Cheap filament for 3d printer

7 Best Cheap PLA Filament Reviews

PLA filaments are a popular printing material for 3D printers. PLA stands for Polylactic Acid and is also known as thermoplastic polyester. PLA has become a top choice for making 3D printed parts and accessories for various reasons.

To begin with, it lies at a lower price point as compared to other 3D printing materials. Moreover, it prints at a relatively low temperature with little to no fumes.

The best cheap PLA filament would be Hatchbox PLA but there are many other good options as well!

If you are in a hurry and don’t have the time to skim through the entire article, have a glimpse of seven of the best cheap PLA filaments for 3D printing

- HATCHBOX PLA 3D Printer Filament <<Best Overall Cheap PLA Filament

- 3D Solutech Real White 3D Printer PLA Filament

- MIKA3D PLA Filament Pack of 24 Different Colors

- 3D Solutech See Through PLA Filament

- PRILINE PLA 3D Printer Filament <<Toughest PLA Filament

- 3D BEST-Q PLA 3D Printer Filament

- Reprapper PLA Filament for 3D Printer

My 7 Reviews of the Best Cheap PLA Filament Options

PLA filaments are primarily derived from renewable sources, making them an eco-friendly material. They are made of corn starch, sugarcane, or other plant-based items instead of a synthetic substrate. PLA filaments are also easy to use, making it a suitable option for people who have just started using a 3D printer.

Despite being low-priced than other 3D printing materials, top-quality PLA filaments don’t feature absolutely cheap price tags. For students and non-professional hobbyists, they can prove to be quite expensive.

We have researched, shortlisted, and reviewed seven of the best cheap PLA filaments available in the market right now. The filaments we have reviewed here lie in the price range of $15-25 and each one has several unique features to set them apart. Please see our Things To Consider section for key points that could impact your final choice.

1. HATCHBOX PLA 3D Printer Filament– A Sealed PLA Filament <<My Top Pick

If you want a large supply of cheap yet good quality PLA filament in a single color, consider buying this 2.20lb spool by HATCHBOX. We like this reasonably-priced PLA filament for various reasons; it is one of those few PLA filaments that are vacuumed sealed.

We like this reasonably-priced PLA filament for various reasons; it is one of those few PLA filaments that are vacuumed sealed.

The manufacturer has used desiccant as the sealant to ensure not even a little amount of moisture can penetrate the filament. We also like this filament because it undergoes minimal warping and produces no strange smell while being crafted into prototypes and art.

- Comes with the dimensional accuracy of +/- 0.03mm

- Available in seven different colors

- Very highly rated by users

- Comes with a 30-day money-back guarantee

Our rating: 99%

>>Check Price<<

2. MIKA3D PLA Filament Pack of 24 Different Colors– Best Color PLA Filaments

If you want to get PLA filament in the maximum number of colors but without spending money on the price of a single roll, consider using this MIKA3D product. It is a spool containing 240 feet long PFA filament with a 1.75mm diameter of high tolerance and accuracy.

This 240 feet long filament features 24 colors in different forms. It has metallic colors, transparent colors, and a whole lot of regular solid colors. What we like about this cheap PLA filament besides its variety of colors is its wider compatibility. You can use it with a range of 3D printers as well as 3D pens.

- Includes two silicone finger caps for 3D pens

- Works without producing smoke and free of toxins

- Comes with a 100% satisfaction guarantee

Our rating: 98%

>> Check Price<<

3. 3D Solutech Real White 3D Printer PLA Filament– Best Overall PLA Filament

If you are looking for a reasonable price, greater qualities, and more working flexibility in a single PLA filament option, consider buying this 3D Solutech product. It is a plain white PLA filament of standard 1.75mm diameter. This reasonably-priced PLA filament has been tested for a range of 3D printer brands, including UP, MakerBot, and PrintBot.

3D Solutech is a genuine PLA filament because it can work with printers that don’t feature heating beds. We also like this filament because it doesn’t produce bubbles and residue like regular cheap PLA options.

- Works at printing temperature of 190-220 Centigrade

- Doesn’t produce any odor

- Comes with a 90-day hassle-free return offer

Our rating: 97%

>>Check Price<<

4. 3D Solutech See Through PLA Filament– Best See-Through Filament

This is the second 3D Solutech PLA filament on our list. Like the first one, this filament also comes at a reasonable price and boasts all the properties that you look in any top-of-the-line PLA filament. It is a see-through PLA filament that comes in four different colors. You can use it to make 3D objects with a lighter, more delicate shade of the same color.

You can also use this see-through PLA filament to make objects that are supposed to feature lights for a glow. The other impressive bit about this PLA filament is its dimensional tolerance. Ideally, it can give you +/- 0.02mm accuracy. And even if you encounter any issue, the filament can still maintain it below +/- 0.05mm.

The other impressive bit about this PLA filament is its dimensional tolerance. Ideally, it can give you +/- 0.02mm accuracy. And even if you encounter any issue, the filament can still maintain it below +/- 0.05mm.

- Compatible with a range of printer models

- Doesn’t warp even without heating bed

- Comes with a satisfaction guarantee

Our rating: 96%

>>Check Price<<

5. PRILINE PLA 3D Printer Filament– The Toughest PLA Filament

This PLA filament by PRILINE is an ideal choice for home printers, schools, hobbyists, as well as professionals. The manufacturer claims that it is the most strong and tough PLA filament among all similar filament options available in the market. The reason behind this claim is this filament’s low shrinkage rate and minimal flex.

You can use it to produce 3D models with high resolution and dimensional tolerance of +/- 0.03mm. The filament comes in nine different vibrant and opaque colors, so you don’t have to finish the printed object afterward.

- Works with all 3D printers that accommodate 1.75mm filament

- Completely made of biodegradable material

- Comes with a 30-day refund guarantee

Our rating: 94%

>>Check Price<<

6. 3D BEST-Q PLA 3D Printer Filament

It is another 2.2lb spool of PLA filament that lies at a lower price point but offers the durability and result of any high-end option. This PLA filament by 3D Best-Q is made of polylactic acid completely derived from biodegradable sources.

The filament exhibits high tenacity and hardness, making it a suitable option for printing both parts and entire prototypes. The most striking bit about this PLA filament is its fast-drying property. This attribute allows you to use it at higher printing speeds and with 3D printers that print quickly.

- Available in five metallic and solid colors

- Offers dimensional accuracy of +/- 0.03mm

- Doesn’t warp even at a low-temperature extrusion

Our rating: 93%

>>Check Price<<

7.

Reprapper PLA Filament for 3D Printer– Most Flexible PLA Filament

Reprapper PLA Filament for 3D Printer– Most Flexible PLA FilamentWe are rounding off our list with a cheap filament that doesn’t warp, doesn’t produce any odor, and is compatible with nearly all 3D printer brands. The Reprapper PLA filament is a spool of 2.2lb 100% polylactic acid produced by Natureworks.

The unique bit about this PLA is that it is not brittle like other PLA items on our list. You can bend it 360 degrees, and it will still regain its original shape. This elasticity helps you in making relatively flexible 3D objects as well. Even with such flexibility, it doesn’t require heating bed printing. You can use it to print at low temperatures without worrying about warping.

- Available in six different color shades

- 100% tangle-free filament

- Works with all 3D printers

Our Rating: 93%

>>Check Price<<

Things to Consider Before Buying a Cheap PLA Filament

Take these factors into account while buying a reasonably-priced PLA filament.

Dimensional Tolerance/Accuracy

Dimensional tolerance or accuracy represents the deformation that a material can undergo while being crafted into an object. If you have noticed, all our reviewed PLA filaments have the dimensional accuracy of +/- 0.03mm. It is a standard for all PLA filaments, including expensive ones. Avoid buying any cheap PLA filament where the label doesn’t mention its dimensional tolerance.

Compatibility

A good-quality PLA filament works with all 3D printers without facing warping and adhesion issues, regardless of its price. You can easily find cheap options, including the seven we have reviewed that are compatible with most of the 3D printer brands.

Color Options

If you want to make 3D objects with uniform designs and overall consistency, make sure you use the filaments from the same manufacturer. Therefore, first, confirm if a manufacturer offers its product in different colors.

FAQs

Why one needs to use PLA filament as 3D printing material?

PLA filament is perfect for 3D printing because they are easy to use, less prone to warping, and doesn’t require a heated build platform, which doesn’t come with all printers.

What items can be printed from PLA filaments?

You can print toys, household items, and other prototypes that don’t require too much flexibility.

Are PLA filaments better than ABS filaments?

PLA filaments are better than ABS filaments for their lower price points and less warping. However, if you want more flexibility in your 3D printed objects, ABS filaments will be a better

Videos

PLA features

Tips for success

Conclusion

We hope that the above reviews and discussion help you in picking the best cheap PLA filament for your 3D printing. If we are to make any suggestion, we recommend you should buy HATCHBOX PLA filaments. They are available in various colors, don’t warp, and make for durable 3D projects.

Best 3D printing filament on a budget

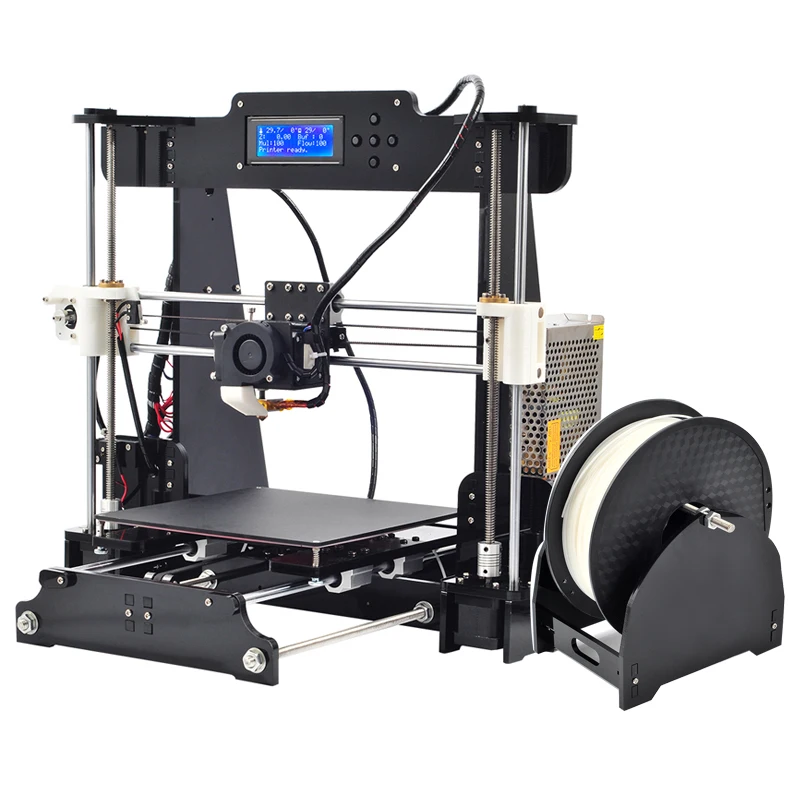

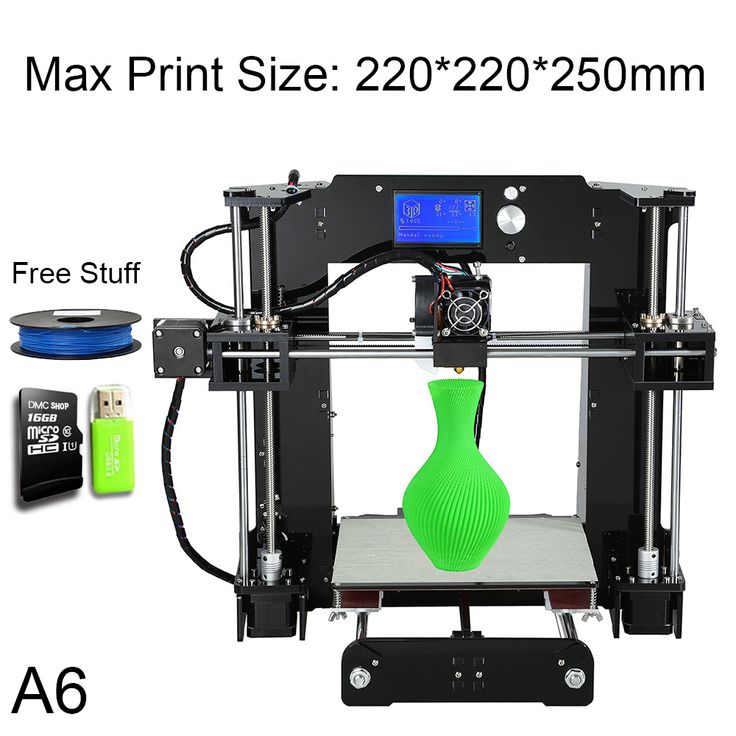

Filament and printer (Image credit: Windows Central)This list is to give you an overview of each material and the best product you can pick up on a budget in each category. For my money Inland PLA is the very best you can buy for the cheapest price possible. It won't let you down.

For my money Inland PLA is the very best you can buy for the cheapest price possible. It won't let you down.

Note: This list is made of 1.75mm diameter filaments, as it is the most common width used by home 3D printers. Most of the products here can be found in 3mm diameter as well.

- Polylactic Acid (PLA)

- Acrylonitrile Butadiene Styrene (ABS)

- Thermoplastic Polyurethane (TPU)

- Polyethylene Terephthalate Glycol (PetG)

Polylactic Acid (PLA) Filament

PLA is the most commonly used filament for beginners and general use. Made from organic polymers, PLA is a biodegradable, rigid material that has a low melting point. It's used often as a base for models that you want to paint and for objects kept indoors. The downside of PLA is it can become soft in relatively low heat, around 60 Celcius, or 140 Fahrenheit for the U.S. makers, and doesn't do well out in the elements.

Inland PLA

My Choice

Inland PLA is my go-to when I want cheap, reliable PLA for large projects. When you dial it in, it has an almost matte finish that looks beautiful on unfinished models.

When you dial it in, it has an almost matte finish that looks beautiful on unfinished models.

MatterHackers build series PLA

Designed for building

MatterHackers' build series is custom made for printing objects you are going to sand or paint. Use it for making cosplay items or painted models.

AmazonBasics PLA

Amazon Branding

While not the cheapest of the filaments, AmazonBasics' PLA is surprisingly good quality with the added advantage of a bulk buy option. Buy it in rolls of five, if you can, to reduce the cost per kilo.

Esun Silk PLA

Pushing the envelope

The latest release from eSun, the Silk PLA is one of the prettiest filaments I have ever used. It prints like butter.

It prints like butter.

Hatchbox PLA

A fan favorite

In my many Facebook groups about 3D printing, Hatchbox is mentioned often as a favorite for people all over. For me, it's hit or miss, but so many people swear by it, so it had to make the list.

Polymaker Polylite

The real deal

When Lulzbot sent me its Mini 2 to review they sent along a roll of Polymaker Polylite to use with it because it claims it's one of the best filaments to use with its printer. I tested it, and the claim is true: it's pretty great.

Prusament

The newcomer

Prusa, the creators of one of the best 3D printers available, have made something pretty special here. Prusament has an amazing accuracy that allows for super smooth prints.

Acrylonitrile Butadiene Styrene (ABS)

ABS is used in many products around the world and is lauded for its high temperature and environmental resistance. It's also extremely tough once printed and can be wet sanded to a super fine finish if you want to take the time. The biggest drawback of ABS is its noxious fumes. If you're thinking of printing with ABS, make sure you are in a well-ventilated place and use an enclosure if you can.

AmazonBasics

My choice

The same applies to the ABS as the PLA. AmazonBasics is a solid filament choice. Buy it in packs, so you can reduce the price to $16 a roll.

MatterHackers Glow

Glow in the dark!

MatterHackers has an amazing glow in the dark ABS. You'll need to make sure you use a hardened nozzle though.

eSUN ABS

A little extra

eSUN ABS+ has some extra properties that make it easier to print with. It warps less and adheres better, but you'll need a really hot bed, over 100 degrees Celsius, to get it to work.

Monoprice ABS

Sure and steady

Monoprice filament comes standard with any Monoprice printer and is more reliable than most. It's a solid, dependable choice for a filament. They are super cheap too.

Thermoplastic Polyurethane (TPU)

TPU is the softest of the four filament types and can be used to create rubberized models such as phone cases or tires. It also works very well to create flexible hinges or protective covers when dual printed with another filament type. TPU tends to be more expensive than other materials so not everything is under budget, but these are still your bargain choices.

Tianse TPU

My choice

I often use Tianse filaments on a variety of projects, but I use a lot for TPU. It's affordable and reliable, and that's all you can ask for.

Ninjatek Ninjaflex

The one that started it all

Nijaflex is easily the best of the bunch. It's a little pricey but works well with every printer I've used it on.

Sunlu TPU

It rhymes!

I have only used this once but it was recommended by several people on the Facebook groups. It also has an excellent dimensional accuracy of 0.02mm.

Tronxy TPU

Made by a printer

Tronxy TPU is made by an actual 3D printer manufacturer and so feels well engineered compared to some others. Don't worry: you can use it with any printer.

Don't worry: you can use it with any printer.

Polyethylene Terephthalate Glycol (PETG)

PETG is the happy mix between PLA and ABS. It has the strength and temperature resistance of ABS while being safe to print indoors. It can be a little difficult to get right, but once you do you'll never look back. You may need to use a Micro Swiss Hotend as PETG needs a very high temperature to print.

MatterHackers Build

My choice

This build series PETG from MatterHackers is the prettiest darn filament you'll ever see. The translucent colors are just beautiful when printed correctly.

AmazonBasics

Basics

AmazonBasics is cheap in bulk and great for the price. It's also a great way to fill out your supply of colors early on.

eSUN PeTG

Here comes the sun

Another beautiful, semi-transparent material, the eSUN PeTG is reliable and strong when printed.

Polymaker Polylite PeTG

Polyamorous

The Polymaker Polylite is always best in class and the PeTG is no exception. Expect stunning results from this filament.

3D Solutech

Budget again

Another clear but colorful choice, the 3D Solutech PeTG is a super cheap option to start you off. You should buy a lot of them to start your collection.

Hatchbox PeTG

Hatch a 3D print

Hatchbox's PeTG is far more consistent than it's other materials and the colors are always vibrant.

There are a lot of choices

Source: Windows Central (Image credit: Source: Windows Central)If you picked any of these products across the different material types you would have a great shot at making excellent prints. Some will work better than others on different printers so it's always a good idea to try different filaments until you find the right for you.

Some will work better than others on different printers so it's always a good idea to try different filaments until you find the right for you.

I've titled the ones I use regularly as My choice because they give me the best results but remember everybody's printers are unique so your mileage may vary.

For my money, the Build series from Matterhackers is an excellent choice across the gamut of different filament types. From ABS to PETG, the build series just works.

You should also be looking at eSun Silk PLA if you don't plan on painting your models. The glossy finish is just beautiful on unpainted prints. The Moon City by kijai design above is a perfect example of how good the Silk PLA looks.

James built his first PC when he was 13 and has never looked back. He can be found on Windows Central, usually in the corner where all the 3D printers are, or huddled around the Xbox playing the latest games.

How to calculate the cost of printing on a 3D printer

For some ideas, 3D printing is the fastest and easiest solution. In some situations, purchasing your own 3D printer can be a good solution, but sometimes it is much more profitable and faster to order the necessary product from a company specializing in 3D printing. Yes, and many owners of a 3D printer are thinking about how to “monetize” their hobby, but how to correctly calculate their costs?

In some situations, purchasing your own 3D printer can be a good solution, but sometimes it is much more profitable and faster to order the necessary product from a company specializing in 3D printing. Yes, and many owners of a 3D printer are thinking about how to “monetize” their hobby, but how to correctly calculate their costs?

Despite the fact that it is customary to indicate the price per gram of working material, simply multiplying the weight of the model by the cost of 1 gram will be wrong. In addition to the cost of consumables, many more, at first glance, non-obvious costs are added to the price of the product.

Each 3D printing technology uses its own consumables. Let's analyze the most popular and affordable of them.

Available technologies and key differences

Currently, a huge number of 3D devices have appeared, from small desktop ones that fit on the desktop to huge industrial machines. Among the most affordable, 2 technologies can be distinguished - FDM and photopolymer printers (LCD / DLP / SLA).

FDM 3D printing

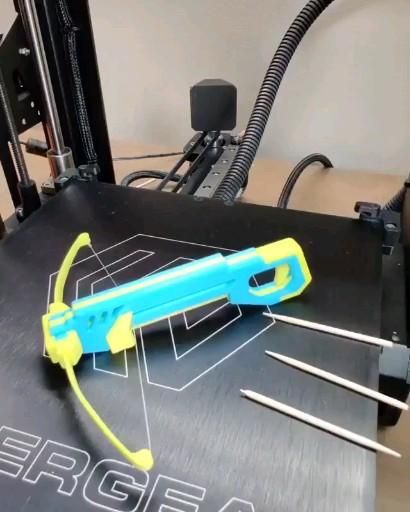

Today, the most affordable 3D printing technology is FDM. A variety of materials and 3D printers allow FDM to be applied to a wide range of applications.

Schematic operation of FDM printer

A large selection makes it easy to choose a 3D printer for a specific task or find a universal device.

The material for printing is a plastic thread - filament. On the market you can find filament for various tasks, for every “taste” and budget. These can be very inexpensive ABS and PLA plastics or specific ones - conductive, burnable, etc.

Pros:

Cons:

Despite the fact that FDM allows you to print a wide range of plastics with different properties, the technology has some limitations. For example, it is impossible to obtain a perfectly smooth surface, to produce miniature and very thin elements, or to produce parts with very complex internal geometry with high accuracy.

Photopolymer printing

Photopolymer printers can work on one of 3 technologies - SLA, DLP or LCD. These devices will come to the rescue if you need to make a small but very detailed model with many small details.

How photopolymer printers work

As a consumable material, a photopolymer resin hardened by UV radiation is used. Now there is a wide variety of photopolymer resins for every taste. From particularly strong and precise engineering or jewelry resins to soft flexes.

Pros:

-

High print precision

-

Good surface quality

-

A wide variety of printers and consumables

Minuses:

Photopolymer printers have shown themselves well in a variety of industries that require a perfectly smooth surface and high accuracy. They are used in dentistry, the jewelry industry, for making miniature master models for casting, and much more.

Industrial printers

These are already industrial machines, which require a separate room and sometimes certain requirements for ventilation, etc. In this article, we will not analyze these devices in detail, but briefly consider the most popular technologies.

FDM

In addition to desktop devices using FDM technology, industrial printers that work on the same principle are common.

This category includes devices with a large print area (from 30x30x30 cm and more). For example, Raise Pro2 with a print area of 30x30x30 cm.

Raise Pro2

Or machines designed for printing with refractory materials (eg PEEK). Such 3D printers usually have an active thermal chamber, and the extruder can be heated above 400 degrees.

CreatBot F160-PEEK designed to work with refractory plastics

Photopolymer printers

Industrial photopolymer devices usually have a much larger working area, compared to their "home" brothers. In addition, many processes have been optimized and automated for faster operation. On such printers, you can quickly and accurately produce a small batch of models, a large prototype or a master model.

In addition, many processes have been optimized and automated for faster operation. On such printers, you can quickly and accurately produce a small batch of models, a large prototype or a master model.

Prismlab Large Area Industrial Resin Printer Family

3DP

3DP - Three-Dimensional Printing (translated as three-dimensional printing) is a logical continuation of conventional two-dimensional printers. Printing is done using nozzles that selectively apply a binder to the material (usually gypsum). A dye can be added to the binder and the model will be colored.

Colored plaster model

Since the plaster model is fragile, a similar principle is used for printing with metals. Only the finished product needs to be treated in an oven to remove the binder and improve strength. But despite the processing, such metal prints will still be inferior in strength to cast products.

MJM

This is a proprietary technology of 3D Systems. MJM is a mix of FDM, 3DP and sometimes SLA (depending on material chosen). Printing is done using a variety of small nozzles (from 96 to 488) located on the head of the machine. The accuracy and quality of the surface of models made in this way is in no way inferior to photopolymer printers.

Models made with MJM technology

Such devices can work with photopolymer resins, wax or thermoplastics. You can combine several materials at once - for example, for complex models, you can use wax as a support.

SLM

SLM is the layer-by-layer sintering of metal powder using a powerful laser. There are several similar technologies - SHS/SLS. The principle of operation is the same, only a thermal print head is used instead of a laser beam.

SLM Turbine

As a material for printing, you can use powders of various metals - gold, stainless steel, aluminum, various alloys, etc.

During printing, the working chamber is filled with an inert gas to prevent oxidation of metals. This allows printing even with titanium powder.

Models made by this method are in no way inferior, and sometimes even superior, to cast products. SLM allows you to produce models with complex internal geometry that cannot be produced by another method (casting or milling).

Cost of 3D printing

The cost of a model usually consists of several factors.

-

Equipment depreciation. The printer, like any machine, requires maintenance and periodic replacement of some parts. During operation, belts gradually stretch, bushings or linear bearings wear out. For example, when bushings or linear bearings are worn; shafts may wear out and need to be replaced.

Cost of materials

The main cost item for a 3D printer is, of course, the printed material.;

FDM (plastic filament)

Since FDM technology is by far the most common, the choice of filaments is very diverse.

-

Engineering plastics are usually nylon with various fillers added to improve the physical characteristics of the finished model. Special cost. plastics starts from 2000r per coil and above. It all depends on the manufacturer and filler (carbon fiber, fiberglass, etc.).

-

Decorative plastics are used to imitate various materials. Plastic can simply be unusually colored (luminous, transparent plastics) or a special filler is added to it (plastics with metal powder). The cost of decorative plastics starts from 1500 rubles per coil and more, depending on the filler.

A big advantage of FDM is the diverse choice of materials to work with. This allows, having one printer, to produce almost any product - from a child's toy to a complex engineering prototype.

Photopolymers (resin)

Photopolymer resin printing technology is becoming more and more accessible. There are many different resins.

-

The cost of ordinary colored resin starts from 2500 rubles per 0.5 kg (volume +/- 0.5 l). You can find a smaller volume of resin (250 gr) on sale. You can buy several different resins in small containers and find out in practice which one is best for a particular model.

-

Engineering resins are resins with increased strength. They can be used not only for printing decorative items, but also for making functional prototypes and models. The cost for 0.5 kg starts from 5900r and above.

-

Special resins - burnable, dental, soft flexes, etc. Depending on the resin, the price for 0.5 kg can start from 4800 rubles and more. It all depends on the characteristics of the resin.

Photopolymer resins have not yet reached such a variety as FDM filaments, but they are surely catching up. Although due to the fact that a liter of resin costs significantly more than a spool of filament, the cost of the product is much higher.

Print examples

FDM

Mag Pull (quick release loop) for G3 magazines.

The model was downloaded for free from an open source (the file can be downloaded here). Printing with engineering carbon-filled plastic (price per spool from 4700 rubles). The weight of the model with support is about 25 grams. Post-processing was not needed. The cost of the finished model is 250 rubles.

Plastic fastener

The file was downloaded from an open source (can be downloaded here). Plastic - carbon-filled nylon (price per coil from 4700r). The weight of the finished product is about 20 grams. Print without post-processing. The total cost is 200 rubles.

Model watch

The model is modeled to order (the cost of modeling is from 1000 rubles). The product is printed on an industrial printer using soluble support. Print without post-processing. The cost of the finished product - from 700 rubles per piece (depends on the number of required products).

Print without post-processing. The cost of the finished product - from 700 rubles per piece (depends on the number of required products).

Traction prosthesis

The model is taken from an open source (you can download the modified version of the prosthesis here). The weight of the used material is about 600 gr, printed with ABS plastic (the cost of the coil is from 800 r). After printing, post-processing and assembly took place. The total cost of the product - from 3000 r (depends on the print material, support material, filling, etc.).

Pedal layout

Production of a 3D model according to the drawing (from 1000 r). The weight of the finished model is about 200 gr. The product was printed with engineering carbon-filled plastic (the cost of the coil is from 4700 r). Post-processing was not needed. The cost of the finished product is about 3000 rubles.

Photopolymer printers

Model jaws for crowns

Files for printing were obtained using a 3D scanner and finalized in a 3D editor (the cost of scanning is from 3000 r, the cost of manual revision is from 1000 r). Printing on an industrial photopolymer printer. Post-processing is not needed. The cost of the finished product is from 80 r per gram.

Printing on an industrial photopolymer printer. Post-processing is not needed. The cost of the finished product is from 80 r per gram.

Burnout resin rings

The model is made to order. Printing on a desktop SLA printer with a burnable polymer. Post-processing is not needed. The cost of the finished product is 200 rubles per product.

Miniatures

The models were bought on the myminifactory website (the cost of the model is from $2). Made with a desktop DLP printer. Post-processing was not required. The cost of the finished figurine is from 70 r per gram.

Custom 3D printing

Many owners of 3D printers are thinking about monetizing their hobby. But you should understand that the price of 3D printing “for yourself” and the price of commercial printing are very different.

When starting to print to order, it is better to have several printers working on different technologies.

Cost of commercial 3D printing

In addition to the cost of the model, to the commercial production of products, you can add:

-

Modeling. Often the client needs not only to make a part, but to pre-model it. It can be a simple cogwheel that doesn't take long to model, or it can be a complex sculpture that takes more time to model than it does to make.

-

Model post-processing. This can be simply the removal of supports, with cleaning of the place of their contact with the product, or a complete processing cycle (puttying, surface grinding, painting, etc.).

It should be borne in mind that it is not always possible to print the model the first time. Sometimes it may take several attempts. And these are additional costs.

What is unprofitable to print

Despite the wide possibilities of 3D printing, there are models that are unprofitable to make on a 3D printer. For such models, it is better to use other manufacturing methods.

For such models, it is better to use other manufacturing methods.

Commercial print examples

Jewelry for further casting

Manufacture of promotional items and souvenirs

Piece miniatures or master model for further casting

3D printed model

Profitable to print on a 3D printer:

-

If the item is only sold as an assembly. For example, a small gear broke in the mechanism, but the mechanism is sold only “assembly”. It is much cheaper to make the desired gear on a 3D printer than to buy the entire mechanism.

-

A small batch of parts. Small batches, especially models with complex geometry, are more profitable to produce on a 3D printer than by casting or other methods.

Totals

If you need several models or a small project, sometimes it will be more expedient to outsource manufacturing. After all, in addition to buying equipment and materials, you will have to understand the nuances of the settings and the characteristics of various materials.

After all, in addition to buying equipment and materials, you will have to understand the nuances of the settings and the characteristics of various materials.

Buying a 3D printer for commercial use is justified if you can fully load it with work or then it can be used for other purposes.

To print to order, you need to have several printers working on different technologies. It is better to get several devices with a smaller print area than to buy just one printer, albeit with a large working area.

Cheapest 3D pen

3D pen is a new plastic drawing device aimed at both children and adults. The principle of operation of a 3D pen is quite simple. The 3D pen mechanism feeds the plastic filament into the heating head (extruder) where it melts to a predetermined temperature and is extruded to the surface and hardens very quickly. Thanks to this, your child can draw like a regular pencil or felt-tip pen, but with a 3D pen, his imagination is not limited to paper and a sketchbook. With a 3D pen, you can draw on any surface (glass, wood, plastic or plain paper).

With a 3D pen, you can draw on any surface (glass, wood, plastic or plain paper).

Today there are many models on the Russian market, at various prices, for various family budgets. In most cases, the price of a 3D pen depends on the quality of the body materials, the number of different temperature settings, the speed, the ability to work from USB, and the number of different types of plastic for drawing. But the main thing remains the same, almost all models of 3D pens have a similar principle of operation and draw in the same way.

At the moment in our assortment, the cheapest 3D pen model is Myriwell RP100A .

The Myriwell RP100A 3D pen is considered to be the first generation 3D pen, although it differs from the second and third generation pens only in the absence of a display, manual temperature adjustment and can draw with only one type of plastic. But it is just as pleasant and easy to draw with her as with more expensive models.