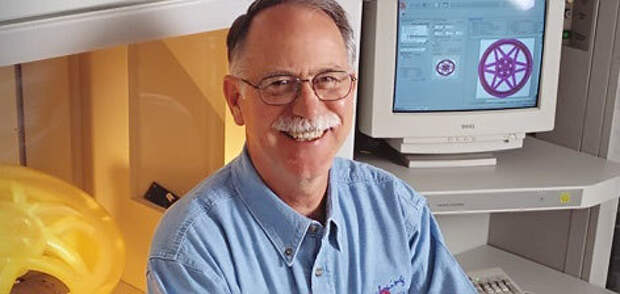

Chuck hull 3d printer

Pioneers of Printing: Chuck Hull and the Beginning of 3D Printing

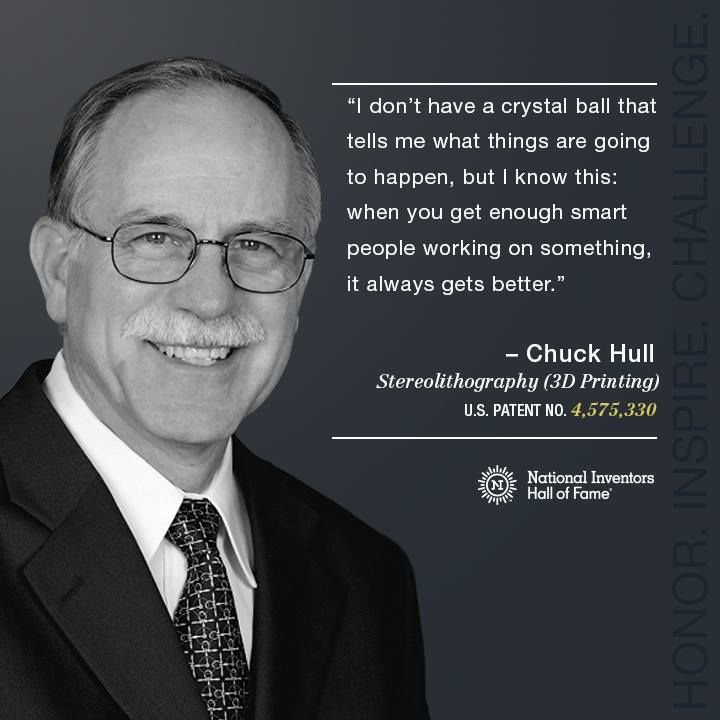

In this edition of Pioneers of Printing we focus on the ground-breaking achievements of Charles “Chuck” Hull. His success story of the “father of 3D printing” shaped the print industry forever. Nowadays, 3D printing is playing an important part in the future of our industry, manufacturing and medical printing.

In this edition of Pioneers of Printing we take a look at the life of Charles “Chuck” Hull, the father of 3D printing. In 1983, Chuck Hull invented stereolithography, also known as 3D printing. That very year he created the first 3D printed part ever. His innovation has changed print forever and opened new doors to revolutionize not only our industry but also other fields like car manufacturing, the aerospace sector and medical printing.

Humble Beginnings

Chuck Hull was born as Charles W. Hull on May 12, 1939, in Clifton, Colorado. After graduating from Central High School in Grad Junction, Colorado, he went on to study engineering physics at the University of Colorado. In 1961 he received his Bachelor of Science and started out his career.

The Basic ‘Aha’

Hull says, he started out to solve a problem. In 1983, when he first came up with the idea of printed 3D parts, he was working at a company using UV light to harden tabletop coatings. During his work, he had to prototype plastic parts that had to be injected into a mold, which he called a “really tedious process”. Seeing the time and effort it took to fulfil this job, he thought about a way to not only speed up but simplify the process of occupying his workdays. There had to be a more efficient way to approach the task:

“I saw it as a big impediment to design a plastic part because I had to design a plastic part now and then so I would get frustrated. I kind of put two and two together. If I could print lots of these layers, I can have a proper plastic part, so that was just the basic ‘aha’.”

Chuck Hull applied for his patent “Apparatus for production of three-dimensional objects by stereolithography” on August 8, 1984, coining the term stereolithography. The patent was granted on March 11, 1986, changing the print industry forever. It soon became a widely used technique in rapid prototyping and direct manufacturing. True to his occupancy at the time, Hull’s initial invention worked with thinly printed layers of ultraviolet curable materials stacked on top of each other.

The patent was granted on March 11, 1986, changing the print industry forever. It soon became a widely used technique in rapid prototyping and direct manufacturing. True to his occupancy at the time, Hull’s initial invention worked with thinly printed layers of ultraviolet curable materials stacked on top of each other.

After his patent was granted in the United States, he co-founded 3D Systems. At the beginning he was working with solid imaging technology only. Just one year later, in 1987, his company produced the first-ever 3D printer: the SLA-1 Stereolithography (SLA) printer.

His 3D printing technology was a sales hit among car manufacturers, the aerospace sector and companies designing medical equipment. Soon, industry giants like General Motors and Mercedes-Benz used his systems to build prototypes.

Today, Chuck Hull holds 93 US and 20 European patents to his name and was awarded the European Inventor Award in the Non-European countries category in 2014 by the European Patent Office and the Industrial Research Institute’s IRI Achievement Award in 2015 for his ground-breaking invention of stereolithography.

What the Future Holds

Around 2010, more than 20 years after Chuck Hull started out with his humble idea, 3D printers became a comparatively inexpensive product that even made its way into private households – a development the inventor predicted from the start, telling his wife it would take between 25 and 30 years before the technology would find its way into the home.

Talking to the father of 3D printing today, he is surprised about what exactly his own creation was capable of achievingand curious to see where the future will lead.

“If you’re innovative and creative there’s just a tremendous opportunity.”

In an interview with Industry Week Hull said:

“I always say, first disclaimer, I’m not much of a futurist. But certainly, the benefits are no tooling, customizable fasts, and so a lot of plastic parts will be automated and built with 3D-printing. It’s another step toward digital manufacturing, and it fits right into the whole movement. In the future, people won’t even think about it. It’ll be the recognized way to manufacture plastic parts. The same with metal parts, except right now the provision is that those tend to be more specialized parts. Maybe they’ll advance to the same level.

It’ll be the recognized way to manufacture plastic parts. The same with metal parts, except right now the provision is that those tend to be more specialized parts. Maybe they’ll advance to the same level.

The trend we’re on right now is more aerospace parts and medical parts.”

Do you have any predictions about the future of 3D printing?

3d3d print

You Can Now See the First Ever 3D Printer - Invented by Chuck Hull - In the National Inventors Hall of Fame - 3DPrint.com

Today, when you mention the name Charles (Chuck) Hull to the average individual, they probably have no clue who the heck you are talking about. However, if you were to mention this name to someone who is as enthused about additive manufacturing/3D printing as I am, they will probably know that he is the Thomas Edison of the entire 3D printing industry. Chuck Hull was the man who created the first 3D printer capable of printing an actual part. While today, his name certainly doesn’t come close to being anywhere as noteworthy as Thomas Edison, Ben Franklin, or Alexander Graham Bell, one day in the future it very well may.

While today, his name certainly doesn’t come close to being anywhere as noteworthy as Thomas Edison, Ben Franklin, or Alexander Graham Bell, one day in the future it very well may.

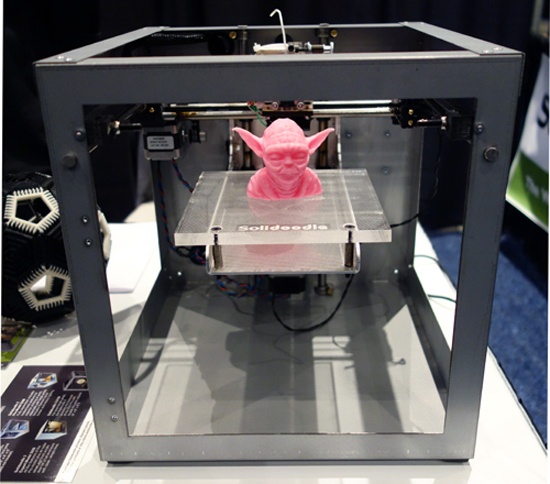

Hull’s first 3D printer proved successful over 30 years ago, on March 9, 1983. I was merely a one-year-old toddler back then, and “3D printing” was still decades away from even being considered a term. “Rapid Prototyping” was the description given to Hull’s unique new machine, the “SLA-1,” as it was created in order to speed up the lengthy time-frame it took to have prototypes of products created. It would take approximately 6-8 weeks using one-off tooling processes back in the early ’80s, so a machine that could print a part in just hours was a major breakthrough within the manufacturing industry.

Three years later, in 1986, Hull formed a company called 3D Systems to better market and sell his “Rapid Prototyping” machines which have since earned the name “3D printer” or “Additive Manufacturing” machine.

On May 21 of last year, Hull earned the honor of being inducted into the National Inventors Hall of Fame in Alexandria, VA, joining the ranks of many tremendous inventors before him, including Wilbur Wright, Henry Ford, Steve Jobs, and the aforementioned Thomas Edison. Hull was noted for inventing Stereolithography (SLA) 3D printing as well as co-creating the STL file format, the most common 3D printing file format that has been used to date.

Now it has just been announced that visitors of the National Inventors Hall of Fame will not only have an opportunity to see a 3D printed bust of Hull, printed on a 3D Systems ProJet x60 printer, but they will also be able to see the first-ever 3D printer that Hull invented, the SLA-1.

When Hull invented this machine, he never envisioned one day having a 3D printed bust of himself displayed in the Hall of Fame. In fact, he never thought 3D printing technology would end up becoming so popular. Today, 3D printing is available to just about anyone, with printers ranging in all different sizes and price points.

“The consumer and maker movement has created a lot of awareness about the possibilities that technology makes available to people, and that has made people look at 3D printing as something they can now do,” Hull explained. “3D printing is just another tool, but it’s a very powerful tool that can create anything.”

Without a doubt, Hull’s contributions to the manufacturing sector, as well as the Maker Movement, have been extremely valuable. Perhaps one day kids will be learning about him in history books, right besides the Thomas Edisons and Benjamin Franklins of the world. Have you had a chance to visit the National Inventors Hall of Fame? What was your opinion of the first ever working 3D printer? Discuss in the First 3D Printer Sent to the Hall of Fame forum thread on 3DPB.com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d systems • charles hull • chuck hull • first 3d printer • inventor of 3d printing • national inventors hall of fame • sla 1 3d printer • sla-1

Please enable JavaScript to view the comments powered by Disqus.

The night 3D printing was born: the story of inventor Chuck Hull

The night that 3D printing was born

3D printing

the story of inventor Chuck Hull

March 9, 1983, San Gabriel, California. In the evening, the telephone rang at Engineer Hull's house. Antoinette picked up the phone and heard her husband's excited voice. Mrs. Hull was not too surprised by the call - her husband was constantly late at work until late at night. But instead of the usual apologies, the engineer insistently asked his wife to drop everything and urgently come to the laboratory. Antoinette stood in her pajamas and was already getting ready for bed, but she could not refuse. She only replied, "It's in your best interest to make it worth my attention."

New Gutenberg

The night 3D printing was born.

Part 1

In the early 1980s, the US economy was in recession: unemployment was rising, incomes were falling, and a third of industrial enterprises were idle. The economic crisis shook faith in traditional technologies - enterprises needed modernization, unexpected and fresh solutions. It was obvious to everyone that the future belongs to computers and microelectronics - it remains to find people who would combine IT technologies and conveyor production. The world needed inventors again.

The economic crisis shook faith in traditional technologies - enterprises needed modernization, unexpected and fresh solutions. It was obvious to everyone that the future belongs to computers and microelectronics - it remains to find people who would combine IT technologies and conveyor production. The world needed inventors again.

In 1983, Charles "Chuck" Hull worked for Ultraviolet Products (UVP). Unlike the eccentric geniuses of that era, Steve Jobs and Bill Gates, distinguished by anything but patience, Chuck did not seek to conquer the world at all costs. His path to invention was reminiscent of the life of Johannes Gutenberg, a German jeweler and minter whose inquisitive mind led to the creation of the first printing press. Like Gutenberg, until the age of 40, Hull was a typical modern "craftsman" - an engineer with a good university education and a standard career. After traveling around the country, in the late 70s, Chuck and his family settled in San Gabriel, a small town in California, where he took the position of vice president of UVP development.

Ultraviolet Products focused on ultraviolet solutions: equipment, lamps, photosensitive polymers. Furniture factories bought UVP technologies - such materials replaced conventional varnishes and paints for wood. A special polymer was applied to a countertop or wood slab and then cured under ultraviolet light. It turned out a strong plastic frame, an analogue of wood veneer.

While testing another polymer, Chuck Hull wondered what would happen if successive exposure to ultraviolet light was applied to not one, but several layers of the polymer.

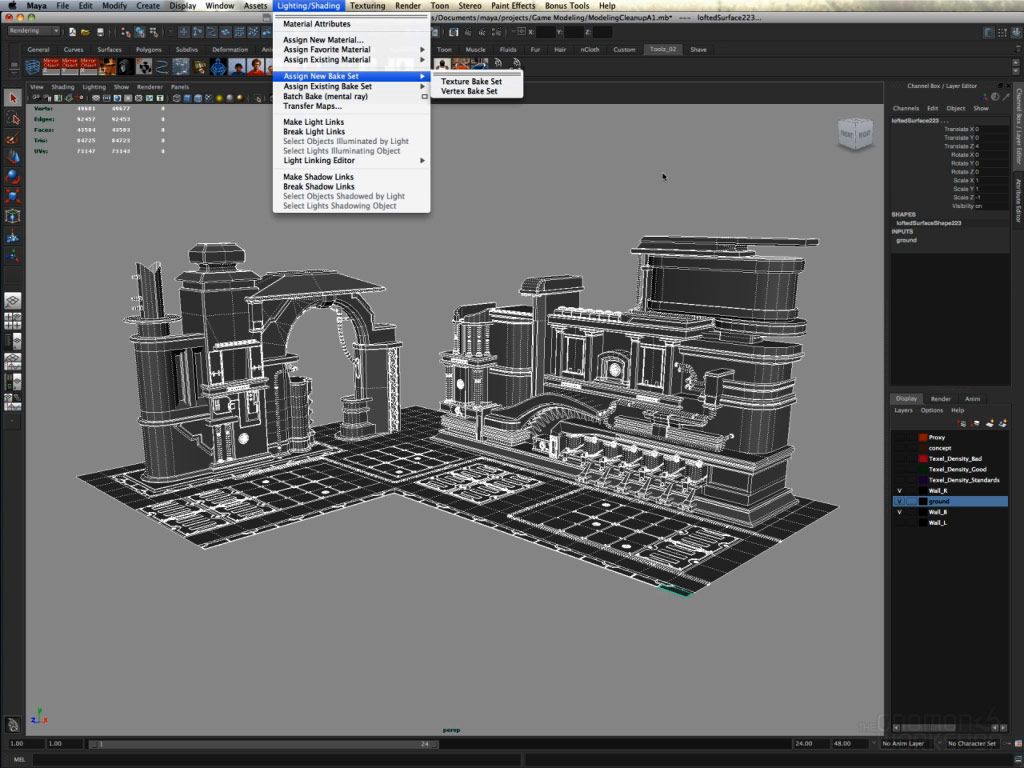

At UVP, Hull worked on the production of those UV curing furniture paints. While testing the next polymer, Chuck Hull thought: what would happen if not one, but several layers of plastic were successively exposed to ultraviolet radiation. If the layers are formed by curing them in turn with UV radiation, it is possible to arrange a plastic product of absolutely arbitrary shape. For this, it is necessary that the process be controlled by a computer - then the probability of marriage will be negligible. This is how the first idea to combine computer modeling and photochemistry appeared.

This is how the first idea to combine computer modeling and photochemistry appeared.

Post-apocalyptic

kluge

The night 3D printing was born.

Part 2

Chuck needed a lab to get started. With only service equipment on hand, the engineer turned to his boss for help. The UVP president didn't share his subordinate's enthusiasm: after all, his firm makes ultraviolet lamps, not Star Trek replicators. If Hull wants to invent, let him do it in his spare time. So they agreed: during the day, Hull performed direct duties, while he devoted his nights and weekends to independent research.

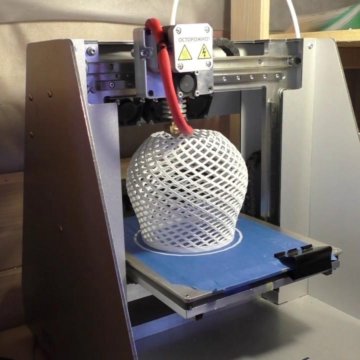

The first 3D printer turned out to be a kludge — that's what technicians call mindless-looking but workable junk.

The engineer was assigned a small room for research. It was there that 3D printing was born in experimental pains. Chuck set up equipment, tested polymers, and wrote programs. Hull later admitted that, as a discoverer, he made every mistake he could. But after months of work, Chuck was lucky - the inventor finally designed a working system in which an ultraviolet lamp illuminated a container of photopolymer.

But after months of work, Chuck was lucky - the inventor finally designed a working system in which an ultraviolet lamp illuminated a container of photopolymer.

Hull wrote the code that tells the printer how many layers to use on his own. Therefore, initially the device could only produce structures of a very simple form. And in appearance, the world's first 3D printer did not shine with grace. Chuck described it with the word “kluge,” the technical term for mindless-looking but workable junk: “The 3D printer looked post-apocalyptic, like a piece of equipment from the Water World movie.

March 9, 1983 is considered the birth date of 3D printing - on this day, Hull's "monster" produced something similar to the first 3D model. Then Chuck, as usual, stayed up late in the laboratory, experimenting with the settings of the apparatus. Recently, the polymer, although it hardened evenly, turned into spaghetti due to the low sintering of the layers. But not at this time. The settings were correct, the kluge did not fail, and after 45 minutes of buzzing, the device reproduced a small bowl.

Hull recalled in an interview: “I called it the eye cup because it looked like the eyedropper my wife wore all the time. It appeared to Antoinette as a communion cup. It must have been God directing my efforts.” But Chuck didn't exactly feel like a monk that night, more like a medieval alchemist who created a piece of gold from liquid slime.

The accomplished “father of 3D printing” called his wife and urgently asked her to come to the laboratory. In response, he heard Antoinette's angry voice: "It is in your interest that this be worth my attention." As his wife entered, Chuck showed off the first 3D printed object. It was an ordinary cup, unremarkable, except for the circular sections on the walls. Years later, Antoinette recounted the events of that night: “He held this cup in his hand and said, “I did it, now the world will never be the same.” We laughed and cried and stayed up all night just fantasizing about the future.”

First patent

The night 3D printing was born.

Part 3

Hull called his brainchild stereolithography: “I sat at night and tried to come up with a name for a new technology. I wanted the title to necessarily include the term "lithography", as a synonym for printing, and the Greek word "stereo", which means "volumetric", "spatial". Then I just put those two words together.”

U.S. Patent 4,575,330 titled "Apparatus for creating three-dimensional objects using stereolithography" was filed August 8, 1984 years old.

Convinced of the viability of the method, Chuck worked on the device in his small laboratory. A year later, he managed to bring the development to patenting: “As soon as I got a normally working machine, I immediately turned to a lawyer. He wrote a document for the patent office." U.S. Patent 4,575,330 entitled "Apparatus for creating three-dimensional objects using stereolithography" was filed August 8, 1984. In the application, Chuck described stereolithography as a technique for creating solid objects by successively printing thin layers of material and treating them with ultraviolet light. Hull was listed as the author of the development, the rights to the invention were transferred to UVP.

Hull was listed as the author of the development, the rights to the invention were transferred to UVP.

The largest manufacturer of 3D printers in the world could well have been called Ultraviolet Products, but it turned out differently. The company was affected by the economic crisis - sales fell sharply, and in order to preserve the core business, the management decided to sacrifice promising areas. During a meeting with the president, the inventor insisted on continuing research, but he could not allocate funds for the refinement of the apparatus and marketing. Then Hull suggested that the boss register a new company and become partners: overall management and promotion fell on the shoulders of Chuck, while the president was entitled to a share of the profits. Seeing the seriousness of the intentions of the already former subordinate, the boss agreed and ceded the license to the invention to Hull.

Founding of 3D Systems

The night 3D printing was born.

Part 4

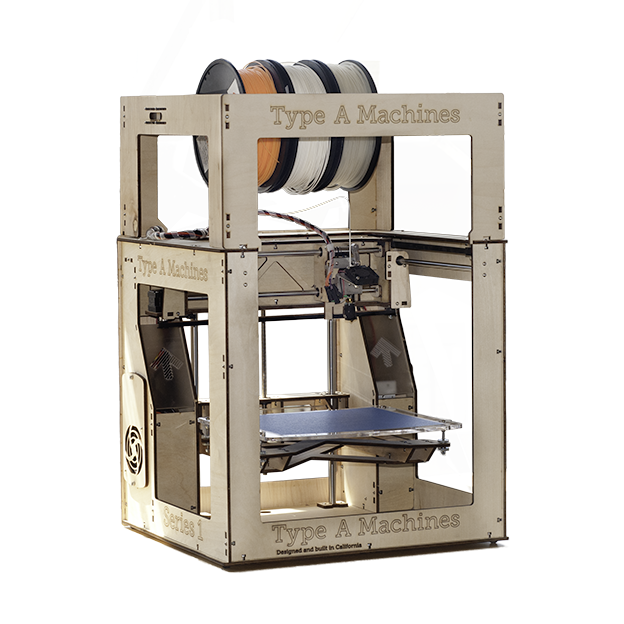

In 1986, the partners founded the first 3D printer company and named it 3D Systems. Since Chuck had never been in business, he had to put in a lot of time and effort to get his name out there: “I was calm about the technology, I never doubted that 3D printing would become popular. But I was never very confident in myself, so at first it was difficult. He attended scientific forums, consulted with colleagues from leading US universities, traveled to social events to make useful contacts. His activity paid off - a Canadian investor agreed to invest $6 million in 3D Systems.

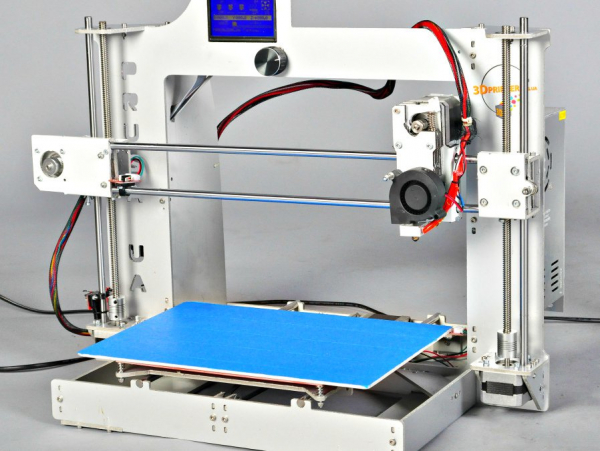

The first mass-produced 3D printer was released in 1987 and was named SLA-1.

Refinement of the original device to marketable form lasted another year, until 1987. The first mass-produced 3D printer was named SLA-1. The huge and heavy cabinet was not very suitable for presentations, so Hull recorded short videos to demonstrate the capabilities of the 3D printer: “These films were quite corny, but we got a huge response from our customers. ”

”

Hull had high hopes for automakers. In the 1980s, the US auto industry lagged far behind Japan's, and American companies were desperate for a secret weapon. They became a 3D printer. With the help of 3D printing, engineers could quickly prototype small parts such as door handles and gear levers. Hull's predictions were fully justified: General Motors and Mercedes-Benz soon introduced stereolithography for the manufacture and testing of prototypes.

American companies were desperate for a secret weapon. They became a 3D printer.

Hull later found out that 3D printing was applicable not only to liquids, but also to any gradually solidifying materials that could change their physical state. Over the course of several years, he patented dozens of new solutions and technologies, including STL, a new data format for digital models. This format represents the object as a set of triangular faces and supports layering.

Despite the success of 3D Systems, the invention of 3D printing did not initially cause the industrial revolution that computers did. The real boom in additive manufacturing (as well as the recognition of the merits of the inventor himself) occurred later, in the 21st century. But fame and fame never bothered Hull - he was always distinguished by patience. At one time, the developer told his wife that 3D printing technology will take 25-30 years to take its rightful place in the market, but after that it will play an important role in the industry. Both of Hull's predictions turned out to be correct.

Today, 3D Systems is one of the largest 3D printer manufacturers in the world with a market capitalization of $1.1 billion. 78-year-old Chuck Hull continues to work in his native company, combining the positions of executive vice president and chief engineer. He has over 100 patents in the US, Europe and Japan, including 7 3D printing technologies. In 2014, Hull was inducted into the US National Inventors Hall of Fame, placing his name alongside other notables such as Henry Ford, Nikola Tesla, and the Wright brothers.

2018 Project of the Information and Analytical Agency 3Dpulse.ru .

Marketing group " Tekart ".

We thank 3D Systems for providing access to photo and video materials.

How Chuck Hull Invented 3D Printing / Habr

3D printing was born in 1983, long before people began to massively use the World Wide Web. But the Internet has long become an ordinary part of life, and additive technologies still cannot be called widespread.

At the same time, Chuck Hull, the inventor of 3D printing, believes that we have already passed the period of hype and are only now beginning to understand the real field of application of the technology. This post is about how Chuck (Charles) Hull invented and patented laser stereolithography in a small utility room and how he now evaluates his invention.

Spoiler: just like industrial robots, the automotive industry has greatly helped the development of 3D printing.

Table tops and prototyping

It all started in the 80s. Then Chuck worked as a technologist in California Ultra Violet Products. The company produced UV curing resin for countertops. There was no question of high speed of work - it took months to develop and test even small details. Chuck's responsibilities, as responsible for organizing the production process, included prototyping. The inventor was looking for a method that would allow him to speed up the process.

One of his ideas was to apply several hundred layers of plastic and shape them using ultraviolet light. This would make for a relatively cheap and quick prototype. With this idea, he went to the leadership of the UVP. Chuck, of course, was not allowed to invent during working hours - but they were given a room and equipment.

After a year of overtime, the inventor created the first prototype of an electrolytic 3D printer. He worked with a photopolymer, a substance that can change from liquid to solid under the influence of ultraviolet rays. Hull learned how to write code to program a printer to create a prototype of a particular geometric shape. The first 3D printed object was a small plastic cup.

Hull learned how to write code to program a printer to create a prototype of a particular geometric shape. The first 3D printed object was a small plastic cup.

First SLA-1 3D printer

“Get dressed and come to the lab right now”

The night when the discovery was made was forever imprinted in the memory of Chuck's wife, Antoinette Hull. In an interview for The Telegraph, she even gives the exact time - 20:39 on Wednesday, March 9, 1983.

“I was at home that night and had to look at my watch when the phone rang,” she said. "I was already in my pajamas and getting ready for bed, but Chuck was still working."

"Get dressed and come to the lab right away," Chuck said on the phone. She got into her car and drove to the lab, a small room that Ultra Violet Products had given Hull for research.

In it, Antoinette saw the first 3D printed object in the world. “Holding this strange detail in his hand, he said that he had done it and the world would never be the same. That night, I knew he had achieved something great.”

That night, I knew he had achieved something great.”

Chuck Hull and his wife

Chuck's company didn't have the funds to finance development. He recalls: “I received a patent for a 3D printer in 86. And so I come to the head of the company and say: “We need to find a commercial application for this.” To which he replies, “Sure, but we can’t afford it.” I had no choice, so I decided to start my own company. This was the start of 3D Systems." The first clients of his company were General Motors and Mercedes-Benz.

The company is still operating. Chuck, now 79, does too. “My job is too interesting to quit,” he once said in an interview with CNN. In another, he gave more details: “In the late 90s, I really retired. A new manager took my place, and about three months later he called me and said, “Chuck, it's bad. Can you come back and help with some technical issues?” Since then, I've been there again, continuing to do interesting things. "

"

3D Systems is currently focusing on programmable injection molding systems that will allow objects to be printed without first having to design molds. In addition to his work at 3D Systems, Chuck gives lectures and speaks at conferences. For example, he became one of the main speakers at last year's ASME - International Mechanical Engineering Congress.

Chuck Hull remains a very humble person. In 2014, the European Patent Office presented him with a prize for the best inventor working outside of Europe. To this he replied only: “I am pleased to receive recognition of my merits. I've worked hard and hard, and that's what I'm going to do next."

He rarely interacts with the media. Below is one of his few interviews given to Industry Week. It is from 2013, but has not been fully translated into Russian. In it, Chuck Hull told how he himself did not believe in the commercial success of his invention for a long time and about whether it could ever compete with traditional production.

You invented stereolithography in 1983. After 30 years, the market for additive manufacturing began to grow rapidly. People think that this is some kind of new phenomenon. What do you think about this boom? Did it start too late?

When we first started doing 3D printing, I couldn't imagine for a long time that it would become so popular.

It seemed to me that this path would take 25 years, if not more. Such is the history of all inventions. It doesn't happen that you invent something like a 3D printer and a crowd of buyers immediately starts to beat on your door. It takes a long time to understand what you have invented and how it can be improved.

3D printing isn't easy. You see the finished device. You think that it is very easy to use it, but it is not. We at 3D Systems have been perfecting the first printer for 10 years. During this time, we managed to go from an idea to the implementation of a finished device in the industrial sector.

But the last few years have surprised me. It certainly came as a surprise that people recognized 3D printing as mainstream.

It certainly came as a surprise that people recognized 3D printing as mainstream.

When did you get the idea to create 3D printing? How did you come up with the stereolithography method?

I started out as a design engineer. The development of new plastic injection moldings that we were engaged in was a very laborious and costly process. In the beginning, you designed the look of the part, made drawings, discussed everything with the toolmaker who made the mold for the plastic part. Then this form was sent to the caster, who made the spare part. The whole process took 6-8 weeks.

It took a long time to make, and the first part that came out was never perfect. It had to be redone and the production cycle started again. Many months passed before you received a part that you can test.

Naturally, we tried to do something about it.

I decided to see if I could think of a way to get that first part faster, so that all iterations would go through quickly, and then quickly get the final version for production.

I went through a bunch of ideas that didn't work and then came up with what ended up being stereolithography. On March 9, 1983, I produced the first part with this method.

Then you applied for a patent in 1986 and co-founded 3D Systems. But who were your clients? Did any of the industries see the potential at such an early stage?

When we first launched the company, we immediately sent “scouts” to see if there was any interest from the industry. And he was. In fact, interest in prototyping has been huge, mostly from automakers.

Car companies at that time were trying to produce high quality cars. American concerns at that time were rather clumsy. They could not quickly release new models, and the quality of production lost in the global competition.

So they had a huge interest in any technology that could improve the situation. We immediately began to move in this direction, to develop technology for the automotive industry. Shortly thereafter, many manufacturers followed the same path.

Also in those years we developed methods for prototyping metal parts. Our technology was supposed to offer an alternative to traditional lost wax casting, and it was the first major offshoot of prototyping plastic parts.

We called the developed method Quick Cast. It allowed the rapid casting of metal parts from a variety of alloys and is still in use today. Mainly in the aerospace and related industries.

Now that manufacturers and consumers have realized the full value of 3D printing, what's next? Will it ever be able to compete with traditional production?

I'm not a futurist and I don't have a predictor's crystal ball - I don't know what's going to happen next. But I know that when enough smart people work on something, it always gets better.

The main advantages of additive technologies now are fine-tuning and the ability to work with complex structures. If your manufacturing process needs a lot of parts, or you need parts with many different parameters, 3D printing can come in handy.

Medical applications come naturally to 3D printing, because every body is different. When you try to do something for teeth, for example, that thing will be different for different patients. The same goes for the knees and other joints.

If you're looking into the future of 3D printing, it's probably parts with complex shapes and patterns, even at high production volumes. The speed and economic benefits of 3D printing are constantly increasing. This means that it has more and more chances to compete with traditional production.

Looking back over these 30 years, what would you say is your biggest achievement outside of the technology itself?

Back in the 1980s and 1990s, it was clear that production would gradually leave the country. This concerned not only the United States - everyone went to countries with cheap labor. I always thought it was bad. In my opinion, manufacturing should be a key capability, especially for the US. Today, the return to production in the country is associated with higher technological capabilities.