Dimension bst 3d printer

| ||||||||||||||

Dimension 1200 Review 2022 - Why This 3D Printer Is AWESOME [Updated]

Should you buy the Stratasys Dimension 1200 printer? Check out our review here to find out whether it's worth the money or not.

By Justin Evans

4.4

See Price

If you work in the medical or aerospace department, you might benefit from the faster prototyping and flexibility that a 3D printer offers. However, not just any will do: for these industries, you’ll need a highly specialized printer. Bad news first: these are usually very pricey. Good news? We’ve found one that might be suitable.

We’re talking, of course, about the Stratasys Dimension 1200. This is a heavy-duty printer in every sense of the phrase, but is its performance as high as its price tag? Today, we’ll take a closer look to try and find out. Keep reading to see what we thought.

| Size | 33 x 29 x 45” |

| Extruders | 1 |

| Supported Materials | Proprietary ABSplus filament |

| Connectivity | Ethernet |

| Layer Thickness | 0. 254mm (quality)/ 0.33mm (fast) 254mm (quality)/ 0.33mm (fast) |

| Build Volume | 10 x 10 x 12” |

Table of ContentsShow

Design

Let’s address the elephant in the room: standing 45” tall without the base, this printer is absolutely colossal. Setup is a two-person job since the Dimension 1200 weighs over 300lbs. Additionally, there’s just one extruder – something of a rarity in high-end 3D printers. However, with an enclosed (and exceptionally large) build area, maintaining a consistent temperature is easy.

We were pretty surprised by the lack of connectivity and limited OS support, too. There’s not even a USB port – everything has to be controlled via the Ethernet connection, and only Windows devices are supported. This is hardly ideal, particularly in the design sector, where Macs are more common.

There’s a small, neat control panel on the right-hand side. This allows you to select CAD files and make minor tweaks before printing. It’s a nice touch, but with even mid-range printers offering mobile app support, we have to wonder what the designers were thinking. After all, it’s not like this is a specially cheap model.

It’s a nice touch, but with even mid-range printers offering mobile app support, we have to wonder what the designers were thinking. After all, it’s not like this is a specially cheap model.

Printing

Say what you like about the aesthetics of this machine, it does an extraordinary job of recreating virtual models. Complex shapes are no problem, and the layers are all but imperceptible. If you value speed more than quality, you can slightly increase the layer size, but even this produces models to a higher standard than many other printers on the market.

Unfortunately, the Dimension 1200 supports only a handful of materials, all proprietary. There’s a more durable, ABS-based filament named ABSplus, as well as both water-soluble and snap-off support material. It seems as though Stratasys wanted to do one thing very well, rather than including half-baked support for as many materials as possible.

It’s hard not to be impressed here: there’s very little filament wasted, and finished models usually require very little post-processing. Evidently, this depends on what exactly you’re printing, but for prototyping, there are very few 3D printers that can match this one.

Evidently, this depends on what exactly you’re printing, but for prototyping, there are very few 3D printers that can match this one.

Features

One of the things that takes the most time when printing is bed-leveling and calibration. Thankfully, both of these things are done automatically with the 1200, so you can spend more time actually getting work done. That said, there’s very little advanced functionality included, considering the price.

The Dimension 1200 uses RFID chips on the filament cartridge to help keep track of how much material is left. As long as you keep an eye on the reading, you’ll never run out mid-print again. On the other hand, this does mean that there’s no way to use third-party materials.

There are a few additions that really would have made this printer shine: we’re talking of course about greater connectivity options and increased OS support. There’s really no excuse for not including a USB port, or SD card slot, at the very least. It’s disappointing, especially when you consider how little they’d cost to add.

Cost

This is not a cheap machine. It retails for around $35,000, meaning it’s priced well out of the reach of the vast majority of people. Stratasys has instead focused on marketing to the top-level businesses in the world. It’s a good thing too because this isn’t the only cost you’ll have to deal with.

How much do you think a 56” spool of ABSplus costs? If we said almost $180, you’d think we were crazy, right? Well, it’s the truth. Let’s be clear: this is not a printer you’d use without a specific item in mind. To put it another way, for the price of two spools, you can buy a fairly decent, mid-range 3D printer.

Still, if you work in one of the industries that this model is designed for, the cost is likely not a huge issue. After all, ABSplus claims to be 40% more resilient than standard ABS and can be used to create everything from engines to tank parts.

Support

To its credit, Stratasys offers a good selection of customer support materials. There are user guides, quick start manuals, and FAQs for all of the company’s 3D printers. You can also download the latest firmware patches here, but for some reason, the Dimension 1200 isn’t included. It may not be the newest model around, but legacy customers have the right to be supported too.

There are user guides, quick start manuals, and FAQs for all of the company’s 3D printers. You can also download the latest firmware patches here, but for some reason, the Dimension 1200 isn’t included. It may not be the newest model around, but legacy customers have the right to be supported too.

There are a couple of additional services that this company offers. Users can attend 3D printing seminars explaining how to use their products, and there’s even a recycling service for old cartridges.

A one-year warranty is included with all of Stratasys’ 3D printers, which is fine if a little underwhelming. For $35,000 you’d really expect to see a five-year guarantee at least. Customer support can be reached by email, phone, or live chat, although there are no details on whether it is 24/7 or not.

FlashForge Finder 3D Printer Review

Stratasys bst 1200es Used equipment

- Description

- Detailed information

- About this seller

The Dimension 1200es has the largest envelope available in a Design Series 3D printer.

Powered by FDM technology, it prints in nine colors of real ABSplus plastic.

This 3D printer allows you to select thinner or finer prints with a thickness of 0.254 mm (0.010 in.) or 0.33 mm (0.013 in.).

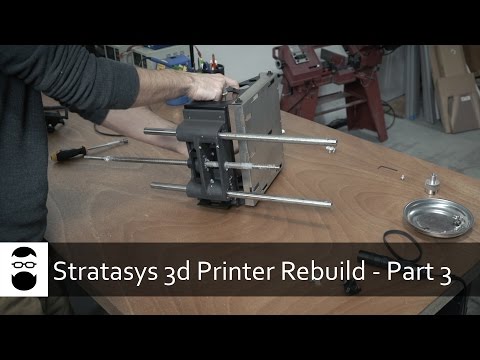

Dimension BST1200es 3D

Dimension 1200es uses ABSplus thermoplastic to create your models. The model and soluble support materials are supplied in convenient sealed cartridges that have a latch for loading.

Inside the 3D printer, the plastic filament passes through a tube to the printhead, where it is heated to a semi-liquid state and extruded into thin, precise layers.

Model bases provide a stable platform on which to build your prototype. Once the print is complete, you simply take the recycled flexible plastic out of your 3D printer and separate the model.

This description can be translated automatically. Please contact us for more information. The information in this announcement is for guidance only. Exapro recommends that you check with the seller before buying a machine.

Exapro recommends that you check with the seller before buying a machine.

| ------------------- | |

| L x W x H | 838.0 × 737.0 × 1143.0 |

| Weight | 148kg |

| Operating hours | 3000 hours |

| Switching hours | 2000 watch |

| Condition | good condition |

| CE marked | --------- |

| Status |

| Client type | End user |

| Active with | 2015 |

| Offers online | 1 |

| Last activity | November 21, 2020 |

Description

The Dimension 1200es has the largest envelope available in a Design Series 3D printer.

Powered by FDM technology, it prints in nine colors of real ABSplus plastic.

This 3D printer allows you to select thinner or finer prints with a thickness of 0.254 mm (0.010 in.) or 0.33 mm (0.013 in.).

Dimension BST1200es 3D

Dimension 1200es uses ABSplus thermoplastic to create your models. The model and soluble support materials are supplied in convenient sealed cartridges that have a latch for loading.

Inside the 3D printer, the plastic filament passes through a tube to the printhead, where it is heated to a semi-liquid state and extruded into thin, precise layers.

Model bases provide a stable platform on which to build your prototype. Once the print is complete, you simply take the recycled flexible plastic out of your 3D printer and separate the model.

This description can be translated automatically. Please contact us for more information. The information in this announcement is for guidance only. Exapro recommends that you check with the seller before buying a machine.

Exapro recommends that you check with the seller before buying a machine.

Details

| ------------------- | |

| L x W x H | 838.0 × 737.0 × 1143.0 |

| Weight | 148kg |

| Operating hours | 3000 hours |

| Switching hours | 2000 watch |

| Condition | good condition |

| CE marked | --------- |

| Status |

About This Seller

| Customer Type | End user |

| Active with | 2015 |

| Online offers | 1 |

| Last activity | November 21, 2020 |

3D printer print size - 1.

2 x 1.5 x 1.8 m. by Sprint 3D.

2 x 1.5 x 1.8 m. by Sprint 3D. Rapid prototyping of large-scale art products

In the minds of many contemporaries, 3D printing is a technology capable of creating extremely small objects - spare parts, souvenirs, various kinds of models, and so on. Moreover, many believe that it takes many hours. In the meantime, a whole car has already been created through 3D printing. And it didn't take weeks. Let's consider which print size 3 D printer is possible today and what speed 3 D print is currently achieved. But first, a few words about prototyping.

Rapid prototyping of 3D models is a process of rapid creation of mock-ups of models (prototypes), which will later be used to improve and finalize design solutions. In some cases, such prototypes can also be used as finished products.

500x500x800 cm Satellite 3D Printer

The Capabilities of Modern 3D Printers

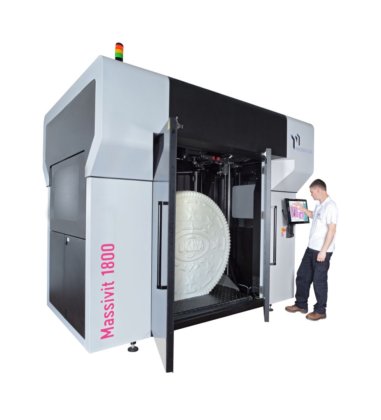

3D printing equipment has made a huge leap forward in recent years. One of the brightest representatives of the new generation of printers for rapid prototyping of dimensional art products is the 3D printers that we use in our work.

One of the brightest representatives of the new generation of printers for rapid prototyping of dimensional art products is the 3D printers that we use in our work.

Main equipment features:

- Working area - up to 1.2x1.5x1.8 m.

- Speed 3 Printing D along the Z axis (in height) - 35 cm / hour.

How do you achieve high print speeds and the ability to produce large items? First of all, due to the use of special photopolymer gel compositions with a high degree of viscosity, as well as due to the rationalization of the placement of supporting structures. The so-called GDP-technology (Gel Dispensed Printing) is used. It is based on the use of liquid light-sensitive compounds that quickly harden under the influence of ultraviolet lamps. Those are located directly above the print heads and act directly on the material. This system ensures fast curing.

Due to the fact that the GDP technology cures faster than other technologies, it is not necessary to use supports for horizontal surfaces. Obviously this saves time. And at the same time, the materials of production.

Obviously this saves time. And at the same time, the materials of production.

We also note that 3D printer models and some analogues use two print heads that work independently of each other. This allows you to create two objects at the same time in one workspace or separate components of one large product. Accordingly, print size 3 D of printer in this case, when gluing, it increases at least twice and can exceed 3 meters.

Large-scale 3D printing: how much more difficult it is than small-sized

If in older models of printers there could be cases when the material clogged the nozzle and the work done simply went down the drain, then modern equipment is devoid of such shortcomings. You don’t have to worry that something will go wrong in the many hours of printing and you will have to redo everything from the beginning, wasting time and a lot of resources.

Separately, we note the simplicity of the post-processing process. After hardening, the gel lends itself perfectly to a wide variety of processing. It is perfectly painted and varnished, which opens up the widest possibilities for creating a wide variety of dimensional objects: stands, product models, models of equipment and much more. Everything is fast, convenient and at the same time quite inexpensive. The printing process itself and finished products meet the requirements of environmental friendliness and safety of use. During production, no harmful and dangerous substances are emitted, and the printed products fully comply with modern environmental standards and are hypoallergenic. This is a particularly important factor at the present time.

After hardening, the gel lends itself perfectly to a wide variety of processing. It is perfectly painted and varnished, which opens up the widest possibilities for creating a wide variety of dimensional objects: stands, product models, models of equipment and much more. Everything is fast, convenient and at the same time quite inexpensive. The printing process itself and finished products meet the requirements of environmental friendliness and safety of use. During production, no harmful and dangerous substances are emitted, and the printed products fully comply with modern environmental standards and are hypoallergenic. This is a particularly important factor at the present time.

How 3D prototyping works

The process is actually similar to standard 3D printing, except for the large dimensions of the final product. A physical structure is built according to a previously prepared mathematical model.

The advantages of prototyping are obvious:

1.

Visibility of the whole process;

Visibility of the whole process; 2. Minimization of the time required for preparation of production;

3. Reduce engineering and design costs.

The first step in prototyping is mathematical modeling, which creates a mathematical model in STL format. After that, prototypes are finalized to create the necessary surface textures. Prototyping also includes the development of technologies, the production of specific models and their finishing. Everything is almost identical to small-sized printing, although products are made with many times larger sizes.

Advantages of rapid prototyping in large-scale printing:

- Accurate and fast verification of the conformity, function and form of the printed design.

- Extensive design flexibility and versatility with the ability to quickly transition between different stages of production.

- Increased speed 3 D printing and no waste of materials that are already used in large quantities.

Learn more

The basket measures 10" x 10" x12" (254 x 254 x 305 mm), which allows more than one model to be cleaned at a time.

The basket measures 10" x 10" x12" (254 x 254 x 305 mm), which allows more than one model to be cleaned at a time.

5 in)

5 in)