Black filament for 3d printer

Amazon.com: HATCHBOX 1.75mm Black PLA 3D Printer Filament, 1 KG Spool, Dimensional Accuracy +/- 0.03 mm, 3D Printing Filament : Industrial & Scientific

4.7 out of 5 stars 51,824 ratings

#1 Best Seller in 3D Printing Filament

Currently unavailable.

We don't know when or if this item will be back in stock.

Color: Black

Product details

| Brand | HATCHBOX |

| Material | Polylactic Acid |

| Color | Black |

| Item Weight | 1000 Grams |

| Item Diameter | 1. |

- Make sure this fits by entering your model number.

- FILAMENT SPECS: SIZE: 1 kg (approximately 2.20 lbs) Spool, 1.75 mm Filament Diameter (Dimensional Accuracy +/- 0.03 mm), TEMPERATURE: Recommended Extrusion/Nozzle Temp 180°C - 210°C (356°F - 410°F)

- EASY TO USE PLA FILAMENT: Unlock your creativity with our hassle-free PLA Filament! Designed to give you the best 3D printing experience, Hatchbox PLA can conveniently be used on various mainstream printers. With improved toughness and fluidity, our PLA offers wide temperature and speed ranges to suit all of your innovative needs.

- BEGINNER & EXPERT FRIENDLY: Hatchbox 3D Prtiner Filaments are made with quality and consistency in mind, making it easy for novice users to get started with basic settings. Seasoned printers can push their designs to the limit without worrying about purity, tolerance or printing issues.

- TOP QUALITY 3D PRINTING FILAMENTS: Clog, bubble and tangle-free! Hatchbox PLA is formulated to offer minimal warping and little to no odor without the use of a heated bed. PLA is vacuum-sealed with desiccant to prevent moisture absorption, allowing for high-detail resolution.

- WHY HATCHBOX? We’re proud to be known in the 3D printing community for producing the highest quality PLA on the market, with the largest selection of filaments and colors at an unbeatable price. From art and design, to prototypes and models, Hatchbox is trusted to deliver the best in 3D printing technology.

This fits your .

Shop products from small business brands sold in Amazon’s store. Discover more about the small businesses partnering with Amazon and Amazon’s commitment to empowering them.

Learn more

Small Business

This product is from a small business brand. Support small. Learn more

Flashforge Black PLA Filament 1.

75mm 0.5kg/roll for Adventurer 3, Dreamer and Finder series 3d printers.

75mm 0.5kg/roll for Adventurer 3, Dreamer and Finder series 3d printers.Flashforge Halloween best offer: Finder 3 US$339 plus get 5 transport stl files. Creator Pro 2 US$549, Guider Ⅱ US$799!

- Home

loading

Share the product to

Worry-free warranty

Dedicated support

Fast shipping.Free shipping for items available at USA/UK/AU/EU warehouses.

- Overview

- Parameter

- In the Box

What is PLA Filament?

With easy accessibility, greater heat resistance, simple post-production process, PLA filament becomes one of the most popular 3D printing materials in the market. Flashforge develops world-class black PLA filament for FDM 3d printers, odor, and bubbles-free. The following lines show its black filament properties. Some featured Flashforge 3d printers offer printers and filament buddle for more cost-effective 3d printing.

Flashforge develops world-class black PLA filament for FDM 3d printers, odor, and bubbles-free. The following lines show its black filament properties. Some featured Flashforge 3d printers offer printers and filament buddle for more cost-effective 3d printing.

- RoHS certified;

- Nozzle temperature requirement: 190-220°C;

- Build plate temperature requirement: non-essential;

- Outstanding diameter accuracy +/- 0.02mm;

- Smoothen filament extrusion;

- Ultra-pure grade material & strict quality control standards to guarantee print quality;

- Minimal filament warping, curling, shrinkage, and bubbles during 3d printing process;

- Compatible with most FDM 3D Printers, perfect for Flashforge Adventurer 3, Finder, and Dreamer series 3D printers.

- Permits longer storage time without any compromise on filament quality;

Tech Specifications

| Spool Diameter | 180 mm [7. 1 in] 1 in] |

| Spool Hub Hole | 20 mm [0.8 in] |

| Spool Width | 76 mm [3.0 in] |

| Filament Diameter | 1.75 mm |

| Shipping Weight | 0.9 KG (2.0lbs) |

| Net Weight | 0.5 KG (1.1lbs) |

Comparison between Flashforge PLA, PLA Pro, PLA-CF, ABS, ABS Pro, PETG, PETG Pro, PETG-CF.

| Spec & Print Setting | PLA | PLA Pro | PLA-CF10 | ABS | ABS Pro | PETG | PETG PRO | PETG-CF10 |

|---|---|---|---|---|---|---|---|---|

| Tensile Strength (MPa) | 45-49 | 45.5-49 | 40-45 | ≥43 | ≥53 | 40-45 | 35-40 | 40-43 |

| Flexural Strength (MPa) | 69-75 | 73-76 | 85-95 | 50-55 | 45-50 | 75-85 | ||

| Modulus of Elasticity (MPa) | 1000-1100 | 950-1050 | 1100-1300 | 1000-1100 | 1100-1200 | 2100-2400 | ||

| Elongation @ Break (%) | 13. 5-15.5 5-15.5 | 14.5-16.5 | 11.5-13.5 | ≥10 | ≥20 | 6.0-8.0 | 6.0-8.0 | 7.5-8.5 |

| Heat Deflection Temp (oC) | 53 | 53 | 60 | 88℃ | 88℃ | 74 | 68 | 70 |

| Nozzle Temp (℃) | 200-220 | 190-210 | 200-230 | 230-250 | 230-250 | 240-250 | 220-240 | 230-250 |

| Bed Temp (℃) | 50-55 | 50-55 | 40-50 | 100-110 | 100-110 | 80-90 | 70-80 | 60-80 |

| Printable with Glass Plate | YES | YES | ! (with glue stick) | ! (with glue stick) | ! (with glue stick) | YES | YES | ! (with glue stick) |

| Printable with PEI Sheet | YES | YES | / | ! (with glue stick) | ! (with glue stick) | YES | YES | / |

| Print in Enclosed Chamber | / | / | / | YES (recommend) | YES (recommend) | / | / | / |

| Print with Hardened Nozzle | / | / | YES | / | / | / | / | YES |

| Dryer Box | / | / | YES | / | / | / | / | YES |

Flashforge Filaments Key Features

| Key Features | PLA | PLA Pro | PLA-CF10 | ABS | ABS Pro | PETG | PETG PRO | PETG-CF10 |

|---|---|---|---|---|---|---|---|---|

| Filament Type | Standard | Standard | Carbon fiber filament | Standard | Standard | Standard | Standard | Carbon fiber filament |

| Food Safe | YES | YES | / | / | / | YES | YES | / |

| Low Warping | YES | YES | YES | / | / | YES | YES | YES |

| High Tenacity | YES | YES | YES | / | / | YES | YES | YES |

| Dissolvable | / | / | / | YES | YES | / | / | / |

| Chemical Resistance | / | / | / | / | / | YES | YES | / |

Your questions will be answered by the users who have purchased this product

May not be greater than 255 characters.

Read All Reviews

FAQ

No questions.

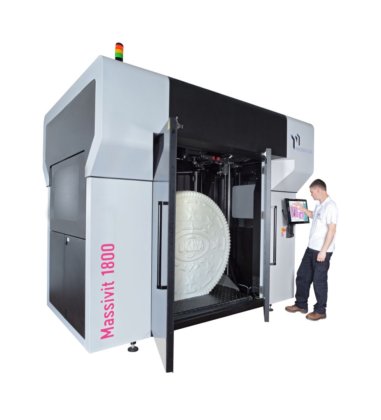

0373100001016000110 Supply of 3D printer and consumables for 3D printer

×

Free period expired

Favorites, color tags and changes in favorite purchases

available on Standard and Expert tariffs.

Choose a plan close

×

Payment required

Detailed results are available on Standard and Expert tariffs

Choose a plan close

×

An error occurred, the last action was not saved

Try again or refresh the page

- Initial contract price

-

$452,100.00

- Contract security

-

$45,210.

00

00

- Contract service

-

Location - 123182, Moscow, pl. Academician Kurchatov, d.1 Postal address - 123182, Moscow, pl. Academician Kurchatov, d.1 Email address – [email protected] Contact phone number – + 7 (499)196-71-00 ext. 78-89 Responsible official of the Contract Service - Head of the Contract Service Kurachenko Inna Anatolyevna

Contact details

Placement order Moscow time is indicated

44-FZ, Request for Quotations

Go to EIS

- Application

-

04/04/2016 12:00 15.04.2016 10:00

- Envelope opening

-

15.

04.2016 10:00

04.2016 10:00

The documents

Customer

Federal State Budgetary Institution "National Research Center "Kurchatov Institute"

TIN 7734111035 Checkpoint 773401001

Customer analysis

All customer purchases

Procurement items

Participation conditions

Membership requirements

-

The requirement that the register of unscrupulous suppliers (contractors, executors) provided for by Federal Law No. 44-FZ contain no information about the procurement participant, including information about the founders, members of the collegial executive body, the person performing the functions of the sole executive body of the procurement participant - a legal entity ( in accordance with Part 1.

1 of Article 31 of Federal Law No. 44-FZ)

1 of Article 31 of Federal Law No. 44-FZ) -

Uniform requirements for participants (in accordance with paragraph 1 of part 1 of Article 31 of Federal Law No. 44-FZ)

Participants and results 04/15/2016

More information is available if you login or register.

| Member | Price, ₽ | Results |

|---|---|---|

| Winner Kor-Service LLC | ░░░ ░░░░░░ | ░░░░░ |

| ░░░░░ ░░░░░░░░ ░ ░░░░░░░░░░░░ ░░░░░░░░░░░░░░░░ ░░░░░░ ░░░░░░░ ░░░░░░ | ░░░ ░░░░░░ | ░░░░░ |

| ░░░░░░░░░░░░ ░░░░░░░░░░░░░░░░░░░░░ | ░░░ ░░░░░░ | ░░░░░ |

Protocols

Minutes of consideration and evaluation of applications for participation in the request for quotations dated April 15, 2016 15:40 (Moscow time)

- 110 - 3z (.

doc)

doc)

Supplier contracts

| ░░░ ░░░░░░░░░░░░ ░░░░░░░ ░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░ No. 1773411103516000209 dated 04.05.2016 | ░░░ ░░░░░░ ░ |

Similar purchases

- Request for proposals in electronic form for the right to conclude a contract for the provision of...

- Provision of repair and maintenance services for office equipment

- Supply of workstation

×

Free period expired

Reminders are available on Standard and Expert plans

Choose a plan close

3D printing filaments

Hello friends!

This article would like to highlight the appearance of threads in printing. I will try to note the main factors influencing the appearance of threads.

1) Idling speed and acceleration. The idle run consists of the following stages - first there is a retract, then the movement of the extruder, then again a retract. The plastic is spontaneously squeezed out precisely during the idle time, forming various kinds of defects. Now imagine an example if the idling takes zero seconds. Under this condition, the plastic will not have time to spontaneously extrude. Therefore, the higher the speed and acceleration, the less time the idling lasts, which means there will be fewer threads. But speed and acceleration are limited by the motor driver, the motors themselves, and the rigidity of the printer frame.

Therefore, you can try to slightly increase the speed and acceleration with each print, but at the same time make sure that the motors do not overheat, otherwise microsteps may be skipped, which will lead to print rejects.

2) Idling path. Different slicers process parts according to different algorithms, which means that the idling trajectory may differ. Some slicers build more rational extruder motion than others. Therefore, you can try to prepare the same part in several slicers and stop at the option that will be more rational.

3) Feeder dependent, i.e. from the plastic supply system. Printers most often have one of two options: "bowden", i.e. far-distance or "direct", this is when the "feeder" is located near the extruder. Under the same printing conditions with direct, there will always be fewer threads than with bowden. But this does not mean that you can always switch from Bowden to Direct. It may also be that your printer will not be able to work with "direct" for one reason or another. The transition to "direct" must be considered with each printer individually.

4) Retract setting, i.e. plastic rollback - its task is to remove the residual pressure in the extruder during idling. Without retract, the threads will appear more intensely. For most printers, the values are as follows - for direct, the range is from 1 to 6mm, and for bowden, from 4 to 12mm. (the amount of retract also depends on the diameter of the nozzle).

Without retract, the threads will appear more intensely. For most printers, the values are as follows - for direct, the range is from 1 to 6mm, and for bowden, from 4 to 12mm. (the amount of retract also depends on the diameter of the nozzle).

5) Plastic quality. If you are constantly printing only budget plastics and are unhappy with the result, then try to buy plastic in a higher price category, and more importantly, with good reviews. And then compare the print quality. But the main thing - from different manufacturers, compare the same types of plastic - you should not compare, for example, ABS from one manufacturer, and PLA from another.

6) Plastic drying. By the way, this applies to almost all plastics, not just nylon. If you have unnamed or cheap plastic in your hands, it is recommended to dry it after opening it, because. it is not known whether the plastic was dried before packaging.

7) Nozzle diameter. The larger the diameter, the more plastic will spontaneously squeeze out during idling. There is nothing you can do about it, it just needs to be taken into account when choosing a nozzle diameter.

There is nothing you can do about it, it just needs to be taken into account when choosing a nozzle diameter.

8) Extruder temperature. If you heat the extruder to the upper limit of the recommended range (indicated on the plastic that is being printed), then the fluidity of the plastic will be higher, and it will be more easily extruded from the nozzle. Plastic manufacturers give a temperature range for a reason. If you set the print speed to high, then the extruder temperature should be in the upper limit of the range. But if the print speed is low, then there is no need to heat up the extruder much, otherwise filaments may appear due to overheating of the plastic.

Therefore, you can try to reduce the temperature of the extruder as follows - during printing, every couple of minutes, reduce the temperature by 5 degrees over and over and watch the print closely. If the threads disappear, remember the temperature and stick to it. But if the temperature is greatly lowered, then the plastic will not be able to extrude at all. Don't overdo it.

Don't overdo it.

9) Dependence of temperature on the type of extruder. There are many different models of extruders. For example, consider the E3D V6 and E3D V6 Volcano extruder. The E3D V6 Volcano has an extended nozzle and an extended aluminum block. And this means that the zone where the plastic is in the molten state is larger, so it can push through a larger volume of plastic per unit of time. As a result, this extruder will be able to print at higher speeds than the regular E3D V6. But here you need to understand the following - if you have a "powerful" extruder, and you print at low speeds, then the plastic will overheat, which will lead to the appearance of threads. Therefore, for powerful extruders, it is better to set the temperature in the lower limit of the recommended range. And on the contrary - for an extruder that cannot heat up a large amount of plastic, the temperature should be kept in the middle or at the upper limit of the recommended one.

The conclusion here is the following - for different models of extruders, different printing temperatures are needed.

10) Free travel distance. If you are printing multiple parts at once, try to space them closely to reduce the dry travel distance. Well, if a solid part is printed, with individual elements at a great distance from each other, in this case, you can try to change the location of the part in space so that there are fewer idle moves.

11) File analysis before printing. When your G-code is ready, do not be lazy and meticulously analyze it before printing, because. at the verification stage, you can detect unwanted elements that can create various kinds of defects, including the appearance of threads. By the way, in whatever slicer I prepare the file, I almost always check the finished code with the help of “Repetier-Host”, because it shows all the movements that can lead to certain defects.

12) Plastic type. All plastics have both strengths and weaknesses. For example, PETG plastic has a high tendency to filament. ABS, on the other hand, has a low predisposition to threads, but it will have to concentrate on the problem of shrinkage and a low degree of sintering of the layers.

Therefore, before printing, familiarize yourself with the pros and cons of the plastic with which you plan to print.

13) Using the "Lift Z" function. When enabled, a gap will be created between the extruder and the printed part. It is needed so that during idle the extruder does not cling to the outer walls of the part. This feature can significantly reduce the number of threads. But it should be used if the printer has a powerful driver and a motor along the Z axis, as well as a screw with a thread pitch of at least 8mm. This is necessary to achieve high speed and acceleration on the Z axis. Well, if you try to use this function at low speeds, the problem will only get worse and there will be more threads, because. idle time, taking into account "Lift Z", will increase significantly. The idling time with the "Lift Z" function consists of: movement along the Z axis + retraction + idling + retract + movement along the Z axis.

Therefore, you can try to experiment with this function and see the result.

14) Problems with the extruder. Imagine a situation where you put a large retract, but a large plug of melted plastic formed in the thermal barrier between the nozzle and the Teflon tube. In such a situation, no matter how big you put the retract, this plug will not disappear, but will remain in its place. And, therefore, the retract will not be able to completely relieve the pressure in the system. Therefore, keep your extruder clean and in good working order.

15) Problem with the driver on the motor in the feed system (motor on the feeder). It's a rare phenomenon, but it's still there. I've run into a problem where the driver only spins the motor in one direction, regardless of the command, whether it's spinning one way or the other -- the motor only spins in one direction.

And in practice, it looks like this: the motor advances the plastic during printing, and at the moment of idling, when a retract should occur, the motor sharply squeezes out additional plastic (because the driver rotates the motor in only one direction).