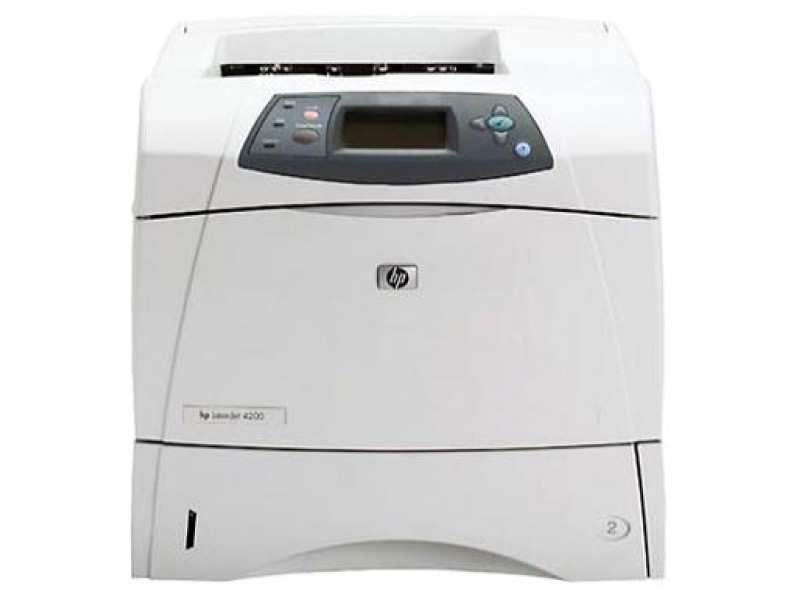

Hp 4200 3d printer

HP 3D Jet Fusion 4200 - Commercial & Industrial 3D Printer | HP® Official Site

The content of this site is for information purposes only and it is showing the product configuration for the US market only.

Availability, pricing, product configuration and specifications may differ according to geographical location, local laws and practices.

Please contact us or talk to your local HP 3D Printing representative for further information or for product configurations specific to your local country.

1. Continuous printing requires an additional HP Jet Fusion 3D build unit (standard printer configuration includes one HP Jet Fusion 3D build unit.

2. Compared to manual print retrieval process used by other powder-based technologies. The term “cleaner” does not refer to any indoor air quality requirements and/or consider related air quality regulations or testing that may be applicable.

3. Industry-leading surplus powder reusability based on using HP 3D High Reusability PA 11 and PA 12 at recommended packing densities and compared to selective laser sintering (SLS) technology, offers excellent reusability without sacrificing mechanical performance. Tested according to ASTM D638, ASTM D256, ASTM D790, and ASTM D648 and using a 3D scanner. Testing monitored using statistical process controls.

4. For advanced data features charges may apply in the future.

5. Continuous printing requires an additional HP Jet Fusion 3D build unit (standard printer configuration includes one HP Jet Fusion 3D build unit).

6. HP 3D High Reusability PA 11 image is data courtesy of NACAR.

7. HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PA 11 provide up to 70% powder reusability ratio, producing functional parts batch after batch. For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy.

8. Testing according to ASTM D638, ASTM D256, and ASTM D648 using HDT at different loads with a 3D scanner for dimensional accuracy. Testing monitored using statistical process controls.

9. HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PA 12 provide up to 80% powder reusability ratio, producing functional parts batch after batch. For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy.

10. Supplies price, and maintenance costs recommended by manufacturer. Cost criteria: printing 1.4 full build chambers of parts per day/5 days per week over 1 year of 30 cm3 parts at 10% packing density on Fast print mode using HP 3D High Reusability PA 12 material, and the powder reusability ratio recommended by manufacturer, and printing under certain build conditions and part geometries.

11. HP 3D High Reusability PA 12 GB image is data courtesy of NACAR.

12. HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PA 12 Glass Beads provide up to 70% powder reusability ratio, producing functional parts batch after batch. For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy.

For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy.

13. ESTANE ® 3D TPU M95A image is data courtesy of HP-Lubrizol.

14. Available for the HP Jet Fusion 4200 3D Printing Solution.

15. Supported industrial management systems: 3D Control Systems, AMFG, LINK3D, Siemens NX AM, Siemens Opcenter. Access to additional data modules available only for the HP Jet Fusion 5200 Series 3D Printing Solution. Additional purchases required.

16. This product is only available in Europe and in the Americas. HP does not design, manufacture or sell the Girbau product or provide any warranty for the Girbau products. HP believes that the information herein is correct based on the current state of scientific knowledge and as the date of its publication, however, to the maximum extent permitted by law HP EXPRESSLY DISCLAIMS ANY REPRESENTATIONS AND WARRANTIES OF ANY KIND, WHETHER EXPRESS OR IMPLIED, AS TO THE ACCURACY, COMPLETENESS, NON-INFRINGEMENT, MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR PURPOSE (EVEN IF HP IS AWARE OF SUCH PURPOSE) WITH RESPECT TO ANY INFORMATION PROVIDED. Except to the extent that exclusion is prevented by law, HP shall not be liable for technical or editorial errors or omissions, and damages or losses of any kind or nature that result from the use of or reliance upon this information, which is subject to change without notice. Recipients of the Girbau product are responsible for determining the suitability of Girbau products with HP Jet Fusion 3D products, ensuring compliance with applicable laws and regulations, and being aware that other safety or performance considerations may arise when using, handling or storing the product.

Except to the extent that exclusion is prevented by law, HP shall not be liable for technical or editorial errors or omissions, and damages or losses of any kind or nature that result from the use of or reliance upon this information, which is subject to change without notice. Recipients of the Girbau product are responsible for determining the suitability of Girbau products with HP Jet Fusion 3D products, ensuring compliance with applicable laws and regulations, and being aware that other safety or performance considerations may arise when using, handling or storing the product.

17. Data courtesy of Meidai.

18. Data courtesy of GoProto Inc. Printed with HP 3D High Reusability TPA enabled by Evonik. Post-processed with AMT PostPro chemical vapor smoothing.

19. Based on published specifications as of September, 2020. HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability TPA enabled by Evonik provide up to 17% lower printed part weight when compared to common powder-based thermoplastic elastomers printed under similar conditions.

20. Available only for the HP Jet Fusion 5200/4200 Series 3D Printing Solutions.

21. The content of this site is for information purposes only and it is showing the product configuration for the US market only. Availability, pricing, product configuration and specifications may differ according to geographical location, local laws and practices. Please contact us or talk to your local HP 3D Printing representative for further information or for product configurations specific to your local country.

HP Jet Fusion 3D 4200 Review 2022

4.9

See Price

Having dominated the inkjet printer market for decades, HP was bound to dip its toes into the 3D printer market at some point. Today, we take a look at one of these attempts with the HP Jet Fusion 3D 4200, marketed as an industrial grade solution adapted to weather sustained daily usage while providing quality prints.

Having got our hands on one of these bad boys, here’s everything you need to know about the HP Jet Fusion 3D 4200 and our verdict on whether it lives up to HP’s reputation for quality products. Here we go.

Here we go.

| Printing Area | 380 mm x 284 mm x 380 mm |

| Layer Resolution | 80 Microns |

| Supported Filament | PA 11 and PA12 |

| Technology | HP Multi Jet Fusion |

| Connectivity | Ethernet and USB Flash Drive |

Table of ContentsShow

Design & Features

Let’s start by admiring HOW big this printer is, tallying up to an altogether impressive 2178 mm x 1238 mm x 1488 mm footprint with a total weight of 730 kg while the processing station is 2990 mm x 934 mm x 2400 mm with a load of 480 kg. Unlike the majority of industrial 3D printers, the HP Jet Fusion 3D 4200 extends horizontally rather than vertically making it more akin to a large photocopier in terms of its physical presence.

Aesthetically, it keeps all the futuristic contours and functional allure we’ve come to expect from HP products allied to a wonderful dual color scheme of stylish dark gray and black. The model is effectively made up of a printer, a build unit, and processing station that when combined create an all-in-one printing solution.

The model is effectively made up of a printer, a build unit, and processing station that when combined create an all-in-one printing solution.

The HP Jet Fusion 3D 4200 employs HP’s proprietary Multi Jet Fusion technology, an additive printing method that uses jets to simultaneously deposit fusing agent and detailing agent voxels to melt an even layer of powder on the build bed in the shape of a model layer by layer within a fully enclosed temperature controlled chamber. An infrared lamp/heater passes across the surface of the bed selectively fusing the powder to the layer underneath. Completed layers are then lowered to make way for the next and so on.

In practical terms, there are three global steps to using the HP Jet Fusion 3D 4200. First, the mobile build unit inserts into the processing station where defined quantities and levels of materials are automatically mixed and loaded into a tank inside the build unit. The build unit is then transferred to the printer where the Jet Fusion process creates the model.

Once the printing process is complete, the build unit is transferred back to the processing station where finished models are cooled, unpackaged, and cleaned of excess powder. The printer has two build units to produce prints uninterrupted.

Process aside, let’s look at some specifications. The HP Jet Fusion 3D 4200 has a build volume of 380 mm x 284 mm x 380 mm with a maximum layer thickness of 80 microns, a print resolution of 1200 dpi, and build speed of 4115 cm3 per hour.

Connectivity is assured through Gigabit Ethernet for network use, and USB flash drive, alongside HP’s tandem of SmartStream 3D Build Manager and SmartStream 3D Command Center software with support for 3MF, STL, OBJ, and VRML file types.

Additional features, include constant quality monitoring via the touchscreen (the touchscreen has an eight icon display running the gamut of settings and monitoring options) throughout the printing process to minimize mistakes, excess powder recycling, and the ability add new parts to a print already in progress.

Material support is limited to HP products; HP 3D High Reusability PA 12, HP 3D High Reusability PA 12 Glass Beads, and HP 3D High Reusability PA 11 shipped in three-liter boxes that sit alongside the processing unit. Colors are currently limited to grey with plans to expand soon by working with third-party material manufacturers.

Packaging & Assembly

Due to its voluminous size, the HP Jet Fusion 3D 4200 ships on a massive encapsulating wooden crate for protective reasons. Removing the container is a four-person job and takes time. In most cases, the point of purchase will offer unpacking services to do just this. Fortunately, all three units are fitted with wheels for easy maneuverability once the packaging is removed.

Installation is complex and best left to trained technicians or in house tech teams and includes wiring, part installation, and the like.

Printing

As a printer designed for volume alongside a sustained and predictable level of quality, the HP Jet Fusion 3D 4200 performs as expected; systematic high-quality prints fit for purpose with no errors or manufacturing inconsistencies. The parts we produced were perfect for high-level prototyping, end-user products, and everything in between. Seeing the Multi Jet Fusion technology in action is impressive with an almost hypnotic back and forth between the layering of powder and the sweep of the halogen lights.

The parts we produced were perfect for high-level prototyping, end-user products, and everything in between. Seeing the Multi Jet Fusion technology in action is impressive with an almost hypnotic back and forth between the layering of powder and the sweep of the halogen lights.

The only real gripe was the lengthy cooling period for the materials, which although aided by the processing station’s cooling mechanism was more prolonged than other additive techniques we are accustomed to and found in competing industrial level 3D printers. The issue is, however, offset by the sheer detail and flawless quality of the prints.

The software is remarkably well designed for a proprietary product with an intuitive slicer-like preparation phase alongside error checking features that help the process immensely. HP is stressing simplicity to maximize productivity with a helping hand at every turn.

As for long terms costs, one of the core concepts behind the HP Jet Fusion 3D 4200 is prolonged affordability, and this is seen in smart money-saving features such as the ability to reuse powder, maximize production via the dual build unit setup where the processing station and printer can work continuously to create prints. The error monitoring system also ensures no prints end up botched or unfit for purpose. The initial cost of buying the printer is balanced out by the ongoing cost-effectiveness of production.

Support

HP offers a one-year warranty for the Jet Fusion 3D 4200 with the possibility of paying for extended warranties with servicing options with on-site support and maintenance. Customer support adheres to the standard set by other HP products with a dedicated technician phone line and a wealth of guides, tutorials, and videos on the company’s web site to aid with any troubleshooting, operational, and general maintenance issues.

Verdict

The HP Jet Fusion 3D 4200 is quite expensive. There’s no circumnavigating this fact. As such, it is uniquely suited to large scale professional operations that have the capital to invest in such a costly device. Cost aside, we are hard pressed to find a better model within the industrial 3D printer market.

The quality of the prints, the ease of use, the strength and variety of the materials, and the all-in-one solution combine to make the Jet Fusion 3D 4200 one of, if not, the best 3D printer on the market today.

HP Jet Fusion 4200 review of 3D printer

In 2016, Hewlett Packard in Florida held a presentation of the first generation of 3D printers using Multi Jet Fusion (MJF) technology. For printing, powder thermoplastics are used, which are formed by inkjet arrays.

HP Jet Fusion 3D 3200 and HP Jet Fusion 3D 4200 are among the first MJF devices.0002 HP Jet Fusion is not just a 3D printer, but an entire 3D printing system. It consists of the printer itself, as well as a recycling station, which is responsible for processing the remaining consumables. Powder that was not used up during printing can be reused: according to the manufacturer, 80% of the material can be used for subsequent printing cycles.

To do this, old powder is mixed with new powder, sieved and converted into a ready mix for printing. This whole process is almost completely automated and does not require active human participation.

The performance of the HP Jet Fusion 4200 printer is reflected in its name: the device print volume is 4200 cm³/hour. Products are recreated in the classic way for 3D printers - in layers. The layer thickness in this case reaches 70–120 µm.

Products are recreated in the classic way for 3D printers - in layers. The layer thickness in this case reaches 70–120 µm.

INFORMATION! Compared to the more modest model HP Jet Fusion 3D 3200, the printer in question is sharpened for small-scale production, has a large number of settings. This allows you to make adjustments to the current production process - to add models to fulfill emergency orders.

Recycling plant reduces production costs, including temporary costs. It incorporates an improved cooling system, thanks to which the time spent on preparing material for processing is reduced.

HP Jet Fusion 4200 3D Printer

- Energy consumption 9-11 kW

- File formats 3mf, stl

- Dimensions, mm 2300 x 1325 x 1983

- The weight 730 kg

- Max workpiece size 406 x 305 x 406 mm

- Seal MJF

- Print resolution 1200 dpi

- Working chamber area 406 x 305 x 406 mm

- Speed 4200 cm3/h

- Layer thickness from 70 µm

Go to product

The performance of the MJF printer is far superior to that of popular SLS printers. According to HP, the HP Jet Fusion 3D 4200 model is 10 times more productive than SLS devices, and 50 times more productive than FDM printers.

According to HP, the HP Jet Fusion 3D 4200 model is 10 times more productive than SLS devices, and 50 times more productive than FDM printers.

At high print speeds, the printer also provides a large amount of work due to the working chamber with dimensions of 406 × 305 × 406mm. In addition, the printer can print several products at the same time.

The printer's extruder is equipped with three arrays. Each of them has 10 thousand nozzles, providing a resolution of 1200DPI. The printhead delivers 350 million drops per second with an accuracy of 21 microns. The total performance of the work reaches 1.8 teravoxels, and with each movement, up to 276 million voxels are processed.

By measuring the temperature in the working chamber in 900 points in real time, the shrinkage of printed products is minimized. If there is a temperature difference at different points, an adjustment is made.

The software was developed with the participation of experts from Materialize, Siemens and Autodesk. The system provides support for STL and 3MF formats. For management, HP offers software HP SmartStream 3D Build Manager and HP SmartStream 3D Command Center with an intuitive user-friendly interface in Russian

The system provides support for STL and 3MF formats. For management, HP offers software HP SmartStream 3D Build Manager and HP SmartStream 3D Command Center with an intuitive user-friendly interface in Russian

In the future, the manufacturer is going to focus on the more promising 3MF file format. The company also plans to develop a color MJF printer.

Main features

The main features of the device and printing on it include the following:

- the printer is equipped with a system for processing the remaining consumable powder;

- large build area for simultaneous printing of several products;

- advanced MJF printing technology for thermoplastic powders;

- the ability to use up to 80% of the material for the next print cycles;

- print layer variation from 70 to 120 microns;

- high print speed with maximum productivity;

- Multi-level gun array for maximum print quality on precise, flexible, durable products;

- uniform heating of the product during printing;

- economical consumption of consumables and electricity;

- optimization of the printing process due to the possibility of continuous printing, closed mixing technology and reduced operating costs;

- rapid cooling system;

- highly detailed products;

- specially designed software for easy management of HP SmartStream 3D Build Manager and HP SmartStream 3D Command Center.

Package contents

When ordering the device, the buyer receives a complete system for 3D printing, which includes:

- 3D printer;

- device for processing consumables;

- network adapter;

- instructions in Russian;

- commissioning;

- job training.

Print quality and product examples

High print quality can be considered one of the characteristics of the printer.

Patented multi-jet technology uses a multi-level nozzle array that allows multiple fluids to be applied simultaneously during the printing process. Due to this, the printing is of the highest quality, and the products are flexible and durable in all three dimensions.

INFORMATION! Multi Jet Fusion (MJF) technology delivers high strength and an order of magnitude higher detail than other 3D printing technologies. As an example, HP printed out a chain link that can withstand a load of up to 4.

5 tons. At the same time, the printing time was only 30 minutes with a layer thickness of 70 microns.

00 points and automatic temperature correction, which ensures uniform heating of the product and eliminates shrinkage.

Who will fit

The printer is too expensive and bulky for home use. The device is aimed at various industries, as well as small-scale production. It can be used to print souvenirs, prototypes and layouts for use in educational institutions, parts for cars, some household and electronic appliances, tools and accessories.

Modern polyamides such as PA 11 can be used to create shoe insoles and sporting goods. Other types of consumables allow the printer to print rigid cases and parts of tools, light and durable plastic products with increased flexibility, moisture resistance and resistance to aggressive chemicals (for example, kitchen utensils: spatulas, ladles, etc.).

What materials are used?

The printer creates products from thermoplastic powders, on which a bonding material is applied in layers. Its quantity can be adjusted and depends on the requirements for the quality and physical properties of the finished model.

Its quantity can be adjusted and depends on the requirements for the quality and physical properties of the finished model.

As a consumable for the HP Jet Fusion 4200 printer, the manufacturer suggests using thermoplastics of its own production. The advantages of introducing their own materials are obvious: the company uses high-quality raw materials, carefully selects the composition and manufacturing technologies.

This results in finished models that are highly detailed, accurate, and durable, while reducing costs significantly.

Initial setup and preparation instructions

The printer is delivered assembled, however, before starting work, you need to perform a few simple steps: install the software, correct the fusible lamp and prepare the device for printing.

The control panel is located on the front of the printer. To have extended access to printer settings, you need to install software on your computer - HP SmartStream 3D Build Manager and HP SmartStream 3D Command Center programs. Software download pages are listed in the user manual.

Software download pages are listed in the user manual.

After activating and launching the program, click on the gear, then click "Manage Printers" > "Add Printer". Next, you need to create an HP PrintOS account and follow all further instructions on the monitor: after synchronization with the printer, you can proceed with the settings.

After installing the software, you can turn on the printer. To do this, you need to connect the network cable and plug it into the network and make sure that the device is working. This can be seen from the switched on breakers in the bottom two rows on the front of the printer on the right, as well as three green lights.

If the printer is OK, the platform and tray need to be adjusted. The calibration tray must be installed according to the printer model, but the setup process is the same for all devices.

Calibration requires the latest FW release (minimum required BD9) to be installed on the printer.

Next steps:

- place the tray on the build block platform as directed in the instructions for use;

- insert assembly block;

- On the front panel on the front of the printer, click on the gear icon, click "Maintenance Menu" > "Calibration of Fused Lamps with Calibration Tray" > "Adjust Calibration Tray Offset".

INFORMATION! The tray is inserted into the printer with the label facing down.

Next, the tray adjustment menu will appear as shown in the picture below.

Operate the UP (up) and DOWN (down) buttons to set the tray to the desired position. You can refer to the service kit leaflet. In case of an error, press BACK and repeat the procedure. After the calibration is completed, click OK.

Calibration instructions appear on the display, so all the necessary settings can be made without problems, even without experience. The main thing is to follow safety precautions and precautions so as not to damage printer parts and avoid injury. Calibration usually takes no more than 40 minutes.

Any desired settings can be made using the panel control: you can set the date and time, set an access password, adjust the speaker volume, select the units of measurement (imperial or metric) or restore the factory settings.

Software installation and tray calibration are the first necessary printer settings. The device can then be switched on:

- Set the main switch to the on position.

- Wait until the printer is ready to reboot message appears on the front panel.

- Visually inspect the printer.

- Press the blue reset button on the front left side of the printer. All printer subsystems with high power consumption will turn on.

- Wait for the front panel to indicate that the printer is ready. This may take several minutes. When initialization is complete, the message "Ready" will appear on the front panel.

If everything is correct, you can load the printing powder into the cartridge by following the instructions in the user manual.

Another breakthrough in the field of 3D printing was the emergence of devices using MJF technology. The consumables are polyamide powders with good physical properties, which produce strong, environmentally resistant, flexible and durable products.

The HP Jet Fusion is a professional 3D printer for use in a wide range of industries and small batch production. It is possible that in the near future the model will be improved and the scope of its application will expand, as well as the possibility of color printing.

- August 10, 2020

- 849

Get expert advice

HP start shipping Jet Fusion 3D 4200 Printer0001

HP has begun shipping its Jet Fusion 3D 4200 Printer to customers. The first to receive the devices are the company's partners who supported the development of the novelty - Jabil, Materialise and Shapeways.

Jet Fusion 4200 operates on the basis of “HP Multi Jet Fusion technology”, which is a modified SLS (Selective Laser Sintering): layers of special powder are poured layer by layer, the desired areas of the layer are selectively sintered under special lighting. Powder from unused areas can sometimes be reused. HP claims that its devices are more reliable, print faster (advantage up to x10) and better, and the infrastructure being created in the form of professional software and the market for materials will make their use as convenient as possible.

The printing process is as follows: the model file and powder are loaded into the Processing Station, which prepares the printing process in the ”Build Unit”. Next, the Build Unit is removed from the station and installed in the printer itself, and printing starts.

Main specifications of the Jet Fusion 3D 4200 Printer (without Processing Station):

- Maximum part size: 406 x 305x 406 mm

- Layer height: 0.07 to 0.12 mm

- Unit size: 2178 x 1238 x 1448 mm @ 730 kg (unpackaged)

- Features: powered by 380 volts, HDD 2 terabytes, Ethernet interface

Processing Station weighs from 450 kg and measures from 1926 x 1245 x 2400 mm to 3121 x 1571 x 2400 mm (with fast cooling installed).

Read more about HP Jet Fusion 3D printers here.

The Jet Fusion 4200 is currently printing with HP's proprietary 3D High Reusability PA12 resin (with the ability to reuse “excess” powder). The device will also support materials from alternative manufacturers (the concept of Open Platform).