Using zbrush for 3d printing

3D Print Hub | ZBrush Docs

Pixologic

Step into the future of product development and manufacturing with the awesome power of ZBrush and the 3D Print Hub plugin.

Open up to a world of 3D printing. Extend your design concepts beyond the confines of your computer screen. Pixologic’s ZBrush supports all major 3D printing file formats including STL (stereo lithography), OBJ and VRML. STL files are the standard files used to output your ZTools as physical objects. The VRML file format takes this one step further by providing support for UV’s, textures and PolyPaint, giving you the ability to print in color. In addition to these, you get the versatility of OBJ file support.

Take your digital designs from photo-real, to desktop-real!

Main features

-

- Export in STL, Binary and Ascii.

- Export in VRML.

- Size in Inches and millimeters.

- Export the current or all the SubTools.

3D Print Hub in 5 Steps!

Using this plugin is very easy and can be done by just pressing few buttons!

Before beginning you will need to load a ZTool to export, such as the Demo Soldier.

This Tool must be a PolyMesh 3D. If your model is a Primitive or a ZSphere model, you

need to convert it first.

With your model selected, open the ZPlugin >> 3D Print Hub menu. Let’s start!

- Click the “Update Size Ratios” button to capture the ZTool’s bounding box size.

- A window will appear with several size settings. Choose the one which best fits your model size, scale and units (millimeters or inches).

- Change one of the three sliders to define the size of the object to export. The values here will depend on the units chosen in Step 2.

- In the Export options, choose if you would like to export all SubTools, only the visible SubTools or just the currently selected SubTool.

- Finally, click the file format that you wish to export: OBJ, STL or VRML.

You can also click the appropriate link to open the model in the compatible target application of your choice, like Preform for Formlabs 3D printers.

You can also click the appropriate link to open the model in the compatible target application of your choice, like Preform for Formlabs 3D printers.

It’s done!

Of course, you can modify the different settings and options available in the “Size options” and “Export options” to fit your needs.

Preparing the Model

If you want to have your model printed in 3D, you should check several things prior to using 3D Print Hub. Please be aware of these items in order to avoid complications during the printing process.

Notice

If you know which company will print your model, visit their website or contact them to learn about their restrictions or advice. Some of them have dedicated FAQs or tutorials about their printing processes.

The Exporting Process

The export process is quite easy but needs to be done in separate steps. For most of the basic and simple usage, you only have to modify a very few settings and can ignore the advanced options. Even if you do need to use the advanced options, you will still need to first set or change the basic items.

Even if you do need to use the advanced options, you will still need to first set or change the basic items.

The 3D Print Hub plugin with its tools

1. Updating the size information

To accurately set the size of your model and export it to the correct scale, you must tell ZBrush what the ZTool’s real-world measurements actually are. This is done by updating the size information for your loaded ZTool. This step must be done for each model you will export.

Simply click the Update Size Ratio button to update the size of the loaded ZTool. This action will open a window which will let you choose the scale of your model. It also provides alternatives for the model’s size and your choice of units. ZBrush does not natively work with units. For this reason, even if you have set TransPose Units and are working with accurate proportions, ZBrush doesn’t know whether you are using inches or millimeters.

This dialog box lets you choose between four solutions which mix the unit and the scale in what is basically a 2. 54 ratio between mm and in. By selecting the size which is close to your target size, you will help the plugin to start with the most convenient size values.

54 ratio between mm and in. By selecting the size which is close to your target size, you will help the plugin to start with the most convenient size values.

The computation of the size/scale is based on the advanced options found in the Size Options section. If the option “Use size of the selected SubTool” is enabled, the size of the whole model will be based on the selected SubTool and all the other SubTools will be scaled accordingly. If this option is disabled, the bounding box will be computed from all visible SubTools as if they are a single model. (Hidden SubTools are always excluded.)

Please read the Advanced options section for more information.

2. Set the Unit and Size

In this step, you specify the dimensions of the exported model and whether that size is in inches or millimeters. This value applies to the entire model, including all visible SubTools.

3. File Format and Exporting

When all your basic options have been set (and any advanced option), the last step is to choose the file format you need:

Clicking one of these buttons immediately opens a system dialog box so that you can name your file and specify where it and any corresponding textures will be saved. When the export process is completed, a note will be displayed on-screen to let you know it was successful.

When the export process is completed, a note will be displayed on-screen to let you know it was successful.

4. Exporting to a 3rd party 3D printer

3D Print Hub includes a mechanism for sending the 3D model directly to the printing software provided by certain 3D Printer manufacturers. This functionality will export the model at the set size, automatically opening the target software and loading the file into it.

For most uses, this process makes the 3D printing export process truly seamless.

Preform and Formlabs printers

Preform is the software from Formlabs which manages their 3D printers: Form1, Form1+ and Form2. Using the function Send to Preform will automatically:

-

- Launch Preform

- Fix your model’s topology if needed

- Launch the one click print functionality

Of course, you can override the one click functionality and take the full control of the printing process.

To learn more about Formlabs and Preform, visit their website.

5. STL import

3D Print Hub can import the STL file format, which is commonly used by 3D scanners. This allows you to import your scan data for use in ZBrush, as well as loading your STL files back into ZBrush.

When clicking on the STL Import button, a system dialog box will open so that you can browse your hard drive and select the desired STL file. ZBrush will then import the model. If another 3D object is currently in Edit mode, ZBrush will replace that model with your imported model — just like it does with the default Import process.

ZBrush will retain a record of the model size from the imported model, but it has no information about the units used in the software that generated the model. If the model was 10mm width in the original software, it will become 10 “units” in ZBrush.

Advanced Options

3D Print Hub includes several advanced options allowing you to fine tune your imports, size settings and exports. It is strongly advised to look at these settings as in some cases you may need to make use of several of them. For example, if you need to scale a figurine based on the size of its base.

For example, if you need to scale a figurine based on the size of its base.

To display these settings, click the Import, Size and/or Export options buttons. You must modify these settings prior to clicking the desired main action.

1. File Import Options

-

- Skip color: This option will ignore any color information included in the imported STL file. Only a few programs support exporting color as part of an STL file, so this option is enabled by default.

- Weld Threshold: This option will automatically weld all the imported model vertices which are very close to each other in 3D space. The STL format doesn’t have welded polygons, which means that when the file is imported, the vertices must be welded to produce a watertight mesh and clean surfaces.

The default setting will work for the vast majority of imported models but one very rare occasions you may need to increase or decrease the value. - Store Import settings: This option will save a configuration file containing the current Import settings for future uses of the 3D Print Hub plugin.

This is convenient if you always need the same settings for all your 3D model imports.

This is convenient if you always need the same settings for all your 3D model imports.

2. Size Options

-

- Move bounding box axis to origin: Move the origin of the bounding box for the exported 3D object (even if the object is comprised of multiple SubTools) to the 0,0,0 location.

- For all SubTools: All SubTools will be moved to the new Origin location, while retaining their positions relative to each other. This is the default option when using the Move to Origin feature.

- Per SubTool: When enabled, all SubTools will be individually moved to the origin location and scaled to fit the bounding box size.

- Use the size of the selected SubTool: Defines the size of the bounding box based on the currently selected SubTool. All other SubTools will be resized relative to this one. This option is convenient if one item must have an exact predefined size – such as a support object, in which case all other parts need to be resized according to the support.

- Original Size: This option will only work for a model that has been imported into ZBrush. Enabling it instructs ZBrush to use the original dimensions of the model as they were set by the source program. In this case, 3D Print Hub will ignore the size dimensions specified in the basic settings.

- X, Y and Z: Enable one of these to keep the ratio constant based on the specified axis. The sizes for the other two axes will be recalculated.

- Store size settings: This option will save a configuration file containing the current Import settings for future uses of the 3D Print Hub plugin. This is convenient if you always need the same settings for all your 3D model exports.

3. Elements to Export Options

-

- All: When enabled, all the SubTools are exported, including those which have been hidden.

- Visible: When enabled, only the visible SubTools are exported. Non-visible SubTools won’t be exported.

- Selected: When enabled, only the current SubTool is exported.

- Export in separate files: When enabled, each SubTool is exported as a separate file (OBJ, VRML or STL). When disabled, all visible SubTools will be exported as part of a single file.

- Textures: Exports any textures on the SubTools using the Texture Format. (See next section.) Only the VRML and OBJ file formats can export textures.

- PolyPaint: Exports any vertex color painting information (PolyPaint) on the SubTools as part of the saved file. Only the VRML and STL file formats can export vertex painting.

4. Texture Format Options

Image file size can be important with some printers. It is critical to choose a texture file format that will fit your printer’s limitations.

-

- The JPG, PNG and BMP buttons are used to specify the image format which will be used when 3D Print Hub needs to include any textures that are applied to the SubTools.

- JPG provides a destructive compression (data and quality loss) but has a very small file size.

- PNG provides a non-destructive compression. It produces files larger than with JPG but a lot smaller than that of uncompressed formats.

- BMP provides uncompressed images with no quality loss, but produces very large files.

- Quality: This setting is used only when the JPG file format is selected. It specifies the amount of compression. Values under 60 will see significant image degradation.

5. STL Export Options

These options are specific only to the STL file format.

- Binary and Ascii: Save your STL file as a clear text (ASCII) file or in binary format. Binary format results in a smaller file size and is the default setting since almost all printing companies and software can read the binary format.

- Magics and SolidView: These options set the way vertex color information is written within the STL file format. Please check your other 3D packages or with your printing company to determine which file formats they support.

- Store Export settings: This option will save a configuration file containing the current Import settings for future uses of the 3D Print Hub plugin. This is convenient if you always need the same settings for all your 3D model exports.

For a PDF of this documentation, see 3D Print Hub PDF.

Become an insider

Sign up to access exclusive tools, giveaways & tutorials

Get Access

Is ZBrush good for 3D printing? – 3D Solved

Are you looking to create your own designs for 3D printing? If so, then you probably found out there are a lot of programs you can use to bring your ideas to life and might be asking yourself if ZBrush is the right one for you. Look no further! In this article, I will cover ZBrush’s most important aspects and compare them to similar software so you can decide whether it is a good fit for you.

ZBrush is a great option for 3D printing if you want to design organic shapes and can afford the subscription to use it. Due to the nature of this program, it is not well suited for projects that require precision and technical details. Anyone interested in artistic design will appreciate this tool and the amazing level of detail it can bring to your models.

Due to the nature of this program, it is not well suited for projects that require precision and technical details. Anyone interested in artistic design will appreciate this tool and the amazing level of detail it can bring to your models.

Table Of Contents

- Is ZBrush easy to learn?

- Is ZBrush popular in 3D printing?

- Can you design anything using ZBrush?

- Online resources for learning ZBrush

- Popular alternatives to ZBrush

- ZBrush vs Blender

- ZBrush vs Maya

- Frequently asked questions

- Is ZBrush free to use?

- Do you need a tablet for ZBrush?

- Can you use ZBrush on iPad?

- What operating systems does ZBrush support?

- Can you export STL files in ZBrush?

- Conclusion

- Check out our recommended products section

Is ZBrush easy to learn?

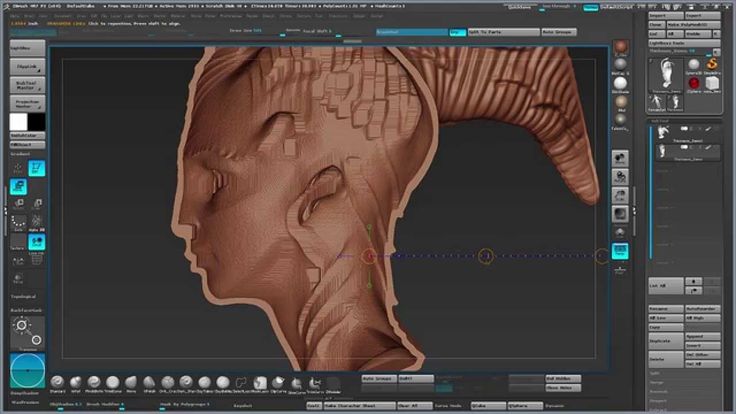

ZBrush can be tricky to learn, especially if you are a new user without background experience in 3D modeling. Learning to use this tool takes a significant amount of time as ZBrush does things its own way and doesn’t really follow the traditional conventions. When you are getting started the user interface feels counterintuitive resulting in a user-unfriendly experience.

Learning to use this tool takes a significant amount of time as ZBrush does things its own way and doesn’t really follow the traditional conventions. When you are getting started the user interface feels counterintuitive resulting in a user-unfriendly experience.

For beginners, I would recommend starting with ZBrushCoreMini, which is a free and lite version of Zbrush. Fewer functionalities will help in the learning process since there won’t be as many distractions and the user interface will be cleaner. In the beginning, you don’t really need more than 4-5 brushes, just focus on understanding how navigation works. Once you get that and know how to add resolution to a model, you are set to start modeling whatever you want.

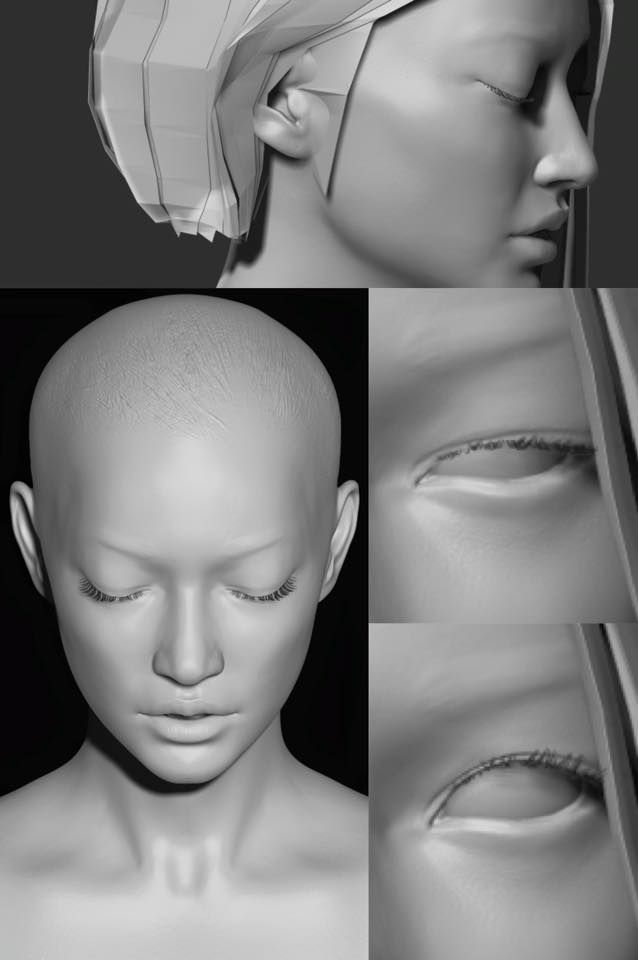

Besides learning how to use the software, you need to learn the sculpting fundamentals skills to reproduce anatomy. ZBrush won’t magically allow you to create amazing stuff, you still need the fundamentals.

Is ZBrush popular in 3D printing?

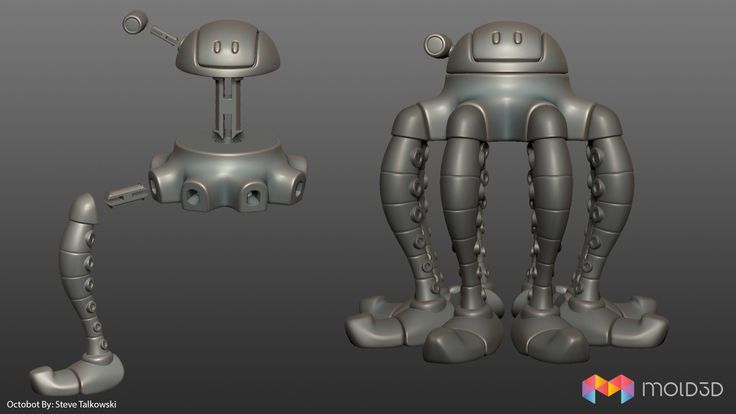

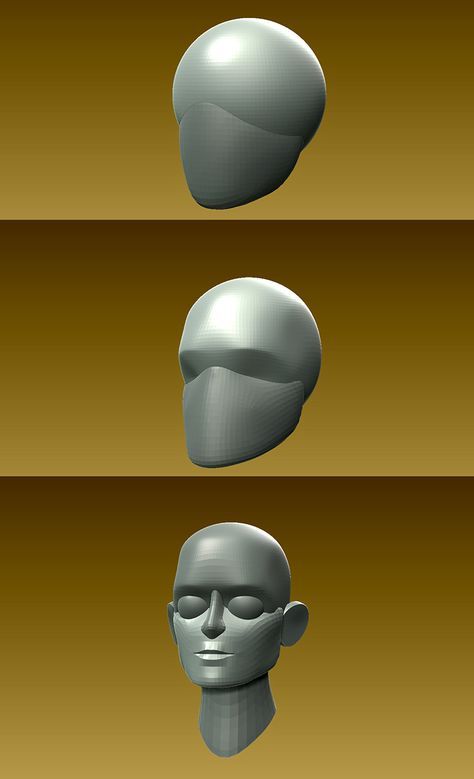

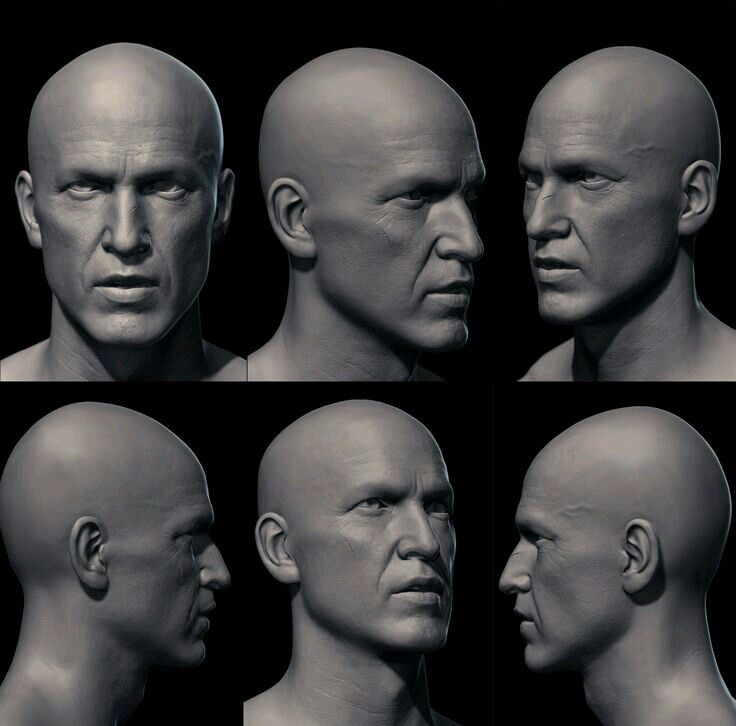

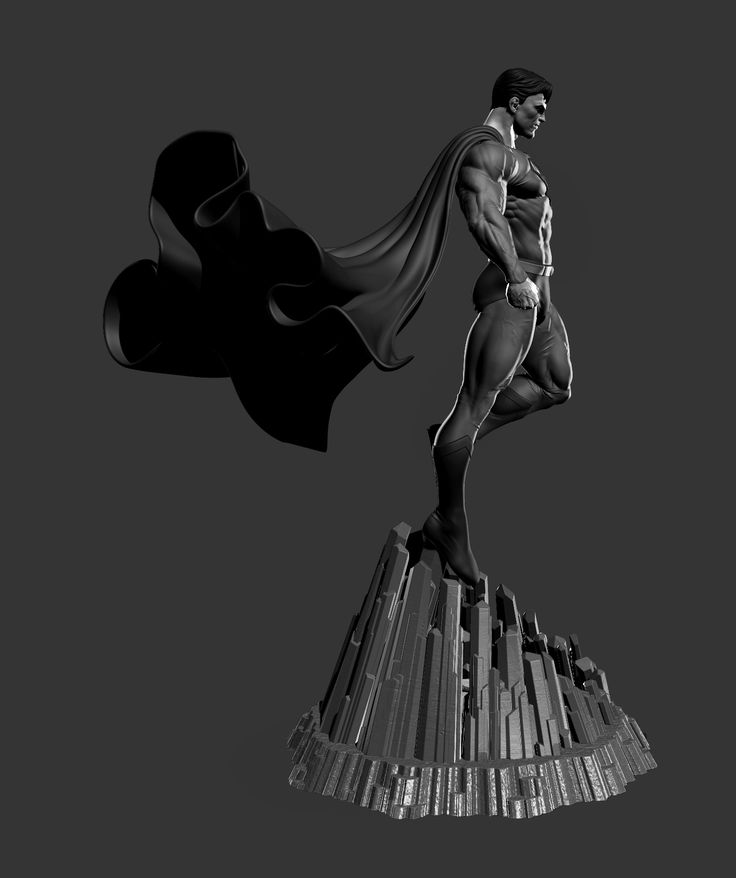

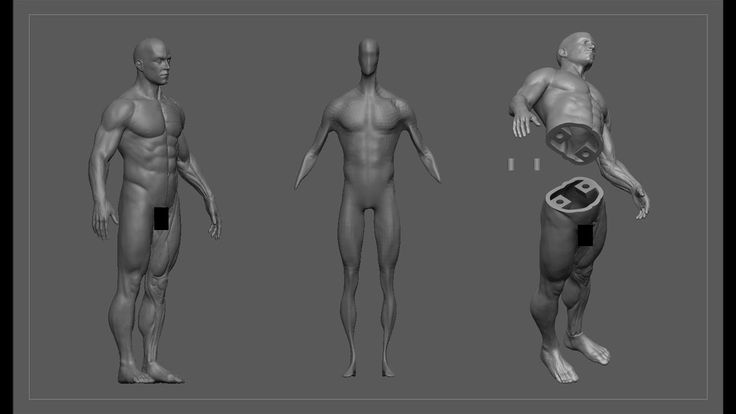

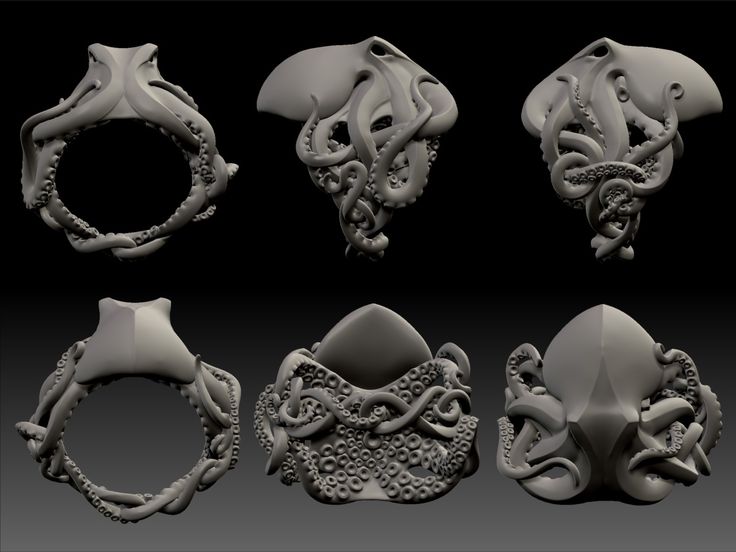

ZBrush is a popular 3D modeling software that you can use to create intricate designs, and you can even reach a high level of detail on small models. It is ideal to sculpt organic shapes like humans, creatures, and jewelry with 3D printing in mind.

ZBrush is an industry-standard when it comes to working with high-resolution geometry, and it is mostly used by professionals given that a subscription is required in order to use the software. Hobbyists may opt for ZBrushCoreMini or Blender for similar purposes as those programs are free to use.

Can you design anything using ZBrush?

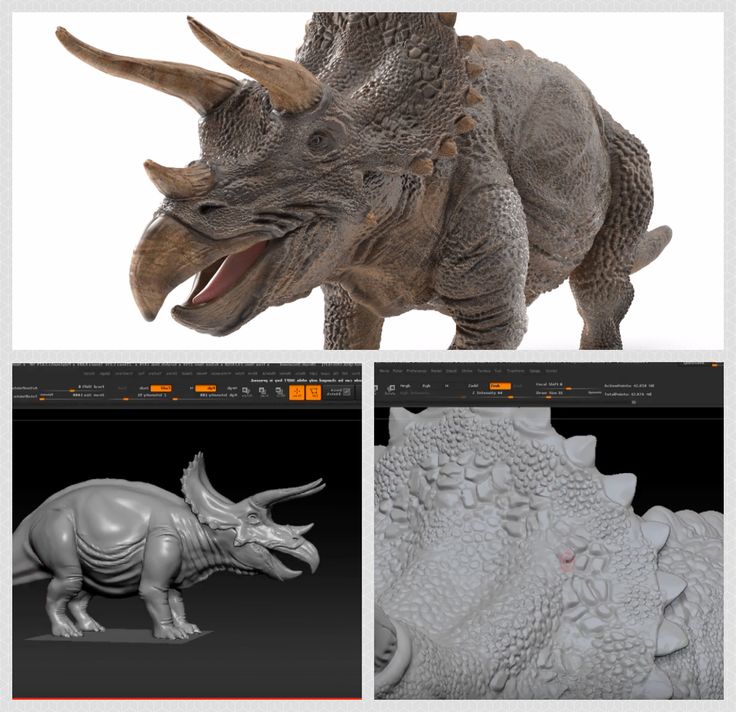

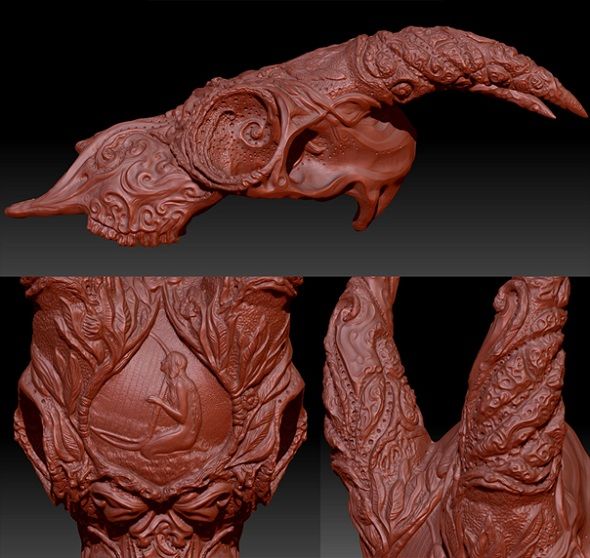

ZBrush is a 3D modeling software that resembles traditional sculpting. It is mainly a tool for sculpting high-resolution 3D models, and it is arguably the best at it as it has an immense and refined selection of sculpting brushes.

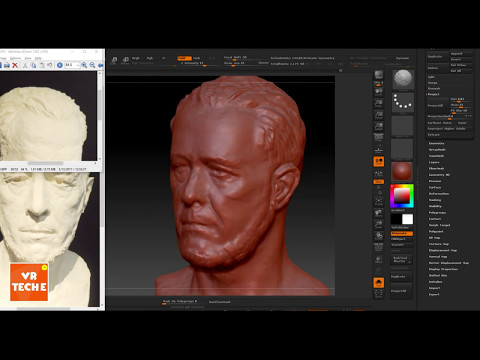

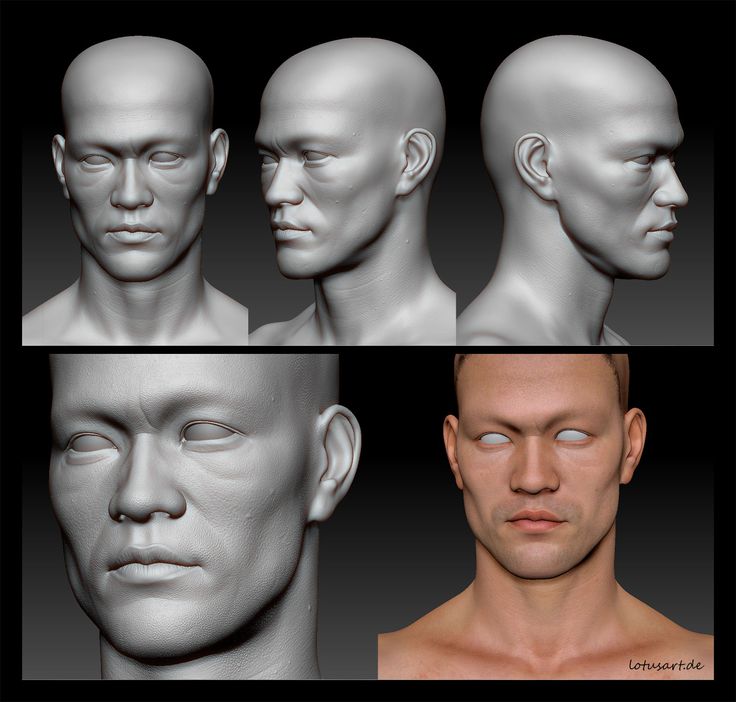

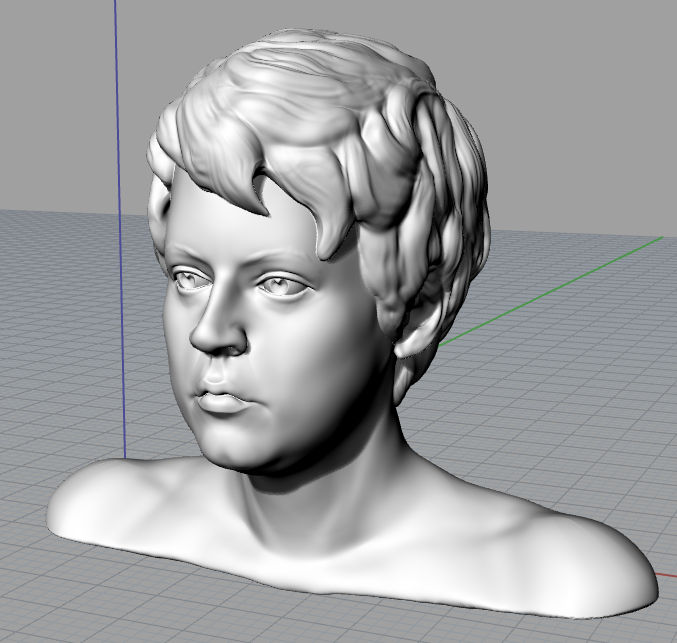

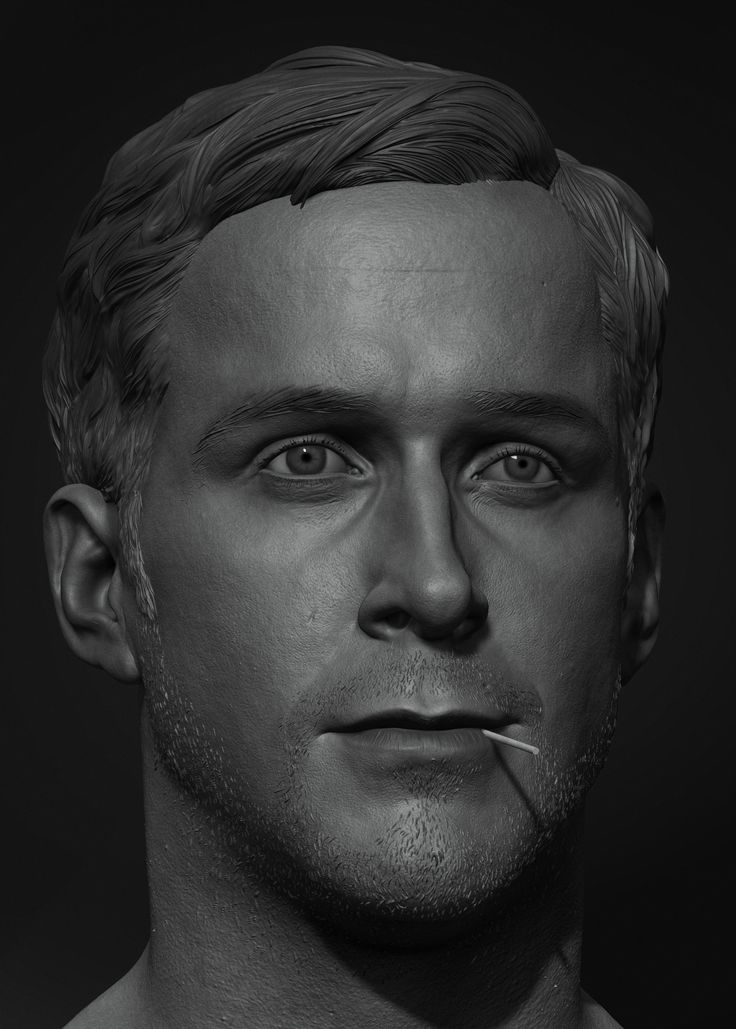

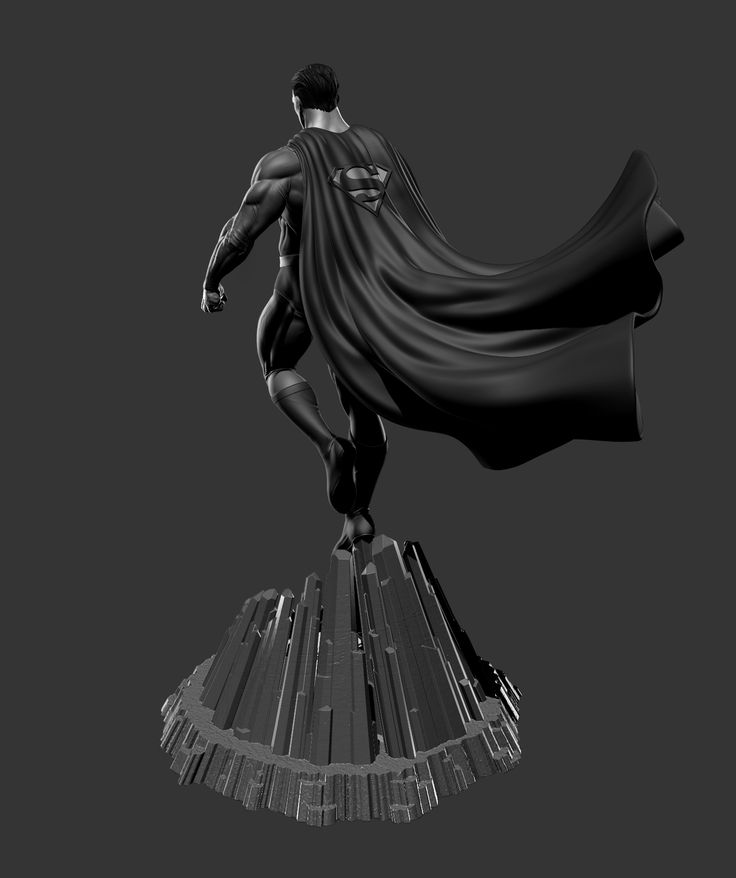

An example of the incredible details that can be achieved using Zbrush. SourceYou won’t be using ZBrush to design parts for mechanical engineering or industrial manufacturing because it is not dimensionally accurate like traditional CAD software. ZBrush is used for artistic design and organic shapes where you seek the natural appearance of lifelike forms.

ZBrush is used for artistic design and organic shapes where you seek the natural appearance of lifelike forms.

Hyperrealism art is possible with ZBrush as it can handle a very high polygon count. This allows you to get an incredible quality of detail, you can literally see the pores on the skin of a character!

Considered to be the industry standard for digital sculpting, ZBrush sees more use in the professional scene, where big studios use it to create models for movies, games, and animations.

Online resources for learning ZBrush

Given that ZBrush is a popular software there is a plethora of educational content you can use to learn any of the program’s features. The Pixologic site has hundreds of great training videos, and the company provides its own courses there and they are all for free. You can also check their YouTube channel for videos and tutorials.

Outside the company’s official educational content I found that Michael Pavlovich’s YouTube channel videos are awesome for those new to ZBrush. He has an “Intro to ZBrush” video series that will guide you from the very start all the way through the most complex techniques.

He has an “Intro to ZBrush” video series that will guide you from the very start all the way through the most complex techniques.

Popular alternatives to ZBrush

ZBrush vs Blender

Unlike ZBrush, Blender is free and open-source software. Whether you want to use it for personal or commercial purposes you won’t need to spend any money to use this software, and because it is open-source, Python developers can make use of Blender’s API to extend the software’s functionalities by creating their own tools. Both programs are great for artistic design and mastering their features will take time.

Blender’s user interfaceZBrush specializes in sculpting and no other software comes close to its immense and refined selection of sculpting brushes, while Blender has a wider range of uses as it supports the entirety of the 3D pipeline (modeling, rigging, animation, simulation, rendering, compositing, motion tracking, even video editing, and game creation).

For anyone looking to create hyperrealism art, ZBrush is the go-to option as it can handle a much higher polygon count than Blender. This allows you to reach incredible levels of detail in your designs.

Given that ZBrush is the industry standard for digital sculpting it is mainly used by big studios that can afford the subscriptions while Blender is the preferred choice for hobbyists and freelancers. Wanna know more about Blender? Check out this article!

ZBrush vs Maya

Both programs are considered industry standards, Maya for VFX and animation, and ZBrush for digital sculpting.

Maya is an all-in-one 3D package software used for 3D animation, simulation, modeling, and rendering. Like ZBrush, you need to pay a subscription in order to use the program, but Maya is a lot more expensive.

Students and educators may use Maya for free if they qualify for the educational plan, check here to see if you qualify! Otherwise, there is a 30-day free trial, after which you have to pay the subscription if you want to continue using the program.

Even though it is possible to design industrial parts for mechanical engineering and industrial manufacturing with Maya, it is meant to be used for organic modeling. While you can do a lot of things with Maya, ZBrush is still king when it comes to digital sculpting, with all their sculpting brushes and its capability to work with a high polygon count.

When it comes to user interfaces, Maya’s interface provides a cleaner and simpler experience as its features are more intuitive to use.

Maya’s user interface is more intuitive for newcomersFrequently asked questions

Is ZBrush free to use?

In order to use ZBrush, you need to pay a subscription fee. If you are a beginner and would like to check ZBrush’s basic features before paying the subscription, you can try with ZBrushCoreMini which is completely free for non-commercial use.

Do you need a tablet for ZBrush?

My Wacom Intuos drawing tablet that I use along ZBrushYou can use ZBrush without a tablet, but it is built around using one. It will take a little bit of practice to get used to a tablet, but most of the time you will want to be using one, especially for organic modeling. A sculpting tablet provides a more natural motion and most importantly, pressure sensitivity. Wacom’s tablets are the preferred choice for most designers.

It will take a little bit of practice to get used to a tablet, but most of the time you will want to be using one, especially for organic modeling. A sculpting tablet provides a more natural motion and most importantly, pressure sensitivity. Wacom’s tablets are the preferred choice for most designers.

Can you use ZBrush on iPad?

There is no native support for Zbrush on iPad, as ZBrush is not a tablet application. However, if you don’t care about subpar performance, there are some workarounds to make it work. Check out this video to see how you can make ZBrush work on an iPad.

What operating systems does ZBrush support?

ZBrush is being developed and maintained for both Windows and Mac operating systems. Linux users might want to try Blender, which fully supports it.

Can you export STL files in ZBrush?

ZBrush supports a wide range of file formats that can be used to import and export, including STL, which is the most common format for additive manufacturing.

Conclusion

After looking at ZBrush’s most important aspects and comparing them to similar software we can safely say that it is an excellent tool for digital sculpting objects with 3d printing in mind, if not the best.

If you invest the time to learn how to use the software the reward is well worth it, as you will be able to design and print any kind of organic shape with a hyperrealism grade of detail.

The only downside to ZBrush is that you need to pay a subscription in order to use it, so hobbyists might want to check ZBrushCoreMini as it is free to use for non-commercial use.

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

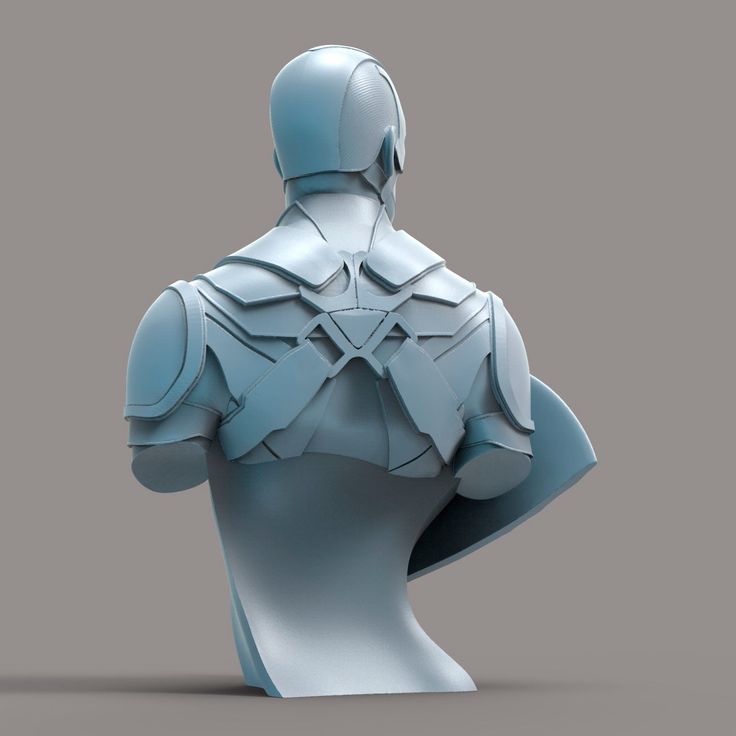

Modeling and 3D printing by art. Zbrash and comics.

Among digital artists, those who like them are sometimes given fanarts of their characters or from their setting. So these figures will mainly come from this opera. Models were sculpted in Zbrush by art. I'm not an artist, so the digital models are "amateur" level. ABS material from various manufacturers, more often DEXP. Execution time: after hours and weekends in 2018 - 02.2019.

#1 - Den Diesel from FurryGuys .

I decided to make it only in the form of a bust, since by that time I had not opened zbrush for more than a year, and without that the initial skill was completely lost. Full height, I was afraid I wouldn't pull it =))

Several links to the art of the character. 1, 2.

Large, 11 cm high, safely sent to the Author (must be in the VK group) .

Since I'm not looking for easy ways, and I suffer from pathological masochism, I decided to make the model with my mouth ajar. Moreover, with a bust size of 11 cm, the oral gap came out 1.5 mm. You can't get support out of your mouth. Having beaten the head against the wall, the lower jaw was made separately, and the head was printed upside down. Hairstyle separately, on a pile of supports. It is very "fun" to separate them when the strength of the tip of the hair is close to the strength of the support. And for a vertical small element not to fall sideways on a support, you have to print them without gaps.

Moreover, with a bust size of 11 cm, the oral gap came out 1.5 mm. You can't get support out of your mouth. Having beaten the head against the wall, the lower jaw was made separately, and the head was printed upside down. Hairstyle separately, on a pile of supports. It is very "fun" to separate them when the strength of the tip of the hair is close to the strength of the support. And for a vertical small element not to fall sideways on a support, you have to print them without gaps.

When printing the jaw for the first time encountered the problem of overheating (small part), which was solved by cooling and simultaneously printing the technological turret in the distance.

Since I'm not looking for easy ways….. I modeled my hairstyle in such a way that it didn't sit on my head, didn't stretch. It's like putting on a retaining ring if it didn't spring back. – the jamb is fixed manually. A kink with a neat seal of the seam.

Now the normal method has been mastered after work No. 5 of the current post: ABS heating to Т > Тrsoftening ≈ 110…120 deg. I prefer a low heat burner. The selection of the height above the flame and, consequently, the temperature - with a multimeter thermocouple. The plastic remains softened for at least a few seconds - enough to pull-put a thin-walled hairstyle on your head.

5 of the current post: ABS heating to Т > Тrsoftening ≈ 110…120 deg. I prefer a low heat burner. The selection of the height above the flame and, consequently, the temperature - with a multimeter thermocouple. The plastic remains softened for at least a few seconds - enough to pull-put a thin-walled hairstyle on your head.

Attention! In the process of heating above Trasoft. the model is slightly deformed, including under its own weight. So the method is very limited in terms of the subject of processing.

Acrylic primer, paint with acrylic brush. Acrylic allergy =((

№2 - Jelani, webcomic "Eighth".

More precisely, his chibi, children's-anime version. I tried to sculpt an adult (art) - too tough. Printed kite, size 13 cm, safely sent to Author

My favorite miniature in terms of productivity. It was possible, for the first and only time, to position the 3d model with rigging - the internal skeleton, and print it without problems. It consists of only 3 parts: 2 hands and everything else. The base green color is the color of the most pro-acetone ABS - glitter =)). Paint eyes, hands and hair in 4-6 layers of acrylic, due to the lack of primer. The eyes are stained using molar tape as a limiter.

The base green color is the color of the most pro-acetone ABS - glitter =)). Paint eyes, hands and hair in 4-6 layers of acrylic, due to the lack of primer. The eyes are stained using molar tape as a limiter.

No. 3 - Jonty from " Stories with known endings »

Sculpted according to reference. The first, 21 centimeter, went to the Author.

A hell of a lot depends on the coloring and, somewhat less, on the photograph. In the photo above, Jonty was made by the first with a purchased paint job. I painted the second and third in the photo below - failure on the left, success on the right.

A difficult model for my skill. But I wanted something more ... In an original way for me, the tail was printed in a prickly design. It consists of 3 parts, however, the spines of the underlying element overlap the butt seam. That is, landing with a seam inward, as well as shoulder-body, legs-body.

By the way, for a long time I could not find the Boolean subtraction operation in Zbrush, which is common for 3D programs. Previously, he made dragons with joints along the planes.

Previously, he made dragons with joints along the planes.

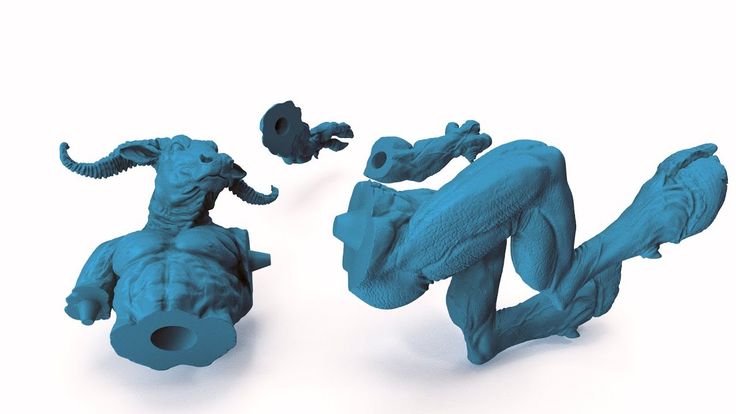

No. 4 - Sergal.

Specifically, this sergal is not from any setting, but the character of the customer, for which there is a concept art, and the model of which had to be made.

Disassembled photo and the result of the collage:

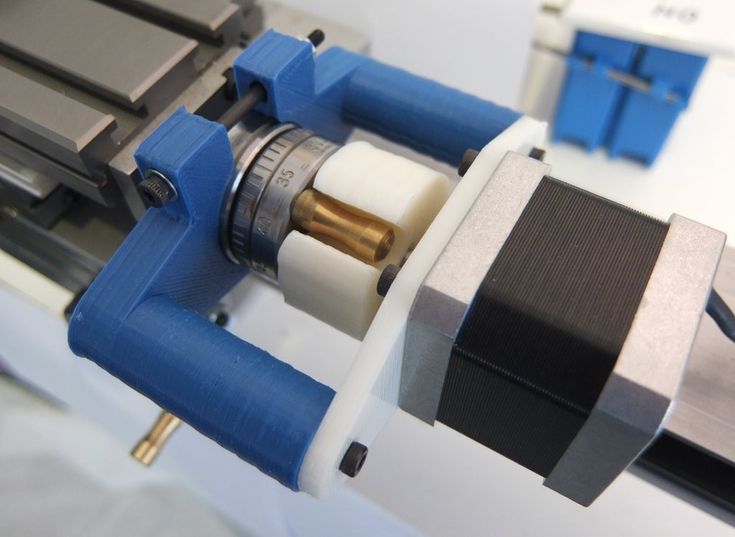

I got the machine from the network. Printed from the bottom up from the stock of 2 parts. Came out about 7 cm in length - terrible. Too small elements for FDM, but no DLP or SLA =(

#5 - Clementine from " Stories with a known ending "

My favorite work. One, 21 centimeter, went to the Author. Sculpted according to reference. As always, not without problems. Master Plaster from the DNS went to the poor thing. Absolutely terrible filament =(

+ Convenient fast delivery of DNS.

+ Attractive price. With the possibility of payment upon receipt. in the upper temperature range.Measurement of resistance by pushing by hand, so without measurements and not according to GOST.

in the upper temperature range.Measurement of resistance by pushing by hand, so without measurements and not according to GOST.

- The roughness is subjectively higher, both before and after dip acetoning, compared to other manufacturers. The reason is not known to me.

It took a long time to finish the locksmith method. Processes and results:

Wings and tail deeply recessed into the body. Their bases are pinned with a wire ⌀2 mm, 15 mm long. Drilled and planted with heated wire.

There is a problem with kinks in the mail delivery process. Jonti (work No. 3) and Sergal (No. 4) came to customers with breaks in small parts. So for Clem, I crafted a special package with fixation on the pedestal using cardboard and hot melt adhesive. Sent by sdek.

Approximate labor input:

On the example of Clementine in my performance for 1 model. Timing did not lead, accuracy ± 20%.

Production preparation.

1) Model (I don’t know how but I try): 150…180 h. 5 hours

5 hours

Production .

4) Camera work (excluding machine time, of course): 1 hour

5) Post-processing + assembly. 8 hours

6) Painting: Outsourcing. Painting related works: No. 4 Sergala and No. 3 Jonti took me under 15 hours. Therefore, it is better to buy the operation.

7) The painting came unsatisfactory. Repainted +10 hours

______________________

Total. Satisfied with the result, categorically not with labor productivity! The most terrible stage, of course, is the model. In order to sculpt quickly and on a level, it is very desirable to work in this area, or at least practice from school and student time. On the financial side, materials and other costs paid off, the machine did not start. But the pleasure is received =)

HOW TO CREATE A MODEL FOR 3D PRINTING

Hello everyone, my name is Bogdan, I'm a concept artist, I'm most interested in Hard Surface. He graduated from several courses, for example, Super Maya - Yuri Snytko's video course, Hard Surface XYZ course. Now I'm studying the Movie Man XYZ course. Participated in various concept art competitions:

Now I'm studying the Movie Man XYZ course. Participated in various concept art competitions:

https://www.ggac.com/v2/work/detail/169998

https://render.ru/ru/gallery/artwork/211240

At the moment I'm just starting out in the gaming industry, so I'm open to any job offers.

My favorite hobby is board games, I really enjoy building and painting models and then playing with them. Having mastered the basic skills of design and modeling, I decided to start developing my own wargame from the lineup. The first unit was the Ferus BMP (here it is on ArtStation: https://www.artstation.com/artwork/8wo90m) because Hard Surface is my favorite direction and I could test the assembly without glue, turning wheels and the tower. After choosing a topic, I began to select references. Usually I don't limit myself in the number of images, as they can be conveniently saved and sorted in the wonderful PureRef program.

I usually use ZBrush and Maya for modeling. In Maya, you can very quickly make Blockout and Kitbash for a future model, after which you can work on the shape, silhouette and guide lines in ZBrush, put the model together.

In Maya, you can very quickly make Blockout and Kitbash for a future model, after which you can work on the shape, silhouette and guide lines in ZBrush, put the model together.

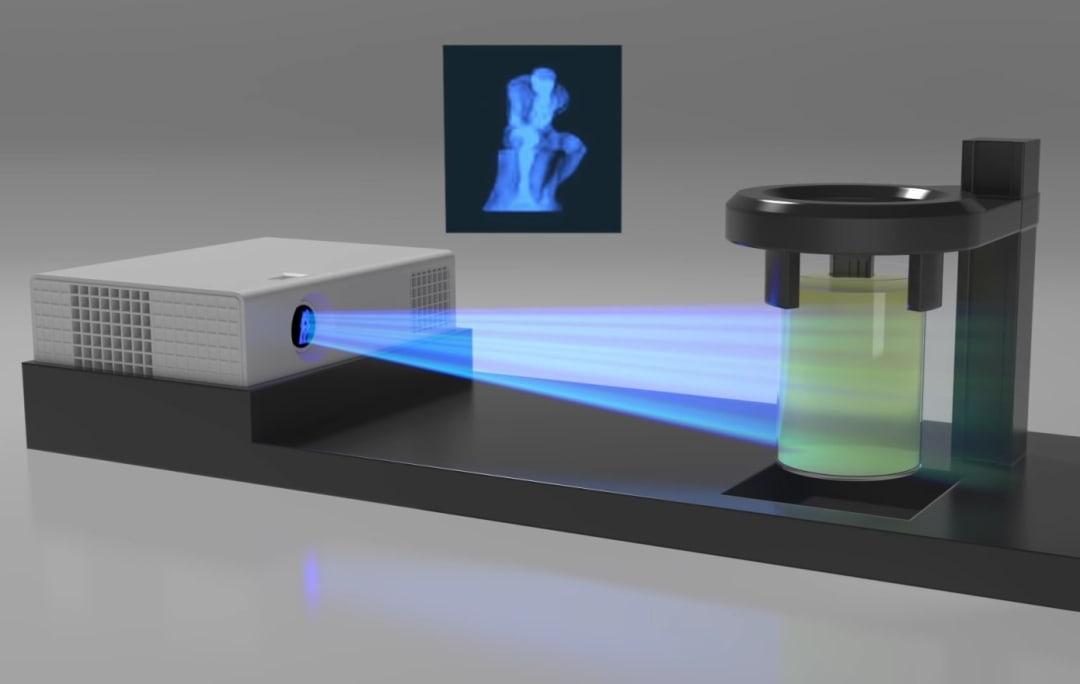

Due to the lack of clay modeling skills, as well as the absence of my own 3D printer (but it will appear soon :)), I turned to a company that prints on an SLA printer.

Before sending the model to be printed, I went through a few steps. Below is a short guide.

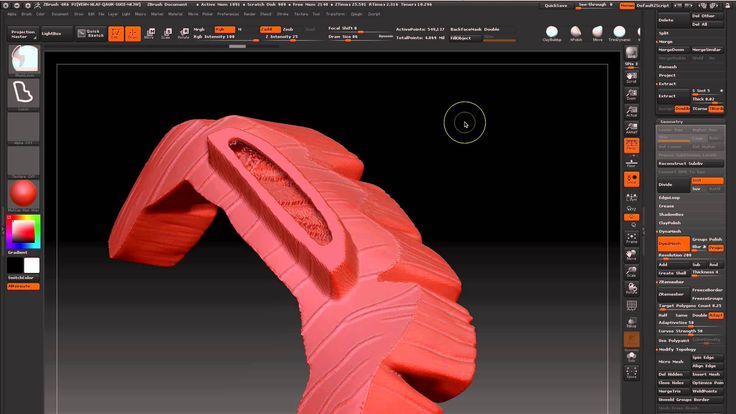

1) Make sure the model is solid. This can be verified in ZBrush using the 3D Print Hub plugin. If the parts do not pass the test, then you can correct the geometry using the functions in the Geometry menu.

2) Then you need to reduce the number of polygons using the Decimation Master plugin, and then repeat the test.

3) Next, check that all parts are to the correct scale. Since OBJ and FBX do not contain information about the size of parts in real dimensions, you need to use the 3D Print Hub plugin to export from ZBrush (watch the dimensions carefully!), Or use a simple but long method so as not to be mistaken. I decided on the dimensions and, using a box, scaled each detail and saved it in STL format.

I decided on the dimensions and, using a box, scaled each detail and saved it in STL format.

4) After that, don't forget to make holes in the parts to reduce material consumption, check the mesh again.

5) Next, you need to arrange supports for printing, many programs can help you with this, which will place them automatically, you just have to add additional supports in the necessary places or move already generated ones.

After all the preparations, I sent the model to the company, where it was printed, dried in an ultraviolet oven and the supports were cut off. I recommend additionally cleaning the model in an alcohol or soapy solution after production, because even small residues of the polymer are quite toxic. For additional protection, you can varnish the model or paint it.

I learned all the necessary information to prepare the model for printing when communicating with the company's employees, or found it on the Internet.