Gold 3d printer

Shapeways: Gold 3D Printing

14K and 18K Gold

Wax Casting

Upload a model

Loading contents...

Show menu

14K and 18K Gold

Wax Casting

Upload a model

Material info

About Gold 3D Printing

Gold 3D printing is perfect for creating everyday wear, and timeless pieces too. Available in yellow, white, and rose, as well as 14K and 18K, Gold is one of the highest quality materials Shapeways offers. Capable of showcasing intricate details, Gold offers a professional, finished look and feel.

Color & Finishes

Yellow

Available in 14k and 18k

Rose

Only available in 14k

White

Only available in 14k

Technology

- Wax Casting

Description

Material Highlights

High quality, shiny finishing, skin-friendly, 14K and 18K gold. 3D printed Gold is capable of showing intricate details.

Handling and Care

Skin-friendly, 3D printed Gold offers high electrical conductivity and is heatproof to 800°C/1472°F.

Design Guidelines

Bounding Box

Bounding Box Max

89 × 89 × 100 mm

Bounding Box Min

2.4 × 2.4 × 0.6 mm

The bounding box is a 3D imaginary outline of a box that encloses the smallest area occupied by your model. Your model must be within the minimum and maximum bounding box sizes. If the size of the model is close to the maximum bounding box, then the printing orientation will be restricted.

Supported Wall Thickness Min

0.8 mm

Unsupported Wall Thickness Min

0.8 mm

A supported wall is connected at least on two sides of the wall, while an unsupported wall is connected only on one side of the wall. Walls that do not meet the minimum requirements may not survive printing and cleaning processes. Additionally, models may still be rejected based on the wall geometry of the model. Please consider the size of your model and reinforce the walls or add support structures as needed as minimum guidelines will not always be adequate for large models.

Walls that do not meet the minimum requirements may not survive printing and cleaning processes. Additionally, models may still be rejected based on the wall geometry of the model. Please consider the size of your model and reinforce the walls or add support structures as needed as minimum guidelines will not always be adequate for large models.

Supported Wires Min

0.8 mm

Unsupported Wires Min

1.0 mm

A wire is a circular, rectangular or even triangular feature that is thinner in its unconnected directions than its length. A supported wire is connected at least on two sides of the model, while an unsupported wire is connected on one side of the model. Wires that do not meet the minimum requirements may not survive printing and cleaning processes. Additionally, models may still be rejected based on the wire geometry of the model. Please consider the size of your model and reinforce the wires or add support structures as needed as minimum guidelines will not always be adequate for large models.

Please consider the size of your model and reinforce the wires or add support structures as needed as minimum guidelines will not always be adequate for large models.

Details

Details Min Embossed

0.4 mm high & wide

Details Min Engraved

0.35 mm high & wide

For text, the ratio between width and depth, should be 1:1 and sans-serif fonts are preferred for line weight consistency.

Escape Holes

Single Escape Hole Diameter (Min)

4.0 mm

Multiple Escape Hole Diameter (Min)

2.0 mm

Escape holes are necessary to empty the support material of a hollow model. Two escape holes at the opposite ends of the model is optimal for the support removal process. Please consider the size of your model and make the escape holes bigger or add more escape holes as needed as minimum guidelines will not always be adequate for large models.

Please consider the size of your model and make the escape holes bigger or add more escape holes as needed as minimum guidelines will not always be adequate for large models.

A single escape hole at the end of a cavity will not allow material in the corners near the escape hole to fully escape. So we recommend multiple escape holes at both ends of the cavity.

Clearance

Min

0.3 mm

Clearance is the space between two individual parts in a model. If the space among the individual parts do not meet the minimum clearance, then parts can fuse together or can be difficult to clean. This is important for movable pieces like hinges, gears, etc.

Interlocking & Enclosed Parts

Interlocking

No

Enclosed

No

Parts in File

Max

Upload as many as two identical parts, like earrings or cufflinks, in the same model file for the Gold 3D printer. Multiple, unique, non-interlocking parts cannot be ordered in the same model files; therefore, separate files are required for unique parts.

Multiple, unique, non-interlocking parts cannot be ordered in the same model files; therefore, separate files are required for unique parts.

Accuracy

Accuracy Your Gold 3D printing model may shrink about 0.25 mm plus 2.5% after casting and finishing. For rings the inner diameter is accurate within +/- 0.1 to 0.15 mm. On average, the Gold 3D printing model shrinks about 2.5% after casting and finishing. We do our best to polish the internal diameter to match your model file.

For example: A product with dimensions of 50 x 50 x 100 mm can be 0.25 mm + 0.025*100 mm = 0.5 mm smaller in any direction.

Stay up to date on promotions, case studies, and more.

Newsletter Sign up

Stay up to date on promotions, case studies, and more.

Email Address

Online Gold 3D Printing Service

Design Specifications

Minimum Wall Thickness

0. 8 mm

8 mm

Minimum Details

0.35 mm

Accuracy

±5% (with a lower limit of ±0.35 mm)

Maximum Size

88 x 88 x 125 mm

Clearance

0.3 mm

Enclosed Parts?

No

Interlocking Parts?

No

Pricing Info

The pricing for Gold is based on model volume, which is the volume of your model used to calculate the material cost (mm³).

Additionally, a startup cost is applied to the price of your model. This is a fixed cost independent of the parameters of your model. If you order two or more copies of a model, the price automatically decreases because the preparation of multiple copies can be carried out more efficiently.

Hallmarking

The hallmarking of gold is a way of guaranteeing that you’re getting the correct level of purity in your precious metals. We don’t use an assay office; instead, we have permission from the Royal Mint of Belgium to mark cast models with a master (also called a maker) and purity stamp. The purity mark will indicate the purity of the precious metal. For 14k gold, the mark is a diamond (or rhombus) with the text “au 585”. For 18k gold, the text “au 750” is featured in the same diamond shape.

We don’t use an assay office; instead, we have permission from the Royal Mint of Belgium to mark cast models with a master (also called a maker) and purity stamp. The purity mark will indicate the purity of the precious metal. For 14k gold, the mark is a diamond (or rhombus) with the text “au 585”. For 18k gold, the text “au 750” is featured in the same diamond shape.

The master or maker stamp has been registered and approved by the Royal Mint of Belgium. It displays the symbol of a lightbulb with the letters “i.m” inside the outline of a barrel.

Hallmarking is performed to the highest extent possible, either with a laser or by stamping the metal. However, if there is a risk of damaging the final product, the marks may be missing. In every case, you will always receive an invoice as proof of authenticity. Pursuant to the Belgian Law of 11 August 1987 on the warranty of works on precious metals and the Belgian Royal Decree of 18 January 1990 on the warranty of works on precious metals, i. materialise guarantees that the object of the Invoice fulfills the standards of purity for 14K gold at 58.5% purity or 18K gold at 75% purity, whichever is applicable.

materialise guarantees that the object of the Invoice fulfills the standards of purity for 14K gold at 58.5% purity or 18K gold at 75% purity, whichever is applicable.

For customers outside the EU, hallmarking is not provided.

i.materialise complies with Belgian legislation and the free movement of goods in Europe.

Typical Use

Gold is mostly used for jewelry.

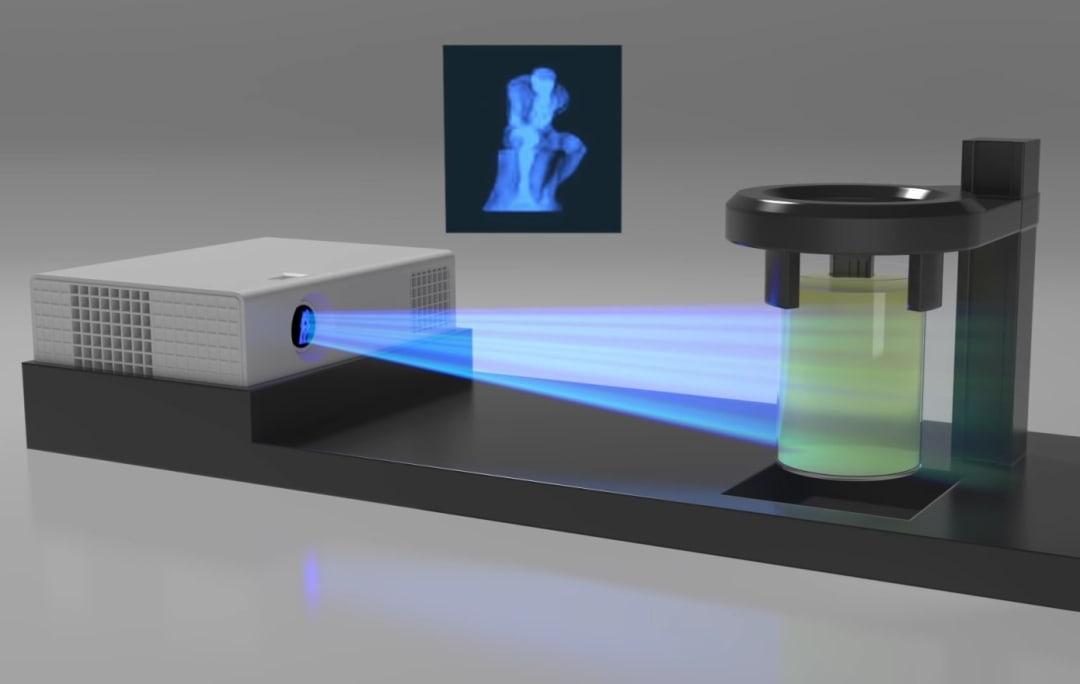

Technology

Wax 3D printing and lost wax casting are used to build your design when using this material. The wax printing process is a type of Stereolithography that uses a wax-like resin. Support structures are printed along with the model to make sure your model doesn’t fall apart. These support structures are automatically generated and manually removed after the printing process. After support structures are removed and your model is cleaned, the model can be prepared for casting.

First, one or more wax sprues will be attached to your model. Next, the sprue and model will be attached to a wax ‘tree’, together with a bunch of other models. The tree is then placed in a flask and covered in fine plaster. When the plaster solidifies, it forms a mold for gold casting. The plaster mold is then put in an oven and heated for several hours to a point where the wax is completely burned out.

Next, the sprue and model will be attached to a wax ‘tree’, together with a bunch of other models. The tree is then placed in a flask and covered in fine plaster. When the plaster solidifies, it forms a mold for gold casting. The plaster mold is then put in an oven and heated for several hours to a point where the wax is completely burned out.

Then, molten gold is poured in to fill the cavities left by the wax. Once the gold has cooled and solidified, the plaster mold is broken and the gold models are removed by hand and polished.

Additional Information

- Because pure gold would be too soft for durable jewelry, solid gold is mixed with an alloy (usually with metals like silver, copper or zinc) to harden the material for longer wear

- Due to the nature of the process (lost-wax casting and printing) used in the production of gold, interlocking or enclosed parts are not possible

- In order to comply with European regulations (REACH), we use nickel-free white gold.

Consequently, the color of white gold models may appear slightly yellow

Consequently, the color of white gold models may appear slightly yellow - Please also be aware that we do not use rhodium plating to whiten our white gold because plating eventually wears off. If you really want to whiten your model, you can always turn to your local jeweler to apply rhodium plating. Keep in mind that this plating will need to be reapplied each time it wears off and that the natural, slightly yellow color of white gold will reappear

- 14k yellow gold consists of 58.5% gold, 12.6% silver, 25.4% copper, and 3.5% zinc

- 14k white gold consists of 58.5% gold, 17.43% silver, 9.13% copper, 4.15% zinc, and 10.79% palladium

- 14k red gold consists of 58.5% gold, 39.5% copper, and 2% zinc

- 18k yellow gold consists of 75.2% gold, 12.1% silver, 10.8% copper, and 2.1% zinc

- 18k white gold consists of 75.2% gold, 10.42% silver, 5.45% copper, 2.48% zinc, and 6.45% palladium

- 18k red gold consists of 75.

3% gold and 24.7% copper

3% gold and 24.7% copper

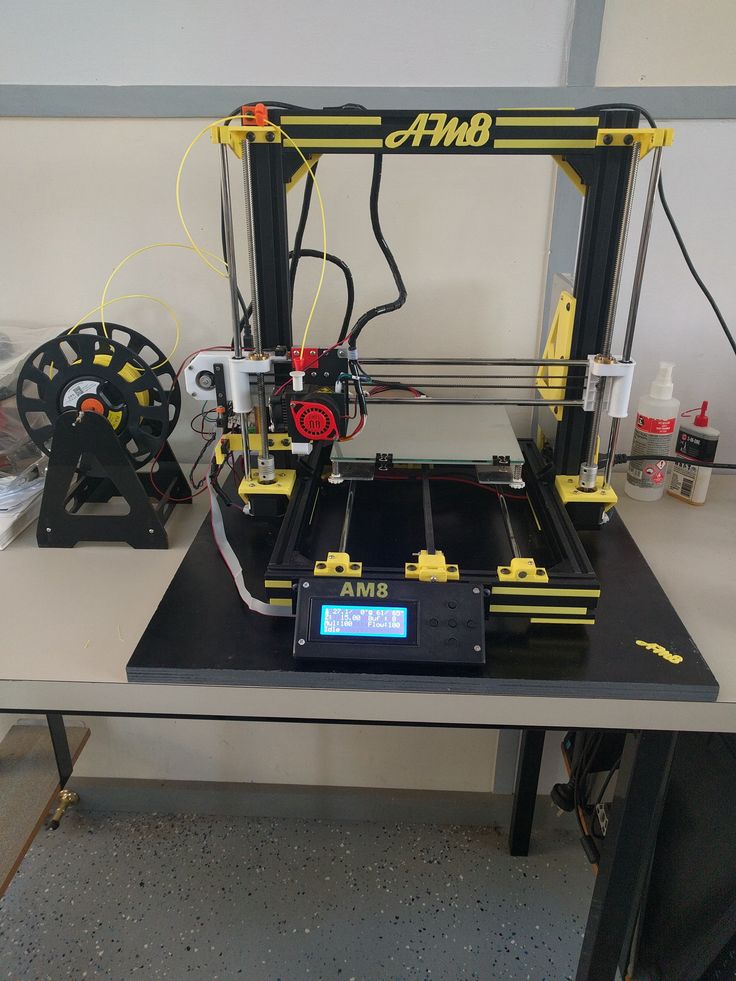

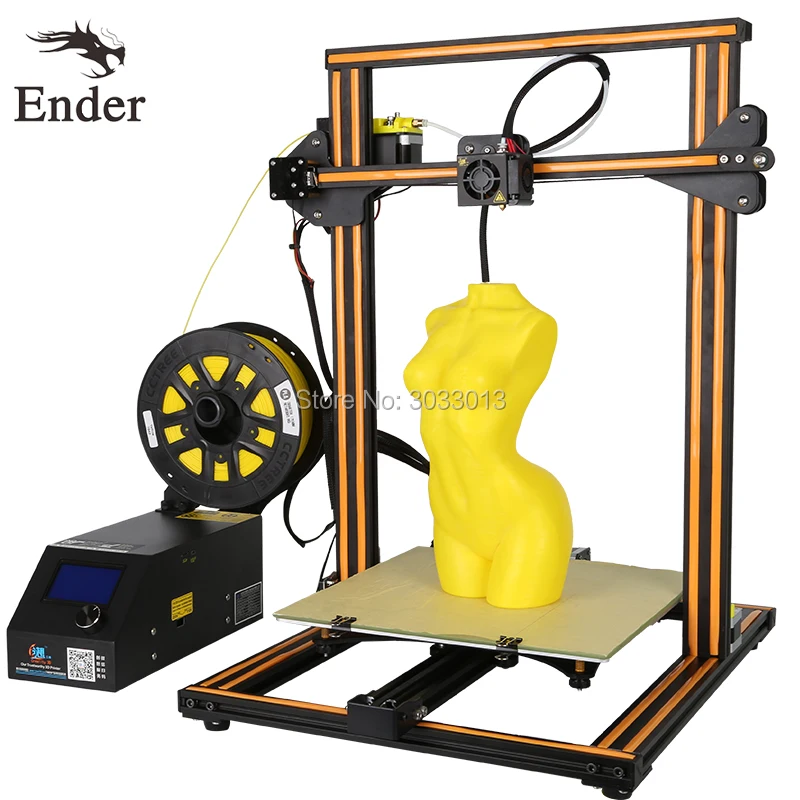

Use of a 3D printer in jewelry

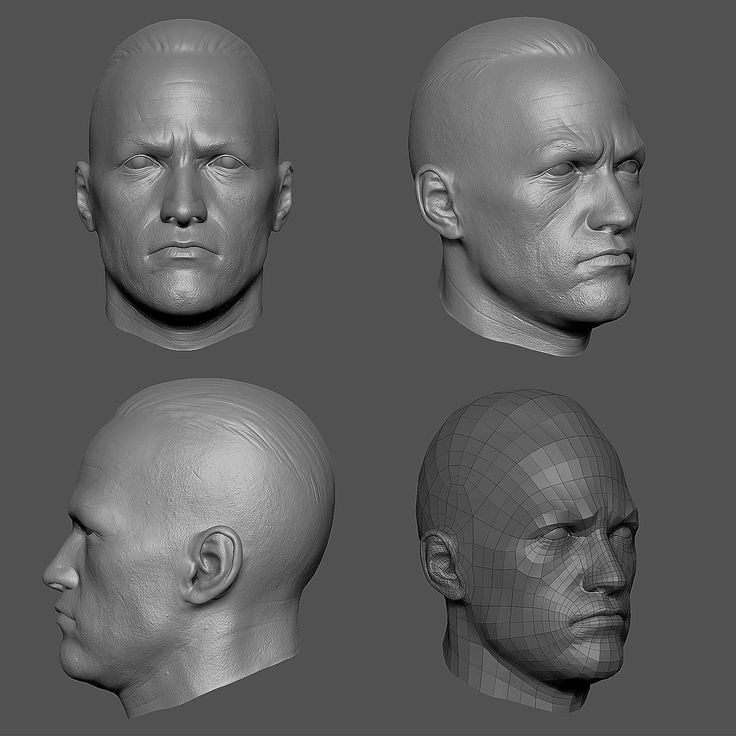

The design of modern fashion jewelry requires innovative approaches in production technology, and here 3D printing comes to the rescue. Rings, bracelets, pendants, brooches and more can now be easily modeled in a special 3D program and printed on a 3D printer. The design can be the most daring. The range depends only on the imagination of the creator.

With photopolymer printing, designers and jewelers can create custom-made pieces easier, faster and cheaper. In addition, a prototype made on a 3D printer allows you to see how the final product will look like, make any adjustments in a timely manner and ensure the most comfortable fit.

The owner of the jewelry company told us more about how he uses advanced 3D technologies in his work « GOLD S.S.A.M. » and our esteemed client Sargis Machkalyan . GOLD S.S.A.M. started in Buenos Aires, Argentina. But in 2002, Sargis decided to develop his business in Armenia.

But in 2002, Sargis decided to develop his business in Armenia.

- Sargis, please tell us how you came to use 3D printing?

I had this idea a long time ago, but we started working with 3D printing about 2 years ago. Basically, we make products by hand, according to individual orders. We make a lot of wedding rings. We also do casting. With the help of a 3D printer, we print products that cannot be made by hand or take a very long time.

- Were there any difficulties in the transition to digital?

There were no difficulties with the transition itself, and finances, thank God, allowed it. There are problems with the fall in production due to the coronavirus and military operations, unfortunately. It is not easy in Armenia now.

- Do you see the advantages of technology over traditional methods?

There are benefits. Manufacturing has become much easier. It is not required to attract a large number of jewelers. Increased work speed. And design - you can produce whatever you want, so to speak. And most importantly, the advantage for the client is that the products look much better, much more beautiful and more modern.

Increased work speed. And design - you can produce whatever you want, so to speak. And most importantly, the advantage for the client is that the products look much better, much more beautiful and more modern.

- Does 3D printing save money and time?

Time yes. I would not say that you can save a lot of money on 3D printing, because it also requires its own costs.

- Do private individuals or businesses apply to your company?

We work with everyone: both companies and individuals.

- How long does it take to produce a 3D decoration?

It depends on the model itself. There are models that are made quickly: you can assemble a model in half an hour or an hour in a modeling program, and printing will take 3 hours. More complex models can be assembled in two hours, printing takes the same 3 hours.

- What 3D equipment do you currently have at your disposal?

PCs and Phrozen Shuffle Lite 3D printer only. There is also an excellent Phrozen Shuffle 4K, but it is currently under repair.

There is also an excellent Phrozen Shuffle 4K, but it is currently under repair.

- What resin do you print with?

We print on ESUN, X10 burn-out resin and recently started using HARZ Labs.

- Do you see the modern jewelry industry without 3D technology?

No, I don't.

On behalf of the Tsvetnoy Mir company, we would like to wish Sargis success in his future work, do not stop there, continue to make customers happy thanks to the unusually beautiful and modern designs and the consistent quality of his products. In the photo you can see prototypes made of photopolymer resin, printed on a 3D printer, and final products made of gold, created by burning the former.

3D printed products

Ultimate gold jewelry

Sargis Machkalyan at work

You can read more about the technology of 3D printing of jewelry on our website at the link: 3D printing of jewelry

3D printing with gold thread: properties and uses

Author Kirill Sokolov Reading 7 min. Views 84 Posted by

Views 84 Posted by

Gold, with its characteristic color and luster, has always been a highly valued metal throughout almost the entire history of mankind. Often used in the jewelry industry, the ability to work with gold and create custom pieces remains a valuable and exclusive skill set. Those with 3D printers might ask: Can 3D printing technology be used to create custom designs that are made of gold or mimic the look of gold?

Both of these questions are still answered. . As you might expect, budget comes into play. What options do you have if you want to 3D print your own gold jewelry?

Contents

- Option 1: Silk Gold PLA Filament

- Option 2: 3D SoluTech Real Gold PLA Filament

- Option 3: GizmoDorks Gold ABS Filament

- Is there a technology for real gold 3D printing?

- Closing thoughts

Option 1: Silk Gold PLA Filament

This Silk Gold PLA Filament from CC3D is one of the most popular options for those who want to try their hand at 3D printing something that looks like gold. The average reason for the popularity of this thread is that it is very cheap. This is just another way of saying that the filament does not contain real gold.

The average reason for the popularity of this thread is that it is very cheap. This is just another way of saying that the filament does not contain real gold.

This filament uses gold colored silk filaments embedded in a PLA matrix. The use of silk is an amazing idea that makes the material reflective enough to mimic the sheen of real gold. Prints made with this filament naturally come out shiny and glossy, although a little sanding and polishing won't hurt to get rid of the layer lines.

Besides the low cost of the filament, another advantage of using silk instead of metal particles is that the filament is not exclusively abrasive. Using the standard brass nozzle of most solid filament 3D printers is always problematic as solids tend to wear down brass materials fairly quickly. This is not a problem for silk threads.

Silk Gold PLA filament prints at normal PLA printing temperatures - ranging from 195 to 230°C. As with regular PLA, a heated bed is not a strict requirement when working with Silk Gold PLA, although a bed heated to around 60°C is still ideal. Silk Gold PLA is a relatively simple and beginner-friendly filament that provides visually pleasing results.

Silk Gold PLA is a relatively simple and beginner-friendly filament that provides visually pleasing results.

Since the filament does not contain solids, you will miss the characteristic mass of 3D printed projects. made from solid thread. This weight gives 3D prints a certain level of premium quality. A print made from PLA Silk Gold looks good, but you're not going to fool anyone that it's made from real gold.

Option 2: 3D SoluTech Real Gold PLA Filament

This real gold filament from 3D SoluTech is another viable and inexpensive option if you want your prints to be elegant. Even though the thread's marketing used "real gold", nothing could be further from the truth. This is a standard solids-free color PLA, which is both a good and a bad thing.

The absence of any metallic particles in this true gold filament means it is no more difficult to print than standard PLA. You can print at low temperatures and without a heated bed without worrying about layer sticking or warping issues. You can also safely use the standard nozzle without worrying about wear.

You can also safely use the standard nozzle without worrying about wear.

Since almost everyone who has tried 3D printing knows how to work with PLA, this might be the easiest way to add some gold to your 3D prints.

However, in this case, quality takes a backseat to ease of use. Prints made with Real Gold filament look more like brown bronze than gold. The closest metallic analogue of a thread made of real gold will be copper. Because it does not contain any naturally shiny materials, a full range of finishing techniques, from sanding and polishing to priming, will be required to achieve the "shine" of the finished print.

Despite its shortcomings, the SoluTech Real Gold Filament is still a compelling choice for 3D printer hobbyists who want to get a little creative but don't want to work with complex filament material. The filament still looks great and "pops out" when properly tuned. This is an inexpensive filament that is easy to work with and requires no modification to your standard 3D printer. Just met your expectations, as it can not be like "real gold" in any way.

Just met your expectations, as it can not be like "real gold" in any way.

Option 3: GizmoDorks Gold ABS Filament

Famous 3D filament brand GizmoDorks uses their ABS based gold filament instead of PLA. This should be a good choice for those who want their gold prints to have an extra factor of strength and heat resistance. Naturally, GizmoDorks gold filament comes with the usual difficulties of ABS printing.

Like SoluTech Gold Thread, GizmoDorks Gold Thread does not contain solids, but is simply colored ABS. This simplifies the whole technique of 3D printing this gold filament, especially if you are already used to working with ABS. Compared to PLA, ABS printing is slightly more stable in terms of chemical and thermal resistance. It's also robust enough for limited functional use, although we assume you'll be using this thread to build display elements.

The finish of this gold thread is also somewhat dull, but closer to toffee yellow than bronze. The bright finish looks great even without any trim. However, this thread is a great opportunity to practice ABS finishing techniques using an acetone steam bath. This technique melts a very thin layer of plastic onto an ABS print, giving it a perfectly smooth and shiny surface.

The bright finish looks great even without any trim. However, this thread is a great opportunity to practice ABS finishing techniques using an acetone steam bath. This technique melts a very thin layer of plastic onto an ABS print, giving it a perfectly smooth and shiny surface.

If you have worked with ABS before, you probably know that it is not easy to print with it. The high printing temperature required for ABS, combined with its thermal shrinkage index, makes it especially prone to warping. Achieving the perfect combination of bed temperature, print speed, and nozzle temperature takes a bit of work. The consistency and quality of this thread from GizmoDorks is pretty good, so it should help you eventually improve your technique.

Is there a technology for 3D printing with real gold?

The only thing that all of the above options have in common is that none of them uses real gold. Unlike other metals such as brass or copper, gold is very expensive even in small quantities. A 1kg spool of filament impregnated with real gold would likely cost tens of thousands of dollars, which is not very suitable for a process that requires repetitive cycles of trial and error.

A 1kg spool of filament impregnated with real gold would likely cost tens of thousands of dollars, which is not very suitable for a process that requires repetitive cycles of trial and error.

way to turn 3D models into solid gold objects, but they rely on different 3D printing technologies. The most commonly used are direct metal laser sintering (DMLS) and investment casting. Sintering is carried out using a laser to cure the powdered raw material, similar to the selective laser sintering (SLS) process.

Lost wax casting is a more indirect way of using 3D printing to work with gold. Instead of printing in gold, this method starts by using a 3D printer to create a wax model. An impression is made of the model, usually enveloping it with plaster. When the mold hardens, the bottom of the mold is pierced and subjected to high temperatures to allow the wax to run off. The mold is then filled with liquid metal—in this case, gold alloy.

Unfortunately, none of these methods can be done at home. A DMLS machine can cost up to $150,000 and houses aren't quite equipped to handle molten metal. Think about how valuable gold is and how technically complex and expensive the equipment is, it is best to entrust this work to specialists. Gold 3D printing services are offered by professional 3D printing companies such as i.materialise and Cookson Gold.

A DMLS machine can cost up to $150,000 and houses aren't quite equipped to handle molten metal. Think about how valuable gold is and how technically complex and expensive the equipment is, it is best to entrust this work to specialists. Gold 3D printing services are offered by professional 3D printing companies such as i.materialise and Cookson Gold.

Closing thoughts

3D printing in gold will be a dream come true. many manufacturers of jewelry and decorations. The sheer versatility of 3D printing, combined with the value and manufacturability of gold, will open up many opportunities for more imaginative uses of one of the most precious metals in human history.

However, 3D printing technology is not. not quite there yet. You can create faux gold 3D printer designs using filaments that mimic the look of gold, but real gold will use more traditional methods. 3D printing is still used in the art of gold working, but in a more indirect way, such as in the production of a wax model for lost wax casting.