3D printer hands

Hand best STL files for 3D printing・Cults

Skip to contentM-LOK Rail Covers and Handbrakes

Free

AWARD / HAND

Free

HAND

Free

2 vases pot look woman and man in 3 parts

€2.50 -50% €1.25

Hands statue

€1

Thanos

€2 -50% €1

ANIME Fan Art Free low-poly 3D model

Free

Big Daddy Drill

Free

Lagoon Monster Hand

€1.53

Weaponized Miner Fantasmagoria! Specialized gun arms! (22 arm sets)

€6. 67

Robotic hand(prosthetic)

€5.12

3pc Pillar Candle Bath Bomb Mold

€6

Hand Model 3

€10.23

TAP WRENCH M5 M6 M8

Free

Rail Grip, Rail Cover and Hand Stop

Free

Stylized Female Base Mesh

€5.11 -10% €4.59

Fuck You Keychain

€0.67

Halloween Hand 1

€4.59

Mickey Hands - Controller holder!

€5.82

Space knight hand holding pizza that would feed 40 marines

Free

Hand Saw { Micro Tool Set } (28mm Scale)

Free

Hand Drill { Micro Tool Set } (28mm Scale)

Free

Articulated hand

Free

Hand Model 2

€10. 23

23

Graceful Death (supportless FDM)

€2 -30% €1.40

RC Truck - TAM 110 T7 B/BV

€76.89

hand axe

Free

Chongtong 총통 - Korean Hand Cannon

Free

Hand of Fatima beaded pendant charm 3D print model

€4.09

Hand Model

€10.23

Halo 4 Master Chief Hand Armor

Free

wooden wallet

€13.36

Dremel table saw with cutting angle adjustment

Free

Hand Skeleton Pendant

Free

Hand - peace

Free

FIST - keychain

Free

Hand keychains

Free

Hand Pendant

Free

Alien bracelet

Free

Need A Hand?

Free

SPLINT HAND (WRIST) _ RIGHT M

€39. 90

90

SPLINT HAND (WRIST) _ LEFT M

€39.90

SPLINT HAND (WRIST) _ RIGHT L

€39.90

SPLINT HAND (WRIST) _ LEFT L

€39.90

Wrist Brace and Tensioner for Prosthetic Hand - No Support Needed!

Free

Gym accessory handle

€2

Thumb free version of Phoenix hand

Free

Unlimbited hand wiring accessory to insure a 30° angle

Free

Hands best 3D printer models・Cults

Skip to contentHands statue

€1

Hand of Iron Terminator

Free

Hand Of Iron Shoulder

Free

Hand of Iron Shield

Free

2nd Death Division Grenadier Assembly Kit (50+ parts)

€20. 36

36

VEGETABLE HAND - AI vs HUMAN (HAPPY HALLOWEEN)

€1.02

Extended Fightstick Handle for Larger Hands

Free

Giant Mechanical Cyberpunk Hands

€21.80

Ghost BOO Hands UP

€1.92 -20% €1.54

my versio de ferrus manus

€6

Skeleton Hands Bookshelf / Door Halloween Decoration (NO SUPPORT)

€2.50

ghost eye

€0.97

Keychain hands heart

€0.65

Monster Claws Bookshelf/Cupboard decoration (no support)

€2.50

Monster Claws Bookmark (No Support)

€2.50

holloween Skeleton hands

€1.50

Medical Corps! (3 Good Doctors and medical bits)

€7. 50

50

man outstretched hands grid

€0.87

man outstretched hands

€0.67

This Printer Fought Covid 19

Free

Pillikan - Easy to print pill puncher

Free

Hand gadget eye and moustache

€0.62

Bones Hand Halloween - shelf support

€2.50

APE NFT

Free

Gator Grabber: Ultimate Touch-less door tool w/ Stylus holder

Free

Fingers Crossed

Free

A OK Hand

Free

Crawler Hand

Free

Hand Holding Plants Flower decoration

€3.58

Articulated fingers Hand harnesses

Free

Replacement hands and arms for giant monster high dolls

€5

Alien Articulated Fingers

€5. 61

61

1pc + 2pc +3pc Crystal Ball in Hands Bath Bomb Mold

€6

New Clock Face Hollow Clock with Flying Hands

Free

See No Evil Halloween Decoration Candle Holder or Bowl

€1.02

Day of The Dead Sugar Skull bowl, Halloween Candy dish decoration

€1.28

Beaky Imperator's clenched hands helmets for new heresy

€3

Replacement parts for Monster High giant body type - articulated

€9

Mini Hulk Hands

Free

Hand holding heart in heart, outline, continuous line, love symbol

€1.02

Hands-free faucet handle

€0.59

Abstract Art Face WallArt Lucid Dream The Backup

€4

iron hands shoulder pads

€2

3d model of hand bones

€10. 62

62

CSM Arms Pack (with soure blender file)

Free

Iron Hands Shoulderpad

€1.25

Anatomy of a hand

€2.50

COOKIE CUTTER PET LOVERS HEART HEART HANDS AND PAWS

€0.50

our way from idea to realization

Share on Facebook Share on Twitter Share on Vkontakte

A few months ago, our idea for an affordable prosthetic hand was just an idea, an intention. Today we are happy to share our results with you!

How did it all start? The first prosthesis printed with the 3D printer was created in South Africa by Richard Van As. His video went around the world and inspired many people, including us. Having studied the issue of limb prosthetics, we were surprised how difficult it is in our country. Those prostheses that are available perform only a cosmetic function. And those that are functional cost fabulous money and require compliance with certain conditions, in particular, a person reaching a certain age.

Building a team and searching for a patient

It was decided by the general council that we would take on a project to create an affordable mechanical hand prosthesis for people of almost any age. First of all, we needed to find colleagues from different professions - 3D designers , designers, doctors and, of course, find a patient who will try out the first prosthesis created using 3D printing . It cannot be said that it was quick and easy, but the necessary specialists were found. Young engineers from the company 9 joined the project0010 W.E.A.S. Robotics who work in the field of robotics and are known for their desire to develop this area in Russia, as well as their passion for engineering, which is expressed in their projects . As well as an orthopedic surgeon from the St. Petersburg Institute of Prosthetics, who liked the idea. It was up to the patient. We were approached by several people who could become testers of the prosthesis, but either they were too far away, or their age was too young. We continued to search and found Alexander from Yaroslavl, where we were also advised by an excellent doctor, who later agreed to install a prosthesis. Thus, we have a fully formed team and a patient.

We continued to search and found Alexander from Yaroslavl, where we were also advised by an excellent doctor, who later agreed to install a prosthesis. Thus, we have a fully formed team and a patient.

Work started

Alexander lost his fingers on both hands in an accident, but his wrist joints remained fully functional. The first step was to take the necessary measurements in order for the prosthesis to fit.

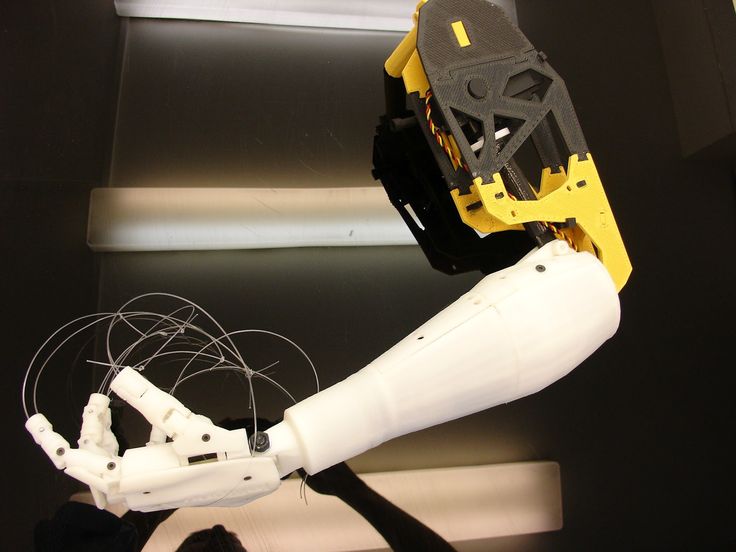

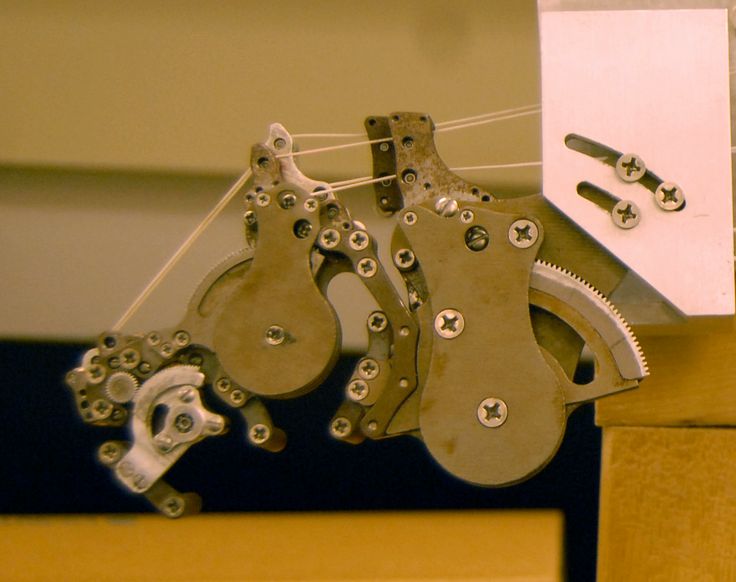

Then came the collaborative effort of 3D designers . As a result, we very soon had a ready-made 3D model for printing:

The next step was perhaps one of the simplest - the individual parts of the prosthesis went to print. Unfortunately, we did not have time to take disassembled photos, as we were eager to put all the parts together as soon as possible and see the almost completely completed prosthesis.

It is worth noting that the final assembly of the prosthesis takes place already on the patient’s arm, and, in addition to the parts printed on a 3D printer, cables or rope, screws and a turbocast are also needed. If everything is clear with cables and cogs, then it is worth mentioning the turbocast separately. This is a special thermoplastic that, when heated, for example, in hot water, becomes flexible and it is easy to give it the desired shape, after a few minutes it hardens again, and the rest of the prosthesis structure is attached to it. It was sold to us at a discount at company Horse , which manufactures retainers from similar plastics.

If everything is clear with cables and cogs, then it is worth mentioning the turbocast separately. This is a special thermoplastic that, when heated, for example, in hot water, becomes flexible and it is easy to give it the desired shape, after a few minutes it hardens again, and the rest of the prosthesis structure is attached to it. It was sold to us at a discount at company Horse , which manufactures retainers from similar plastics.

Installation of the prosthesis and the first test

We had the most exciting action - the installation and the first test of the prosthesis. Choosing in advance a convenient time for everyone, we went to Yaroslavl and for the first time personally met with the doctor and Alexander. Alexander turned out to be a very cheerful and cheerful person, and the process of installing the prosthesis went under his playful comments.

This short video shows the mechanics of the prosthesis in action:

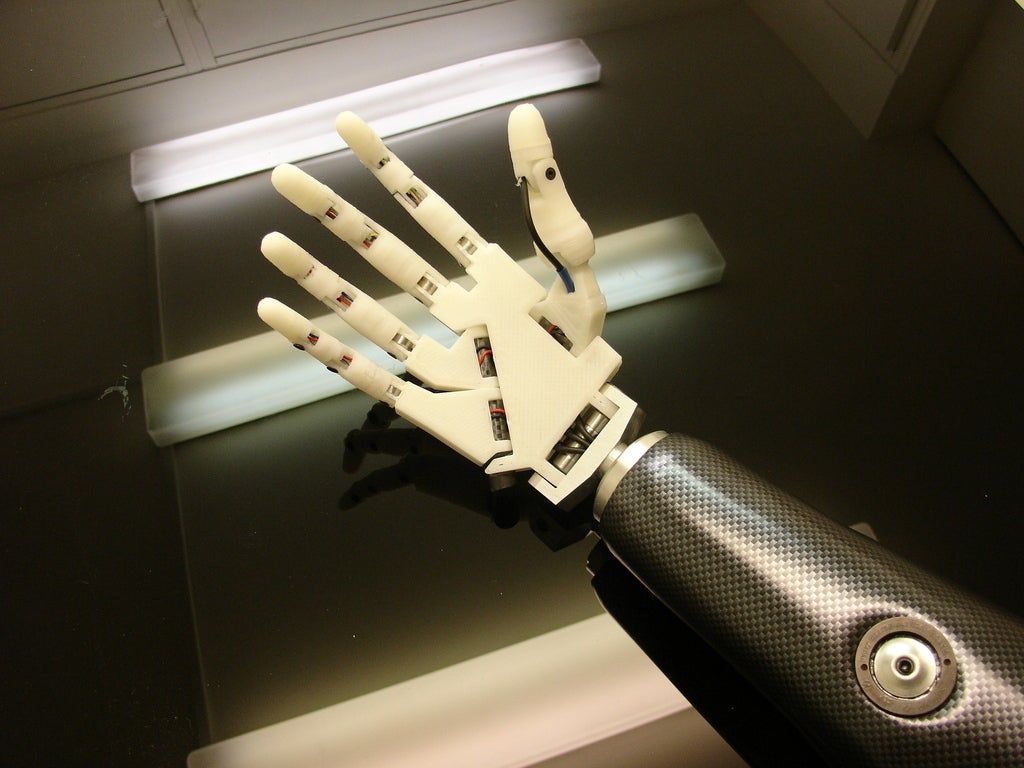

Practical tests of the prosthesis not only proved its functionality, but also importantly, helped to find some flaws in the design developed by Richard, which will be solved in the following design prosthesis iterations. We decided to completely redo the prosthetic hand model and it is almost ready, and by the way, now it looks like this:

What conclusion can be drawn after going from the idea of creating a prosthesis to its implementation? We made sure that an affordable mechanical prosthesis created using 3D printing is more than just an idea, it is a real and tangible help to many people - both children and adults. We are very grateful to everyone who, by deed or word, has contributed and continues to contribute to this good deed. It's nice to know that there are caring people who are willing to spend their time and money to create something really useful.

You can also contribute to the common cause of helping those in need of a prosthesis by sharing a link to our article, and perhaps this will allow a person in need to solve their problem with the help of our project. Just a couple of clicks, and one more good deed.

Just a couple of clicks, and one more good deed.

To be continued, friends!

More news about our 3D printed hand prosthesis project:

Applying 3D printing: updated mechanical hand prosthesis and first sample of myoelectric prosthesis

Autodesk Gorgeous gift for our prosthesis

Social Impact Award 2014 and first place for express processing

9000

6

3D printing medical prosthesis

Hands of gold: an American figured out how to make unique prostheses on 3D printers

- Technology

- Alex Knapp Author

22-year-old inventor from the United States, in collaboration with powerful corporations, creates ingenious prostheses

Easton LaChapelle created his first robotic prosthetic arm when he was 14 years old, and eight years later he founded Unlimited Tomorrow, which focused on the production of modern technological prostheses. Today, his company is partnering with industrial and technology giants such as Microsoft, Dassault Systèmes, and Stratasys to expand production. In particular, together with Stratasys Unlimited Tomorrow will organize research and development plans to make the company the company's exclusive partner-provider of 3D printing services.

The ultimate goal of Unlimited Tomorrow is to 3D print a robotic prosthesis that will cost far less than those on the market today and that will perfectly fit human needs.

“Apart from some nuts, bolts and electronic mechanisms, the device is almost entirely 3D printed,” says LaChapelle.

It's not just a prosthesis. The PolyJet technology used on Stratasys' 3D printers allows Unlimited Tomorrow to create robotic arms that mimic human skin tones and may even have imperfections such as freckles. These hands also have magnetic "nails" that can be manicured. There is also the ability to remotely charge the robotic arm, and its haptic feedback gives the user the ability to touch surfaces.

- Printing organ: how 3D printing helped create a cheap prosthetic hand

The company has tested its model with the first prototype - now it is ready for large-scale production. In collaboration with crowdfunding platform Indiegogo Unlimited, Tomorrow launched a fundraising campaign and aims to produce 100 of these prostheses by the end of 2018. In the future, the company plans to develop a process that will allow for the rapid production of customized products.

In the future, the company plans to develop a process that will allow for the rapid production of customized products.

The desire to create custom prostheses in large volumes distinguishes Easton LaChapelle from other market players who want to use 3D printing technology for the manufacture of prostheses. This is what attracted Stratasys.

"We wanted to partner with Unlimited Tomorrow primarily because of the breadth of their vision," says Mike Gaisford, medical director at Stratasys. — Other existing programs aim to solve the same problem, but do so on an ad hoc basis. Designing processes and systems that use automation to scale quickly is a far-sighted decision, since one-time measures do not aim to cope with a global problem.

One method of streamlining processes that Unlimited Tomorrow uses is to target amputees directly rather than selling products to doctors or hospitals. The company hopes to achieve this by using 3D scanning to create customized prosthetics.