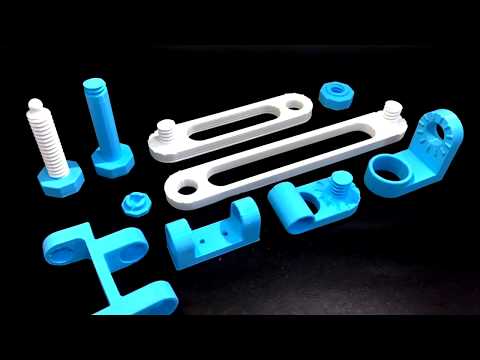

3D print tube connector

▷ round tube connectors 3d models 【 STLFinder 】

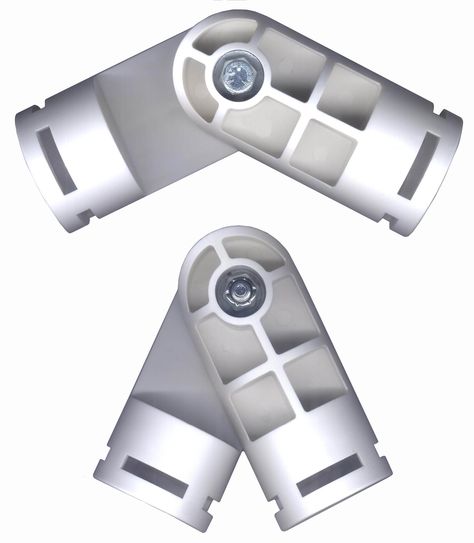

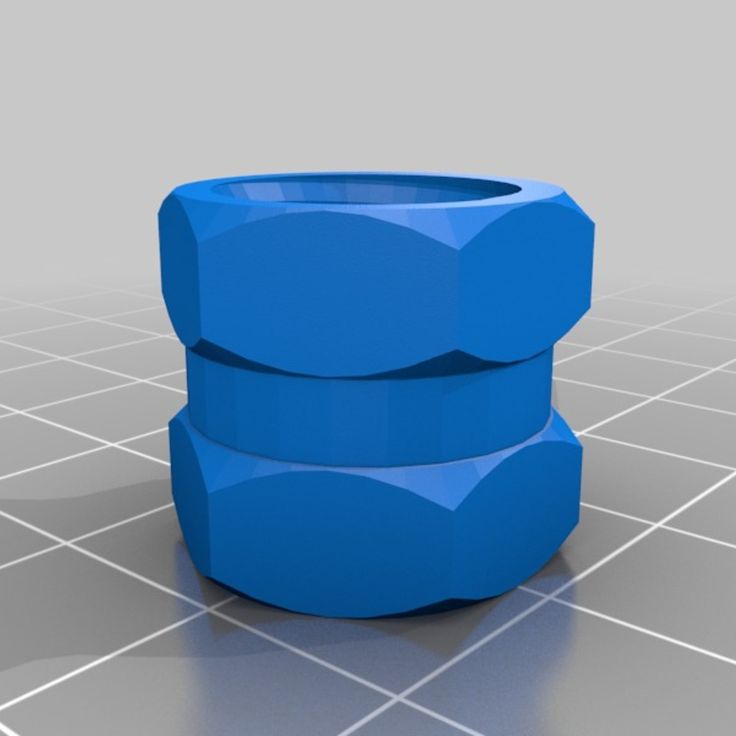

PVC Round Tube Connectors

thingiverse

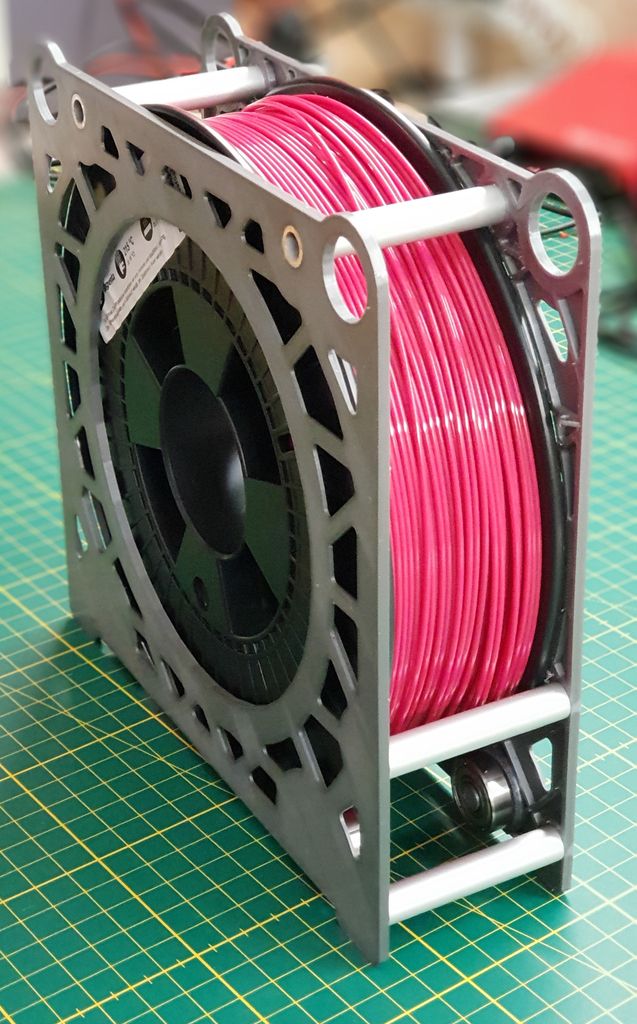

... pipes in desired lengths, you can create different kind of frames (e.g. for a 3D-printer housing, spool holdes etc.). The rounded pieces can be used as feet if used in an angle (e.g. ...in a spool holder https://www.thingiverse.com/thing:3507395)

Tube Connectors

thingiverse

... is 8mm if you want to test the fit. There may be some strange artifacts in some of the more complicated models, but they all should print fine. Let me know if anyone has any problems or requests. If you want some extras check out tube extras

Round Tube

thingiverse

This is just a 90º round tube with 33mm tall. ...You can ajust the scale on the slicer

Square tube connectors

thingiverse

An assortment of 1"x1" with 1/8" thick wall aluminum tube connectors. One can either epoxy or screw the pieces to the tubing. ... Print with a material, number of perimeters and infill that meets your needs.

Popcorn Round connectors

pinshape

Summary Attaches to popcorn joint - gives a round end to glue things to (e.g. ...magnet), useful in helping hands

Electrical hose tube connectors

thingiverse

Simple part to connect electrical tubes from different sizes - 40 -> 25 - 40 -> 20 - 25 -> 20 Edit: Added version with triple 25 input Edit2: Added straight versions with triple 20-20 25-25 40-40 input

Popcorn Round connectors

thingiverse

Attaches to popcorn joint - gives a round end to glue things to (e. g. magnet), useful in helping handsUpdate improved STL Not quite what you wanted? Feel free to tweak these designs. ...The tinkercad source files are published here:...

g. magnet), useful in helping handsUpdate improved STL Not quite what you wanted? Feel free to tweak these designs. ...The tinkercad source files are published here:...

5/8" tube connectors

thingiverse

... I wanted to build something similar. Unfortunately I could not find the corners they are using so I went with 5/8" plastic tube (used for electricity wires) and designed a few angles in order to couple them together. ...

Customizable Universal Connectors - round

thingiverse

As this is Version 1 only, the connectors are round (both outside shape and the holes), but next version will be more versatile. A few parameters to use: 1.) Outer diameter - how thick the connector wall will be (in mm) 2.) Inner diameter - hole...

A few parameters to use: 1.) Outer diameter - how thick the connector wall will be (in mm) 2.) Inner diameter - hole...

Round tube fixture

thingiverse

Round tube fixture

Round tube plug cap

thingiverse

Simple round cap for round tube openings. Scale to desired size. ... No rafts or supports needed.

Silver Round Storage Tube

youmagine

Silver Round Storage Tube holds 20 silver Eagles or other like sized silver rounds.

SKADIS - Round Tube 40mmx50mm

thingiverse

Just a round tube 40mm diameter and 50mm height ... ...for small long things Ikea SKADIS Pegboard

Round Tube End Cap

thingiverse

This is a Round Tube End Cap for gt omega racing pro cockpit,

round tube clip

thingiverse

quickly and securely attach to round tubes or posts 25mm option suits most modern round seat posts read description tab below for more options

T-Joint Round tube

thingiverse

This a replacement T-Joint for my greenhouse. ...The outer diameter of the round tubes is 15.3.mm.

...The outer diameter of the round tubes is 15.3.mm.

Round tube expansion plug

thingiverse

... of thing. Instructions round-plug-a.stl is a test for 25mm OD tube with 1mm wall. Solid ABS would probably work best but my test was PLA with %40 fill. I sliced it to .4mm and printed it with a .5mm nozzle on my printerbot. ...Seems to work well.

Tube Round Welding

grabcad

Fixture for all-round welding

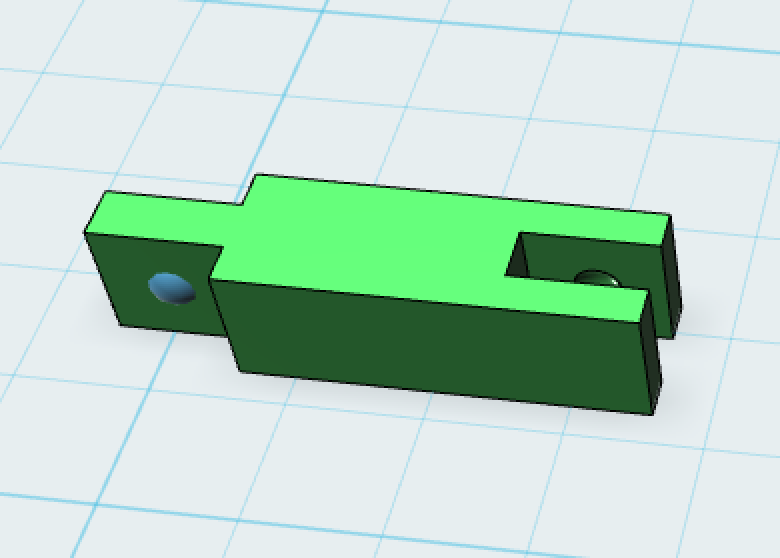

12MM round tube clamp

thingiverse

A small, lightweight clamp for 12MM OD CF tubes. Made for M3 screws, but also has a hole for an anti-rotation M2.5 screw. ... Holes are intentionally tight.

Made for M3 screws, but also has a hole for an anti-rotation M2.5 screw. ... Holes are intentionally tight.

customizable round tube endcap

thingiverse

Just another customizable tube endcap :) I needed some for storing my sewing patterns. ... I liked this: https://www.thingiverse.com/thing:1652151, but wanted a model that prints nicely without support.

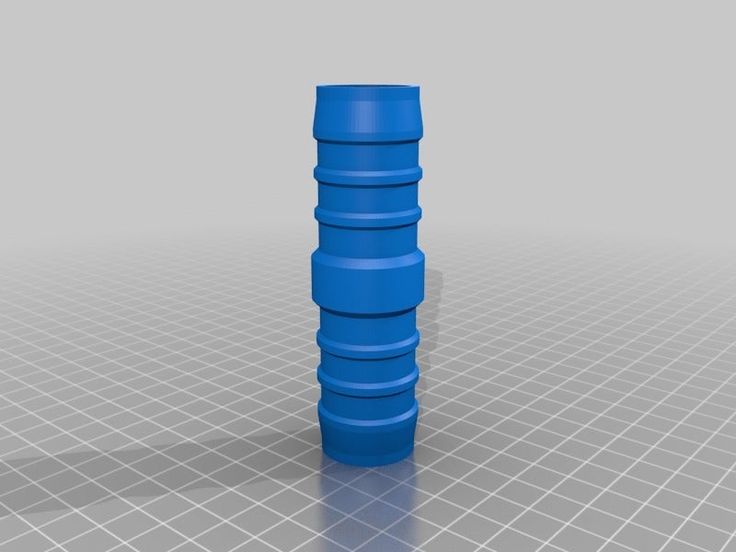

Tube Connectors - Joiner Hose Pipe

thingiverse

Watering Tube Connector - Joiner Hose Pipe

Small tube connectors for modelling

grabcad

tube connectors to fit 8mm dia plastic tube. ... Good for 3D printing

... Good for 3D printing

Test tube connectors for ants

thingiverse

Use these connectors to join test tubes together when transferring ants between test tubes I will be adding more sizes: 16 mm - 16 mm (scaled up by 3% from remixed model 16mm connector to give a little more leeway to fit thick glass 16mm test tubes)

PTFE Tube Dry Box Connectors

thingiverse

I created a PFTE tube pass through for the filament through the top of an IKEA Lack table along with a connector to mount on the Sterilite 32 Quart Gasket Box I'm using to hold my filament. I was surprised the threads worked out with the IKEA Lack. ..

..

Pilot Mask Assemblies - Tube Connectors

thingiverse

3D MODEL DESCRIPTION: Pilot Mask Assembly / MBU - TUBE CONNECTORS Display. 1:1 Scale Assembly. IMPROVE YOUR PROPS or COLLECTION DISPLAYS. -- Pilot Mask Assembly / MBU - 12 MASK Type ...

Simple round box tube 36x53mm

thingiverse

Simple round tube box demension: 36x53mm Perfect for my other Boxes.

10-Round Tube Speed Loader

thingiverse

This is a speed loader for 10-round paintball tubes. It is best used with a motorized hopper but it will work with gravity fed loaders. ...Please see the Readme file for required materials and assembly instructions.

It is best used with a motorized hopper but it will work with gravity fed loaders. ...Please see the Readme file for required materials and assembly instructions.

Paintball 10 round tube cap

thingiverse

I lost a few of my tethered caps for my 10 round tubes (paintball), so here's a quick design for some tube caps. I went through a couple iterations to make sure the caps fit tight enough, but also easy enough to pop off with a thumb. ... Printed in...

10 Round Tube Holder V2

thingiverse

This is designed to hold 3 10 round paintball tubes. This will fit on any standard battle belt or molle vest. If used for molle vest/belt, put an M3 screw into the little hole to prevent it from falling out.

...

If used for molle vest/belt, put an M3 screw into the little hole to prevent it from falling out.

...

10-Round Tube Speed Loader

myminifactory

This is a speed loader for 10-round paintball tubes. It is best used with a motorized hopper but it will work with gravity fed loaders. Please see the Readme file for required materials and assembly instructions. ...A demonstration of it in use can be...

▷ tube connector 3d models 【 STLFinder 】

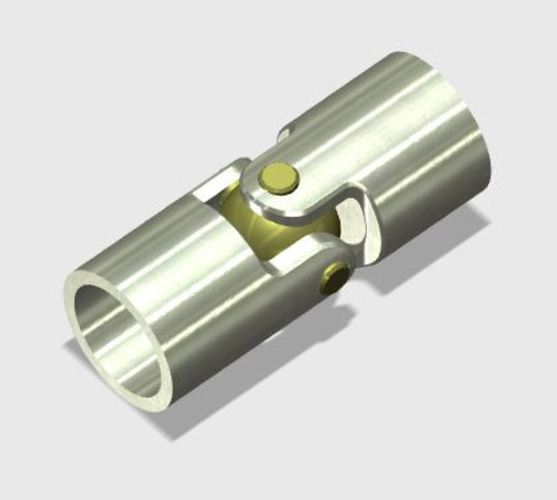

tube connector

grabcad

tube connector

Tube Connector

thingiverse

Tube Connector diff Versions

Tube Connector

thingiverse

3 Way Tube Connector for Aluminium tubing (EasyFix). You should be able to easily modify it to create different "Ways". ... Instructions Cut aluminium to length and tap in connector.

You should be able to easily modify it to create different "Ways". ... Instructions Cut aluminium to length and tap in connector.

Tube connector

thingiverse

Connector for 8mm tubes

Tube Connector

thingiverse

This is a design challenge that resulted in my classroom due to a need in another design challenge. ...We needed to find a way to connect two different sizes of plastic tubing.

Tube connector

thingiverse

After a quick think I though it would be easier enough to print some connectors to allow the pipes to be connected together. The OD of the pipe is 16mm but after a few test's I set the the ID of the connectors to 16.8mm and these fit on...

The OD of the pipe is 16mm but after a few test's I set the the ID of the connectors to 16.8mm and these fit on...

Tube connector parts

grabcad

Tube connectors

74mm-76mm tube connector

thingiverse

simple tube connector

creator 3 tube connector

thingiverse

feeding tube connector for Flashforge creator 3

Parametric Tube Connector

thingiverse

Parametric tube connector with 50% increase of inner tube diameter.

Iron tube connector

thingiverse

This is easy tube connector designed by me in 10 minutes. It allow 30 min to print and you get relatively strong thing. ... Instructions Print and play!

Tube connector 20mm

thingiverse

Connector for 20mm tubes lenght : 60mm Internal : 17mm External : 20mm For a 20mm tube angle connector see : https://www.thingiverse.com/thing:2698837

Tube Connector - Airline - Silicone

thingiverse

I designed this dynamic flange/ tube connector so I can use it for multiple applications. The fusion file attached allows you to change parameters to your requirements, i.e. 1-4 outputs, and tube size. I designed this project because I required a...

The fusion file attached allows you to change parameters to your requirements, i.e. 1-4 outputs, and tube size. I designed this project because I required a...

Square-Tube-Connector

thingiverse

This Project Square Tube Connector I made this connectors because i need them for project all our base on "Square Tube" from 20x20mm I will add more as I will make them because with setting i have before sometime parts break i alter my setting I will...

Tube Connector Extras

thingiverse

... for me, but you will need to silicone up the bottom to stop leaks.

All these things may change or move to other uploads, i just wanted to put these things out. Maybe better pictures later too.

Tube Connectors and Many Formicarums at the links

Maybe better pictures later too.

Tube Connectors and Many Formicarums at the links

GB3 Filament Tube Connector REAR

sketchfab

Replacement GB3 Tube Connector REAR

Tube connector cross Dia 30

grabcad

Tube connector cross Dia 30,Rohrverbinder Kreuz Dia 30

Boat Biminy Canopy tube connector

youmagine

This tube connector was made to replace broken or cracked 3/4" Bimini tube connectors for your boat canopy. ...This is part 1 of 2 components that are part of the tube connectors set.The original CAD file and STL files have been provided.Print...

...This is part 1 of 2 components that are part of the tube connectors set.The original CAD file and STL files have been provided.Print...

1/8 inch tube connector

thingiverse

A small yet nice model of a one sided 1/8 inch tubing connector one with both is in profile Please donate!!

MP Select Teflon Tube Connector

thingiverse

Replacement of the MP2 Select mini Teflon Tube Connector. ...This adapter needs a standard PC4-M6 Fittings Push like this one https://www.amazon.de/dp/B06VSJ5K3L/ref=sspa_dk_detail_8?psc=1&smid=AW49AOMG6J7W3

Guide tube connector for M10

thingiverse

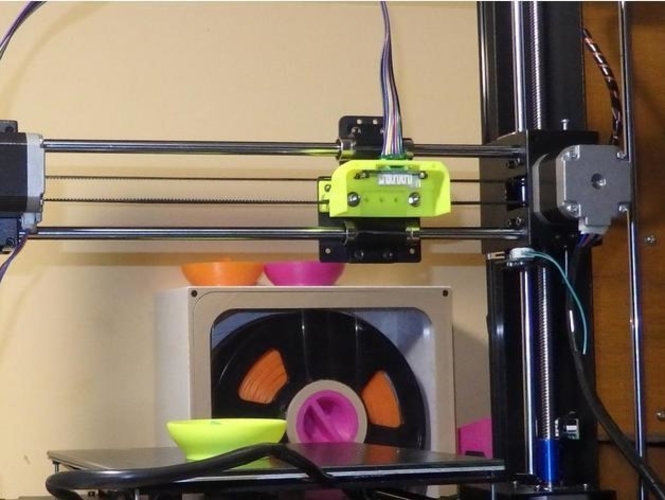

This is a guide tube connector setup for an M10 fitting for this amazing MMU spool holder: https://www. thingiverse.com/thing:3228827 . I had several M10 fittings laying around and wanted to use them with this spool holder design, but it didn't...

thingiverse.com/thing:3228827 . I had several M10 fittings laying around and wanted to use them with this spool holder design, but it didn't...

Dyson ® DC05 Absolute Tube Connector

thingiverse

- Ne pas oublier de partager votre impression 3D ;) #-------------------------------------------- **[EN]** >Dyson (*"DC-05 Absolute"*) telescopic tube connector. *"DC05"* model publication year : 1999 Accuracy model designed on SolidWorks 2016. ...

Tube Connector with Captured Nut

prusaprinters

I need to be able to slide the mated aluminum along the tubing, and be able to lock it in place. This thing is the tube connector, with a captured nut on the side. Although somewhat related to this thing: http://www.thingiverse.com/thing:8356 It is...

This thing is the tube connector, with a captured nut on the side. Although somewhat related to this thing: http://www.thingiverse.com/thing:8356 It is...

Tube Connector with Captured Nut

thingiverse

This thing is the tube connector, with a captured nut on the side. Although somewhat related to this thing: http://www.thingiverse.com/thing:8356 It is not a strict derivative, but rather in the same family. You can easily create a mashup of this...

25mm ant tube connector

thingiverse

Needed a larger diameter connector to fit my larger tubes.

14mm X_tube connector

thingiverse

14mm X connector. ...Use this for my ant nest tubes.

...Use this for my ant nest tubes.

120mm Tube Connector

thingiverse

Simple connector to connect 2 120mm flex tubes with brackets

25mm Tube Connector

grabcad

Simple 90' corner connector for a 25mm square tube

PVC tube connector

thingiverse

Connector for PVC tube 40 mm aka reprap morgan style. ...For a home-made table.

Square tube connector, joint

thingiverse

Some joints and connectors for 14mm sqare pipes/tubes and an wall of 1mm.

Free 3D file Tube connector - overhead line

Floating plant ring - aquarium with plants

Free

Soda Bottle Shrimp Brine Air Bubbler Incubator

Free

Adjustable aquarium overflow - self-filling water bridge

Free

Best 3D Printer Files in the Miscellaneous Category

Key ring heavy

Free

Low-Cost Opensource Mechanical Ventilator

Free

UTMShield Face Shield

Free

Covid19 Decathlon mask

Free

BMP 1/16 RC MODEL

35 €

Baby elephant Dumbo

2.94 €

Airsoft - Muzzle Break 6

3 €

Bestsellers in Miscellaneous category

Ciberpunk 2077 Gun Rebecca "Guts"

4 €

Black Phone Movie Invader 2 Piece Mask 3 Style Frowning Smile Without Mouth STL

10. 13 €

13 €

Articulated Gyarados

1.99 €

Gengar - pokemon with flexible articulation (seal in place, without supports)

2 €

Chainsaw Man - Denji

18.44 €

Articulated Raykuaza Flexible Dragon Pokémon

1 €

Articulated axolotl

3.50 €

Ghost Boom x10

€1.99 -ten% 1.79€

hinged shenron

3 €

Eeveelution articulated mega pack

10 €

Halloween haunted house lamp with 3d moon - NO PREPARATION AND PAINTING NEEDED

4,56 €

Lord of Chaos

5.50 €

Halloween pumpkin lantern ItsLitho

1,90 €

Giarados - articulated sea serpent

1,50 €

Articulated pretty spider

2. 49 €

49 €

MiniAdder v2

12.50 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people , so support us in keeping the activity going and making future designs of is very easy. Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

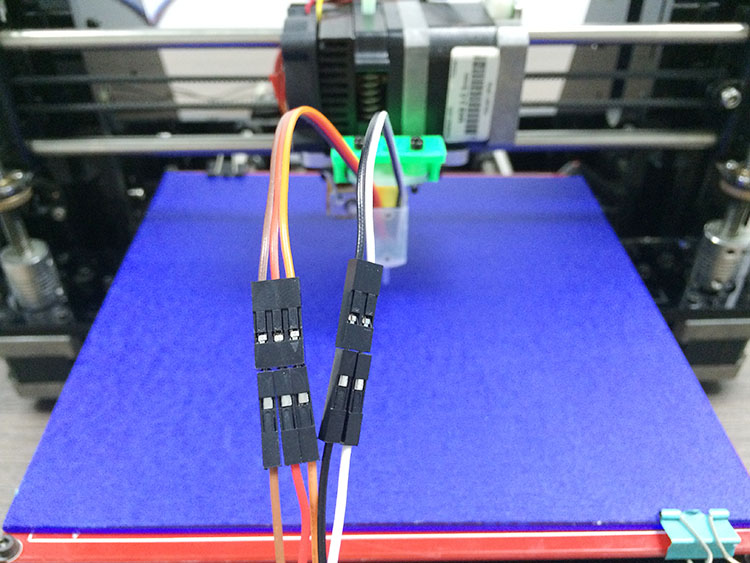

3D Printing Basics / Sudo Null IT News

KolianM

Working with 3D graphics *Prototyping *DIY or DIY 3D printers or milling. This is due to the technical features of the 3D printer, from which you need to either squeeze the maximum benefit, or adjust to the disadvantages of printing.

As a caveat, I note that these recommendations relate mainly to the FDM (FFF) 3D printing method, in which a plastic rod is heated by a moving extruder that forms the part layer by layer.

3D model development starts with a sketch. It can be a drawing on paper, a material prototype, a mental image, etc. What is important to pay attention to when creating such a sketch and the model itself, we will analyze in detail.

Part strength

Here and further down the text there are several sub-points that must be taken into account at the same time, kept in mind from the very beginning.

- Be aware of the layering or anisotropy of the material: it is much easier to break a part in layers than across.

This must be taken into account in advance, given the location of the 3D model on the 3D printer table.

This must be taken into account in advance, given the location of the 3D model on the 3D printer table.

- Add fillets. The leg of the stool and the tabletop at the junction should have a rounded corner. At the same time, the larger the radius of curvature, the stronger the leg will be fixed on the table top. Similarly for various body parts. Modeling a box All right angles are rounded. It doesn't matter what plane they are in. Even where a right angle is needed, we make a radius of 0.5 mm. The printer will pass through such a section more easily than an unrounded one, there will be no impact from a sharp stop of the extruder, the part will not sway, and other pluses.

- Wall thickness and filling. The maximum strength at 100% infill is a fact, but if you need to lighten the part or save plastic, you can make a much larger wall thickness in the print settings, while setting the infill much lower. This works with parts that have holes for fasteners.

When creating machine code for a printer, absolutely all the outer walls are thick, so the fastener will be surrounded by a reliable thick layer of plastic of your part.

When creating machine code for a printer, absolutely all the outer walls are thick, so the fastener will be surrounded by a reliable thick layer of plastic of your part.

- Support. This element affects the strength in that the layers supported by the support are not always ideal in structure. This can be solved by increasing the wall thickness, filling, but it is better not to do support at all. Support is added by the slicer depending on the angle between the part wall and the table plane. Often the default is 60 degrees, sometimes 45. This setting is selected experimentally for each 3D printer. You can check this with the help of special test parts. For example, https://www.thingiverse.com/thing:2806295 - do not forget to turn off support to check the real quality of 3D printing in its absence. For example, you need to print a T-piece for tubes. Cast products are made in a T-shape. 3D printing makes the product L or even Λ-shaped. In the second case, support can even be avoided, and the part will be stronger due to the layers located at an angle of 45 degrees to the tubes.

We, in the workshop, set up slicers for each machine and ask the client about the strength requirements, and, depending on this, choose a 3D printer to print.

We, in the workshop, set up slicers for each machine and ask the client about the strength requirements, and, depending on this, choose a 3D printer to print.

Geometric restrictions

- The wall thickness is limited from below by the size of the 3D printer nozzle. Its diameter is constant and in the vast majority of cases it is 0.4 mm. Smaller thickness - long 3D printing for most parts. The larger the nozzle, the bonds between the layers are less strong, the steps between the layers are more visible. And in general, the wall thickness should be a multiple of 0.4 mm, then the 3D printer will be able to accurately make the wall in two passes (0.8 mm), in 3 passes (1.2 mm), etc. Other thicknesses will cause the 3D printer to leave a gap or overflow, which negatively affects the strength and appearance of the printed part.

- 3D printing of thin cylinders and "needles". For 3D printing of such products, special 3D printer settings are needed: low 3D printing speed, allow time for cooling, otherwise such a structure will bend.

Vertically standing thin elements are best avoided at all costs. Even if they are printed, they will be very fragile. It makes sense to leave them only for decorative purposes, but you must be prepared that their quality will be worse than the quality of other elements of the 3D part.

Vertically standing thin elements are best avoided at all costs. Even if they are printed, they will be very fragile. It makes sense to leave them only for decorative purposes, but you must be prepared that their quality will be worse than the quality of other elements of the 3D part.

- 3D printed holes. I note that if the hole is straight and through, then it can be drilled, if it is curved and requires support, then it may turn out that it will be impossible to get support.

- When 3D modeling, it is important to consider the overall dimensions of the 3D printer. We use convenient 3D printers, table 250x250 mm, diagonal 353 mm. This is where you need to enter the dimensions, if possible. Otherwise, you need to order either an industrial 3D printer with a large print area, or use gluing, but assembly is better, so the assembly process will be controlled by the developer, and not by the 3D printing master.

- Large footprint may cause edges to peel off the table.

We use special glue, but this does not always help. We are periodically approached with a complaint about colleagues in the shop that for them such “minor” defects as a folded edge are not a reason to restart 3D printing, take it as it is. But an engineer who 3D models a part can take this into account in his work and make either assemblies or thin-walled flat 3D parts that “do not have enough strength” to compress the outer contour and, as a result, raise the edge.

We use special glue, but this does not always help. We are periodically approached with a complaint about colleagues in the shop that for them such “minor” defects as a folded edge are not a reason to restart 3D printing, take it as it is. But an engineer who 3D models a part can take this into account in his work and make either assemblies or thin-walled flat 3D parts that “do not have enough strength” to compress the outer contour and, as a result, raise the edge.

- Tall and thin "towers" may not work well due to vibrations that occur when the 3D printer is running closer to the top, and layer shifts are also possible.

Dimensional stability, accuracy

- Precise 3D printing is quite rare. I don’t want to speak in engineering terms here, but the likelihood that a complex composite structure will assemble the first time is very low. Here, rather, you need to take into account the fact that you can then mechanically refine the details.

- Holes for fasteners are best done with a margin of 0.5 mm in diameter. This will not reduce strength, the fasteners will also not dangle due to tightening forces, but if you do it without a margin, you will definitely have to drill it out. Reducing the size of a large shaft, >10mm sandpaper is much easier than making a hole, which requires a huge drill that cuts into the plastic walls and breaks the part, or gets stuck in it. It is also important to consider that when drilling, the plastic melts and the drill can melt into it so that it cannot be removed. There have been cases.

- Heat shrinkage is not always compensated, more precisely, it is very difficult to catch it, it is not the same in different directions, so it is extremely difficult to take it into account. It's easier to print a test version, and then make adjustments.

When looks matter

- Think about how the craftsman will orient the part on the 3D printer table.

3D printing proceeds in layers, which is clearly manifested when printing surfaces that are at a small angle from the horizontal of the table. Skinning will be long and painful, because you will have to cut this "ladder" to the deepest depressions of the "steps". It is better to place such surfaces either horizontally, for example, put on a table, or increase the angle. In some cases, even adding support that spoils the wrong side of the wrong side saves time and effort on post-processing.

3D printing proceeds in layers, which is clearly manifested when printing surfaces that are at a small angle from the horizontal of the table. Skinning will be long and painful, because you will have to cut this "ladder" to the deepest depressions of the "steps". It is better to place such surfaces either horizontally, for example, put on a table, or increase the angle. In some cases, even adding support that spoils the wrong side of the wrong side saves time and effort on post-processing.

- Support. First, the surface it supports has significantly more defects than without it. Secondly, thin and high support is weak, wobbly, which leads to the fact that the supporting part may have serious defects, or not work at all.

- First layer quality improvement. You need to add a bevel. Even where a sharp corner is not needed, I recommend adding a chamfer of 0.5 mm. It will not be clearly visible, but the edge will be neat.

What you need to know in order not to make a mistake when ordering 3D printing

When appearance is important

- Location of the part on the table.

Remember about anisotropy.

Remember about anisotropy.

- Wall thickness and filling. What you can run into here: the filling is 20% cells, which are either visible through a thin outer wall, or the filling slightly tightens the outer wall during shrinkage, but at the same time it is visually easy to determine that there is support inside. Here, first of all, an increase in the thickness of the outer wall, or an increase in the filling density, helps. Please take this into account when ordering.

Postprocessing

The elimination of stepping is achieved by mechanical and chemical methods. It is possible to use putty. Acrylic paint available. If the part has a complex color structure, then we use the ProJet 4500 printer, which works on a different technology. He glues the powder particles together with colored ink glue. It turns out well.

Morality

In conclusion, I would like to note that these recommendations and the accumulated experience will make it possible to produce parts by 3D printing, which in their properties will not be inferior to cast ones, which makes it possible to save significant funds in the presence of a customized printer and small production volumes.