Delta 3d printer advantages

3D printing technology – Delta versus Cartesian

Back

The 3D printing market is quite competitive and each printer has its own 3D printing technology and unique capabilities, so it’s important to know which printer is most suited for the results you want to achieve. As most 3D printers, Tractus3D printers use the FFF 3D printing method (also known as FDM 3D printing), which means everything is printed layer by layer using filament.

In the FDM 3D printing technology, two types of printing systems can be distinguished: Cartesian and Delta. The biggest difference between these two systems is the method of moving. Because each system has its own way of moving, you will achieve different results.

First more about the FDM technology

There are several different 3D printing technologies, but the most used is Fused Deposition Modeling (FDM 3D printing). The FDM technology is a Stratasys-patented additive manufacturing 3D Printing method of rapid prototyping. This process is also known as FFF 3D printing (Fused Filament Fabrication). The FDM technology is very popular. Over the past two decades, the FDM 3D printer has become even the most used 3D printing technology in the world.

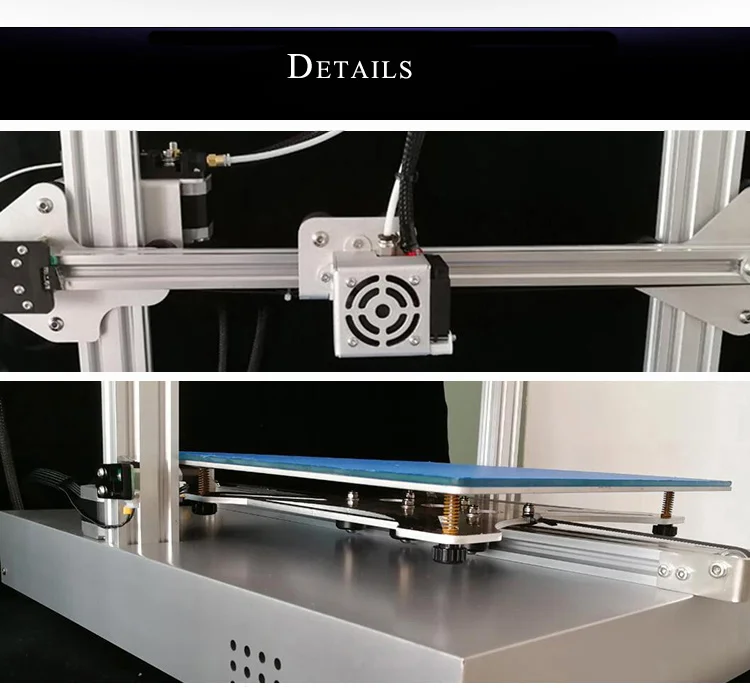

With FDM 3D printing technology, the extrusion nozzle moves over the build platform horizontally and vertically. Thermoplastic material is heated to its melting point and then extruded, layer by layer, to create a three dimensional object. Each of these layers can be seen as a sliced horizontal cross-section of the eventual object. Once a layer is completed, the base is lowered to make room for the next layer of plastic. Once an object comes off the FDM 3D printer, its support materials can be removed.

In FDM 3D printing technology, there are two types of printing systems: Cartesian and Delta. The biggest difference is the method of moving. We will explain…

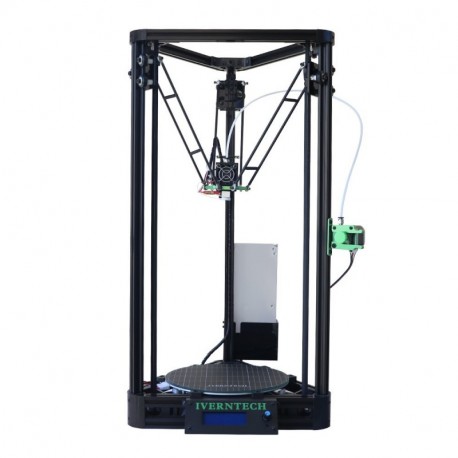

Delta 3D printer

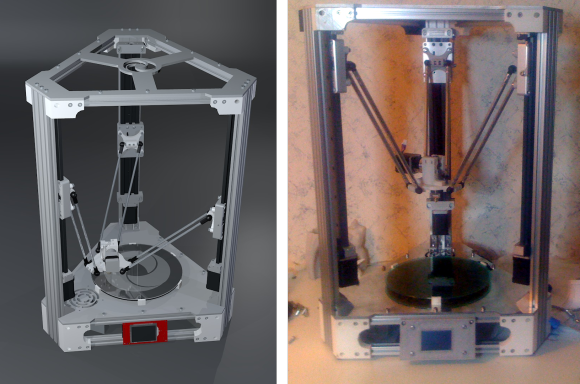

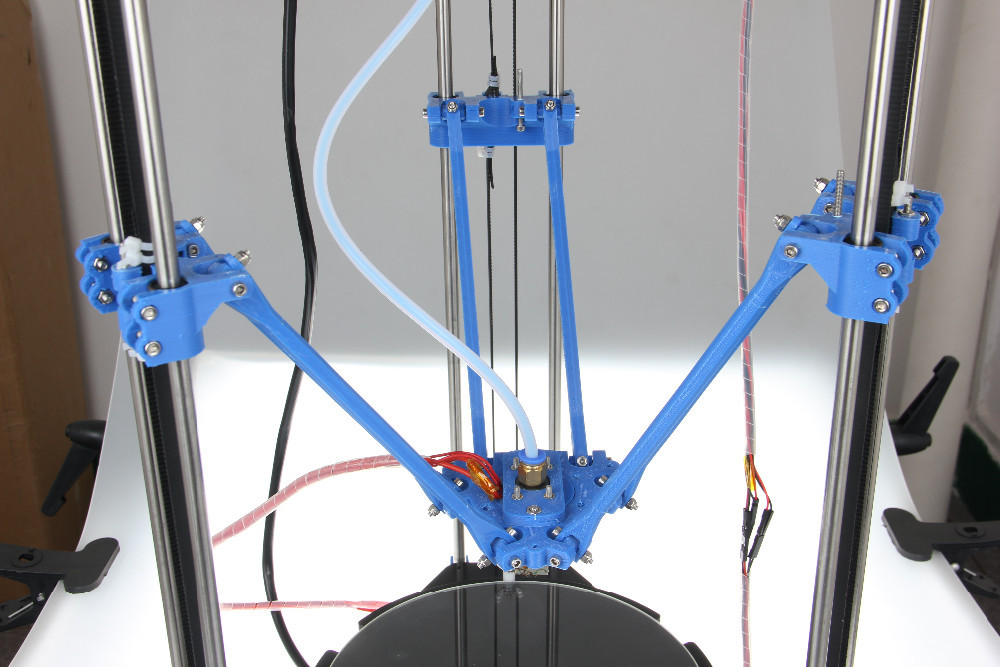

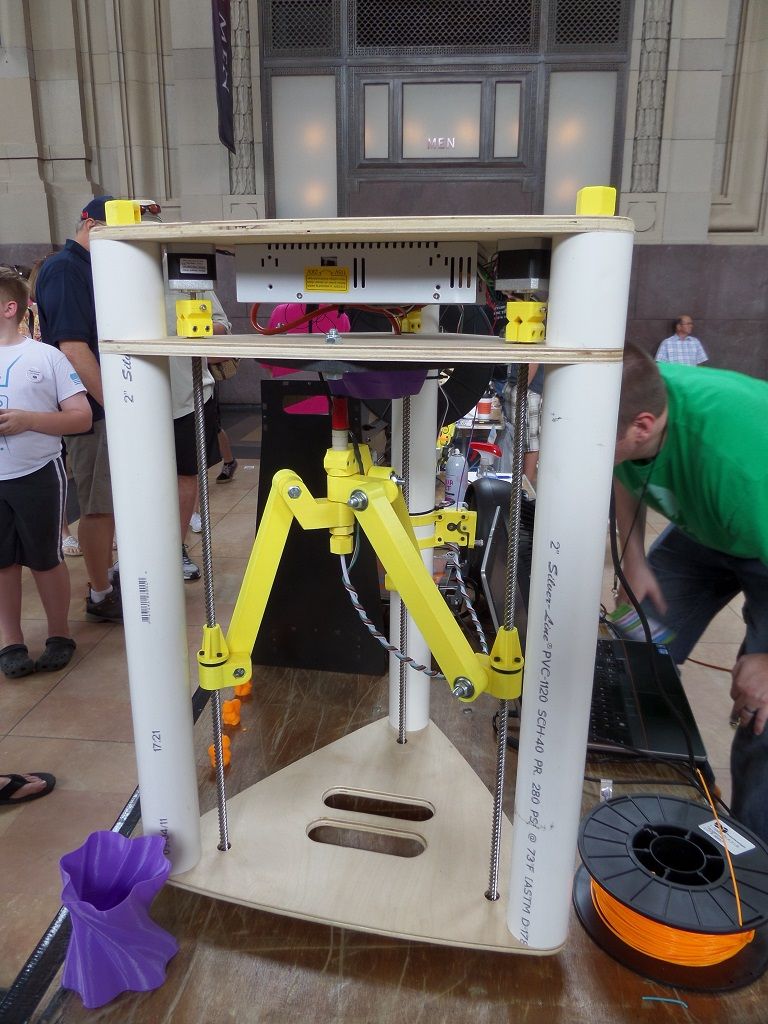

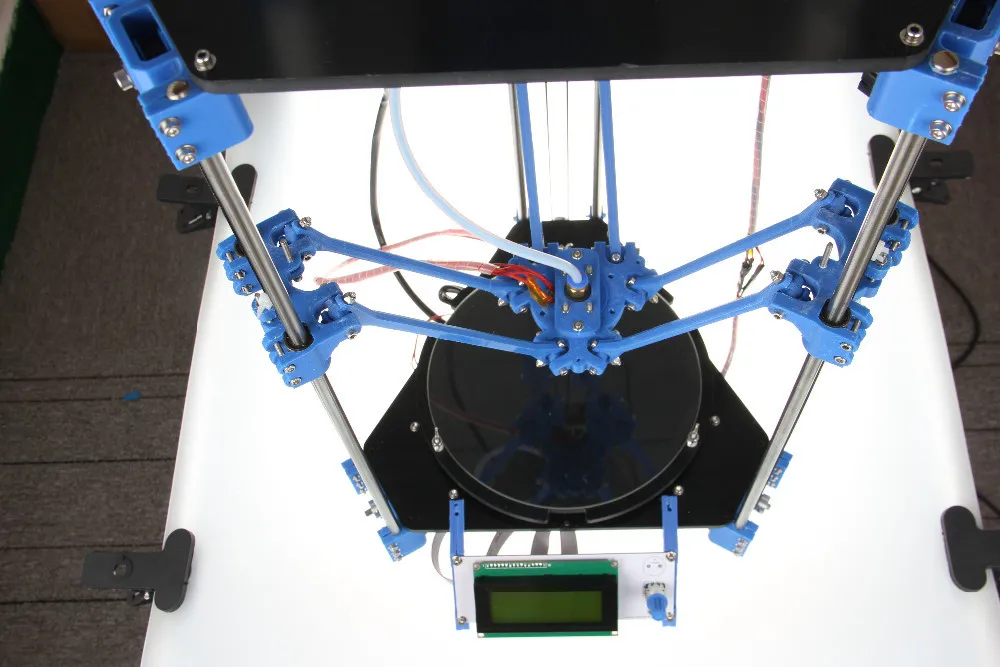

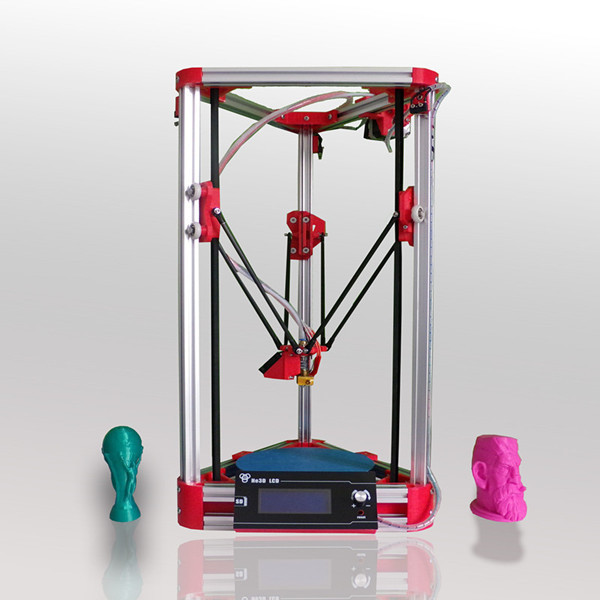

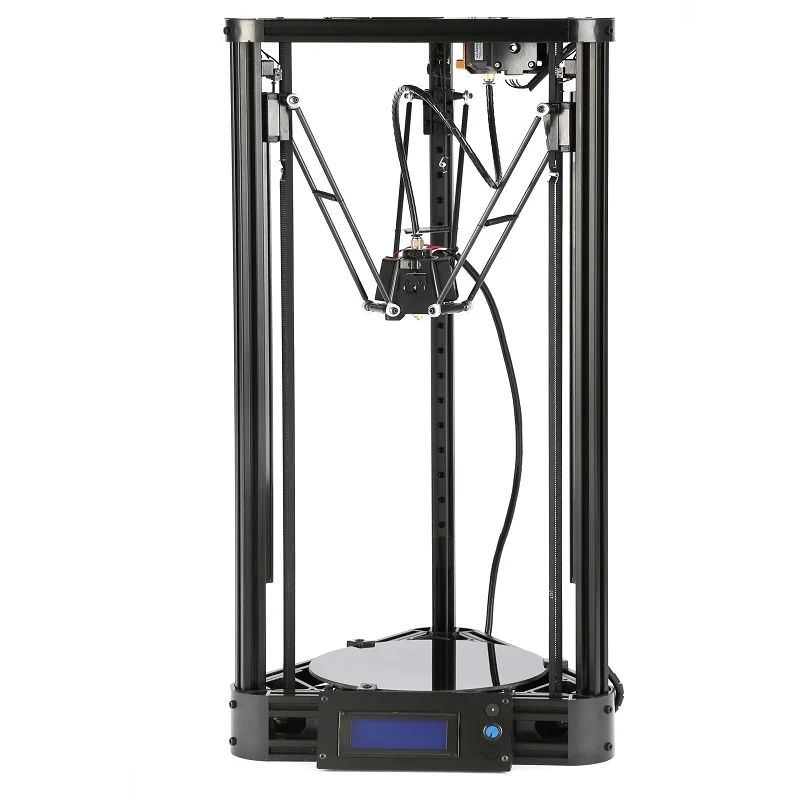

Delta 3D printers also use the Cartesian coordinate system, but do not use linear-motion tracked movement to deposit the filament. Instead, they use three arms, each consisting of a parallelogram. They also move from one X or Y point to another, but do so by changing the angles of these parallelograms. The arms of a Delta 3D printer hang down from a fixed platform. All of the mechanics that drive the motion of the arms are located in that platform. As a result, the print head of the Delta 3D printer is a lot lighter than if it also had to contain motors for movement. This reduced weight leads to reduced inertia. By reducing the inertia, particularly at the end of a movement, the production head is able to respond quickly, while retaining its accuracy.

Instead, they use three arms, each consisting of a parallelogram. They also move from one X or Y point to another, but do so by changing the angles of these parallelograms. The arms of a Delta 3D printer hang down from a fixed platform. All of the mechanics that drive the motion of the arms are located in that platform. As a result, the print head of the Delta 3D printer is a lot lighter than if it also had to contain motors for movement. This reduced weight leads to reduced inertia. By reducing the inertia, particularly at the end of a movement, the production head is able to respond quickly, while retaining its accuracy.

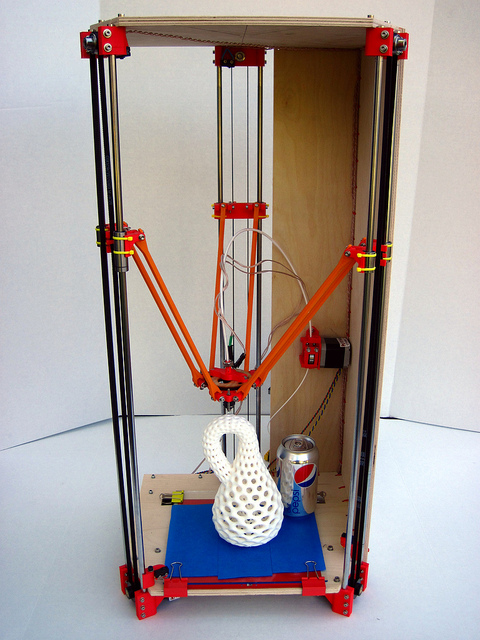

A Delta 3D printer usually features a circular print bed, which is immovable. Due to its circular print bed, the natural shape of a Delta printer is a circle. Therefore, rectangular objects tend to be rather small in comparison to a Cartesian 3D printer. What a 3D Delta printer excels at, in comparison to the 3D Cartesian printer, is its capability to build tall objects. Especially the highest point of the print can be made exceptionally accurate. It is also fairly easy to make them bigger, especially in height, due to their design. With an overall less complicated construction and less parts to be used, it reduces maintenance and costs. If you do not have/need a lot of horizontal space, but instead want to build a lot of layers on top of each other (vertical), then you should definitely consider a Delta 3D printer.

Especially the highest point of the print can be made exceptionally accurate. It is also fairly easy to make them bigger, especially in height, due to their design. With an overall less complicated construction and less parts to be used, it reduces maintenance and costs. If you do not have/need a lot of horizontal space, but instead want to build a lot of layers on top of each other (vertical), then you should definitely consider a Delta 3D printer.

Its downside comes in the fact that a Delta 3D printer must be much taller than its build volume, due to the arm construction of the machine. This is why you will generally need more space to place your printer than you would with a Cartesian 3D printer.

Delta 3D printer disadvantages

- Format, it requires more space (in height)

- More difficult to pinpoint errors

- Harder to print objects with large surfaces (horizontal)

Delta 3D printer advantages

- Excels in printing in height

- Light, thus easy to move

- Instant change of direction possible

- More accurate in the centre than on outer limits

- Easy to maintain and upgrade

- High print speed and accuracy

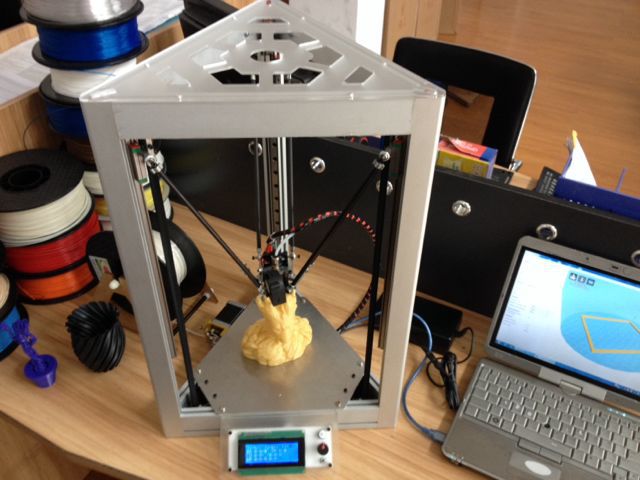

Cartesian 3D printer

Cartesian printers owe their name to the Cartesian coordinate system they use, which was invented by Rene Descartes. They don’t just function based on an X and Y coordinate system, but also drive the print head on a mechanism that travels linearly on both the X and Y axis.

They don’t just function based on an X and Y coordinate system, but also drive the print head on a mechanism that travels linearly on both the X and Y axis.

Cartesian printers move from left to right, front to back and up and down. Simply put, it gets from A to B by moving just one axis at a time. Most Cartesian printers consist of a square, moving print bed. Instead of having the nozzle move towards the print bed, the print bed moves towards the nozzle in some cases.

Cartesian 3D printers see their downside in the fact that their moving parts are quite heavy. Because of this, it is hard for a Cartesian printer to stop or change direction in an instant. The constant jerking of the platform can lead to prints coming loose and to inaccurate prints, especially when the prints get higher.

Cartesian 3D printer disadvantages

- Weight

- Hard to modify due to spatial constraints

- No instant change of direction

- Not fit to print tall objects

- Small build volume

Cartesian 3D printer advantages

- Excels in width (horizontal) prints

- Easier to learn due to understandable kinematics

- Consumer friendly

- Easy to enclose most models due to cubic frame

- Cheaper

Delta Vs Cartesian 3D Printer – Which Should I Buy? Pros & Cons – 3D Printerly

You’re presented with countless variations to choose from when it comes to picking a 3D printer. One such case is where you have to decide between a Delta or a Cartesian-style 3D printer.

One such case is where you have to decide between a Delta or a Cartesian-style 3D printer.

I faced a similar hassle and experienced nothing but tough luck for a long while. That is why I’m writing this article to make the decision easier for you.

If you’re after simplicity and speed, I suggest a Delta 3D printer while on the other hand, Cartesian-style printers bring the best of quality with them if you go for one, but you’ll have to spend a bit extra on these.

In my opinion, both of the printers are exceptional, and choosing between the two ultimately boils down to your personal preference and budget. The main difference between these two 3D printers is the style of movement.

The rest of the article will guide you on which 3D printer to choose at the end of the day. Therefore, continue reading for an in-depth analysis of both printer types, how they work, and what are the pros and cons of each.

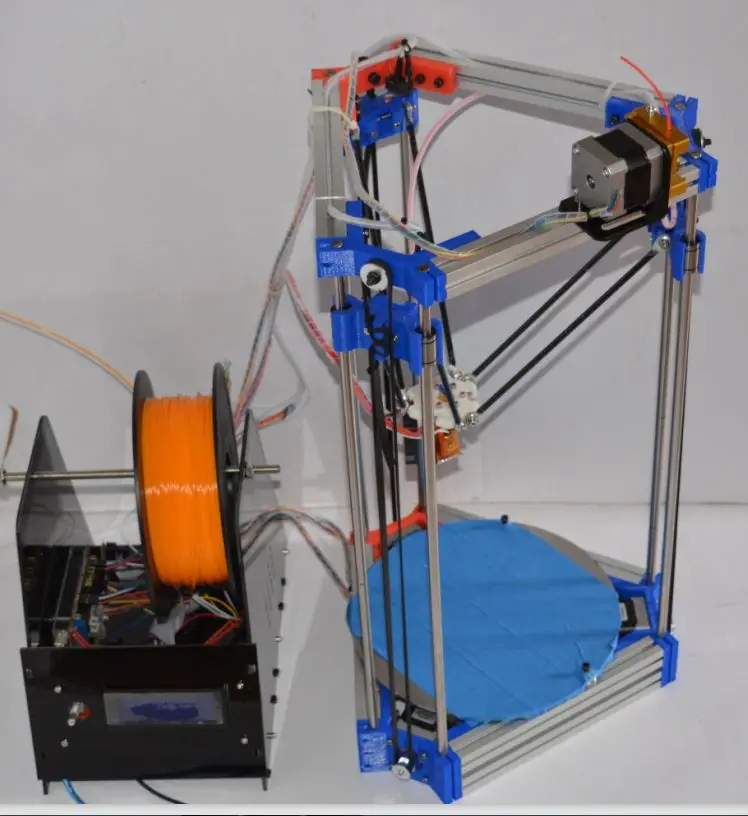

What is a Delta 3D Printer?

Delta-style printers are gradually on the rise to popularity, as an exceeding amount of these machines continue to deliver beyond expectations. You’ve probably heard more of Cartesian printers making the headlines, but that’s not all there is to 3D printing.

Delta printers are unique in movement. They are structurally engineered in such a way that they adapt to a triangular shape, thus the name “Delta”.

Unlike Cartesian-style printers who are fashioned according to the XYZ coordinate system in Mathematics and follow those three axes, Delta printers consist of three arms that only move up and down.

A great example of a Delta 3D printer is the Flsun Q5 (Amazon) which has a touchscreen and an auto-leveling feature to make life a little easier.

Nevertheless, what’s exclusive about these printers is the individual motion of the arms that are directly in contact with the extruder, allowing it to print in all directions seamlessly. Nothing short of a visual phenomenon, to say the least.

On the contrary, when Delta and Cartesian printers go toe to toe against each other, you’ll find that they mostly have the same components, only the placement is different.

Both run common thermoplastic filaments like PLA, ABS, PETG comfortably and you probably wouldn’t be able to guess a Delta-style finished 3D print from a Cartesian one.

However, there are key differences to shed light on too. Speed, for one, is where Delta printers excel and shine.

No doubt that they are built with heavy parts and a solid extruder, but they’re kept on the sides and the actual printhead doesn’t take up too much weight. This allows them to move swiftly and as accurate as they are, these are made with pace in mind.

This allows them to move swiftly and as accurate as they are, these are made with pace in mind.

Want to know the best part? Quality doesn’t even suffer one bit. You got that right, Delta 3D printers are known to produce some of the most amazing quality prints you’ll ever see, all in good time.

Moreover, these printers have a circular build platform, unlike the standard rectangular ones you see on Cartesian printers.

In addition, the beds are kept much smaller as well, apart from the fact that they are considerably taller than other types of 3D printers. Lastly, the print surface does not move and remains stationary for the whole of the print job.

This is a trademark that applies only to Delta printers where Cartesian ones are highly different in this regard.

What is a Cartesian 3D Printer?

Cartesian 3D printers are no joke either. You’ll be amazed at what these machines are capable of in a genuinely distinctive approach.

You’ll be amazed at what these machines are capable of in a genuinely distinctive approach.

Speaking of their mode of action, these printers are based on the Cartesian coordinates system, which was formed by the French philosopher René Descartes.

Simply put, the three axes that make up the foundation of Cartesian printers’ working mechanism are X, Y, and Z.

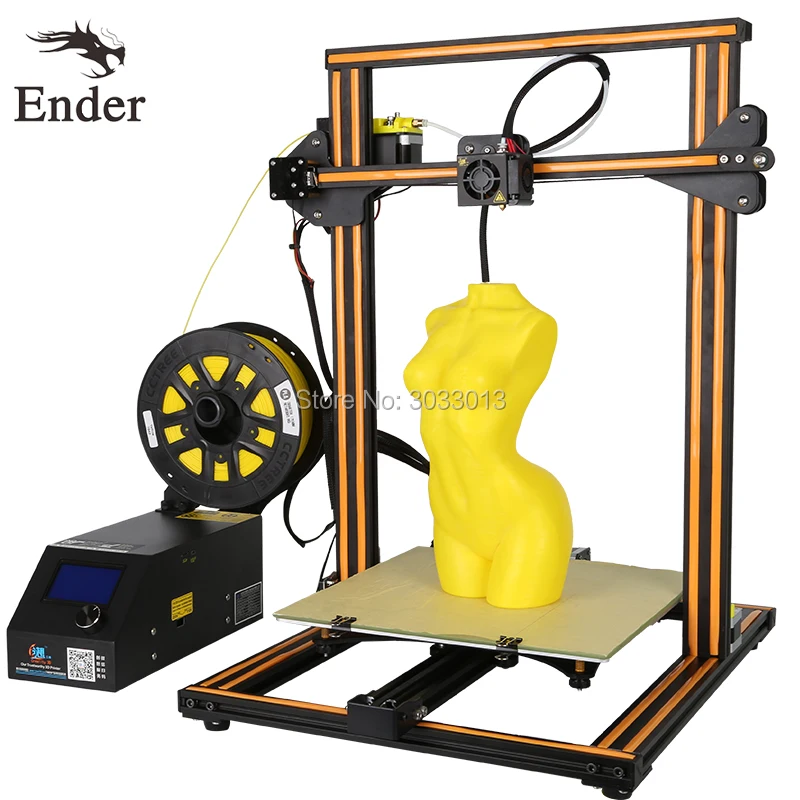

A great example of a Cartesian 3D printer is the Ender 3 V2 (Amazon) which is a very popular 3D printer that is loved by both beginners and experts.

There are some notable differences in varying printers but generally, you’ll observe that these machines take up the Z-axis as their main driving focus, with a two-dimensional peripheral work on the X and Y-axis.

This way, the printhead attributes back and forth, up and down, and left and right movements. This might seem a little bit complicated, but Cartesian 3D printers are much simpler and more user-friendly than Delta-style ones.

There’s one more thing worth adding here. The mode of the mechanism of these printers might not change for many printers, but there are still heavy differences in how they work in several printers.

Taking into account the LulzBot Mini, it has got the build platform moving back and forth on the Y axis, while the printhead delivers by moving up and down. Finally, the movement of the X-axis is associated with the gantry, and that’s that.

On the other hand, there’s Ultimaker 3 whose build platform moves upwards and downwards, unlike the LulzBot Mini where it moves back and forth.

Additionally, the X and Y axes are controlled by the gantry here as well. All this goes on to show that there are substantial variations in Cartesian 3D printers where they might not be what you are anticipating about them.

What makes these axis-driven printers so sought-after is their minimalistic design and easy maintenance due to the simple mechanics involved. However, all that comes at a cost, and that is speed.

However, all that comes at a cost, and that is speed.

As the printhead isn’t as light as it is in Delta variants by far, fast directional changes can’t happen without them ruining your print.

Therefore, you have to compromise speed with Cartesian printers, but it’s safe to say that the outcome is very well worth the wait.

Indeed, the accuracy, precision, detail, and depth are unmatched by any other printer type however long may that take you.

Cartesian printers are famous for prints of the highest standard with intricate, detailed delicacy. Delta printers fall short and bow down in defeat in terms of a quality standard, therefore.

This is mainly because of high rigidity in the axes of these printers, purely paving the way for a lesser room for error.

Pros and Cons of a Delta 3D Printer

Let’s delve into the part where I tell you the major advantages and disadvantages of owning a Delta 3D printer. Let’s start with the pros first.

Let’s start with the pros first.

The Pros of a Delta 3D Printer

Speedily Efficient

Delta printers are acknowledged as one of the fastest 3D printer types out there. They are known to produce prints very quickly and with great quality as well.

The rate at which they print can go as up as high as 300 mm/s, which is quite insane for a 3D printer. Maintaining such speed, these highly admired machines do their best to deliver fantastic quality with satisfactory details.

Made with rapid production in mind, Delta-style printers aren’t going to run out of fashion for a very long time. They’re truly for those who have a short turnover time and their businesses demand such efficiency.

Therefore, it’s like these printers are built to handle this challenge and complexity. This is one of their major plus points and genuinely hard to overlook when buying a 3D printer.

Technically speaking, Delta printers owe their speed to the courtesy of three stepper motors working the three vertical arms individually.

It means that it has three motors powering the XY plane movements rather than two for Cartesian 3D printers.

In addition, most of these have the Bowden extrusion setup, which takes the extra weight off the printhead, making it lightweight and invulnerable to jerks while quick directional changes.

Compared to a Delta printer’s counterpart, Cartesian printers are most likely to print at approximately a fifth of 300mm/s. You can call this a tricycle going up against a Bugatti. No competition.

Great for Making Tall Prints

Delta printers may have a small print bed but that doesn’t mean it’s of no use. To compensate for the lack of sizeable volume, the makers urged the people to look at things in a different light.

In doing so, they’ve built the print bed’s height to an exceptional level, making it eminent for producing tall models.

When it comes to printing towering architectural models, there’s no better printer out there than Delta-style ones.

This is because the three movable arms can travel a good distance both up and down, enabling them towards catering to large models effortlessly.

A Circular Print Bed

The fact that the build surface of Delta printers is in a circular shape is truly special and dedicated to them. This gives these types of printers a hefty advantage over some situations, especially when you have to make rounded, circular prints.

A nice feature, if you ask me.

Another major difference that draws a fine line between Cartesians and Deltas is the movement of the print bed. In Delta printers, the bed remains stationary and fixed, providing a more compact and beneficial experience in several cases.

Reduced Moving Weight

This advantage is how speed is levels above a Cartesian 3D printer. There is a lot less moving weight so you can have quicker moves without the inertia, or vibrations negatively affecting print quality.

There is a lot less moving weight so you can have quicker moves without the inertia, or vibrations negatively affecting print quality.

It also leads to great accuracy in the centre of the print bed as compared to the outer sides.

Easy to Upgrade & Maintain

Although troubleshooting can be difficult, the actual upgrading and maintaining of a Delta 3D printer is fairly easy, and doesn’t require all sorts of complex knowledge of your 3D printer.

You do have to keep in mind that the Delta print head has to be light, so you don’t want an aftermarket print head which weighs too much, as it can start to dig into your print quality.

They Look A Lot Cooler

I had to throw this pro in there. Delta 3D printers just look way cooler than any other types of 3D printers. The bed stays still, yet the three arms are moving in unusual ways, slowly building your 3D print in an interesting way.

The Cons of a Delta 3D Printer

A Lacklustre of Precision and Detail

Not everything goes right with the Delta printer. It may have unparalleled speed and prompt mass productions, but there can be a significant sacrifice on precision and detail.

It may have unparalleled speed and prompt mass productions, but there can be a significant sacrifice on precision and detail.

Speed can come at a cost especially if things aren’t fine-tuned, but even though it still holds up pretty well in terms of quality, the difference is apparent when faced off against a Cartesian-style 3D printer.

Surface detail and texture can suffer to a good extent as well. You may notice roughness here and there when you’re finished printing and all this is mainly from decreased precision.

Limitations with the Bowden Extrusion Setup

The Bowden-style extrusion may be great and all, removing excessive weight off the printhead and allowing it to print more swiftly, but there are caveats associated with it.

First off, as the Bowden setup uses a thing, long PTFE tube, you’re going to have trouble when printing with flexible filaments such as TPU and TPE.

Flexible thermoplastics are known to cause wear and tear inside the PTFE tubing which leads to deformation of the filament. This, in turn, can cause clogging and obstruct the extrusion process.

This, in turn, can cause clogging and obstruct the extrusion process.

However, all this doesn’t imply that you can forget about printing with such a filament using a Delta printer, no.

It only means that you’ll have to be careful about a lot of factors, tune your printer with great regard, and master the art of making relentless attempts.

Small Build Platform

The build platform is circular and you can probably print a tower inside, but the size is limited and this is something vastly important to consider.

Truth be told upfront, if you don’t intend to make tall, narrow models with a Delta printer and only seek to create other types of regular models, take into thought very closely the small build platform when buying this hunk of metal.

Again, it’s not going to be impossible, but you’ll have to divide your model into separate parts and print them likewise. This, obviously, is more work as compared to printing on a Cartesian printer.

This, obviously, is more work as compared to printing on a Cartesian printer.

It’s perfect if you need to build tall objects which don’t have a large horizontal size. The great thing is you can divide your models and make better use of your 3D printer’s height with a Delta 3D printer.

Small Community

Another key con to appraise the Delta-style 3D printer on is it’s developing, currently small-scale community that don’t have the same level of support, advice and communication that the Cartesian community has.

Delta 3D printers are more known to run into troubleshooting issues, so this, mixed with a lesser support channel could be a bad combination. There are several users who love their Delta 3D printers, so I wouldn’t let this factor deter you so much.

Additionally, the Delta printer fanbase isn’t flooded with content, blogs, how-to tutorials, and thriving communities just yet, so you’ll have to have a good grasp on 3D printer mechanics, the necessary settings, and of course, the assembly.

You won’t have as many of those cool upgrade videos on YouTube and new projects such as the super-sized 3D printers, but you’ll still be able to do the main functions that you need.

If you are just starting out in the field of 3D printing, you may run into problems of troubleshooting, but honestly, you’re going to get that with most 3D printers at some point down the line!

It’s just part of the hobby that you’ll get used to.

Harder to Troubleshoot

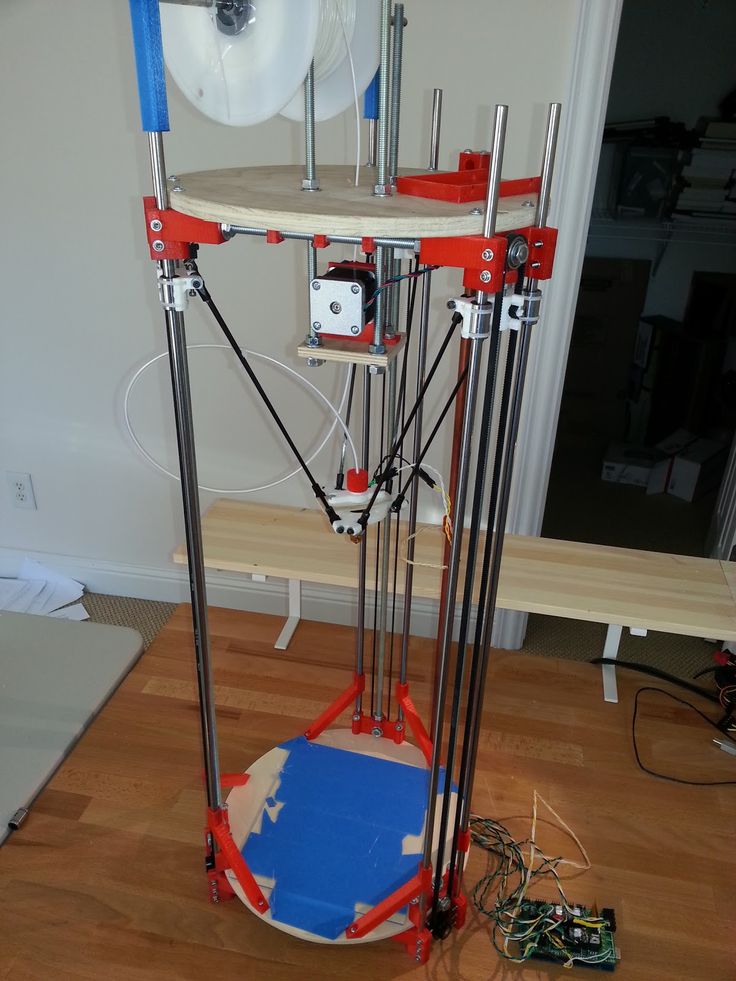

Since the three arms of a Delta printer move in a parallelogram and extrude while changing angles, the mechanics of a Delta 3D printer are a little more complex than a Cartesian.

This results in print imperfections and reductions in print quality being harder to figure out and troubleshoot.

You want to make sure you assemble a Delta 3D printer almost perfectly, or you might need to do regular calibration, which is especially difficult with the long Bowden tubes.

For newcomers, calibrating a Delta machine can be quite challenging.

Pros and Cons of a Cartesian 3D Printer

Here’s why Cartesian-style printers are exceedingly principled and well-liked among the diversity of 3D printers. Side by side, the cons are also there for you to reckon with.

The Pros of a Cartesian 3D Printer

Immense Community and Far-Flung Popularity

Probably the most tremendous advantage of owning a Cartesian 3D printer is its popularity and robust community to draw from.

The main reason behind the success of these printers is their glaring popularity, allowing them to be very user-friendly, arriving at your doorstep fully pre-assembled, awesome customer support, and a terrific fanbase to consult with.

With some Cartesian 3D printers, assembly can take only 5 minutes!

You’ll find a plethora of generous experts out there fervent to answer your questions and help you troubleshoot your Cartesian printer. At no point in owning this type of 3D printer, you’ll find yourself alone.

At no point in owning this type of 3D printer, you’ll find yourself alone.

Furthermore, as they require a simple setup, get ready to start printing with these mavericks as soon as they are out of the box.

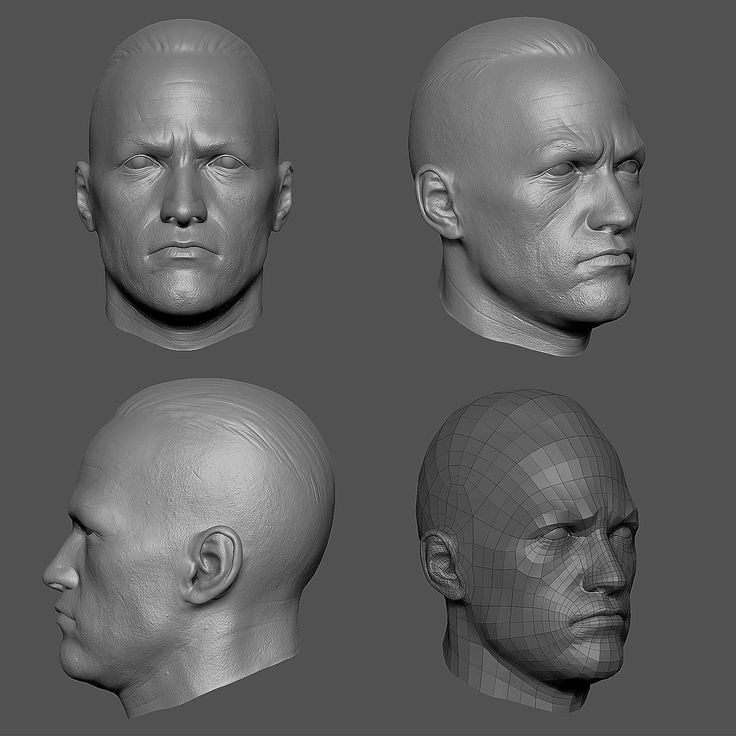

Detail and Precision

Cartesian 3D printers are a class above Delta ones when you talk about the precision. This attribute is up there in the top rankings unequivocally, as the detail is something that matters the most in 3D printing.

Fortunately, Cartesian printers have such a mode of mechanism that allows them to perform with a depth effect while drawing each line with power and accuracy.

These might be slower than Delta printers but that’s all for good reason- terrific print quality. Models are known to have smooth texture with clear definitions- quality traits that are highly desired in the 3D printers of today.

A fine-tuned Cartesian 3D printer can bring you some seriously amazing print quality, especially if you get a high quality extruder and hotend combination.

The Hemera Extruder is a great option. You can check out my E3D Hemera Extruder Review here.

Parts Availability

Another advantage that roots from the widespread popularity of Cartesian printers is the abundant availability of spare parts, both cheap and expensive- whatever that fits the scenario.

There’s a huge market online that’s yearning for you to make Cartesian printer purchases, often offering great deals and massive discounts as well.

For an example of the kind of parts you can easily get, check out my Ender 3 Upgrade article or my 25 Best Upgrades You Can Do On Your 3D Printer.

Great Compatibility of Printing

With a good Cartesian 3D printer, you are able to 3D print more materials easily, especially those flexible materials such as TPU, TPE and soft PLA. You may have a little trouble printing those same filaments on a Delta 3D printer.

You can easily convert your Cartesian 3D printer to a Direct Drive setup to reap the rewards of printing flexibles more accurately, and faster.

Check out my article about Direct Drive Vs Bowden 3D Printer Setups for more detailed information.

The Cons of a Cartesian 3D Printer

Lower Speed

As the printhead of Cartesian 3D printers is large and heavy, it builds up momentum as it moves along to draw the print lines. In doing so, it’s only sensible to foresee that it cannot change direction instantly and print at a fast pace.

That would only ruin the print quality instead because you cannot hope to stop and turn very quickly if you have great momentum. This is one of the disadvantages of a Cartesian printer and you can see why it’s not built for speed, unlike its rival.

You can still get a pretty high speed, but nothing matching a solid Delta 3D printer.

Delta 3D printers can instantly change their direction, but Cartesians need to slow down before moving, related to your Jerk & Acceleration settings.

High Weight on 3D Printer

This is also linked to the speed, where the higher weight limits the amount of fast movements you can commit to without reducing print quality. After a high enough speed, you will start to notice ringing in your 3D prints.

There are methods to reduce the weight, but it won’t be as light as a Delta 3D printer due to the design of the machine. The fact that the print bed also moves contributes to the higher weight.

People have seen bad print quality from having a heavy glass build plate because of the movement.

Should You Buy a Delta or Cartesian 3D Printer?

On to the real question here, which printer should you go for then? Well, I guess it’s not that hard to determine by now.

If you’re a seasoned veteran who’s looking for a different challenge and already knows the ins and outs of 3D printing, Delta 3D printers will keep you happy and satisfied with their remarkable speed and reasonable quality.

They’re also going to cost you less and give you tons of functionality.

On the other hand, if you’re fairly new to 3D printing and still getting used to the basics, prepare yourself to spend a bit extra and get a Cartesian-style 3D printer.

This thundering monster truck of a printing machine is a breeze to set up, surrounded with cheerful people to help you on your 3D printing journey, and produces insanely good quality- all at a trivial price of speed.

Oh, and don’t forget how these printers are flexible in filament variety and will let you print with different thermoplastics painlessly.

In conclusion, buy whatever that seems more suited to your needs since Delta and Cartesian printers both are the best at what they do. There are noteworthy differences in the two of them, so this is where your own taste comes into play.

We just recommend to check out the pros and cons before making the purchase.

What About a CoreXY 3D Printer? A Quick Review

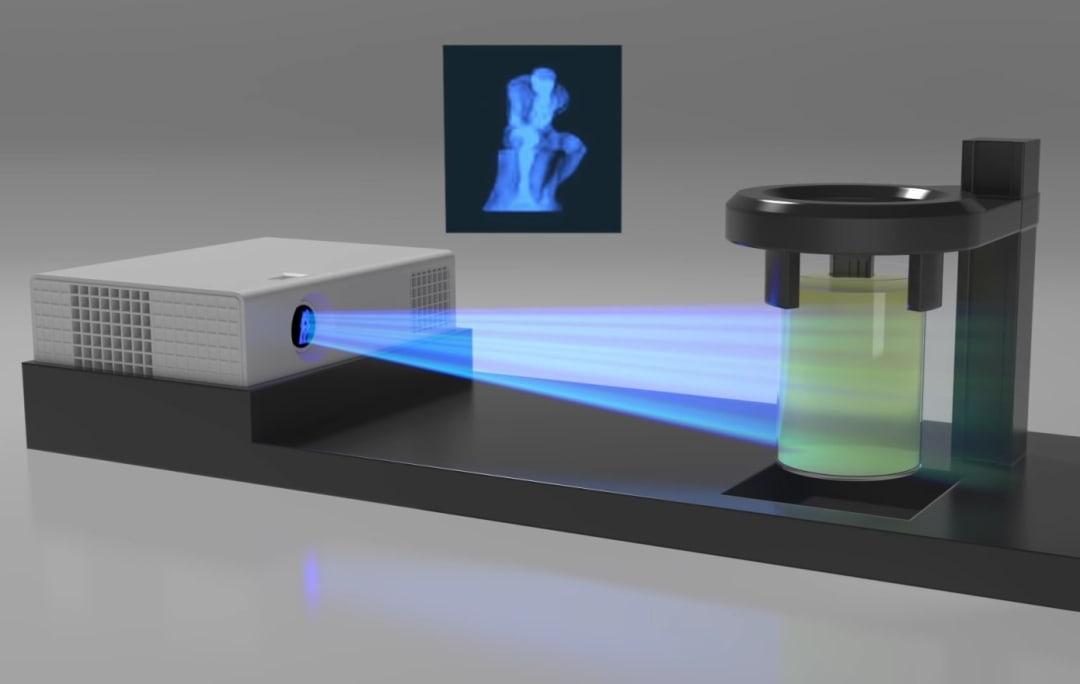

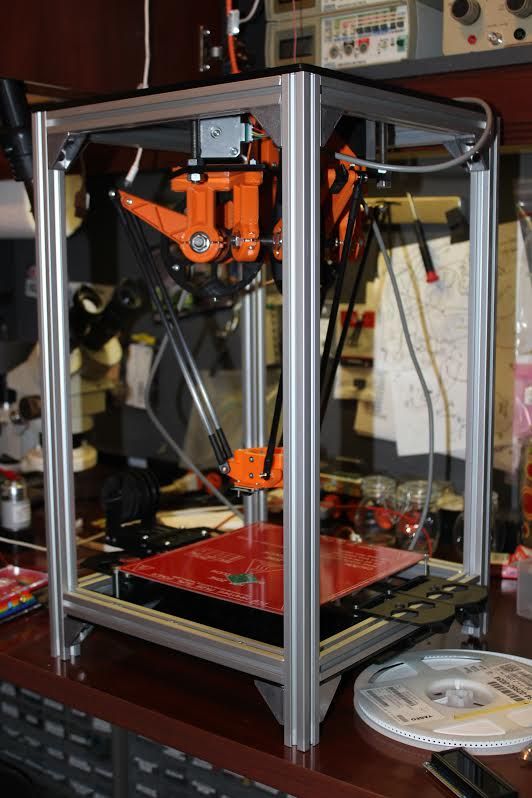

A relatively new foray into the realm of 3D printing is a CoreXY 3D printer. It uses the Cartesian motion system but comprises belts in which the two separate motors rotate in the same direction.

These motors on the X and Y-axis are kept unchanging and constant so the moving printhead doesn’t become too heavy.

CoreXY 3D printers are mostly cube-shaped while the belt and pulley system incorporated in them distinguishes them from other printers in terms of length.

Moreover, the build platform has its movement in the vertical Z-axis atypically and the printhead does the magic in X and Y-axis.

What can concern you about a CoreXY 3D printer is its unanticipated advantages over other FDM printers.

For starters, the stepper motor that amounts to all the weight on the moving part is fixed, and the tool head is exempt from any attachments. This makes a CoreXY 3D printer print at unbelievable speeds while catering to quality in every possible way.

There’s no worrying about recurrent printing mishaps like ghosting and ringing as well.

Therefore, this supersized stability is what keeps CoreXY 3D printers at a top-notch level. Adding to their pros is the compatibility with almost every popular firmware and great quality print results.

Beware though, a printer of such category requires you to be exorbitantly careful about its assembly.

This mainly involves two facets – frame assembly and appropriate belt alignment. When your printer’s frame is off point, the dimensional accuracy of your prints is bound to suffer radically.

This is followed by a boatload of issues arising from wrongful belt alignment and cheap counterparts that stop working halfway.

All in all, a CoreXY 3D printer measures to be a breath of fresh air for many enthusiasts and professionals out there. It may set you back a bit higher compared to other printers, but at the end of the day, it lives up to the expectations.

To sum it up, these printers are a great alternative for Delta and Cartesian-style ones and pose a promising future.

Advantages and disadvantages of delta 3D printers

Among the various designs of 3D printers, the delta system is considered the most successful. Its kinematics has a number of advantages over classical 3D printers with a Cartesian coordinate system. In addition, delta printers look interesting, and the process of their work is simply mesmerizing.

Cartesian 3D Printer Problems and Delta Dominance

80% of all printers are Cartesian. Their axes of movement are independent of each other. Each is responsible only for its own displacement vector, miscalculations for one axis cannot affect the movement of others in any way.

Their axes of movement are independent of each other. Each is responsible only for its own displacement vector, miscalculations for one axis cannot affect the movement of others in any way.

The problem with Cartesian printers is that it takes too long to travel from point A to point B. It takes a long time for the system to accelerate and decelerate before the print head reaches its position. As a result, the printing of one part, instead of two hours, can drag on for four.

Of course, you can increase the movement speed, reduce the acceleration and deceleration times by accelerating the stepper motors to higher speeds and adjusting the settings in the firmware. But electronics may not be able to cope with the task, and besides, no one has canceled physics: the parts of the head are too heavy to be accelerated or slowed down at high speeds in time, and therefore the head simply cannot accelerate sharply or stop in time. Engines will have skipping steps, which will inevitably lead to displacement of the layers of the part.

Delta printers do not have this problem at all. At a low engine speed, the head moves as quickly as possible due to the unique system of rods. With this design, the printer prints at ultra-fast speeds while using far less effort to move the print head.

Pitfalls of delta printers

The movement axes of a delta 3D printer are dependent on each other. A small change in one axis will move the print head in all three directions. To move the head at least in one direction, you need to make calculations using a complex formula, which must take into account the entire design of the printer, the working surface, the length of the rods, the dimensions of the device itself and the backlash.

If you decide to build your own delta 3D printer, get ready for the fact that the calibration will take weeks. The disadvantage is precisely in the setting, since the slightest backlash or deviation in the geometry of the structure will cause serious distortion of the part when printed.

Another drawback of the delta is its height dimensions. In addition to the selected area for printing, part of the printer's volume is needed to move the head itself.

A few words about the electronics of the Delta 3D printer

Since the delta printer uses complex formulas, you will have to worry about a good controller when building it. For such a printer, it is desirable to have a 32-bit board. If you take the usual 8-bit, you may have problems moving over long distances. Computation resources will be sorely lacking, and the head will move not along a straight line, but along an arcuate path. In addition, it is worth worrying about the exact calibration of the delta 3D printer - we already talked about how to do it earlier.

Despite all the shortcomings, the delta design is considered the most successful. If you make the geometry correctly, minimize backlash and install good electronics, you will enjoy your homemade printer for a very long time.

Delta printer

Reviews

FLSUN 3D Metal Frame Kossel Delta Kit Anycubic Kossel linear plus FLSUN 3D Metal Frame Large Print Area 3D Printer

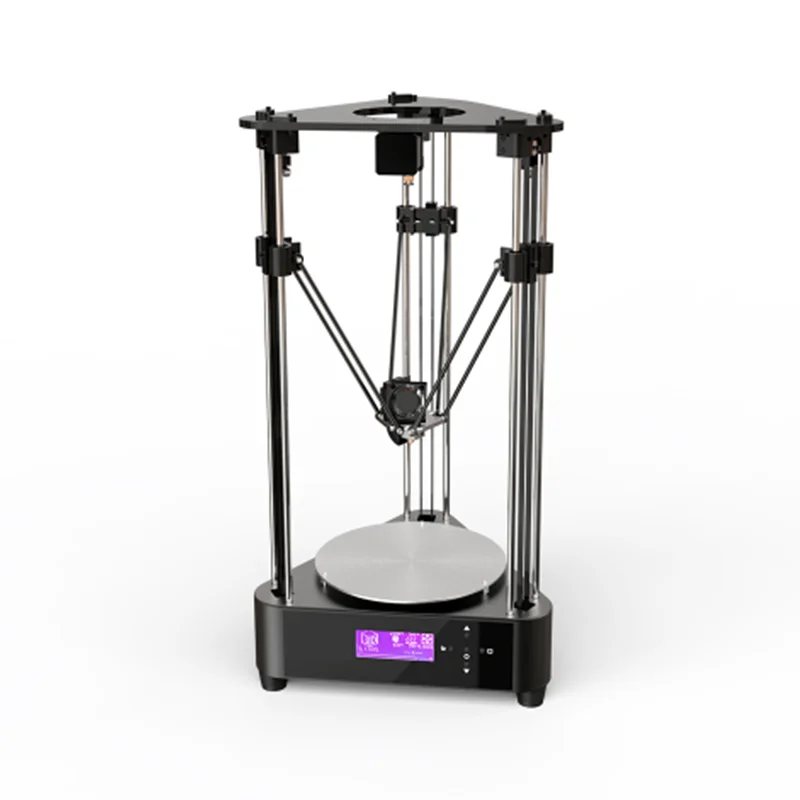

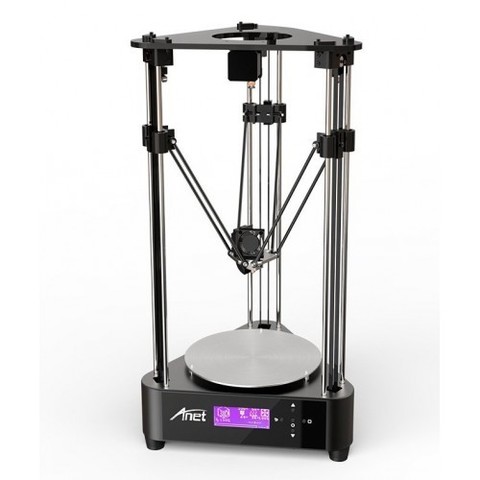

The Delta printer is a 3D printer with Cartesian kinematics (Delta - kinematics) operating in the XYZ coordinate system. They differ from counterparts with other types of kinematics, higher printing speed, a fixed platform, which avoids “wobble” and the likelihood of distortion, and a large print height along the Z axis due to the vertical arrangement of the rails.

The very popular Anycubic Kossel and Anycubic Prediator on the Russian market were discontinued and Anikubik did not offer any alternative. But to the delight of fans of fast and beautiful 3D printing, a young and successfully developing Chinese company FLSUN from Shenzhen City and introduced the line of Delta 3D printers to the market. In the sale of the 3DSN store there are models from a warehouse in Russia and on order, wholesale lots.

- Budget delta printer - 3D printer Flsun Q5 Delta (Kossel)

Compact budget Delta 3D printer with a modular structure. It has simple assembly, maintenance and convenient operation.

Ø 200 x 200 mm model building area

Automatic alignment

32-bit motherboard with TMC2208 drivers

High-speed 3D printing up to 120mm/s.

- Flsun QQ S PRO 3D Printer Delta Kossel

The FLSUN QQ S PRO 3D Printer (Delta Kossel) is an affordable delta 3D printer offering a fairly large build volume of 255 x 365mm diameter and easy to using features such as automatic bed leveling and the ability to remotely control the printer via a Wi-Fi connection.

working chamber Ø 255x365 mm

Operating temperature of the nozzle - up to 270 ℃

The temperature of the heating table - up to 110 ℃

Automatic leveling

SUMM SUILLY: BOUDENE 9000,9000 DIAMEMEN mm

Nozzle diameter: 0. 4 mm

4 mm

Interface: SD card, Wi-Fi, USB

Size: 286x348x780 mm

Weight: 13 kg

- SR 9005

Delta printer with print area Ø260 x 330 mm. Equipped with linear rail guides. Glass coated with a special layer for better adhesion.

Construction material: aluminum alloy 6063

Nozzle temperature: ≤ 240℃

Table temperature: ≤ 100℃

Leveling type: automatic

Motherboard: 32bit

-10mm Print speed:mm from

Maximum idle speed: 300 mm/s

Extruder cooling: double fan

Print size: 260x330 mm

Printer size: 440x390x960 mm

Package size: 88x42x20.5 cm

Weight: 16.5 kg More interesting articles

eleven

Subscribe to the author

Subscribe

Don't want to

Here I will try to make a review not about the printer out of the box and first impressions, but about what is interesting .