3D print hair

How to create realistic hair for 3D hair printing

Introduction

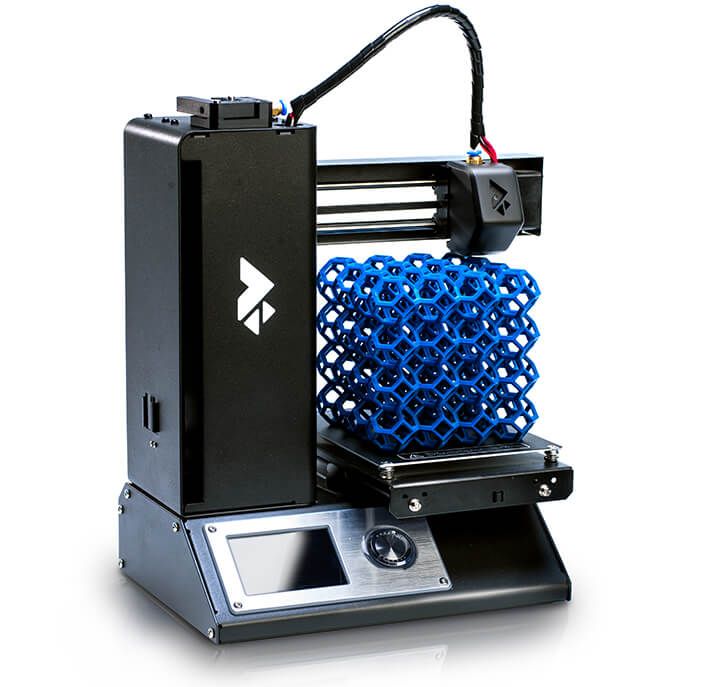

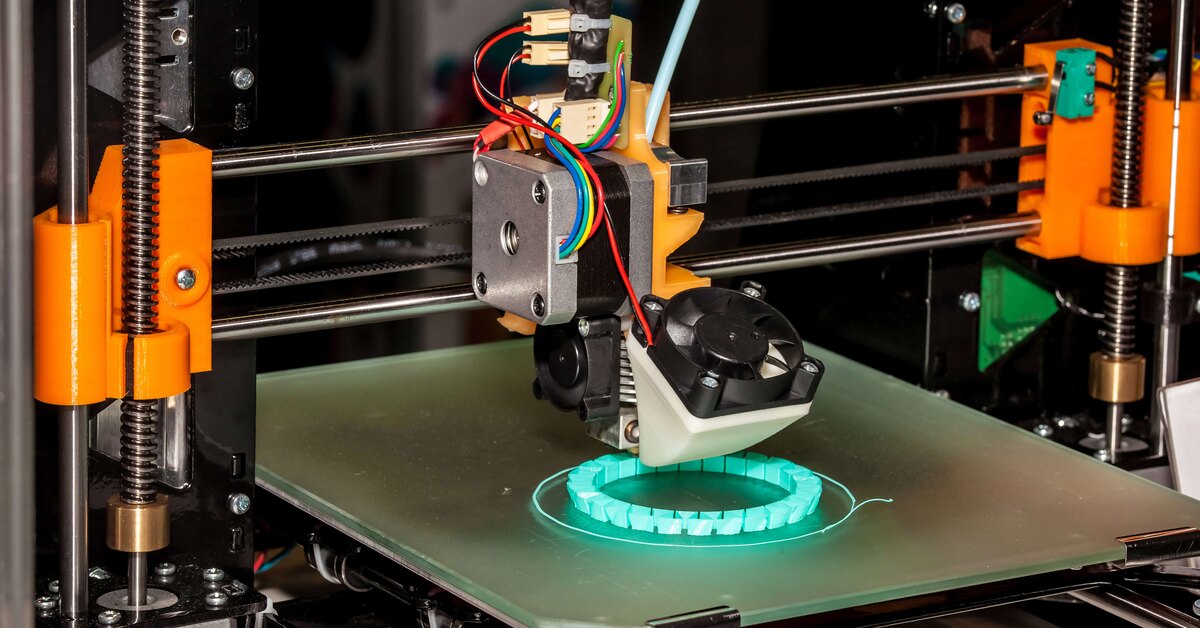

3D printing is a very interesting topic for every startup and company, both for the creation of proof of concept, both for very specific unusual parts, such as 3d hair printing.

In our company, we use the 3D printer several times to print the most varied things: we create and print custom cases for boards, joints for robotic parts, humanoid robot parts, gadgets, etc … For example, take a look at our article about an IoT application with a custom case: https://www.makarenalabs.com/nebul-iot-a-simple-embedded-smart-device-for-greenhouse/

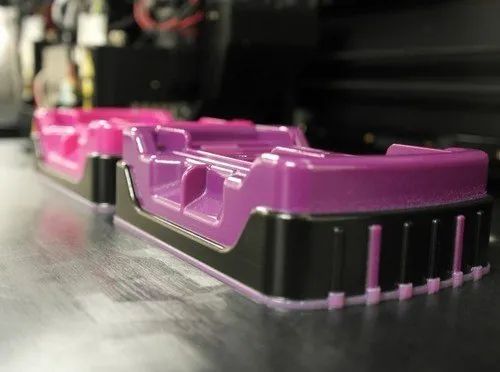

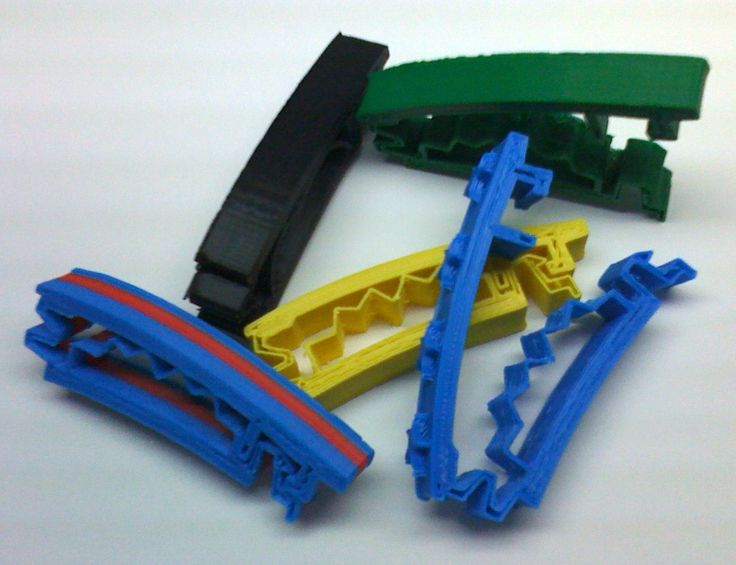

We also use different materials for different purposes, for example:

- PETG for strong large models;

- TPU for soft models;

- UV resin for small, extremely precise, and detailed models.

For each model, there is the right material.

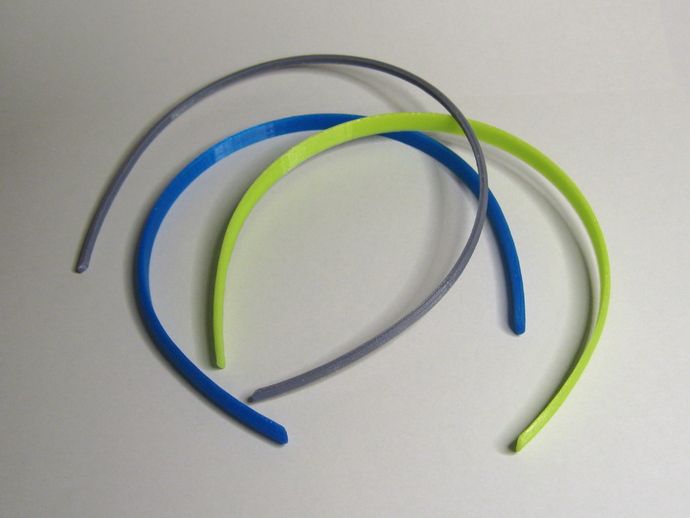

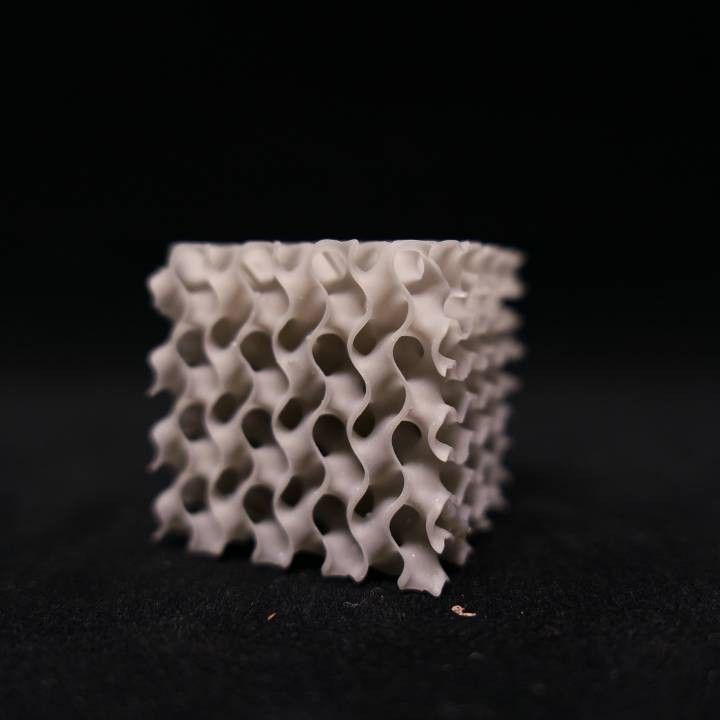

We were looking for new printing techniques when we had discover 3D printed models of animals or people with realistic hairs or fur. So, we decided to replicate this type of model and, not finding any tutorial about it, we decided to do it ourselves.

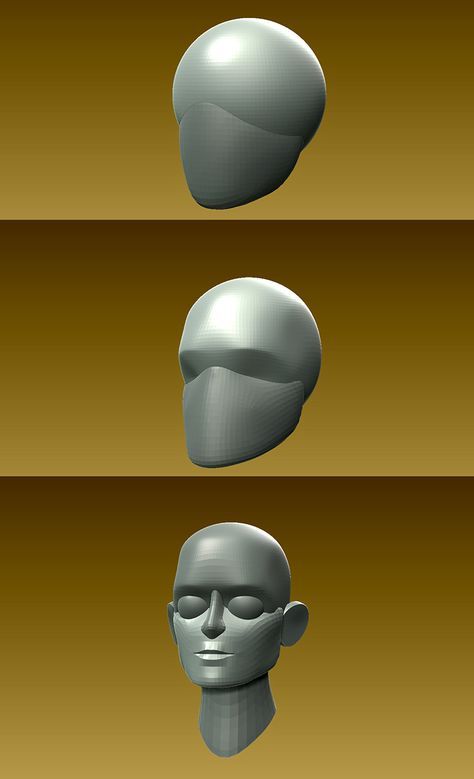

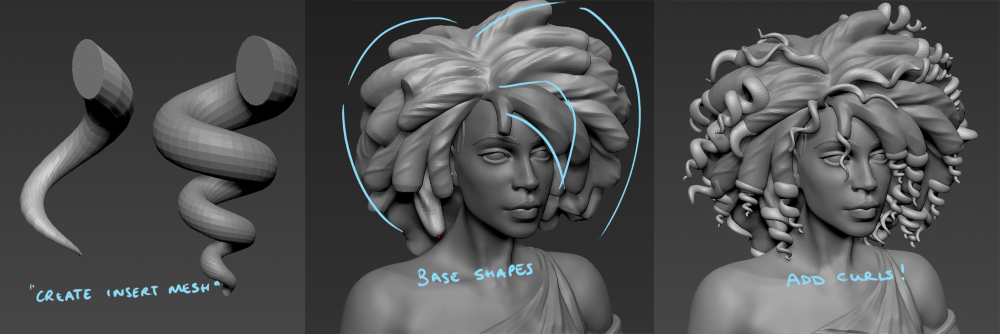

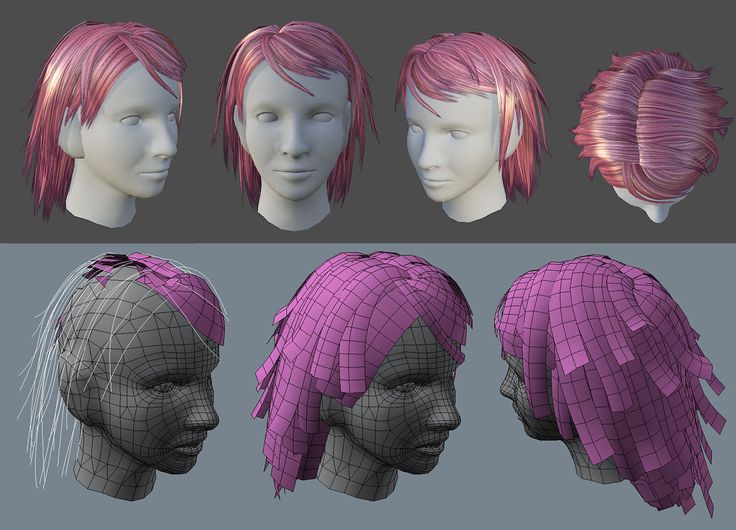

Mesh creation for 3d printing

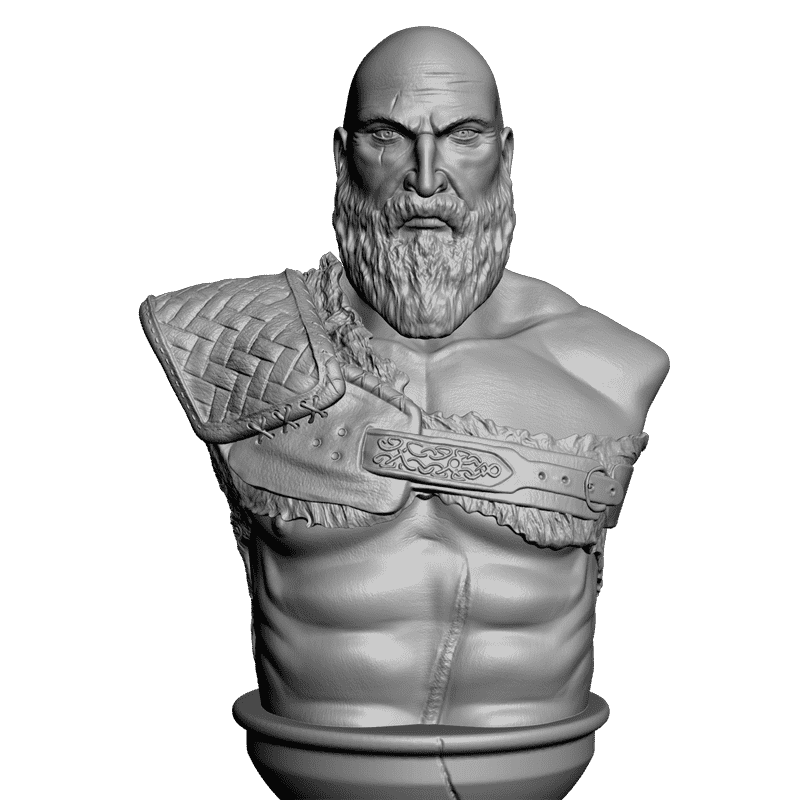

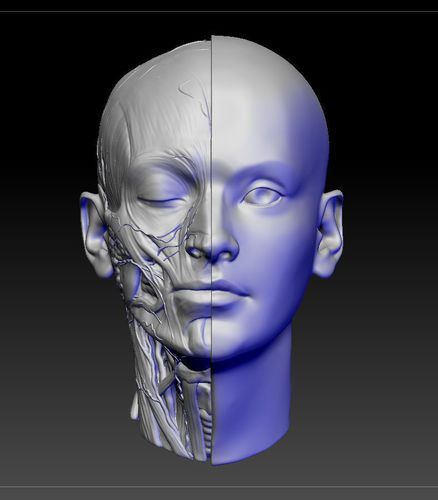

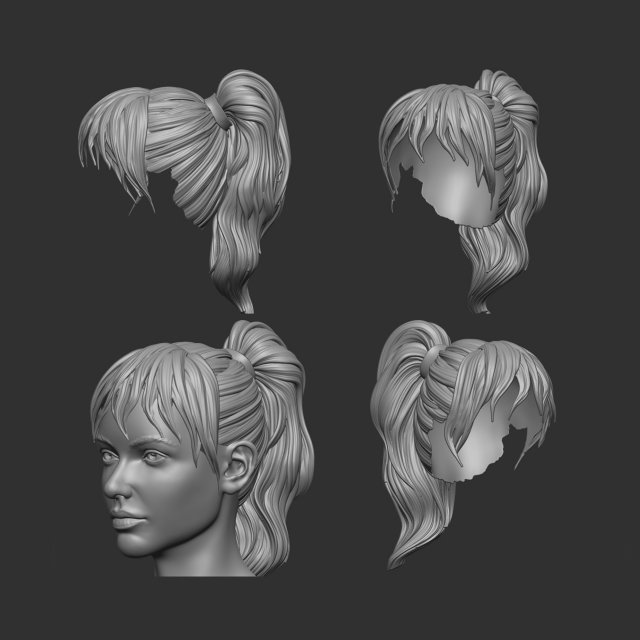

First of all, we need a head or a part of the body to create hair. For the majority of the projects, we use Blender.

The starting mesh must be manifold, with correct normals, avoiding faces without thickness, otherwise, it is impossible or very difficult to print it.

I do not recommend using a particle system and converting it into a mesh (it is extremely heavy) for the construction of the entire mesh.

The starting point to create a solid object that represents hair could be a cylinder, a cube extruded in a single axis, or a similar mesh. To speed up your work you can use a single “hair” mesh to create two hair. Each hair is crafted individually.

A few points of the procedure before we begin talking about the starting mesh (the head to be clear):

– first, the mesh, as I said before, must be manifold

– then, the mesh must need a few supports to be print

– then, the mesh mustn’t have graphic obstacles around the affected area, like ears too massive, hollows or concave areas, etc…

– finally, the base on which rests must be stable.

The hair creation

Let’s begin from the first single hair:

– I recommend you to use, for the mesh, a cylinder shape or parallelepiped shape

– the mesh length will be what you want, but remember that once settled the hair length, it could cover some detail about the head mesh.

– I recommend you a mesh thick about 0.5 millimeters but it depends on how much your printer is able to create thin objects.

For a full head of hair, we use the “spin tool” in edit mode. For example, in our demo model, we have rotated the model in a way that will be horizontal, and in the spin tool settings, we used a dozen steps in the Z axis.

You have to duplicate the hair mesh enough to cover the head.

After that, you have to delete the parts of the mesh that cover the details of the head.

Remember: all of the hair mesh must be horizontal to the head because then we have to create the support for the hair.

in conclusion, you have to use unite all the hair with the head: add a boolean modifier and, with union option, connect the hair to the head.

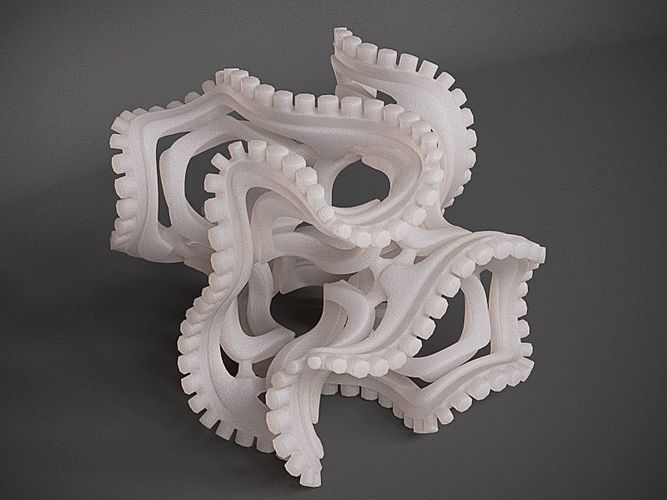

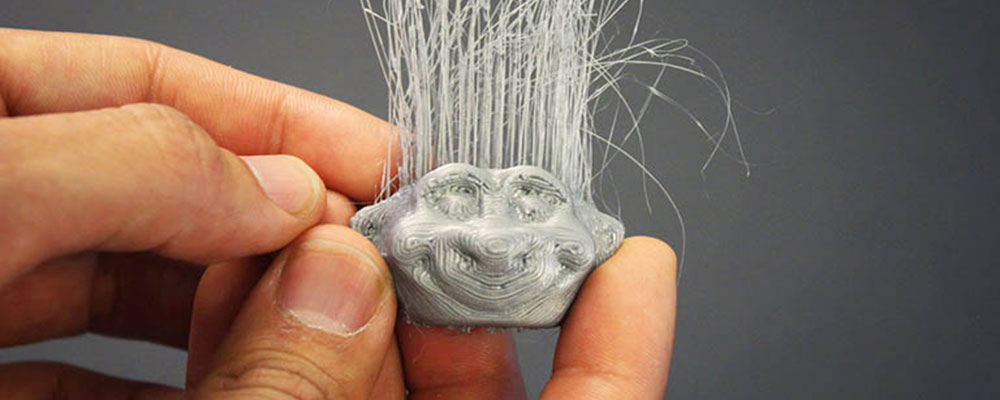

Supports for 3d printing

we will create some supports that will hold up all of the hair mesh. It’s very easy: you must create a hollow cylinder with a thickness of roughly 2 – 3 millimeters that surrounds the entire structure and encompasses 1-1.5 millimeters of the end of hair mesh.

If you need to print your model with additional supports, you will, unfortunately, do it by hand with Blender.

in conclusion, you have to unite the cylinder with the other mesh.

Hairstyle

To finish your hair head and create a styling, you’ll need to do one of these options:

– A thermo-gun (best choice)

– An hairdryer (safer choice)

– Very hot water (we have never tried it)

Arm yourself with special thermal gloves (don’t do like the video) and an object similar to a hairbrush for combing the hair.

Now, melt slowly the hair (try to not melt the head), make some pauses, and comb continuously the hair to keep the shape.

If you want to use the hot water, put your object in a basin and pour the hot water over the head.

Let me know if you manage to do it!

Enjoy

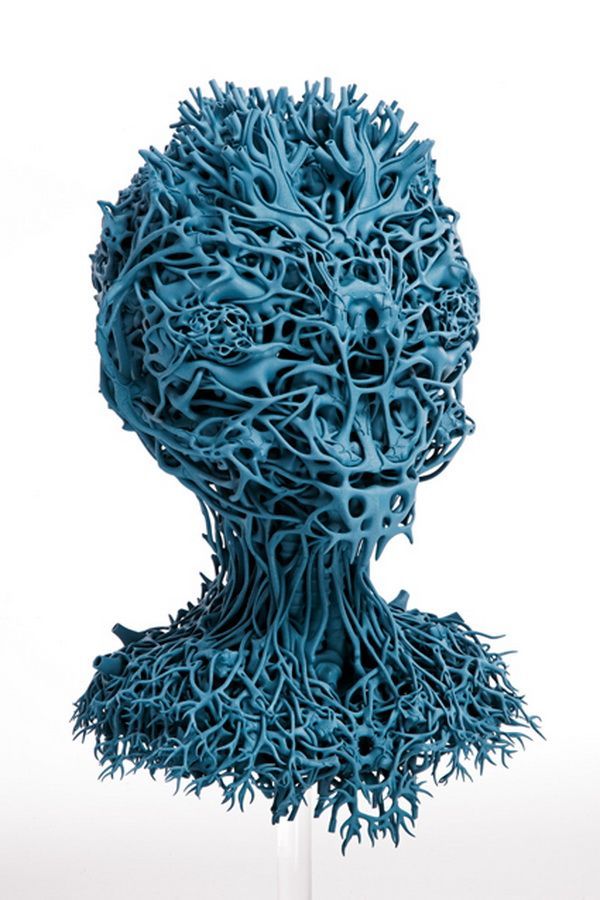

3D Printed Hair: Can We Print Transplantable Hair Follicles?

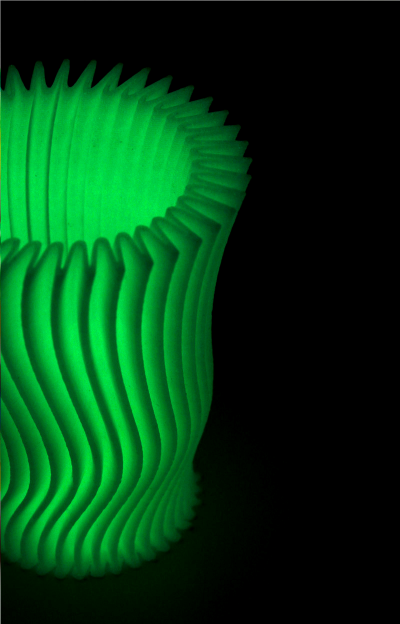

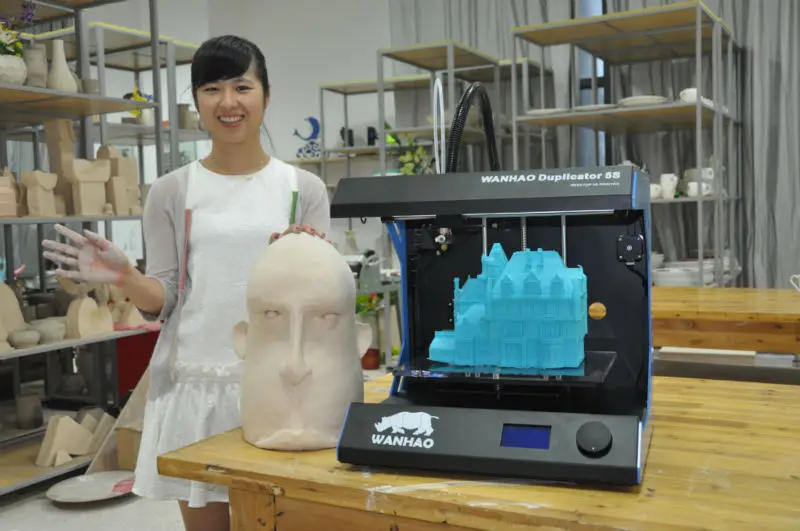

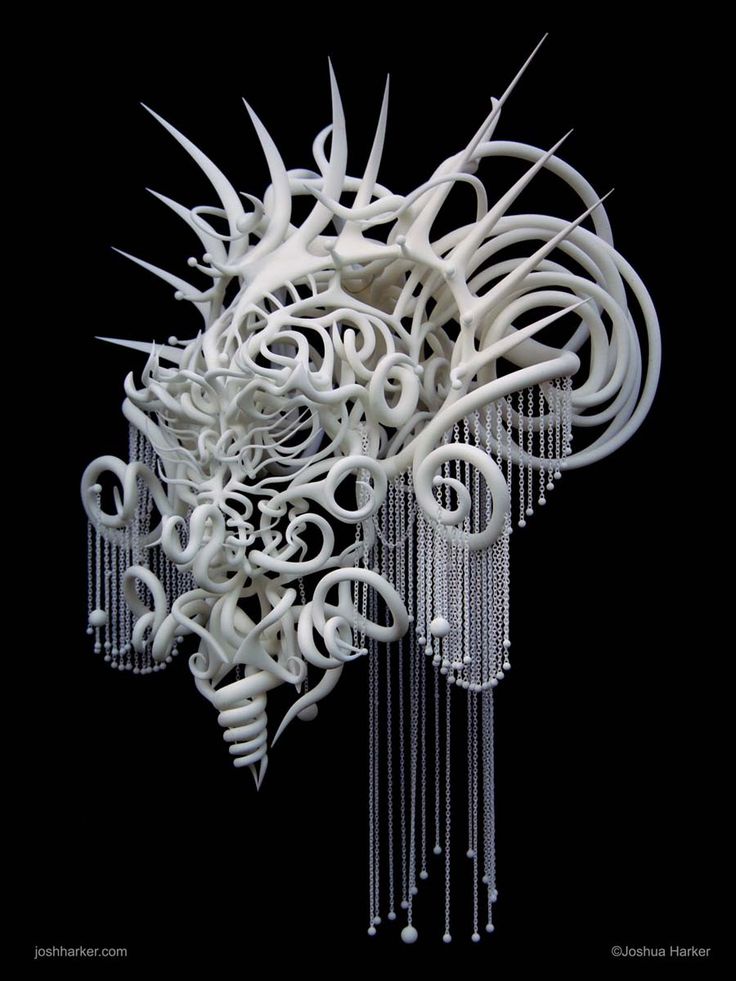

3D printing has been able to mimic the look of hair for a while, like in the lion print seen below. By printing thin filament layers onto a wall of plastic, and then melting and styling it with a hairdryer, the desired hair-like look can be achieved.

However, most balding men can’t rock the PLA plastic hair look (who can?), so we need a better alternative when it comes to 3D printed hair for transplants.

What we haven’t been able to do is 3D printed hair grafts that can grow human hair.

Wigs and toupées offer solace for many with receding hairlines, but for a lot of people, the loss of confidence goes beyond the aesthetic. Thinning hair or complete hair loss is a huge issue for thousands of men and women all over the world.

Thinning hair or complete hair loss is a huge issue for thousands of men and women all over the world.

3D printed hair offers a hopeful solution to this issue, and breakthroughs have already been seen across the scientific community.

Here, we will look at the history of 3D printed hair, and what it means for the future of transplants and grafts.

Early Research into 3D Printed Hair

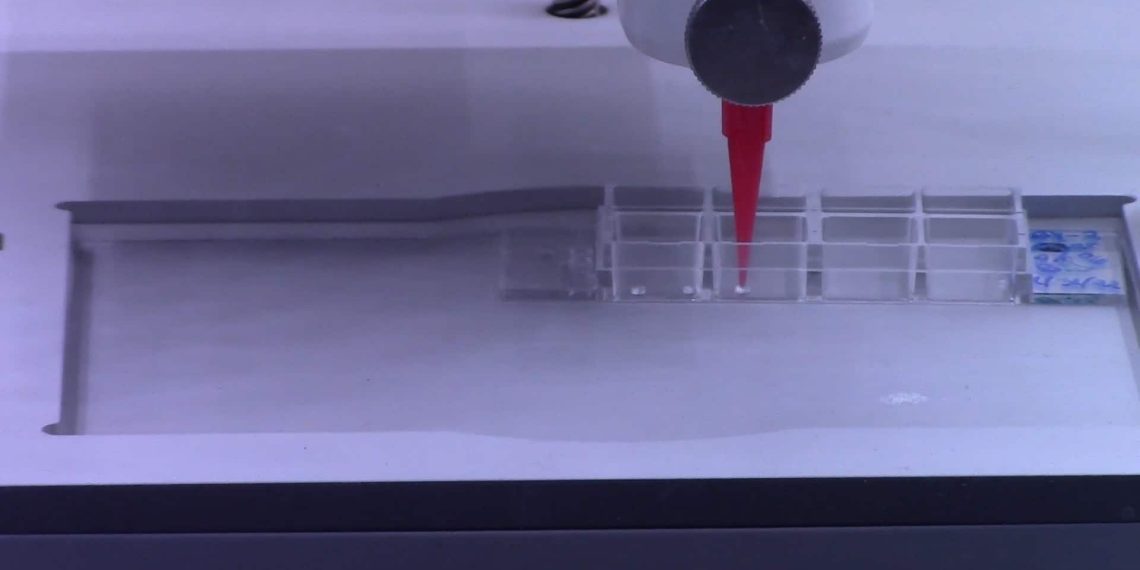

While making filaments look like hair is a simple enough process, the first notable breakthrough in usable 3D printed hair was in 2016, when L’Oreal took a new step in their 30-year-long research into artificial biological tissue by partnering with 3D bioprinting company Poietis.

This was big news at the time, as the combination of L’Oreal’s expertise in hair biology and Poietis’ breakthroughs in bioprinting brought with it exciting potential for viable 3D printed hair.

In 2017, Poietis used this research to further its existing partnership with German chemical company BASF to help develop 3D printed skin as a means to develop cruelty-free testing of drugs and cosmetics.

In 2019, Poietis CBO Bruno Brisson claimed:

“I can confirm that we have gone successfully through interesting validation steps over time on a project that is a real challenge since no one has so far managed to bio-print the most complex organ of the human body: the hair follicle!”

He further cited that there would be “some scientific communication within the next months as an outcome of this collaborative research agreement.”

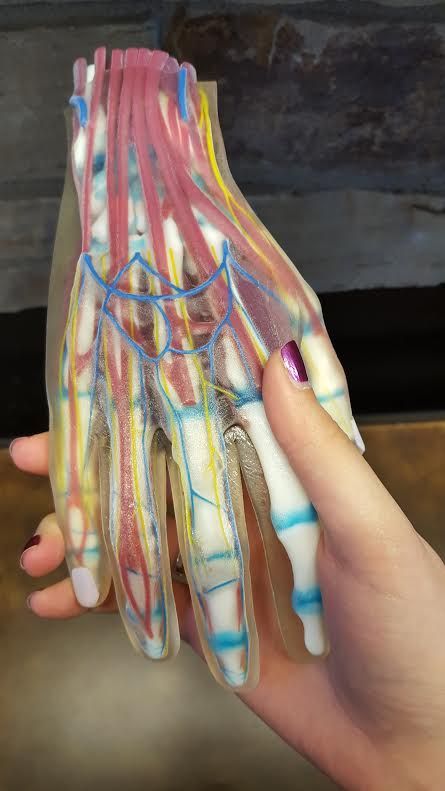

The results of this research were kept relatively quiet until 2020, when L’Oreal announced the findings of their research into mimicking embryonic cells to cultivate 3D printed hair follicles that could be used to ‘clone’ human hair.

L’Oreal has been making strides in hair growth therapies using what they call follicle culturing, which involves growing hair from follicles in vitro and making them ready for transplant, rather than actively encouraging natural hair growth.

Columbia University Research

It’s important to note that 3D bioprinting hair follicles, and creating an environment/skin they can grow on, are two completely different things.

In researching the viability of 3D printed human hair, researchers at Columbia University looked to mice as they, among other animals, seem to have natural inhibitors to stunt fur growth after a certain length.

Specifically, they wanted to see if they could revitalize what they called ‘dormant follicles’ into promoting hair growth where none was occurring. In essence, they wanted to see if they were able to trick the body into creating more fur where it otherwise wouldn’t have grown at all.

They found that they could stimulate hair growth on grafted mouse and rat skin. However, the same process was unsuccessful in human trials.

They reported that they believe this happens due to cell loss as skin grows, concluding that these follicle revitalization techniques won’t work in humans in the same way they work for rats.

Dr. Angela Christiano, a specialist in regenerative therapies for skin and hair in Columbia University’s Florence and Herbert Irving Centre for Dermatology and Skin Cancer Research, said: “Cells from rats and mice grow beautiful hairs, but for reasons we don’t understand, human cells are resistant. ”

”

Instead, they looked into 3D printing a mold that replicates the conditions in which hair follicles grow. The skin itself grows around the mold, replicating how human hairs grow.

Within these molds, the cells have a structure to follow. Cells can be placed within this mold, as well as keratin and collagen gel. The follicles would float on the gel in these microwells, which mimics the way they would grow on the human body.

The reason this is possible is down to newer technology within 3D printers. Whereas previously, they may have attempted to use techniques like soft lithography.

This method is used to create stamps and molds using elastomeric materials, hence the term soft. The new techniques “allowed for creation of structures with high aspect ratios”. The ratio for a human hair follicle is different from that of a rat, so that’s something that will make a clear difference.

They observed hair growth after around three weeks. Hairs even grew at different angles, replicating how human hair naturally grows.

Three weeks may seem like a long time to grow a small amount of hair, but this is a massive step towards helping people who suffer from hair loss, as this process encourages further hair growth rather than simply transplanting existing hairs.

Dr. Christiano is keen to perfect research into 3D printed hair follicles as a means to treat all kinds of hair loss, from receding hairlines to those suffering from severe burns.

The Benefits of 3D Printed Hair Follicles

The obvious use for the growth of hair follicles on bioprinted skin is in hair transplants. Currently, FUE hair transplants involve taking hair follicles from the back of the head, where men do not commonly lose hair, and transplanting them to the area of the head where hair loss has occurred.

However, regardless of how much hair can grow, the number of follicles is roughly the same in every human being, this means that there is only a finite amount of follicles that can be transplanted. Anyone without enough transplantable hair follicles could ideally instead have hairs 3D printed and transplanted instead, leaving their remaining hairs intact.

In addition, any removed hair follicles leave scars on the back of the head that can itch, and remain visible for a long time. Because of this, many people choose to avoid going through the process of hair extractions. 3D printed hair follicles could theoretically remove the issues of these scars and the need for painful hair extraction.

As well as creating artificial skin and hair for cruelty-free testing of cosmetic products and drugs, the ability to 3D print hair follicles could also aid research into the physical and psychological reasons for hair loss, and further studies into prevention methods.

The Future of 3D Printed Hair

While current research into 3D printed hair follicles looks promising, we’re nowhere near being able to 3D print hairs that grow and act like our hairs do.

However, research has shown that functioning human hair follicles can be 3D printed. This breakthrough displays exciting and vast potential for the future of the cosmetic industry.

The science still has a way to go, but 3D printed hairs could offer a solution for the millions of people who have lost their hair through various means, be they genetic or through an accident. These future treatments have the potential to be life-changing via massively increased confidence and self-esteem in those for whom hair loss has negatively affected their lives.

Though difficult, 3D printing human hair goes far beyond the original plastic or wooden 3D printed hairs hobbyist projects use, and we look forward to seeing further advancements.

Other articles you may be interested in:

- 3D bioprinting and 3D printed organs – top projects

- 3D printed kidneys

- 3D printed hearts – how long until we can 3D print a heart?

- 3D printed livers – feature story

Problems, defects, 3D printing errors and solutions

Often during the operation of a 3D printer, problems may arise due to which defects appear on the finished model. Or instead of a neat product, plastic noodles suddenly appear on the table.

Or instead of a neat product, plastic noodles suddenly appear on the table.

In fact, the causes of defects can be conditionally divided into 2 types - these are physical and software.

Physical ones are those that arise due to problems with the mechanics or any other causes that can be eliminated physically. These include problems with printer mechanisms (belt tension, backlash), clogged or deformed nozzle, incorrect table geometry, etc.

Software - these are defects that occur due to incorrect slicer settings or, less often, errors in the printer firmware. For example, incorrectly selected print speed, retract settings, incorrectly selected temperature for plastic, etc.

Very rarely, the problem may lie in the wrong or “flying” printer firmware (although usually the printer simply will not start then), overheating of some boards during printing, etc. These are rather special cases, so we will not consider them.

Model peels off or does not stick to the build plate

This is the most common 3D printing problem. Every 3D printer has had a case when the first layer treacherously rolls, clinging to the extruder, or the most offensive - when it tears off a partially printed model from the table. The first layer must stick tightly otherwise nothing will be printed.

Every 3D printer has had a case when the first layer treacherously rolls, clinging to the extruder, or the most offensive - when it tears off a partially printed model from the table. The first layer must stick tightly otherwise nothing will be printed.

Gap between table and nozzle 9 too large0023

This is the most common reason. You just need to set the correct gap between the table and the nozzle.

Modern printers often use an auto-calibration (auto-leveling) table system or an auxiliary table leveling program. To calibrate such printers, use the instructions. If there is no manual, it can be downloaded from the manufacturer's website.

If you have a simple printer without auto-calibration, a self-assembly or KIT kit, use a probe or a piece of paper folded in half to calibrate. The probe should be slightly pressed against the table by the nozzle. Before calibration, the table and extruder must be heated. Align the table surface over each adjustment screw (there may be 3 or 4) in turn, and only then check the center point.

If you're having trouble getting your table surface perfectly level, try raft printing. Raft is a thick substrate in several layers that is printed under the model. It will help smooth out the slight curvature of the table.

A small cheat sheet to determine the correct gap on the first layer

Plastic with poor adhesion

Some types of plastic, due to various reasons, such as large shrinkage, do not adhere well to the surface of the printing platform. In this case, try using stickers or special 3D adhesives to improve adhesion between the table and the first layer of plastic.

In the early days of 3D printing, there were experiments with different homemade 3D adhesive recipes. ABS diluted in acetone, BF glue, sugar syrup and even beer. Some experiments have been successful. Until now, some enthusiasts use some types of hairspray or glue sticks as 3D glue. But still they are inferior in their properties to industrial 3D adhesives.

Some types of high temperature plastics with a high percentage of shrinkage (ABS, Nylon, etc.) may peel off the table during printing. This is due to uneven cooling and “compression” of the model (the lower layers have already cooled down, but the upper ones have not yet). For such plastics, it is imperative to use a 3D printer with a heated table and a closed case.

Plastic temperature too low

The hotter the plastic is when it exits the nozzle, the better it will adhere to the print bed. It is better to print the first 5-10 layers at a higher temperature (+ 5-10 degrees) and turn off the blower fan.

Wrong first layer settings (speed and thickness)

A thicker layer sticks easier, so the standard first layer is 0.3mm thick. With an increase in print speed, the heating block may simply not have time to heat the plastic to the desired temperature and it will stick to the table worse. Before printing, check the speed and thickness settings of the first layer in the slicer.

A lot depends on how the 3D printer prints the first layer. Try to control the printing of the first layer and only then leave the printer to work alone.

Plastic does not choke from nozzle

The printer has already begun to print, but the print table remains empty. Or part of the model did not print.

Clogged nozzle

In 3D printing, a nozzle is a consumable. The nozzles are clogged or worn out (frequency depends on the type of plastic). The simplest thing is to replace the nozzle. But if there was no spare at hand, you can try to clean the old one. To do this, there is a whole set of thin needles. Or you can heat a clogged nozzle above the melting point of the plastic and “burn out” the blockage. But later it is still better to replace the nozzle.

Low temperature nozzle

You need to increase the temperature of the extruder in the slicer settings or check the thermistor and heating block. Sometimes the thermistor may not read the temperature correctly due to a malfunction or incorrect 3D printer firmware settings.

Sometimes the thermistor may not read the temperature correctly due to a malfunction or incorrect 3D printer firmware settings.

If the problem occurs after replacing the thermistor - contact the manufacturer or read articles about PID tuning.

Empty extruder

As the extruder heats up, plastic begins to ooze out of the nozzle. Because of this, the extruder may start printing half empty. Because of this, part of the first layer is not printed. You can push the plastic manually by simply pushing the bar into the nozzle. Or solve this problem programmatically - in the slicer, add a contour print around the model (one line).

Some manufacturers and 3D enthusiasts add a line print on the edge of the table at the beginning of each GCode. This is done so that there is plastic in the nozzle by the time the model is printed.

Feed mechanism does not push through plastic

The plastic pushes the feed mechanism to the extruder - a motor with a special pulley put on the shaft. If for some reason the plastic is not pushed through (nozzle clogged, extruder temperature low, etc.), then the pulley “gnaws” through the bar. You need to push the plastic bar with your hands or cut off the damaged piece.

If for some reason the plastic is not pushed through (nozzle clogged, extruder temperature low, etc.), then the pulley “gnaws” through the bar. You need to push the plastic bar with your hands or cut off the damaged piece.

Elephant foot

The first layers of the model are wider and protrude beyond the boundaries of the model. This is due to the fact that the upper layers put pressure on the first ones that have not yet cooled down and flatten them.

High table temperature

Due to the too high temperature of the table, the lower layers remain soft for a long time. Try lowering the table temperature. It is better to reduce gradually (in increments of 5 degrees). You can try to turn on the blower when printing the first layers.

Small gap between nozzle and platen

If, when printing the first layer, the nozzle is too close to the table, then excess plastic will be forced out. After a few coats, this will not be as noticeable, but can lead to the effect of an “elephant's foot”.

Plastic re-extrusion

When too much material is squeezed out of the nozzle, the walls of the model are not smooth, but bumpy, with sagging.

The solution is software - in the settings of the slicer, you need to set the material feed rate (fluidity) to a lower value. The average value is 95-98%.

It is worth checking the diameter of the rod. If its size is greater than 1.75, then the plastic will be squeezed out more than necessary.

Plastic underextrusion

The plastic is squeezed out too little, because of this, gaps may appear between the layer. The finished model will be fragile and fragile.

Wrong thread diameter

Check the filament diameter in the slicer settings. Sometimes, instead of the popular 1.75, the default is 2.85.

Incorrect feed factor settings

Check the fluidity settings in the slicer. The average should be 95-98%.

Clogged nozzle

Something could get into the nozzle and partially block the exit of the plastic. Visually, the plastic will choke from the nozzle, but in a smaller amount than necessary for printing.

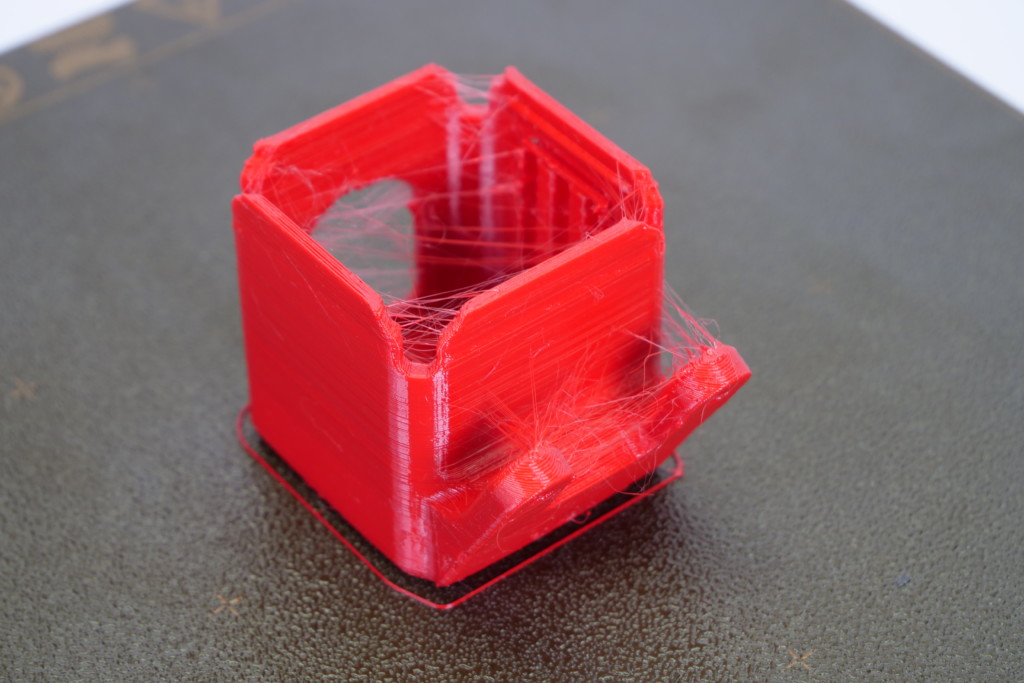

Hairiness or cobwebs on finished model

Thin threads of plastic protrude from the outer wall of the model (most often on one side). The defect appears due to the flow of plastic from the nozzle during idle movement.

Insufficient retract

A retract is a slight pull of a plastic filament from an extruder. Due to the retract when the extruder is idle (from layer to layer or from model to model), heated plastic does not drip from the nozzle. For some flowable plastics (eg PETG) the speed and amount of retraction must be increased.

"Hairiness" can be easily removed by grinding or cutting off the threads with a sharp scalpel.

High temperature extruder

The higher the extruder temperature, the more fluid the plastic becomes. It is important to find a balance so that the plastic is not too liquid and sticks well in layers.

It is important to find a balance so that the plastic is not too liquid and sticks well in layers.

In the selection of the optimal extruder temperature, a test model - a tower - helps a lot. It clearly shows how plastic behaves when printed at different temperatures.

.

Temperature test

Top "perforated" or uneven

The top of the model is bumpy or with holes. The problem may arise if the top of the model is flat. For example, like a cube.

Insufficient airflow

When printing the top plane (cover), the plastic does not have time to cool down and remains too liquid. Because of this, the threads are torn and holes are formed. Increase the fan speed on the last layers.

Few top layers

The top of the print may be too thin and deform as a result. Check slicer settings. The number of upper layers is not recommended to be set less than 6.

Low percentage of filling

If the infill percentage is too low, then the top layer will simply have nothing to rely on. Increase the fill percentage in the slicer settings.

Increase the fill percentage in the slicer settings.

Model deformation

Some parts of the model seem to have melted in some places or on one side. The problem most often occurs when printing with PLA plastic. The defect appears due to the fact that the plastic does not have time to cool and deforms.

Insufficient airflow model

Turn the fans on to maximum. If their power is not enough (in some printers, the fan is located only on one side), you can put a regular desktop fan and direct it to the 3D printer table.

Small model

Small models are difficult to blow well. Try to print small items alongside larger ones, or place several identical models in different corners of the table. So the plastic will have more time to cool.

Layer offset

Layers shift along the x or y axis during printing.

Print head jam

Turn off the printer and try to move the extruder along the x and y axes with your hands. The extruder must move freely. If there are jams, check the mechanics of the printer. Bearing wear or the curvature of the shafts may be to blame.

The extruder must move freely. If there are jams, check the mechanics of the printer. Bearing wear or the curvature of the shafts may be to blame.

Electronics overheating

Sometimes electronics problems can be to blame for misaligned layers. The most common cause is overheating of the drivers or too low current exposed to them.

Table top is loose

This is most often seen in 3D printers with glass. During printing, the nozzle may hit the model and move the glass slightly. Before printing, check if the glass or other printing surface is well fixed on the heating table.

Skip layers

Small holes are visible on the print, or the shell of the model is not continuous.

Teflon tube deformed

There are 2 types of thermal barriers - all-metal and with a Teflon tube. If overheated, the Teflon tube may deform. Plastic will pass through it, but in a smaller amount.

Low extruder temperature or high print speed

If the extruder is not heated enough, then the plastic will not be liquid enough and simply will not have time to be forced through the nozzle. The higher the print speed, the higher the extruder temperature should be.

Sometimes the outer walls print well, but the infill is “torn”. In this case, slow down the infill print speed in the slicer.

Model bundle

Cracks form on the surface of the printout during or after printing. Cracks can be large or very small. Most often, this problem occurs with plastics with a high percentage of shrinkage - ABS or Nylon.

Sudden temperature difference (if model delaminates during printing)

With a sharp temperature difference (for example, a draft), part of the model cools down faster. This leads to uneven shrinkage and incorrect distribution of internal stress. For plastics with low shrinkage, this is not critical. But if the shrinkage percentage is more than a few percent, the model may burst in layers.

But if the shrinkage percentage is more than a few percent, the model may burst in layers.

For printing with such plastics, it is recommended to use a printer with a closed housing. If this is not possible, try to avoid drafts and sudden temperature changes in the room where the 3D printer prints as much as possible.

Print temperature

Due to too low printing temperatures, the layers may not “stick” well to each other. Raise the print temperature in the slicer settings.

Hardening (if the model cracks after printing)

Sometimes cracks appear on the model a few days after printing. This is due to uneven distribution of internal stress after cooling. You can try to “harden” the finished product.

For hardening, the model is placed, for example, in an oven, and heated to the softening temperature of the plastic. After that, the heating is turned off and the oven is left to cool slowly with the model inside. Due to this, the stress inside the print is distributed more evenly. But accuracy is very important in this method - if you make a little mistake with the temperature, the finished product can “float”.

Due to this, the stress inside the print is distributed more evenly. But accuracy is very important in this method - if you make a little mistake with the temperature, the finished product can “float”.

Ringing

In places where the extruder changed direction, ripples are visible. Most often it looks like a shadow around the “sharp” protruding elements of the model.

Mechanical problems

Sometimes the problem occurs due to extruder play. Check if the extruder mount to the rails is loose. Be sure to check the tension of all belts.

High print speed or high accelerations

Moving the extruder too fast can cause vibrations that cause ripples on the wall of the model. The lighter the weight of the extruder, the less noticeable the ripples will be. To get rid of ringing, simply reduce the print speed in the slicer settings.

Slits for thin-walled models (not solid shell)

The thin wall of the model is not solid, but consists of two thin walls with a narrow gap between them. This problem is often faced by fans of printing "cutting" for baking.

This problem is often faced by fans of printing "cutting" for baking.

Left model with wall defect, right without

Wall thickness and nozzle diameter mismatch

If the wall thickness is 1 mm, and the nozzle diameter is 0.4, it turns out that for a solid wall, 2 nozzle passes are few, and 3 are already many. The result will depend on the slicer algorithm, but most often you will get 2 walls with a thin slot in the middle (the slicer cannot change the wall thickness). The solution to the problem may be a slight refinement of the 3D model or the use of a different slicer.

Algorithms for calculating 3D models are constantly being improved and refined, and now this problem is less common.

When modeling, take into account not only the thickness of the nozzle, but also the percentage of “overlapping” of lines on each other. If you have a nozzle with a diameter of 0.4 - make the wall in your model not 0.

8, but 0.7 - 0.75.

Wrong model geometry

When instead of a circle you get an oval, and instead of a square you get a semblance of a rhombus.

The main reason is malfunctions in the mechanics of the printer. Be sure to check:

Belts

Check belt tension in x and y. Belts stretch over time and may need to be tightened or replaced. Each 3D printer has its own way of tightening the belt. If the belts are slightly stretched, you can tighten them with the help of a "spring".

Loose pulleys, etc.

Check if all bolts and nuts are tight. Are there backlashes. Pay special attention to tightening the pulleys located on the motors along the x and y axes.

Sagging of some parts of the model

Some parts are not printed, broken, or instead of a neat surface, a swollen plastic snot is obtained.

No support for overhangs

A 3D printer cannot print in the air, so if there are overhanging elements in the model, you need to set supports - supports. The slicer can set the necessary support itself, you need to check the appropriate box in the settings.

The slicer can set the necessary support itself, you need to check the appropriate box in the settings.

When printing with soluble support, you can set the gap between the model and support - 0. This will make the surface smoother. If the support material and the model are the same, you need to add a small gap. Otherwise, it will be difficult to separate the support from the model.

Split model

Sometimes the supports can take more plastic than the model. In this case, to save material and time, it will be more convenient to cut the model. If you have more than one 3D printer, then the model will print several times faster.

When cutting the model, you can leave grooves or mortgages so that the pieces of the model are connected without displacement.

Totals

In this article, we talked about the most popular 3D printing defects and how to solve them. Don't be intimidated by such a long list. Some problems are rare and you are unlikely to encounter them.

Some problems are rare and you are unlikely to encounter them.

There is a list of problems that arise due to the design features of a 3D printer, so try to choose a printer that suits your needs. To do this, you need to understand what products and what material you need.

Problems associated with printing algorithms are quickly eliminated by software developers.

Do not be afraid of possible difficulties and each print will be successful.

Fixing the 20 Most Common 3D Printing Problems

3DPrintStory 3D printing process Fixing the 20 Most Common 3D Printing Problems

3D printing allows you to create amazing models. But everyone faces unpleasant moments when even a simple model does not print well.

You've checked the model, making sure that many have already printed it and had no problems. What are you doing wrong?

This article has collected 20 of the most common 3D printing problems. We hope that the article will help you quickly identify the problem and find a solution for it. In addition, the article details the causes of problems during 3D printing, which will help you avoid them in the future.

Model tearing off

Problem description

At the base, the model rises up relative to the table (English - warping). In addition to the quality of the manufactured part, this problem can prevent the printing of tall parts that can finally fall off the table.

What causes this problem during 3D printing?

Part breakage is a very common problem due to the nature of the printable plastic. As the ABS or PLA plastic cools, it begins to make poor contact with the surface, so the "warping" effect occurs when the plastic cools too quickly.

Solve the problem: part is torn off

- Use a heated table. The simplest solution is to use a heated table slightly below the melting point of the plastic. If the temperature is set correctly, the first layer will be in firm contact with the table. Most often, the platform temperature is set in the program to generate the g code for the model. The recommended temperature is often indicated on plastic packaging.

- Use adhesive. If your model still wraps around the corners, apply some glue to the print table.

- Try another table. Replace your print bed with a model that offers better adhesion. Manufacturers such as Lulzbot use PEI (Polyetherimide) surfaces. XYZPrinting add special tape to the printer box and that works great too (but they don't have heated tables). Zortrax 3D 3D printers solve the problem differently - with the help of small holes in the table.

- Level the print table.

It may be worth calibrating the print platform. During calibration, make sure that the tip of the extruder is at a suitable, uniform height from the stage along its entire plane.

It may be worth calibrating the print platform. During calibration, make sure that the tip of the extruder is at a suitable, uniform height from the stage along its entire plane. - Reinforce contact. Increasing the contact between the model and the print bed is another easy way. Most 3D printing software has the ability to add additional layers to the base.

- Play around with the temperature. If none of the above work, try increasing the print bed temperature in 5-degree increments. Also pay attention to the operating modes of the coolers. Usually coolers start to work at full capacity when the model height is about 0.5 mm. Try increasing this height to 0.75mm so that the base layers have more time to cool naturally.

And finally - even if you have a heated table, applying a little glue is unlikely to hurt.

3D Printing Problem Checklist: Part 9 Tear Off0429

- Use a heated bed

- Add glue to the print bed

- Use a high adhesion print bed from quality manufacturers

- Calibrate the print bed

- Add extra layers to the model base in your 3D printing software

- Play around with temperature and settings cooler

Elephant leg

Description of the problem

The base of the model is printed with a distinct indentation to the outside. It is called - “elephant's foot”

It is called - “elephant's foot”

What causes this problem during 3D printing?

This undesirable effect is caused by the mass of the model itself, which presses on the first, insufficiently cooled layers. In particular, this problem occurs if you have a heated table.

Solve the problem: "Elephant's foot"

- Correct balance. In order to avoid this problem, it is necessary to properly cool the layers at the base of the model. The base layers must be able to support the mass of the part, but not overcool, so that the part does not start to come off the table. Finding the right balance can be tricky. Start by lowering the table temperature in 5 degree increments (within +/- 20 degrees from the recommended temperature). If your bottom and top layers are set to 0.6mm, start cooling earlier.

- Level the table. Most 3D printing problems are caused by improper table alignment. Start with calibration recommendations from your printer manufacturer.

After that, print a square for calibration and evaluate how the plastic lays down. After printing, you will be able to see how evenly the plastic lays down depending on the height of the extruder relative to the table.

After that, print a square for calibration and evaluate how the plastic lays down. After printing, you will be able to see how evenly the plastic lays down depending on the height of the extruder relative to the table. - Raise the extruder. Simply increasing the distance between the extruder and the table can help. But if the distance is too large, the plastic will not stick to the table.

- Chamfer the base of the model. If none of the above work, you can chamfer the base of your model. Of course, this is only possible if you developed the print model yourself or have access to the original file. Start with a 5mm 45º bevel and experiment for the best result.

3D Printing Issue Checklist: Elephant Leg

- Adjust Table Temperature and Cooler Speed

- Calibrate the table

- Check the distance between the extruder and the table

- Chamfer the base of the model

If you are interested in more detailed information on this problem, we recommend that you read our detailed material on fixing the "elephant leg" problem.

Other first layer problems

Description of the problem

The first layer does not adhere well to the table and some parts come off. Unwanted lines appear at the base of the model.

What causes this problem during 3D printing?

Such problems are a sign that the table has not been correctly calibrated (table calibration on the example of the Anet A8 3D printer). If the extruder is too far from the table, unwanted lines appear on the base and/or the first layer does not stick. If the extruder is too close, voids may appear.

Important: The print bed should be as clean as possible. Even fingerprints can cause the model to come off.

Solve the problem: The remaining problems of the first layer

- Calibrate the table. Each printer has its own table calibration features. For example, the latest Lulzbot models have an automatic calibration system. Ultimaker 3D printers are configured manually according to the corresponding guide.

With Prusa i3 printers, you have to tinker a little longer and think for yourself.

With Prusa i3 printers, you have to tinker a little longer and think for yourself. - Adjust the distance between the extruder and the table. If the extruder is too high, the plastic will not grip the platform. If too low, you may damage the table.

- Clean the print table. It is advisable to clean the table before each new print. Especially if you are using glue. Fingerprints and adhesive residue may cause the model to come off.

- Add adhesive. A small layer of adhesive can greatly improve adhesion. But do not forget that if you do not clean the table, then the use of glue can lead to the opposite effect.

- Special tape for non-heated table. If you are using an unheated platform, try applying tape to improve the contact between the base of the model and the table.

Problem Solving: Layer Mismatch

- Check belts. Start by checking belt tension.

You should feel resistance as you bring them together with your fingers. If the top of the belt is stiffer than the bottom, this is a clear sign that they need to be tightened.

You should feel resistance as you bring them together with your fingers. If the top of the belt is stiffer than the bottom, this is a clear sign that they need to be tightened. - Check the table top plate. Check the top plate and screw sets in the printer. Make sure everything is taut and aligned where needed.

- Check the Z-axis screws. Most 3D printers use a screw-nut pair instead of a ball screw. In general, this does not particularly affect the print quality, but over time, the screw may deform. Do not disassemble the printer to check the screws. It is enough to use a program like ‘Printrun’ and move the extruder up and down. If one of the screws is deformed, you will notice it. Unfortunately, it's almost impossible to fix this. But, on the other hand, this is a great chance to modify your 3D printer and replace the screws with screw-nut pairs. 9

The printer did not feed the required amount of plastic. This may be due to problems with the plastic (for example, it has a different diameter), the extruder, or the plastic feed mechanism.

Friction has caused the table to stop temporarily. The reason may be that the vertical screws are not calibrated.

There is a problem with one of the screws or the Z-axis nut. For example, the screw is damaged, dirty, or not well lubricated.

Fixing the problem: Missing layers

- Mechanics check. A 3D printer, like any other piece of equipment, needs maintenance. If you have this problem, this is a clear sign that you should pay attention to its service. Start by checking the screws. Make sure they are well seated in the bearings/holes, with no undue misalignment.

- Screw alignment check. Check that all screws are aligned and not bent. You can appreciate this by turning off the power and carefully moving the extruder along the coordinate axes (depending on the layout of your 3D printer). If you feel resistance, then something is wrong.

- Damaged bearings. Damage to the bearings is manifested in the characteristic vibration during the operation of the 3D printer.

If you notice vibrations, turn off the power and manually move the carriage with the extruder to find exactly where the bearing failed.

If you notice vibrations, turn off the power and manually move the carriage with the extruder to find exactly where the bearing failed. - Check lubrication. Many people forget about the lubrication of joints. But this is a very important point for the correct operation of your 3D printer. Regular machine oil is inexpensive and is great for maintaining printer connections. Before lubricating, check the guides. They must not be dirty. You need to apply a little oil. If you have applied too much lubricant, simply wipe off the excess with a rag. Naturally, after lubrication, check that the carriages run smoothly.

- Plastic feed problem. The last possible problem is insufficient plastic supply. The solution to this problem may not be simple, so it is considered separately below.

3D Printing Problem Checklist: Missing Layers

- Check mechanics and make sure all screws are tight

- Check screw alignment

- Check bearings

- Add grease 9015 In high troughs

Description of the problem

Dimples form on the sides of the model, especially on tall models.

One of the most unexpected problems, the solution to which is usually not where you are looking for it.

One of the most unexpected problems, the solution to which is usually not where you are looking for it. What causes this problem during 3D printing?

In higher layers, the material cools faster because the heating from the table does not reach this height. Because of this, adhesion on higher layers is lower.

Solve the problem: Dimples on high models

- Extruder temperature. Start by raising the extruder temperature in 10ºC increments. The specifications for your plastic should list operating temperatures. Try to keep the temperature within the specified range.

- Cooler direction and speed. Check the coolers, make sure they work and point to the model. If so, try reducing their speed.

3D Printing Problem Checklist: Dimples on Tall Models

- Check extruder temperature and raise it in 10 degree increments

- Check the location and speed of the coolers aimed at the 3D model

Dimples, holes on the top of the model

Description of the problem

Dimples or even holes form on the top of the model.

What causes this problem during 3D printing?

The two most common causes are improper cooling of the top layer or insufficient thickness.

Solve the problem:

hollows, holes on the top of model- Printable plastic diameter. Most common when printing with 1.75 plastic. Similar problems can appear in any 3D printer, but most often they appear when using plastic with a diameter of 1.75 mm, not 2.85.

- Check cooler location. Any cooling problems are naturally related to coolers. At the start of printing, the coolers run slowly or turn off altogether, but after the first coat they should work much harder. Be sure to rate the performance of the coolers at the end of the print. If everything works, just in case, check the direction of their rotation. Cold air should flow to the model, and not vice versa.

- Set the fan speed in G-code. As the last layers of the model are formed, the cooling must be very intense so that the plastic does not fall into the holes of your mesh in the model.

Cooler speed can be configured in G-code. The standard code for an on cooler is M106 and M107 for off. That is, adjust the maximum speed for the upper layers. An example would be a 1 cm by 1 cm cube with a layer thickness of 0.1 mm. In this case, the G-code obtained from CURA for the Prusa i3 3D printer will be 97 layers. Knowing that we have the 'Bottom / Top Thickness' settings set to 0.6mm, we can look at ;LAYER:91 and add M106 S255 at the end of the line. The M106 kicks off the cooler, while the S255 makes it run at full capacity.

Cooler speed can be configured in G-code. The standard code for an on cooler is M106 and M107 for off. That is, adjust the maximum speed for the upper layers. An example would be a 1 cm by 1 cm cube with a layer thickness of 0.1 mm. In this case, the G-code obtained from CURA for the Prusa i3 3D printer will be 97 layers. Knowing that we have the 'Bottom / Top Thickness' settings set to 0.6mm, we can look at ;LAYER:91 and add M106 S255 at the end of the line. The M106 kicks off the cooler, while the S255 makes it run at full capacity. - Increase the thickness of the top coat. The simplest solution is to increase the thickness of the top layer. In most applications, this can be done in the advanced settings under ‘Bottom / Top Thickness’. It is desirable to form a minimum of 6 layers and 8 for extruders with a smaller nozzle diameter and, accordingly, a smaller plastic diameter. So if the layer height is 0.1mm, set ‘Bottom / Top Thickness’ to 0.6mm. If this does not help, increase the thickness to 0.

8 mm.

8 mm.

3D printing problem checklist:

hollows, holes on the top of the model- Increase the diameter of the plastic for printing

- Make sure the coolers are correctly installed and working

- Specify the speed of the cooler in manual mode - in G-code 9044 Increase top layer thickness

Plastic residue

Problem description

Unwanted plastic residue forms between parts of the model.

What causes this problem during 3D printing?

When the extruder is moving and not printing (in idle mode), plastic residue is still coming in.

Solving the problem:

plastic residue (more detailed article on troubleshooting plastic residue between parts of the 3D model)- Activate the Retraction option. Retraction is a very useful option, especially when it comes to finishing. It works very simply - before the print head begins to move, the plastic flows back into the extruder, and is not fed.

Thus, the problem can be nipped in the bud.

Thus, the problem can be nipped in the bud. - One-click backfeed activation. Most applications like Cura offer a one-click option to activate this option. The default settings are used, which is sufficient for most cases. However, if you want more flexibility, there should be other options. For example, you can set the minimum printhead path before activating plastic backfeed.

- Minimum travel (mm). Reducing the minimum path is usually the quickest fix if the default retraction settings didn't help. Decrease this value by 0.5 mm until the problem goes away. By the way, activating reverse feed will increase the speed of 3D printing.

What causes this problem during 3D printing?

There may be several reasons. The first is that the diameter of the plastic for printing does not match the diameter specified in the software for forming layers. The second - the amount of plastic supplied is insufficient, due to incorrect settings in the software.

Well, perhaps your extruder is very dirty.

Well, perhaps your extruder is very dirty. Solving the problem: Insufficient supply of plastic

- Check the diameter of the plastic. Start with the simplest case - check the head diameter settings in your software. If you are not sure about the correct diameter, it and the temperature are usually indicated on the packaging of the plastic.

- Measure the plastic diameter. If the problem still persists, measure the plastic diameter manually and enter more precise settings in your G-code generation software.

- Check the print head. In most printers, the print head is retracted from the print table. Check extruder. There should be no obvious contamination on it.

- Set the extrusion ratio. If there is no difference between the actual plastic diameter and the settings in the software, check the extrusion coefficient (extrusion multiplier or flow rate or flow compensation).

Perhaps these settings are too small. Each program handles these settings differently, but the principle is the same - increase the value in the settings by 5% and restart 3D printing.

Perhaps these settings are too small. Each program handles these settings differently, but the principle is the same - increase the value in the settings by 5% and restart 3D printing.

In Simplify3D open Edit Process Settings and go to Extruder tab - extrusion ratio set to 1.0 corresponds to 100%; If you are using Cura, open the Material tab and increase the Flow setting (you may need to activate the Flow settings in the Preferences panel).

3D Printing Problem Checklist: Plastic Insufficient

- Check Printable Plastic Diameter

- Manually Check Plastic Diameter

- Check Extruder Cleanliness

- Increase the extrusion ratio by 5%

Too much plastic feeding

Problem description

Your 3D printer is feeding too much plastic. Because of this, the material peels off at the edges of the model.

What causes this problem during 3D printing?

This is usually caused by the Extrusion multiplier or Flow in your G-code generation software being set too high (see section above).

Solve the problem: Too much plastic feed

- Extrusion ratio. Open your layering software and make sure the extrusion factor is set to the correct value.

- Delivery settings. If the previous point did not help, reduce the flow value (Flow).

3D printing problem checklist: too much plastic feed

- Check extrusion ratio settings

- Reduce plastic feed value

Layer misalignment

Problem description

Bottom and top layers move relative to each other during 3D printing. Usually the offset is not as large as in the figure, but the above case can also occur.

What causes this problem during 3D printing?

Layer misalignment can occur for a variety of reasons, including a blow to the printer during printing! This problem may manifest itself due to incorrect belt tension or misalignment of screws. Or due to the fact that the extruder hooked the model and it shifted a little right during printing.

Solving the problem: Layer misalignment

- Check the stability of the printer. The 3D printer must be placed on a stable surface. Even slight shocks can cause the layers to shift.

- Check table stability. Most 3D printers have removable tables. Although this is convenient in terms of replacing it, over time the mounting screws can loosen. So it's worth checking them periodically.

- Check the bottom layers. If you print at high quality, the underlying layers may break due to cooling. If a break occurs, the plastic rises and the extruder can hit it. In most cases, the model will come off the table, but if there is no lift, the powerful motors can push the model and the table. So if you have problems with the first layers, try reducing the rotation speed of the coolers.

- The print speed is too fast. By increasing the temperature and increasing the feed rate, 3D printing can be accelerated.

However, even though the plastic will feed properly, your printer may not be able to handle the selected mode. If you hear clicks while printing, this is a sure sign that the printer is running at too fast speeds. In this case, check if the plastic breaks in the extruder itself, and then go to the settings for the actual speed of the 3D printer. The speed can be adjusted in your software to generate the g-code. If you are using Simply 3D go to ‘Other > Default Printing Speed (mm/min)’, if Cura go to ‘Basic > Print Speed (mm/s)’.

However, even though the plastic will feed properly, your printer may not be able to handle the selected mode. If you hear clicks while printing, this is a sure sign that the printer is running at too fast speeds. In this case, check if the plastic breaks in the extruder itself, and then go to the settings for the actual speed of the 3D printer. The speed can be adjusted in your software to generate the g-code. If you are using Simply 3D go to ‘Other > Default Printing Speed (mm/min)’, if Cura go to ‘Basic > Print Speed (mm/s)’. - Check the belts. If the layers are still shifting, it's time to check the belts. The tension of all belts must be the same. Timing belts tend to stretch over time (this is clearly manifested when the belts begin to slip on the pulleys). If the tension is very weak, you should consider replacing them. Strong belt tension can also be a problem. But usually this is a problem with DIY 3D printers. Some 3D printers (such as the Prusa i3) have special screws to adjust the tension.

- Guide shafts must be clean and lubricated. Over time, the guides become covered with dirt in places with maximum friction. This, in turn, can cause problems when moving and shifting layers. A quick cleaning and lubrication usually solves the problem.

- Curved or misaligned rails. If you notice that the printhead positioning error occurs in a certain place, this may be a sign that one of the guides is deformed. You can check this by turning off the 3D printer and moving the print head along the coordinate axes. Check axle alignment. If everything is in order, remove the guides and lay them on a flat surface. If there is a bend, you will immediately see it.

3D Printing Problem Checklist: Layer Misalignment

- Check the stability of the 3D printer base.

- Check table stability.

- The first layers of the model should not form breaks.

- The print speed is too fast.

- Check belts.

- Guide shafts must be clean and lubricated.

- Curved or misaligned rails.

Blocked plastic feed mechanism

Problem description

You start 3D printing, but no plastic comes out of the extruder. You took the rod out of the extruder, put it back in, but it didn't work.

What causes this problem during 3D printing?

After replacing the plastic, a small piece of bar remained in the feed mechanism. Most often, the break occurs at the very end. When you insert a new rod, the remnants of the old one block the flow of plastic.

The second option - the remnants of the old plastic dried up at the end of the extruder. In this case, the remnants of the frozen plastic must be removed manually.

Solve the problem: blocked plastic feed mechanism

- Unlock with a needle. If you're lucky, unlocking the feed mechanism is quick and easy. Start by removing the plastic. After that, on the control panel, select the option “heat up nozzle” (heat up the extruder) and increase the temperature to the level of plastic melting.

If you have an Ultimaker 2 3D printer, go to Maintenance > Heat Up nozzle. For PLA plastic, set the temperature to 220 C. When the extruder is hot, use a needle or something with a small diameter and clean the hole (be careful not to burn your hands!). By the way, it is useful to clean the outside of the extruder.

If you have an Ultimaker 2 3D printer, go to Maintenance > Heat Up nozzle. For PLA plastic, set the temperature to 220 C. When the extruder is hot, use a needle or something with a small diameter and clean the hole (be careful not to burn your hands!). By the way, it is useful to clean the outside of the extruder. - Push through the old plastic. If the extruder is still blocked, you may be able to push the stuck plastic through with a new rod. Remove the plastic supply tube from the print head. Preheat the extruder to 220 C for PLA plastic and then, using a new rod, try to push the stuck plastic through the extruder. It may take some effort, but be careful not to bend the printer's horizontal guides. After that, you can clean the nozzle with a needle in accordance with the instructions from point 1.

- Remove and reassemble the extruder. In extreme cases, you will have to disassemble and reassemble the plastic feed mechanism. If you've never done this before, consider taking photos or recording your every step as you take apart the feed mechanism, as you'll need to put it back together afterwards.

First remove the plastic bar. After that, read the instructions for dismantling the print head in the instructions for your 3D printer. Wear gloves while doing this, as the nozzle will be hot. Let's take a closer look at the Ultimaker 2 3D printer as an example. Move the print head to the center of the printer. Loosen the four screws on the print head. Preheat the nozzle to 220 C (for PLA). When the extruder reaches the desired temperature, turn off the power. Holding the cooler's plastic case, remove the rest of the interfering plastic. Clean the nozzle with a needle. You can also clean its outer surface. When the nozzle is cool, assemble the extruder, turn on the 3D printer and load the new plastic.

First remove the plastic bar. After that, read the instructions for dismantling the print head in the instructions for your 3D printer. Wear gloves while doing this, as the nozzle will be hot. Let's take a closer look at the Ultimaker 2 3D printer as an example. Move the print head to the center of the printer. Loosen the four screws on the print head. Preheat the nozzle to 220 C (for PLA). When the extruder reaches the desired temperature, turn off the power. Holding the cooler's plastic case, remove the rest of the interfering plastic. Clean the nozzle with a needle. You can also clean its outer surface. When the nozzle is cool, assemble the extruder, turn on the 3D printer and load the new plastic.

3D printing problem checklist: blocked plastic feed mechanism

- Warm up the nozzle and clean it inside and out with a needle.

- Remove the plastic feed tube and try pushing through the remaining plastic with a new rod.

- Disassemble the feed mechanism and try to remove any remaining plastic.

Faulty plastic

Description of the problem

The plastic looks normal, is correctly seated in the feed mechanism, and exits the nozzle when printing. This happens most often in Bowden-feed 3D printers rather than straight-feed 3D printers, as the plastic isn't visible or noticeable when it's broken.

What causes this problem during 3D printing?

Printing plastic breakage can occur for a variety of reasons, but mostly because the plastic is old or cheap. Most plastics like PLA and ABS last a long time, but if stored in poor conditions (such as direct sunlight), they can become brittle. If you use such plastic, no settings will help.

The second possible reason is the bar diameter, which may vary slightly depending on the manufacturer. And if the pressure in the feed mechanism is too high, it can break.

Troubleshooting: broken plastic

- Remove the plastic. The first thing to do is to remove the plastic from the 3D printer.

If you are using Ultimaker, you can use the Maintenance and Change Material option. Heat up the extruder and remove the plastic.

If you are using Ultimaker, you can use the Maintenance and Change Material option. Heat up the extruder and remove the plastic. - Try another plastic. If the problem persists after reinstalling the plastic, try a different one to make sure the media quality is not the issue.

- Reduce feeder pressure. If the new plastic also breaks, release the pressure on the feed mechanism. Start 3D printing and increase the pressure until the slip is complete.

- Check nozzle. Check nozzle for cleanliness.

- Check flow and temperature. If problem persists, check nozzle heating. Also make sure the pitch is 100% and no more.

3D Printing Problem Checklist: Plastic Breakage

- Check the shelf life of plastic

- Check the diameter of plastic

- Set up the pressure in the supply mechanism

- Check the cleanliness of the nozzle and its temperature

- Set the supply of 100% 9042

Passage Podzal

description 3D printing stage. And it does not depend on the type of plastic. As a result, no plastic is fed.

And it does not depend on the type of plastic. As a result, no plastic is fed. What causes this problem during 3D printing?

Clogged nozzle, insufficient feed force, incorrect nozzle temperature. As the motor rotor rotates, the small wheel that normally grips and feeds the plastic will pinch the bar and prevent it from being printed.

Solving the problem: bar slippage

- Help the feed system. If the plastic has just begun to slip, it will show up as a characteristic noise. Try applying some pressure to the bar to get this section through. This often helps and the 3D printer continues to print well.

- Adjust the feed force. Start by relieving pressure. After that, start increasing the force until the bar stops slipping. Heads vary in diameter, so some require fine tuning.

- Remove the plastic. More one solution is to remove and reload the plastic into the feed mechanism.

After removing the bar, cut off the plastic over the place where the slip marks are visible and reload it into the feeder. If slippage remains, try this operation again. If that doesn't help, replace the plastic as this one is most likely no longer printable.

After removing the bar, cut off the plastic over the place where the slip marks are visible and reload it into the feeder. If slippage remains, try this operation again. If that doesn't help, replace the plastic as this one is most likely no longer printable. - Check nozzle temperature. If you installed a new plastic and the problem persists, or vice versa, check the temperature of the nozzle.

Checount of 3D Problems: slippage of the rod

- Help the supply mechanism with an additional force

- Set up the force in the mechanism of the

- Remove the plastic and load the interior of the interpretation of 9042

428 Description of the problem

The printed product is missing an internal mesh or it is obviously incorrect

What causes this problem during 3D printing?

There can be several reasons why the internal structure of the 3D model does not print well. The most common is incorrect settings in your software for generating a G-code.

It may turn out that the problem is a clogged nozzle.

It may turn out that the problem is a clogged nozzle. Solving the problem: Poor 3D printing of the inner mesh

- Check the fill factor. This is checked in your software. A value of about 20% is quite acceptable. If less, problems may arise. This parameter should be increased for large models.

- Speed for printing inner layers. The speed at which printing occurs can have a direct effect on the quality of the inner mesh. If you see problems, try reducing the print speed of the inner mesh.

- Change the mesh configuration. Most programs allow you to change the grid configuration. Squares, triangles, hexagons, etc. Experiment with these settings.

- Check nozzle. It may be that the cause is a clogged nozzle. At the same time, the outer parts of the model will be printed well, since plastic is fed more intensively on them.

3D Printing Problem Checklist: Poor 3D Printing of Inner Mesh

- Check and Adjust Inflation Ratio of Model

- Reduce Inner Mesh Print Speed

- Change Mesh Configuration

- Check for Clogged Inner Nozzle

2

0015 - Check the thickness of the outer wall of your 3D model. Check that the wall thickness value is proportional to the nozzle diameter.

- Thicken the outer wall. The simplest solution is to increase the wall thickness. Doubling the thickness will most likely help solve the clearance problem.

- Use the filling option after the walls have been formed. Most g-code programs have the ability to generate the internal structure after printing the outer walls.

- In Cura open 'Expert Settings' and in the Infill section activate the option 'Infill prints after perimeters'

- In Simply3D click on 'Edit Process Settings', then select 'Layer' and in 'Layer Settings' select 'Outside-in' next to 'Outline Direction'.

- Check the print table. Examine the printed model. If the effect is more on one of the sides, the cause may be in the calibration. If so, calibrate.

- Use this effect to your advantage. Depending on the task, you can use the print sequence to your advantage. If you need a model of high quality, with a good outer surface and at the same time the rigidity of the model is not critical, choose Outside-in printing (first the outer layer, then the inner filling). If the rigidity of the model is important, print inside-out, doubling the wall thickness.

- Check the outer wall thickness of the model.

- Thicken the outer wall.

- Use the filling option after wall formation.

- Check print bed and calibrate if necessary.

- Use this effect to your advantage.

- Check the parameter of the intersection of the walls and the inner mesh of the model. This is the most common problem and is very easy to fix. Find the "Infill Overlap" option in your gcode generation software and increase this value.

- Cura defaults to 15%. Increase it to 30%.

- In Simplify3D these settings are in the 'Edit Process Settings > Infill > Outline Overlap' tab. Again, increase this value. This setting is directly related to the thickness of your head. So the % value will be % of the bar thickness to be printed. When tuning, do not set this value above 50%, as you will go beyond the walls.

- Form the inner mesh before printing the walls. If at the same time the inner mesh begins to show through, increase the thickness of the outer wall of the model as indicated in the section above.

- Increase extruder temperature. Some newer 3D printing materials (such as XT-CF20) may require finer temperature settings. Try increasing the extruder temperature by 5-10º. It might work.

- Reduce speed. You probably want to print your model faster, but faster speeds can cause a lot of problems. Especially if the 3D printer is not perfectly calibrated. If print speed is still important to you, try lowering it for the top layer only.

- Check the intersection parameter between the walls and the inner mesh of the model.

- Print the inner mesh first and then move on to the outer walls.

- Increase extruder temperature.

- Reduce the print speed.

- Use the latest slicing software. Most recent versions of slicing programs support automatic correction of intersecting objects, but it's still better to make sure that your 3D model is formed correctly.

- Set the Fix Horrible settings in Cura. In Cura, open the Expert Settings tab and have the Match All (Type-A) option selected in the ‘Fix Horrible’ settings.

- Set the Non-manifold settings in Silmplify3D. In the 'Process settings' select the 'Advanced' menu and then 'Heal' next to Non-manifold.

- Use layered representation. Use the layer view in your slicing software to check for problem areas in your model. A superficial view of the layers can help you quickly identify problem areas and fix the problem.

- Use your software to fix object intersections. One of the easiest solutions is to use additional software to solve the problem. Blender and Meshmixer have built-in mechanisms for identifying problems and fixing the 3D model before slicing.

- Combine objects. It's better to fix your 3D model before importing it into the slicing software. When doing this, make sure that if your two objects intersect or overlap, you use the appropriate intersect, merge, or subtract function.

- Use the latest version of the slicing software.

- Use the “Fix Horrible” option (in Cura).

- Use the “Fix Non-manifold” option (in Simplify3D).

- Use layered view to identify the problem.

- To fix errors, use additional software like Blender or Meshmixer.

- Merge objects.

- Add supports. The quickest and easiest solution is to add calipers. In most programs, this is done quite simply. For example, in Simplify3D go to Edit Process Settings > Support > Generate support material; you can customize the quantity, shape and specify other caliper settings. If you are using Cura, just select Support type in the Basic settings.

- Make your own calipers. Software generated calipers may not suit you, so you can create your own in the base 3D model. This will require a little more skill, but can give fantastic results.

- Add an additional object to your 3D model. Most often, problems occur when printing hands and similar details. In this case, adding supports from the base of the model to the arm can also result in a problem, since the distance can be quite large. Considering that the calipers should be easy to remove, the high height may prevent them from being printed correctly.

You can get around this by adding an additional object to your model (a piece of wall, a bench, a box, a flower, etc.) and printing an additional rack already from this object.

You can get around this by adding an additional object to your model (a piece of wall, a bench, a box, a flower, etc.) and printing an additional rack already from this object. - Change the angle. For example, models of people whose arms are raised up to 45º will print well and it is absolutely impossible to print arms extended horizontally at 90º relative to the body.

- Divide the model into separate parts. Another option is to divide the model into separate parts and print two pieces instead of one. The only problem that will need to be solved is how to combine the resulting parts into one model after printing.

- Add SLISING SLISING SLISING

- Add calipers in the original model

- Add an object that can serve as a replacement for the caliper

- Change the location of the problem node LEADING A

Description of the problem

The printed model generally looks normal, but the internal mesh is visible through the outer walls of the model.

What causes this problem during 3D printing?

See-through problem occurs when your model has thin walls and the internal structure intersects with the outer wall line.

Normally the outer wall thickness should be proportional to the nozzle diameter. That is, if your nozzle diameter is 0.4 mm, the wall thickness of the model should be 0.5, 0.8, 0.12 mm, etc. If the proportion is not maintained, the effects of the clearance of the internal structure may occur.

Solving the problem: the inner mesh is showing through

3D printing problem checklist: Inner mesh shows through

Gaps between inner mesh and outer walls

Problem Description

If you look at the bottom or top surfaces of the model, you will see gaps between the inner mesh and outer walls.

What causes this problem during 3D printing?

Gaps between the outer wall and the inner mesh used to be a common problem, but with the increasing accuracy of 3D printers, this is now a rare bug. However, there are new materials for 3D printing that can cause this problem again.

The most common cause of these gaps is that your software does not have an overlap of the mesh and outer walls set, or this value is set to "0". Your 3D printer considers this so that the wall and mesh should not intersect, and gaps may occur.

Another possible reason is the sequence in which you set the printing of the inner mesh and the outer wall.

If you print the outer wall first, there may be no or minimal overlap. Accordingly, there is a chance of occurrence of these gaps.

If you print the outer wall first, there may be no or minimal overlap. Accordingly, there is a chance of occurrence of these gaps. Solving the problem:

gaps between the inner mesh and the outer walls of the 3D model3D printing problem checklist: gaps between inner mesh and outer walls of the 3D model

Intersection of objects

Problem description

Parts of the model are missing or the final model is not rigid enough.

The finished product and the 3D model are different and there are incomprehensible errors in the geometry of the printed product.

The finished product and the 3D model are different and there are incomprehensible errors in the geometry of the printed product. What causes this problem during 3D printing?

Virtual walls are one of the most common causes. Vertical walls only exist in 3D space, not in the real world.

For example, if you have two cubes in the real world and you try to match them, it won't work because the outer walls will not allow the two objects to intersect. In the 3D world you can combine two objects and still exist as two separate objects and your slicing program will also allow them to intersect in the virtual world.

For correct printing, these two objects must be combined into one, so that the inner walls disappear and one object remains.

Another possible problem - for example, you have a cube object and you have deleted one of its surfaces. In fact, you have an object with a hole. It may look like a 3D correct object, but it only exists as such in 3D space.

Such an object cannot exist in the real world.

Such an object cannot exist in the real world. Deleting one of the surfaces leaves only two coordinates. The wall thickness, the third coordinate, has no dimension in the real world. We only see it in 3D modeling software. And when we start to form the layers of the model, the program will try to fix this bug and add the third coordinate. However, in more complex models, this can lead to unpredictable effects.

Solving the problem: object intersection

3D Printing Problem Checklist: Intersection of Objects

No base for next layers

Description of the problem

You have loaded your 3D model into the slicing software and everything looks good. We started printing and as a result part of the model was printed well, and some parts - badly. This is a fairly common problem in 3D printing.

What causes this problem during 3D printing?

During 3D printing, each layer is built on top of the previous one. Naturally, if your model has a part that does not have plastic underneath (for example, as shown in the figure above - horizontally outstretched arms), printing problems will arise.

Ideally, the slicing software should somehow detect and point out this problem. However, in most cases, the programs will let us print without indicating that additional supports are needed for the model.

Problem solved: no base for next layers

3D printing problem checklist: no base for next layers

9014 LEADING 901 problems - Check the X and Y axes. If the model moves to the left or right, the problem is in the X axis. Forward or backward, the problem is in the Y axis. Once you have decided on the coordinate, check the belts and pulleys. If you have a Prusa i3 3D printer, this shouldn't be a problem since the pulleys are mounted on the stepper motors themselves.

Learn more

As the model builds, the layers begin to shift.

As a result, instead of a straight vertical model, displacements appear. In this case, the offsets are not the same over the entire height of the model. The offset can increase/decrease at different heights.

As a result, instead of a straight vertical model, displacements appear. In this case, the offsets are not the same over the entire height of the model. The offset can increase/decrease at different heights. What causes this problem during 3D printing?

The reason is quite simple. One of the belts connected to the stepper motor has lost tension. To eliminate model drift, it is enough to check the tension of the belts and the pulleys that keep the belts in tension.

At first glance, the solution to the problem is simple. However, before you fix it, you should find out which belt is causing it, as getting to the belt can be a difficult task.

Solve the problem: layer shift

- Check belts. Start by checking belt tension.