3D printer casts

Are 3D Printed Casts the Right Choice for You?

A 3D printer may look like something out of a science fiction movie, but this cutting-edge technology is becoming increasingly common in the medical world. Now, a new use for 3D printing is emerging in the field of orthopedics. In particular, 3D printed casts are an alternative to traditional plaster or fiberglass casts.

While 3D printed casts are not yet widely available, they are becoming popular as more patients learn about the benefits that they offer. This blog post will discuss how 3D printed casts work and why you might choose one over a traditional plaster or fiberglass cast.

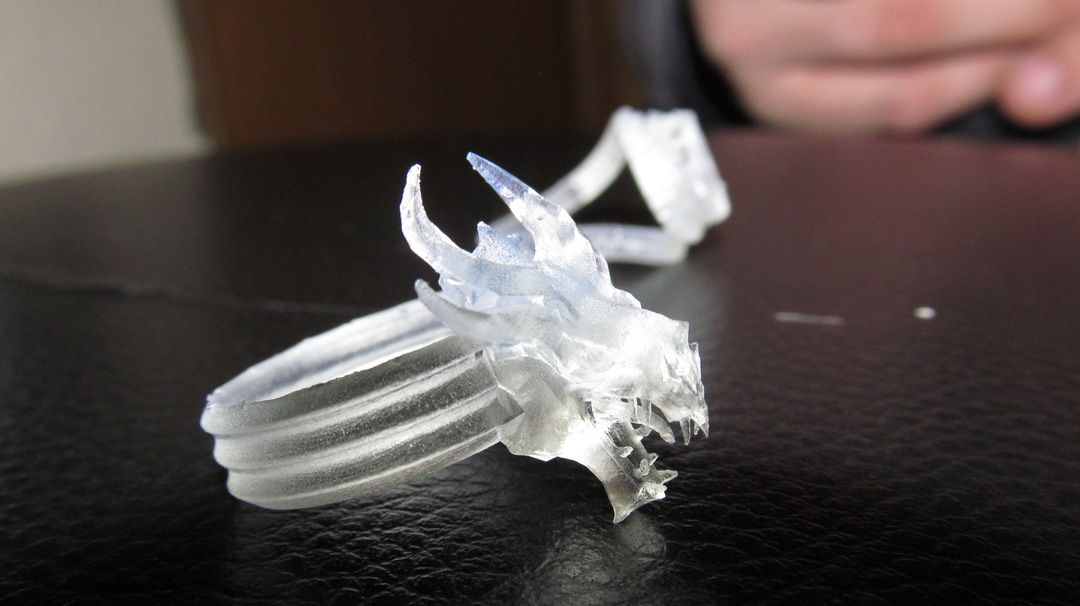

What Are 3D Printed Casts?A 3D printed cast is a medical device created using a 3D printer to support a broken bone as it heals. Unlike traditional casting, 3D printed casts are produced using additive manufacturing technology. This means that they can be custom designed to fit the specific contours of a patient's limb.

3D printed casts can be manufactured with an open design that allows the skin to breathe and helps prevent skin irritation. In addition, 3D printing technology makes it possible to produce casts in different colors and designs.

How Do 3D Printed Casts Work?phonlamaiphoto - stock.adobeA 3D scan is made of the injured limb to make the cast. This scan is then used to create a 3D model of the limb. An engineer uses that model to create a cast design that will fit the limb. The design is then sent to a 3D printer, which creates the cast using a high-temperature thermoplastic. The final product is then put on the limb and can be removed when the injury has healed.

Step 1: ScanThe process of creating a 3D-printed cast begins with taking a scan of the patient’s limb. This may include x-rays, CT scans, or other imaging techniques. This allows the doctor to determine the broken bone's exact position and the shape of the patient's limb.

Once the scans are complete, a 3D model of the limb is created. The patient's hand is scanned with a 3D scanner to create an accurate and detailed three-dimensional model. This model can then be used to create a custom device design without the need for casting.

Step 3: 3D printingThe next step is to print the cast. This can be done using a high-temperature thermoplastic or by sintering powder. The print may require post-processing to make the materials safe to touch and strong to wear for long periods of time.

What Are 3D Casts Made Of?Most 3D casts are created using a high-temperature thermoplastic. The plastic is heated to a high temperature and then cooled, creating a hard, durable cast that can support broken bones or immobilize joints for non-surgical treatment. The exact composition varies depending on the manufacturer, but it typically includes a variety of polymers and resins.

3D-printed casts offer a number of benefits over traditional plaster casts or fiberglass casts, including a better fit, greater breathability, and decreased itchiness. They are much easier to remove, so you can wear them in showers or baths without worrying about this type of cast getting wet. They are also weather-resistant, so you don't have to worry about them getting ruined if caught in the rain.

Additionally, 3D printed casts can be custom-fit to your body, making them more comfortable to wear and less likely to cause skin irritation. Finally, because they are lightweight and breathable, 3D printed casts are less likely to cause swelling and discomfort than traditional casts.

Drawbacks of 3D Printed CastsAlthough they offer a number of advantages, there are also some potential drawbacks to consider. One of the main risks associated with 3D-printed casts is that the cast may not fit properly if the limb is swollen during the initial scan. When swelling occurs, the affected area can increase in size, which may cause your print to not fit properly. The process will then need to be repeated, which can be both time-consuming and costly.

When swelling occurs, the affected area can increase in size, which may cause your print to not fit properly. The process will then need to be repeated, which can be both time-consuming and costly.

Another limitation is that 3D printed casts are not suitable for patients who need immediate care. This is because it can take some time to create and process the print, which may not be practical for patients with serious fractures. Additionally, 3D printed casts are not suitable for patients who require manipulation of the bones back into place.

The last disadvantage to consider is that 3D printed casts are more expensive than traditional casts, and insurance companies may not cover the cost. Although this technology is constantly improving, it is important to be aware of the potential disadvantages before choosing a 3D printed cast for your injury.

3D Printed Casts Costphonlamaiphoto - stock.adobeAlthough 3D printing technology is often associated with a low-cost manufacturing process, the reality is that the cost of 3D printed medical devices can be quite high. When it comes to the cost of 3D printed casts, there are a few key factors to consider.

When it comes to the cost of 3D printed casts, there are a few key factors to consider.

First, the materials used in 3D printing are typically more expensive than traditional plaster or fiberglass. Second, the scanning equipment required to create a 3D model of the injury can be fairly costly. Finally, most hospitals or clinics would need to hire additional personnel to operate the 3D printers to create the designs or hire an outside firm to complete the tasks.

Overall, the cost of 3D printed casts is likely to be higher than traditional casting methods. However, it is worth noting that the price may come down as the technology becomes more common. Additionally, some insurers may start to cover the cost of 3D printed casts as they become more widely used for bone fractures.

3D Printed Cast CareWhen it comes to caring for a 3D printed cast, the process is quite simple. Unlike traditional plaster or fiberglass casts, which must be kept dry at all times, 3D printed casts are water-safe and can be fully submerged. This makes showering and bathing easier for patients, as they no longer need to worry about keeping their cast dry. Wounds are visible through the material of the 3D-printed cast, and they can be monitored at all times.

This makes showering and bathing easier for patients, as they no longer need to worry about keeping their cast dry. Wounds are visible through the material of the 3D-printed cast, and they can be monitored at all times.

While 3D-printed casts have been hailed as a game-changer in the medical field, they still have several drawbacks. Cast21 was developed as an innovative solution to overcome the problems of current casting technology.

FDA listed, the Cast21 system is the next generation of cast technology. The injured limb is simply placed into an open lattice sleeve and filled with a fast-curing proprietary formula. This patented system creates a perfect-fit, fast-acting solution for joint care. The result is a strong, yet seemingly weightless cast alternative that is comfortable to wear. In addition, Cast21 is waterproof, so patients can easily shower, and swim allowing patients to stay active while they heal.

With its unique design and versatile applications, Cast21 is changing the way we think about healing. It's no wonder that Cast21 is quickly becoming the preferred choice for patients and doctors worldwide.

3D-printing the casts used to set broken bones improves patient outcomes

ActivArmor’s 3D printing process allows production of a wide range of custom-fit casts and splints for people of all shapes, sizes, and ages. Images: ActivArmor

Fans of the NFL’s Jacksonville Jaguars football team will be happy to learn that there’s a new and improved way to treat the broken bones and sprains players occasionally suffer. Northern Florida high school and college athletes who hurt themselves while playing sports will be similarly pleased, as will anyone else with a broken bone who visits Dr. Kevin Kaplan, an orthopedic surgeon with the Jacksonville (Fla.) Orthopaedic Institute and the Jaguar’s head team physician.

“I was looking for a better treatment option for my athletic patients,” he said. “Traditional plaster casts present all manner of problems in terms of sweat, dirt, and itching. And when you’re trying to get a fracture or broken bone to heal, taking a cast off to assess the healing process—while often necessary—isn’t the best thing.

“That’s when I met Diana.”

Kaplan’s talking about Diana Hall, the founder and CEO of Pueblo, Colo.-based ActivArmor and a 2022 recipient of Colorado’s Manufacturing Woman of the Year award.

Building Solutions

In 2014, Hall began offering the better treatment option Kaplan referred to. A chemical engineering graduate of the Colorado School of Mines, Hall was running a mentoring program for children in poverty when she—like Kaplan—began looking for an alternative to plaster casts. Having had previous experience with 3D printing at various Fortune 500 companies, it didn’t take her long to come up with a solution.

Said Hall: “Kids like to play. They get their casts dirty, they get them wet, and because of this, we need a hygienic, washable alternative for immobilizing broken bones. I quickly realized that if we could additively manufacture a cast from biocompatible plastic, it would provide a sanitizable and custom-fitted orthotic device that would lead to a much better outcome.”

They get their casts dirty, they get them wet, and because of this, we need a hygienic, washable alternative for immobilizing broken bones. I quickly realized that if we could additively manufacture a cast from biocompatible plastic, it would provide a sanitizable and custom-fitted orthotic device that would lead to a much better outcome.”

ActivArmor has since 3D-printed tens of thousands of such casts throughout the U.S. and established an ever-increasing number of corporate partnerships in Canada, Australia, Greece, the Middle East, and elsewhere. Hall also has collaborated with additive manufacturing technology firms such as Denmark’s Create it REAL, which makes the slicing software used by ActivArmor, and Twikit, a design-automation software developer based in Belgium.

She’s also a devoted user of FFF (fused filament fabrication) printers. Several dozen FFF-style machines of varying sizes from Fusion3, Greensboro, N.C., are on ActivArmor’s Pueblo production floor. Most of them have been fitted with special hot-end nozzles and other features to maximize print speed.

Printing Process

Hall and the ActivArmor team have developed an end-to-end workflow that assures compliance with FDA regulations. Its casts and splints are made of ABS and have been thoroughly tested for any microporosity that could lead to fluid absorption and bacterial growth, as well as biocompatibility and mechanical strength. The result is an efficient, repeatable process that allows ActivArmor to deliver custom-fitted orthoses to its medical partners within four days. (Rush orders ship in a shorter time period.)

When a patient in need of a cast arrives at a medical facility participating in the ActivArmor program, the attending physician scans the injured limb with a cell phone equipped with the ActivArmor Scan app. Next, the physician takes a few measurements of the injured limb and answers a series of questions the app poses, then transmits the results to ActivArmor for processing.

ActivArmor can deliver finished, 3D-printed casts in four or fewer days.

While waiting for the cast to arrive, patients are fitted with a temporary splint—also 3D-printed by ActivArmor—that gives the edema (swelling) common with broken limbs some time to dissipate. It’s also an easy-to-use process, so much so that ActivArmor will soon begin leasing preconfigured 3D printing cells to participating clinics for use in their facilities, further expediting patient care.

Click here to read more about the program.

Rethinking Casts

One clinic looking forward to the printing cell roll-out is Motion Is Medicine, a North Richland Hills, Texas, primary-care sports and family medicine founded by Dr. Daniel Clearfield.

“Anybody who’s worn a plaster cast knows the experience. They’re itchy, smelly, and uncomfortable,” said Clearfield, who’s also the team physician for USA Wrestling and USA Judo. “With 3D-printed casts, my patients can do all the activities they’re accustomed to.” He laughed. “I’ve started referring to ActivArmor casts as ‘summer savers.’ ”

“I’ve started referring to ActivArmor casts as ‘summer savers.’ ”

Dr. Laurence “Laudi” Laudicina of ABQ Orthopedics in Albuquerque, N.M., agrees. He said patients know “there’s something special going on” when he begins scanning their wrist or ankle with his smartphone. “And when I pull that colorful 3D-printed cast out of the box, the response is always, ‘That’s so cool.’ What’s even more cool is that they can hop in the shower, play sports, and jump in the pool with their friends.”

Hall is clearly pleased to have hit a 3D-printed home run, but she is even happier that people of all ages now have an affordable alternative to the “smelly, itchy” orthoses of yesteryear. She said the cost of an ActivArmor cast is about the same as the two plaster casts it replaces. (A plaster cast must be cut off and replaced for every exam and X-ray.)

And because an ActivArmor cast eliminates annoyances common with a plaster cast—like snaking a coat hanger inside to scratch an itch—patient compliance is better. That greatly improves outcomes, said Hall.

That greatly improves outcomes, said Hall.

She expects that plaster casts eventually will go the way of the iron lung.

“Plaster casts make it difficult for anyone to even practice basic hygiene like washing their hands—especially kids,” said Hall. “You have people in the food service and medical industries who end up on short-term disability because they can’t sanitize their hands, so workers’ comp providers love ActivArmor.

“Additive manufacturing has changed all that. It’s become a tool to improve people’s quality of life, and now it’s available to all fracture-care providers worldwide,” said Hall.

Digital 3D printer in Orthodontics Restom

The key to the success of any medical procedure is a correct diagnosis and competent treatment planning, and modern technologies give doctors great opportunities for this and are good helpers, one of which is digital 3D printing. Dentistry is closely intertwined with innovative diagnostic methods, and three-dimensional printing fits perfectly into high-tech techniques that are actively being introduced into all aspects of dental services. nine0003

nine0003

The Restom clinic complies with all modern standards of dental treatment and offers its patients treatment and diagnostic methods using modern technologies and equipment. One of such equipment is the NextDent 5100 high-precision 3D printer.

A digital printer is equipment with which our specialists can print surgical templates and accurately plan operations, create aligners for orthodontic treatment, print templates and jaw models for diagnostics and orthodontic treatment planning, print temporary orthopedic structures, print unloading mouth guards, etc. nine0003

With the advent of modern 3D printing technology, there is no longer a need to hand-make bite impressions or dental templates and then send the blanks to a laboratory where custom fixtures will be made. All manipulations carried out using a 3D printer take several hours, do not cause discomfort, and save time for both the doctor and the patient.

Equipment operation principle

There are several ways to print, we use the method of digital LED projection - DLP. DLP stands for Digital Light Processing and is one of the fastest and most accurate digital printing methods. It is based on the use of a special mirror matrix, where each of its individual elements is a microscopic mirror. The difference from other methods: in DLP printing, the layer of the working material is not drawn by rays, but is entirely projected onto a photopolymer, which makes the technology similar to stamping. Due to this, the method made it possible to maintain the high accuracy of laser technology, significantly speeding up the operation of the device. nine0003

DLP stands for Digital Light Processing and is one of the fastest and most accurate digital printing methods. It is based on the use of a special mirror matrix, where each of its individual elements is a microscopic mirror. The difference from other methods: in DLP printing, the layer of the working material is not drawn by rays, but is entirely projected onto a photopolymer, which makes the technology similar to stamping. Due to this, the method made it possible to maintain the high accuracy of laser technology, significantly speeding up the operation of the device. nine0003

Benefits of using 3D printer

- The main advantage of digital data acquisition is patient comfort. Modern equipment reduces the time from diagnosis to prescription of therapy. Virtual imaging allows Restom doctors to use a smaller number of invasive procedures, to make prostheses with high accuracy.

- Digital dentistry speeds up the treatment process, the patient will no longer have to visit the doctor multiple times, which means he will save both time and money.

nine0022

- The high precision of the equipment allows to produce the most comfortable prostheses. Modern technologies will allow you to forget about repeated visits to correct prostheses, crowns, implants and other dental appliances.

Clinic "Restom" takes care of each patient, offering the most modern methods of diagnosis and treatment. Strong, healthy teeth, a snow-white smile - this is what we are fighting for in each case. And in this, Restom doctors are assisted by high-tech equipment - a 3D printer, with which we can quickly produce the necessary models, templates and designs that help make the reception better and more productive. nine0003

Customized ear tips - 3D printing

3D printing is used extensively in many industries. It has become indispensable in the production of hearing aids and their parts. In particular, with the help of modern additive technologies, individual ear plugs are made.

Medicine and prosthetics have come a long way, and now hearing aids are used to solve hearing problems of I-II-open prosthetics and III-IV-degree - closed prosthetics. In this case, a variety of techniques and devices, made individually, are used. nine0003

The custom earmould is an in-ear anatomical element that provides a perfect connection between the hearing aid and the ear. A distinction is made between earbuds that serve only as an adapter (connected with a tube to a behind-the-ear hearing aid), and products with a built-in device.

Manufacturing process

Individually made earmoulds are made in several steps:

- impression;

- scan;

- creation of a digital model of the ear canal;

- simulation;

- product seal;

- processing.

The production of earmoulds starts with an impression. An ottoblock is inserted into the patient's ear and a special silicone mass is injected. It quickly hardens and a ready-made anatomical cast of the ear is obtained. This impression is placed in a 3D scanner, which allows you to digitize the workpiece and get an accurate three-dimensional image of the ear canal.

An inlay is modeled in a CAD program, which is then sent to a 3D printer for printing. The resulting product is additionally processed: it is cleaned, polished, the necessary holes are made. nine0003

The earpiece can be completely discreet and can be inserted directly into the ear canal. There are also products that occupy half of the auricle or its entirety. These parameters are determined directly by a specialist.

What materials are used for earmoulds

There is a wide range of materials that are used for printing earmolds. These are, as a rule, liquid photopolymer resins that allow the production of transparent or colored products. Depending on the requirements, the liners can be soft rubber-like or hard. In accordance with this, a photopolymer is also selected. For example, specialized photopolymer resins from EnvisionTEC can be used:

- E-Shell 200

- E-Shell 300

Of course, there are serious requirements for materials: hypoallergenicity, biocompatibility, durability. A wide color palette allows you to choose the best option. It is possible to manufacture earbuds that are firm in the hands, but become elastic in the ear when heated from the body, which ensures maximum wearing comfort and invisibility of their use.

Benefits of 3D printing in audiology

3D printing and 3D scanning allows you to achieve maximum precision earmoulds and match the anatomy of the patient's ear. In addition, the advantage is the reduction of production time and cost of products. All this together serves to improve the comfort and quality of life of people with hearing impairments.

On average, an individual earmold lasts about 1.5-2 years with proper care. It is resistant to wax, sweat, etc. In children, due to their growth, replacements must be done more often. Thanks to new 3D printing technologies, this is not a problem. And if you purchase a 3D printer, then once you have completed professional modeling, a person can, if necessary, print ear molds for hearing aids with his own hands.