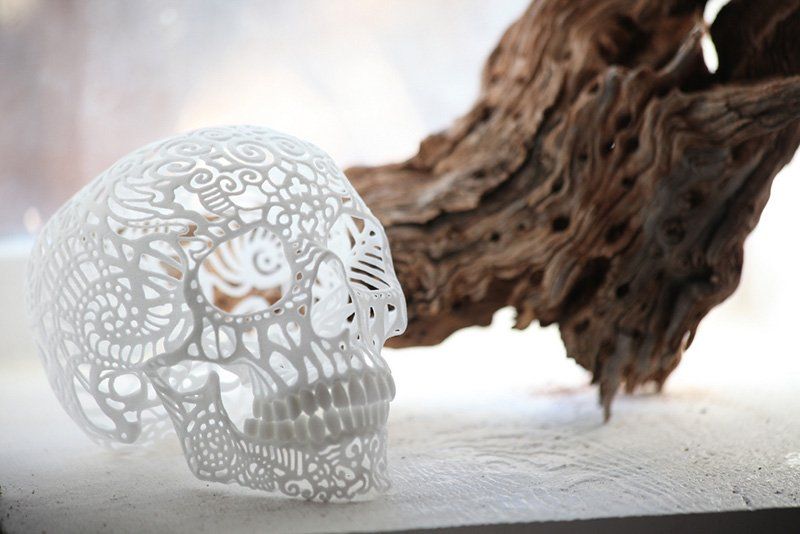

Scanning object for 3d printing

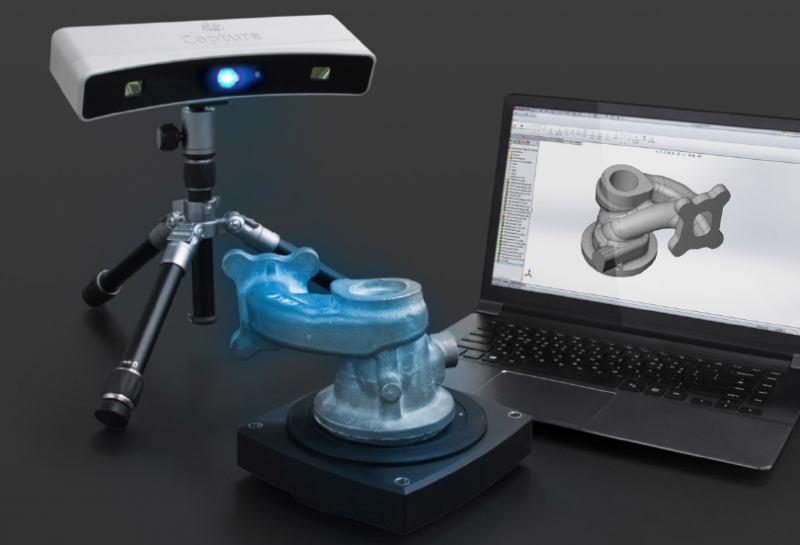

How to Use 3D Scanning and 3D Printing for Reverse Engineering

Reverse engineering is a powerful way to create digital designs from a physical part, and can be a valuable tool in your prototyping toolkit alongside technologies like 3D scanning and 3D printing.

3D scanners measure complex objects very quickly, and can speed up your design workflow tremendously when real-life references are involved. With the ability to capture and modify physical shapes, you can design 3D printed parts that fit perfectly on existing products of all kinds. 3D printed jigs allow you to repeatedly locate a drill or saw, or assemble parts precisely with adhesive. Create close-fitting, reusable masks for sandblasting, painting, or etching.

In this post, we’ll walk through the step-by-step reverse engineering process for an aftermarket digital gauge and explain how to scan a part for 3D printing, with tips along the way for using the right reverse engineering tools, from CAD software to to 3D scanners and 3D printers.

For a full breakdown of 3D scanning workflows and technologies, download our white paper.

Download the White Paper

Looking for a 3D scanner for your 3D printer? Read our detailed guide on choosing the best 3D scanner to use with your 3D printer.

One of the biggest challenges people encounter when converting physical objects to digital is a major incompatibility between two different types of 3D models: meshes and solids.

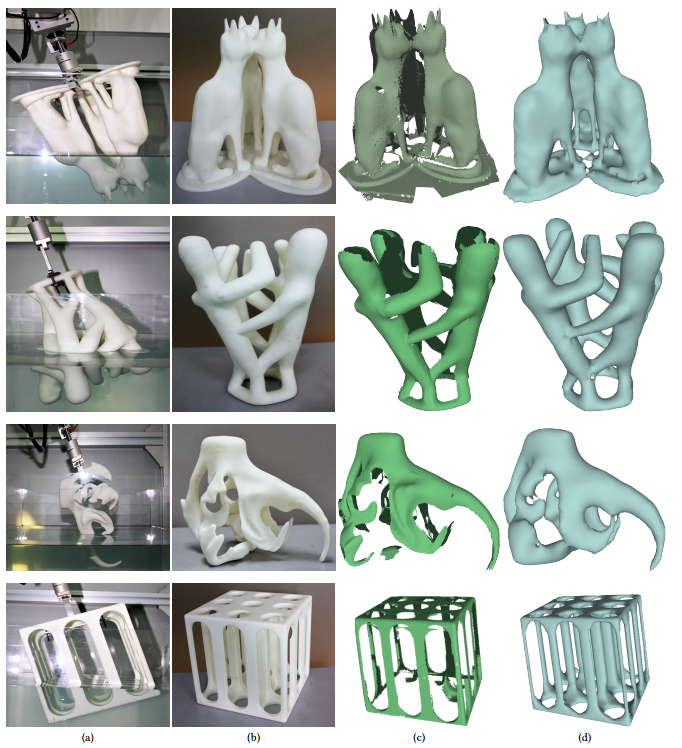

A 3D scanner outputs a mesh, rather than a constructive “solid” model. Meshes need to be reverse engineered to be made editable.

Meshes are the main output of all 3D scanners, and the format commonly understood by 3D printers (STLs). A mesh represents the surface of a shape with a large number of triangles, connected edge to edge. Mesh models don’t contain any information about the object, besides the position of the triangles that define the shape.

On the other hand, engineers are trained to work with solid models. Solid models hold information about how an object is designed, and this information is explicitly encoded into the model as features in a ‘stack’ of logical steps. In solid CAD, it’s possible to change the dimensions for a single feature, and the rest of the model will update to accommodate the change.

Solid models hold information about how an object is designed, and this information is explicitly encoded into the model as features in a ‘stack’ of logical steps. In solid CAD, it’s possible to change the dimensions for a single feature, and the rest of the model will update to accommodate the change.

Since meshes lack information about the construction of the object, the ways you can alter a mesh model are limited—CAD software like Solidworks and Onshape can’t directly modify meshes. If you need to make major modifications to the underlying design of a scanned part, the mesh needs to be converted to a solid CAD drawing: this process is reverse engineering.

Reverse engineering is important when you want to create new parts that reference or incorporate older designs, where the original CAD design isn’t accessible.

For example, you can create replacement parts that match the original design of damaged existing pieces, or use reverse engineering processes to integrate complex surfaces from existing objects into 3D printable jigs, which are useful when modifying mass manufactured and handcrafted products.

To demonstrate the basic steps in a reverse engineering workflow, let's take a look at the process for creating an assembly jig for an aftermarket digital gauge that fits onto the air vent of a Volkswagen Golf.

Spray coat the object with a temporary matte powder to improve scan accuracy. Even slightly glossy surfaces tend to degrade scan quality, while reflective and transparent surfaces cannot be scanned at all without a matte coating.

Use a temporary matte powder to improve the scan accuracy of your object.

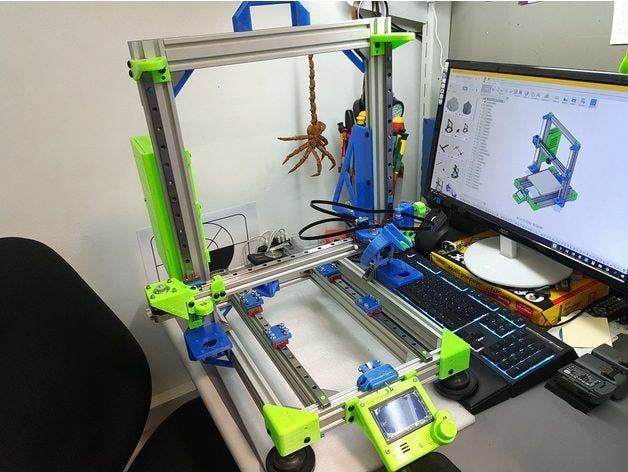

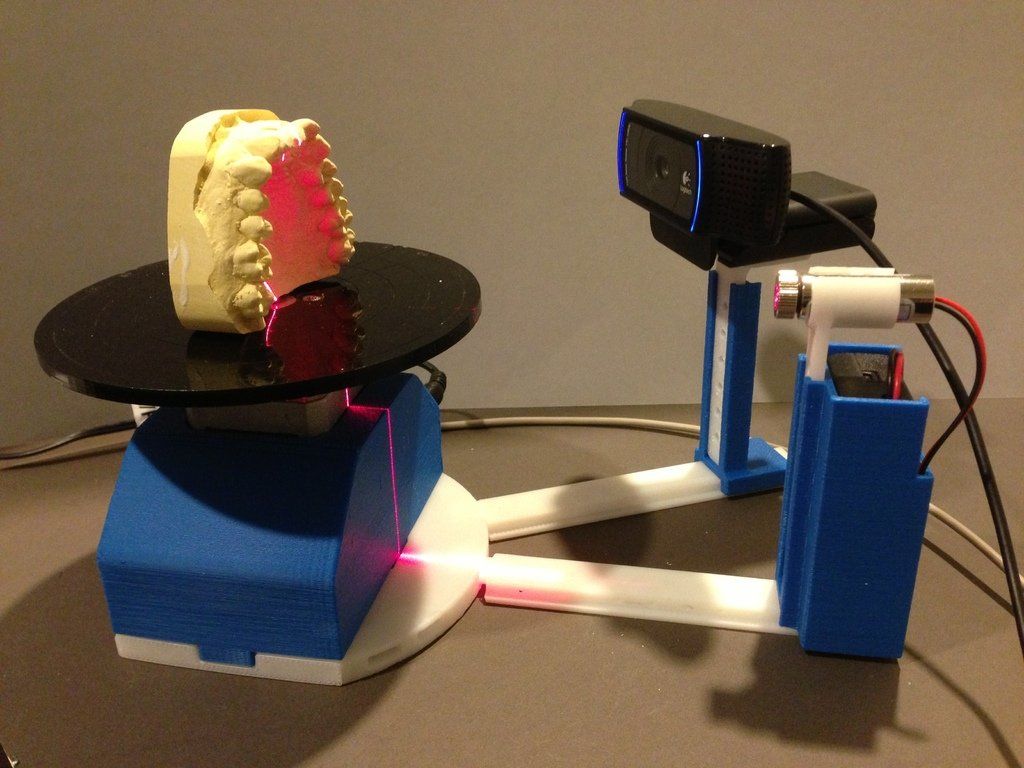

Use a high accuracy 3D scanner to capture the important sections of the part. Tabletop structure light or laser scanners are the right tools for the job, with accuracy of ±100 or better.

Learn more about how to choose the right 3D scanner for your application in our 3D scanning white paper:

Note: You may need to orient and re-scan your object several times if the object has deep recesses.

Some scanners produce extremely large mesh files, which will make later steps grind to a halt.

Scanner software repairs small gaps and simplifies the scan, making the data more manageable in CAD. Try to reduce the model as much as possible without destroying important details.

Tip: If you need more control, Meshmixer is a great choice for refining scanned meshes.

Import the mesh into CAD software equipped with reverse engineering tools. Geomagic for Solidworks is a powerful choice for resurfacing complex, organic shapes.

If you are reverse engineering a part with simpler flat surfaces, Xtract3D is a less expensive, lightweight alternative.

In this step, move and rotate the scan mesh into alignment with any existing design components.

Tip: Make drawing easier by rotating and aligning your scan to face the orthographic view directions.

There are three paths to extract the shape of the scan in order to create a solid model that is editable with CAD tools: semi-automatic surfacing, automatic surfacing, and manual redrawing.

Semi-automatic surfacing

Complex curved surfaces are difficult to manually draw, so you may choose to use semi-automatic surfacing. This function generates surfaces that fit to detected regions of the scan. By varying the sensitivity of the surface detection function, different surfaces will be found.

Tip: Geomagic for Solidworks detects surfaces on the scan to fit 3D curves. Use a “brush” to manually add or subtract areas on the scan from each region.

You may need to repeat this process several times with different sensitivity settings to detect all your surfaces. These surfaces can then be trimmed and knit together to create an editable solid.

Use semi-automatic surfacing to re-create curved shapes when you want maximum editability later on, and when sharp edge accuracy is important.

The re-surfaced result, after trimming.

Automatic surfacing generates a solid model from any watertight scan. You can use standard CAD tools to subtract and add to this auto-surfaced body, but it will be more difficult to move basic features around on the body itself.

You may not need control over edge placement. For example, if you are scanning a part of the human body to create custom ergonomically-shaped products, or want to create a jig to precisely or repeatably modify a handmade object. In these cases, automatic surfacing is a great way to save modeling time.

Note: Compare the results of a automatic surfacing to semi-automatic surfacing: some accuracy is lost, especially around sharp edges.

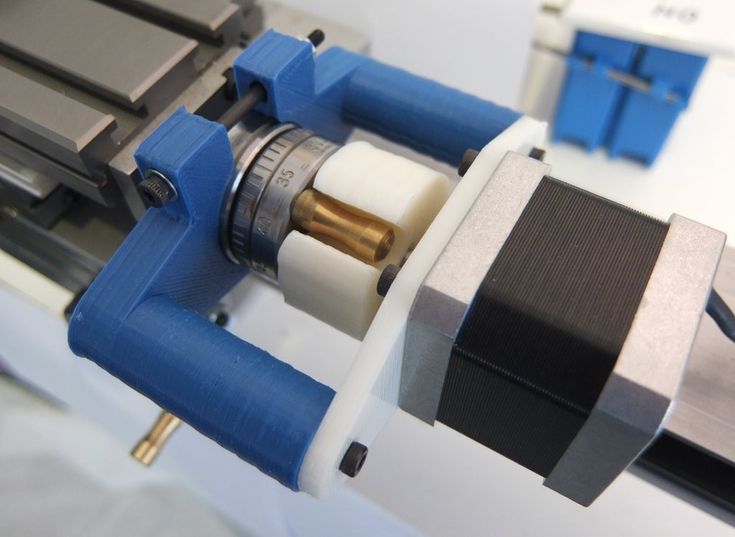

For simple features such as bosses, holes, and pockets, it’s usually fastest and most accurate to redraw the features using the scan model as a reference. Reverse engineering software allows you to create sketch planes aligned with flat surfaces on the scan and to extract cross sections from the scan mesh, which helps you match the shape of the original object.

Once the scan has been converted to a solid, it can be subtracted from another solid body to create a jig that securely holds the original part.

The design of the new gauge component also references the dimensions of the scan, using curves extracted with semi-automatic surfacing.

Printing the jig on a Formlabs stereolithography (SLA) 3D printer gives you a high degree of accuracy comparable to the output of engineering-grade 3D scanners. Use Formlabs Rigid 4000 Resin for its strength and precision.

Once these steps are complete, the 3D printed jig is ready to use to assemble the new gauge onto the OEM air vent.

The final 3D printed assembly jig, printed in Rigid 4000 Resin.

How to Scan 3D Objects for 3D Printing – 3D Printerly

3D scanning objects for 3D printing can be tricky to get the hang of, but once you learn the right software and tips to follow, you can create some pretty cool models. This article will give you some good insights into scanning objects to create 3D prints.

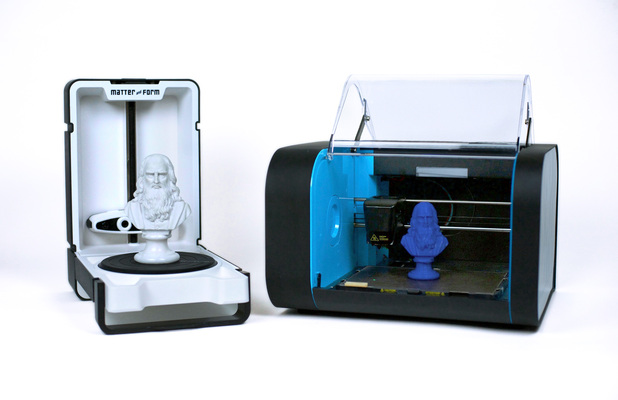

To 3D scan 3D objects for 3D printing, you either want to get a 3D scanner or use your phone/camera to take several pictures around the object and stitch them together using photogrammetry to create a 3D scan. Make sure you have good lighting while scanning to get the best results.

Make sure you have good lighting while scanning to get the best results.

Keep on reading for more information and tips to 3D scan objects for 3D printing.

Can I Scan an Object to 3D Print?

Yes, you can scan an object to 3D print using various scanning methods. One example of this is by a grad student who 3D scanned and 3D printed a Shuvosaurid Skeleton for a museum exhibit. It’s an ancient crocodile-like creature that he 3D scanned using a premium professional scanner called the Artec Spider.

It’s currently priced at around $25,000 but you can get much cheaper 3D scanners, or use free options such as photogrammetry which is creating 3D scans through taking several pictures.

He mentioned an open access repository called MorphoSource which is a collection of several 3D scans of animals and skeletons.

This student further revealed that he then used a visualization software called AVIZO to prepare STLs for the surface of each scan, after which he 3D printed it.

When it comes to more standard objects that you might have around the house, or even with cars parts, it’s definitely possible to 3D scan and 3D print them. People have been doing it for many years successfully.

I also came across a user who scanned and printed his friend’s farm with the help of a drone. Not only was it a significant success, but it had a fantastic architectural look.

I scanned and 3d printed a friends farm using a drone and my new 3d printer. from 3Dprinting

He started by generating a mesh model after mapping using Pix4D and then processed it afterward using Meshmixer. The Pix4D was costly, but there are free alternatives such as Meshroom that you can use if you can’t bear the cost.

It took around 200 photos and in terms of the scaled dimensions and detail from the drone, it works out to be around 3cm per pixel. The resolution mainly depends on the drone’s camera and height of flight.

3D scanning is not only limited to what you interact with daily, but as seen on NASA’s 3D scan page, many types of objects can also be 3D scanned.

You can see more about this on the NASA page of printable 3D scans and see several 3D scans of space-related objects like craters, satellites, rockets, and more.

How to Scan 3D Objects for 3D Printing

There are a few methods on how to scan 3D models for 3D printing:

- Using an Android or iPhone App

- Photogrammetry

- Paper Scanner

Using an Android or iPhone App

From what I have gathered, it’s possible to scan 3D objects straight from the apps you have installed on your device. This is possible because most newly manufactured phones have LiDAR (light detection and ranging) by default.

In addition, some apps are free, and others require paying for them first before using them. See below a brief explanation of some of the apps.

1. Polycam App

The Polycam app is a popular 3D scanning app that works with Apple products like the iPhone or the iPad. It currently has an app rating of 4.8/5.0 with over 8,000 ratings at time of writing.

It’s described as the leading 3D capture application for the iPhone and iPad. You can create plenty of high quality 3D models from photos, as well as quickly generate scans of spaces using the LiDAR sensor.

It also gives you the ability to edit your 3D scans directly from your device, as well as export them in many file formats. You can then share your 3D scans with other people, as well as the Polycam community using Polycam Web.

Check out the video below to see how a Polycam user scans a large rock and captures plenty of detail.

The lighting is a very important factor when it comes to 3D scanning, so consider that when you are scanning your objects. The best type of light is indirect light like shade, but not direct sunlight.

You can check out Polycam’s Official website or the Polycam App page.

2. Trnio App

The Trnio app is a great method of 3D scanning objects for 3D printing. Many people have created some stunning 3D prints using existing objects, then scaling them as they desire to create new pieces.

One great example of this is the video below by Andrew Sink who 3D scanned some Halloween decorations and made it into a pendant for a necklace. He also used Meshmixer to help achieve this result.

Previous versions of the app weren’t the best, but they have done some useful updates to scan objects faster and easier. You no longer have to tap during scanning, and the app automatically records and compiles the video frames.

This is a premium app so you’ll have to pay to download it, currently priced at $4.99 at time of writing.

You can check out the Trnio App page or the Trnio Official website.

Photogrammetry

Photogrammetry is an effective method of 3D scanning objects, used as a basis for many apps. You can use raw photos directly from your phone and import than into a specialized software to create a 3D digital image.

It’s a free method and has some impressive accuracy. Check out the video below by Josef Prusa showing off 3D scanning from just a phone with the photogrammetry technique.

1. Use Camera – Phone/GoPro Camera

Someone had posted how he scanned a broken stone and then printed it, and it came out perfectly. GoPro camera assisted him in achieving this. He also used COLMAP, Prusa MK3S, and Meshlab, and he reiterated how important lighting is.

GoPro camera assisted him in achieving this. He also used COLMAP, Prusa MK3S, and Meshlab, and he reiterated how important lighting is.

Uniform lighting is the key to success with COLMAP, and outdoor during an overcast day gives the best results. Check out the video below for a useful COLMAP tutorial.

He also mentioned that it is difficult to deal with shiny objects.

He actually used a video clip as the scan source and exported 95 frames, then used them in COLMAP to create a 3D model.

He also mentions that he did some tests with Meshroom in terms of getting good scans with bad lighting and it does a better job at handling unevenly lit objects.

You have to handle the GoPro camera carefully because you may get a distorted image if you do not take care of the wide-angle. Follow the link to get a detailed explanation.

Follow the link to get a detailed explanation.

2. Professional Handheld Scanner – Thunk3D Fisher

There are many professional handheld scanners out there with varying levels of resolution, but for this example, we’ll look at the Thunk3D Fisher.

Even though the scanner takes detailed pictures and is specialized, it still falls under photogrammetry. One 3D user wrote about how through 3D scanning and printing, he managed to come up with Mazda B1600 front headlights.

3d scanning and 3d printing a perfect match, we recreated a front headlight for a Mazda B1600. Car owner only had right side, scanned and flipped it fits the left side. Printed in generic resin and post processed with epoxy and painted black. from 3Dprinting

The car owner only scanned the right side using a handheld Thunk3D Fisher scanner then flipped it to fit on the left side.

This scanner gives accurate scans and it is said to be ideal for scanning large objects. It is also perfect for objects that have intricate details. It uses a structured light technology.

It is also perfect for objects that have intricate details. It uses a structured light technology.

The good thing with this scanner is that it scans objects ranging from 5-500 cm in high resolution and 2-4 cm in low resolution. It has free software that is frequently updated. The exciting bit is that the Thunk3D Fisher Scanner has additional software for Archer and Fisher 3D scanners.

3. Raspberry Pi-Based OpenScan Mini

I came across a piece on how someone had used a Raspberry Pi-based scanner to scan a 3D printed rook. It was 3D scanned using a combination of the Raspberry Pi based OpenScan Mini, along with an Arducam 16mp camera with autofocus. They mentioned that the increase in detail was significant.

The camera resolution for these types of scans is very important, but proper lighting along with surface preparation may even be more important. Even if you had a bad quality camera, if you have good lighting and a surface with rich features, you can still get pretty good results.

3D scanning this 3D printed rook showing some incredible details – printed at 50mm height and scanned with the Raspberry Pi based OpenScan Mini (link&details in comment) from 3Dprinting

He went ahead to reveal that if you want to use this scanner, you should be well aware of how it depends on the Pi camera. You can expect excellent results when using the two together.

Using a Paper Scanner

It’s not the usual method but you can actually 3D scan using a paper scanner. A great example of this in action is with CHEP who experienced a broken clip, then went on to glue the pieces together to then 3D scan it on a paper scanner.

You then take the PNG file and convert it to an SVG file.

Once you’re through with the conversion, you can download it to your chosen CAD program. Then, after a few processes, you can convert it into an STL file before taking it to Cura for slicing as you prepare to 3D print it.

Check out the video for a visual tutorial on getting this done.

How Much Does it Cost to 3D Scan an Object?

A 3D scanning service can cost anywhere from $50-$800+ depending on various factors such as size of the object, level of detail the object has, where the object is located and so on. You can 3D scan your own objects for free using photogrammetry and free software. A basic 3D scanner costs around $300.

There are even options to rent your own professional scanner so you can get a really high quality scan for several objects.

Many phone 3D scanning apps are free as well. When it comes to professional 3D scanners, these can cost around $50 for a DIY kit, upwards of $500+ for low range scanners.

3D scanners can definitely get pricey when you are looking for high specs, like the Artec Eva for around $15,000.

You should also be able to find 3D scanning services in your local area through searching on places like Google, and these costs will vary. Something like ExactMetrology in the US and Superscan3D in the UK are some popular 3D scanning services.

Superscan3D determine the different factors for the cost of 3D scanning being:

- Size of the object to be 3D scanned

- Level of detail the object has or complex curves/crevices

- Type of material to be scanned

- Where the object is located

- Levels of post-processing required to get the model ready for its application

Check out this article from Artec 3D for a more detailed explanation of 3D scanner costs.

Can You 3D Scan an Object for Free?

Yes, you can successfully 3D scan an object for free using various software 3D scanning apps, as well as photogrammetry which is using a series of photos of your desired model and a specialized software to create a 3D model. These methods can definitely create high quality 3D scans that can be 3D printed for free.

These methods can definitely create high quality 3D scans that can be 3D printed for free.

Check out the video below for a visual explanation of how to 3D scan with Meshroom for free.

Turning a 3D scan or photos to an STL file can be done using software like this. They usually have an export option to turn the series or photos or scans into an STL file that can be 3D printed. It’s a great method to make 3D scans printable.

3D scanning of objects - accuracy and quality of 3D models

3D scanning of objects

One of the components of 3D technologies is the 3D scanning technique, which allows you to quickly and easily obtain a digital model of the desired product. In short, 3D object scanning is the process of transforming the physical form of a real object into a digital form. This preserves the texture and even the color of the original sample. Thus, a 3D model of the required product can be obtained without any extra effort. 3D scanning of objects helps to prepare the necessary model for 3D printing and in some cases can play a decisive role in building a digital product.

This preserves the texture and even the color of the original sample. Thus, a 3D model of the required product can be obtained without any extra effort. 3D scanning of objects helps to prepare the necessary model for 3D printing and in some cases can play a decisive role in building a digital product.

The key device in the process of 3D scanning is a 3D scanner - a device that reads the physical parameters of objects and creates a 3D model based on them.

3D scanning of objects can be useful in the design of any complex elements, 3D modeling of which manually is extremely laborious. In particular, 3D scanning is useful for modeling various fixtures, components, main and spare parts. Often it is used in the absence of drawings and other documentation for the product, as well as when it is necessary to convert figured surfaces into a digital form, including art forms and casts.

3D scanning process

The 3D scanning process generally resembles a human three-dimensional vision system. The process of obtaining data with a 3D scanner resembles the formation of a three-dimensional image seen in the human brain. To do this, the 3D scanner compares two images that are offset from each other. The required accuracy of building a 3D model is achieved through the use of additional technological methods, for example, a periodic flash or laser illumination.

The process of obtaining data with a 3D scanner resembles the formation of a three-dimensional image seen in the human brain. To do this, the 3D scanner compares two images that are offset from each other. The required accuracy of building a 3D model is achieved through the use of additional technological methods, for example, a periodic flash or laser illumination.

As for scanning accuracy, it depends both on the specific device and on the characteristics of the original product. It is possible to carry out 3D scanning of objects from 1 cm (with all the details), the maximum dimensions are not limited. To achieve the best detail, upon completion of the 3D scanning process, the 3D model is subjected to additional refinement by a specialist. Thus, thanks to 3D scanning of objects, digital models are almost flawless. Error for 3D scanning of objects with a surface area of 100 cm 2 is 1 mm and can be eliminated with subsequent refinement. 3D scanning of large objects can be implemented by batch processing of object photos from all sides.

Other questions and answers about 3D printers and 3D printing:

- Basics What is 3D printing?

- Basics What is a 3D model?

3D scanning methods

For a better understanding of the technology, it would not hurt to list the existing 3D scanning methods. There are two of them: contact and non-contact. The first one requires direct contact of the 3D scanner with the object. The non-contact method divides peripherals into two types:

- Active 3D scanners that emit a beam of directed waves onto an object and record their reflection. Possible types of radiation include x-rays, ultrasound, and light;

- Passive 3D scanners that capture ambient radiation reflected from an object, most often light.

All 3D scanning methods have their advantages and disadvantages, which affect the cost of 3D scanners, the speed and accuracy of scanning, as well as the range of objects available for scanning. When buying your own 3D scanner, it is recommended to study this issue in more detail, but it is better to get high-quality advice from professionals. The 3DDevice team is ready to help you with this and recommend the best 3D scanner model.

When buying your own 3D scanner, it is recommended to study this issue in more detail, but it is better to get high-quality advice from professionals. The 3DDevice team is ready to help you with this and recommend the best 3D scanner model.

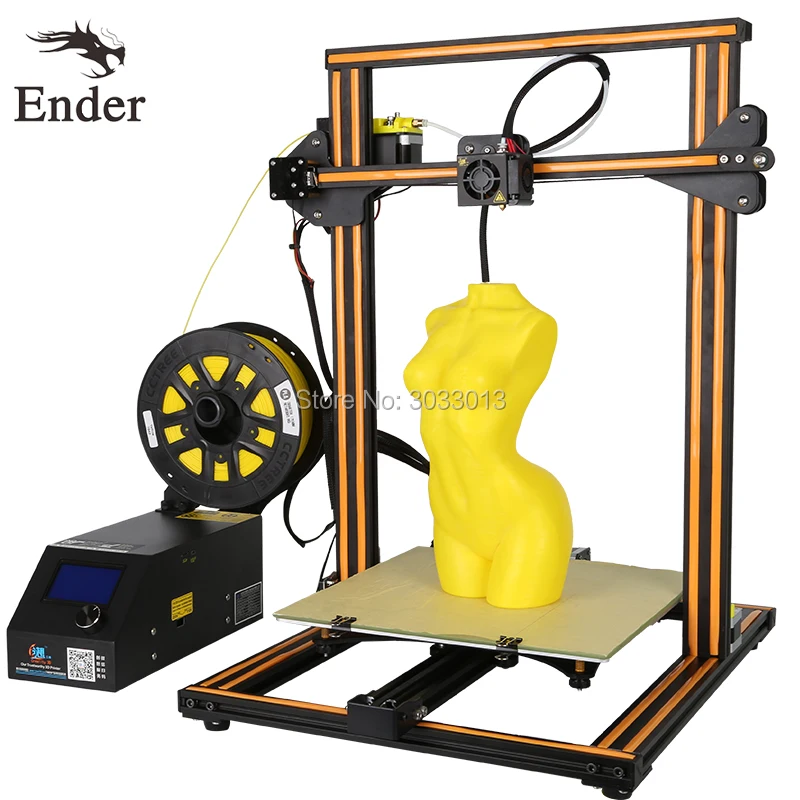

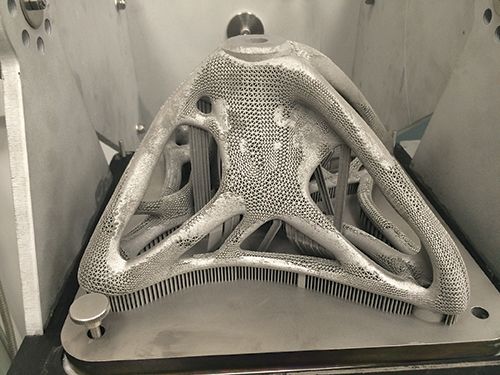

3D scanning and 3D printing

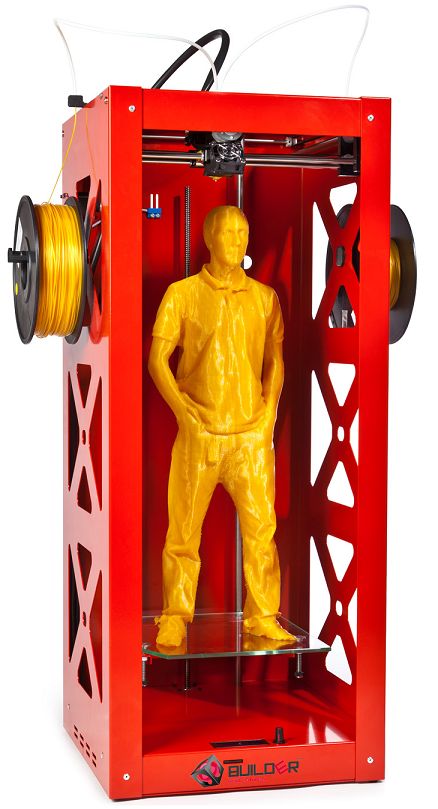

3D scanning and 3D printing complement each other, since the scanned 3D models are most often used for subsequent reproduction on a 3D printer. At the moment, 3D scanning is used for a variety of purposes and industries. Using a 3D scanner, 3D models of real people are created, which can then be reproduced through full-color 3D plaster printing. A more promising use of 3D scanning is in medicine, where it is used to create ultra-precise surgical models and implants. You can read more about our contribution to this branch of medicine here. Also interesting is the direction of using technology in the production of individual footwear and clothing.

In general, the possibilities of using 3D scanning of objects are quite enough. We hope we were able to explain in detail the essence of the technique. If you have additional questions that we have not covered, write to us by e-mail and we, if necessary, will add your questions! Best regards, 3DDevice team.

We hope we were able to explain in detail the essence of the technique. If you have additional questions that we have not covered, write to us by e-mail and we, if necessary, will add your questions! Best regards, 3DDevice team.

Our company also separately provides a 3D scanning service for objects of any size. For all questions, please contact us in any way convenient for you. Contacts are listed here. We look forward to collaborating!

Back to main page

3D scanning of any objects throughout Russia: high quality and fast

We offer services of professional 3D scanning of any objects at a favorable price. The price calculation is formed after determining the scope of work and is compiled individually for each project.

How the price is formed

The result of the work is a 3D model of the object in .stl or .RCP format. The data error can vary from 0.008 mm to 0.3 mm depending on the type of scanner.

Work examples

We work in Moscow and St. Petersburg, in all cities of Russia, as well as in the CIS countries.

Petersburg, in all cities of Russia, as well as in the CIS countries.

If you need to order a 3D scan, you can email us at [email protected], call +7(495)223-01-21 or leave an online request.

3d scanning is the process of creating a three-dimensional copy of a real object, or digitizing it, using a special device - a 3D scanner. Today, there are many ways and settings for creating a digital model of objects.

3D scanners make it easy to 3D scan even the smallest details from a wide variety of materials.

Basic scanning methods

There are currently two main 3D scanning methods: contact and non-contact.

Non-contact 3D scanners can scan both small and large objects such as buildings or monuments. They are divided into photogrammetric, laser and 3D devices using structured white light technology. The non-contact 3D scanning method involves the use of laser and light beams, allowing you to scan fragile objects without damaging them.

Applications

3d scanning is popular in a wide range of industries due to its versatility and simplicity. Key industries that use 3D scanning include:

Key industries that use 3D scanning include:

- mechanical engineering, fabrication of complex structures and parts

- aviation, space industry, ship and automotive industry

- medicine and dentistry

- construction and architecture

- defense industry

- science and education

- jewellery, etc.

A variety of 3D scanners allows manufacturers to choose exactly the device that is fully suitable for the purpose and size of the production tasks. Some 3D scanners are designed to digitize only small objects, while others are suitable for measuring buildings, structures and building structures.

Benefits of 3D scanning

Key benefits of 3D scanning include:

- The easiest way to create 3D copies of a physical object

- High measuring speed

- High-precision originality and reproduction of the smallest details of the product

- Ability to transfer and save data not only about the shape and size of an object, but also about its texture and color

- Significant savings in time, physical and material resources

3D scanning: price

The calculation of the price for 3D scanning is formed after determining the scope of work and is compiled individually for each project.