Dot product 3d scanner

Mobile 3D Scanning for Android, Windows, & iOS!

|

reality capture software for tablets & Phones

|

Dot3D Pro for Windows / Android More Info |

Dot3D X for Windows / Android More Info |

Dot3D for iOS LiDAR More Info |

POwering our full suite of handheld 3d capture kits

| DPI-10 / DPI-X Accurate, rugged, indoor 3D scanning kits for Windows | iPad & iPhone LiDAR Large-scale, daylight-capable 3D scanning | Intel® RealSense™ Kits Portable, affordable 3D cameras for mounting to Windows/Android tablets and phones. |

Customize your kit with the right tools for the job

| Dot3D Edit Edit-only version of Dot3D, intended for desktops/laptops. | Dot3D View Free, view-only version of Dot3D, available for Windows & Android | DPI Light Kit Add-on light kit for scanning in dark areas with DPI / RS kits |

| DPI Extension Kit Add-on extension kit for capturing hard to reach spaces | InfiPoints DP Android app for converting DP scans to surfaces / cylinders | Pointfuse for DP Windows app for converting DP scans to lightweight 3D meshes |

Take it for a spin.

..

.. With a free trial of Dot3D ProClick here to obtain a free Dot3D Pro 7-day trial license. Activate on any Intel® RealSense™ equipped device for live scanning, or on any Windows/Android device for free viewing and editing of DotProduct scan data (Dot3D Edit functionality). Sample DP scan data is available below.

|

| Click here to access a free sample data captured with various DotProduct handheld 3D scanning kits, including the DPI-10 / DPI-10SR. Download Sample Data |

|

Click here for a video on getting started with Dot3D for RealSense™! | 3D scanning is more accessible than ever with today's Intel® RealSense™ depth cameras. Start scanning now with a total hardware investment as low as $149! Purchase through DotProduct for custom calibration (and magnetic mounting / USB-C compatibility) or through Intel® directly for the lowest initial investment (USB-A cable provided).

|

| See it all live in action! Schedule a web demo with or team to experience a live broadcast of our tablet-based 3D capture kits during scanning, editing, post-processing, data export, import, and more.

|

Instant, accurate 3D data input for your digital twin

|

Captured with Dot3D Pro | Processed with bloom Cloud Engine |

Direct integration with your workflows |

Proven solutions across industries

| "All it takes is a quick scan and then we can take as many measurements as we need after the fact. | “more detail than ever expected out of a handheld device.” | "A stable product that can be easily imported into AutoCAD" |

| DotProduct BLog | Monthly Newsletter |

Dot3D - DotProduct

| Accurate 3D scanning from Windows & Android

|

| The one powerful app behind all DPI kits

|

| The #1 3D scanning solution for Intel RealSense

|

Sign Up for A Free tRial

Core features:

|

Minimum System Requirements

One application. Three flavors...

Three flavors...

|

Complete professional 3D scanning application Subscribe |

3D digitalization, measurement, and editing within Dot3D Subscribe |

Affordable 3D capture solution for smaller projects Subscribe |

Which Dot3d is right for You?

DownLoad Now

ANNOTATE

MEASURE

OUTDOORS

INDOORS

DESIGN

COMPARE

| Download spec sheet | Schedule a Demo | Video tutorial |

technologies, types, how 3D devices work

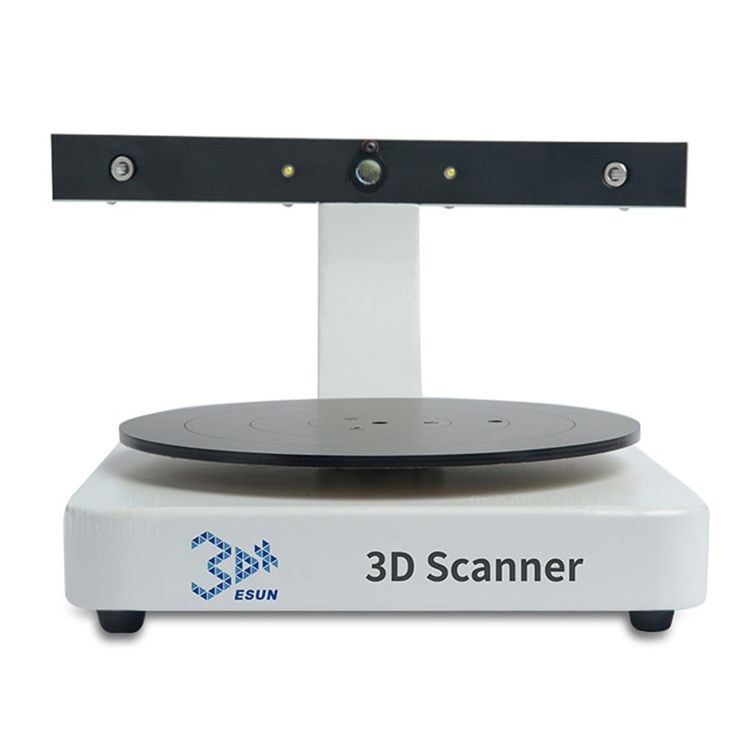

Many digital engineering strategies for the future of development, manufacturing, quality control, and product release start with 3D scanning. 3D scanners work with advanced technologies and specialized software to create a tool that allows you to achieve revolutionary results. For those still working with power tools and traditional coordinate measuring machine (CMM) technology, 3D scanners serve as an easy gateway to advanced manufacturing and engineering strategies.

For those still working with power tools and traditional coordinate measuring machine (CMM) technology, 3D scanners serve as an easy gateway to advanced manufacturing and engineering strategies.

Read below to learn more about how 3D scanners work and what this technology can do, so you can start enjoying its benefits now.

What are 3D scanners?

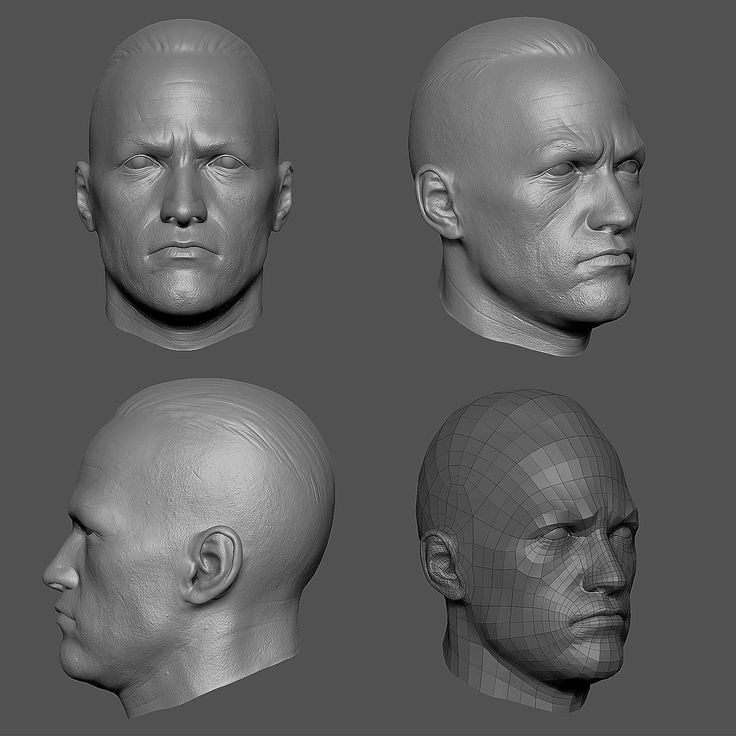

A 3D scanner works by capturing data from the surface of a physical object to describe its shape in an accurate digital 3D format. Unlike CMM measurement data, high quality 3D scan data is used for more than just inspection and dimensional analysis. The data obtained by non-contact measurement allows faster and more accessible digital analysis and inspection using a visual, in-depth method of examination.

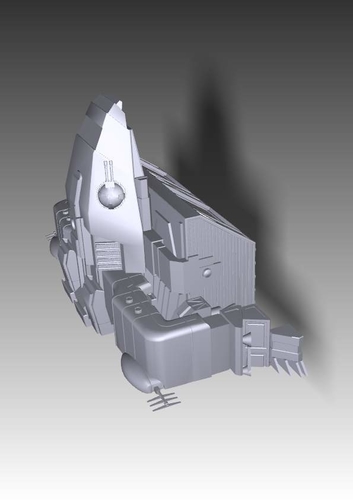

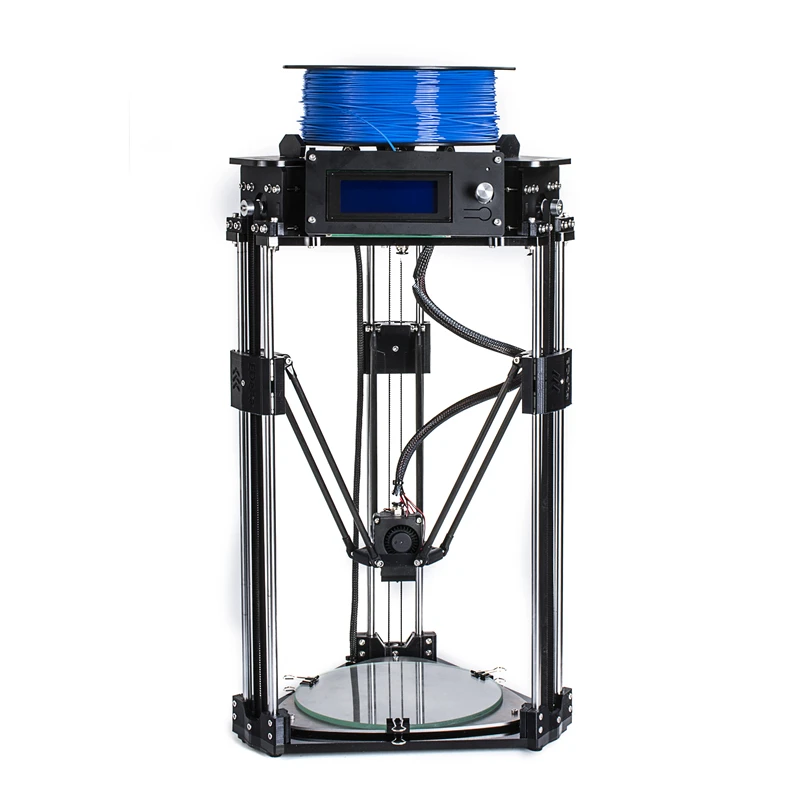

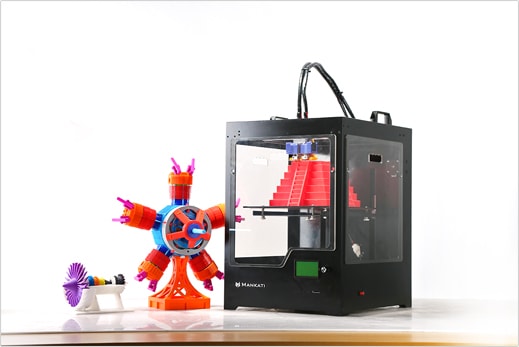

3D scanners are also used to replicate parts in reverse engineering, check the fit, shape and function of components in remote locations, and check CAD models of 3D printed parts. 3D printers can use 3D scan data to create physical objects.

What is 3D scanning?

3D scanning is the process of collecting data about the surface of an object in digital format to determine its shape, allowing users to either reproduce the part by reverse engineering or verify it by dimensional analysis.

To do this, operators use scanners that use lasers, light or sensors to determine the surface of the scanned object and assign data points to this surface. These data points will eventually recreate the . Depending on the type of laser, light, or sensor used, the level of detail and scanning performance may vary.

3D Scanning Technologies

Photogrammetry

Originating from photography, photogrammetry is an incredibly useful technology in various fields. This technology allows you to take multiple images taken at different positions and triangulate points on those images to determine their location in 3D space.

For example, cartographers use this technology when compiling maps. When it comes to hard-to-reach places like mountains, surveyors can use photogrammetry to take measurements.

When it comes to hard-to-reach places like mountains, surveyors can use photogrammetry to take measurements.

Many modern technologies use photogrammetry, and the quality of the images is the main factor determining accuracy. If the images are poor quality, there will be holes in the grid. The more images you can get, the higher the scan accuracy will be.

Shining 3D offers a solution - DigiMetric Photogrammetric System.

Read also DigiMetric case study “Scanning with a Digimetric Photogrammetric System and a FreeScan Handheld 3D Laser Scanner”

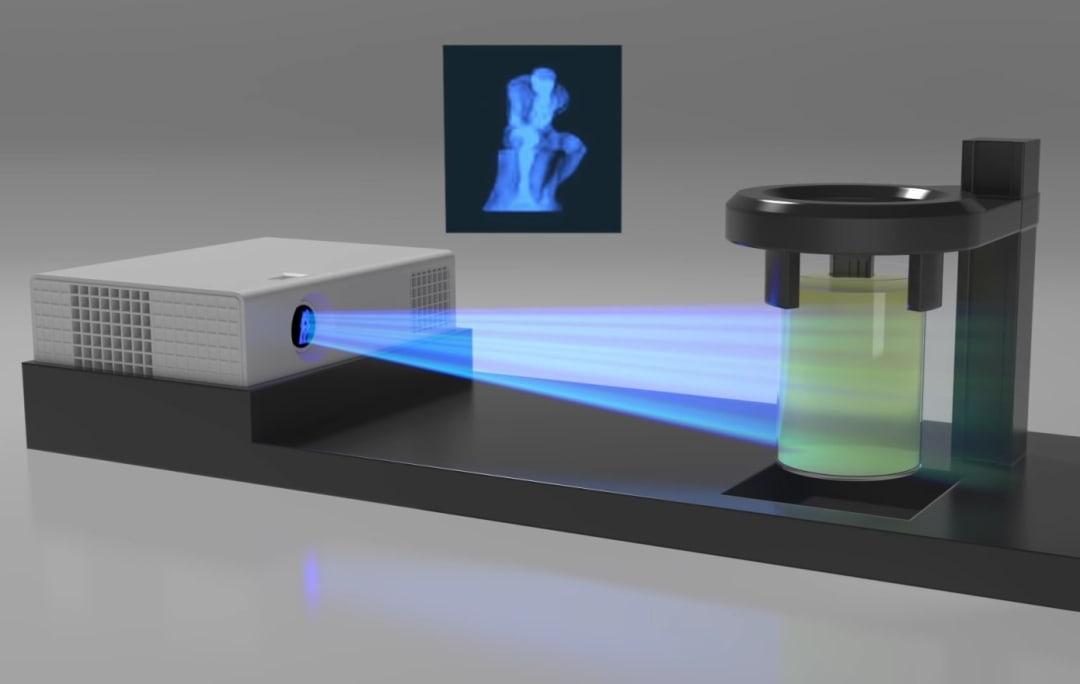

Structured Light

This technology is created by applying geometric patterns to an object while simultaneously capturing an image with a camera. In this case, the camera registers the deviation of the image.

Based on this template offset, all existing points can be located. It is necessary to conduct many scans from different positions, and then merge them until the mesh is 100% complete. Computer programs automatically combine all images to form a complete grid.

Computer programs automatically combine all images to form a complete grid.

3D laser scanning method

3D laser scanning data acquisition

3D laser scanning process

The object to be laser scanned is placed on the scanner platform. Specialized software directs the laser probe over the surface of the object. A laser probe projects a line of laser light onto the surface, and 2 sensor cameras continuously record the change in distance and shape of the laser line in three dimensions (XYZ) as it passes along the object.

Acquired data

The shape of an object is displayed as millions of dots, called “point clouds”, on a computer monitor as the laser moves around, capturing the entire shape of the object's surface. The process is very fast and laser scanning is more accurate than infrared.

Point cloud data for inspection

If the data is to be used for inspection, the scanned object can be compared with the designer's nominal CAD data. The result of this comparison is provided as a “color map deviation report” in PDF format, which clearly describes the differences between scanned data and CAD data.

The result of this comparison is provided as a “color map deviation report” in PDF format, which clearly describes the differences between scanned data and CAD data.

Reverse engineering CAD model

Laser scanning is the fastest, most accurate and automated way to obtain digital 3D data for reverse engineering. Again, with the help of specialized software, point cloud data is used to create a 3D CAD model of the geometry of the part.

The CAD model can accurately reproduce the scanned object, or the object can be modified in the CAD model to correct imperfections.

Types of 3D scanners

Active scanners emit some radiation or light. The scanner detects the reflection to collect information about the object. Let's take a look at the active views of 3D scanners below.

3D Laser Scanners

3D Laser Scanners use a process called trigonometric triangulation to accurately display a 3D shape as millions of dots. Laser scanners work by projecting a laser line or lines onto an object and then capturing its reflection using one or more sensors.

The sensors are located at a known distance from the laser source. Accurate point measurements can be made by calculating the angle of reflection of the laser light.

Laser scanners are very popular and come in many designs. These include handheld, manipulator-based, CMM-based handheld devices, long-range trackers, and long-range single-point trackers.

Benefits of 3D laser scanners:

- Ability to scan complex surfaces such as shiny or dark surfaces.

- Less sensitive to changes in lighting conditions and ambient light.

- More accurate data, available for inspection.

Learn about FreeScan UE 3D laser scanner features, features, features and benefits.

An example of using FreeScan UE and photogrammetry can be found on our blog page - Large Part 3D Inspection.

As well as the article The rebirth of historic motorsport icons.

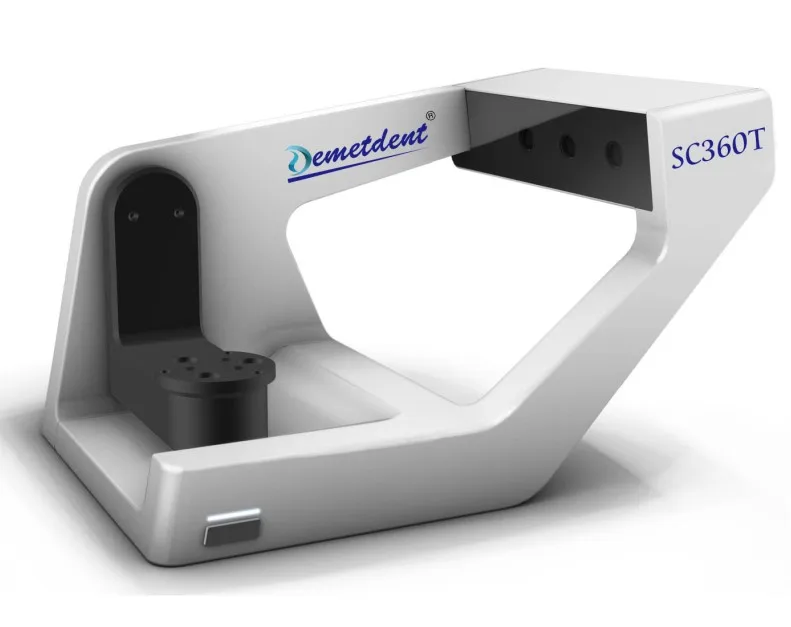

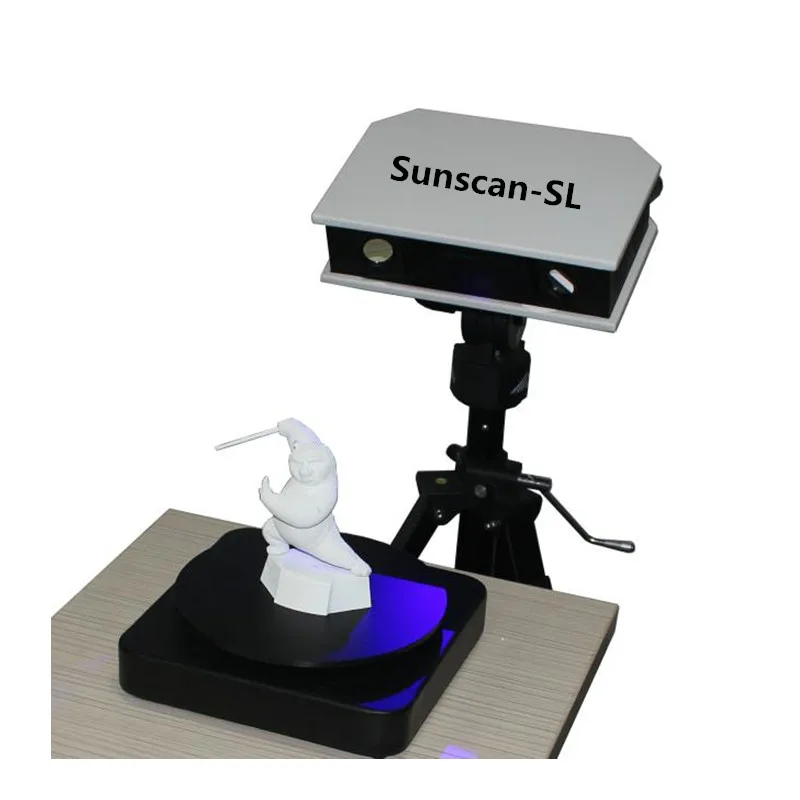

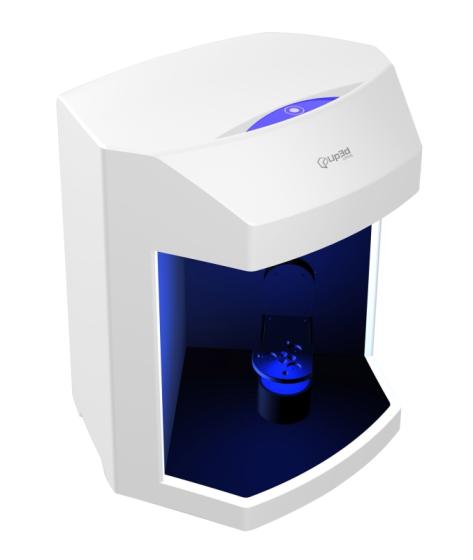

Projected or structured light 3D scanners

Historically known as “white light” 3D scanners, most structured light 3D scanners today use blue or white LED projected light. These 3D scanners project a pattern of light onto an object, consisting of stripes, blocks, or other shapes. A 3D scanner has one or more sensors that look at the edges of these patterns or structural shapes to determine the object's 3D shape.

These 3D scanners project a pattern of light onto an object, consisting of stripes, blocks, or other shapes. A 3D scanner has one or more sensors that look at the edges of these patterns or structural shapes to determine the object's 3D shape.

Using the same trigonometric triangulation method as in laser scanners, so the distance from the sensors to the light source is known. Structured light scanners can be mounted on a tripod or hand held.

Benefits of structured light 3D scanners:

- Very fast scan times of only 2 seconds per scan.

- Versatility - multiple lenses for scanning small and large parts in one system.

- Portability - handheld systems are highly mobile.

- Eye friendly for 3D scanning of people and animals.

- Color 3D scans available.

- Various price ranges from inexpensive to expensive depending on resolution and accuracy.

An excellent solution to 3D scanners with structured light, are models:

- Einscan HX

- manual 3D scanner Einscan H.

Examples of scanning using 3D 3D scanners EINSCAN:

- https: // www.shining3d.ru/blog/perfectly-equipped-for-emergency-with-the-einscan-hx/

- https://www.shining3d.ru/blog/at-the-intersection-of-craftsmanship-and- technology-einscan-h-and-fusion-360-in-traditional-boat-building/.

Coordinate Measuring Machine (CMM)

Coordinate Measuring Machine (CMM) is mainly used for parts inspection. The machine can be controlled manually or through autonomous control by software and computers. Measurements are determined by attaching a sensor to the machine. The sensor usually has a small ball at the end of a shaft of known diameter. The CMM is then programmed to make contact with the part. When the machine senses contact with the probe tip, a value in XYZ space is measured. The most common type of CMM is the bridge type, which has 3 x, y, and z axes. The attached sensor system can be rotated to provide an additional 3 xyz axes, giving a total of 6 degrees of freedom (DOF).

For very precise measurement of parts down to a few microns, CMMs are usually installed in a controlled room.

The room includes a reinforced floor, controlled humidity and temperature, and isolation from vibration and other forces that may affect accuracy.

In addition, most CMMs have a large granite table surface that is perfectly flat. Details are fixed on a granite table in such a way as to exclude their movement during the measurement process.

Advantages of CMM:

- One of the most accurate way to measure an object

- With the appropriate machine, both small and large parts can be measured

- There are industry standards and certifications for measurement and software

Solutions provided by Shining 3D – FreeScan Trak CIM Portable Wireless Scanning System.

Application example – Mobile precision testing for the highest requirements.

The practical use of 3D scanning is already a reality today. The principle of operation of 3D scanners is based on accurate measurement of distances to the characteristic points of the object under study, which makes it possible to determine their coordinates in space and build a digital three-dimensional model. In the future, it can be displayed on a computer screen or formed on a 3D printer

In the future, it can be displayed on a computer screen or formed on a 3D printer

What types of 3d scanners exist?

Pelevin N. 0 Comments 3d scanner, 3d scanning, Equipment

According to market research, the growth of the 3d scanner industry is increasing, and by 2018, the turnover should reach 4.08 billion dollars, respectively, the annual profit rate will increase by 14.6%.

The reason for this growth lies in the technological features and capabilities of 3d scanners, personal 3d scanning may appear in the future, for example, using products from Google or Microsoft Kinect. We can imagine a future where every person has a 3d camera in their pocket, and with a personal 3d printer, a person could recreate any part of the world around him.

For those who are looking to purchase a 3d scanner for home or commercial use, or are simply interested in the various options available for modern physical data capture, we have compiled this list based on considerations of the appropriateness of the purchase of the device. Many scanners can be built at home, which will be much cheaper than buying a ready-made system.

Many scanners can be built at home, which will be much cheaper than buying a ready-made system.

3d scanners with LED illumination

Such scanners use stripes as a template for detecting objects, and the main methods for creating models are: creating laser noise and projections. The latter uses two flat laser beams to create two equidistant lines. This method is useful for creating an image with a practically unlimited depth of field, that is, the object can be both far and close to the lasers, while the quality of the resulting image will not change. The high accuracy of the projection, which is obtained using such an installation, makes it practically unaffordable in terms of price, for most consumers.

More affordable and common are SL scanners, which work on the principle of a standard video projector that projects a set of alternating black and white stripes onto an object. One or two cameras are used to capture the shifts and distortions of the bands. In this way, offset points are obtained to recreate the object in 3d.

In this way, offset points are obtained to recreate the object in 3d.

Features of :

- data will be better read in low light;

- can be built at home;

- has a high speed, some systems can even scan objects in motion;

- scanning accuracy is almost as good as laser scanners.

Examples :

- Artec Eva

- RVScanner

- OptiNum

3D laser scanners

One of the most common 3d laser scanners on the market are 3d laser scanners, they come in several varieties: from large ones that are mounted on tripods for collecting data over long distances, to handheld ones that can measure textures on a person's face. They work based on different principles (acoustic-optical deflectors, surface-emitting lasers with a vertical cavity, etc.). Surface-emitting lasers are used to calibrate docking on space shuttles that NASA uses.

Typically, 3D laser scanners are used for scanning over long distances, and the principle of operation is similar to the operation of a laser range finder: in three-dimensional space, the speed of the laser pulse from the point where the device is installed to the object and back is calculated. If you combine all the data obtained, you get a kind of point cloud in three-dimensional space. Another way to obtain and calculate data is triangulation.

If you combine all the data obtained, you get a kind of point cloud in three-dimensional space. Another way to obtain and calculate data is triangulation.

Triangulation is used in portable 3d scanners, and the principle of operation is to record the position of an object, which is then used in the location of the object relative to the camera's field of view. To speed up the process, a laser pulse is used to calculate several points at the same time.

Features of laser 3d scanners:

- can be used in rooms with any illumination;

- can scan parts of any material;

- large depth of field;

- laser light can be damaging to the eyes, so do not stare at the beams.

Examples :

- Creaform HandySCAN

- Faro Focus3D

Photogrammetry

When photographing, several photos taken from different angles are stitched together using certain algorithms to create a 3d model. This method, with skillful setup, can be called the fastest 3d scanning. Companies such as Infinite Realities used 50 to 120 high-speed cameras to create photogrammetric setups to make 3d models as realistic as possible. Google uses stitched aerial photographs and creates three-dimensional, topographical models of the earth. If you only have one camera, then the shooting process will slow down, as you will need to move around the subject and take a large number of photos in order to get the best possible result. But this is a fairly cheap solution, since you will need a camera and several programs from the equipment. Depending on the quality of the captured images, you may get good or mediocre results.

This method, with skillful setup, can be called the fastest 3d scanning. Companies such as Infinite Realities used 50 to 120 high-speed cameras to create photogrammetric setups to make 3d models as realistic as possible. Google uses stitched aerial photographs and creates three-dimensional, topographical models of the earth. If you only have one camera, then the shooting process will slow down, as you will need to move around the subject and take a large number of photos in order to get the best possible result. But this is a fairly cheap solution, since you will need a camera and several programs from the equipment. Depending on the quality of the captured images, you may get good or mediocre results.

Photogrammetry is based on artistic algorithms that identify unique features in an image and, based on the results, stitch them together.

Features of :

- only one chamber possible;

- is one of the easiest ways to create a 3D image at home;

- is an excellent method for aerial photography.

Examples :

- Autdesk 123D Catch (Freeware)

Contact 3d scanner

The probe moves along the surface of the object using a hand or special mechanisms and transmits movement data to a computer. Due to the accuracy of measurement in this way, probes are often used to check the accuracy of any manufactured parts.

The main disadvantage of these scanners is their limitation in scanned surfaces, especially moving objects. Another disadvantage is the need for the scanner to directly touch the object. If the latter is quite fragile, then there is a possibility of damaging it. The last drawback is the low speed of operation, combined with the need to constantly move the scanner.

Features :

- high work accuracy, with the possibility of subsequent export to CAD packages; The

- can be purchased at a relatively low price, especially for older systems.

What to look for before buying a 3d scanner?

If you are still thinking about purchasing a 3d scanner, you should consider all aspects:

Mobility .

Also compatible with the DPI-10/SR

Also compatible with the DPI-10/SR

We'll even send you the data right after for review. This experience very closely emulates a live scanning session, as if the scanner were in your hands.

We'll even send you the data right after for review. This experience very closely emulates a live scanning session, as if the scanner were in your hands. ”

” )

)