President obama 3d printing

Barack Obama on 3D printing and America's manufacturing industry

0Shares

In his eight years as President of the United States, Barack Obama has shown a lot of interest and support for 3D printing.

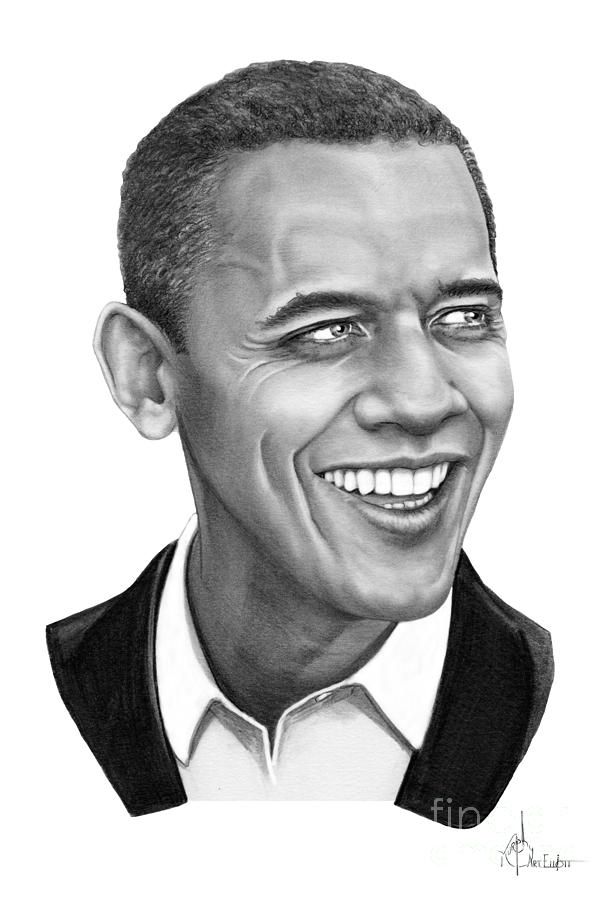

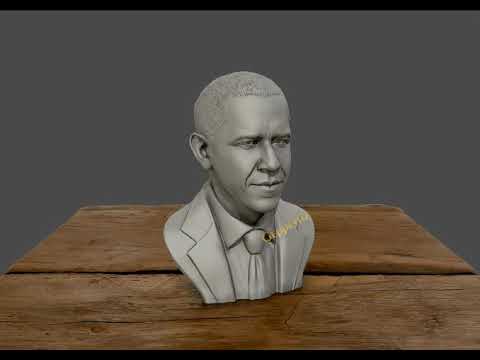

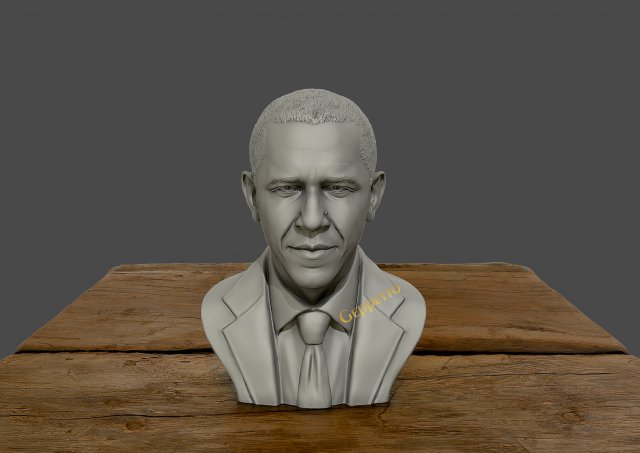

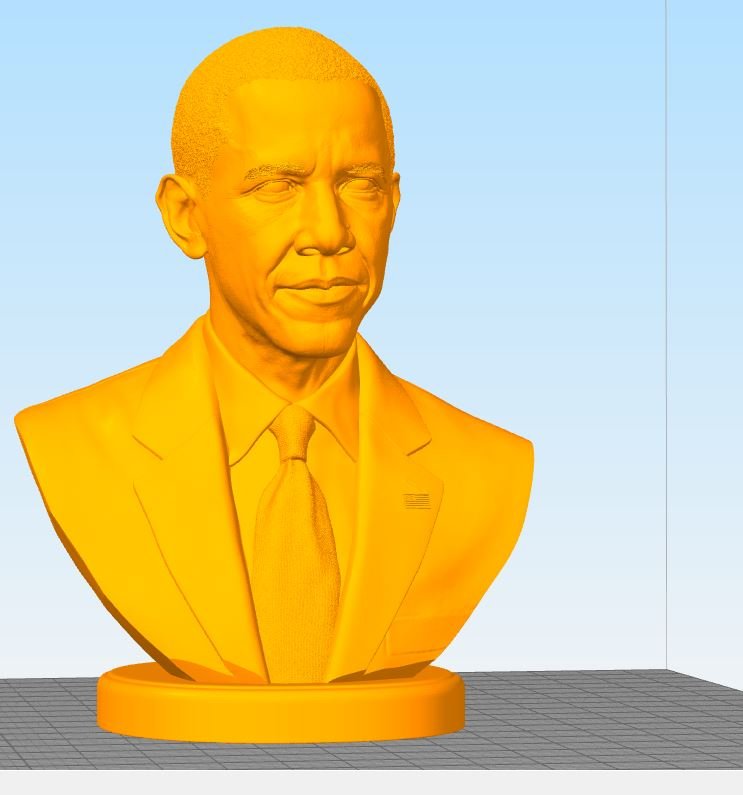

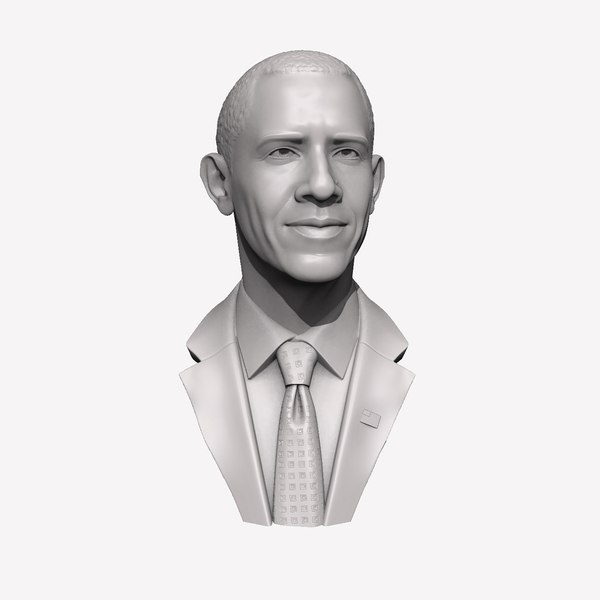

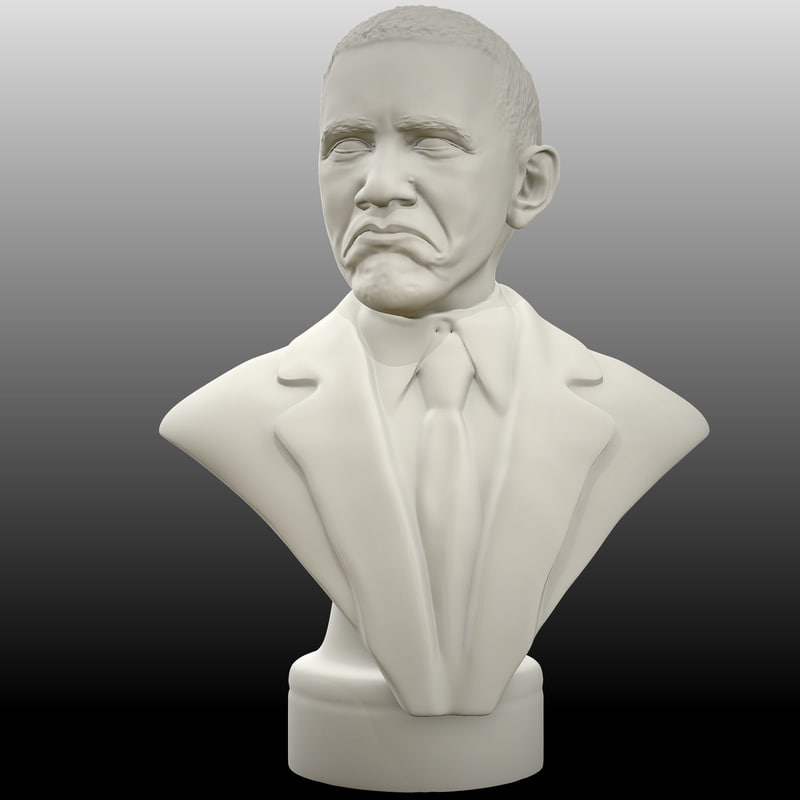

In a presidential first, the Smithsonian institute 3D printed a bust of President Obama for the White House Maker Faire in June 2014.

President Obama is scanned for his 3D printed bust. Screenshot via: WhiteHouse.govIn 2016, the White House also hosted the National Week of Making with 3D printed projects from elementary school student Jacob Leggette.

The National Week of Making at the White House. President Obama tries Jacob Leggette’s 3D printed bubble wand. Also in the collection: 3D printed cups, bowls, cookie cutters, and a replica of the White House. Photo via: APBeyond these snapshots of America’s 44th President and 3D printing, it also becomes clear that he takes the application of additive manufacturing in industry very seriously.

Manufacturing hubs program

The manufacturing hubs program is Obama’s initiative to continue the progress of bringing industry to the US. In a speech opening a new hub in Clinton, Tennessee he explains, “When I took office, I believed that if the last decade was characterized by outsourcing, I wanted to define this decade for in-sourcing.”

The program itself sets up manufacturing facilities, like Maker Labs or Fab Labs, in colleges and communities with the expressed purpose of connecting people in varied areas of expertise. Explained by Obama himself in the same speech in Clinton,

We’re working to grow the jobs of tomorrow through a national network of manufacturing hubs. We’re launching these hubs around the country, and the concept is simple. We bring businesses, research universities, community colleges, state local and federal governments together. And we figure out, where’s the key opportunities for manufacturing int he future? […] these hubs are working on everything from 3D printing, […] to flexible computer chips.

The former President visited a number of manufacturing hubs in his term, including Boise State Univeristy’s Product Development Lab that 3D prints product prototypes for partnered businesses, and Pittsburgh’s community-based workspace TechShop.

The National Additive Manufacturing Innovation Institute and America Makes

The first manufacturing hub was opened in Youngstown, Ohio and was mentioned in Obama’s State of the Union speech from 2013,

A once-shuttered warehouse is now a state-of-the art lab where new workers are mastering the 3D printing that has the potential to revolutionize the way we make almost everything. There’s no reason this can’t happen in other towns.

In 2013’s State of the Union Address, Obama also mentions the National Additive Manufacturing Innovation Institute. Affiliated with the America Makes program and the country’s national labs like Oak Ridge National Laboratory, the collective produces new materials, methods and technologies typically for aerospace, medicine and defence.

Chiefly concerned with on-shoring America’s industries, we’re hoping Trump’s presidency will be just as welcoming to the 3D printing industry as Obama’s has been, and look forward to hearing from him soon!

With the proliferation of manufacturing hubs and more companies adopting 3D printing capabilities it certainly seems like the right initiative to take.

To stay up-to-date with the latest 3D printing insights, you can like 3D Printing Industry on Facebook, or sign up to our newsletter here.

Featured images shows the 3D printed bust of Obama. Photo via the Smithsonian Institute

Tags Barack Obama Donald Trump ORNL president of the United states US Election US manufacturing

Beau Jackson

Obama's speech highlights rise of 3-D printing

Story highlights

Obama's State of the Union address puts focus on emerging 3-D printer field

President calls for 15 innovation centers like one promoting the printers in Ohio

Consumers can buy 3-D printers for the price of a high-end desktop

They're being used to make everything from jewelry to buildings

The burgeoning field of 3-D printing got a big boost Tuesday night when President Obama highlighted it as something that could fuel new high-tech jobs in the United States.

The shout-out in Obama’s State of the Union address was perhaps the biggest public endorsement so far of a technology that has its roots in the 1970s, but has recently begun to boom on two fronts – as an increasingly accessible consumer product and an industrial one that advocates say could change the face of manufacturing.

Obama spoke about the National Additive Manufacturing Innovation Institute, a public-private partnership established in the hard-hit manufacturing city of Youngstown, Ohio, last year to research how cutting-edge 3-D printing technology can be moved from the research phase to day-to-day use.

“A once-shuttered warehouse is now a state-of-the art lab where new workers are mastering the 3-D printing that has the potential to revolutionize the way we make almost everything,” Obama said.

The process of 3-D printing (also known by the clunkier “additive manufacturing” moniker) uses computer-created digital models to create real-world objects – everything from simple chess pieces to more complex objects such as functioning clocks. The printers follow the shape of the model by stacking layer upon layer of material to make the objects.

Obama announced plans for three more manufacturing hubs where businesses will partner with the departments of Defense and Energy “to turn regions left behind by globalization into global centers of high-tech jobs. ”

”

“And I ask this Congress to help create a network of 15 of these hubs and guarantee that the next revolution in manufacturing is made in America,” Obama said.

Edward A. Morris, the director of NAMII, said the organization was “tremendously honored” to be mentioned by the president in such a high-profile speech.

3D printed shoe

Courtesy 3D Systems Corporationvideo

The 3-D printing revolution

3D printer at work

video

3-D printing buildings of the future

tsr pkg joe johns 3-d guns_00015918

video

Could 3-D printers make a gun?

mclaughlin uk digital dolls_00000607

video

Printing toys in 3-D

“It is rewarding to know that NAMII’s efforts to promote innovation and entrepreneurialism within the additive manufacturing sector is highly recognized and supported,” he said in a statement on the partnership’s website.

While primarily a novelty among the tech-obsessed, 3-D printing been used successfully for a variety of tasks, from making jewelry or medical supplies to larger projects in industrial design and engineering.

A Dutch architect has even announced plans to print an entire innovative building, piece by piece. That’s an outlier to be sure, but one that could signal things to come.

That’s an outlier to be sure, but one that could signal things to come.

READ: The woman who wants to print buildings

Three-dimensional printing has entered the public consciousness enough for Congress to be considering legislation banning people from making guns using the technology.

A weapon made with a 3-D printer could theoretically be formed from plastic, making it undetectable by traditional security measures. No one is known to have created an entire working firearm with a 3-D printer, although usable parts of one reportedly have been printed.

No one is known to have created an entire working firearm with a 3-D printer, although usable parts of one reportedly have been printed.

MakerBot, the most prominent maker of 3-D printers that the public can buy, has cracked down on printed guns by enforcing terms on its website that prevent users from sharing blueprints for firearms.

It’s also MakerBot that’s been at the forefront of of the move to put 3-D printers in the hands of the general public.

One of the biggest obstacles has been cost. But the company’s Replicator 2 desktop printer is now selling at a relatively accessible $2,200, roughly the equivalent of a basic Apple iMac computer.

But the company’s Replicator 2 desktop printer is now selling at a relatively accessible $2,200, roughly the equivalent of a basic Apple iMac computer.

READ: Our top tech wishes for 2013

MakerBot was listed this week as one of tech blog Fast Company’s top 10 most innovative consumer tech companies with the likes of Apple, Samsung and Google. CEO Bre Pettis said Wednesday that the company’s goals are in line with those voiced Tuesday by Obama.

“We created MakerBot to help innovators iterate faster, more affordably and (to help them) invent more,” Pettis said. “We’re proud to be recognized by the president in his State of the Union address and we’re going to do our part to get it done.”

“We’re proud to be recognized by the president in his State of the Union address and we’re going to do our part to get it done.”

While some consumers may have new visions of 3-D printers in their garages, Obama was speaking mostly of the technology’s industrial potential.

He pitched it as a way to prod what he called an encouraging recent trend: the return of tech-industry and other manufacturing jobs to the U.S.

Apple has announced it will begin manufacturing some of its iMacs in the United States this year, a fact Obama noted in his speech. Lenovo, the world’s second-largest PC maker, is starting a production line in North Carolina, and Intel is spending a whopping $5 billion to build an Arizona plant to make its processors.

Lenovo, the world’s second-largest PC maker, is starting a production line in North Carolina, and Intel is spending a whopping $5 billion to build an Arizona plant to make its processors.

Analysts have said that as regulations and wages increase in places like China, and as U.S. workers gain expertise in tech manufacturing, it will increasingly make more sense for U.S. companies to keep their plants closer to home.

Why do we need 3D printing at school?

Today, the use of 3D printing technologies in education is only just beginning to gain momentum, but already there are amazing prospects. 3D printing can be introduced to primary and secondary schools, universities and other educational institutions. One of the reasons 3D printing has been slow to take off is the lack of awareness of the technology among education decision makers.

3D printing technology is still quite new, so the introduction of it in schools can have a significant impact on further development. At an earlier age, it is much easier to introduce new ideas and methods to a person. That is why children learn foreign languages much faster than adults. And that's why elementary and middle schools are the perfect place to introduce 3D printing courses.

Almost every subject taught in school can benefit from 3D printing – here are a few examples.

3D printing in mathematics

3D printing is already being used in teaching mathematics, in particular for the visual demonstration of graphs and mathematical models. Some students find it difficult to understand the numbers and charts they see on paper. This does not mean that they are not capable of learning - it is just a feature of the brain. 3D printing helps these students see equations, graphs, and complex mathematical models in a real-life way – and thus understand them. It is also important that 3D printing brings an element of variety to a subject that is usually quite boring.

It is also important that 3D printing brings an element of variety to a subject that is usually quite boring.

3D printing in geography and geology

3D printing technologies can be used to show students geological formations at a scale that cannot be seen in a 2D image. We have already seen not only successful examples of the use of 3D printing in the teaching of geography and geology, but also how scientists used 3D printing to land a lander on a comet, choosing the best place to land on a 3D model. In addition, earthquake models were printed on a 3D printer for comparative analysis, as well as models of the causes and consequences of hydraulic fracturing in the development of oil and gas fields. Of course, living in a 3D world, it is best to teach geography and geology using visual 3D models. If textbook authors agree on the importance of 3D printing and want to incorporate it into lesson planning, they can include 3D printing files in each chapter. This will make the lessons more interesting and informative for both students and teachers - for example, you can print reduced models of mountain ranges, rivers, canyons and other geographical objects on a 3D printer. Thus, children will be able to observe some famous places of the world with their own eyes without leaving the classroom.

This will make the lessons more interesting and informative for both students and teachers - for example, you can print reduced models of mountain ranges, rivers, canyons and other geographical objects on a 3D printer. Thus, children will be able to observe some famous places of the world with their own eyes without leaving the classroom.

3D printing in history

It can be said that history as a subject will benefit the most from the introduction of 3D printing. Museums around the world are finally beginning to recognize the enormous potential of 3D scanning and 3D printing, not only to create replicas of ancient objects, but to give visitors the chance to literally touch them. Previously, throughout the museum there were signs "Do not touch the exhibits with your hands." Now that replicas of objects can be produced using high-precision 3D printers and scanners, museum visitors have the opportunity to touch the exhibits, many of which are virtually indistinguishable from the originals. Now imagine that in every history class, students will have the opportunity to print copies of historical objects on a 3D printer from the mass of STL files available for download. Now every school will have access to museum exhibits right in the classroom. In addition, it is much more interesting than reading chapter after chapter in a textbook, when many students cannot concentrate, are distracted and do not understand what they read. Being able to show an item from the era in question will make the lesson more fun.

Now imagine that in every history class, students will have the opportunity to print copies of historical objects on a 3D printer from the mass of STL files available for download. Now every school will have access to museum exhibits right in the classroom. In addition, it is much more interesting than reading chapter after chapter in a textbook, when many students cannot concentrate, are distracted and do not understand what they read. Being able to show an item from the era in question will make the lesson more fun.

3D printing in art

Of course, 3D printing can be used with great success in art classes. This technology opens up a range of possibilities for teachers, such as incorporating 3D design into the curriculum. With the help of 3D printing, students can bring the models they have designed to life - this will also make the lessons more interesting. In addition, there will be no need to be limited to a two-dimensional screen to demonstrate three-dimensional models. It will be possible to carry out design projects at the national and even international level, providing other schools with open access to models for printing on a 3D printer. Schoolchildren from New York will be able to work on joint projects with their peers from India, and then both schools will be able to print the result on a 3D printer.

It will be possible to carry out design projects at the national and even international level, providing other schools with open access to models for printing on a 3D printer. Schoolchildren from New York will be able to work on joint projects with their peers from India, and then both schools will be able to print the result on a 3D printer.

In recent years, a number of opportunities that 3D printing provides to the arts have already been shown, but this is still the smallest part of its potential. 3D printing allows you to take a fresh look at the creation of art objects. If 3D printing is available to schoolchildren around the world, it will be the next generation that will bring these technologies to all possible areas of art and ensure that their full potential is realized.

3D printing as a tool

Not only does 3D printing provide ways to explore different subjects, but it can also become the center of a new academic discipline. With due aspiration and the right approach to the implementation of this task, 3D printing can be taught as a separate subject.

We live in an era of rapid development of new technologies, and one of them is 3D printing. At the same time, schools still live in the past, having not changed the teaching methods used by previous generations for decades. It's understandable that new technologies can be intimidating, especially for the conservative old guard, but there is a need for change. The introduction of 3D printing is a change that schools around the world should be thinking about.

Already, some companies are starting to develop and popularize curricula that include 3D printing as a tool or a separate discipline – and there should be more such initiatives. It is impossible not to take into account another fact that hinders the development of technology - the lack of budget, which most schools have. Also, most people just don't know much about 3D printing.

It is logical that when it comes to financial matters, people who are not familiar with the technology will vote against investments related to it. Given this fact, the government at the national and regional level should take on the responsibility of informing school authorities about the potential of new technologies. Particularly in the US, President Barack Obama is already taking important steps to raise awareness of 3D printing. More efforts will need to be made in this direction, with particular attention to the education sector.

Given this fact, the government at the national and regional level should take on the responsibility of informing school authorities about the potential of new technologies. Particularly in the US, President Barack Obama is already taking important steps to raise awareness of 3D printing. More efforts will need to be made in this direction, with particular attention to the education sector.

How 3D printing will change the jewelry industry

Three-dimensional printing is one of the revolutionary inventions that have become quite widespread in recent years.

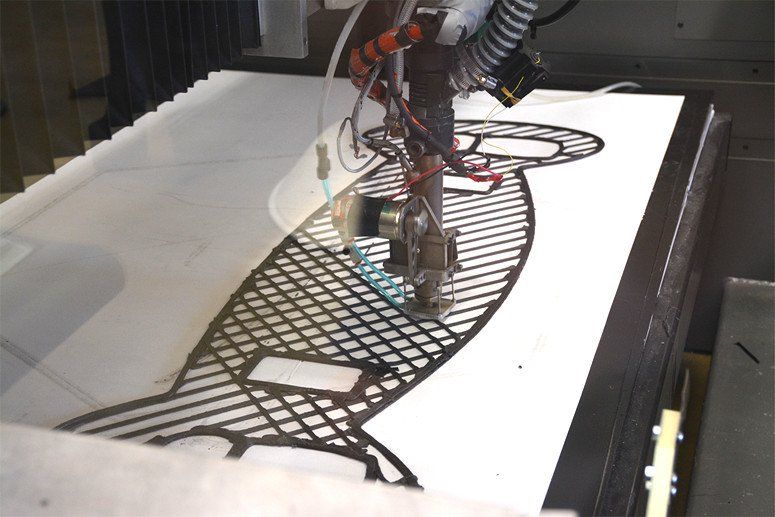

It can fundamentally change the traditional jewelry industry, and today we will talk about what changes await us in the next five years.In 1983, American engineer Charles Hull discovered a new printing method that allows the creation of three-dimensional objects. 3D printers work on the principle of layer-by-layer “growing” of a solid model and form an exact copy of a digital 3D prototype.

Unlike a two-dimensional printer that prints two-dimensional information on a sheet of paper, its three-dimensional counterpart is already capable of outputting information in three dimensions at once, that is, creating three-dimensional physical objects.

3D printing has exploded in the last few years thanks to the mass production of 3D printers at more affordable prices, the development of digital technologies and the expansion of the list of materials used in printing. They say that the third industrial revolution is just around the corner.

Jewelry belongs to the category of products that can be created with 3D printers today. Amazon.com, the number one online supermarket in the US, already has a 3D merchandise section where "printed" jewelry has a whole "shelf" in its own category called "jewellery for those who keep up with fashion."

This is a great opportunity for independent designers looking to tap into a large consumer market. Printing your own designer jewelry is already becoming a fashion trend in the West.

The list of materials for the production of jewelry using 3D printing is also constantly expanding. For example, New York-based Shapeways, a 3D printing hub for designers and developers, added platinum, 18k gold, 14k rose gold, and 14k white gold to its range of metals that can be used for 3D printing. Today, this company offers the widest selection of materials for 3D printing of jewelry.

Today, this company offers the widest selection of materials for 3D printing of jewelry.

US President Barack Obama, in his 2013 State of the Union address, said that 3D printing has great potential to revolutionize the manufacturing method by which almost everything is made.

What does all this mean for the traditional jewelry industry?

From the point of view of the end user, this means simplicity, convenience and high speed of receiving your order. For example, you have lost one of your earrings and want to order a replacement for the lost one. With 3D printing, you can simply purchase a file with a three-dimensional model of your earrings (CAD file) and print the missing pair at home on your own 3D printer or contact one of the printing centers. True, if there are stones in the earrings, you will need the help of a jeweler who will install them in the product.

From a jewelry retailer's point of view, there are also many advantages. Firstly, you do not need to spend money on inventory and its maintenance. It will exist in virtual form, as a catalog of designs and accompanying samples. It will be enough for the seller to stock up on raw materials, materials and computer files to make an order.

It will exist in virtual form, as a catalog of designs and accompanying samples. It will be enough for the seller to stock up on raw materials, materials and computer files to make an order.

High print-on-demand speeds mean that the need for stockpiles of finished goods is reduced, so manufacturers can cut costs for warehouse space, storage, and warehousing personnel.

3D printing will allow manufacturers to significantly reduce the cost of production, in particular by reducing labor costs. In other words, instead of jewelry masters, the main work will be done by ... industrial printers. In small-scale and piece production, this can reduce the cost by 2-3 times.

“With our platform, the cost and labor savings are phenomenal. There is no longer a jeweler with a blowtorch on our bench. We empower consumers to create jewelry in real time,” Forbes quoted Eddie Bakhash, CEO of New York-based jewelry company American Pearl, as saying.

American Pearl is one of the pioneers of 3D printing in the jewelry world. The company offers the service of recreating a piece of jewelry from its photograph. First, a 3D computer model of the product is prepared. Then a three-dimensional printer based on it forms an exact copy. The polisher and stone setter complete the process by presenting a sparkling duplicate of the piece to the client. Ideal for restoring lost family values, for example. American Pearl has a patented computer-aided design (CAD) system and a Solidscape T-76 3D printer.

The company offers the service of recreating a piece of jewelry from its photograph. First, a 3D computer model of the product is prepared. Then a three-dimensional printer based on it forms an exact copy. The polisher and stone setter complete the process by presenting a sparkling duplicate of the piece to the client. Ideal for restoring lost family values, for example. American Pearl has a patented computer-aided design (CAD) system and a Solidscape T-76 3D printer.

3D printing has the potential to bring production back to countries that today mostly import goods. The main problem of competitiveness, in particular, of American jewelry manufacturers is the high cost of labor in the United States. They cannot compete with cheap foreign production (read: China, Thailand and India) in the cost of production.

3D printing solves this issue simply - the printer does not need to pay a salary, only the purchase price and materials.

In addition, there will be localization of production, it will be concentrated closer to the consumer.