3D printing health and safety

3D Printing Safety at Work | NIOSH

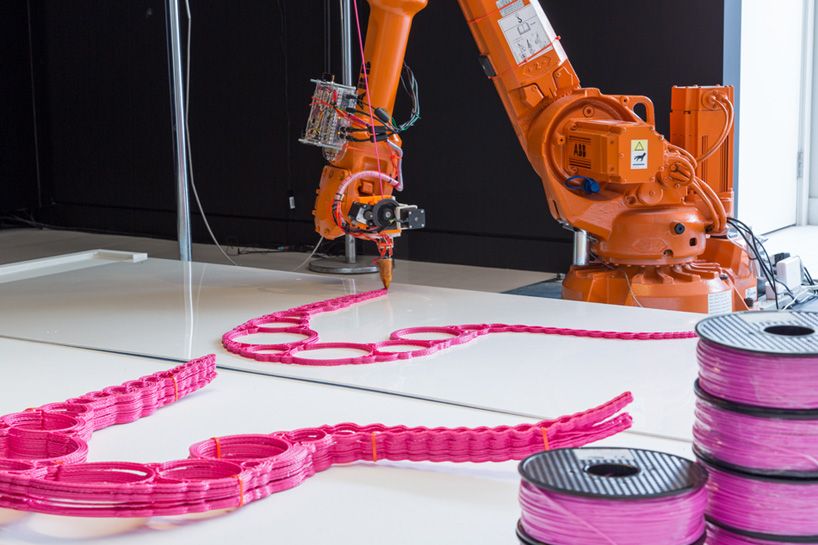

3D printing, or additive manufacturing, is increasing in popularity. This technology is becoming less expensive and more accessible to both businesses and consumers. It is currently used in a wide variety of settings, such as labs, factories, hospitals, schools, libraries, and homes. Despite its popularity, 3D printing is still a relatively new technology and there are many gaps in the information available about health and safety risks. The National Institute for Occupational Safety and Health (NIOSH) is studying the potential hazards of 3D printing and ways to reduce health and safety risks for workers.

What is 3D printing?

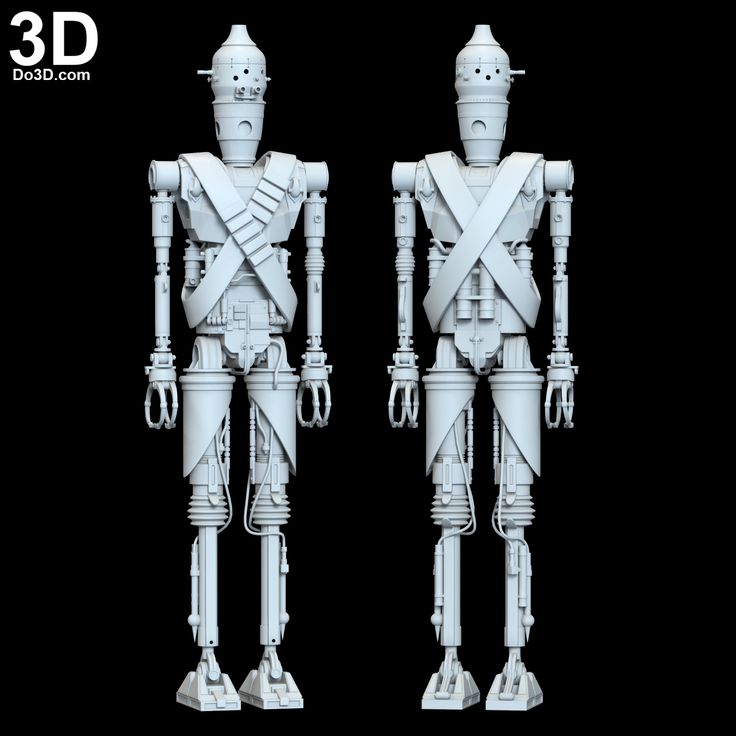

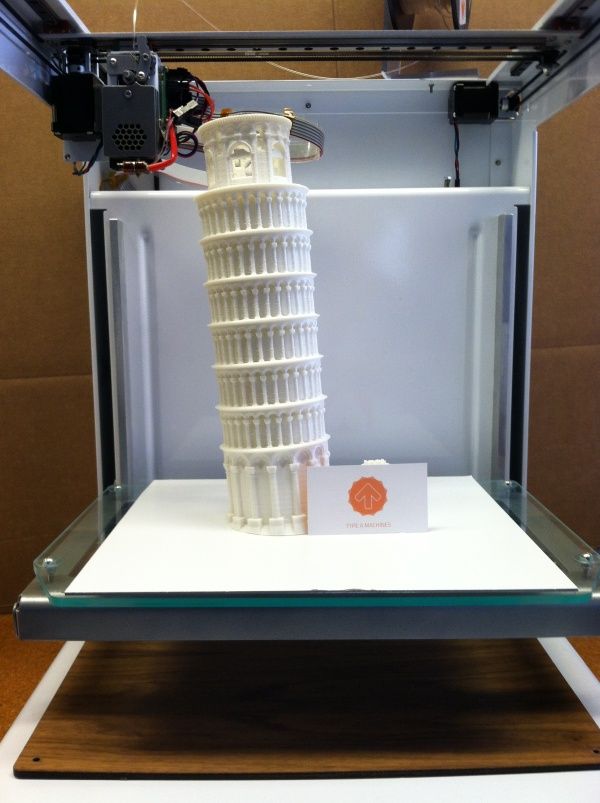

3D printers create three-dimensional (or 3D) objects via computers. A computer file “tells” the 3D printer what object to create and how. 3D printers essentially stack layers of a material to get the desired product. Different types of 3D printers do this in different ways. For example, some use high temperatures, some use ultraviolet light, and others use lasers. 3D printers also use different print materials, such as plastics, rubbers, and metals.

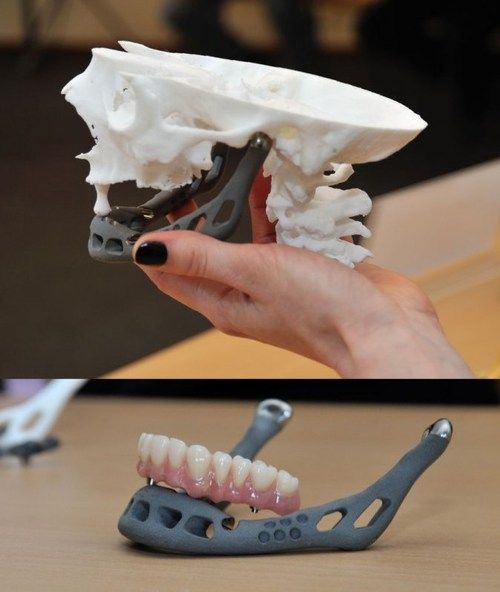

Industries traditionally used 3D printing for prototyping. However, it is now also used for production. Industries using 3D printing include the automotive, aerospace, electronics, medical, and many others.

Potential Hazards of 3D Printing

3D printing hazards vary depending on the type of printer and materials used. For example, print materials that are powders are more likely to be inhaled or cause skin problems than others. 3D printers that use lasers have different hazards than printers that use high temperatures to melt materials. Some common hazards include:

- Breathing in harmful materials: 3D printing can release particulates and other harmful chemicals into the air.

- Skin contact with harmful materials: Users can get hazardous materials, such as metal powders, solvents and other chemicals, on their skin.

- Static, fire and explosion: Some materials used can be flammable or combustible.

High temperatures from some printers can cause burns.

High temperatures from some printers can cause burns.

Ways to Protect Workers from 3D Printing Hazards

NIOSH has studied multiple ways to reduce exposure to 3D printing hazards. Some options include

- Limiting equipment access to trained or authorized personnel

- Using enclosures for 3D printers and ventilation to capture chemical emissions

- Using materials with lower emissions

- Reducing time spent near the printer while it is running

- Training workers on potential hazards and how to protect themselves

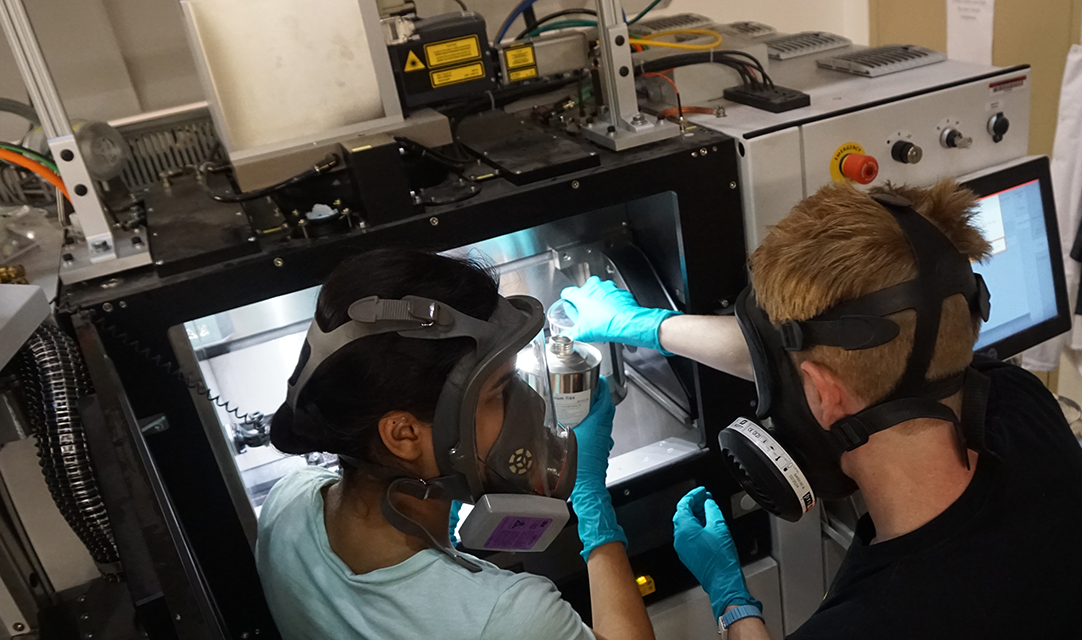

- Wearing appropriate personal protective equipment, such as safety glasses, gloves, or lab coats

The ways to reduce exposure depend on the type of printer and materials used. NIOSH has created two posters to help workers explore ways to reduce potential 3D printing hazards. One poster focuses on 3D printing with metal powders and the other focuses on filaments:

- 3D Printing with Metal Powders: Health and Safety Questions to Ask

- 3D Printing with Filaments: Health and Safety Questions to Ask

Help NIOSH Learn More about 3D Printing

Do you use 3D printing in your workplace? You can help NIOSH continue assessing 3D printing hazards and controls. Companies can contact the Nanotechnology and Advanced Materials Field Studies Team to assess possible work-related health hazards with 3D printing in their workplace.

Companies can contact the Nanotechnology and Advanced Materials Field Studies Team to assess possible work-related health hazards with 3D printing in their workplace.

More Information

- Additive Manufacturing

- NIOSH Science Blog: Characterizing 3D Printing Emissions and Controls in an Office Environment

- 3D Printing with Metal Powders: Health and Safety Questions to Ask

- 3D Printing with Filaments: Health and Safety Questions to Ask

3D Printing Health Hazards and PPE for Proper Protection

Also known as additive manufacturing, 3D printing has rapidly gained traction in the manufacturing industry. This innovative technology allows producers to create products using a combination of inexpensive materials and highly accessible equipment.

While the popularity of 3D printing has grown, many 3D printing health hazards are just starting to gain recognition. For the protection of all workers involved in 3D printing, it is critical that organizations get familiar with the unique health hazards involved and how to properly combat those risks with the use of proper practices and personal protective equipment (PPE).

The 3D Printing Processes

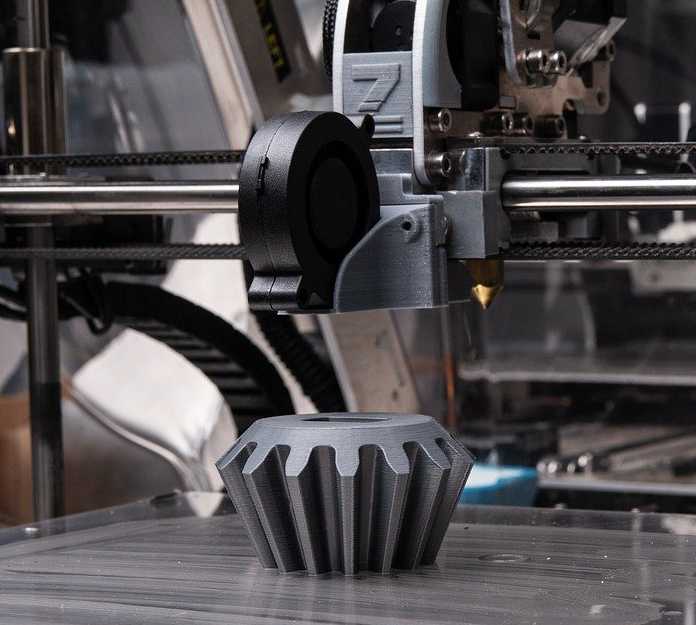

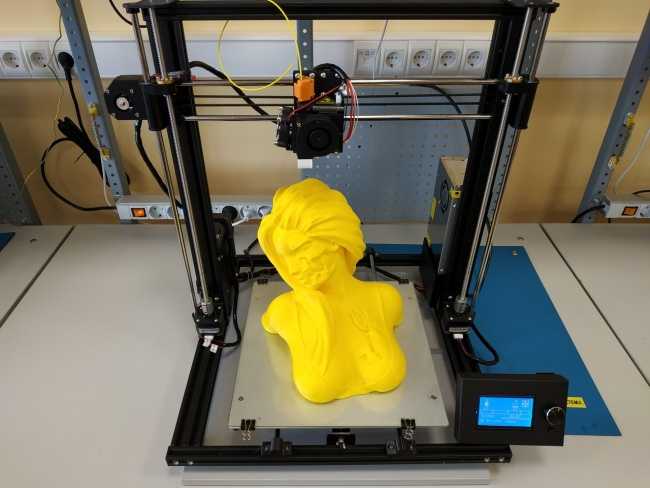

The 3D printer is an advanced piece of equipment that can utilize user inputs on a computer and filaments or printing materials to create dimensional objects layer by layer. Essentially, the printer stacks multiple layers of a raw material until the three-dimensional shape has been created.

The majority of 3D printers use what is referred to as feedstock, which is a plasticized filament. The threaded filament gets fed through a heating element where it is liquefied, and then the fluid plastic is released through a controlled nozzle to create an object.

Numerous types of thermoplastics may be used as feedstock, including Acrylonitrile Butadiene Styrene (ABS), nylon, and Polylactic Acid (PLA). However, some 3D printers also rely on ultraviolet light to cure a piece, lasers for shaping a piece, and even metal powders to create a piece.

Industries That Use 3D Printing

One of the biggest benefits of 3D printing is that the process offers the ability for product engineers to quickly and inexpensively create parts and products in-house. Therefore, initially, 3D printers were primarily put to use in engineering processes.

Therefore, initially, 3D printers were primarily put to use in engineering processes.

Engineers could use a 3D printer to build a prototype from the ground up with little cost involved. However, now this tech-based form of printing has grown to be a common process in everyday manufacturing and production processes. Some companies now use numerous 3D printers in their operations on a daily basis.

You don't have to look far to find 3D printing technology in action. To date, 3D printers have made their way into numerous settings, including medical laboratories, automotive parts manufacturers, electronics manufacturers, and even the aerospace industry.

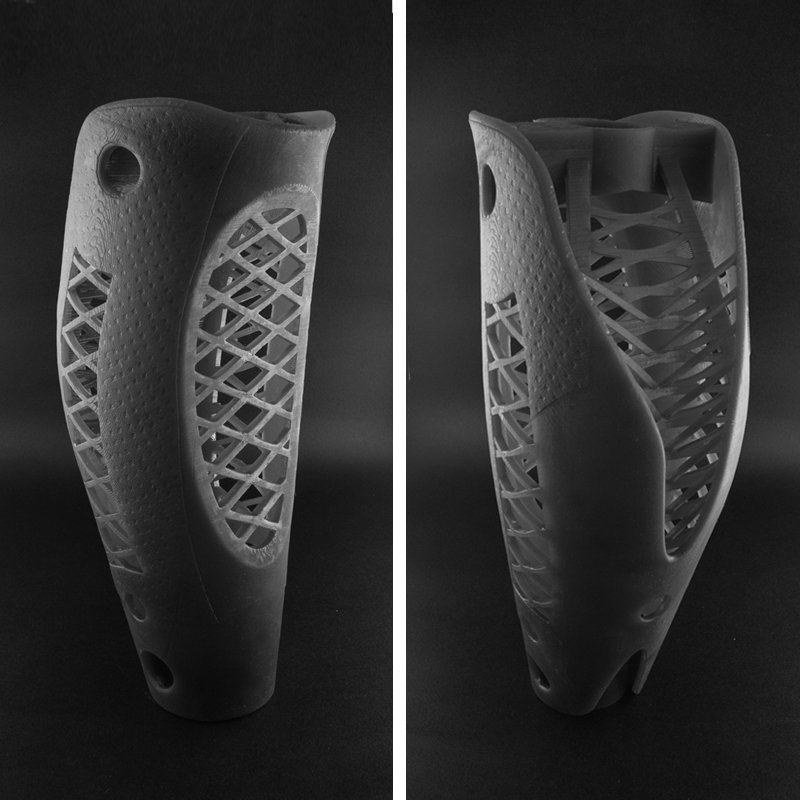

The ways in which these industries rely on 3D printing can vary drastically from one to the next. For example, some medical practices are using 3D printers to create custom, built-to-fit prosthetics for patients. Likewise, some automotive parts manufacturers use 3D printers to create plastic parts for automobiles.

Potential Hazards of 3D Printing

3D printing hazards can include breathing in harmful chemicals or compounds, skin exposure to harmful chemicals or solvents, and the risk of fire and explosion. Some printers operate at extremely high temperatures, which could also mean the user is at risk of getting burned.

Some printers operate at extremely high temperatures, which could also mean the user is at risk of getting burned.

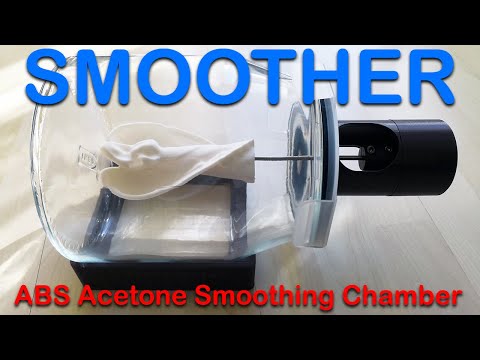

3D printing hazards vary depending on what type of equipment, materials, and setup are used. For instance, some printers use fine powders that can cause skin or respiratory hazards, while others may use ABS filaments that produce hazardous emissions upon heating. Two primary threats come along with exposure to ultrafine particles (UFPs) and volatile organic compounds (VOCs).

UFPs are referred to as nanoparticles because they are anywhere from 1 and 100 nanometers in size. These particles are so small, they can be inhaled, travel through the bloodstream, and even make their way into bodily organs. UFP exposure has been linked to:

- Cardiovascular disease

- Respiratory infection

- Lung cancer

- Chronic obstructive pulmonary disease (COPD)

VOCs can vaporize even at room temperature. These organic chemicals can then saturate the surrounding environment's air and pose health hazards. Some materials commonly used in 3D printing processes, such as nylon, PLA, and ABS produce particularly concerning VOCs like butanol and styrene.

Some materials commonly used in 3D printing processes, such as nylon, PLA, and ABS produce particularly concerning VOCs like butanol and styrene.

Some VOCs are thought to be active carcinogens (cancer-causing agents). However, VOCs can have a variety of other

damaging health effects, including:

- Central nervous system damage

- Irritation of the throat, nasal passages, and eyes

- Loss of general coordination

- Headaches

- Nausea

- Skin irritation

Some 3D printers also use chemical solutions to dissolve unnecessary support pieces that are printed during the creation of a 3D piece. These solutions are corrosive, so they pose risks to the eyes and skin such as blindness or chemical burns.

How Organizations Can Protect Workers from 3D Printing Hazards

The National Institute for Occupational Safety and Health (NIOSH) has rapidly taken initiatives to help organizations protect their workers while using 3D-printing equipment.

3D printing may not be the most complicated task, but only trained employees or authorized individuals should have access to the equipment. Untrained or inexperienced workers using the equipment can experience unnecessary exposure to hazards.

Place 3D printing equipment in the proper location.3D printers should be in isolated enclosures equipped with ventilation to control emissions. If you do not have an isolated enclosure for printing equipment, select a room or location that has high airflow, operable windows, and exhaust to the outdoors.

Opt for 3D-printing materials and equipment with lower emissions.Printing equipment should be purchased from reputable manufacturers who have created the unit with emissions and safety in mind. A standard has been developed that shows a printer has been designed to reduce emissions.

Look for those that meet the ANSI/CAN/UL 2904 Compliance Standard. Likewise, the filaments used should be carefully chosen. As noted above, some filaments create higher emissions, and some create more toxic emissions.

Likewise, the filaments used should be carefully chosen. As noted above, some filaments create higher emissions, and some create more toxic emissions.

Although watching a 3D printer in action is interesting, employees should not spend any more time near the operational 3D printer than necessary. Some organizations set up alternative cameras or other mechanisms to oversee the printer without an employee having to be nearby.

Train employees on 3D printing hazards.Employees must know and understand the risks associated with 3D printers. There are many useful resources to help ensure proper training for employees. For example, the NIOSH offers informational posters on 3D printing with metal powders and 3D printing with filaments.

3D Printing PPE to Protect Workers

PPE for 3D printing can be the employee's first line of defense against the many hazards they can face when operating or working near 3D printing equipment.

Therefore, make sure every employee has the proper PPE , understands its importance, and knows how to properly don it.

Fit-Tested Respirators

General dust masks are not designed to block out the particulate matter that's often released during 3D printing processes. Instead, workers need commercial respirators that are NIOSH-approved for protection against both VOCs and UFPs. All respirators should be fit-tested to ensure proper functionality.

Neoprene or Nitrile Gloves

Wearing gloves while working with the feedstock, handling heated pieces, or interacting with solvent chemicals will prevent workers from sustaining injuries on their hands and forearms. All uncured materials coming out of the printer should also be handled with protective gloves.

Splashproof Eye Protection

Wearing gloves while working with the feedstock, handling heated pieces, or interacting with solvent chemicals will prevent workers from sustaining injuries on their hands and forearms. All uncured materials coming out of the printer should also be handled with protective gloves.

All uncured materials coming out of the printer should also be handled with protective gloves.

Splashproof Eye Protection

To protect the eyes from small particulate matter and potential chemical splashes, employees should always wear protective eyewear while using 3D printing equipment. Consider protective goggles over basic safety glasses because these PPE pieces can block out exposure to UFPs and VOCs by sealing off the eyes.

Coveralls: Flame-Retardant, Chemical-Resistant, or Fine Particulate Protection

3D printing can involve working with hazardous chemicals, powders (particulates), and even pose the risk of flames or explosions. It’s important to identify which hazards are present throughout your 3D printing process to provide the proper PPE for workers.

When working with ultrafine particles and volatile organic compounds, particulate protection is needed. Body Filter 95+® disposable coveralls and garments are breathable and designed to filter out 95%-99% of 0. 3-micron particles—similar to an N95 respirator.

3-micron particles—similar to an N95 respirator.

Browse all Body Filter 95+® coveralls and disposable clothing

If corrosive chemical solutions are used in your 3D printing process, chemical-resistant coveralls are necessary to protect against chemical burns and chemical splash. ChemSplash® 1 coveralls, splash aprons, and sleeves protect against light chemical splash and less hazardous chemicals. This line includes styles with taped seams for added protection against liquid chemicals that can seep through exposed seams.

For protection against more aggressive acids, chemicals, and caustics, ChemSplash® 2 coveralls offer the safety you need in more hazardous environments.

Browse all ChemSplash® chemical protective clothing

If your 3D printer uses volatile chemical compounds that can ignite and pose a fire or explosion hazard, consider fire-retardant coveralls. Better yet, chemical and fire-retardant coveralls provide protection against both flames and chemicals such as PyroGuard CRFRTM.

PyroGuard FR® coveralls are flame retardant and pass ASTM D6413 vertical flame testing as well as NFPA 2113 requirements for section 5.1.9. Our PyroGuard CRFMTM increases protection levels by safeguarding against a broad range of chemicals as well as being flame-retardant.

Browse all PyroGuard® coveralls

Safety and 3D Printing

By 2026, the 3D printing market is slated to reach 51.77 billion dollars. As more industries take advantage of this innovative form of production, more attention must be given to health hazards that can be involved.

While 3D printing seems relatively safe, a deeper look proves that compounds, chemicals, and materials used and emitted during printing are hazardous. From ensuring proper safety training to becoming more familiar with which equipment and materials pose the most risk, there are numerous paths to providing adequate protection.

Potential dangers of a 3D printer. Part 1

In early February, a great tragedy occurred in the United States - a young family and pets died in their house under unclear circumstances. And the first suspect was a 3D printer. Allegedly, carbon monoxide released during 3D printing could cause poisoning for people and their pets. While the police cannot reliably establish the source of the gas leak and the causes of the tragedy, however, we decided to remind once again what potential dangers lie in wait for the owners of home printing devices and how to protect yourself and your loved ones from their impact.

And the first suspect was a 3D printer. Allegedly, carbon monoxide released during 3D printing could cause poisoning for people and their pets. While the police cannot reliably establish the source of the gas leak and the causes of the tragedy, however, we decided to remind once again what potential dangers lie in wait for the owners of home printing devices and how to protect yourself and your loved ones from their impact.

1. Getting burned

It must be remembered that the principle of operation of the FDM printer is based on the melting of a plastic filament. Thus, the heating elements of the device present a great danger when touched. As a rule, the temperature of the extruder of a working device can vary from 170 to 300ºС. The specific figure depends on the type of material and appearance of the product you choose.

The melting temperature of the filament used in printers is sufficient to cause burns. For ABS plastic, it is about 210-270ºС, for PLA - 180-190ºС. This is enough to get painful damage in contact with both the material itself and the heating elements of the printer: the table and the extruder nozzle.

This is enough to get painful damage in contact with both the material itself and the heating elements of the printer: the table and the extruder nozzle.

For PLA printing, this risk is lower because a heating bed is not needed, but if you are working with ABS, be extremely careful not to touch the hot elements. The risk of injury is directly proportional to the area of the heating surfaces. Remember that the temperature should be checked only by the readings of the sensors that are displayed in the printing program or on the display of the device, and not by hand or improvised means.

In situations where direct contact with hot surfaces is required, such as when cleaning the nozzle, special tools and personal protective equipment must be used, and extreme care and discretion must be exercised.

Also, keep children and pets away from the printer and never leave them alone with the printer. It is always easier to prevent danger than to deal with its consequences.

2. Electrical injury

Like any mains powered device, a 3D printer can cause electrical injury to a person. Naturally, with proper operation of the device this will not happen. Even in the event of a ground fault, the voltage in the exposed parts of the 3D printer will usually not exceed 12-24 V, which is considered safe and will only cause a slight shock.

However, when disassembling the case of the device for repair, replacement of a part, or cleaning of plastic, the possibility of receiving a 220 V electric shock increases many times over.

It must be remembered that any electrical appliance must be disconnected from the mains before servicing. Some printers have an external rather than an internal transformer, but this should not be a reason to forget about safety and leave the plug in the outlet.

Also not to mention the risks of short circuits. The probability of such an event in a 3D printer, as in any other household appliance, is small. But if you are assembling a set according to the drawings, be careful when connecting the wires. In the best case, the printer simply will not turn on or the fuse will burn out, but in the worst case, everything can end in an electrical injury or fire.

But if you are assembling a set according to the drawings, be careful when connecting the wires. In the best case, the printer simply will not turn on or the fuse will burn out, but in the worst case, everything can end in an electrical injury or fire.

Evgenia Kurochkina, Development Director at ZENIT 3D, comments:

“There is no more danger from using a 3D printer than from any other electrical device used in everyday life or in professional activities. But, nevertheless, they are presented on the market as 3D printers with a high degree of security and, let's say, ordinary ones. What you should pay attention to when choosing a 3D printer using FDM technology and when working with it.

Such devices, as a rule, have two heating elements: an extruder and a heated platform or simply a table. The temperature of these nodes can reach up to 310ºС (extruder) and 110ºС at the table. To avoid burns during printing, the printer must always be with closed walls (so that a child or a pet does not accidentally climb in). The presence of a display and light indication will help to understand, even if the printer is already idle, what is the temperature of its heating elements at the moment.

The presence of a display and light indication will help to understand, even if the printer is already idle, what is the temperature of its heating elements at the moment.

Many manufacturers save money at the expense of safety. One of the options for such savings is to "power" the heating table directly from 220 V. In our opinion, this is wrong and unsafe. For example, when working with a 3D printer, many people use a spatula to remove a part, it is quite sharp, and any inaccurate action with a spatula when the table is on can lead to a short circuit and a 220 V current shock. Realizing this, we went the other way, and instead of 220 All ZENIT 3D printers supply only 24V to the table.

The extruder is the hottest part and must be handled with the utmost care. To remove the remaining plastic from the extruder, it is imperative to use a special tool.

As for the electrical part, there is also something to look for when choosing a 3D printer. All wires and connections must be insulated, and best of all, hidden in the printer case. Any open connections, contacts, wires, boards in the event of an accidental short circuit can at least damage the equipment, at worst - harm health

Any open connections, contacts, wires, boards in the event of an accidental short circuit can at least damage the equipment, at worst - harm health

Our company, developing 3D printers, considers the safety of its devices to be one of the important tasks. In particular, when developing the new ZENIT 3D model, which will be launched on the market in 2017, we paid a lot of attention to the safety aspect.”

3. Fire hazard

While we're on the subject of fires, let's talk about fire hazards not related to electricity. In point 1, we already wrote about high temperatures of heating surfaces in the context of burns, but an open printer case can also ignite materials lying around the printer. Paper and flammable liquids that have a low flash point should be kept away from a working printer, especially if it is an open type.

Another problem could be overheating of the extruder. For example, the ignition temperature of PLA plastic is about 388ºC. Purely theoretically, it may happen that a broken printer temperature sensor will cause spontaneous combustion of the material. If your printer also has a plywood or plastic case, this automatically turns it into fuel for the resulting fire.

Purely theoretically, it may happen that a broken printer temperature sensor will cause spontaneous combustion of the material. If your printer also has a plywood or plastic case, this automatically turns it into fuel for the resulting fire.

Therefore, it is recommended that you install a fire alarm in areas where you print and keep a fire extinguisher handy at all times. Also, you can not leave a working device alone for a long time. It is clear that it is impossible to constantly monitor the printing for several hours, but it is better to monitor the operation of the printer from time to time.

A compromise would be to purchase a compact camera installed in the print room and broadcast to a smartphone or tablet.

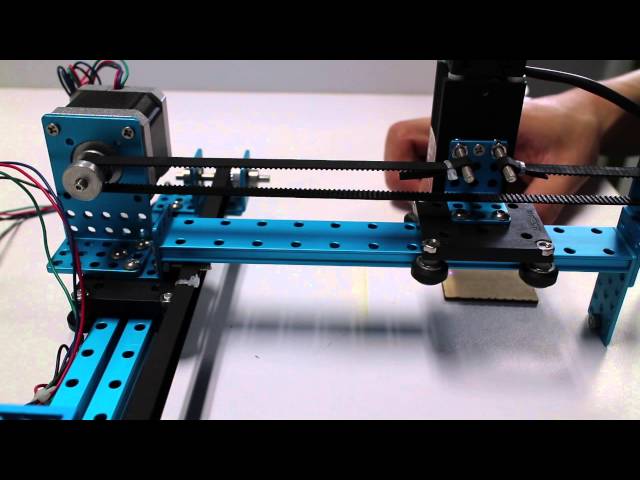

4. Moving parts

3D printers have a lot of moving parts. These are motors, pulleys, threaded rods, carriage and fans. All this can easily grab you by the protruding part of the body and cause a lot of trouble. Avoid contact with moving parts of the printer while it is in operation! Do not reach in or attempt to correct a sliding object or push the carriage by hand.

If your 3D printer is an open type, wear tight-fitting clothing and keep an eye on your hair to minimize the risk of cloth and hair getting caught in moving parts. It is also worth worrying about the placement of the spool with consumables in advance, so that in the future the thread does not catch on foreign objects and knock the printer to the floor.

If the device does grab your clothing or hair, turn off the printer immediately and manually move the carriage until the pinched part of your body is completely free.

Irina Solomnikova, Commercial Director of IMPRINTA comments:

“If we talk about the possibility of carbon monoxide poisoning, then yes, such tragedies as in the USA are possible and, unfortunately, common. If we consider the 3D printer as the cause of the tragedy, then the repetition of such a case is unlikely. However, the source of carbon monoxide in this tragedy has not been established. As many people know, there can be many reasons for the occurrence of carbon monoxide. This includes the operation of a car, a fire, the operation of gas water heaters and stoves, improper operation of stoves, damage to a gas pipeline, etc.

This includes the operation of a car, a fire, the operation of gas water heaters and stoves, improper operation of stoves, damage to a gas pipeline, etc.

But it is definitely worth remembering that when using a 3D printer, you should follow safety precautions and use it for its intended purpose. Misuse of any appliance, such as a game console, microwave oven, telephone, iron, etc., can lead to unpleasant consequences.

The rules for using the 3D printer are very simple:

- The 3D printer must be installed in a ventilated area.

- The 3D printer must be placed on a level, stable surface.

- Before connecting to the network, it is worth checking the reliability of the power supply.

- Some parts of the printer get very hot. Do not touch them while the printer is in operation to avoid burns.

- The printer has moving parts. During the operation of the 3D printer, it is necessary to avoid getting foreign objects into the moving mechanisms of the printer, this can lead to injury and damage to the equipment.

- Do not place anything on the 3D printer.

- Be aware that some media may be toxic. When choosing a material, you must carefully read the description, temperature conditions and use only trusted manufacturers of printing materials.

- Do not leave small children unsupervised while the printer is in operation.

- Don't leave your printer running when you leave home.

If you follow these simple rules, as well as following the instructions, the use of a 3D printer will be safe both in the office and at home.

In conclusion, we add that a 3D printer, like any device, can harm a person. But let this not be a reason to abandon its use, but a reason to think about safety precautions. In particular, pay attention to your workplace, study the instruction manual and follow basic safety precautions. Then, instead of problems, a 3D printer will bring only the joy of creativity and positive emotions.

In the next part of the article, we will talk about the potential dangers of 3D printing consumables.

If you know or have encountered any other risks that come from 3D printers, write about it in the comments.

Tags: Irina Solomnikova, Evgenia Kurochkina, ZENIT 3D, IMPRINTA, 3D printer, 3D printing

Working with a 3D printer - so, safety measures when working with a 3D printer!

Working with a 3D printer! We have already written about “5 printing problems and how to solve them”, and today we will talk about the mistakes that you can make, or rather the article will be about precautions when working with a 3D printer.

I think everyone knows that the most dangerous is the print head (extruder) and platform, which are heated to temperatures above 100 degrees and touching them can leave a burn.

Working with a 3D printer

So, safety measures when working with a 3D printer:

1. It is strictly forbidden to touch anything other than the printer control buttons during operation. Violating this rule, at best, you can get bruised by a moving part, and at worst, a serious burn. If your 3D printer is an open type, then it is worth working with it in tight-fitting clothing to minimize the risk of wrapping fabric around moving parts. You can check the heating of the printer only based on the readings of the thermal sensor of the device itself, which are reflected on the display or in the printing program.

Violating this rule, at best, you can get bruised by a moving part, and at worst, a serious burn. If your 3D printer is an open type, then it is worth working with it in tight-fitting clothing to minimize the risk of wrapping fabric around moving parts. You can check the heating of the printer only based on the readings of the thermal sensor of the device itself, which are reflected on the display or in the printing program.

Working with a 3D printer

Tips for printing on a 3D printer:

Sometimes, for a more uniform unwinding of the bobbin, the thread is thrown over the eaves or back of the chair - in this case, the plastic thread can be wound or caught on foreign objects. The results of this are unpredictable - the printer can fall off the table, or, conversely, hang in the air, which, in turn, can lead to its breakdown or fire (do not forget about the heated parts of the 3D printer).

V

3. Allow children to work on a 3D printer only when they are able to fully consciously approach the process. The first work should be carried out under the supervision of adults.

The first work should be carried out under the supervision of adults.

4. Heating ABS plastic produces a small amount of acrylonitrile fumes. A 3D printer on average emits up to 200 million ultrafine particles of this substance per minute. When using PLA plastic, up to 20 million particles per minute are emitted, it is safer, but still harmful to health. Settling in the lungs, plastic particles can lead to the most serious consequences - lung cancer, asthma, of course, there are currently no data from clinical trials, but the work area on the 3D printer must be well ventilated.

Working with 3D printer

It is better to leave the room while the device is in operation. If this is not possible for some reason, it is advisable to use a respirator with a carbon filter. Closed printers with a filtering system are already on the market, but they are not very common on the market yet, and they are also quite expensive. They are safer, but the properties of the materials used have not been fully studied, so you should not neglect additional safety measures when working with them.