Sellable 3d prints

14 Things to 3D Print and Sell – Clever Creations

Thinking about starting a 3D printing business? Want to try to sell 3D printed items on the side? You may be wondering where to start.

There are several ways to make money with a 3D printer, for example, you can open an online shop to sell 3D printed items, or offer print-on-demand 3D printing services.

In this article, we’ll cover how and where you can sell 3D printed items. We’ll also show cool (and profitable) ideas for things to 3D print and sell, and explain what you need to know before you turn your passion for the hobby into a business.

What to keep in mind when selling 3D prints

Selling 3D printed items can be a lucrative business. However, you need to consider a few things before opening your shop and taking your first orders.

Profit margins

Before setting a price for your 3D prints, you should calculate your costs and margins. This isn’t unique to 3D printing, since all business owners need to know if their product will make a profit.

You need to consider all costs associated with 3D printing the item and selling it. This includes the 3D printer cost, but also the print materials, shipping supplies, 3D printer power usage, seller platform fees, and wages for your time. The more thorough you are, the more accurate the results of your calculations will be.

Copyright

The issue of copyright when selling 3D prints is twofold. If you are printing and selling a 3D model created by someone else, you must follow the designer’s license. If the designer has listed the model as non-commercial, you cannot sell it. If you still choose to do so, they can take legal action against you or your business for infringing on their copyright.

Another layer of the copyright issue is that you cannot sell prints of copyright or trademarked material. This is true even if the model has a commercial license. For example, Bulbasaur is a trademarked and copyrighted character of Nintendo. Thus, you can’t sell Bulbasaur planters even if the 3D model has a public domain license.

Where to sell 3D prints

You can sell your 3D prints using many different channels. Live events like craft fairs, festivals, and trade shows are a great way to garner in-person sales. Consignment shops and displays in local businesses can give your 3D prints a brick-and-mortar presence without the overhead.

Online eCommerce platforms are by far the easiest and most widespread sales channels to use. You can start your own website and sell directly from there or use an existing marketplace.

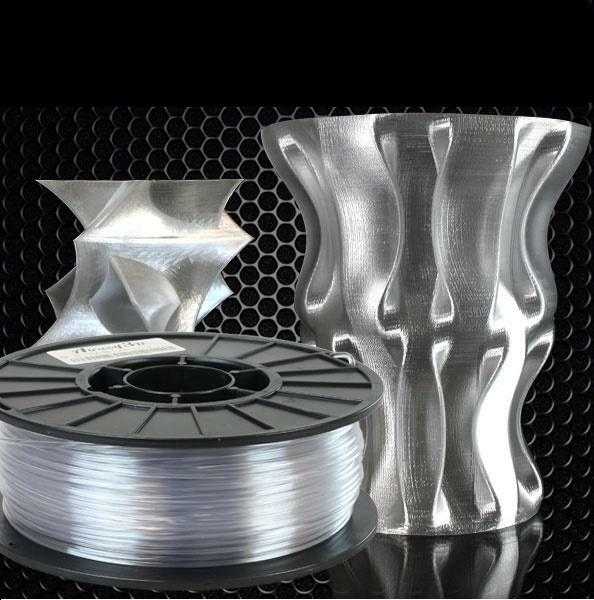

Image: crosslink via MyMiniFactory

3D printed vases are a hit on almost any platformThe latter option is much easier for beginners who don’t know much about online retail. By using existing marketplaces, you can leverage their existing audience and make money with a 3D printer in no time.

Etsy

The online marketplace Etsy focuses on handmade, vintage, and handmade supply products. They charge a $0.20 listing fee per item every four months (or until it sells and is relisted). They also take a percentage of the sales revenue when an item sells.

They also take a percentage of the sales revenue when an item sells.

Many 3D printing shops have been very successful in selling items like planters, cookie cutters, and toys on the Etsy platform. Aside from those, there are plenty of other things to 3D print and sell on the platform.

Recommended:

The 5 Best 3D Printers for Making Cookie Cutters

Amazon

The Amazon marketplace is the largest eCommerce platform available. Amazon integrates third-party sellers into their warehouse system. An independent 3D printing shop using the platform can send their prints to the nearest warehouse and Amazon would process them and ship them out as they sell.

eBay

More dated than most of the other platforms on this list, eBay never quite left its days as an auction site behind. It has at least integrated the ‘Buy It Now’ functions that allow it to work more like an eCommerce platform.

New sellers get free listings to get started, then pay a flat fee per listing and a percentage of their revenue.

eBay shouldn’t be your main eCommerce platform for making money with your 3D printing business. However, it works well as a supplement to the other services we’ve listed.

Fiverr

Starting as a place to pay people to do menial tasks for $5, Fiverr has grown into a labor outsourcing giant. They are now competing with the likes of Upwork, Freelancer, and so on.

Fiverr’s system pays you for your labor, so you are not listing your product. You are listing your ability to 3D print cool 3D prints for other users.

Best 3D Printed Items That Sell

1. Miniatures (D&D, Warhammer, etc.)

Image: BaconuCrazy via MyMiniFactory

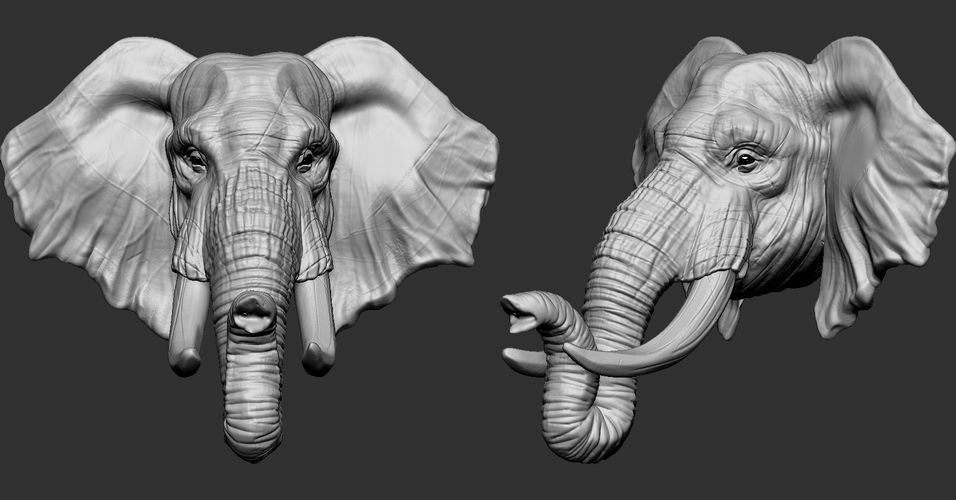

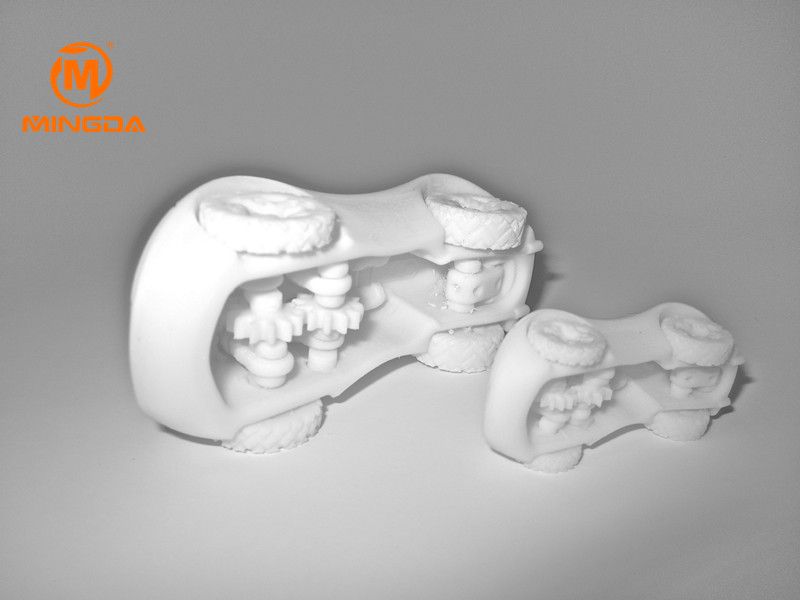

One of the best things to print and sell with your 3D printer is miniatures for tabletop games like D&D and Warhammer.

These figurines are small and highly detailed. This means that if you want to make money by 3D printing miniatures, you are best off with a resin 3D printer. On the other hand, larger terrain pieces are best suited for traditional fused deposition modeling (FDM) 3D printers.

Recommended:

Resin vs Filament 3D Printers: What’s the Difference?

Part of the appeal of miniatures is that they are customizable. They are sold unpainted (similar to some model kits) so the buyer can decorate and paint the miniatures as they see fit. This is excellent news for anyone looking to make money printing by selling 3D printed miniatures. No painting means there is less need for post-processing work.

3D printed miniatures are well-liked among consumers, as customers can buy miniatures that aren’t available to them through traditional manufacturing companies.

Consumers also enjoy commissioning customized minis. These figurines are often original characters in their campaigns or stories. If you have the level of skill needed to model and/or sculpt these personalized minis, that can be a significant upcharge for your 3D printing business.

If you want to go this route, you might want to check out our article on the best 3D printers for miniatures.

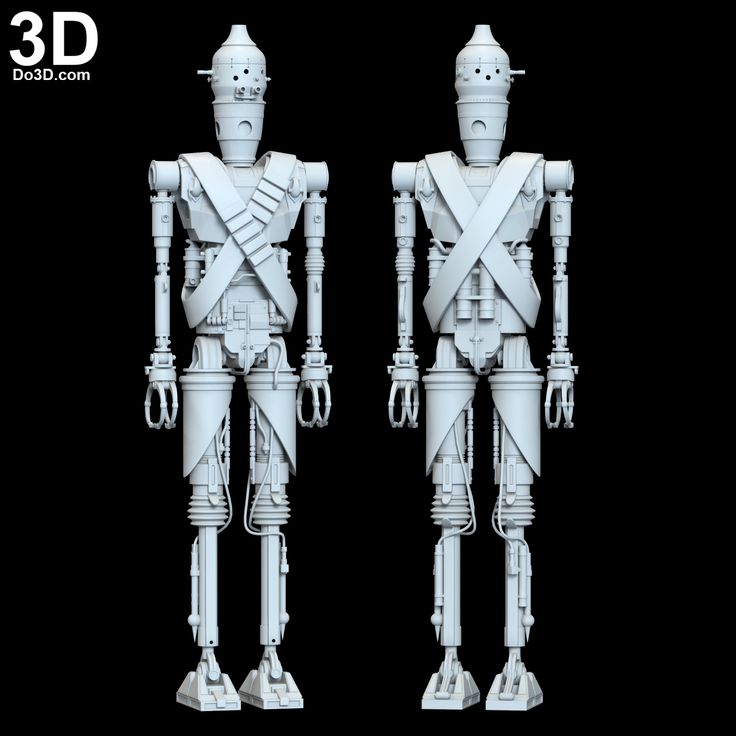

2. Cosplay items (helmets, armor, props, etc.)

Image: TieKai via MyMiniFactory

Cosplay items are one of the most labor-intensive options on the list of things to 3D print and make money with. Taking hours or days from start to finish, making cosplay costumes and props to sell is not for the faint of heart. These items (especially 3D printed armor sets and 3D printed helmets) are large parts that take hours to print and post-process.

Most users expect their cosplay items to be finished and painted to a professional level when they buy them. This takes a great deal of time and effort on your part as the seller. The upside to this is that you can charge a premium price for these items to make up for the extra time spent 3D printing and assembling them. Customers are often willing to pay well for these items.

If you want to make money 3D printing and selling cosplay items, it is a good idea to use a 3D printer with a large build volume. That way, you won’t need to spend time splitting parts to fit the build plate and gluing them together when the printing is complete.

Use a large 3D printer for cosplay, and you can simply 3D print full-size pieces in one go.

3. Jewelry

Image: Muttonheid via MyMiniFactory

The jewelry market is a high mark-up market with excellent profitability if approached correctly. Its main problem is that it is oversaturated with artisans and hobbyists. Your designs and marketing both need to be unique and strategic in this space. Otherwise, it is impossible to have any visibility on most of the eCommerce platforms mentioned in this article.

Since jewelry pieces tend to be small, you need negligible amounts of raw material to print each piece. This keeps production costs low and makes it possible to create many at once. Like miniatures, jewelry requires a high level of detail. For the highest-quality pieces, you will need a 4K resin printer or higher (6K/8K).

Recommended:

The 8 Best 4K+ Resin 3D Printers

FDM 3D printers are not entirely ineffective for jewelry making. They can still print forms for silicone molding material. Then use those molds with things like polymer or precious metal clays, resins, low-temperature metals, and other castable materials.

Then use those molds with things like polymer or precious metal clays, resins, low-temperature metals, and other castable materials.

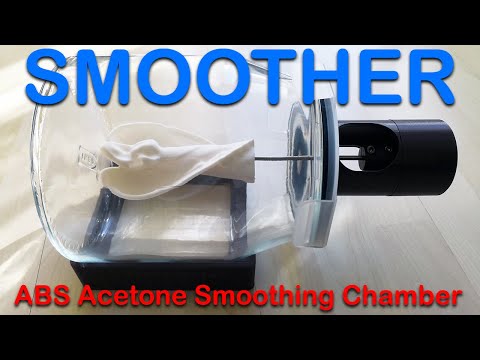

3D printed mold forms need to be smooth and non-porous before molding. You’ll need to sand, fill, or use other extensive post-processing work to achieve the right look.

If you can keep the cost low and produce (customized) jewelry that you promote effectively (e.g. through social media), you will have a good chance at creating a successful 3D printing business in the jewelry niche.

4. Toys

Image: animm07 via MyMiniFactory

3D printed toys are a great option to sell. However, you need to be cautious about regulations on children’s products when choosing to manufacture them with your 3D printer. Some countries require certification to make and sell certain items. This mainly pertains to products for babies and very young children. The guidelines vary from country to country.

Fidget toys and articulated creatures geared towards older kids and adults run a much lower risk of liability and are quite popular. These items are even more memorable when printed from something like color changing, glow in the dark, or filled (Woodfill, Copperfill) PLA filament.

These items are even more memorable when printed from something like color changing, glow in the dark, or filled (Woodfill, Copperfill) PLA filament.

Recommended:

The 8 Best 3D Printers for Kids

Most toys are quick and efficient to make. They print easily on a traditional FDM 3D printer and don’t require much post-processing. Plus there are plenty of cool toy ideas out there that you can 3D print.

5. Nerf gun accessories

Image: GoKidd via MyMiniFactory

Customized or unique Nerf gun accessories and gun bodies are a popular niche in the 3D printing community. They also have quite a demanding retail market.

Items like sights, dart holders, extra clips for discontinued products, larger magazines, and improved barrels are all popular Nerf-related 3D prints. They are easy to create on most 3D printers and fit well with the other ideas of things to 3D print and sell.

It is also not uncommon for Nerf-enthusiasts to want custom guns that the company has not or will not make. Sometimes this means turning a cosplay prop into a functioning dart gun. Other times it means making a gun body that is not commercially available.

Sometimes this means turning a cosplay prop into a functioning dart gun. Other times it means making a gun body that is not commercially available.

Cosplay prop and customized Nerf gun designs are great designs to sell. They have high markup potential and popularity. You can have a profitable business in this niche as long as you don’t overstep trademark rules.

The name Nerf is technically protected under trademark laws. It can help to use generic terms like dart gun, foam dart weapon, etc. in place of the brand in your product listings. This makes sure you don’t gain the attention of any corporate lawyers. They do periodic intellectual property sweeps on popular eCommerce platforms.

Accessories have a lower profit margin than 3D printing full Nerf guns. However, most users don’t care if their dart holders or magazines are not sanded smooth, so they are a quick and easy way to make money with a 3D printer.

6. Architecture models

Image: Format3D via MyMiniFactory

Architectural models are a difficult 3D printing project. They often recreate both the interior and exterior design of a building. They are usually printed in pieces so that the roof and separate levels can be removed for easy access to all the interior elements. Because of their complexity, they can be sold at a high markup and are a great option to 3D print and sell.

They often recreate both the interior and exterior design of a building. They are usually printed in pieces so that the roof and separate levels can be removed for easy access to all the interior elements. Because of their complexity, they can be sold at a high markup and are a great option to 3D print and sell.

Architectural prints can be used for prototyping/visualization, education, play, and decoration. Selling house models as a dollhouse toy or a recreation of a famous building for education or decoration purposes is a great way to market them to consumers.

Some architectural and engineering firms like to have tangible models of their designs. This is helpful for prototyping, sales meetings, and even for troubleshooting the design. Aligning yourself with local companies looking for this 3D printing service could be a beneficial opportunity.

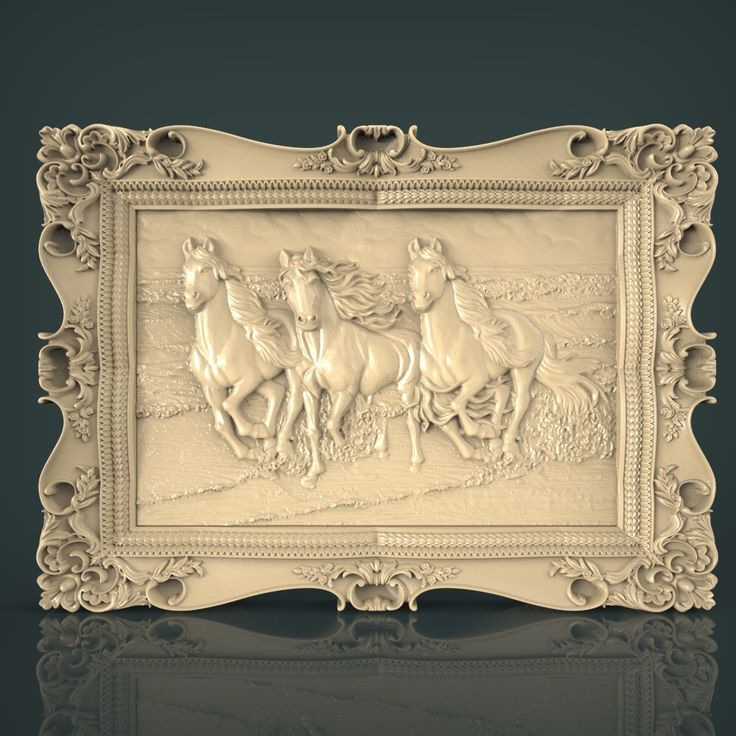

7. Figurines and statues

Image: philippeb66 via MyMiniFactory

Figurines and statues are yet another group of 3D printed products that sell exceptionally well. Many of the figurine and statue 3D models that are available online are of copyrighted content. Things such as characters from video games, movies, or tv shows. These are not particularly helpful resources for making commercial items.

Many of the figurine and statue 3D models that are available online are of copyrighted content. Things such as characters from video games, movies, or tv shows. These are not particularly helpful resources for making commercial items.

Yet, there are still plenty of options for unbranded designs either through ready-made models or customized ones that you design yourself. Animals, mythological creatures, etc. are all popular designs to 3D print and sell without fear of copyright infringement.

Custom figurines of either customers or their pets are another option to diversify your product offerings. This does require an advanced skill level for 3D modeling and/or sculpting. If you aren’t there yet, keep it as an option for the future. In the meantime, you are welcome to look at our recommendations for free 3D modeling software.

8. Phone cases

Image: Malex via MyMiniFactory

Phone cases are a large market, and 3D printed versions are no exception. There are countless possibilities for making and selling phone cases with your 3D printer. You can print basic stretch cases using a flexible filament like TPU, or decorative hard cases made from PLA or ABS.

You can print basic stretch cases using a flexible filament like TPU, or decorative hard cases made from PLA or ABS.

Recommended:

The 10 Best PLA Filaments for 3D Printing

Basic cases are inexpensive and readily available to the consumer from most stores and online retailers. If you want to sell cases, it’s best to use unique or customized models.

The most eye-catching 3D printed options emphasize the technical capabilities of 3D printing. The geared iPhone case is a great example.

A large difficulty with 3D printing a phone case to sell is that there are so many different phone models available and they update constantly. As such, you may find it difficult to source consistent phone case models. You may also realize your designs are becoming quickly outdated if you model them yourself.

The best solution to the variability of phone case compatibility is to start out 3D printing and selling cases for only a handful of different phone models. From there, you could make the decision to scale up or down as needed.

9. Self-watering planters

Image: diegopvp via MyMiniFactory

Planters in general are a hot seller in the 3D printing world, but self-watering planters are even more popular. They are hard to find in stores, making them a fantastic item to add to your business’ offerings.

Self-watering planters are typically designed in two parts: the planter and a water reservoir.

Since both pieces are in contact with water, they need to be watertight in order to not leak. Typical 3D prints have microscopic gaps between each layer. Water can seep through these layers and onto whatever surface the print is sitting on. A clear, non-toxic sealant is a great solution for this problem and gives customers a much better experience with their planter.

10. Designer vases

Image: didierklein via MyMiniFactory

3D printed vases are another home décor product capable of generating a large number of sales. With the exotic shapes that can be created in CAD and made on a 3D printer, the end results are far more modern and sophisticated than vases that are commercially available.

Like the planters mentioned above, vases need a sealant to make them watertight. They are quick and easy to make and can be 3D printed as one continuous spiral. The continuous print lines that this creates improve the speed and quality of the print job.

Items like vases can be printed on either FDM or resin 3D printers (if the print bed size is not an issue for the latter). Extruder-driven ceramic and clay 3D printers are also an excellent option if you are lucky enough to have access to one.

Regardless of the type of 3D printer you use, vases are an excellent choice for making money with a 3D printer.

11. Raspberry Pi cases

Image: Laza via MyMiniFactory

Raspberry Pi boards are a common component in homemade electronics projects. Pi boards are inexpensive single-board computers that are suitable for many projects. For example, they can control smart home equipment, act as a controller for other projects, power a video game emulator console, or run as an underpowered but functional DIY computer.

Since Raspberry Pi’s are so small, it is easy to print cases and enclosures for them. The cases not only protect their components but also make them look more functional and professional. Selling the cases to interested tinkerers has sales potential by itself. If you happen to be handy with electronics, you could also sell fully assembled Raspberry Pi projects.

12. Eyeglasses frames

Image: Sacha_Zacaropoulos via Thingiverse

3D printed eyeglass frames have risen in popularity over the years. Several major eyewear companies have started selling FDM-produced 3D printed eyeglass frames. These products are usually made from WoodFill and other specialty filaments.

Even so, consumers are also flocking to smaller businesses that can design a new pair of frames. Sometimes they want new frames designed for their existing lenses if their store-bought frames break. Other times, they want to transfer blue light or sunglass lenses to a new pair of 3D printed frames for comfort or aesthetic reasons.

We don’t recommend using PLA or other low-temp filaments on this project. If the person wearing them spends enough time outside on a hot day, the frames could soften and warp from the heat. ABS and Nylon are safer filament choices, as they have a higher glass transition temperature (i.e. they melt at higher temperatures).

13. Lamps

Image: Frank Cheung via MyMiniFactory

You can make a variety of different types of lamps on a 3D printer. They are popular choices when it comes to making and selling 3D printed items. Home décor is a thriving market. When you can offer something unique for their living space, design-minded consumers take notice.

Lamps (especially pendant lights) most often require a 3D printer with a medium to large build volume. Because of their shape and texture, most designs don’t fare well when split and glued back together. Seams also change the way light passes through the filament, so they may be noticeable once the light is on.

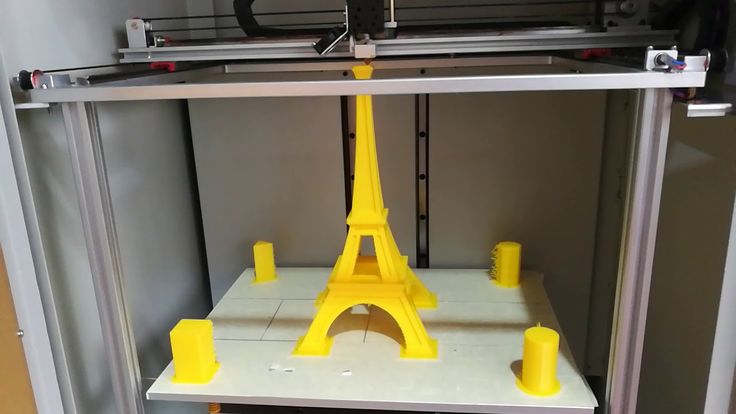

14. Landmarks

Image: ShakeandB1ake via MyMiniFactory

Landmark models and statues recreate well-known buildings, places, statues, and other monuments. They vary from highly-detailed architectural models of famous buildings to sites like Stonehenge. They don’t usually come apart as architectural models do.

These models are popular sellers with tabletop gamers. They are sometimes used in tabletop campaigns and world or story-building exercises. They also make excellent educational tools and are great additions to the modern classroom.

Frequently asked questions

What are the most popular 3D printed items?

Cosplay props, planters, and miniatures are some of the biggest sellers. The popularity depends on which platform you are selling on. For example, on Etsy, the main customer base is looking for pretty, trendy things. Beautiful planters, jewelry, and the like will be most popular.

The best way to learn what is selling on your platform is to do a little research. Find the shops with the best sales numbers, see what their bestsellers are. Use that as an estimate of which categories and niches are most popular. It will be much easier to make money with a 3D printer by finding the niche that works best for you and to fill it with unique products.

Find the shops with the best sales numbers, see what their bestsellers are. Use that as an estimate of which categories and niches are most popular. It will be much easier to make money with a 3D printer by finding the niche that works best for you and to fill it with unique products.

Is it legal to 3D print and sell?

It is perfectly legal to sell your 3D prints. Issues rarely arise if you follow licenses of the models you download and you don’t sell trademarked goods. There are some extra considerations for certain groups of products. For example, you sometimes need special certification to make or sell items directed at young kids or babies.

Certifications vary from country to country, so research the limitations and laws of your country to find out more.

The easiest way to avoid liability is to design your own models to 3D print and sell. Creating your own models avoids the complications of using other people’s intellectual property.

Image: TobiasKuijper via MyMiniFactory

Designing your own 3D models is a good way to avoid copyright issues when selling 3D printsIs selling 3D prints profitable?

Depending on what you make and how you market it, selling your 3D prints can be a very profitable way to make money online. To get the best results from selling 3D printed items, you need to do thorough market research.

To get the best results from selling 3D printed items, you need to do thorough market research.

You should look at what items are selling, where they are selling, and what you can do to stand out.

Do people buy 3D printed objects?

They sure do! As awareness of 3D printing technology increases, more people understand it is an easy way to get their hands on custom or unique items.

Be sure you are very clear in your descriptions about what material the item is made from. It is common to see customers confuse 3D printed items with wood in their reviews.

Conclusion

That’s everything you need to know about selling your 3D printed items. Do you sell your prints? What’s the most difficult part of running a 3D printing business? Let us know in the comments below!

16 Cool Things to 3D Print & Actually Sell – Etsy & Thingiverse – 3D Printerly

3D printing has endless possibilities, especially when it comes to making money. There are so many items that people 3D print and sell successfully, even making a living from home doing it. I decided to write an article describing some popular products that you can 3D print and sell, so you can hopefully get involved as well.

I decided to write an article describing some popular products that you can 3D print and sell, so you can hopefully get involved as well.

You do have to make sure you have the rights to 3D print and sell specific designs, so keep this in mind. You can click each of the numbered titles to go to a search for the products.

Some of the listings do change so they may not be available over time.

1. Personalized Soap Dish

The first item on the list of cool things to 3D print and sell is personalized soap dishes. These aren’t the first thing people think of but there is a huge market of people who love soap dishes that have a personal name or phrase on it.

It gives people’s bathrooms and kitchen more of a unique and dapper look that visitors can appreciate. If you want a good item to 3D print and sell, soap dishes can do well.

A quick search on Etsy for “3D printed soap dish” shows several listings of people selling them for anywhere from $10 to around $30, and they have plenty of reviews from happy customers.

This Skeleton Hand Soap Dish is a really cool idea that customers rate highly. It costs $12 and you have the option to pick multiple colors, as well as the left or right hand. It’s made from PLA so customers shouldn’t use hot water, just cool or warm water.

For more of a personal touch, you can 3D print and sell something like the Personalized 3D Printed Soap Dish for around $13. It has a unique honeycomb design so the soap can drain and dry properly. The seller allows customers to use any words up to 10 characters with choices of many colors.

Users can choose between different colors and sizes in many cases so it would be useful if you can deliver multiple colors if you want to sell them.

2. 3D Printed Cities

3D printing and selling 3D printed cities is a much less common but lucrative item people are getting in to. You’ll be surprised by how much people love having a city that’s special to them modeled in their homes in 3D, especially enthusiasts.

They can enjoy the small details, landmarks, and buildings right in front of them.

Check out the Midtown Manhattan 3D Cityscape design for around $100. It’s made of PLA plastic and is quick to set up, only taking around 20 seconds without the need of power tool.

A unique idea I found is this Seattle City Themed Letter Decor on Etsy for around $80.

It has various landmarks built into the design such as:

- S – Public Market Center Sign, Starbucks Cup, Amazon Spheres, 1201 Third Avenue, Pacific Science Center Arches

- E – Space Needle, Mt. Rainier, Pike’s Place Market Sign

- A – The Seattle Great Wheel, Columbia Center, F5 Tower, 12th Man

Prices for 3D printed cities range from $20 to $300 depending on the complexity and demand from users. You could even do fictional cities from popular movies or TV shows that people love.

You’d have to find a designer that is willing to work with you to let you sell these, usually for a cut of the profits, unless you can design these yourself!

3.

Flexi Octopus

Flexi OctopusThe Flexi Octopus is a really cool 3D printed item you can print and sell to users. It can be used as a toy for kids or even a piece of decoration in your home, on a shelf, or dresser.

Home decoration and toys is big business, so don’t underestimate how much money people are making by selling items like this.

You could go a step further by providing personalization of the Flexi Octopus by printing something like an initial on the head. These little gestures can create lasting memories for kids and even strengthen your bond with them.

One of the Bestseller listings for this is the Flexi Octopus Articulated Sea Animal starting from $7. You can choose from several beautiful colors and even go up in size, giving customers 7 different options, up to the price of $108 for an extra large octopus.

I’d make sure to print this in a material that isn’t too weak since the design is quite fragile.

4. Personalized Keyrings

Another cool item you can 3D print and sell is a personalized keyring. People nowadays don’t always want generic or regular accessories anymore, they want personalized stuff, and this is where you pitch your tent.

People nowadays don’t always want generic or regular accessories anymore, they want personalized stuff, and this is where you pitch your tent.

According to different customers’ preferences, you can print something nice for them.

Some people have so many keys that they can’t keep track of which one belongs to what, so they can label/customize 3D printed keyrings to serve the purpose of identification.

An example is the Personalized 3D Printed Keyring for around $3. You can choose a primary color and secondary color, then print any text you want on it like a name, a location to open, a car, number plate, or whatever the customer requests.

There are different designs of a similar nature such as the 4D Number Plate Key Ring for about $7, with a length of 8cm. They give free shipping, being ready to dispatch in just 1 day. Customers can choose between white or yellow for the primary color.

5. Fidget Toys

A 3D printed fidget toy is another amazing multipurpose item you can sell as it can serve as a desk toy, stress reliever, or even a companion. Dazzle your customers by printing great designs.

Dazzle your customers by printing great designs.

Using high-quality PLA, you can print a fidget toy in any color or shape as desired by your customer. A fidget spinner that had massive popularity in the past are an example of a fidget toy.

I saw a pretty cool 3D Printed Fidget Star – Stress Relief/Anxiety Toy selling for around $9 on Etsy. It’s a simple model that comes in several different color options, only being around 3 inches across.

You can message the seller if you want a larger or smaller model so customers have more choice. They mentioned that the design was created by a guy called Chuck Hillard, so the seller didn’t actually design the model.

They also let customers know the nature of 3D printing and how there might be slight defects or differences.

Another fidget toy is the Honeycomb Fidget Slider for $15, where the seller also added magnets in there for function. It’s a nice slim model with 6 magnets per base, enclosed within the design for better durability.

They give customers the option for a loud clicky slider or a quiet one. It shows as “popular now” on the Etsy listing.

Fidget toys can have prices ranging anywhere from $3 to $16.

6. Personalized or Famous Statue Busts

Many people are interested in having busts of famous people or even a personalized statue of themselves. There are plenty of examples where you can 3D print and sell these to willing customers.

I saw prices ranging from $40 to $210 for especially unique and highly detailed designs. I’m sure you can think of some famous people who you would love to have 3D printed and have on display somewhere around your home.

This is a really cool item to 3D print and sell if you can gather some designs that designers are willing to work with you for.

I saw a Custom Bust Unique Personalized Statue listing on Etsy where you send in three pictures and they model your face and send you the 3D model made from resin which is high quality.

It has an option of three heights 10cm, 14cm, 18cm, priced at $100, $115 & $130 respectively. They do make use of SLA resin 3D printing to get those higher details in the model, but FDM filament 3D printing can still work fairly well.

They do make use of SLA resin 3D printing to get those higher details in the model, but FDM filament 3D printing can still work fairly well.

There’s also a Charmander Pokémon Statue starting from $7, a David Statuette for $43, Batman Statue for $25, and a painted Deadpool Statue starting from $65.

7. Famous Landmarks

Famous landmarks are among the many interesting objects to 3D print and sell. A lot of the world’s most popular landmarks have already been 3D modeled or scanned by enthusiasts and experts. It’s similar to the 3D printed cities, but has many more options.

You can 3D print famous landmarks for people that love art, ancient history, geography, or architecture in general.

Your customers can use them for educational purposes, or as reminders of places they have visited or would love to visit in the future. For decoration purposes, they can hang it on the wall (3D printed frame), place it on a table, or display it in their place of work.

Think of historical landmarks or famous places in TV shows or movies.

One of the models to sell I found on Etsy was the Eiffel Tower made out of gray resin for around $18. It’s a great memento for a Paris trip you want to remember.

Another cool item to 3D print and sell is the Colosseum in Rome for around $22. It’s made from PLA and allows customers to choose between several colors, having dimensions of 15.2 x 12.6 x 4.1cm (L x W x H).

The model on Thingiverse is able to be sold under it’s licensing since it doesn’t have the “Non-Commercial” badge, but you just have to give credit or attribution.

Another example of a famous landmark model is Midtown Manhattan 3D CityScape, coming in two sizes, $97 for 6 inches and $120 for 8 inches. One more cool example of a cool landmark to print and sell is the 3D Printed Cleveland Skyline, sold for $30.

8. Flower Pots/Planters

To have an indoor feel of nature or just for aesthetic purposes, people buy 3D printed flower pots/planters. You can 3D print and sell flower pots/planters in various colors and sizes. It might not necessarily be a pot– it could be anything that can hold flowers.

It might not necessarily be a pot– it could be anything that can hold flowers.

When you search for 3D printed flower pots on Etsy, you’ll come across some cool and unique designs that are getting plenty of sales from customers.

The one that stood out to me the most was the 3D Printed Polyface Planter for around $30. You have the choice of many colors and three different sizes depending on your preference, made out of PLA.

It is an original design by the seller, but you could work with a designer to make your own unique flower pot or planter.

Another cool model is the 3D Printed Polyleg Planter for about $55. Its design incorporates 19th century statue legs to create a really cool aesthetic around your home.

The Extra Extra Large Flower Pot with Saucer from Etsy is a popular design that comes in a rainbow color, with the option to add a drainage hole at the bottom.

Lastly, the Modern Geometric Planter – Succulent Planter for $20+ looks amazing. With these types of designs and good audience outreach, you could sell plenty of these types of models.

Once again, your creativity is valuable here; depending on the customers’ preferences, you can put drain holes in the bottom of the pot or planter. Prices range from $10 to $50.

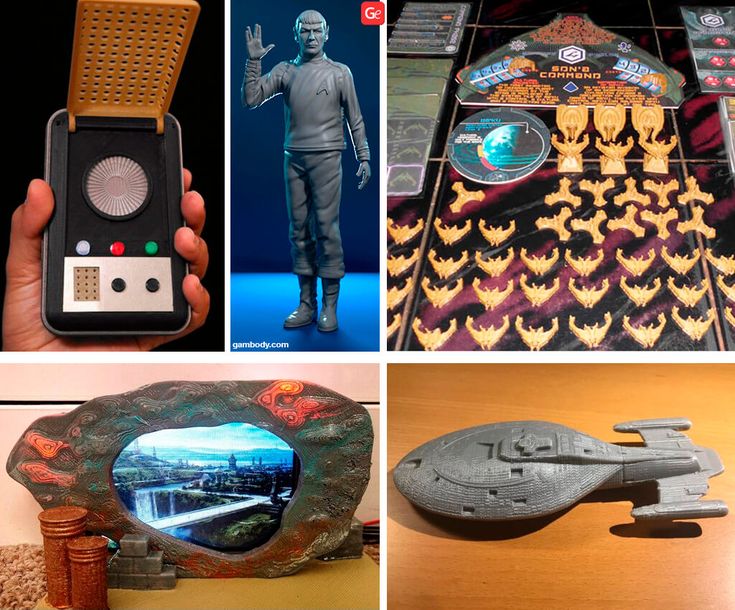

9. Replica Props, Items & People

No matter what kind of person is out there, you’ll always have some kind of replica items that they would love. Replicas are really cool items that people are willing to buy depending on what they grew up watching or are even currently enjoying.

A search on Etsy for 3D printed replicas brings many items such as the Star Wars Sith Holocron ($25), a Maria Replica Pistol ($60), the Lady Loki Sylvie Crown ($25), an Ace of Spades Hand Cannon ($73), a Daredevil Cowl Helmet ($50), a Sabre-Toothed Tiger Skull ($34), and plenty more.

The cost of creating these models should be pretty cheap compared to how much you can sell it for, especially if you get a model that’s high in demand. People are more willing to pay for things that have sentimental value or that are really high quality.

10. Vases

A vase is another item that you can 3D print and sell. Vases add a stylish setting on tables either at home or the office. Many people obviously like to beautify their homes; 3D printed vases can do just that.

There are going to be many similarities with flower pots and vases but there are many unique vase designs that I thought it deserved its own category.

3D printed vases can hold a variety of flowers, giving your customers the luxury of choosing different themes and colors. Advise your clients to handle the vases with care so it can last long.

The 6″ Spiral Vase is a $20 item that is being 3D printed and sold to people out there, made out of PLA. When you know the price of PLA and how many you could make out of 1KG of PLA, the potential earnings are significant.

How about the Unique 3D Printed Vase for Dried Flowers – Lunga, for around $33. It’s 20cm high and 8cm wide, using a larger amount of material so the product is thicker and more solid. They print the model with a specific pattern that is unique and full of lovely textures.

They print the model with a specific pattern that is unique and full of lovely textures.

It’s a modern, yet minimal design that complements all types of materials around the home like concrete and wood. They say it’s good for holding pampas grass, cotton, preserved eucalyptus, bunny tail, and other dried flowers out there.

Then we have the 3D Printed Woman Body Vase that would definitely catch the eyes of guests, and give a little chuckle. It’s a change from the usual vases you see around a house but artistic and unique. You can choose from many colors, including the rainbow effect.

The seller lets customers choose custom dimensions if they choose to. If you find a good vase to 3D print and sell, you’re looking at prices anywhere from $10 to $30.

11. 3D Printed Stands – Laptop, Gaming & More

If you are interested in improving people’s workspaces and giving them something to ease workflow, then consider 3D printing stands for popular electronics like laptops, gaming devices like VR headsets or even for a rifle.

I came across many different types of stands by search for 3D printed stands on Etsy.

A nice one that is selling quite well is the 3D Printed Laptop/Notebook/MacBook Stand for $15+. You can use it to prop up your laptop and have it act as a second screen. If customers get neck strain while using their laptop, this can help out a lot.

Many buyers have testified to the effectiveness of these stands as it allows space for better cooling and airflow.

It’s made out of PLA and customers get a 100% money-back guarantee, but they do charge for shipping.

The Charging Stand for Oculus Quest 2 is a functional 3D printed object made out of HTPLA (High-Temp PLA) for $33+. It was actually designed in a flat pack design to save on shipping costs and reduce waste. Users just need to use the included 4 screws and the hex key to assemble it.

Many users have shown pictures of the assembled stand, and they look great.

For the gamers out there, you can 3D print and sell the Headphone & Game Controller Stand, also made out of PLA for around $18.

12. D&D Miniatures & Characters

3D printed Dungeons & Dragons is a huge industry because they create such highly detailed models that these users crave to improve their gameplay.

Even though the rise of video games has made many people shift attention from board games, there are still die-hard fans of miniatures.

A 3D printed D&D miniature’s quality is perfect for playing peoples’ favorite board games.

Many people are now opting for 3D printed miniatures with their own preferred custom models rather than buying games made through injection molding, a more expensive option.

Based on your customers’ preferences, 3D printed D&D miniatures can be painted with acrylic paints, sanded, or polished.

There are all sorts of 3D printed D&D & board game miniatures that people 3D print and sell.

One seller is selling a Set of 11 D&D Townsfolk made out of high quality resin for $18.

This set includes 11 miniatures:

- 1 x Drunkard

- 1 x Farmer

- 1 x Hunter

- 1 x Milkmaid

- 1 x Minstrel

- 1 x Oaf

- 1 x Sailor

- 1 x Scoundrel

- 3 x Varieties of nondescript townspeople

They mention that resin is a delicate material, but you could do something like partially add flexible resin to improve the durability of these parts. I wrote an article about Mixing 3D Printer Resins Together & Dying Resin, so feel free to check that out.

I wrote an article about Mixing 3D Printer Resins Together & Dying Resin, so feel free to check that out.

This Hydra Monster Tabletop Miniature goes for around $15+ depending on the size of the model. It’s solid and advertised as having little to no support marks.

Another D&D model is the Lady of the Marsh, a 3D printed 28mm tabletop gaming model made out of gray resin. It is priced at $19 and is delivered unpainted, so the seller doesn’t have to do that extra work.

A more expensive model that is 3D printed and sold is the Ancient Red Dragon Miniature for $38, up to $75 for the largest size. This one is primed and ready to be painted by the end user.

They also have to glue the wings, body, and base together since it’s better for safety to have them apart for delivery.

13. Jewelry

3D printed jewelry is big business whether it is filament plastic, resin plastic, or even metal cast jewelry. If you search around for 3D printed jewelry, you’ll find no shortage of listings with premium prices for creative and unique designs.

A lot of fashion is geared towards being unique, so if you can deliver a nice design with a range of colors, you can definitely 3D print and sell these.

An example of 3D printed jewelry is The Heart – Modern 3D Printed Earrings from Etsy for around $40. Some reviewers mention that the actual earrings look a lot better in person than in the pictures. They are very lightweight and beautiful.

Another popular earring design is the Leafy 3D Printed Earrings, for around $50. They are made from Nylon with a choice of 925 sterling silver or 304 stainless steel in gold for the lever back hooks. Each set comes with a jewelry box.

There are many other earrings designs, and even another Elegant Geometric Leaf Earring Design for around $13.

If you are willing to do some casting in metals by using silicone molds, you can create and sell something like the ZiPlane 3D Printed Ring for $45. Some users said they got many compliments after wearing this ring.

A really unique model is the Custom Baseball Earrings for $12 where you can add your team/player and a desired number. It’s rated as a “Bestseller” and is made from PLA using two colors, a base color, then a top color.

It’s rated as a “Bestseller” and is made from PLA using two colors, a base color, then a top color.

Prices range anywhere from $5 to around $50.

14. Wall Decoration

This is yet another potential cool item to print and sell. Designing aesthetically pleasing spaces has become a lot easier, thanks to 3D printing. As far as your imagination and creativity can take you, you can design and 3D print any form of wall art.

Homeowners are continually in search of amazing wall art that will beautify their homes and hold their visitors spellbound. You can step in to bridge the gap.

I found this cool 3D Printed 3-Piece Skull Wall Decor for $30 which can be customized with colors using a Mica Powder. It has an inbuilt hole so you can hang it by a nail in the wall for a flush look.

There weren’t too many ideas I could find on Etsy, but you could get really creative here and create some nice wall art picture outlines. A quick search on Thingiverse for “Wall Art” showed some cool wall art sculptures.

You could contact the designers and see if he will let you sell them since they are under a Non-Commercial license, or design your own similar model. The Homer Wall Art Model just has an Attribution license so you can sell it as long as you credit the designer.

15. Personalized Lithophane

A lot of people haven’t heard of lithophanes, so when they first see how they work, it really impresses them. They are basically thin 3D printed tablets that create an image within the model that shows up clearer with a light behind it.

I even wrote an article describing How to Create a Lithophane & the Best Filament to Use. All you need to do is have the personal picture that a customer would send you, input it into a website with settings to create the STL file, then 3D print it with white PLA.

They can use it as a gift for any occasion, whether birthdays, marriages, or anniversaries. It is lovely to create memories and design the pictures in a cool item like lithophane, so this niche is not going away anytime soon.

Encourage your customers to send quality pictures as this affects the overall quality of the 3D printed Lithophane. People have gotten really creative with these by designing lithophane in different shapes, or coming with stands that have lights behind them.

You can get lithophane light boxes, night lights, keychains, ornaments, moon lamps, cylinders, or even a heart-shaped lithophane.

This Lithophane Box with Remote Controlled RGB LED Lights is a really creative way to have a unique product. It sells for $75, with dimensions of 5″ x 5″ x 5. You just send the seller your four pictures, pick a color for the box then they will create it and send it to you.

Prices of personalized lithophanes range from $5 up to $700 for a Custom 3D Printed Lithophane Wall of 30 pictures!

16. Specialized Bookmarks

A simpler item you can 3D print and sell are bookmarks, whether they are a standard design, specialized design to some kind of niche, or a personalized design that customers request.

When you search for bookmarks on Etsy or Thingiverse, you’ll find plenty of models there that you can potentially 3D print and sell depending on the licensing. This one shouldn’t be too difficult to design yourself though if you put some time into learning.

I found a quick video showing people how to design a 3D printed bookmark in TinkerCAD that you could follow.

One of the best things about selling 3D printed bookmarks is that they are easy to ship, can be made quickly, and require very little filament to create. The returns you could get on 1KG of PLA filament should be hefty.

A popular one that would work well on Etsy would be the Hanging Cat Bookmark, going for around $10, or you can buy sets of up to 20 to get a discount. Cat designs make a lot of sense since a lot of people who read have cats.

Cat designs make a lot of sense since a lot of people who read have cats.

Another Cat Bookmark sells for $8 each, made out of PLA. It has plenty of positive reviews for the item.

This 3D Printed Game of Thrones Wolf Bookmark is another popular one that people love, going for around $6. It works because it has a specific niche audience who love the book or the TV series.

Finally, we have the Personalized Bookmark that simple has the customer’s name, so they put in an order with their name in the description, and the seller creates the bookmark to order, rather than beforehand like you can with the other models. It sells for $5+ depending on length.

There is another Personalized Bookmark Custom Design which is the letters joined together, a different type of design, but of similar nature. This one sells for $7.

Prices range from $2 to around $10.

3D printed food. Food from the printer.

The concept of 3D printed food is already beginning to take shape. But before such delicacies hit our table, the process must be faster and the result tasty.

But before such delicacies hit our table, the process must be faster and the result tasty.

Today, 3D printers work on plastic, metal, resins and other materials. Creative people can do real miracles with their help. But a major revolution in 3D printing will come when we can eat the result.

Engineers and gourmets alike are making efforts to ensure that edible ingredients are used as the starting substrate for 3D printing. If everything works out the way they envision, then we will get food of previously unattainable shapes and textures, personalized messages from sweets, and a varied menu from astronauts who went to Mars. Jeffrey Lipton, CTO of Seraph Robotics, Ph.D. from Cornell University, says there are interesting developments in this area.

The first food from a 3D printer was obtained a few years ago using the Fab@Home printer. The heart of the machine is a syringe that works on the same principle as inkjet printers. Layer by layer, he lays down a viscous liquid, forming an object of a given shape. The university has made the drawings of this printer publicly available, to the delight of many enthusiasts. Lipton says people have started their own experiments with epoxies and silicones. At the same time, gourmets appeared who began to put cheeses, glazes, etc. into the printer. It can use anything that is forced through the head of the syringe. Although it is possible to produce food with unique textures or decorations that were not previously available with this equipment, it is still far from commercial use.

The university has made the drawings of this printer publicly available, to the delight of many enthusiasts. Lipton says people have started their own experiments with epoxies and silicones. At the same time, gourmets appeared who began to put cheeses, glazes, etc. into the printer. It can use anything that is forced through the head of the syringe. Although it is possible to produce food with unique textures or decorations that were not previously available with this equipment, it is still far from commercial use.

In fact, 3D-printed products are already on store shelves. Almost all microwavable pancakes sold in Dutch supermarkets are printed. This information was revealed by Kjeld van Bommel, a scientist from the Danish Organization for Applied Scientific Research. He calls them "two-and-a-half-D-seals," since they are formed in one pass of the head through which the dough passes. But there are other products that can be called the result of 3D printing. For example, the British manufacturer Choc Edge sells printers capable of layering chocolate into various shapes. On the last Valentine's Day, the Japanese FabCafe 3D printed chocolate faces that are significant to customers. And last summer, large-scale printed paste appeared in cafeterias for Google employees.

On the last Valentine's Day, the Japanese FabCafe 3D printed chocolate faces that are significant to customers. And last summer, large-scale printed paste appeared in cafeterias for Google employees.

The first steps use a simple one-ingredient process. So far, no one makes complex food on the printer, say, a hamburger, with all its components. It is very difficult to combine ingredients and structures in one product that are formed at different temperatures and require different sterility conditions. As van Bommel says, making one grain of wheat is many times more difficult than making something out of flour. In many cases, this is not economically justified. Why would we print complex structures (lettuce leaves or cuts of meat) if they already exist and are relatively inexpensive?

Instead of repeating already existing organic objects, it is much more important to learn how to create new products with individualized nutritional value. Let's say a person needs more calcium or omega-3 fatty acids in their diet, why not start printing out the appropriate foods for them. That is what the work of the van Bommel group is aimed at. They want to help older people with dysphagia, chewing and swallowing problems. They usually get their food in the form of unattractive mashed chicken, broccoli, and the like. This leads to loss of appetite and malnutrition. Van Bommel's group received a grant from the European Union to develop a 3D printed meal containing all the necessary components.

That is what the work of the van Bommel group is aimed at. They want to help older people with dysphagia, chewing and swallowing problems. They usually get their food in the form of unattractive mashed chicken, broccoli, and the like. This leads to loss of appetite and malnutrition. Van Bommel's group received a grant from the European Union to develop a 3D printed meal containing all the necessary components.

Printed products may also use cheaper protein sources such as algae. This would reduce the need for relatively expensive meat. It is unlikely that we will print steaks from k

ovo protein, but from one that is extracted from algae - it is quite possible. In one experiment, van Bommel added crushed flour beetles to a 3D cookie recipe. Few of us will eat an insect, but if it is turned into a cookie, then why not?

How about a versatile 3D food printer like the Star Trek replicator that can make anything we want. While this is theoretically possible, it comes with a number of problems. Obviously, we can't build a 3D food printer containing 50 million cartridges just to print a tomato. Someone will say that it is enough to install a cartridge of fat, protein and carbohydrates. But each of these classes includes an incalculable number of individual substances. Probably, when printing, their variety will have to be greatly reduced. Van Bommel says: "Maybe it will be three types of proteins, three types of carbohydrates ... It's quite feasible, but we still need to know how to make different types of products from these components."

Obviously, we can't build a 3D food printer containing 50 million cartridges just to print a tomato. Someone will say that it is enough to install a cartridge of fat, protein and carbohydrates. But each of these classes includes an incalculable number of individual substances. Probably, when printing, their variety will have to be greatly reduced. Van Bommel says: "Maybe it will be three types of proteins, three types of carbohydrates ... It's quite feasible, but we still need to know how to make different types of products from these components."

A significant obstacle is the slow speed of 3D printing from edible components, after applying each layer it takes some time to cure. “If we start printing a steak using modern technology, the result will be ready in three months. Nobody will wait that long. The result should be in minutes or hours,” says Lipton.

Some scientists are working to speed up the 3D printing of food. Van Bommel created a process that uses a laser to cook food locally. He can fry an egg in a minimal amount. Nedvano TNO demonstrated a PrintValley machine that can do everything much faster. PrintValley has 100 platforms under sequentially passing nozzles. This "conveyor" can create 100 objects at the same time, each the size of a square inch, in less than 10 minutes. Bommel wants to prove that 3D food printing can happen much faster.

He can fry an egg in a minimal amount. Nedvano TNO demonstrated a PrintValley machine that can do everything much faster. PrintValley has 100 platforms under sequentially passing nozzles. This "conveyor" can create 100 objects at the same time, each the size of a square inch, in less than 10 minutes. Bommel wants to prove that 3D food printing can happen much faster.

In most situations, printing on a 3D food printer is not justified. But in space it can be a real salvation. Michel Terfansky of the University of Southern California explored this concept in his master's thesis. He learned about the occasional annoyance of astronauts on the International Space Station with poor diets. What will it be like for those who go on a multi-month expedition to Mars? With the help of 3D printers, friends and family could send recipes to Earth messengers. 3D printers will help save space and rid the ship of warehouses of meat and vegetables. Terfansky believes that this technology will make people happier. On the Moon or Mars they will feel at home.

On the Moon or Mars they will feel at home.

But today, 3D-printed food lacks palatability. Lipton noticed that some of his employees call the meat printed on a 3D printer shmit (meat - meat in English). Here you have to work in a team with culinary schools and rely on suggestions from food preparation specialists. “So far, on a 3D printer, we get something that looks good and does not poison. We call it 3D food, van Bommel jokes. “But in the future, the recipes need to be improved so that we get real food. So far, techies, not chefs, are working on this problem. ”

Main source: popularmechanics.com

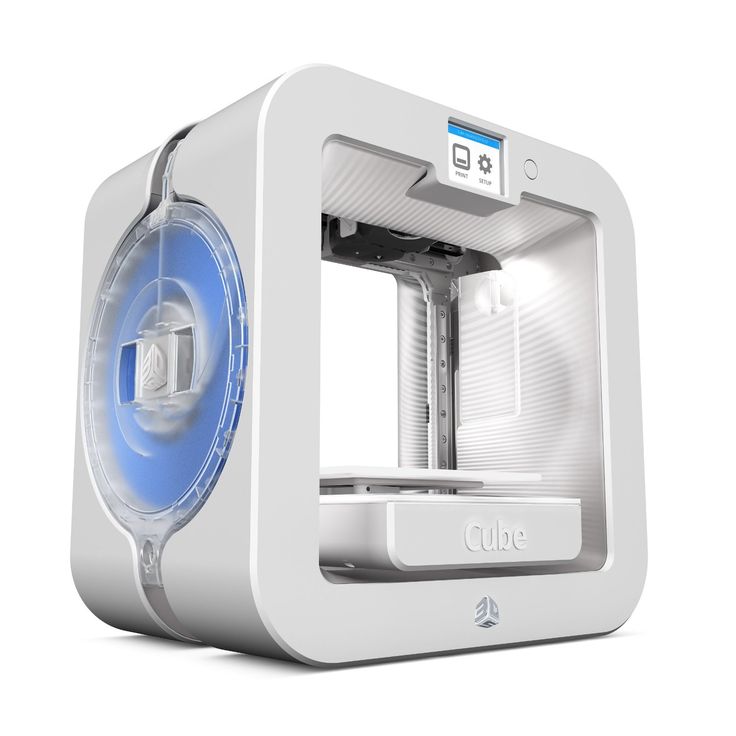

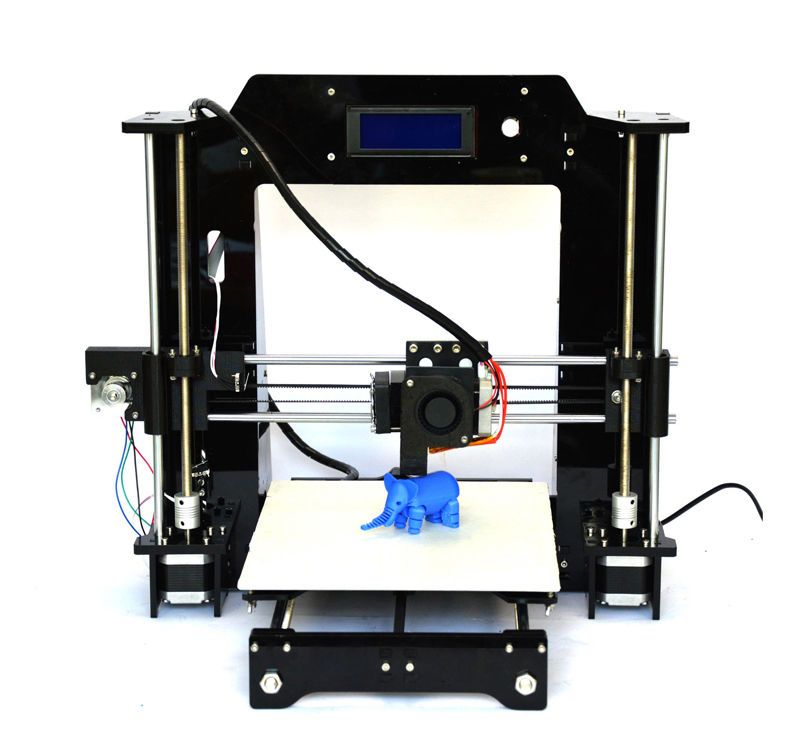

How 3D printers work - How it's done, how it works, how it works - LiveJournal

No one can be surprised today by technologies that have stepped out of science fiction books. We have become so accustomed to them that we think little about how we used to live without them. Now we actively use them, study, communicate, earn money with their help, have fun, in general we do a lot of things, but there is one area that still surprises with its capabilities.

Today at kak_eto_sdelano a report about how 3D printers are designed and work.

I'll tell you a little about the history of these amazing machines of the future. The first 3D printer was born over 30 years ago, in 1984. It was invented by Chuck Hull, founder of the world's largest company "3D Systems" - a leader in the production of 3D printers. Since then, technology in this area has stepped far forward and the capabilities of such devices have expanded significantly. Now 3D printers can print almost anything from anything. The size of the thing being created is limited only by the working area of the printers, however, this problem can also be solved - there is a special superglue that glues the details of the future product.

But first things first. The printer is connected to a computer, which asks it to print a future product from a 3D model prepared in a special program. This 3D printer uses a gypsum-based composite material for printing, which allows you to print at high resolution, reproducing up to 6 million colors.

The principle of operation is as follows - the printer has a container into which fine powder is poured in a thin layer, leveled, a carriage with a cartridge passes over it and sprays a hardener of different colors on the desired areas. Again, a layer of powder is poured, leveled, a binder with paint is applied, and so on many times. The layers are so thin that the previous ones are visible underneath.

The operation is repeated layer by layer, and the bottom of the chamber gradually goes down. It takes up to several hours to print a 3D model, depending on the complexity of the product.

Today we will print a personalized 3D case for Yota 4G modem, made of gypsum composite with meteorite particles. Yes, now you can print such interesting things.

This shows how many layers have been printed so far.

This video shows how the printing process works.

But while the process is going on (it will last about an hour), we will see what things can be printed on a similar printer, I will tell you what printers exist and what technologies are used at the moment.

One of the technologies allows you to make a 3D model of a person and print these figures. A good gift for an anniversary, Comrade Stalin approves.

Heads of one politician. I think you guessed who it is.

And other interesting figurines.

Human hand sculpture and 3D printed sculpture.

Any company can now create a prototype of some part on a 3D printer, and it will be much faster and cheaper than producing a sample using traditional methods. Here is, for example, a printed prototype of an engine part.

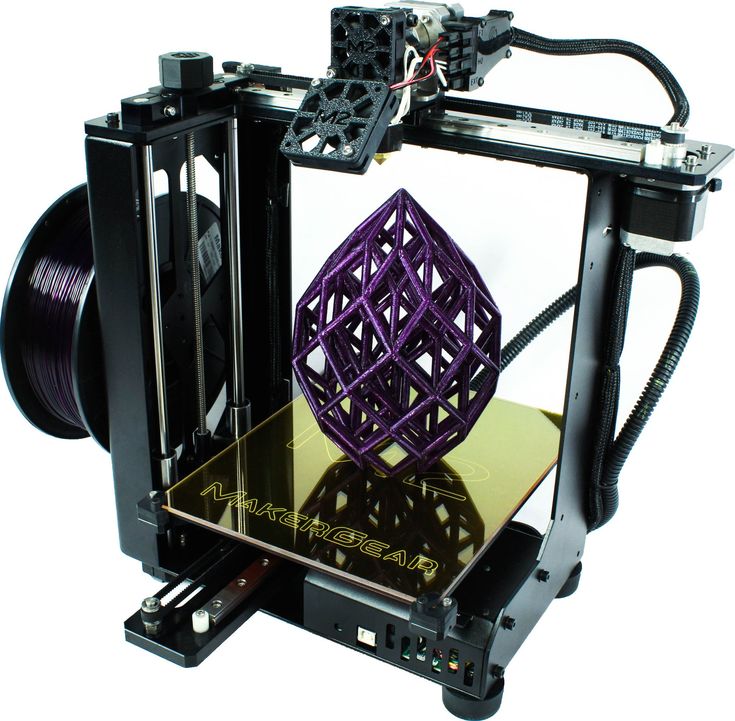

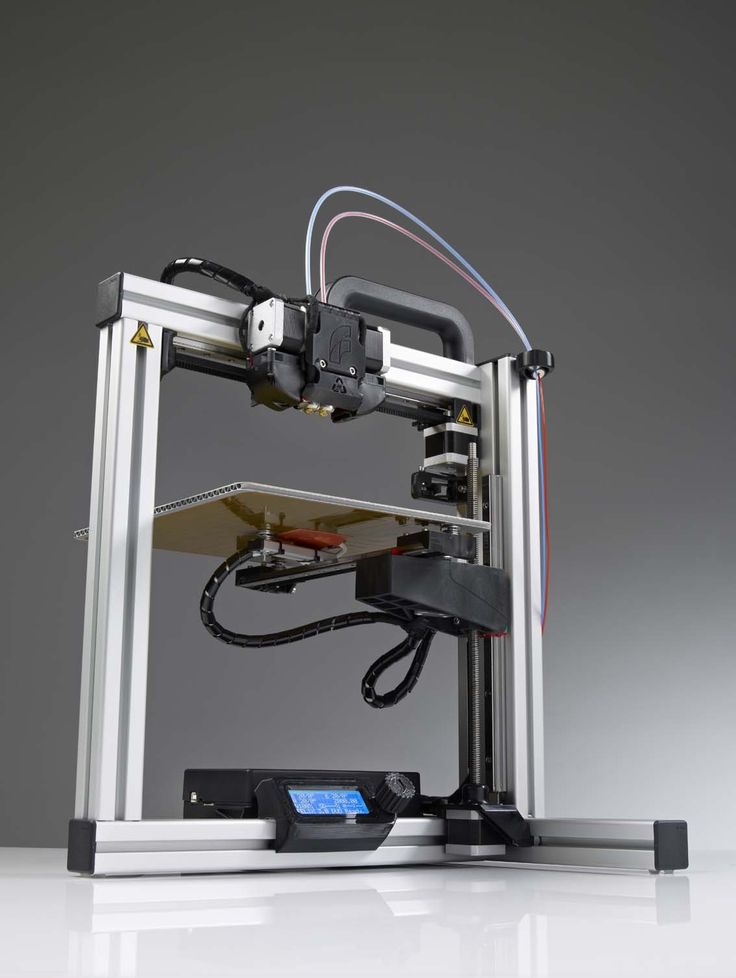

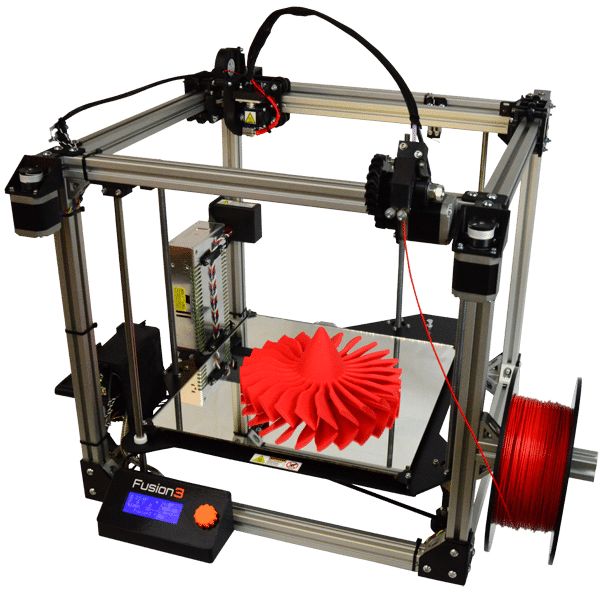

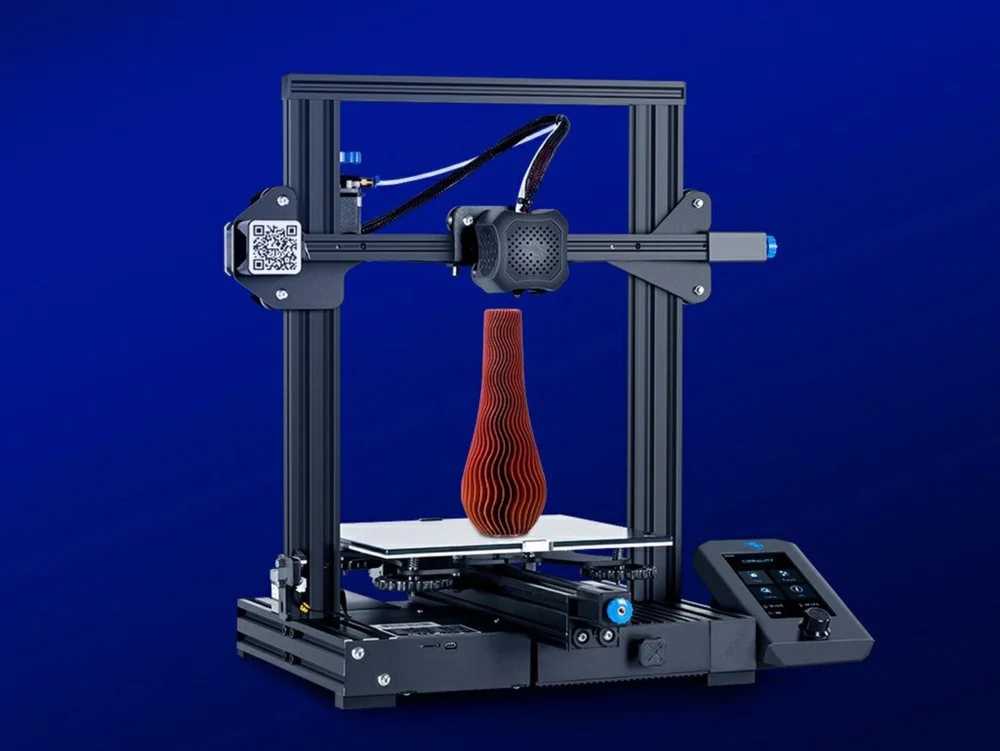

But the machines of the future began their development with printers, which we will discuss below. This printer uses plastic to print. FDM technology (Fused Deposition Modeling) - layer-by-layer application of molten plastic thread.

Plastic available in a variety of colors.

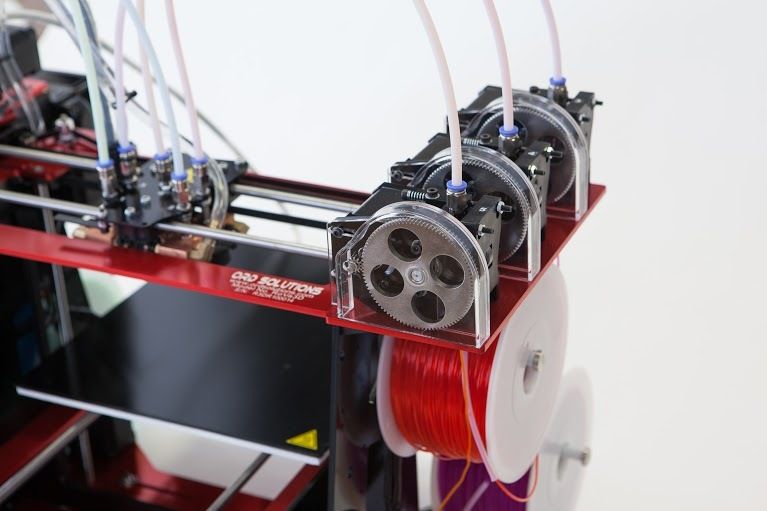

The printer does not run on a cartridge, but on ordinary spools of plastic connected to it in the form in which they are sold. The plastic filament is fed into the extruder, where it heats up and the print head applies the material to the moving platform.

The plastic filament is fed into the extruder, where it heats up and the print head applies the material to the moving platform.

This is a more modern version that you can buy at home. If prices for home 3D printers start at 35 thousand, then this one costs 165 thousand.

The printer is slightly more expensive. The types of plastic they have are about the same. This printer features a large build area among home 3D printers.

This printer can print a Jedi sword. And it adds up.

Or an ordinary sword. Since the dimensions of the printer do not allow printing long or large products, they are printed in parts and then glued together.

These masks are also printed on this printer.

I don't recognize you in makeup, Innokenty Smoktunovsky? Who recognized the character?

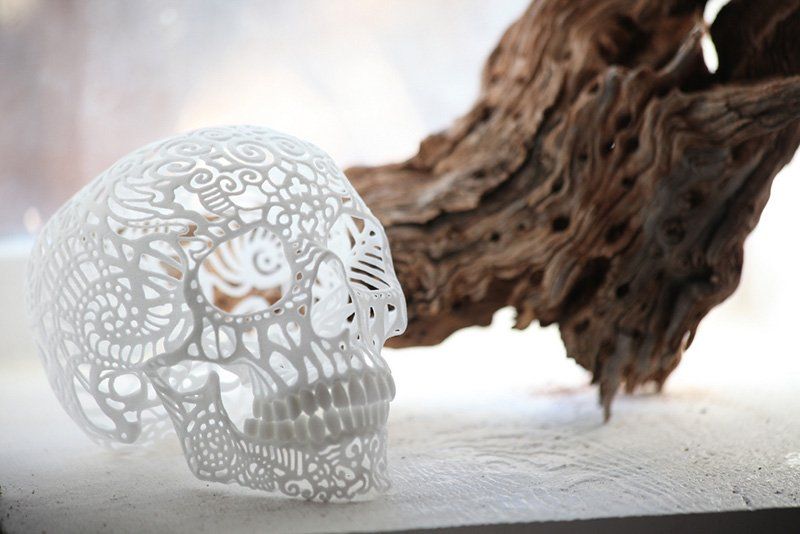

Next, our story will be about other types of printers. The ProJet 6000 printer uses SLA technology (stereolithography). By the way, this technology was invented by Chuck Hull. In it, the hardening of the photopolymer occurs due to the ultraviolet flash of the laser.

By the way, this technology was invented by Chuck Hull. In it, the hardening of the photopolymer occurs due to the ultraviolet flash of the laser.

When printing almost any model, there is a need to support the protruding, overhanging parts of the model being grown, and for this purpose, the material itself is used from which the print is made.

And here the product is already being cleaned, washed, and supports are removed.

As I was told, 3D printing technology has advanced so much lately that there are printers that can print anything from chocolate to metal to sand!

In this video, for example, you can see that the printer prints both plastic and rubber.

This video shows a unique solar powered printer. The author of the project used sand as a material, which he collected right there in the desert. Instead of laser beams, he used a large Fresnel lens, which concentrated the sun into a point and melted the sand. The author of the project himself acted as a filling and leveling device. The printer's coordinate system and computer, as I said earlier, were powered by solar panels. During several hours of being in the desert, he made an incomprehensible horseradish and a bowl.

The printer's coordinate system and computer, as I said earlier, were powered by solar panels. During several hours of being in the desert, he made an incomprehensible horseradish and a bowl.

This printer prints from metal chips. The powder particles are sintered together by a laser, after which the tray cools down for another day. However, the product is fragile, the sintering of metal particles does not give strength to the product, it is quite porous and can break in the hands, so it is processed again in a special oven, placed in another tray with another metal powder, which fills the pores and makes it strong enough.

3D printer in Shanghai prints at home!

In this video you can see other possibilities of 3D printing, from printing cakes to weapons and prosthetics. Now the possibility of printing individual organs for humans is being actively explored.

While we are waiting for the Yota modem cover to be printed, we were shown other gizmos that are exhibited at various exhibitions.

This amazing piece was printed from polyamide. Its peculiarity is that all the details in it are moving. Moreover, it was not glued from different parts, it was printed at one time.

Made a gif to show it in action.

Articles made of other materials.

But we return to our printer, which is finishing printing the modem case.

Only 43 layers left to print.

After everything is finished, all the powder is collected by a special vacuum cleaner that is connected to the machine itself. It will again go into business with the next printing, so we can say that the production is waste-free.

In the next booth, the cover is cleaned of powder with compressed air and a soft brush.

Almost done.

It remains only to impregnate it with a special glue that will fill all the pores and make it stronger.

And this is the meteorite powder that is added when printing these covers.

That's all, the modem case is ready.

On April 12, Cosmonautics Day, mobile operator Yota launched an experiment with 3D printing and offered its customers the opportunity to order a personalized case made of a high-tech composite with meteorite particles along with a modem.

You can place an order on the 3d.yota.ru page when purchasing a 4G modem. The user himself can create a cover design on the site, cutting off the virtual edges of the composite with the help of clicks and entering an inscription into the sample. Delivery of covers together with modems is made in Moscow within the Moscow Ring Road.

According to Yota representatives, the meteorite used in the experiment was found in 2005 in the Magadan region. The fragment belongs to the type of iron-stony meteorites and is presumably a fragment of the Seimchan meteorite.

Now you know how 3D printers work and work.

If you have a production or service that you want to tell our readers about, write to the address ( shauey@yandex.

Learn more