3D printing process animation

#TOP5 Videos: 3D printing for animation films, shoes and more!

3D printing news News #TOP5 Videos: 3D printing for animation films, shoes and more!

Published on March 24, 2019 by Carlota V.

We found the Top 5 videos of the week about 3D printing and the way additive manufacturing is shaping and changing our society. This week we touch on 3D printing for animation films, shoes and much more! If you enjoy these, you can view even more 3D printing videos on our Youtube channel. Hope you’ll enjoy and have a great Sunday!

Top 1: Formless Generative Design Heels

The Japanese design lab, Digital Artisan has partnered up with chemicals company, JSR Corporation and Castem, a manufacturer of precision casting parts to create the ‘Formless’ high heel shoe using the M2 3D printer from Carbon. Director of Digital Artisan, Masaharu Ono, lead the design and modeling of the heels with the help of the Japanese shoe designer, Ayato Tsumagari. Check it out below!

Top 2: 3D Printing for Animation Films

As we already know, 3D printing is everywhere and even in movies! It makes it possible to create certain accessories, sets and to facilitate the process of creating characters for animated films. This is the case for Laika studio, which uses 3D printers – including Stratasys models – to make hundreds of different faces for its small puppets. This allows him to reconstruct emotions much more easily. The result is amazing! His next animated film, Missing Link, will be released in theatres next April:

Top 3: 3D Printing in Veterinary Medicine

3D printing is also for animals! Virginia Tech University Libraries and Virginia-Maryland College of Veterinary Medicine are working together to create 3D models for complex surgical cases. They print in 3D the part of the animal’s body that needs to be operated on in order to better understand the different stages of the operation and give themselves every chance of success. It also helps to show the owners of these animals what is wrong and reassure them before surgery!

They print in 3D the part of the animal’s body that needs to be operated on in order to better understand the different stages of the operation and give themselves every chance of success. It also helps to show the owners of these animals what is wrong and reassure them before surgery!

Top 4: Drone Scanning and 3D Printing

You’ve probably heard of 3D printed drones, but drones can also be used to help in the process of 3D printing a piece. In this case the drone is used to 3D scan the tree in order to export the data to the design software that will be used for 3D printing. Check it out below!

Top 5: Brief History of 3D Printing

Even though 3D printing is changing and shaping our manufacturing processes, you might not know much about the history of the technology. In actual fact, it has been around for a while before developing exponentially in the last decade. 3D printing was invented back in 1983 by Chuck Hull! Learn more about the history of the technology in the video below!

In actual fact, it has been around for a while before developing exponentially in the last decade. 3D printing was invented back in 1983 by Chuck Hull! Learn more about the history of the technology in the video below!

What do you think of this week’s top 5 videos? Drop a comment below or on our Facebook and Twitter pages! And don’t forget to sign up to our free weekly Newsletter to keep updated on all the latest news in the 3D industry coming straight to your inbox!

How Does 3D Printing Work? | 3D Printing Blog

Begin typing your search above and press return to search. Press Esc to cancel.

by Fabian | February 8, 2018 | 3D Printing,Materials

How Does 3D Printing Work? These Videos Hold the Answer.

by Fabian | February 8, 2018

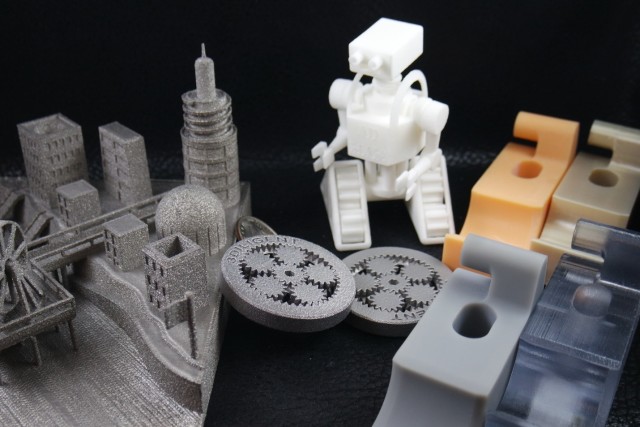

So how does 3D printing really work? Actually, there is no single, easy answer to this, since ‘3D printing’ includes many different technologies. While some printers work with filament, others use powder, and yet others work with liquid. To bring some structure into this, we put together a video overview about the most important 3D printing technologies.

While some printers work with filament, others use powder, and yet others work with liquid. To bring some structure into this, we put together a video overview about the most important 3D printing technologies.

How Does 3D Printing Work?

There are several 3D printing technologies and they all work very differently. What all the technologies have in common is that they are additive. This means that they build up an object layer by layer.

Before the printing starts, you need a 3D file of your design. This file of a three-dimensional object can be created in 3D modeling tools such as Blender, 123D Design, Rhino, SketchUp, etc. Once this file has been created, it can be sent to a 3D printer. If you do not own a printer or if you want a high-quality print with a choice of more than 100 different 3D printing materials, finishes, and color options, an online 3D printing service such as i.materialise is a smart choice.

3D printers print your object layer by layer. The animation below demonstrates this process for Laser Sintering, a popular 3D printing technology.

The animation below demonstrates this process for Laser Sintering, a popular 3D printing technology.

However, there are several important 3D printing technologies that differ slightly from each other. Let’s take a look at how they work and what makes them so unique.

Laser Sintering

- This 3D printing technology spreads out a layer of fine powder.

- A laser beam heats up the areas that need to be sintered together.

- The parts that were touched by the laser are now fused together while the rest continues to remain loose powder.

- A new layer of fine powder is spread out. The next slice of your part is hardened and joined to the previous first.

- At the end your part is lifted out of the box of loose powder. It is then sandblasted and finished by hand.

- Learn more about Laser Sintering in this blog post.

Fused Deposition Modeling

- FDM printers use long plastic filaments.

- The nozzle moves to place one layer of the heated material at the correct locations.

- When a layer is drawn, the platform lowers by one layer thickness so the printer can start with the next layer.

- A second (dissolvable) filament is used for building support material.

- Learn more about Fused Deposition Modeling in this blog post.

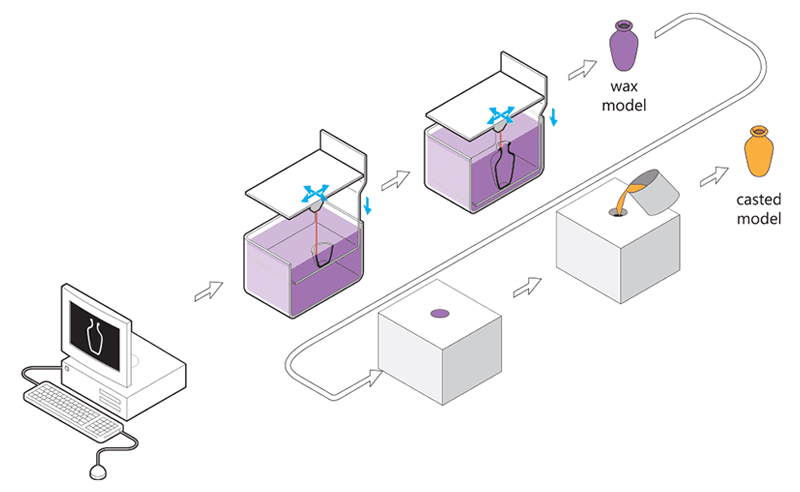

Stereolithography

- The Stereolithography process takes place in a large tank and begins with a layer of liquid polymer spread over a platform.

- Since this piqued polymer is UV-sensitive, a UV laser hardens the area that will become one layer of your 3D print. The rest of the layer stays liquid.

- The platform is then lowered and the next layer is drawn directly on top of the previous one.

- When the object is complete, it is raised out of the tank via the supporting platform with the excess liquid flowing away.

- Learn more about Stereolithography in this blog post.

Direct Metal Laser Sintering (DMLS)

- A super-thin layer of Aluminum or Titanium powder is spread out by a roller.

- The print chamber of the 3D printer is then heated up but the powder does not melt yet since it has not reached its melting point.

- A laser touches the areas of the layer that are part of your design, raising the temperature of those areas just above the melting point.

- Learn more about Direct Metal Laser Sintering this blog post.

- HP Multi Jet Fusion is a powder-based technology that does not use lasers.

- The powder bed is heated uniformly from the outset.

- A fusing agent is jetted where particles need to be selectively molten, while a detailing agent is jetted around the contours to improve part resolution.

- Lamps pass over the surface of the powder bed and the jetted material captures the heat and helps distribute it evenly.

Of course there are still more, related 3D printing technologies. For example, ‘Lost Wax Casting & 3D Printing’ is mainly used for creating jewelry items in gold, silver, brass, and bronze. To learn more about each and every one of our 18 different 3D printing materials, please visit our materials page.

If you have a 3D file that is ready to be printed, upload it here and let us take care of 3D printing and shipping your object.

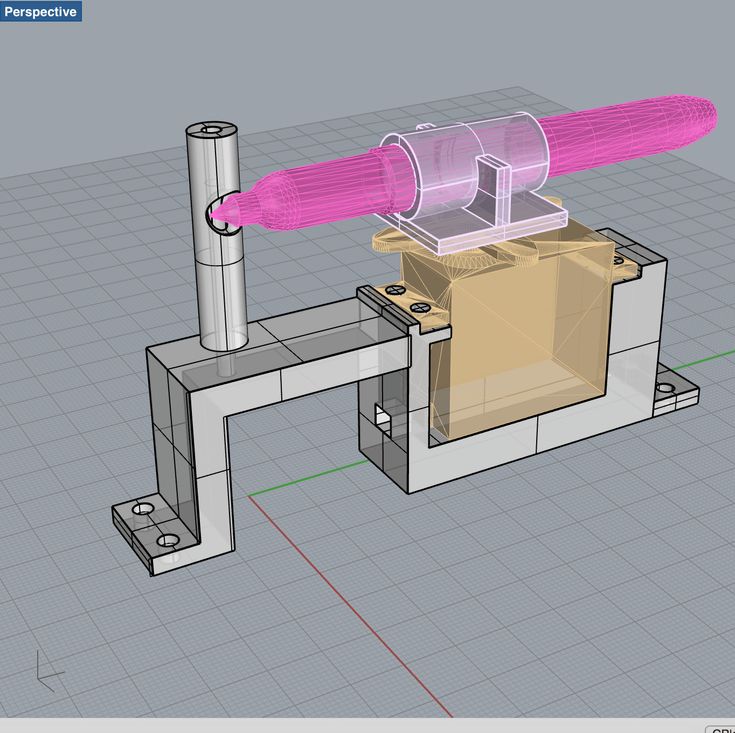

Animatronic 3D Printing - "Reveal Yourself!"

Application

Subscribe author

Subscribe

Don't want

10

Article applies to printers:

UP Plus 2Zihua Creative is China's first online educational resource. It contains a huge amount of videos on photography, art, design, music and other areas of creativity that are aimed at stimulating online learning.

Recently, Zihua Creative collaborated with Goodstein advertising agency, international animation company Pixomondo and 3D printing studio IDEARP to create a creative short film that describes the process of the emergence and development of an idea, called "Unbox yourself" (original "Unbox yourself" - Unbox yourself) . Tiertime's flagship desktop 3D printer, UP Plus 2, was used to create it.

One of the ideologists, the founder of IDEARP, says that the decision to use the UP printer for the project was made due to the high stability and quality of its work.

Designer Shen Jersey notes: “This car really did a great job of capturing the overall art design of the project. We deliberately used the relatively low precision of the print in order to convey a sense of texture and style to the video.”

It took 11 UP Plus 2 3D printers and 240 hours of work to make a 1 minute video, every second frame was printed and photographed with a digital camera. As a result, 688 figures of various shapes and sizes were obtained. The number and total running time was without a doubt the biggest challenge for Tiertime's machines. The developers note very good performance and high stability during long continuous operation of UP Plus 2 printers. In total, the project took about 42 coils and almost 30 kg of ABS plastic, of which almost half went to support.

Compared to traditional materials for this kind of animation: clay, fabric, metal, 3D printing allows you to achieve better results in a much shorter time. Each subsequent frame should differ from the previous one by millimeters, and this is easy to achieve with a 3D printer and plastic, unlike other materials.

The developers of the film assure: “With the advent of 3D printing, the anime industry will move to a new round of development. The accuracy of a 3D printer allows the viewer to better feel and understand the idea of the picture, perceive the emotions of the characters and the scenes in which they participate. Also, this innovative method allows you to attract more creative people to the animation, who can create their own characters not only in 2D. “To feel” the fruits of their imagination is very important for them and perfectly motivates them for further

accomplishments.”

Pablo Picasso once said: "Every child is born an artist, the only difficulty is to remain one after leaving childhood. " And 3D printing can help make that happen.

" And 3D printing can help make that happen.

Follow author

Follow

Don't want

10

Article comments

More interesting articles

Ozamo

Loading

25.10.2022

1086

fourteen

Subscribe to the author

Subscribe

Don't want

Hello everyone. I would like to share my version of the locking clutch for an electric screwdriver. Something in...

Read more

one

Subscribe author

Subscribe

Don't want

SHINING 3D hardware and Verisurf software allows you to digitize original. ..

..

Read more

152

Subscribe to the author

Subscribe

Don't want

As a maker, I use various tools in my work, including a glue gun. For m...

Read more

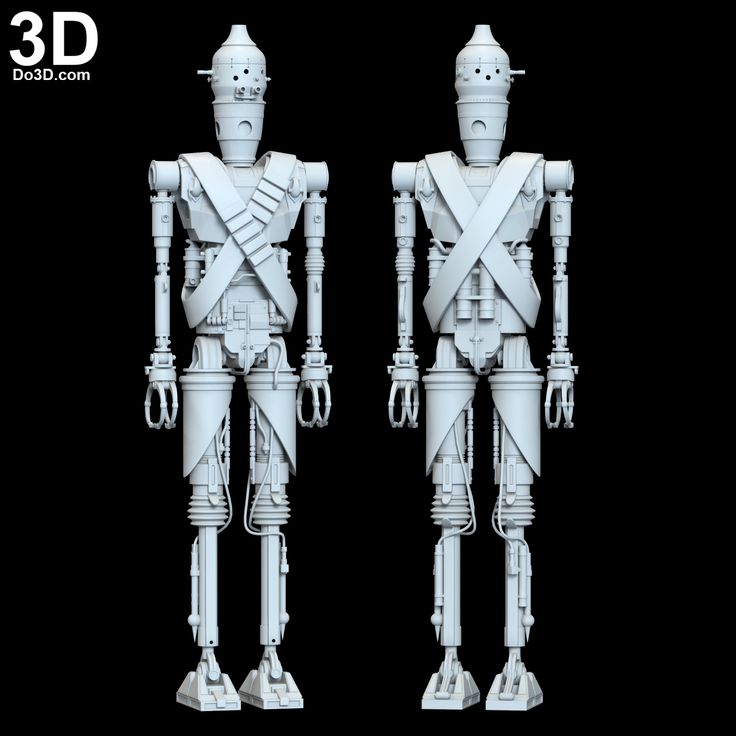

Technology and cinema: 3D printing in animation

The new cartoon from Sony Pictures, "Pirates: A Gang of Losers", still uses puppet figures and traditional frame-by-frame animation to bring their big eyes to life characters, but still its creators, Aardman Animations, are using a new technology to make the action figures talk: 3D printers.

A 3D printer is a lot like a regular printer, only it uses three dimensions, placing a certain substance layer by layer in such a way as to create the desired material object: a ball, a model aircraft or an animated puppet.

"We created about 8000 mouths," says lead animator Ian Whitlock , explaining how they were able to bring the characters to life in such a short amount of time. “We made 257 different mouths for the pirate captain model, and about 130 for Charles Darwin.”

"A 3D printer connects to a computer and receives a file that describes an object in three dimensions," explains Rich Brown , editor-in-chief of cnet.com. “It works almost like a simple printer. A layer of liquid substance is created, when it solidifies, the next layer is created on top of it, and so on, until a real three-dimensional object is obtained.

3D printing all of these mouths speeds up the animation process and adds more details and characters to the movie.

“We would still be filming if we were hand sculpting mouths,” says Whitlock. - "Even with 3D printing, one character can easily take two to three months to complete. In 10 months, I probably made about 5-6 characters.”

The animators differentiated the mouth shapes based on listening to the actors' dialogues. “A special 'key diagram' was created for phonetic classification,” says Whitlock. - “When the director was satisfied with the shape of the mouth, the file was sent to the rapid prototyping machine, and we got the finished mouth. After printing, all mouths are flesh-colored. Approximately the same technology is used to create hearing aids. They have about 14 skin tones… after printing, we sand and color them.”

- “When the director was satisfied with the shape of the mouth, the file was sent to the rapid prototyping machine, and we got the finished mouth. After printing, all mouths are flesh-colored. Approximately the same technology is used to create hearing aids. They have about 14 skin tones… after printing, we sand and color them.”

Whitlock told that Pirates is the only film to use 3D printing so extensively, although 2009's Coraline also used it, albeit on a smaller scale.

“3D animation technology is something completely new to me,” says Brown. - "I didn't think anyone would use 3D printing for this kind of purpose, and I'm surprised it makes the process so much faster than traditional animation."

As 9 says0101 Peter Lord co-founder of Aardman Animations and director of the film, it's not so much faster as it's more convenient.

“This approach gives each face a lot more personality,” says Lorde.

Learn more