Delta 3d printer parts

| Phone Orders or Help: 800-734-3588, 206-458-7550 (Pacific Time) | |||||||||||||

|

Home

Welcome to TriDPrinting, your source for Rostock and Delta 3D printers, parts and accessories.Click on a category below to purchase.

PasstimeGo here for some interesting and fun reading about 3D printers and robots. How true: "If it's not broken, keep fixing it until it is."

Home |

|||||||||||||

Home

3D Printer Basics

Build Instructions

3D Printer Models

Filament Basics

Compare Filaments

Fun Reading

3D Printer Patents

BOM (Parts List)Kossel Mini BOM (Parts List) Kossel Legacy BOM (Parts List) Prusa i3 Rework BOM (Parts List) Electronics Stepper Motors Power Supplies Stepper Motor Dampers Kapton Heaters Azteeg X5 Instructions USBtinyISP FSR/Endstop Controller Limit Switches End Stops Wiring, Connectors, Crimps Power Connector Plastic Parts Mechanical Parts Belts & Gears Bearings Coupling Kossel Nuts Bolts, Screw Rods (Arms) Rod Ends Rod Set Screws Hobbed Drive Gear Spool Fan Kapton Heater Heat Spreader Borosilicate Glass Hot Ends E3D HotEnds E3D HotEnd Volcano E3D HotEnd Nozzles J Head HotEnds Resistors 5.  6, 6.8 Ohm

Thermistors

Push Fit

Teflon Tube, PTFE 6, 6.8 Ohm

Thermistors

Push Fit

Teflon Tube, PTFE

Printing Supplies Kapton Tape Blue Tape Misc Thermal Fuse Heatbed Extrusions Silica Gel Comm Cable Spectra Line Techflex Split Loom T-Slot Aluminum Extrusions Bulk Nuts, Bolts, Screws

Send Us Your Comments Share Site With A Friend Go To Our Site Map Link To Us Related Links Report A Broken Link Contact Information |

|

||||||||||||

FLSUN 3D Printers & Spare Parts

Sort byRelevanceBestsellersCustomer ReviewsPrice, Low to HighPrice, High to LowNew arrivalsHighest Discount

-

FLSUN Q5- Ø 200 x 200 mm build volume

- Automatic leveling

- 32-bit mainboard with TMC2208 drivers

-

FLSUN PEI Flexible Build Plate 3 Model types- Powder-coated finish

- Good adhesion

- Flame retardant

-

FLSUN Heating Cartridge 3 Model types- Original spare part

-

FLSUN Hotend Thermistor 3 Model types- Original spare part

-

FLSUN Hotend Assembly 3 Model types- Original spare part

- For FLSUN 3D printers

-

FLSUN Hotend 3 Model types- Original spare part

-

FLSUN Stepper Motor 3 Model types- Original spare part

-

FLSUN Print Platform- Original spare part

-

FLSUN Extruder 3 Model types- Original spare part

-

FLSUN Belts 3 Model types- Original spare part

-

FLSUN Part Cooling Fan 3 Model types- Original spare part

- Original material fan

-

FLSUN Super Racer- 260 x 330 mm

- Capacitive colour touch screen

- High-speed 3D printing

-

FLSUN Auto Levelling Assembly 2 Model types- Original spare part

- For FLSUN devices

-

FLSUN Heated Bed Including Build Surface- For FLSUN Delta printers

- For good adhesion

- Original spare part

-

FLSUN Touchscreen 2 Model types- Original spare part

-

FLSUN Heated Bed 2 Model types- Original spare part

-

FLSUN Hotend Fan 3 Model types- Original spare part

-

FLSUN Power Supply 3 Model types- Original spare part

-

FLSUN V400- Ø300x410mm

- Printing speeds up to 400 mm/s

- Printing temperature up to 300 °C

-

FLSUN Speeder Pad- 7-inch display

- 2-5x higher print speed

- Print monitoring in real time

-

FLSUN Mainboard 3 Model types- Original spare part

-

FLSUN High Speed Nozzle- Original spare part

- From FLSUN printers

All prices incl. VAT.

VAT.

features, photos and customer reviews

4 745 ₽Go to the storeThis item is no longer for sale, see similar ones there are similar and similar

The price increased by 81.83 ₽

More expensive than average, slightlyReliable seller - 89%

Above average, you can buy, Dave 3D TECH Store

- On the site for more than 4 years

- High overall rating (3244)

- Customers satisfied with communication last 3 months

Prices from other sellers from 556.29 ₽

1 375 ₽

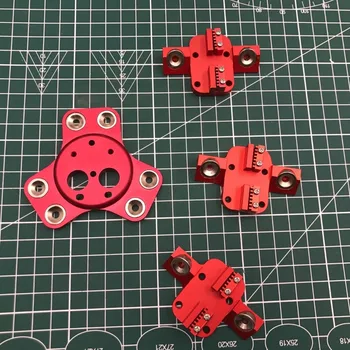

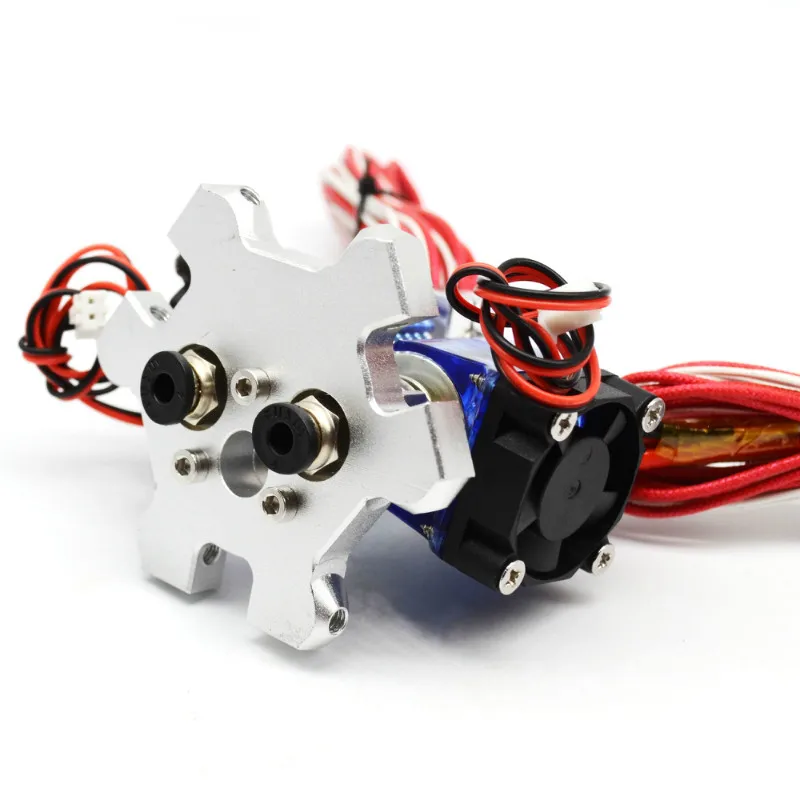

1.75/0.4 mm Delta Kossel V6 aluminum alloy metal double fisheye effector hotend Full kit with fan kit for 3D printer

0 OTOKOK

0 PrOSA

Reliability - 100%

Seller Funssor 3D Tech Store

In the store in the store

9000. 29 - 803.83 ₽

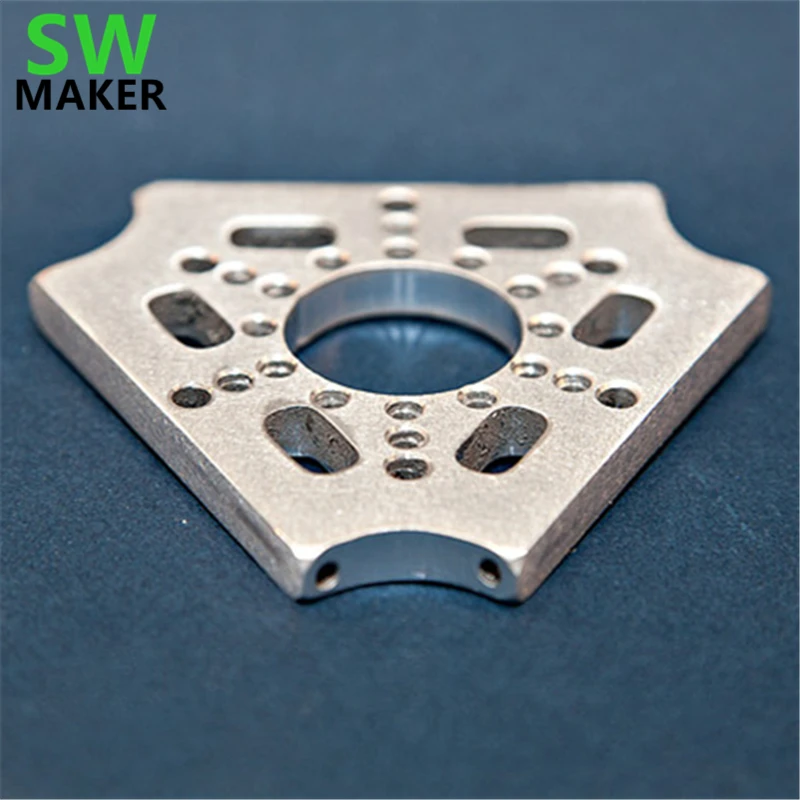

29 - 803.83 ₽ SWMAKER M3 / M4 DELTA KOSEMENTICAL ECTIONAL ECTIVORTION GREATIONAL Effector Glass Great Trick. for 3D printer

0 ratings

0 orders

100% reliable

Seller QUEENYUKI 3D TECH Store

0017 Found 47 similar items

Rs.

556.29 – 803.83 ₽

M3 / m4 delta kossel aluminum alloy, fisheye, effect, double effect, hammock, aluminum end, 3d printer mount

0

0

0003

%

714.44 ₽

2 pcs. kossel mini 3d printer accessories aluminum metal m4 delta kossel fisheye effector pendant stations 4mm for v5/v6 j-head

0

0

kossel fisheye effector hammock aluminum metal pendant stations single double print head

0

0

Seller Reliability 100%

-2

%

783. 20 ₽

20 ₽

M4 Fish Eye Eltor V5 V6 Part Aluminum Gamak Metallic Gamak Suspension station 3 mm Susponder Delta Kossel 3D Participation Printers

0

0 9000 9000 9000 % 9000 % 9000 % 9000 % 9000 % 9000 % 9000 % 9000 % 9000 % 9000 % 9000 % 9000 % 9000 % 9000 % 9000 % 9000 % 1 190 ₽

kossel delta 3d printer parts, complete set/set, 1.75/3mm, m3/m4, v6, hotend, car leveler for kossel delta 3d printer

1

3

Reliability seller 100%

-1

%

2 351 ₽

1 set V6 J -Head Hotend Kit with M4 Delta Kossel Fisheye Effector Fast delivery

0

90001 155 ₽

Delta kossel v6 kit, 1.75/3mm, single, m3, fisheye, effect, hotend, aluminum alloy, m3, fisheye, effect

0

3

Reliable seller 100 %

-2

%

652. 55 ₽

55 ₽

M4 Fish Eye Effector V5 V5 Part Aluminum Gamak Metal Gamak Suspension Station for M4 DELTA Kossel 4 mm Extruder 3D Printers Parts

0

0

9000 Reliability of the seller 83 % 9000.3 9000.3

M3 Dual Nozzle Fisheye Effector Dual Hole Hammock 3mm Full Metal Aluminum Alloy Delta Kossel 3d Printer Parts

0

1

The reliability of the seller is 89 %

-1

%

652.55 ₽

M4 Effector V5 V5 V6 Part Metal Gamak Suspension Stations for M4 DELTA KOSSEL 3D Parts

0

9000 9000) 72%-0.8

%

803.14 ₽

Reprap rostock kossel mini k800 3d printer spare parts, aluminum fisheye holder, m3 hole, for mkiv hotend, v5/ v6 hotend

0

0

The reliability of the seller 100 %

-6

%

Equal data

520. 53 -535.66 ₽

53 -535.66 ₽

MEGA 3D printer M4 Fisheye Easy, double single extruder J -hatend Hotend Hotend V5 V5 Alyumen For Delta Kossel

0

1

, the seller’s reliability 0 %

-30

%

342.44 ₽

m3 m4, fish eyes, effector for gamak, block for Delta Kossel, aluminum metal for aluminum metal 3d printers, hanging stations

4

Reliability of the seller 100 %

-0.8

%

1 437 ₽

Mini 3D printer M4 Delta Kossel, extrusion kit for extrusion with an inductive approach sensor, auto -equalization, 1.75/3 mm mm mm 3 mm mm mm

0

0

Reliability of the seller 100 %

-7

%

652. 55 ₽

55 ₽

M4 Effector V5 V5 V5 V6 Part aluminum Gamaac Suspension stations for M4 DELTA KOSSEL 4M EXPURED 3D 3D PCs 3D Printers 3D Printers0003

0

0

The reliability of the seller 51%

499.90-563.16 ₽

Spare parts for a 3D printer, a Delta M4 hammock printer KOSSEL 3D “Fish Eye” M3

0

9000 5

Establish seller 100%

-4

%

5 569 ₽

Reprap delta kossel k800, metal magnetic effector + carriage kit for DIY 3d printer, aluminum, black, anodized

0

2

The seller’s reliability 100%

Equal data

309.43 ₽

Aluminum metallic extruder for the Fish Eye 3D printer M4

0

0

The reliability of the seller is 0%

9000 -5%

750. 20 – 860.90 ₽

20 – 860.90 ₽

hotend j-head extrusion head, 3d printer metal accessories, parts kit, e3dv6 version, v5 extrusion head, upgraded print head

1

1

The reliability of the seller 89%

1 372 ₽

1.75/3 mm M3 Effector Hotend Set with an approximation sensor Automatic alignment for Delta Kossel Mini 3D Effector

9000 9000 9000 9000 9000 9000) seller 100%-0.6

%

1 372 – 3 658 ₽

Perfect upgrade v6 hotend mount kit 0.4mm 3d printer nozzle ultimaker2 + all metal v6 print head extrusion kit

0

0

The reliability of the seller 100 %

-0.8

%

702.06 ₽

Aluminum Extruder, Fish Eye effector for Rostock Kossel or Kossel Mini Delta M3, Use of openings for 3D Printer 9000 9000 0

1

Reliability of the seller 100%

-3

%

741. 94 – 927.60 ₽

94 – 927.60 ₽

0003

0

1

The reliability of the seller 100 %

-3

%

2 245 -2 264 ₽

New V6 2 in 1 exit Hotend one -folded two -color printing head + cable + fan complete set for 3D 3D Detail printer

0

0

003

0

1

The reliability of the seller is 100%

865.72 ₽

SW M3 Delta Kossel, a 3D printer, the effect of fishing, automatic equalization, the effect of fish eyes for the V5 V6, a regulated level, gamak, nylon

1

2

Seller's reliability 100 %

003

The reliability of the seller is 100%

731.63 ₽

3D printer Accessories Aluminum alloramic alloy M4 Delta Kossel Eye Eye table 4 mm

0

0

Relief of the seller 100%

79. 76 ₽ 9000 ₽ 9000 For the 3D printer REPRAP DELTA KOSSEL FISHEYE, 40 mm

76 ₽ 9000 ₽ 9000 For the 3D printer REPRAP DELTA KOSSEL FISHEYE, 40 mm

1

0

The seller’s reliability is 100 %

-0.4

%

652.55 ₽

9000 m4 Fisheye Effector V6 Parts from the aluminum corner m4 delta kossel 4mm extruder 3d printer parts0

0

The reliability of the seller is 89%

1 856 ₽

Spare parts for the 3D printer RePrap PREAPA I3, a metal carriage with an axis X, V6 Bowden, aluminum alloys for MK8 EXTURDER

0

0 9000 9000 9000 9000 Reliability of the seller 100%

-2

%

1 546 ₽

Reprap prusa i3 3d printer parts, x-axis metal carriage, v6 bowden, aluminum alloy for mk8 exturder

0003

The reliability of the seller is 100 %

-0. 8

8

%

4 269 -4 558 ₽

UM2 + Metal Hotend Silver/Black for a rod 6 mm/8 mm spare parts for 3D printer 9000

0

0

Reliability of the seller 100%

-1

%

0

0

Reliability of the seller 100%

-0.8

%

NTC3950 Cylindrical cartridge for the termistor 100K for V6 Hotend Reprap PRIPA I3 3D Printer

0

0

The reliability of the seller is 89 %

-1

%

9000 3 465 ₽aluminum EXPEL COMPEL 3d printer, 2020 aluminum profile, silver anodized printing size 180mm/220mm/300mm

1

0

The reliability of the seller is 100 %

-7

%

3 465 -5 260 ₽

KOSSIL KOSSEL DELTA Reprap, aluminum profile, silver anodized print size 180 mm/220 mm /300 mm, 2020

0

2

Reliability of the seller 100%0003

7

Reliable seller 100%

-4

%

3D printer

0

0

Seller's reliability 100 %

-1

%

1 856 ₽

Swmaker M4 Delta Kossel Mini 3D printer Hotend EXTEND EXTRACTION STIMENTER Automatic Evivation Printing Automatic Equipation 1. 75/ 3 mm

75/ 3 mm

0

0

The reliability of the seller is 100%

408.45-876.03 ₽

Swmaker 3D printer REPRAP DELTA KOSSEL Fish Eye, a 40 mm/50 mm effecter slot, nylon/CIP Fitting, triangular models, connecting coupling

4

4

Reliability of the seller 100 %

-3

%

1 793 ₽

Min -printer M4 Delta Kossel, extrusion, extrusion, Hotend, inductive contactless sensor, auto -level, 1.75/3 3/3 3/3 3/3 3/3 mm

0

0

The reliability of the seller 100 %

-2

%

1 176 ₽

3D printer, aluminum slippe M3 TACKLE 20*20 mm, effector for Reprap Delta Kossel, mini -frame, work with work with Closed loop belt

0

0

The seller’s reliability 100 %

-0. 4

4

%

2 757 -2 784 ₽

3D Printer Swmaker Delta Kosel Rostock M3/M4, threaded opening, Hotend effector with TLTOUC automatic bed leveling sensor, touch sensor

1

2

Reliable seller 100%

-4

%

1

4

Reliable seller 100%

0

0

The reliability of the seller is 100%

0 OTO TELE

0 PrOS

Photos from buyers not yet

Product characteristics

- Type of goods: Extruder

- Brand name: Funssor

delta, which is better (pros and cons)

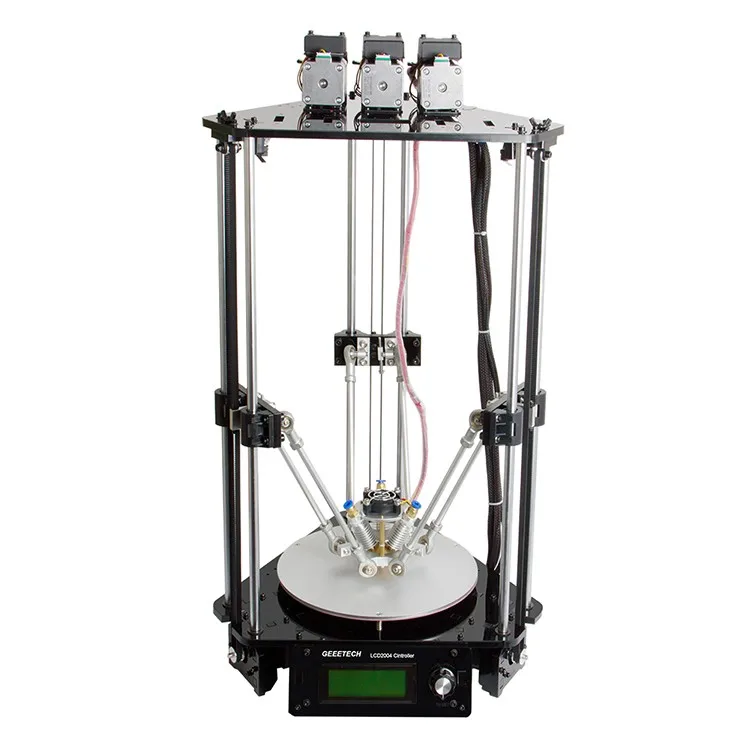

3D printers with delta kinematics stand out from other models with high printing speed of very complex parts. Such devices are quite expensive, but they can be assembled independently. Consider the assembly steps, configuration and nuances of using a delta printer.

Such devices are quite expensive, but they can be assembled independently. Consider the assembly steps, configuration and nuances of using a delta printer.

Which 3D printer is better - delta or cartesian?

Cartesian (also called Cartesian) and delta printers use the same filaments for printing. In addition, they have the same working parts (extruder, platform, motor), but their location is different.

For Cartesian 3D printers, the extruder or platform moves along the X, Y and Z axis rods (Cartesian plane). That is, work items move left, right, forward, backward, up, and down.

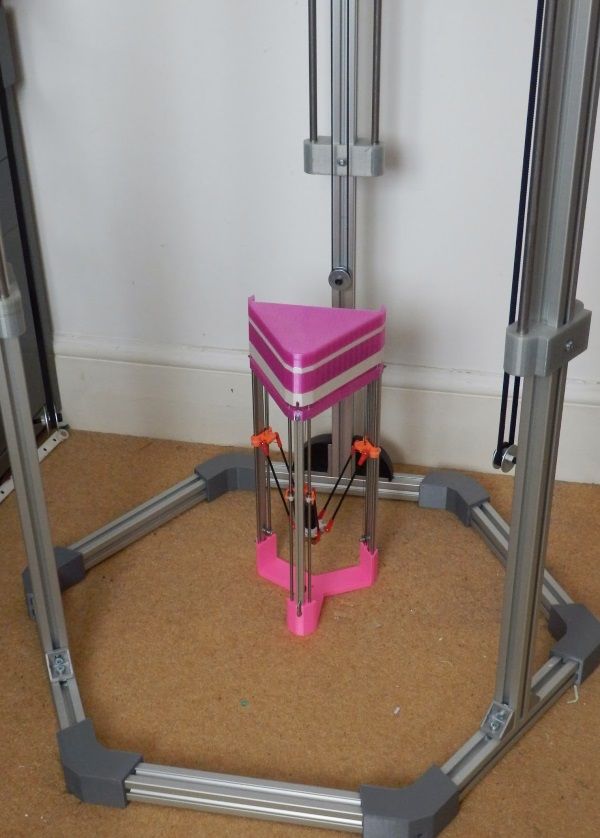

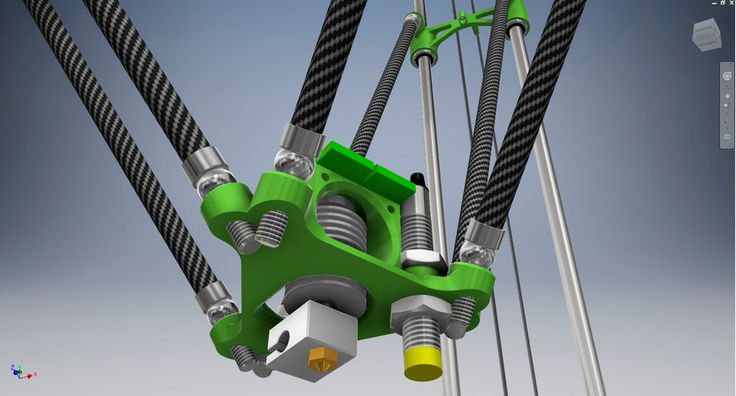

Delta 3D printers are based on a different movement system. The machine is equipped with three brackets that support the extruder. The brackets themselves are attached to three vertical posts, which are arranged in the shape of a triangle. The extruder on a delta printer can move in all directions, and each arm can only move vertically up and down.

Having considered the structural features of both types of equipment, it is possible to determine which of them will be better used for certain purposes. To do this, we highlight the advantages and disadvantages of the Cartesian and delta printers.

To do this, we highlight the advantages and disadvantages of the Cartesian and delta printers.

Pros and cons of the delta printer

The main advantages of the delta printer are:

- very fast printing of complex objects;

- high detail of thin and small parts of the product;

- easy replacement of the extruder.

Along with the advantages of the delta printer, it also has the following disadvantages:

- a small amount of information about the operation, assembly and configuration of the device;

- complex assembly, adjustment and calibration for the correct functioning of the printer;

- Difficulties with the selection of parameters and settings when printing complex objects at high speed.

Pros and cons of a Cartesian printer

Traditional printers based on the Cartesian coordinate system have a number of positive properties when used:

- stable printing results in mass production;

- a large amount of free information about the structure, operation, configuration and maintenance of the printer on thematic forums;

- the size of the created product is not limited, since the model for printing on a Cartesian printer can be divided into its component parts.

The main and significant disadvantage of the Cartesian printer is a much slower print speed than that of the delta device. This is because the Cartesian printer spends a lot of time accelerating and decelerating the system. Because of this, the print head moves more slowly to the desired point.

How to make a DIY Delta 3D printer: step by step instructions

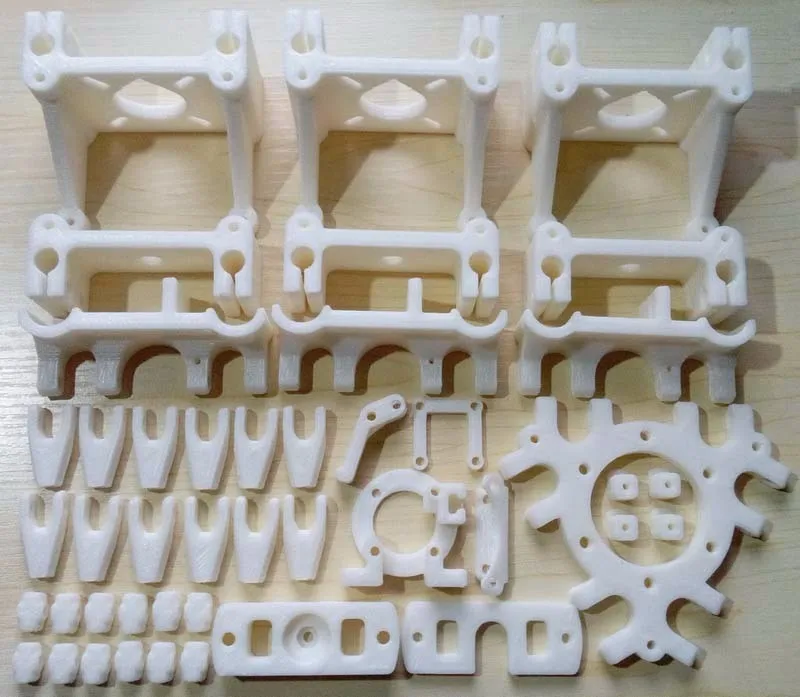

Before assembling the delta printer, all spare parts must be correctly selected. The following components are required to construct a working device:

- frame with plastic bushings;

- guide rollers;

- heated table;

- stepper motors;

- RAMPS 1.4 expansion board;

- mechanical stops;

- microcontroller Arduino Mega 2560 R3;

- Threaded rods M5 format;

- step-down voltage regulator;

- power supply 12 V;

- extruder;

- optical limit switches;

- filament spool;

- two coolers (for blowing parts and for blowing drivers).

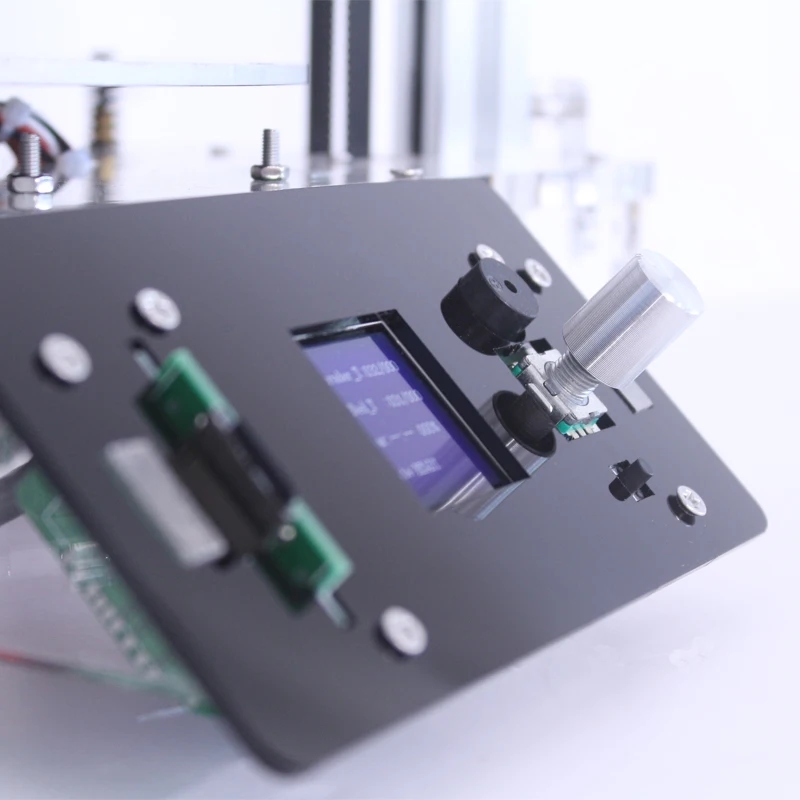

- display and button with 220V terminal.

Assembly of the delta 3D printer is carried out in the following order:

- First, the frame and end supports are designed. The lead screws at the top remain free.

- The voltage regulator is soldered to the power input. A microcontroller is installed and a regulator is attached to it from behind.

- The expansion board is then soldered separately to the legs. Mechanical stops are set in the direction of correct polarity.

- Before setting up the firmware, the printer is connected to electronic components and optical ends. They also install a table, an extruder, coolers and a material reel.

- Firmware for the printer is configured based on its size. Also, when installing, it is important that all the rods are the same length.

Help. To make rods of equal length, it is necessary to screw the hinges on equally cut pieces of the stud on both sides. After that, you should install neodymium magnets on the finished rod and rotate the pin until the hinges are clearly in the middle of the magnet.

After adjusting all the rods, it is necessary to fix the thread at the hinge with glue.

After adjusting all the rods, it is necessary to fix the thread at the hinge with glue.

Setup and calibration

The most convenient way to calibrate the delta printer is with the OpenDACT utility or Pronterface. These programs will auto-calibrate the equipment using electrical contact between the metal nozzle and the table. This procedure is carried out in three stages:

- Aluminum tape sticks to the desktop.

- One end of the wire is crimped into a block, the other two ends are fixed on the radiator and on aluminum tape. After the three ends of the wire are connected to the 3D printer.

- The printer is then connected to a computer from which the auto-calibration program is launched. The whole process can take a long time, as it requires you to select all the necessary geometry parameters.

After or before calibrating the printer, you must also calibrate the device desktop. This will achieve maximum print accuracy. Table calibration is performed as follows:

Table calibration is performed as follows:

- Heat the table to +90 °C, tighten the screws and move the print head to the center of the table. A sheet of white paper is placed directly under the extruder nozzle. It should not be strongly pressed down by the nozzle, but it should not “walk” under it either.

- After adjusting the central part of the table, move the sheet to the corners of the work surface and calibrate the table in the same way.

Errors during creation and tips on how to avoid them

When assembling and setting up the delta printer on your own, the user can make a number of errors that will negatively affect the operation of the device:

- Incorrect printer calibration. It will lead to backlash and deviations in the geometry of the structure. And these problems will cause serious distortion of the part when printed.

- Rods slipping off the magnets. It can lead to deformation of the printed product.

Learn more