3D printer 400

Flashforge WaxJet400 Wax 3D Printer

Application Scenarios

Jewelry Industry

Digital mass production workshop solution for jewelry

Dental Industry

Digital solution for complete dentures

Precision Casting Industry

Digital casting solution

Art Foundry Industry

Digital casting solution

Model Cases

Antique gold bracelet

Printing time: 1hr 10mins

Wax pattern weight: 1.25g

Usage: Replace the water-soluble wax, realizing direct mass production.

Compared with the traditional process

Shorten the time to marketReduce labor costsAntique gold bracelet

-- Product display --

Compared with the traditional process

Shorten the time to marketReduce labor costsDenture base

Printing time: 4hrs

Wax pattern weight: 30g

Usage: Replace artificial wax making. Direct resin injection is used to make full dentures.

Compared with the traditional process

Shorten the time to marketReduce labor costsDenture base

-- Product display --

Compared with the traditional process

Shorten the time to marketReduce labor costsImpeller

Printing time: 4hrs 38mins

Wax pattern weight: 7. 18g

Usage: It is used to cast the In713c turbine.

Compared with the traditional process

Shorten the time to marketReduce labor costsImpeller

-- Product display --

Compared with the traditional process

Shorten the time to marketReduce labor costsBuddha

Printing time: 16hrs 30mins

Wax pattern weight: 100g

Usage: It is used to cast the copper Guan Yin statue.

Compared with the traditional process

Shorten the time to marketReduce labor costsBuddha

-- Product display --

Compared with the traditional process

Shorten the time to marketReduce labor costsParameter Specification

Product Specification

| Printing Technology | MultiJet Printing (MJP) |

| Build Volume | 289*218*150mm |

| Printing Mode | XHD: 1200*1200*1600dpi, Layer thickness: 16um |

| Dimensional Accuracy | ±0.04mm/20mm |

| Power Supply | AC220-240V, 50Hz, 4KW |

| Equipment Dimensions | 1352*775*1600mm |

| Net Weight | 480kg |

| Gross Weight | 630kg |

| Package Size | 1530*900*1837mm |

Software & Connectivity

| Slicing Software | WaxJetPrint |

| Supported File Format | . stl/.slc stl/.slc |

| Email Notification | ✔ |

| Hard Disk Capacity | 500G |

| Connectivity | Network 10/100/1000, Ethernet/USB |

| Supported Operating System | Windows 7 / Windows 10 (64bit) |

| Working Environment | Temperature: 18-28℃, Humidity: 30-70% |

Material Specification

| Material Name | FFWJ1100 | FFWJ1200 | FFMS3100 |

| Material Type | Part material | Part material | Support material |

| Net Weight | 3.0kg/bottle | 3.0kg/bottle | 3.6kg/bottle |

| Composition | 100% Wax | 100% Wax | Wax support material |

| Color | Purple | Pink | White |

| Density@95℃(liquid) | 0.76g/cm³ | 0. 85g/cm³ 85g/cm³ | 0.85g/cm³ |

| Melting Point | 68°C | 80°C | 55°C |

| Softening Point | 63°C | 70°C | - |

| Volumetric Shrinkage① | 1.10% | 0.90% | - |

| Linear Shrinkage | 0.70% | 0.70% | - |

| Needle Penetration Hardness② | 9 | 7 | - |

| Ash Content③ | <0.01% | <0.01% | - |

| Description | High-precision casting wax material | High-precision dental casting wax material | Hands-free dissolvable support material |

*Conditions: ①Volumetric Shrinkage SH/T 0588-1994; ②Needle Penetration Hardness GB/T 4985-2010; ③Ash Content GB/T 14235.3-1993

Working Principle

Core Functions

One-button Automatic Printing

Import the model data via WaxJetprint. Find the file data in the print queue and click the “Print” button. The system will automatically complete printing the model.

Automatic Reloading & Material Run-out Reminder

2*2 material cartridge configuration; When one bottle of material is used up, it will automatically switch to another bottle.

Maintenance Plan

The maintenance plan is pre-installed in the equipment. According to the hours of use of spare parts, it will prompt the user to maintain the equipment in order to keep the equipment in good running condition.

3D Automatic Layout

Import in batch, customize the attributes, and select the area and height for automatic placement. The automatic 3D placement function selects the optimal solution through preset iteration times.

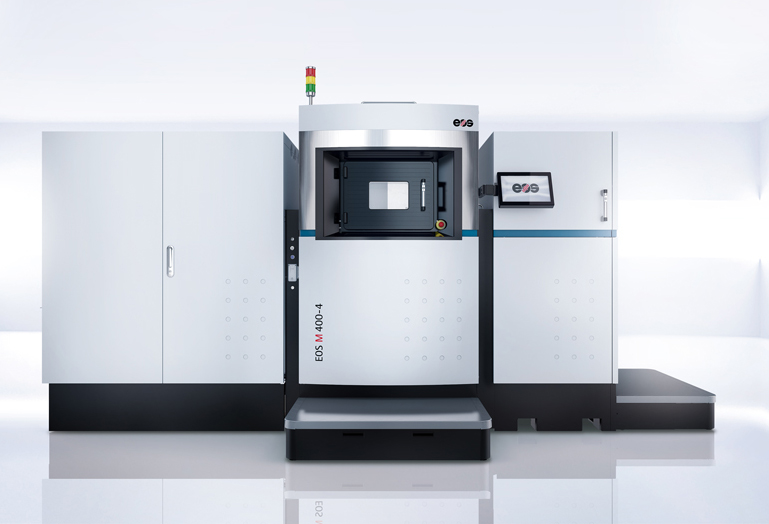

NXE 400Pro Industrial 3D Printer

[Launch Special] Get 20% OFF Purchase of NXE Pro Series Printer. Learn more

Learn more

Ultrafast Industrial 3D Printer

The NXE 400Pro photopolymer 3D printer boasts an unprecedented 17L build volume, delivering unmatched speed and throughput without compromising on accuracy or repeatability. The NXE 400Pro industrial 3D printer features patented Lubricant Sublayer Photo-curing (LSPc®) technology, delivering accuracy and tolerances with a superior surface finish by turning SLA 3D printing technology on its head.

Now $49,995

Save $12,900 was $62,895

Request Free Sample

6.5x Greater Print Speed

Nexa3D’s patented 3D printing LSPc process enables production speeds that are up to 6.5x faster than other industrial 3D printers from the same class. Uniform exposure and process control also ensure production build speeds at the highest quality levels.

2.5x Larger Build Volume

Featuring 2.5x greater build volume (17L) compared to SLA and DLP-based technologies, the NXE 400Pro photopolymer 3D printer allows for much larger parts, higher part throughput, and ultimately lower part cost—all with higher-resolution pixels (76. 5 µm) and isotropic prints.

5 µm) and isotropic prints.

Broad Material Selection

NXE 400Pro industrial resin 3D printers are scalable to meet manufacturing demand, offering a wide range of materials to meet performance needs — including PP-Like, ABS-Like, and engineering-grade functional materials.

Watch Video

Specifications

| Build Volume | 10.8 x 6.1 x 15.7 inch (274 x 155 x 400 mm) |

| Max Resolution | 4K (3840 x 2160) |

| Pixel Pitch | 76.5 µm (0.0030 in) |

| Wavelength | 405 nm |

| Build Materials | UV Curable Plastics; xGPP-Translucent; XGPP-Grey; xPRO410; 3843-ABS-Black; xCE-Black; ABS-Black; xCE-White; xPP405-Black; xPP405-Clear; xPEEK147; x45-Natural; x45-Clear, x45-Black, xFLEX |

Download Brochure

“Our R&D Team is able to reduce time to obtain functional samples by as much 80%, and reduce tooling costs by as much as 90%.

With the NXE 400, we’re able to go from CAD to scale in just 48 hours.”

Max Rodriguez

Senior Manager of Global Packaging

View Case Study

NXE 400Pro vs. Carbon® M3

When it comes to industrial resin 3D printers, the NXE 400Pro and Carbon M3 are the two most popular 3D printers used by OEMs and service providers. Compare Carbon M3 pricing and specs to NXE 400Pro to help you determine which one is better for your particular application.

NXE 400Pro vs Carbon M3

“Because we can iterate so much quicker, print tools faster than we can machine, and eliminate a couple of the steps in the process, our R&D team can afford to be wrong. This helps us to greatly improve our time-to-market, allowing us to be quick and nimble with our design decision-making process.”

Glen Mason

Manager of Advanced Innovation/Industrialization

View Case Study

Post-Production

xWash and xCure post-processing systems accommodate the full build volume of the NXE 400Pro and can accept up to two build platforms simultaneously for streamlined workflow.

xWash and xCure

Buy NexaX Pro

NexaX Pro software enables process stability and print consistency with an API to make integration of a variety of software tools easy, including assembly parts consolidation, generative design, lightweighting, and MES workflows.

Buy NexaX Pro

Open Material Platform

NXE 400Pro has offers a broad range of functional and general purpose photopolymer materials. The materials are specifically tailored to meet your every need, from modeling to final part production.

Material Selector

More Materials, More Options

Download 2022 Materials Guide for Ultrafast 3D Printing

Download the guide now

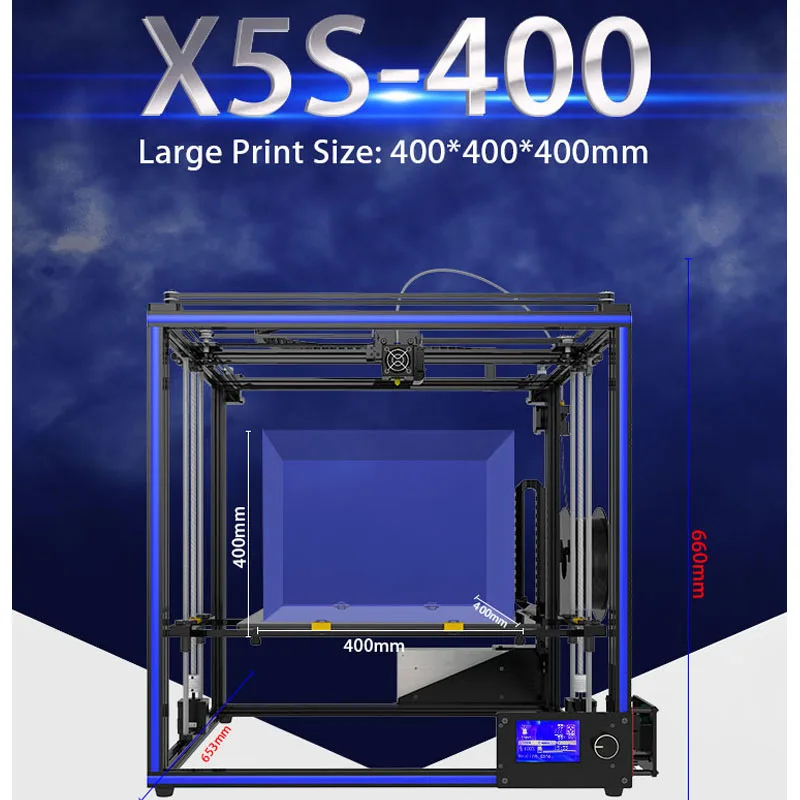

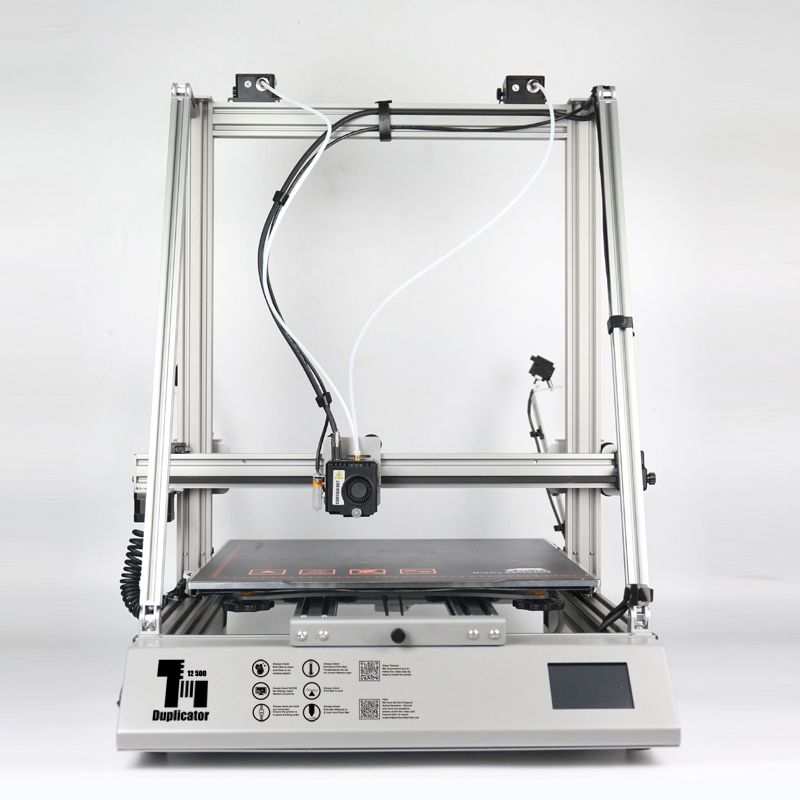

3D printer Gigant large build area 400*400*400

Description

3D printer with large 3D printable area

Large print volume is one of the main advantages of Gigant 3D printer. A significant increase in the printable area is made possible by the use of a rigid metal frame.

The huge print area allows you to print large objects on the Gigant 3D printer, such as a bust of a person, industrial structures, furniture elements, boxes and cases for equipment. Such a printer will be an indispensable assistant in any production.

E3D extruder

The Gigant 3D printer uses the best E3D extruder because The extruder is the most important part of any 3D printer. The E3D extruder, as well as the 3D printer itself, are made in Ukraine. The Gigant 3D printer uses all known types of plastic for printing with the most common diameter of plastic filament for 3D printing.

This is one of the few 3D printers that uses Ultimaker technology and uses plastic with a filament diameter of 1.75mm. You can use for printing: ABS, PLA, PVA, HIPS, PC, PA, POM, FPE, Taulman, Laywood, Laybrick, BendLay, Flex, etc.

The optimum layer height for 3D printing is 200 microns. You can choose the layer height yourself in the 3D printer software. The printer's Z-axis accuracy (minimum layer height) is 3. 75 microns.

75 microns.

The Gigant 3D printer has a rigid and durable metal body that allows you to print ultra-precise products at high speeds. The Gigant 3D printer uses ball screws (ball screws) - the most reliable and accurate way to fasten the 3D printer platform.

Guide rails ensure precise and smooth running of all elements of the 3D printer. Due to the reliable fastening along the entire length of the rail, the rail does not deform during operation and guarantees high quality 3D printing.

Platform heating allows you to create the necessary temperature conditions for 3D printing with all types of plastic. Removable glass platform provides a perfectly flat surface and quick replacement in case of printing a new object.

The display allows you to control all 3D printing parameters and set up your 3D printer without connecting to a PC. An additional option is the ability to control the 3D printer via the Internet. A built-in camera allows you to remotely control the printing process.

Another advantage of this printer is its automatic calibration, which removes human intervention from the platform level calibration process.

3D printer specifications:

Gigant 3D printer

| Model | Gigant |

| Printer dimensions | 500*500*560 mm |

| Printable area | 400*400*400 mm |

| 3D printing type | FDM |

| Number of extruders | one E3D+ |

| Nozzle diameter | 0.4mm |

| Maximum nozzle temperature | 250 degrees Celsius |

| Duotone | single color |

| Plastic diameter | 1.75 mm |

| Plastic filament type | all types |

| PLA recommended temperature | 180-210 |

| ABS Recommended temperature | 220-240 |

| Print speed | 250mm/s |

| Layer height | 50-200 microns |

| layer thickness | 0. 10-0.40mm 10-0.40mm |

| Positioning accuracy | XY axis 0.0128mm, Z axis 0.00125mm |

| Body material | Steel |

| Housing type | semi-closed |

| Z-axis drive type: | Trapeze screw set |

| Linear guides | Precision Rails |

| Platform | with heating and glass cover |

| Maximum platform temperature | 120 degrees Celsius |

| LCD display | graphic display with stand-alone operation without PC |

| Ethernet, Camera, web remote control | optional |

| Software | CURA, PrintRun |

| System | Windows, Linux, Mac |

| Connection | USB, SD Card |

| Print size | STL;GCode;obj;dae;amf |

| Platform Auto Calibration | no |

| Official warranty and support | yes |

| Voltage | 200-240V 4. 0A 0A |

| 100-120V 7.0A | |

| Weight | 20kg |

| Country of origin | Ukraine |

Back to main page

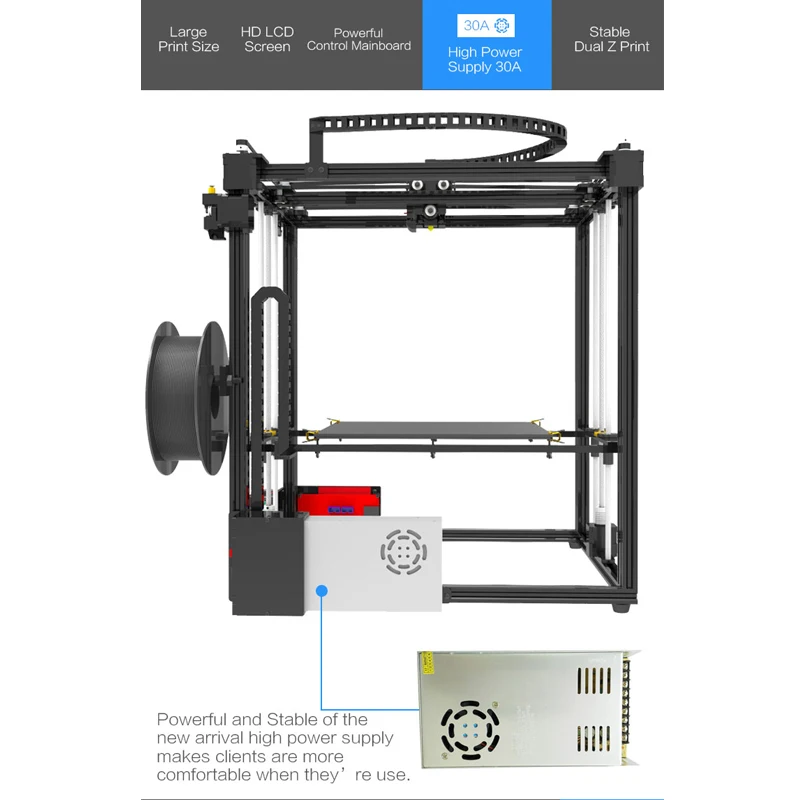

3D printers with a huge printable area / Sudo Null IT News

Over time, everyone is faced with the need to produce large parts using additive technologies. And household 3D printers, for the most part, have a relatively small printing table (a square with a side of 180 .... 220 mm). Not enough. But what if you want more?

There are various interesting solutions for increasing print sizes, including huge expensive industrial printers, but there are also budget options for printing at home.

Greetings to all!

I propose to look at a selection of 3D printers with a large working field. The selection includes models with a print field of 300x300 to 400x400 mm. The height of the models is also up to 400 mm. All printers are relatively inexpensive, the price range in the article is from $289 to $599 for branded models, which is quite good for using the printer at home, in the office or for a small business.

The leader in price and working area is Alfawise U20 Large Scale 2.8 inch Touch Screen DIY 3D Printer.

This is an interesting classic 3D printer with a heated bed. It is possible to print with popular materials: PLA, ABS, PVA, PP, wood and so on. Printing comfort is ensured by a large 2.8" touchscreen display with support for memory cards and USB drives. Type: DIY

Model: U20

Engraving Area: 300 x 300 x 400mm

Frame material: Aluminum Alloy

Nozzle quantity: Single

Nozzle diameter: 0.4mm

Nozzle temperature: Room temperature to 250 degree

Layer thickness: 0.1-0.4mm

Memory card offline print: SD card

LCD Screen: Yes

Print speed: 20 - 150mm/s

Supporting material: ABS, PLA, PP, PVA, Wood Filled

Material diameter: 1.75mm

Language: Chinese, English

File format: G-code, STL

XY-axis positioning accuracy: 0.012mm

Z-axis positioning accuracy: 0.004mm

Voltage: 24V

Host computer software: Cura,Repetier-Host

Packing Type: unassembled packing

System support: Windows / Linux / MAC

Connector Type: SD card, USB

I am attaching a small video review of the printer - last time they asked for additional information on models.

The printer is large, comes partially disassembled (vertical portal removed). Assembly is simple to disgrace and takes a minimum of time. The printer has already been flashed and configured, it is enough to set (check) the table according to the level and start test printing. Auto-calibration provided.

The next champion in this race is Geeetech's A30 Aluminum Large Printer.

This model is slightly more expensive and has a slightly larger print area (320 x 320 x 420mm).

Of the important "chips", I note the support for Wi-Fi connection and work through the EasyPrint 3D application from a PC, tablet and smartphone. To increase adhesion, a special glass is immediately installed on the table, similar to Ultrabase (silicon carbide glass with a special matte finish). A 3D touch sensor is provided as an auto-calibration. I note the presence of a filament sensor. If the filament spool runs out, the printer will simply pause. After "refueling" printing will continue.

After "refueling" printing will continue.

Features:

Brand: Geeetech

Type: DIY

Model: A30

Frame material: Aluminum

Nozzle diameter: 0.4mm

Product forming size: 320 x 320 x 420mm

Memory card offline print: TF card

Print speed: 80 - 110mm/s

File format: G-code,OBJ,STL

XY-axis positioning accuracy: 0.011mm

Z-axis positioning accuracy: 0.0025mm

System support: Windows, MAC, Linux

Size: Large

Connector Type: SD card, USB

I also note that this 3D printer also requires partial assembly.

The list of printer functions is represented by icons below.

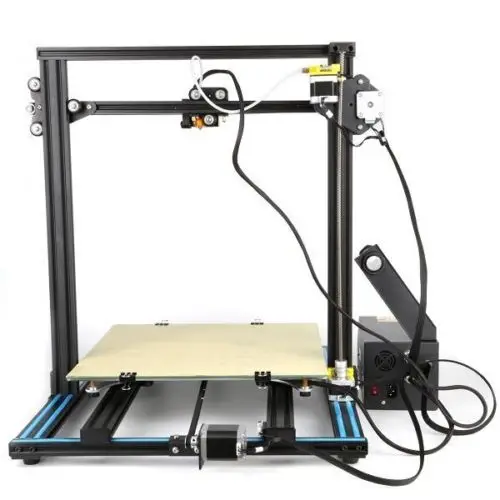

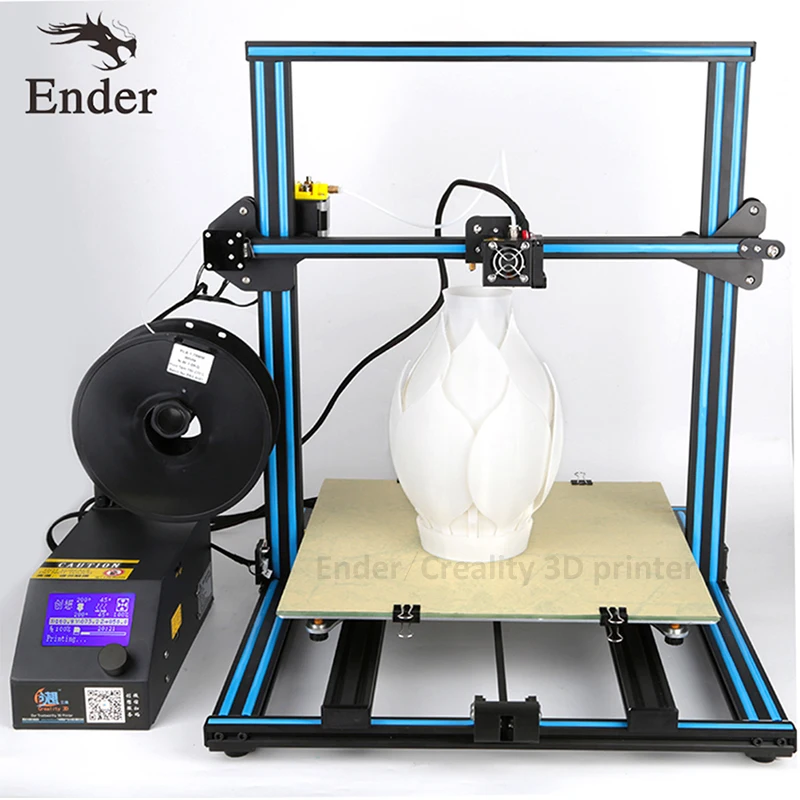

Probably the most popular large printer from Creality3D.

This is the Creality3D CR - 10S Pro 300 x 300 x 400 3D Printer - 300 x 300 x 400mm printable area.

Features:

Brand: Creality3D

Type: DIY

Model: CR-10S Pro

Frame material: Aluminum

Product forming size: 300 x 300 x 400mm

Molding Technology: FDM

Printing Speed: ≤180mm/s, ordinary printing speed 30 - 60mm/s

Print Accuracy: ±0. 1mm

1mm

Printing Height: 0.1 - 0.4mm

Nozzle Number: 1

Nozzle Temperature: ≤260°C

Hot Bed Temperature: ≤110°C

Working Mode: print online or offline with a TF card

File Format: STL, OBI, AMF

Power Supply Parameters: 100 - 240V 5.9A 50 / 60Hz input, DC 24V 21A output

Printing Power: 480W

Printing Material: PLA, ABS, PVA, PP, wood filled, etc.

Consumable Diameter: 1.75mm

The layout is quite convenient - the power supply and control unit is built into the "sole" of the printer, and does not take up a separate place on the table. There is also a filament sensor, pause and resume print, touch screen.

As for the qualitative differences, I note the presence of a special extruder with a double gear (Geared extruder), which ensures a confident supply of even soft plastics.

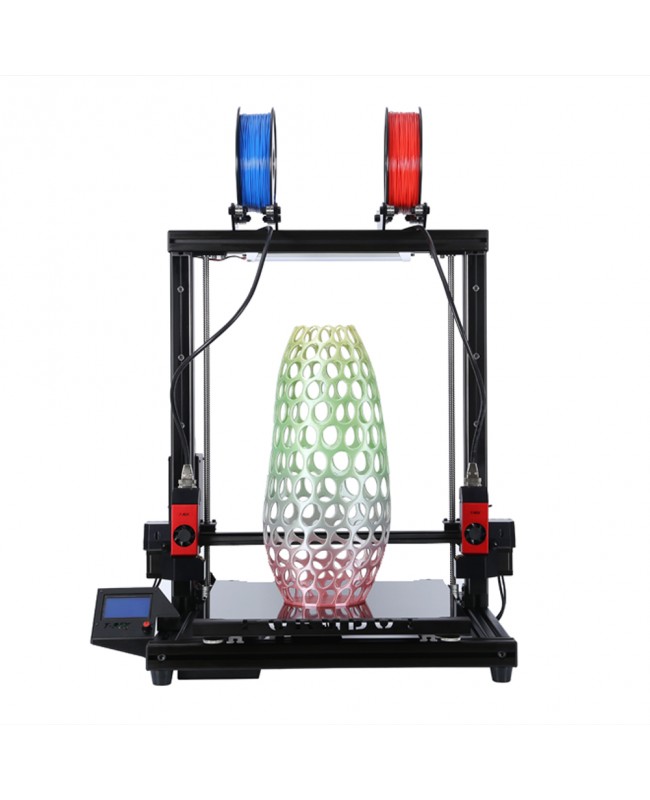

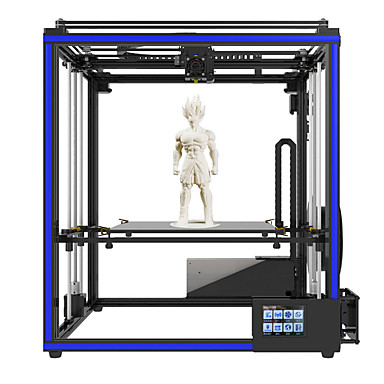

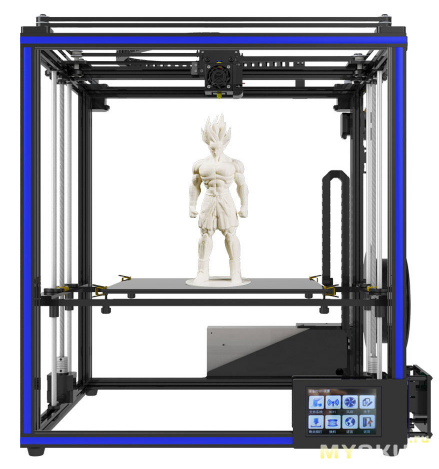

Another representative of these 3D printers is the Xvico X5 Aluminum Alloy 3D Printer 400 x 400 x 400mm.

This printer is even larger (table not 300x300, but 400x400 mm). Also has a pause, filament sensor, auto level.

Also has a pause, filament sensor, auto level.

Features:

Brand: Xvico

Type: DIY

Model: X5

Machine material: aluminum alloy profile + sheet metal

Nozzle diameter: 0.4mm

Printing accuracy: + / - 0.1 - 0.2mm

Layer thickness: 0.1 - 0.4mm

Printing method: SD card

Display: 2.8-inch color touch screen

Machine speed: 10 - 300mm/s

Printing speed: 20-200mm/s

Extrusion head temperature ( highest ): 260Deg.C

Hot bed maximum temperature ( highest ): 100Deg.C

XY axis positioning accuracy: 0.012mm

Z axis positioning accuracy: 0.004mm

Printing materials: ABS, PLA, TPU

Consumable diameter: 1.75mm

Operating language: Chinese English Korean German Spanish Russian French Italian Portuguese

Software format: STL, OBJ, JPG

Print file format: Gcode

Operating system: Windows, MAC

And finally, the revival of the legend.

Anet A8 Plus Aluminum Frame 3D Printer.

Features:

Brand Name: Anet

Type: DIY

Nozzle quantity: Single

Nozzle diameter: 0.4mm

Nozzle temperature: Room temperature to 250 degree

Product forming size: 300 x 300 x 350mm

Layer thickness: 0.1-0.4mm

Memory card offline print: TF card

LCD Screen: Yes

Print speed: 10 - 120mm/s

Supporting material: ABS, HIPS, PA, Wood, PETG, PLA

Material diameter: 1.75mm

Language: Chinese,English

File format: G-code,JPG,OBJ,STL

Model supporting function: Yes

XY-axis positioning accuracy: 0.012mm

Z-axis positioning accuracy: 0.004mm

Voltage: 24V

Working Power: 220V / 110V / 360W

Host computer software: Cura

Packing Type: unassembled packing

System support: Windows, Mac OS

Voltage Range: 100-240V

Current (mA): 15A

Connector Type: TF card, USB

This printer is the only one available with cylindrical rails and is also shipped unassembled.