Mk8 3d printer nozzle

Olsson Ruby MK8 Nozzle - 1.75mm x 0.60mm

- Home

- Store

- 3D Printer Accessories

- 3D Printer Nozzles

- Browse by Nozzle Material

- Ruby Tip Nozzles

Developed for lab use 3D printing with extremely abrasive filaments, the Olsson Ruby 3D printer nozzle is the most wear-resistant nozzle on the market. Capable of extruding upwards of 8kg of carbon fiber filament with zero signs of wear, no filament is too tough for the Olsson Ruby. The original ruby nozzle is a perfect fit for any E3D style hotend, and this version is compatible with the MK8 style hotend.

Remove from wishlist Add to wishlist loading...

Available Add-ons (3)

Show More Addons

Product No. M-9TD-9ZWX

| List Price: | $90.00 |

|---|---|

| Price: | $90. |

| Price: | $... |

| Order Now: | Ships calculating... Free U.S. Shipping |

Print endless amounts of abrasive filament

Born from the same demanding lab that gave us the Olsson heater block, the Olsson Ruby 3D printer nozzle is the most wear resistant nozzle available. Developed for use while printing extremely abrasive Boron Carbide filament, the Olsson Ruby prints kilograms of even the most abrasive consumer filaments with no visible signs of wear.

Why the Olsson Ruby is right for your 3D printer

- One nozzle for any material. While the Ruby has been developed for use with highly abrasive materials, it also produces beautiful 3D prints with less abrasive materials such as PLA, ABS or Nylon

- The ruby embedded in the tip of the nozzle will not wear down when printing even the toughest materials.

Designed for use printing Boron Carbide, the third hardest known material in the world.

Designed for use printing Boron Carbide, the third hardest known material in the world. - The main body of the Olsson Ruby is brass, which means excellent heat conductivity throughout the nozzle to maintain consistent temperature.

- The ruby nozzle has been in field testing since early 2016 and the community has produced stunning prints using this nozzle

- Each Olsson Ruby nozzle is manufactured, assembled and testing at their high-quality facility in Sweden. By controlling their process and keeping it close to home they can guarantee the best quality and tight tolerances on each and every nozzle.

Perfect for printing NylonX

Author of the OpenRC Project, the OpenRailway Project and designer of the Benchy, Daniel Norée has found great success printing many of his designs with the Olsson Ruby nozzle and MatterHackers NylonX filament.

Daniel describes his experience printing NylonX with the Olsson Ruby:

”Other than being a high precision product the Olsson Ruby offers great value when iterating a project like the OpenRC Mini Quad and need that long time consistency in quality as it won't degrade over time nearly as much many of it´s competitors when printing abrasive filament like the NylonX. ”

”

The Olsson Ruby is an excellent nozzle for printing MatterHackers NylonX carbon fiber infused nylon filament. NylonX produces super strong parts, but can quickly wear out a standard brass nozzle. The strength and abrasive resistance of the Ruby nozzle enables makers to print kilograms of carbon fiber filament with zero signs of wear on the nozzle.

The Olsson Ruby is the perfect nozzle for printing with MatterHackers NylonX

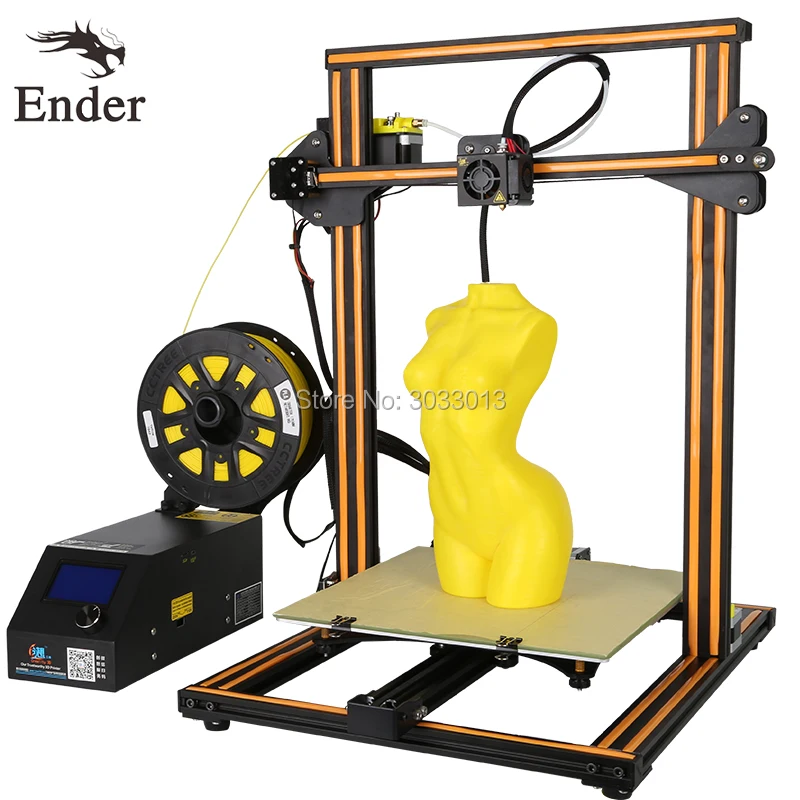

Is My 3D Printer Compatible?This Olsson Ruby has M6x1 external threading and a 5.5mm shaft, making it compatible with the MK8 style hotend featured on many printers. Some of these printers include:

- Creality CR-10

- Creality CR-20

- Creality Ender 2

- Creality Ender 3

- Makerbot Replicator 2/2X

- Makerbot Replicator Smart Extruder

- SeeMeCNC Artemis

- SeeMeCNC Rostock Max v3/v3.2

- Monoprice Mini v1

- Monoprice Mini v2

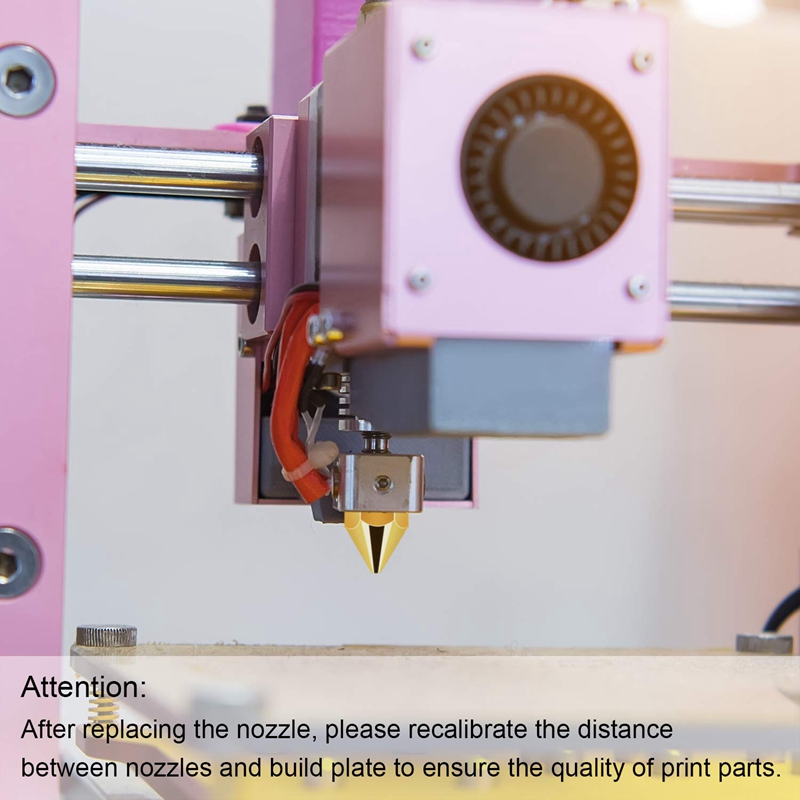

*Olsson Ruby will need to be mounted with the nozzle placed against the heat break/isolator to create a seal, and not against the front face of the heater block.

**Any printer with conductive automatic bed leveling, such as the LulzBot TAZ 6, will need to have the auto leveling disabled as the ruby tip is not conductive.

MK6 Vs MK8 Vs MK10 Vs E3D V6 – Differences & Compatibility – 3D Printerly

Being in the 3D printing field I’m sure you would have seen these MK6, MK8, MK10 and E3D V6 terms thrown around without knowing the actual differences. I’ve made this post for that exact reason, to set out and explain, compare and answer what makes each nozzle different.

Depending on what 3D printer you have, there will be a certain extruder that is compatible for you.

The MK6, MK8, MK10 & E3D V6 are a series of hotends, extruders and nozzle combinations which come together to make a system which allow filament to pass through the 3D printer down to the nozzle, known as an extrusion system. There is compatibility between the MK6, MK8 & V6 range.

The name ‘MK’ came about by the common practice of distinguishing versions in a series of products (shortened from Mark).

It’s similar to how militaries give number designations to their arsenal (Mk 6 assault boat) or even the British Railway production series (Mark 1, 2, 3 British Rail coaches).

It began with the Makerbot brand starting their own series of hotends using MK as their foundation.

It started from MK1 and to my knowledge has gone all the way up to MK11 so far but it isn’t very common in the mainstream 3D printing market. The mains ones you would have come across are the MK8, MK10 & E3D V6 range.

I’m going to get into the details of what makes each nozzle different, while also comparing compatibility and other bits of information so read on to find out.

- Make sure if you are getting an extruder, it is compatible with your 3D printer

- The differences between the nozzle types are quite small, but can make a difference

- If you use the wrong nozzle on a hotend, it might just not work or could actually lead to some damage.

If you are interested in seeing some of the best tools and accessories for your 3D printers, you can find them easily by clicking here (Amazon).

MK6

These terms MK6 and so refers to the version in a long series of different parts. It refers to the extruder, hotend and nozzle and these usually come as a kit so they can all be put together, but can be bought individually.

The MK6 catered more towards 3mm filament since it was before the 1.75mm was as popular as it is today. It also was mainly made for printing ABS rather than PLA.

Check out my article explaining the Differences Between 1.75mm vs 3mm Filament, and giving some useful information behind the two sizes.

The MK6 range, to my knowledge was the first commercially available hotend sold as a whole kit rather than individually. It has a stainless steel heater block whereas the MK6+ upgrade kit has an aluminum block which a different design, making it smaller and lighter.

The MK6 nozzle has an M6 threading size meaning the diameter of the thread measures up to 6mm.

When you want to upgrade a certain part you just have to make sure it follows the same type of threading (screwing in part) and is compatible with your current parts. Once you purchase a 3D printer you’ll know which range is compatible.

Extruders from MK6 and below really don’t have much of a bearing in today’s 3D printing world because they just didn’t keep up to performance and quality standards and had a tendency to wear out and slip/grind up filament.

Comparison

We don’t really compare MK6 to other ranges since it wasn’t up to high standards and was still a working progress at the time. Now we have extruder systems which beat the MK6 and below series with ease.

Now we have extruder systems which beat the MK6 and below series with ease.

The MK7 was the first extruder which made the move to dedicated 1.75mm filament extrusion. The MK6+ had parts which could be adapted to fit a 1.75mm filament but it didn’t work quite as well as they thought.

The MK7 incorporated the all-metal thermal barrier and allowed users to print PLA or ABS.

However, the MK7 feeder used a preload with a plunger and fixed distance washers which was a huge drawback as the plungers wore out and damaged the filament. Unfortunately, they didn’t have V groove bearings either.

3D Printer Compatibility

MK6 – Makerbot, Creality CR10, Ender 3 Pro, Tevo Tornado, Anet A8, Prusa I3 and so on.

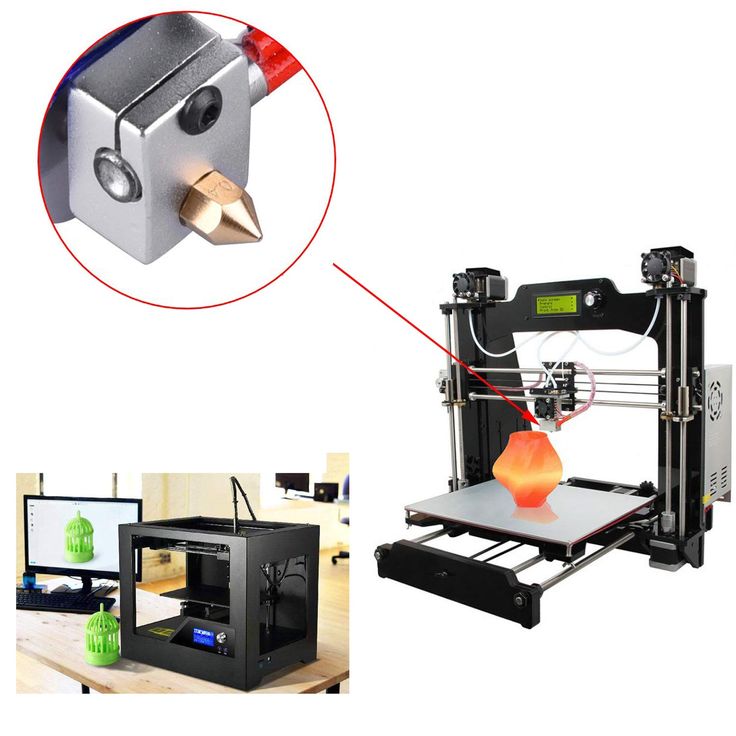

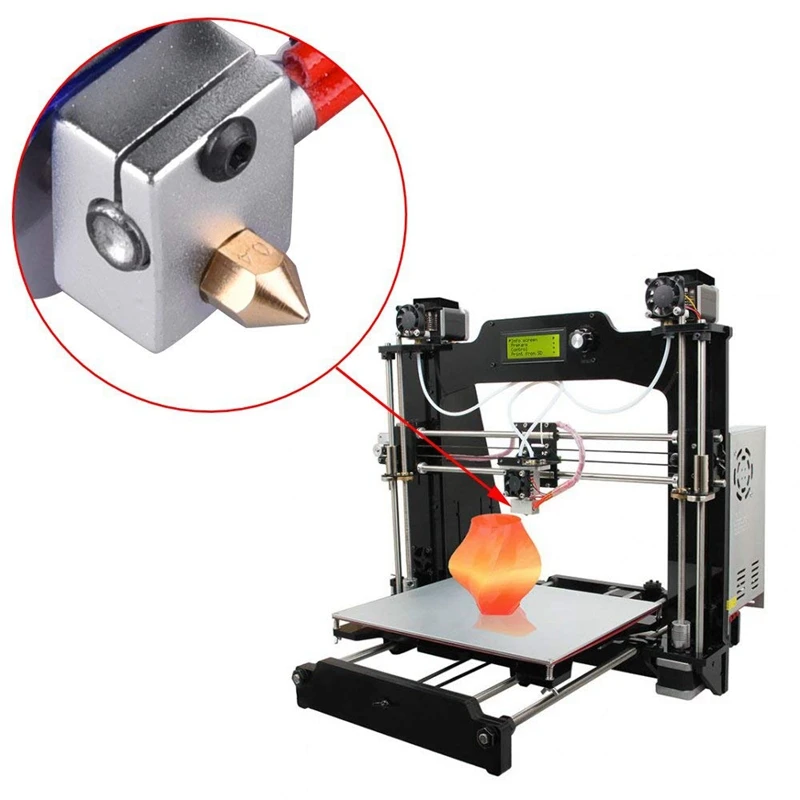

MK8

The Makerbot Replicator was responsible for the all new dual extruder hotend setup called the MK8. It had a cooling bar which was thicker than the MK7 range but it shared the same all-metal thermal barrier.

The MK8 had small differences in the nozzle geometry from within and externally which supposedly had a positive impact on printing performance.

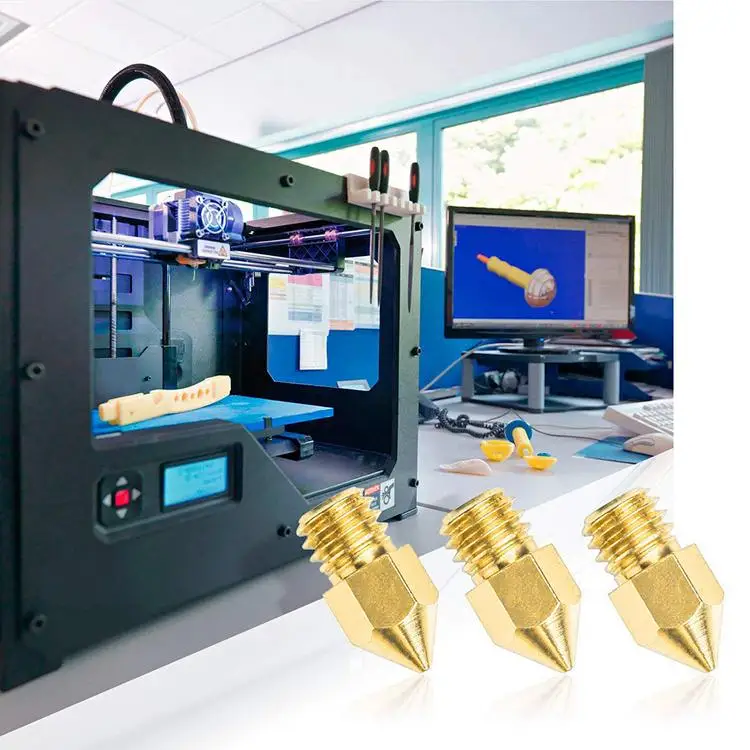

An MK8 nozzle as you can see from the video above has sharper, more angled sides coming off the tip of the nozzle, meaning it’s not as flat as other nozzles. It has a very pointy look to it from the sides all the way through to the tip.

The MK8 nozzle also uses the M6 threading size. This means an MK8 nozzle can be used with an MK6 extruder and vice versa.

You can check the size of the threads of your nozzles by using some simple calipers which is a necessary part of the 3D printing tool kit.

If you don’t have calipers I would recommend the Rexbeti Digital Calipers. It’s a stainless steel, water-resistant measuring tool that allows you to measure precisely with smooth operation. It’s highly reliable and should last you years to come.

The large LCD screen, easy reset button and large battery are only some of the key features.

One of the best MK8 nozzle sets I could find on Amazon is the Disacayson 0.4mm Nozzle with Free Storage Box (30 pcs).

It has the highest ratings out there for MK8 nozzles, it’s very easy to install and they have a 1-month unconditional refund policy, so satisfaction guaranteed!

Comparison

One of the differences between an MK8 hotend and a V6 hot end is the length. The overall length of the V6 is shorter than the MK8 but it has a longer thread.

If you are changing from a MK8 to a V6 nozzle you might have to move your Z-End-stop switch up a little bit so you can still level out your bed.

The E3D V6 nozzles in hardened steel are usually easier to find rather than hardened steel MK8 nozzles.

The threading hole of an MK8 nozzle has a smaller hole compared to an MK10 nozzle.

The stock MK10 design uses a PTFE tube as the thermal barrier within the filament guide tube, resulting in a reduced melt rate of filament compared to the MK8 design with the stainless thermal barrier tube.

You can see this during filament loading, where the same filament at the same temperature will flow a little bit better on the MK8 design. =

=

In terms of stringing, there should be little difference between the two once retraction and temperature are properly adjusted.

The MK10 hotends do run a little hotter than MK8 hotends for their indicated temperatures – so the MK10 may be prone to stringing if you don’t lower the temperature.

In terms of parts costs, there are far more MK8-compatible replacement nozzles out there (due to its M6 thread which is a very popular thread size for a lot of printer builds.

We sell our high lubricity wear-resistant MK8 and MK10 nozzles for the same price though.

3D Printer Compatibility

MK8 – Same as MK6 because it has the same M6 threading.

MK10

MK10 was a complete change of the hotend, using the MK9 as a base model (uses MK9 feeder parts). With this range of hotends you have smooth OD thermal barriers along with a 4mm OD 2mm ID PTFE liner.

One of the main differences is the MK10 uses M7 threads rather than the M6 threads which all the previous models use.

The main reason for this is because a 4mm PTFE liner doesn’t have enough metal to make the outer tube with M6 threads. You won’t be able to use the MK10 range with any other previous hotend models since they have different sized threads.

So make sure you don’t purchase an MK10 nozzle if you have an MK8 extruder and vice versa.

MK10 is completely incompatible with all previous hotend parts. Every part is different.

For a solid MK10 nozzle set, the Umlife MK10 Brass Nozzle Set is a great choice. It comes with:

- 4x 0.4mm nozzles

- 1x 0.2mm nozzle

- 1x 0.3mm nozzle

- 1x 0.5mm nozzle

- 1x 0.6mm nozzle

- 1x 0.8mm nozzle

- 1x 1mm nozzle

- 5x cleaning needles

Comparison

You can identify an MK10 nozzle by looking at the angle of the metal sides that come off the tip of the nozzle. They are at a roughly 45 degree angle and is relatively flat compared to the other nozzles out there.

So you’ll have the tip of the nozzle, then a 45-degree angle then the vertical angle leading to the thread of the nozzle.

The threading hole of an MK10 nozzle will have a bigger hole compared to the other nozzles because its purpose is to fit the plastic PTFE tube which feeds filament straight through to the nozzle.

The threading is called an M7 thread because it measures up at 7mm diameter

3D Printer Compatibility

MK10 – Monoprice Maker Select, Wanhao Duplicator i3 (D4, D6), Qidi Tech, Cocoon Create, Flashforge Creator (Dreamer, Finder)

E3D V6

The E3D V6 range is one that has it’s own ecosystem (M6 thread) of parts that all work together seamlessly. It’s very well-known for having high quality, reliable branded parts that get the job done.

The Hardened Steel nozzle that E3D sell is one that you can rely on when printing abrasive filaments that would rip through standard brass nozzles.

Rather than have to constantly change your nozzle over when wanting to print with abrasive filament, you can just have this nozzle installed, slightly increase the temperature and get great results.

Top reviews, amazing performance and long-lasting durability are just some of the reasons why you would go with the E3D V6 nozzle.

Compatible with any 3D printers that use the E3D V6 ecosystem (M6 thread), including Prusa i3 and i3 MK2 3D printers.

The internal geometry of V6 Nozzles is optimized to reduce back-pressure, ensuring a smooth, easy flow of filament while improving the effectiveness of retraction.

The flat surface tip of the nozzle which flattens down the layer is custom machined to each nozzle size. A small nozzle tip gives you high precision, and a wide nozzle tip assists in the smooth printing of larger layers.

3D Printer Compatibility

E3D V6 – Same as MK6 & MK8 with M6 6mm threading.

Comparison

When you look at the extruders you definitely see differences between them such as some having the block fuse horizontal or vertical with a longer nozzle.

Nozzle Thread Type & Length

There are two main important things you want to take into account when looking at nozzle thread.

That’s the thread type and the thread length. If you don’t have the correct thread type you just won’t be able to the nozzle in so it would be of no use.

If the thread length is incorrect you’ll end up in a situation where, if it’s too long, you have a lot of the nozzle sticking out of the heat-block so it won’t heat up efficiently.

If it’s too short, you’ll have a big gap between your heat-break and the nozzle, which will result in filament not being able to extrude properly and cause blockages.

The good thing here is there is quite a large difference between the thread length so if you know what you’re looking for, you can get the right one.

A standard E3D V6 nozzle will have a 5.5mm length thread and is the M6 x 1mm pitch (the most common thread type).

A Volcano nozzle which also uses the M6 x 1mm pitch has a length of 14mm. The Supervolcano nozzle is even longer.

Your extruder design will have a clear nozzle that it is compatible with.

I would say there isn’t necessarily a thread type which is better than another performance-wise. There are specific design reasons why an extruder will use a thread type.

The main thing you should worry about is the thread length. The longer the nozzle, the longer your heat-block is likely to be. If you have a nozzle which isn’t the correct, your printing performance will be negatively affected.

So, Which Extruder Should I Buy?

There are several extrusion systems that are tried, tested and work very well. Some charge a real premium, while you can still get a high-performance extrusion system for a reasonable price, it really depends on what level of 3D printing you are trying to get to.

If you are happy with a simple, gets the job done, lower range type of extrusion system I would recommend the Redrex Upgraded Aluminum Extruder.

- It’s a durable MK8 Bowden extruder with direct extrusion support and fits perfectly on the CR-10 Ender 3 series, TEVO Tarantula, Anycubic Kossel i3 Mega and much more.

- The ratings on this extruder are very promising and it sports an 18 month warranty

- You can print with all sorts of material including flexible TPU filament.

- Expect long-lasting performance with the 18 months warranty.

- It’s simple, easy to use and comes at a very convenient price!

Some people want an advantage over having the lower range extrusion systems which I can understand. If you’re one of these people who want something mid-tier and are willing to spend a little extra, I’d go for the BMG Bowden Dual Drive Extruder.

- High performance extruder for your 3D printer

- It’s a TriangleLab BMG Clone which is a very high-end extruder for a fraction of the price

- Solves filament grinding issues

- The downside here is it takes a few extra steps to manually advance filament through it

For the 3D printer enthusiasts who take a lot of pride in their 3D printing quality and strive for the top range, I would recommend the E3D Hemera Extruder System. There are many reasons why this is the choice I would go for, you can get more in-depth information by reading my Hemera Extruder review.

There are many reasons why this is the choice I would go for, you can get more in-depth information by reading my Hemera Extruder review.

It not only comes with one of the highest quality extruders in the 3D printing game, but also a state-of-the-art hotend system with patented cooling designs that go above and beyond normal expectations.

- Dual drive extrusion system

- Convenient mounting system with compact design

- Designed to support the user, easy to assemble and disassemble

- Heatsink design that reduces risk of warping and uneven stresses

- Can push filament with up to 10KG of force

If you love great quality 3D prints, you’ll love the AMX3d Pro Grade 3D Printer Tool Kit from Amazon. It is a staple set of 3D printing tools that gives you everything you need to remove, clean & finish your 3D prints.

It gives you the ability to:

- Easily clean your 3D prints – 25-piece kit with 13 knife blades and 3 handles, long tweezers, needle nose pliers, and glue stick.

- Simply remove 3D prints – stop damaging your 3D prints by using one of the 3 specialized removal tools

- Perfectly finish your 3D prints – the 3-piece, 6-tool precision scraper/pick/knife blade combo can get into small crevices to get a great finish

- Become a 3D printing pro!

What about nozzles? Or how happy I was with the nozlam MK8

Technician

Very often, when the issue of print quality is raised, they begin to operate with kinematics, mechanical quality, electronics stability and slicer settings.

At the same time, for some reason, the nozzles are undeservedly bypassed. But if you look, then some printers with the worst mechanics print, while others with the best - make dirt. But few people pay attention to the nozzles!

I must say right away that the topic of nozzles was not invented by me. Once I already saw a material devoted to this, but unfortunately I could not find it either here or somewhere else. So my whole little experiment is based on what I heard about it, but finally I had a chance to try it.

So my whole little experiment is based on what I heard about it, but finally I had a chance to try it.

Few people know, but there are certain standards or subtleties for nozzles. But since they are hidden inside the nozzle, dried apricots from the Middle Kingdom neglect them. Perhaps due to technological difficulties, and perhaps even out of ignorance. Precisely relying on the latter, I decided to test this hypothesis.

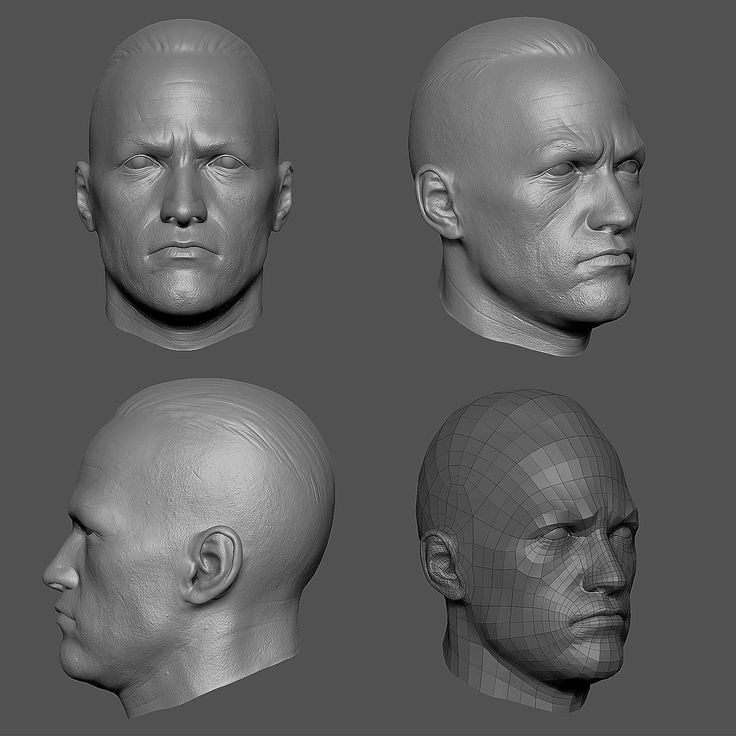

Let's start with the fact that in the correct nozzle, the hole itself is not just located immediately after the plastic heating chamber, but should be a small tunnel. It is logical to assume that it is precisely thanks to this design that the plastic chokes like from a tube, and does not crawl out in different directions as it pleases.

This is what popular nozzles should look like in a section:

In practice, for most sellers, they look like this:

I dare to guess because it's easier to do. They drill a hole to a certain level, with a cone at the base, and then remove the metal from the back until they get the required diameter. From the point of view of the process, everything is simplified - the amount of metal removed is the width of the nozzle. It is logical that drilling a hole is much more difficult. But otherwise the tunnel can not be obtained.

They drill a hole to a certain level, with a cone at the base, and then remove the metal from the back until they get the required diameter. From the point of view of the process, everything is simplified - the amount of metal removed is the width of the nozzle. It is logical that drilling a hole is much more difficult. But otherwise the tunnel can not be obtained.

And then I thought - there are MK8 nozzles. They have a very sharp nose shape, which means there is a possibility that it will no longer be possible to make nozzles in this way. If you deepen the plastic supply shaft too much, then the tip of the spout will fall off. This means that they will be forced to lower the shaft to a certain level, and then drill a hole of the desired diameter.

So the nozzles arrived (I took 0.4 for the test) and immediately ran into the first difficulty - I have a hotend and e3d v6 nozzles. In this hot end, the nozzles have a longer thread, about 2-3 mm. When I tried to screw in the MK8 - thermal barrier from e3d v6, it turned out to be too short, as a result of which the hot end rested on the radiator.

When I tried to screw in the MK8 - thermal barrier from e3d v6, it turned out to be too short, as a result of which the hot end rested on the radiator.

There are long barriers from MK8, but I did not want to wait, and therefore from an unnecessary barrier, I cut off part of the tube and used it as a spacer between the nozzle and the barrier.

There shouldn't be any problems because I have long chosen for myself thermal barriers with a through diameter of 4mm, in which the fluoroplastic tube passes directly to the nozzle itself.

So the system is assembled - started printing and voila!!! The quality is really better than popular Chinese e3d v6 nozzles.....

Here is an example of a part - printed on e3d v6 nozzles running KLIPPER:

And here is the same thing but with an MK8 nozzle running KLIPPER:

And a little spolerno - printing with an MK8 nozzle running 32bit Marlin 2. x on a SKR 1.3 board:

x on a SKR 1.3 board:

I don’t know if the photo could convey the difference, but in fact the result is this - on the MK8 nozzles, the layers are actually smoother, there are almost no snot and sagging. Overall the details look more neat. Even reduced the retract.

Here is such a small experiment with far-reaching conclusions :)

Follow author

Follow

Don't want

41

More interesting articles

oxyfire

Loading

26.10.2022

1110

13

Subscribe to author

Subscribe

Don't want to

So 12 hours killed to finally get the ADXL345 accelerometer to accurately calibrate Input Shaper...

Read more

four

Follow author

Follow

Don't want

Alekmaker G. T. was purchased in 2017, and after 3 years of good work, I have accumulated...

T. was purchased in 2017, and after 3 years of good work, I have accumulated...

Read more

257

Subscribe to the author

Subscribe

Don't want

Snot. Who hasn't encountered them?

How many times this question has been raised. How many topics...

Read more

Worm for 3D printer MK8 in category "Technique and Electronics"

nozzle MK8 MK9 0.2mm under 1.75mm thread for 3D printer PS

128.26 UAH 9000 64.13 UAH

Buy Buy

Online store PRICESS

Nozzle MK8 MK9 0.3mm under 1.75mm thread for 3D printer PS

Delivery in Ukraine

128.26 UAH

9000 64.13 UAHBuy

online store PRICES

003

nozzle MK8 MK9 0.5mm under 1.75mm thread for the 3D printer PS

Delivery in Ukraine

128.26 UAH

64. 13 UAH

13 UAH

online store PRICESS

9000 mK8 MK9 0. -Printer PSDelivery in Ukraine

128.26 UAH

64.13 UAH

Buy

online store PRICESS

Shall MK9 0.8mm thread for the 3D printer PS

Delivery in Ukraine

128.26 UAH

64.13 UAH

Buy

Online store PRICESS

Fabric MK8 MK9 0.2mm thread for 3D printer EP

Delivery 9000.24 UAH

9000Buy

Ephir.com.ua

nozzle MK8 MK9 0.3mm under 1.75mm thread for 3D printer EP

Delivery in Ukraine

156.24 UAH

78.12 UAH

Buy

Ephir.com.ua

Blood MK8 MK90.

Delivery in Ukraine

156.24 UAH

78.12 UAH

Buy

Ephir.com.ua

Nozzle MK8 MK9 0.8mm thread for 3D printer EP

Delivery 9000.24 UAH 9000 9000 9000 9000 9000 9000 78.12 UAH

Buy

Ephir.com.ua

nozzle MK8 MK9 0.8mm thread for a 3D printer

Non -access online store

Nozzle MK8 MK9 0. 3mm under 1.75mm filament for 3D printer

3mm under 1.75mm filament for 3D printer

In stock in Rovno

Delivery across Ukraine

20 — 30 UAH

from 4 sellers

specify30002 Kramnitsa of non-chowed speeches

nozzle MK8 MK9 0.4mm under 1.75mm thread for 3D printer

in a warehouse in Rivne

Delivery in Ukraine

9000-30 UAHof 4 sellers

Clear

Kreumnitsa Non-chief speeches

nozzle MK8 MK9 0.2mm under 1.75mm thread for 3D printer

Delivery in Ukraine

20-30 UAH

of 4 sellers

20 UAH

Buy

Bazaars

nozzle MK8 MK9 0.5mm under 1.75mm thread for 3D printer

Delivery in Ukraine

20-30 UAH

from 4 sellers

20 UAH

Buy

Bazaars

See also MK8 MK9 0.2 0.2 submarine 0.2 mm under 1.75mm thread for 3D printer

in a warehouse in Rivne

Delivery in Ukraine

to 20 UAH

from 2 sellers

20 UAH

Buy

Krons Internet shop

MK9 0. 5mm under 1.75mm thread for 3D printer

5mm under 1.75mm thread for 3D printer in warehouse

Delivery in Ukraine

to 20 UAH

from 2 sellers

20 UAH

Buy

Krons Internet

Stop MK8 MK90.4mm under 1.75mm filament for 3D printer

In stock in Rivne

Delivery across Ukraine

printer

Delivery across Ukraine

20 UAH

Buy

Online store "Dribnytsi"

Nozzle MK8 MK9 for 1.75mm filament for 3D printer (0.4mm) [#X-4]

9002 In stock in stock in ZaporozhyeDelivery across Ukraine

10 UAH

Buy

Ardu.prom.ua (overlay NP from 150 UAH!)

Nozzle MK8 MK9 0.2mm for 1.75mm filament for 3D printer

In stock in Ukraine

25 UAH

Buy

INTERNENT-store Techniki Ta Elektroni

nozzle MK8 MK9 0.3mm under 1.75mm filament for 3D printer

in warehouse

Delivery

25 UAH

Buy

ININTERN shop of equipment and electronics

nozzle MK8 MK9 0.