Softest 3d printing filament

Diabase Engineering Introduces X60, the Softest 3D Printing Material on the Market - 3DPrint.com

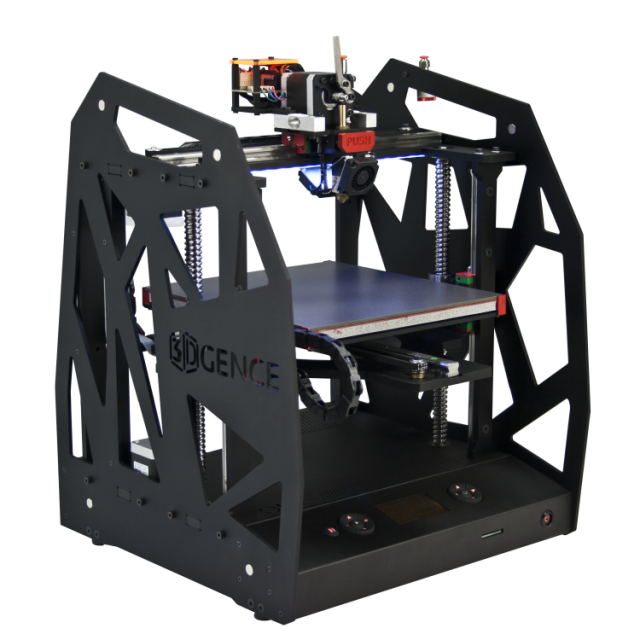

Diabase Engineering is best known for the Flexion Extruder, which has transformed many an average, low-cost 3D printer into a multi-material, industrial-grade machine. One of the key appeals of the Flexion, as its name suggests, is its ability to print with flexible filament, a task that not many lower-end 3D printers are up to. As Diabase Engineering was founded by the inventor of NinjaFlex filament, the company started off with a pretty solid reputation for flexible materials right off the bat, so when they announce that they’ve developed a brand new flexible filament, you can be pretty sure that it’s going to be of high quality.

The flexible, high-strength X60 filament is the result of a collaboration between Diabase Engineering and MakeShaper, also known for their expertise in flexible 3D printing materials. According to Flexion, X60 is the softest filament on the market, with a 60 Shore A hardness – but it’s also tough, with high tensile strength and abrasion resistance, and over 7x elongation at failure.

“We’ve been pushing our contacts in the filament industry for over a year to release some softer material options,” says Stephen Heston, co-founder of Diabase Engineering. “But they have been reluctant to do so because of the headaches of supporting customers who are unable to run these filaments in their off-the-shelf printers. We now have thousands of Flexion units in the field, and many of our customers have been demanding some better material options. So, we finally decided to create this product ourselves. We guarantee that it will work well with the Flexion Extruder…and that it won’t work with any other commercial extruder.”

It’s the first filament that Diabase has developed; until now, the company has been focused on designing an extruder to work with third-party filaments. The introduction of a Flexion-exclusive filament is an interesting choice, and one that shows that Diabase may be looking to further broaden their commercial scope.

“We see a new market developing in the printing of functional and customized athletic gear,” Heston continues.

“Shoes are the obvious example, but especially for outdoor sports products, there are many other areas where we think consumers will see the benefit in designing their own custom modifications to their gear. As design software becomes more accessible and the performance of printed materials continues to improve, this could be a huge growth sector for the industry. Look for some big announcements from us in the coming months related to this direction.”

Diabase Engineering further describes X60 as ideal for “over-molded” parts like handles and robotic grippers, thanks to its ability to bond strongly to other printing materials like ABS and nylon. It’s capable of printing in high detail with print speeds of about 44 mm/s. It’s currently being sold from Diabase’s website in spools of 220 grams for $29 or 650 grams for $79. X60 is available in black and white, but you can feel free to contact Diabase Engineering directly for other color and quantity options. Contact Diabase Engineering here, or follow them on Facebook for further information. Discuss in the X60 forum at 3DPB.com.

Discuss in the X60 forum at 3DPB.com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printer filament • Diabase Engineering • filament • flexible 3d printer filament • flexible filament • flexible materials • Flexion Extruder kit • makeshaper • ninjaflex • X60 filament

Please enable JavaScript to view the comments powered by Disqus.

Best Flexible (TPU/TPE) 3D Printing Filaments in 2022 – Clever Creations

3D printing with flexible filaments opens up a world of possibilities for your projects. From soft washers to shoe insoles to phone cases, you can make all sorts of strong elastic parts from flexible materials. However, with so many different types of flexible filaments available for 3D printing, it can be difficult to know which type, brand, and hardness to choose for your projects.

That’s where we come in! We’ll cover which brands have the best flexible filament, the recommended printing temperatures and other print settings for each brand, the differences between each flexible material, and what to look for when buying so you can always find the best TPU filament possible.

| Best Flexible Filament | Shore | Diameters | Colors | Price | Best Offer |

|---|---|---|---|---|---|

| SainSmart Flexible TPU | 95A | 1.75mm | 18 | $25 per 800g | Amazon |

| Ninjatek TPU | 85A | 1.75mm, 3mm | 11 | $85 per 1kg | Amazon |

| Overture TPU | 95A | 1.75mm | 17 | $24 per 1kg | Amazon |

| FormFutura FlexiFil | 45D | 1.75mm, 2.85mm | 5 | $43 per 500g | Amazon |

| Duramic TPU | 95A | 1.75mm | 5 | $27 per 1kg | Amazon |

| Fillamentum Flexfill TPU | 92A, 98A | 1.75mm, 2.85mm | 20 | $41 per 500g | 3DJake |

| Fillamentum TPE | 92A, 96A | 1.75mm | 5 | $41 per 500g | 3DJake |

| Recreus Filaflex TPU | 60A - 98A | 1. 75mm, 2.85mm 75mm, 2.85mm | 18 | $47 per 500g | 3DJake |

| Polymaker TPU | 95A | 1.75mm, 2.85mm | 6 | $30 per 750g | Polymaker |

| ColorFabb Ngen Flex | 95A | 1.75mm, 2.85mm | 3 | $40 per 650g | MatterHackers |

| MatterHackers Pro Series TPU | 95A | 1.75mm, 2.85mm | 7 | $44 per lb | MatterHackers |

The Best Flexible Filaments in 2022

SainSmart Flexible TPU

Best overall

Check Price

AmazonSainSmart

If you’re looking for a strong and versatile flexible 3D printer filament at a good price point, SainSmart TPU is an excellent choice. With a shore hardness of 95A, it produces durable and rigid 3D prints that are still flexible enough to retain their shape even when significantly bent and deformed.

SainSmart TPU is known for having excellent bed adhesion and virtually no warping when printed with the proper settings. They even provide printer profiles for a wide variety of popular 3D printer models that you can download and load into your slicer for their best-recommended settings for your machine.

They even provide printer profiles for a wide variety of popular 3D printer models that you can download and load into your slicer for their best-recommended settings for your machine.

You have a lot of versatility in terms of color since SainSmart currently offers 18 different shades for this product. It also has the lowest temp range of any of the flexible 3D printer filaments on this list. If you are worried about your 3D printer’s hot end performance, this should be the easiest to get good results with.

Technical Details | |

|---|---|

| Material | TPU |

| Diameters | 1.75mm |

| Spool Sizes | 800g |

| Shore Hardness | 95A |

| Elongation at Break | Not specified |

| Colors | 18 |

| Extrusion Temperature | 195°C - 230°C |

| Bed Temperature | 40°C - 60°C |

Ninjatek TPU

Best high-end

Check Price

AmazonMatterHackers

As one of the more expensive options on the list, Ninjatek TPU filament earns its higher price point for its great print quality, ease of use, and optimal performance. Suggested for use with sports equipment, medical devices, and industrial manufacturing, it is an excellent option for commercial applications.

Suggested for use with sports equipment, medical devices, and industrial manufacturing, it is an excellent option for commercial applications.

Ninjatek TPU is known for its vibration dampening, chemical resistance, and abrasion-resistant properties. Its shore hardness of 85A gives the material enough rigidity to withstand repeated high-impact force without failing.

Optimized for easy 3D printing, Ninjatek is textured for better feeding through the extruder. It also boasts a high degree of dimensional accuracy for easy and consistent extrusion in most 3D printers.

Technical Details | |

|---|---|

| Material | TPU |

| Diameters | 1.75mm, 2.85mm |

| Spool Sizes | 500g, 1kg, 2kg |

| Shore Hardness | 85A |

| Elongation at Break | 660% |

| Colors | 11 |

| Extrusion Temperature | 225°C - 250°C |

| Bed Temperature | Up to 40°C |

Overture TPU

Best on a budget

Check Price

Amazon

Another affordable flexible TPU filament option, Overture, boasts a wide variety of colors, multipacks, and additional discounts for bulk buying. If you have a large project to do and need a lot of filament, this is one of the most cost-efficient brands on the list.

If you have a large project to do and need a lot of filament, this is one of the most cost-efficient brands on the list.

Like other TPU brands, Overture has great bed adhesion and very little warping, so it is easy to get good base layers on your prints. It also has very little odor while printing, so it does not overpower your home if you have to print inside (though a ventilated 3D printer enclosure is a good practice for anyone printing within their home).

Technical Details | |

|---|---|

| Material | TPU |

| Diameters | 1.75mm |

| Spool Sizes | 1kg |

| Shore Hardness | 95A |

| Elongation at Break | 300% |

| Colors | 17 |

| Extrusion Temperature | 210°C - 230°C |

| Bed Temperature | 25°C - 60°C |

FormFutura FlexiFil

Highest temperature resistance

Check Price

Amazon3DJake

When you need a flexible material with higher heat resistance than typical flexible TPU filaments offer, using a TPC product like FormFutura FlexiFil should do the trick. With higher heat resistance comes higher print temperatures and a bigger learning curve. However, TPC filaments usually have little to no warping, so while the temperatures are closer to ABS filament, they won’t have the same adhesion problems.

With higher heat resistance comes higher print temperatures and a bigger learning curve. However, TPC filaments usually have little to no warping, so while the temperatures are closer to ABS filament, they won’t have the same adhesion problems.

In addition to heat resistance, FlexiFil is also resistant to chemicals and UV exposure. With a shore hardness of 45A, it is much softer than the other products we have looked at so far. However, with that added elasticity, it also has something called flexural memory, which means it will return to its original shape with no deformation when stretched.

Even with its softer composition, FlexiFil is strong and durable with high impact resistance. It is also a more eco-friendly option since it is made from 43% bio-materials.

Technical Details | |

|---|---|

| Material | TPC |

| Diameters | 1.75mm, 2.85mm |

| Spool Sizes | 250g, 500g |

| Shore Hardness | 45A |

| Elongation at Break | Not Specified |

| Colors | 5 |

| Extrusion Temperature | 220°C - 260°C |

| Bed Temperature | 90°C - 110°C |

Duramic TPU

Best for Bowden extruders

Check Price

Amazon

Duramic’s TPU filament is notable not only for its affordable price point but also because it is specially formulated to work just as well with Bowden extruders as it does with direct-drive extruders. It’s also designed to be jam-free in general for an easier and more consistent printing experience.

It’s also designed to be jam-free in general for an easier and more consistent printing experience.

It has a shore hardness of 95A and an elasticity of 300% more than its starting length, making it a rigid but impact-resistant option that is perfect for manufacturing parts and tools. Duramic TPU filament has a +/-0.05mm tolerance for good dimensional accuracy. This also helps keep clogging, jamming, and other extrusion issues to a minimum in your 3D printer.

Technical Details | |

|---|---|

| Material | TPU |

| Diameters | 1.75mm |

| Spool Sizes | 1kg |

| Shore Hardness | 95A |

| Elongation at Break | 300% |

| Colors | 5 |

| Extrusion Temperature | 220°C - 230°C |

| Bed Temperature | 25°C - 60°C |

Fillamentum Flexfill TPU

Best UV resistance

Check Price

3DJakeMatterHackers

Fillamentum offers two different versions of their FlexFill TPU filaments: 92A and 98A. These numbers refer to their respective shore hardnesses and overall rigidity. While both have fairly high levels of rigidity, the 92A line of TPU filament has higher elastic and reversible deformation properties. The 98A line of TPU filament is semi-flexible material with improved UV resistance.

These numbers refer to their respective shore hardnesses and overall rigidity. While both have fairly high levels of rigidity, the 92A line of TPU filament has higher elastic and reversible deformation properties. The 98A line of TPU filament is semi-flexible material with improved UV resistance.

Both products have high tear and tensile strength, good rebound resilience, little to no warping, and high abrasion resistance. They are both resistant to oils, greases, ozone, and aliphatic alcohols. They are also both safe to use in and around electrical and electronic equipment.

Technical Details | |

|---|---|

| Material | TPU |

| Diameters | 1.75mm, 2.85mm |

| Spool Sizes | 230g, 500g |

| Shore Hardness | 92A, 98A |

| Elongation at Break | |

| Colors | 20 |

| Extrusion Temperature | 220°C - 240°C |

| Bed Temperature | 50°C - 60°C |

Fillamentum TPE

Best food-safe flexible filament

Check Price

3DJake

Like their TPU products, Filamentum’s TPE filament has two different products named based on their shore hardness: 90A and 96A. The 90A products are flexible while the 96A products are semi-flexible.

The 90A products are flexible while the 96A products are semi-flexible.

These products are both certified as safe for food contact and skin contact and have a soft, pleasant surface texture. They both have high degrees of tear strength and abrasion resistance. They are chemically resistant to alkalis, water, alcohol, and acids. They also have very low moisture absorption, making them ideal for outdoor use.

Their tensile strength and elasticity are much lower than the TPU lines, so consider whether you need greater strength against mechanical stress or weather conditions when choosing between the two options.

Technical Details | |

|---|---|

| Material | TPE (polyolefin + SEBS) |

| Diameters | 1.75mm |

| Spool Sizes | 230g, 500g |

| Shore Hardness | 92A, 96A |

| Elongation at Break | 250% (92A), 150% (96A) |

| Colors | 5 |

| Extrusion Temperature | 224°C - 245°C |

| Bed Temperature | 50°C - 60°C |

Recreus Filaflex TPU

Most eco-friendly

Check Price

3DJake

Recreus Filaflex TPU filament has several different product offerings. They have separate lines based on the product’s shore hardness and include the following measurements: 60A, 70A, 82A, and 95A. They also have specialty flexible filaments, like conductive filament and their Reciflex and Purifier lines.

They have separate lines based on the product’s shore hardness and include the following measurements: 60A, 70A, 82A, and 95A. They also have specialty flexible filaments, like conductive filament and their Reciflex and Purifier lines.

The regular Filaflex options are resistant to solvents, acetone, and fuel. They are also rated safe for skin contact but have not been officially approved for food or medical use. They have good bed adhesion and don’t need adhesives or surface covers to avoid warping. They also are formulated to work well with a wide variety of 3D printers, including those with a Bowden setup.

Their specialty TPU filament options each have their own intended use. Conductive TPU is named as such because it is electrically conductive. This is useful for fabricating conductive prints for devices. Reciflex is a 100% fully recycled TPU filament using waste left over from Recreus’s own production and from waste from the footwear industry.

Filaflex Purifier is especially interesting. It is designed to be a sustainable environmentally-friendly 3D printer filament option. It absorbs pollutants and greenhouse gasses and turns them to mineral waste using a process known as gas mineralization.

It is designed to be a sustainable environmentally-friendly 3D printer filament option. It absorbs pollutants and greenhouse gasses and turns them to mineral waste using a process known as gas mineralization.

Technical Details | |

|---|---|

| Material | TPU |

| Diameters | 1.75mm, 2.85mm |

| Spool Sizes | 500g, 3kg |

| Shore Hardness | 60A, 70A, 82A, 95A, 82A (Purifier), 92A (Conductive), 96A-98A (Reciflex) |

| Elongation at Break | 500% - 900% |

| Colors | 18 |

| Extrusion Temperature | 215°C - 250°C |

| Bed Temperature | 50°C - 60°C |

Polymaker TPU

Check Price

AmazonPolymakerMatterHackers

PolyFlex TPU filament is another excellent option for flexible filaments. It is a rigid material with a shore hardness of 95A, with enough elasticity to keep its impact resistance high. It is designed to be compatible with a wide variety of machines, though it does still suggest the use of a direct drive extruder in your 3D printer.

It is a rigid material with a shore hardness of 95A, with enough elasticity to keep its impact resistance high. It is designed to be compatible with a wide variety of machines, though it does still suggest the use of a direct drive extruder in your 3D printer.

It comes in a resealable aluminum package and has a filament gauge and print settings printed directly onto the spool. It has limited color options, but each color available is vibrant and available in both common diameters (1.75 mmand 2.85 mm).

Technical Details | |

|---|---|

| Material | TPU |

| Diameters | 1.75mm, 2.85mm |

| Spool Sizes | 750g |

| Shore Hardness | 95A |

| Elongation at Break | 300% |

| Colors | 6 |

| Extrusion Temperature | 210°C - 230°C |

| Bed Temperature | 25°C - 60°C |

ColorFabb Ngen Flex

Check Price

MatterHackers

If you want a multipurpose flexible filament for your 3D printing projects, ColorFabb’s Ngen Flex TPU filament is an excellent choice. Designed to work across multiple 3D printer models, you can use it with a Bowden extruder at a normal print speed with little to no issues. This product is as close to using a traditional 3D printer filament as a flexible filament can get.

Designed to work across multiple 3D printer models, you can use it with a Bowden extruder at a normal print speed with little to no issues. This product is as close to using a traditional 3D printer filament as a flexible filament can get.

Because it is temperature resistant up to 125°C, your 3D prints can be steam-sterilized. This trade-off comes at needing a slightly higher printing temperature than the other TPU filaments on this list. It also moves a heated bed from an optional feature to a requirement.

Technical Details | |

|---|---|

| Material | TPU |

| Diameters | 1.75mm, 2.85mm |

| Spool Sizes | 650g |

| Shore Hardness | 95A |

| Elongation at Break | Not Specified |

| Colors | 3 |

| Extrusion Temperature | 240°C - 260°C |

| Bed Temperature | 80°C (BuildTak) |

MatterHackers Pro Series TPU

Most consistent diameter

Check Price

MatterHackers

The Pro Series TPU filament by MatterHackers is another excellent choice for when you need a reliable and strong flexible 3D printer filament. With a +/-0.02mm tolerance, they have some of the most refined dimensional accuracy allowances in the flexible filament market. Most of the other TPU filaments have a tolerance range of +/- 0.05-0.10mm.

With a +/-0.02mm tolerance, they have some of the most refined dimensional accuracy allowances in the flexible filament market. Most of the other TPU filaments have a tolerance range of +/- 0.05-0.10mm.

Dimensional accuracy is especially important when dealing with flexible filaments since jams and clogs are already an issue due to their elasticity, so if you want a brand with excellent quality control and fewer mechanical failures on your 3D printer, MatterHackers Pro Series is an excellent choice.

Technical Details | |

|---|---|

| Material | TPU |

| Diameters | 1.75mm, 2.85mm |

| Spool Sizes | 1lb |

| Shore Hardness | 95A |

| Elongation at Break | 508% |

| Colors | 7 |

| Extrusion Temperature | 220°C - 240°C |

| Bed Temperature | Up to 40°C |

Buying Flexible Filament: Things to Pay Attention To

Material

TPE

Thermoplastic elastomers (TPE) is a term for a broad range of flexible filaments and elastic thermoplastics, including TPU filament. TPE typically refers to polymers with a lower shore hardness, density, and surface smoothness than TPU, but since it covers such a broad range of flexible materials, its properties can vary significantly.

TPE typically refers to polymers with a lower shore hardness, density, and surface smoothness than TPU, but since it covers such a broad range of flexible materials, its properties can vary significantly.

TPU

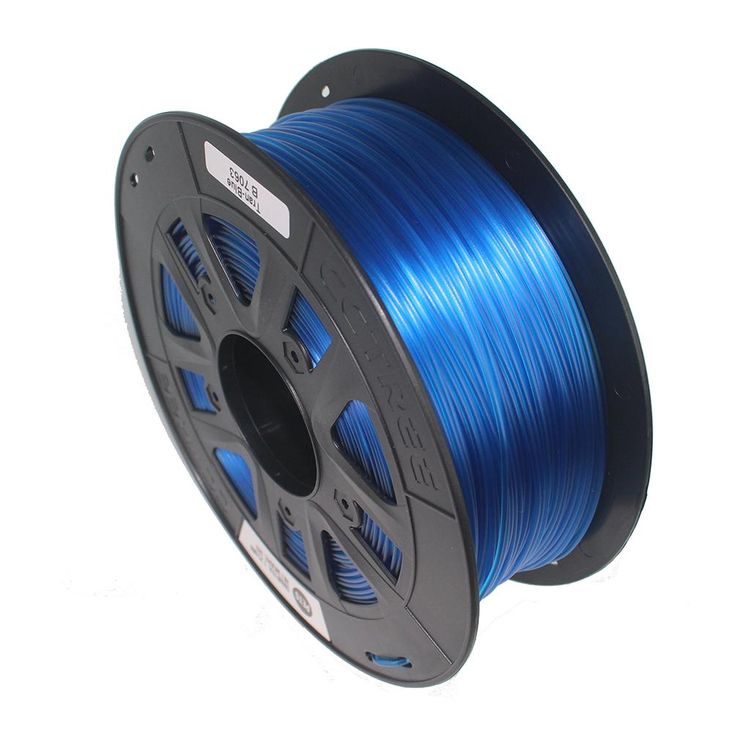

One of the most common flexible filaments made for 3D printing, thermoplastic polyurethane (TPU) is a transparent elastic material that is known for having a high level of shear strength and abrasion resistance. It also has good chemical and impact resistance, as well as resistance to oils and grease. TPU has little tolerance for heat and absorbs moisture much like PLA does. For that reason, it can be useful to use a proper filament storage solution while the filament is not in use.

Recommended:

The 10 Best Filament Storage Containers and Dry Boxes

PEBA

Polyether block amide (PEBA) is a special TPE that was first introduced into the 3D printing industry as a powder for SLS 3D laser sintering. Several companies have now adapted the material into a flexible filament for use in 3D printing.

PEBA is a popular flexible filament material because it has some of the best elasticity with a typical elongation at break range of >500%. It also has excellent chemical, impact, and temperature resistance.

TPS

Thermoplastic polystyrene (TPS) is a softer more rubber-like flexible filament material that is characterized by good elasticity (>500%), higher moisture resistance, and smooth surfaces in 3D printing.

Elongation at Break

Elongation at break is a measurement of how far flexible materials can stretch before they break. Usually represented as a percentage, it shows how much a flexible material can elongate past its original length. A filament with an elongation at break of 500% can stretch five times its original length before breaking.

3D Printer Compatibility

Extruder Type

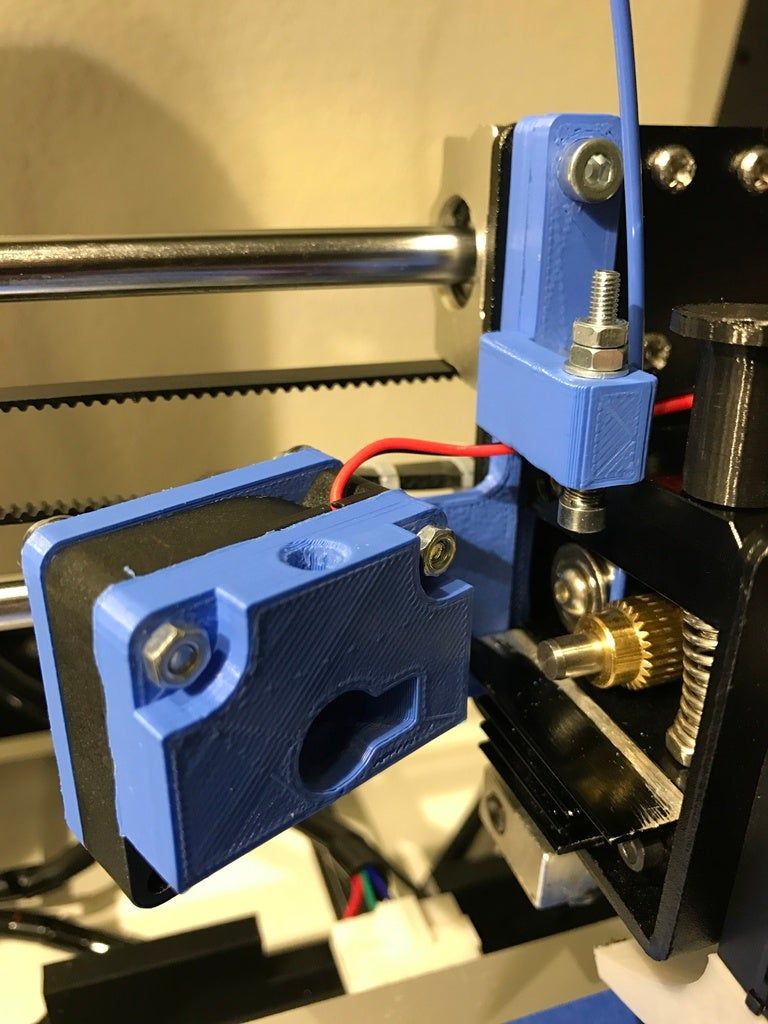

TPU filament and other flexible materials work best with a direct drive extruder. Bowden-style extruders (one of the more popular setups for 3D printers and the factory configuration for several models like the Ender 3) push the filament toward the nozzle through PTFE tubes.

Usually, the Bowden extruder is mounted to one of the body rails of the 3D printer, so the filament has to travel about a foot and a half to the hot end, but that distance can be more or less depending on the printer.

Direct drive extruders are mounted directly to the print head and located right above the nozzle. Since they are so close to the hot end, direct-drive extruders don’t have as many issues with filament bunching, extruder jams, and clogs as Bowden extruders do.

Maximum Nozzle Temperature

To successfully print with TPU filament, 3D printers should have a maximum extruder temperature of at least 250°C. That is the high end of what the majority of flexible filament brands call for. However, there are some exceptions, so if you want more options, a maximum extrusion temperature of 260°C or 275°C is more reasonable.

Maximum Bed Temperature

Most TPU brands don’t require a heated bed to print and don’t recommend a print bed temperature over 60°C if you plan to use one. If you do have a heated bed, you should be fine as long as it reaches 40-60°C. If you don’t have a heated bed, you should still be just fine with several different brands. Ninjatek, MatterHackers, and SainSmart are some of the best brands of TPU to use without a heated platform.

If you do have a heated bed, you should be fine as long as it reaches 40-60°C. If you don’t have a heated bed, you should still be just fine with several different brands. Ninjatek, MatterHackers, and SainSmart are some of the best brands of TPU to use without a heated platform.

There are a few specialty filaments on our list that need a higher bed temperature. ColorFabb Ngen Flex, for example, suggests an 80°C heated bed for their product since it is formulated to have higher heat resistance than a typical TPU filament. Always be sure to double-check the manufacturer’s recommended settings before buying to ensure you aren’t getting an outlier when your 3D printer doesn’t have the necessary hardware for it.

Shore Hardness

Shore hardness is a measurement of how hard rubber and rubber-like objects are. There are technically three different shore hardness scales, but the one most relevant to flexible filaments and 3D printing is the ‘Shore A’ scale. For reference, a rubber band is a 20A, a pencil eraser is a 40A, a car tire is about 70A, and a shopping cart wheel is about 95A.

Shore hardness measures rigidity, but it does not measure flexibility, so keep that in mind. Just because a filament has the same shore hardness as, say, a shopping cart wheel, does not mean it will be as inflexible as the cart tire. Only that it can be. Flexibility is measured by the elongation at break, which we already discussed above.

What Can You Use Flexible Filament For?

Flexible filament has a myriad of uses, including industrial, medical, automotive, sports, hobby, and fashion.

Parts and Industrial Manufacturing

Certain parts can benefit from the elasticity and durability of flexible filament. Industrial parts that need to withstand mechanical stress while retaining their shape and structure are a perfect use for TPU thanks to its high shear strength.

Even replacement washers, sealant rings, hose adapters, cable ties, elastic bands, straps, furniture bumpers, and other household items are good candidates for flexible filament.

Medical

The use of TPEs in the medical field has long been established. With the introduction of TPU filament, greater emphasis has been placed on flexible 3D printing in the medical community to fabricate things like prosthetics, parts for medical devices, models for education, and prototypes for artificial organs.

Sports

Flexible filaments are being widely utilized in the manufacturing of sports equipment. Padding and bracers in helmets, shoe insoles, chin straps, mouth guards, and other parts are easy to fabricate using TPE and TPU filament in 3D printing.

Hobby

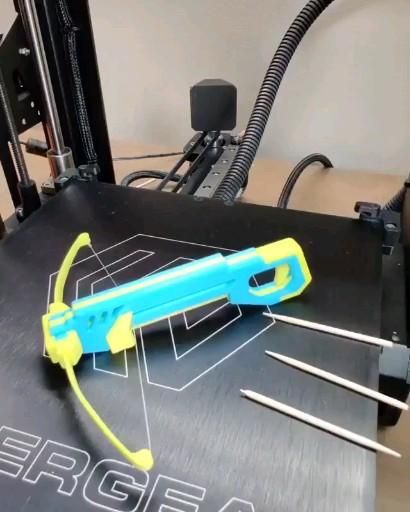

Hobby applications for 3D printing with flexible filament include fabricating parts and upgrades for devices. Drone parts, RC tires, bicycle/motorcycle/etc. handle grips, and more are just a few of the ways TPU filaments can be utilized by hobbyists and prosumers.

Bumper cases for phones, GoPros, and other electronics are good projects for flexible filaments. Laptop sleeves, keyboard covers, and other protective objects have long been manufactured by TPEs.

Fashion

Flexible filament can also work well for applications in the fashion industry. Accessories like watchbands, jewelry, wallets, and belts are easily made with 3D printing TPU flexible filaments.

Some users have also tested the efficacy of TPU filament and other TPE materials for printing footwear with a fair bit of success. Sneakers, sandals, and shoe insoles have all been made from flexible TPU filaments with interesting results.

Tips for Printing With Flexible Filament

Flexible filament can be difficult to use in 3D printing because its elastic properties allow it to bend and elongate in areas where it ideally shouldn’t. Using the proper settings and temperatures for TPU while 3D printing with TPU filament negates some of these issues.

When 3D printing with TPU filament or other flexible materials, be sure to:

- Print slowly. An ideal printing speed for TPU filament is well below the normal printing speed for other filament materials.

- Turn off retraction. Using retraction while 3D printing TPU filament can cause jams, clogs, and mechanical failures in your 3D printers. Turn it off completely or use the lowest retraction settings possible.

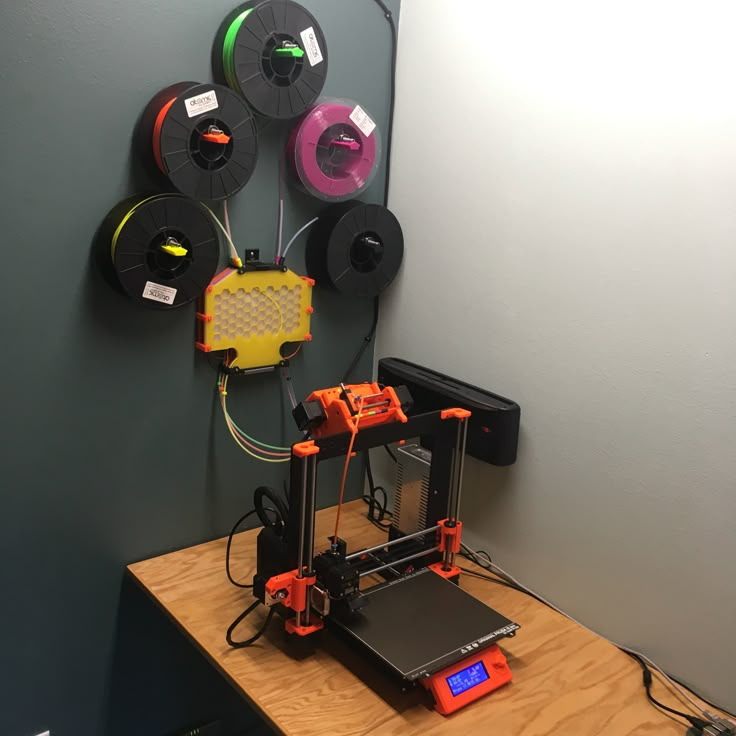

- Reduce tension on your filament spool. Place your spool somewhere that will reduce tension while the filament is feeding into the extruder to avoid print quality issues and mechanical failures like jams and clogs.

- Change your infill settings to make your flexible part more or less elastic. More infill makes your prints stiffer and less flexible, while less does the opposite. Different infill patterns also offer different elasticity results. You might not want to use the strongest infill pattern when looking for flexibility.

Frequently Asked Questions

Is it possible to use flexible filaments in a Bowden extruder?

Yes, you just have to make sure your temperature settings are dialed in, that none of the tubing makes the filament “stick”, and that you adjust the feed rates to a much slower pace. Or you can simply choose one of the brands like ColorFabb Ngen Flex that is designed to work well with a Bowden extruder.

Or you can simply choose one of the brands like ColorFabb Ngen Flex that is designed to work well with a Bowden extruder.

My TPU filament absorbed moisture. Can I salvage the spool or should I toss it?

It’s important to note that TPU filaments are extremely susceptible to moisture. Just as much—if not more—than PLA. It has to be kept vacuum sealed when not in use and placed in an air-tight container with a desiccant pack after it is open to keep it from taking on moisture from the air.

If it does get affected by moisture, a few hours in a food dehydrator or filament dryer should remove enough of the moisture to make the filament usable again.

Which is better: TPU or TPE?

What qualifies as “better” greatly depends on what your specific needs are. TPE is just a category for flexible thermoplastics anyway. Many brands don’t differentiate between the other non-TPU thermoplastic elastomers and just label them TPE. Therefore, TPE filaments can have a broad range of attributes from moisture resistance to heat tolerance to acid resistance. You just need to determine which attributes your project needs the most.

You just need to determine which attributes your project needs the most.

What is the difference between TPU and PLA?

One of the biggest differences between TPU and PLA is that TPU is a thermoplastic elastomer (TPE), while PLA is a thermoplastic polymer (TP). This means that TPU can be both elastic and plastic, while PLA can only be plastic.

TPU is also much more flexible than PLA, absorbs moisture more easily, and has a higher resistance to wear and tear. On the other hand, PLA is biodegradable, easier to print with, and has a lower melting point.

Which is more flexible, TPE or TPU?

TPU is generally more flexible than TPE. However, there are many different types of TPE filament with different levels of flexibility, so it really depends on the specific filament you are using.

Does TPU have toxic fumes?

No, TPU does not have toxic 3D printing fumes. However, just like all 3D printing filaments, it is best used in a well-ventilated area or with an enclosed 3D printer.

Is TPU filament expensive?

Compared to other filament materials, such as ABS and PLA, TPU is significantly more expensive. Typical prices for TPU are 2 to 3 times higher per kg, even though the best TPU filament can increase your 3D printing costs even more. You can, however, find good budget TPU from brands like SainSmart and Overture.

Can the Ender 3 use TPU?

The Ender 3 3D printer is not specifically designed to use TPU filament, but it is possible to use it with some modifications. We have a list of Ender 3 hardware upgrades you can check out to make printing TPU material easier.

Aside from that, you may need to adjust the print settings and increase the extruder temperature to get optimal results.

What is the softest TPU filament?

The softest TPU filament that we could find is Recreus Filaflex TPU, which has a Shore hardness of only 60A.

Can you print TPU without a heated bed?

Yes, it is possible to print TPU without a heated bed. However, you may need to increase the print temperature and/or use a build plate adhesion method like hairspray or glue stick.

However, you may need to increase the print temperature and/or use a build plate adhesion method like hairspray or glue stick.

At what temp does TPU soften?

Because TPU is already flexible at room temperatures, its glass transition temperature is a bit different from that of other filament materials. It transitions from rigid to flexible at temperatures far below 0°C. The exact temperature depends on the specific type and brand of TPU filament you are using.

Final Thoughts

There are countless flexible filaments available on the 3D printing market. Choosing the best one can be difficult, especially since there are so many varieties of flexible thermoplastics as well.

Recreus Filaflex filaments are a top choice for the best TPU filament because they have so many options. Beyond having 5 different shore hardness options to choose from, they also offer a varied color selection for each hardness. Their specialty TPUs add even more options and possibilities for your projects.

ColorFabb Ngen Flex is a great choice for the best TPU filament as well, for its ease of use, ability to run through a Bowden at a normal printing speed, and because the finished prints can be sterilized. However, Filamentum’s TPE filaments also shouldn’t be overlooked for their safe food and skin contact certification, chemical and water resistance, and multiple shore hardness options.

Are you still struggling with using TPU and other flexible filaments for 3D printing? Let us know what questions you still have in the comments below!

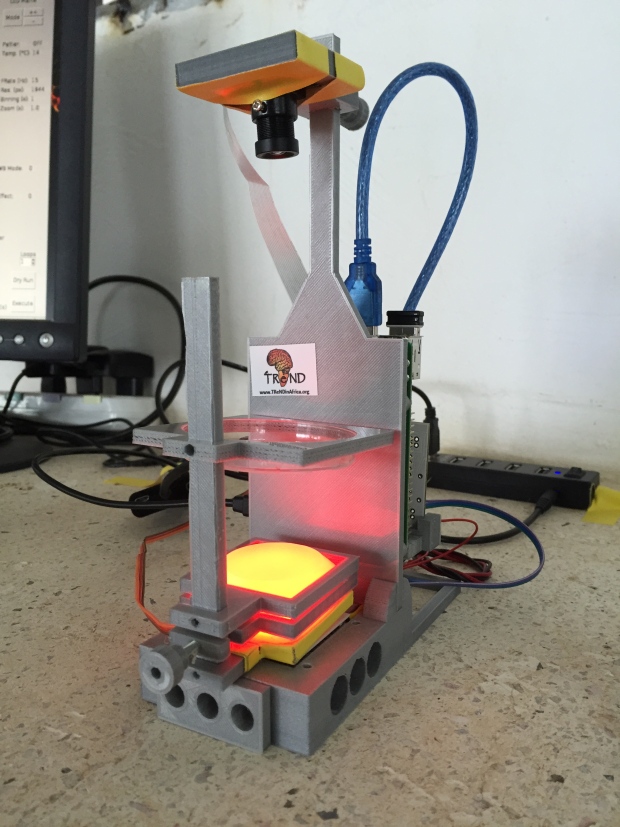

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with. This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

Acetone steam polishing of ABS plastic is a process for smoothing the surface of 3D printed models. The result of this treatment makes your printed products look as if they were made by a professional mold casting method. If you want to understand how this is done correctly, then read this article. Aceto Read more→

New Formlabs 3D Print Materials

New Formlabs 3D Print Materials

New Formlabs 3D Print Materials are regularly introduced as the company continues to search for new photopolymers for 3D printing.

Formlabs Functional Resins are flexible, flexible, strong, rigid or heat resistant finished product materials for a wide range of applications. In the SLA 3D printing process, parts are made from resins for: prototyping, various types of engineering parts (aerodynamic, hydraulic, heat-resistant, etc.), the production of templates, molds for molding small batches of plastic, and much more.

3D Printed Formlabs Resin Samples

We have printed sample models in Formlabs new functional resins. The printing time of each of the samples depends on the thickness of the layer with which 3D printing takes place, the geometry of the model itself and its orientation in space during construction. Each of these photopolymers has a number of interesting characteristics and benefits, which can be found by clicking on the link below.

| Go to sample from Tough 1500 Resin | Go to sample from Flexible 80A Resin |

| Go to sample from Tough 2000 Resin | Go to sample from Elastic 50A Resin |

| Go to sample from Rigid 10K Resin | Skip to paragraph of Draft Resin |

–

Formlabs Tough 1500 Resin: carabiner

Resin mimics the strength and stiffness of polypropylene. The material is well suited for 3D printing spring prototypes and assemblies, tight fitting connectors. That is, for rigid but flexible parts that can bend and quickly return to their original state.

The material is well suited for 3D printing spring prototypes and assemblies, tight fitting connectors. That is, for rigid but flexible parts that can bend and quickly return to their original state.

| Layer thickness, µm | Resin volume ml | Model printing time, min | |

| Tough 1500 Resin | 100 | 5.4 | 45 |

See all resin characteristics Tough 1500 Resin

-

FORMLABS TOUGH 2000 Resin resin: Multitulus

Smol imitates the strength of type ABS. For strong and rigid prototypes, durable fixtures and tools.

| Layer thickness, µm | Resin volume ml | Model printing time, min | |

| Tough 2000 Resin | 100 | 8. 2 2 | 40 |

See all resin characteristics Tough 2000 Resin

-

FORMLABS Rigid 10k Resin: Impeller

A glass-filled material that mimics the stiffness of fiberglass and fiber-filled thermoplastics. The tensile modulus of this resin is 10K.

Best suited for short run templates and mold plates, airfoil test patterns, heat and fluid resistant components, fixtures and tools.

| Layer thickness, µm | Resin volume ml | Model printing time, min | |

| Rigid 10K Resin | 100 | 3.8 | 10 |

See all resin characteristics Rigid 10k Resin

-

FORMLABS FLOXIble 80A Resin Model: Tecetor

imitates the flexibility of rubber or TPU. Flexible and transparent material with a hardness of 80 Shore A for rigid and flexible parts. They are used to create prototypes of wearable devices, elastic cases, soft tissue anatomy - products that must be subjected to repeated bending and compression without destroying the material.

Flexible and transparent material with a hardness of 80 Shore A for rigid and flexible parts. They are used to create prototypes of wearable devices, elastic cases, soft tissue anatomy - products that must be subjected to repeated bending and compression without destroying the material.

| Layer thickness, µm | Resin volume ml | Model printing time, min | |

| Flexible 80A Resin | 100 | 6.1 | 30 |

See all resin specifications0021

The softest engineering resin with a hardness of 50A Shore that mimics silicone flexibility. Flexible and soft transparent material for 3D printing of seals, gaskets and masks, cushioning, damping, soft tissue anatomy and more. For products that will bend, stretch, compress and withstand repeated cycles without breaking.