Best resin for 3d printing miniatures

7 Best Resins to Use for 3D Printed Miniatures (Minis) & Figurines – 3D Printerly

You want to 3D print some miniatures and figurines but are stuck on the many choices of 3D printer resins out there. If you are in a similar position, this article is for you. I went out to do some research after printing some miniatures, and wanted that top quality.

It can be pretty difficult, especially for beginners to identify what to look out for when it comes to getting that best resin to stick with.

This article will have 7 resins that I think are top level resins for miniatures, backed by many users, reviews, and a long-standing reputation of great quality.

At the end of the article, I’ll give some extra advice about curing to improve your resin printing game.

Alright, let’s get straight into the list.

Anycubic is probably one of the most known brands of resin in the 3D printing community, and one that I use all the time successfully. This one specifically though, is their Plant-Based Resin which comes with an ultra-low odor and high precision.

It is well-loved by thousands of users and is very easy to get the hang of.

It hasn’t become “Amazon’s Choice” for no reason. Many reviews have been left to back up this resin’s reputation as one of the best for printing minis in terms of durability and flexibility.

One of the things that customers have loved about this resin is its low-odor. One person said that even though they were sensitive to resin smells, this Anycubic’s plant-based product didn’t even pose half an issue.

Moreover, it has been made using soybean oil which already means that it is an eco-friendly resin. The best part about this is your models will be pretty easy to clean, even with soap and water.

In addition, there are no Volatile Organic Compounds (VOCs), BPA, or harmful chemicals involved so you have that added confidence. It complies with EN 71-3:2013 safety standards.

To talk about print quality, this resin does nothing but impress. Users that have tried and tested the Anycubic Plant-Based Resin say that their prints come out great, and doesn’t require use of a respirator to deal with the fumes.

Another good property is having a slight flex in the models.

Crisp details, smooth textures, and prints of reasonable overall quality are the standard of this resin. Also, it’s rare that you experience problems with adhesion to the build plate.

There are a wide array of colors available for you to choose from. The flexibility here has made several happy as they like to experiment with multiple variations.

Lastly, the color pigmentation on this resin is truly dazzling. Grey is definitely the most popular color so check out the link below to get it yourself.

Check out the Anycubic Plant-Based Resin on Amazon today.

AmeraLabs created a resin specifically for 3D printing tabletop gaming miniatures, giving properties and characteristics that give you great results. It has features such as amazing flexibility, impact resistance and durability.

Tabletops that are 3D printed with non-flexible resins are a lot more likely to break since they don’t have a lot of flexural strength, so using something like the AmeraLabs TGM-7 Tabletop Gaming Resin is recommended.

Even though you have these great physical characteristics, you can still get amazing details and quality in your models.

Here are the features summarized:

- Flexible and less breakage

- Cures relatively fast

- Low odor

- Great details

- Durable surface

One thing to keep in mind is how this resin isn’t resistant to moisture, so avoid using it for models that will be around liquids.

AmeraLabs have put together some base settings that you can get started with. One user mentioned how they used these settings on the website and their 3D prints came out really well. They appreciated the print quality, as well as the adhesion of the model.

You’ll likely clippers to remove the supports rather than popping them off your models since it is flexible and harder to break, depending on the angle of the supports.

Here are some 3D prints created from this resin.

If you want to finally 3D print tabletop gaming models without them breaking while still maintaining great quality, get yourself the TGM-7 Resin from Amazon.

Moving up on the list we have the fantastic Siraya Tech Blu. This resin has received its fair share of praise and has become the number one choice for many for printing mins.

It is a popular 3D printing resin that blends flexibility, strength, and detail in equal measure. For that higher quality, you’ll have to also pay a higher price tag, being the priciest resin on this last at $50 for a 1kg bottle.

When it comes to printing your miniatures, you’ll see great results, though it has many more applications that you can use it for.

It’s a great option for printing functional parts because the resin has excellent mechanical properties and can withstand forces without breaking so easily like other resins.

If you’re looking for tough parts that are also flexible to some degree, then you don’t have to look any further.

Many resins have everyone thinking that they are too brittle, and those needing strong, durable parts should probably rely on FDM printing and filaments.

Siraya Tech’s Blu Resin has deliberately changed that thinking thanks to its terrific mechanical properties and great impact resistance, making it the perfect fit if someone wants to print miniatures and gaming figures.

Many users have figured out that you can actually mix this with a cheaper resin and still benefit from the added strength properties.

Printing this resin by itself can be quite difficult as some users experienced, so I would recommend getting yourself some Siraya Tech Blu Clear V2 and mixing it with the Anycubic Plant Based Resin for a great combination of resins.

Not only that but this resin’s sheer toughness is also for those wanting to print more than just decorative models. Instead, you can 3D print cases and other useful objects too.

You may think this comes at the cost of really long curing times, but one user mentioned how curing times aren’t bad at all.

With this purchase, you’re getting nothing but a great quality resin that you can fall in love with.

Siraya Tech Blu compares pretty closely to the Elegoo ABS-like resin, but Blu incorporates just a little more detail in your 3D printed miniatures. The battle is still very well fought.

Get yourself the high strength Siraya Tech Blu Resin from Amazon today.

Fourth in this list for 3D printing miniatures is the Rapid 3D printer resin which has been developed and manufactured by Elegoo – a giant in the 3D printing industry.

This resin has received plenty of love on Amazon and all for the right reasons. For starters, it’s very cheap (costs about $30 for a bottle of 1 kg) and packs great quality for its price point.

When looking through many of the reviews of this resin, many mention just how low-odor this resin is. Loads of other resins out there have a pretty harsh smell, so you can avoid that by picking the right resin.

I’ve heard stories of pungent smells filling up whole houses, so I’d definitely make sure you get a resin with low odor like the Elegoo Rapid Resin from Amazon.

Another upside is the variation in color of the resins which is appreciated by most customers. The details look stunning when things are done right.

One user says that he likes to print using the gray color because it helps print imperfections stand out more clearly, thus making it easier to fix them with post-processing. Pretty neat to be honest.

The packaging is done properly with Elegoo resins so you don’t have to worry about your bottle of resin arriving broken or leaking. This is one of the reasons why you’ll be quite satisfied with your purchase.

This Elegoo resin has many good points:

- Low shrinkage for accurate dimensions

- High precision and details in miniatures

- Fast curing times for speed

- Good stability and durability of models

- Bright and stunning colors that users love

- Low odor so it doesn’t disturb your environment

- Compatible with most SLA/DLP 3D printers

- Shelf life of 1 year so no rush to use it all quickly

Get yourself some bottles of high quality Elegoo Rapid Resin at a great price from Amazon today.

Longer is an SLA 3D printer manufacturer that isn’t as popular as Anycubic or Elegoo, although they take pride in producing some top-level resin that several users enjoy on a daily basis.

Longer 3D printer resin is excellent for printing miniatures, especially gaming figures, as many customers say in reviews on Amazon.

Even though they make 3D printers and resin, you can definitely use their resin with any 405nm compatible resin 3D printer, which is most resin printersout there.

With this resin, you get accurate, precise prints with commendable stiffness and great impact resistance – something that’s sought after for miniatures and figures. You don’t want to 3D print miniatures with a resin that produces brittle, weak parts.

- Low shrinkage

- High precision

- Fast curing

- Easy to detach after finishing your prints

- Leak-proof bottle

- Great customer service

It’s easy to store, effortless to clean, produces prints with a fair amount of detail, and people have also commented on how easy it is to remove their models off the build plate when they’re finished.

Get the Longer Rapid Photopolymer Resin from Amazon for your resin 3D printer.

The sixth spot on this list belongs to another Elegoo product and this time, it’s the ABS-like resin that draws similar strength, flexibility, and resistance from the common FDM filament – ABS.

The ABS-like resin is a little on the pricier and would set you back for somewhere under $40 for a 1kg bottle. In addition to that, it’s got properties of a very luxurious resin such as ultra-fast curing and top-of-the-line stability.

This resin has a wide range of applications so printing your favorite miniatures and figures should be a breeze.

Most reviews listed on Amazon say that if someone is looking for only printing minis with the ABS-like resin, then they should look no further. Words like these from current customers say a lot about the resin quality.

As previously mentioned, it’s commonplace to find resins with a pungent and irritating smell. However, with the ABS-like resin, customers have approved of its odorless characteristic.

If you want to expand your printing capabilities to tougher parts, that is also possible with this resin.

The manufacturer was aware of how some parts require durability so they made sure that ABS-like resin was less brittle and possessed higher levels of durability.

One user said that he had tried many other resins as well, but none performed as well as the ABS-like resin right out of the box. A commendable quality, to say the least.

It’s pretty easy to clean up afterward too.

You can sometimes get a discount on Amazon if you buy multiple bottles, so check out whether that deal is still on by clicking below.

Pick up some Elegoo ABS-Like Rapid Resin from Amazon today.

One of the highest-rated resins on Amazon with a solid 5-star rating as well, Siraya Tech Fast is a must-have for miniature enthusiasts out there.

A critically acclaimed thing about this resin that people have reviewed is the combination of affordability and immense quality. For 1kg of Siraya Tech Resin, you’re looking at a price around $30, which is very competitive.

For 1kg of Siraya Tech Resin, you’re looking at a price around $30, which is very competitive.

A summary of what makes this a great resin:

- Fast Printing

- Not Brittle

- Easy to Clean and Cure

- Not Smelly

- Great Surface Finish

A user said that he wanted to make miniatures that wouldn’t break easily if they happened to drop, especially if the model consisted of even weaker parts like swords, shields, arrows, or anything else.

This particular person tried Elegoo and Anycubic as well but to no avail sadly. Then, he stumbled on the resin in question and it was a blessing in disguise.

This goes on to show that the Siraya Tech Fast isn’t brittle, as the stereotype with resins goes by. Instead, it’s a strong material that can genuinely hold its ground.

Even more so, it produces great details and has become its users’ go-to material for printing miniatures. Comparatively, it’s quite thinner than the Siraya Tech Blu, which attributes to easier cleanup.

If you are wondering why this resin is called fast, it’s because this resin has very quick curing times. While most resins take around 60-70 seconds for first layer exposure, the Siraya Tech takes just about 40 seconds in comparison.

This may not seem much, but it does add up over time.

Try not to over cure this resin though because it can lose its initial flexibility. 2 minutes under a good UV light can be enough, but do some testing just to make sure.

Get yourself some Siraya Tech Fast Curing Non-Brittle Resin from Amazon for your miniatures today.

How Long Do You Cure Resin Miniatures?

Miniatures require around 1-3 minutes of curing with a 40W UV curing station. It’s a good idea to move your resin 3D printed miniature on different sides so it can be cured all over. If you use a strong 60W UV light you can cure miniatures in just 1 minute, especially really small ones.

Typical curing times inside UV curing stations range from 5-6 minutes. If you feel upon touch that it’s not enough, hold it in for a few more minutes.

If you feel upon touch that it’s not enough, hold it in for a few more minutes.

However, when it ultimately boils down to the curing part of post-processing resin miniatures, there are a few things you should know beforehand.

For starters, there is more than one way of curing your resin prints. To help explain what I mean, take a look at the following.

How Do You Cure Resin 3D Prints?

People use a UV curing station, a UV lamp with a turntable, an all-in-one machine or the natural sunlight to cure resin 3D prints. The most popular options are the UV lamp with the turntable and the all-in-one machines such as the Anycubic Wash & Cure.

Once your resin 3D prints have finished printing, you first have to wash the uncured resin around the print. Next you dry the print with either some paper towels or a fan then it’s ready for curing.

Simple direct a strong UV light at the print, preferably on a surface which rotates 360° for an even curing around your 3D prints. A UV lamp with a solar turntable is great for this, and doesn’t require a separate battery, using the UV light to power it.

A UV lamp with a solar turntable is great for this, and doesn’t require a separate battery, using the UV light to power it.

The more professional solution is an all-in-one machine that washes and cures your 3D prints. These curing options will be explained with more detail below.

Curing Prints Using a UV Lamp

The method that I’m currently using for my resin prints is the UV lamp and solar turntable combination. It’s a cheap, effective and simple solution to curing your prints.

They both came as a package from Amazon for a great price compared to other solutions.

I can get 3D prints cured pretty quickly with the UV lamp, miniatures being only a few minutes under the 6W UV curing light.

You can find the UV Resin Curing Light with 360° Rotating Solar Turntable from Amazon for a great price.

Curing Prints Using a UV Station

If you want a curing solution that looks a little more professional and is easier to handle, you can get yourself an Elegoo Mercury Curing Machine.

Instead of needing two separate pieces, you can rest your miniature inside the UV station and it gets the curing job done nicely.

It consists of 14 UV LED lights through two LED strips, giving resin prints fast curing times.

The ideal things about a curing station are:

- Provides a professional looking design

- Contains an interior reflective sheet inside the cabinet

- Has a light-driven turntable that absorbs the UV light

- Intelligent time controls for your miniatures

- The see-through window that lets you observe the process

You can adjust the time using the +/- buttons on the Elegoo Mercury, with a maximum time of 9 minutes and 30 seconds, but you won’t need anywhere near that for miniatures.

Curing Prints Using Sunlight

The prime source of UV rays that we all enjoy from time to time is sunlight. It turns out that you can even use direct sunlight to post-cure your resin miniatures easily and with equal effect.

It may, however, take considerably more time to do that. You can expect to require curing of around 5-15 minutes to achieve desirable results with your miniatures in direct sunlight.

If you notice your miniature is still pretty tacky and uncured, I’d let your miniature rest in the sun for a little longer. The UV rays from the sun aren’t necessarily strong just because it’s hot, since there are varying levels of UV emitted by the sun.

Using an All-in-One Machine

Last but not least, we have to look towards the real all-in-one solution that not only cures your miniature 3D prints, but assists you with the washing process also.

I think we can all appreciate something that doubles up in one machine to help finish the whole process for resin prints.

One of the best all-in-one devices is the Anycubic Wash & Cure Machine, specifically built for cleaning and curing resin prints so you don’t have to do it manually. It’s a professional solution that does come with a fairly hefty price tag.

The way I see it though, you can expect to be resin 3D printing for many years to come, so the earlier you invest in an efficient and productive solution, the more value you can really get out of this machine.

Several thousand users have grown to love this machine for obvious reasons, but the most popular reason is just how easy it makes the resin printing process.

- 2, 4, 6 minute timer for washing and curing.

- It has a versatile washing mode for thorough cleaning

- A mount where you can put the whole buildplate down for washing

- A smart touchscreen with a sensitive touch for easy operation

- Effective curing with uniform UV light with 360° rotation –

- Auto-pause function if cover is removed for safety

- Polycarbonate top cover which blocks 99.95% UV light emissions

It has a very healthy Amazon rating of 4.7/5.0 at time of writing, with 95% being 4 stars or above.

You can easily wash & cure your miniatures (multiple at once), making your life that much easier in the long run.

Get yourself the professional Anycubic Wash & Cure Machine from Amazon to assist in your resin printing adventures.

To read more about curing your resin prints in general, take a look at another one of my articles here for an in-depth guide.

What is the Best SLA Resin 3D Printer for Miniatures?

The best resin 3D printer for printing miniatures is the Elegoo Mars 3 Pro. It has many features that users will find useful for 3D printing miniatures such as a 6.6″ 4K monochrome screen which speeds up curing times, along with a powerful COB light source with 92% uniformity for smooth surfaces.

I did a whole review of the Elegoo Mars 3 Pro that you can check out, complete with actual 3D prints that came off it. Here’s one example.

Specifications of the Elegoo Mars 3 Pro

- LCD Screen: 6.6″ 4K Monochrome LCD

- Technology: MSLA

- Light Source: COB with Fresnel Lens

- Build Volume: 143 x 89.

6 x 175mm

6 x 175mm - Machine Size: 227 x 227 x 438.5mm

- XY Resolution: 0.035mm (4,098 x 2,560px)

- Connection: USB

- Supported Formats: STL, OBJ

- Layer Resolution: 0.01-0.2mm

- Printing Speed: 30-50mm/h

- Operation: 3.5″ Touchscreen

- Power Requirements: 100-240V 50/60Hz

7 Best Resins For Miniatures In 2023

- Last Updated: March 22, 2023

- Jackson O'Connell

If you’ve ever been on Thingiverse, Printables, or another 3D model repository, you’ve probably seen some small 3D models, usually figurines, with a ton of intricate detail. These models are what we call miniatures, and they’re super popular for 3D printing.

Miniatures are great ways to show off the detail capabilities and precision of your 3D printer, and they’re also useful for playing tabletop games like Dungeons & Dragons or War Hammer.

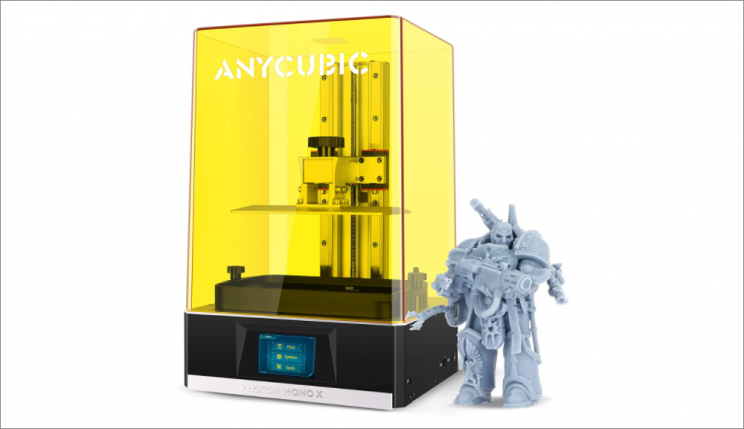

Miniatures are usually printed on resin 3D printers (LCD/DLP), like the Elegoo Mars 3, due to their ability to print small details nicely and hide layer lines on models.

And, if you want the best print quality for miniatures, you’ll need high-quality resin that’s optimized for printing detail. My favorite resin for 3D printing miniatures is Phrozen Aqua 8K, as it yields models with up to 8K pixel resolution. But, if you’re using a 4K printer, then you’ll love Anycubic’s Standard resin as it’s low-cost and high-detail.

Want to hear about more of the best resins for 3D printing miniatures? Just keep reading!

Anycubic Standard

Get Discount Now

Check Latest Price

Elegoo Standard 8K

Get Discount Now

Check Latest Price

Siraya Tech Tenacious

Check Latest Price

Table of Contents

- Best Resins for Miniatures At A Glance

- 1.

Elegoo Standard 8K (Best Choice)

Elegoo Standard 8K (Best Choice) - 2. Anycubic Standard (Best Value)

- 3. Siraya Tech Tenacious (Premium Choice))

- 4. Anycubic Water-Wash Resin+ (Easiest to Use)

- 5. Phrozen Aqua 8K (Best Print Quality)

- 6. Elegoo Water Washable 8K

- 7. Elegoo ABS-Like

- 1.

- What is Resin?

- Printing Resin Miniatures

- What Type of Resin is Best for Printing Miniatures?

- How Long is the Curing for Resin Miniatures?

- Considerations for Miniature Resin

- Resolution

- Durability

- Paintability

- Curing

- Speed

- Value

- Conclusion

Best Resins for Miniatures At A Glance

1. Elegoo Standard 8K (Best Choice)

2. Anycubic Standard (Best Value)

3. Siraya Tech Tenacious (Premium Choice)

4. Anycubic Water Washable 8K (Easiest to Use)

5. Phrozen Aqua 8K (Best Print Quality)

6. Elegoo Water Washable 8K

7. Elegoo ABS-Like

Elegoo ABS-Like

Elegoo is one of the biggest names in the consumer resin 3D printing industry, and their Standard 8K Resin is hands down the best for miniatures.

The resin, as indicated by the name, is meant for being printed on an 8K pixel resolution printer, such as the Phrozen Sonic Mini 8K or Elegoo Saturn 2. But don’t worry if you’ve got a printer with only 4K resolution or lower because this resin will still work. It just won’t be living up to its full potential, detail-wise.

Source: Uncle JessyAnd, on this note, the detail yielded by Elegoo Standard 8K resin is absolutely insane. I was able to print tons of miniatures with boatloads of small details, and each came out basically perfectly.

As it’s Elegoo’s “Standard” version of their 8K resin, you’ll need some isopropyl alcohol, acetone, or another compatible solvent to wash your miniatures prints once completed.

Get Discount (Official Store)

Check Latest Price

2. Anycubic Standard (Best Value)If you’ve ever bought a 3D printer, then you probably have heard of Anycubic, one of the leading brands in FDM and resin 3D printing. Anycubic makes all sorts of 3D printing products, and their standard 3D printing resin is easily the best value resin for printing miniatures.

For under $30, you get a whole kilogram of high-quality resin that yields amazing, well-detailed miniature 3D models. And this Anycubic resin also is available in a couple of colors, including green, grey, aqua blue, black, and more. I personally love this because I hate having to paint models, so the color options let me avoid this.

Source: M3DMUnlike the Elegoo Standard 8K resin, this Anycubic resin isn’t optimized for 8K pixel resolution printing, so the detail likely won’t be as nice. But, based on my own experiences as well as countless positive reviews, this resin still yields exceptional print quality for small models.

But, based on my own experiences as well as countless positive reviews, this resin still yields exceptional print quality for small models.

And, because this resin is so popular, there are tons of slicer setting recommendations out there that you can try out to perfect the quality of your models.

Get Discount (Official Store)

Check Latest Price

3. Siraya Tech Tenacious (Premium Choice))Unless you’re deep in the resin 3D printing industry, you probably haven’t heard of Siraya Tech, but their Tenacious resin, despite its odd name, is perfect for printing miniatures.

If I’m being completely honest, Siraya Tech Tenacious resin costs a pretty penny, especially when compared to other options on the market. But I promise you every cent is worth it if you’re trying to maximize the quality of miniature 3D prints. No, seriously, though; I only buy myself Tenacious resin on special occasions, but I’m always fascinated by the overall quality of models printed in the resin.

No, seriously, though; I only buy myself Tenacious resin on special occasions, but I’m always fascinated by the overall quality of models printed in the resin.

On top of being extremely detailed, which is basically a given for resins on this list, Siraya Tech Tenacious resin also provides a decent amount of strength and durability for prints. While this doesn’t seem super important for miniature prints, strength is always something nice to have, especially if you’re like me and tend to drop everything.

So if you’ve got a little extra dough in your 3D printing budget this month, definitely give Siraya Tech Tenacious resin a try. You won’t regret it!

Check Latest Price

4. Anycubic Water-Wash Resin+ (Easiest to Use)Another option from Anycubic is their Water-Wash Resin+. This resin is meant for being printed on an 8K pixel resolution machine, like the Phrozen Sonic Mini 8K, but it also works on printers of lower resolutions, like the Anycubic Photon Mono.

The 8K element of the resin obviously means it’s exceptional when it comes to the detail on prints. But that’s not the only thing going for this resin; it’s also water washable. This means you can use plain tap water to wash prints once they’re done instead of having to use a difficult chemical like acetone or alcohol.

While this doesn’t seem super useful, it makes the post-printing process so much quicker because you don’t have to worry about conserving how much solvent you use because water is free (basically).

So, if you want a solid resin for printing miniatures that are amazing with detail and make your life 100 times easier, try out Anycubic Water-Wash Resin+!

Get Discount (Official Store)

Check Latest Price

5. Phrozen Aqua 8K (Best Print Quality)Next, Phrozen, one of the leading manufacturers of 8K resin printers, has made a resin designed specifically for being printed in 8K resolution.

Phrozen Aqua 8K is easily the best resin on this list when it comes to print quality. This likely comes from the fact that the manufacturer, Phrozen, knows exactly what 8K printers need because they make them.

The detail of resin prints made in Phrozen Aqua 8K resin is actually insane, though! Just check out these prints!

Sadly, though, in an effort to make the resin as detail-maximizing as possible, the resin isn’t water-washable. As such, you’ll have to get your hands dirty with a solvent like acetone or isopropyl alcohol to properly wash prints.

But, overall, this resin is one of the highest-quality resins I’ve ever seen, and I strongly recommend it for anyone looking to maximize the detail of their miniatures!

Check Official Website

Check Latest Price

6. Elegoo Water Washable 8KElegoo strikes again on this list with their Water Washable 8K resin. This resin is very similar to their standard 8K resin, which I already went over. But, as the name of the product suggests, you can wash parts made of this resin with water instead of having to deal with a toxic solvent chemical like acetone or IPA.

This resin is very similar to their standard 8K resin, which I already went over. But, as the name of the product suggests, you can wash parts made of this resin with water instead of having to deal with a toxic solvent chemical like acetone or IPA.

This resin is optimized for printing in 8K pixel resolution, so detail is guaranteed for prints!

But you will have to watch out when printing miniatures because water-washable resins, like this one, are known to have negative effects on the strength of parts, especially when they’re small. Don’t worry, though, because you can prevent this from happening by increasing the layer exposure time in your slicer to ensure all resin prints come out decently strong.

Sadly, Elegoo Water Washable 8K resin only comes in one color, but Elegoo will probably come out with more as 8K resin printing gets more popular. And, like with the other 8K resins, don’t worry if you’re using a 4K resolution printer because these resins will still work well!

Get Discount (Official Store)

Check Latest Price

7. Elegoo ABS-Like

Elegoo ABS-Like Lastly, we’ve got another option from Elegoo: their ABS-like resin. As you probably could tell by the name, this resin was developed to allow you to capture the benefits of ABS filament but for LCD 3D printing instead of FDM.

The main reason you should use Elegoo ABS-Like resin is when you want to print detailed models, such as miniatures, with a decent amount of strength and durability.

First off, Elegoo ABS-like resin is a lot stronger than your average 3D printing resin, with parts printed in the resin having a proven tensile strength of up to 52 MPa. This is a lot higher than most detail-focused 3D printing resins, which usually have a tensile strength under 30 MPa.

Additionally, because this resin was made to have similar properties to ABS, it’s also very temperature resistant. Elegoo says parts made in this filament work in temperatures up to 100 °C. Personally, I’ve only used parts out of this resin in hot outdoor temperatures (~35 °C), but it’s always good to have a high-temperature resistance!

Source: 3DPrintingProAlso, Elegoo ABS-like resin is surprisingly very inexpensive, but I guess this makes sense because ABS is one of the least expensive plastics on the planet. And the resin is also available in a handful of colors, including white, baby blue, yellow, red, clear green, mint green, black, and more.

And the resin is also available in a handful of colors, including white, baby blue, yellow, red, clear green, mint green, black, and more.

But if the color you want to print a model in isn’t included on the list of available colors, don’t worry because Elegoo ABS-Like resin is very easy to paint, according to reviews.

The resin should also work well for miniatures because Elegoo has reported that this material has very low shrinking, meaning your prints will be very accurate. This resin is also known to respond well to curing, which stems from the ABS-like properties of the material.

Get Discount (Official Store)

Check Latest Price

What is Resin?

Source: Uncle JessyResin is the printing material for resin printers, also known as LCD or DLP 3D printers. Just like FDM 3D printers require filament, LCD/DLP printers require resin to make 3D prints

Resin is a liquid plastic-y material that’s the juice of a resin 3D printer. Resin is poured into a VAT, which is a tub on resin printers used to store the liquid before it’s solidified by the laser.

Resin is poured into a VAT, which is a tub on resin printers used to store the liquid before it’s solidified by the laser.

Resin comes in many different variations and can vary depending on the specific plastic material, resolution, durability, paintability, washing and UV light curing process, and more!

Printing Resin Miniatures

If you want to print miniatures, whether it be War Hammer characters or D&D figurines, you’ll want to make sure you’re maximizing the amount of detail in your prints.

The best way to do this is by using a resin 3D printer with a high-resolution LCD. That’s because the resolution, measured in pixels, of the LCD on a resin printer, controls the precision of the laser. As such, the higher the resolution of the LCD, the higher the quality of your prints and the more detail they can have.

Most resin 3D printers today have 4K resolutions, but some, like the Phrozen Sonic Mini 8K, have 8K resolutions, which can make even more detailed 3D prints. You can check out our article about the best resin 3D printers and best 3D printers for miniatures specifically to find a machine that can output your desired level of detail for miniatures.

You can check out our article about the best resin 3D printers and best 3D printers for miniatures specifically to find a machine that can output your desired level of detail for miniatures.

On top of having a high-resolution 3D printer, you’ll also want a high-resolution resin. Moreover, resins are optimized for being printed at different resolutions, so an 8K resin will print best on an 8K 3D printer, yielding more detail than a 4K resin on an 8K printer or a 4K resin on a 4K printer.

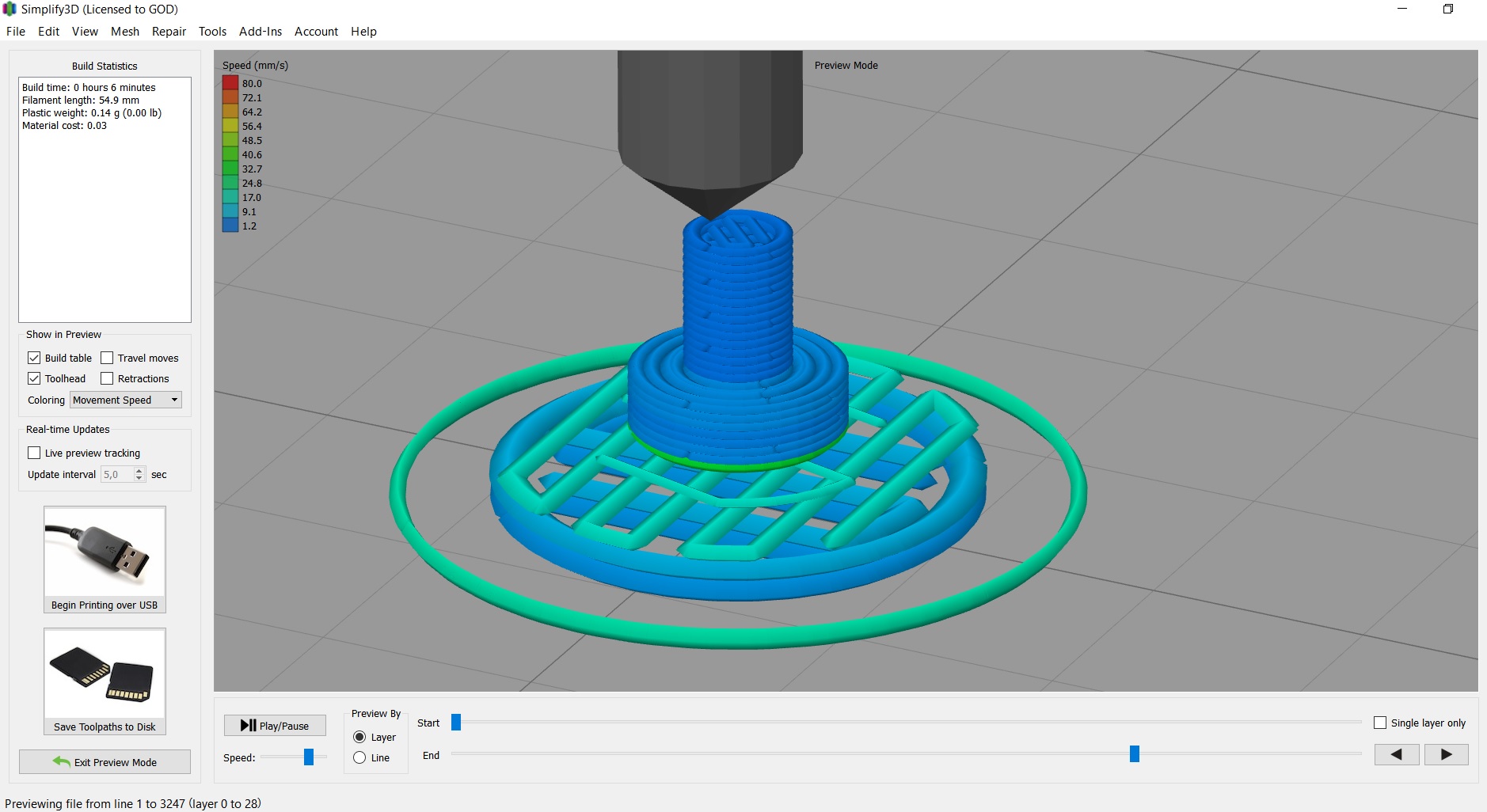

Lastly, you should fine-tune the slicer settings for your resin 3D printer. While slicer settings are less adjustable than with FDM 3D printers (e.g. Ender 3), they’re still a great tool you can use to improve the quality of your prints and maximize the detail in your miniature 3D prints.

What Type of Resin is Best for Printing Miniatures?

The best type of resin for 3D printing miniature 3D models is high-resolution resin. That’s because these resins are optimized for high-resolution printing, meaning they can handle a higher level of detail on prints than normal resins.

You can find a high-resolution resin by looking at the pixel resolution listed by the manufacturer (higher is better). Additionally, terminology like “maximum detail” or “miniature” typically indicates a resin is better for printing miniatures because it can handle more detail.

How Long is the Curing for Resin Miniatures?

Source: MiniacCuring is an important step for any resin 3D print because it solidifies any remaining resin on a model, which can perfect the detail on a print. And the curing process differs in how long you leave the 3D print in the curing chamber (UV light).

Because miniatures are small in volume, they require less curing time than a normal-size 3D print. I like to cure my resin miniatures for 2 minutes. But if I see any uncured plastic still on the model, I’ll stick the model back under the UV lamp for another minute so that it’s fully cured.

Check out our article on the best wash and cure stations here.

Considerations for Miniature Resin

Resins are inherently complicated products with many different properties and features. Below, I’ve gone over some important elements to consider when looking at a resin for printing miniatures:

Resolution

The most important factor for a resin meant for printing miniatures is the resolution of the resin.

Most resins have a listed resolution, such as 4K or 8K. The higher the resolution of your resin, the better your prints will come out.

But it’s important to note that you should try to get a resin with a resolution that matches the maximum resolution of your resin 3D printer. That’s because a “4K resin” means that the liquid resin is optimized and can handle 4K printing.

For example, I use an Elegoo Mars 3, which has a 4K resolution LCD screen. As such, I make sure to get a resin with a 4K resolution so that my miniature prints turn out best!

Durability

While strength for miniature prints doesn’t typically matter, it’s always a good thing to have.

As such, you should look at the durability of a resin. Most resin manufacturers don’t state the tensile strength of their resins, but you can check the reviews to see how strong users’ prints turn out.

Paintability

Next, you should consider the paintability of a resin because not all resins are as easy to paint as others.

This mainly applies if you plan on painting your resin 3D prints because, if you don’t, then the paintability of a resin doesn’t matter.

I like to look at the reviews for a resin to determine how easy it is to paint, and I suggest you do the same!

Curing

If you’ve used a resin printer before, then you know that washing and curing are everything for achieving high-quality 3D prints.

Different resins require different processes for washing and curing. Some can be washed in tap water, while others require acetone or isopropyl alcohol. What liquids work for washing a specific resin print is almost always listed on the selling site for the resin by the manufacturer, so check that!

As for curing, some resins are easier to cure than others, and some also cure better than others. You can check the suggested curing time on the resin manufacturer’s website. I also like to look at the reviews to see the quality of cured prints from different users.

Speed

Looking at how fast you can print a certain resin is also super important. That’s because not all resins perform well at fast print speeds.

Usually, the manufacturer of a resin will list the recommended print speed for a specific resin, so you can always check that for comparisons. But if a manufacturer doesn’t provide this information, you can also check the reviews for the resin!

Value

Lastly, you should consider the value of any resin you buy. Resins, especially those catered towards printing miniatures, can get somewhat pricey, so in the interest of your wallet, you should make sure you’re getting a good bang for your buck.

If you’re looking for a resin for miniatures that has the most value, the Standard resin from Anycubic is perfect!

Conclusion

While many factors go into the print quality of resin 3D printed miniatures, one of the most important ones is the resin material.

If you’re printing miniatures, you’ll want a resin that’s optimized for high-resolution printing, as this will maximize the detail in your 3D model.

My favorite resin for printing miniatures is the Phrozen Aqua 8K, as you can use it on an 8K resin 3D printer, like the Phrozen Sonic Mini 8K. It also works on 4K and lower-resolution printers, providing tons of detail for prints!

Now, if you’d rather have an easier post-printing experience, then I’d suggest using Anycubic’s Water-Wash Resin+. With this resin, you can use water, rather than acetone or IPA, to wash models before curing them.

And, lastly, if you’re on a budget, then check out Anycubic’s Standard resin, as it performs well with detailed 3D models and won’t break the bank!

Enjoy!

Related Articles:

- Best Resin 3D Printing Service

- Is UV Resin Toxic?

- Best 3D Printer for Jewelry

- Largest Resin 3D Printers

Types of resins for photopolymer 3D printer, characteristics, application

In recent years, the introduction of photopolymer printers in various areas of production is gaining more and more popularity. In order for the printer to reach its full potential, it is necessary to choose the right material - photopolymer resin.

Now there is a wide variety of resins designed to solve a wide range of problems. Sometimes it can be difficult not to get confused in such a variety of materials. It is conditionally possible to divide photopolymer resins into several types - standard, engineering, dental, jewelry (burned).

Standard resins

Standard resins are well suited for making decorative models. They are strong and hard enough for making miniatures, master models, paintable figures or mock-ups, but their strength is usually not strong enough for functional products.

But standard resins are different from each other. Some of them can be washed not with alcohol, but with plain water, there are transparent types of resins or, for example, with a wide color palette.

Standard

Compared to other types of photopolymers, standard resins have a richer color palette. The main advantages are an inexpensive price, good detail and fast curing time.

ESUN Standard

A good resin for professionals and beginners who are just getting acquainted with photopolymer printing. The advantages of ESUN Standard are a large palette of colors, no smell and fast printing speed.

ESUN Standard is suitable for printing decorative models or any other product that will not be subjected to heavy physical exertion.

Print Technology: DLP/LCD/LED

UV wavelength: 395-405nm (transparent 395-410nm)

Shore hardness: 80-82 D

Impact strength according to Izod: 18 - 40 J/m

Bending strength: 46-72 Mpa

Modulus of elasticity: 1000 - 1400 MPa

Elongation at break: 28-35%

Exposure time per layer (recommended): 5-10 sec.

Color palette: white, black, gray, red, blue, yellow, green, light green, flesh, orange, transparent.

Volume: 0. 5 kg, 1 liter.

Deadpool figurine

Bust of a military man

Moving castle, miniature

Users note good detailing, a good balance of strength and light elasticity, and excellent adhesion to the platform. The print time of the layer corresponds to the one declared by the manufacturer (5-10s) even on 3D printers with a weak UV source.

Of the minuses - sometimes the resin can be difficult to stir and a fine suspension comes across. This does not reduce print quality, but it does make me nervous. The gray color is slightly transparent, many users would like the color to be more “dense”.

ESUN eResin-PLA

eResin-PLA is based on PLA monomer, familiar to many from FDM printing. This makes the resin environmentally friendly and the finished product very tough and scratch resistant.

Resin is well suited for decorative items, master models or functional models without load.

Print Technology: DLP/LCD/LED

UV wavelength: 395-405nm

Shore hardness: 75-80 D

Elongation at break: 20-50%

Modulus of elasticity: 600 - 800 MPa

Impact strength according to Izod: 15 - 32 J/m

Tensile strength: 35-50 Mpa

Exposure time per layer (recommended): 15-20 sec.

Color palette: white, black, gray, red, blue, yellow, green, light green, flesh, orange, transparent.

Volume: 1 liter

Shoe model

Figurine of a cartoon girl

Play miniature

Non-standard focusing rings for lens

Phrozen Aqua 4K

The Phrozen Aqua 4K is specifically designed to unlock the full potential of 4k resolution photopolymer printers. A pleasant bonus is the almost complete absence of shrinkage.

Resin is well suited for precision printing of decorative patterns. The manufacturer specifies that all properties of the resin are revealed when using printers with high resolution, such as Sonic Mini 4K / Sonic Mighty 4K.

Print Technology: DLP/LCD/LED

UV wavelength: 395-405nm

Shore hardness: 77 D

Color palette: gray, ivory.

Volume: 1 kg

Armor printed in gray resin Phrozen Aqua 4K

Bust Predator

Figurine war with a bear, to demonstrate the capabilities of Phrozen Aqua 4K

Phrozen Beige Low Irritation

This resin is hypoallergenic. Phrozen Beige Low-Irritation has passed the ISO-10993 10 test, which means that the resin does not contain heavy metals and the finished models can directly contact the human body.

The resin can be used in dentistry or for products that will come into contact with the skin.

Print Technology: DLP/LCD/LED

UV wavelength: 395-405nm

Color palette: beige

Volume: 0. 5 kg

Decorative figurine

Jaw

ESUN Precession Model

Resin is designed for fast printing of high-precision models. In addition, finished products are tough and can withstand heat up to 80 degrees.

ESUN Precession Model is a good choice for models that need high detail.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 85 D

Elongation at break: 12.1%

Bending strength: 77 Mpa

Tensile strength: 335-410 Mpa

Color palette: red.

Volume: 1 liter

DC Universe Riddler's Head

Miniature model of ICE

Clear resins

Clear resins are present in other photopolymer ranges, but may become yellow or cloudy over time. If optical transparency without yellowness is important in the finished model, then you should pay attention to special polymers.

Phrozen SC-801 Clear

The main advantage of Phrozen SC-801 Clear is its optical transparency. Models made from Phrozen SC-801 Clear will not become hazy or yellow during post-curing or use.

This photopolymer is suitable for the manufacture of durable and accurate models for which optical transparency is important.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 70 D

Color palette: transparent

Volume: 1 liter

Material transparency model

Left product made of Phrozen SC-801 Clear, right RESINMAGIC3D High-Grade Clear

Figure printed with Phrozen SC-801 Clear

Miniature bottles printed for a articulated doll. Left made from Phrozen SC-801 Clear, right made from another polymer.

Washable

Finished models made on a photopolymer printer are recommended to be washed from photopolymer residues with alcohol. There are situations where this is not acceptable, such as when the printer is being used in schools. For such cases, manufacturers have created the Washable line. Washable are resins that can be washed with plain water.

ESUN Water Washable

ESUN Water Washable is as strong and precise as ESUN Standard resins. The only difference is that the finished product can be washed not with alcohol, but with plain water.

ESUN Water Washable is well suited for printing at home or in educational institutions due to its low toxicity and odorlessness.

Print Technology: DLP/LCD/LED

UV wavelength: 395-410 nm

Shore hardness: 76 D

Tensile strength: 68 MPa

Elongation at break: 5-10%

Bending strength: 45-70 MPa

Modulus of elasticity in bending: 900-1400 MPa

Izod impact strength: 18-39 J/m

Color palette: white, transparent, flesh, gray, black.

Volume: 0. 5 kg

Rings and pendant printed in clear ESUN Water Washable

Fox figurine

Phrozen Water Washable

Phrozen Water Washable compares favorably with other water-washable resins in terms of strength, durability, and short flash-over time.

The resin is suitable for making prototypes and other models at home and in educational institutions where it is undesirable to use strong-smelling alcohols for washing.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 80 D

Color palette: gray, black.

Volume: 1 kg

Bust made from Phrozen Water Washable

Alien printed from Phrozen Water Washable

Bust of Spiderman

Wanhao Water washable

It is a resin with high resolution and good hardness. Wanhao Water washable has very little shrinkage and a wide range of colors.

Resin is well suited for printing master models and decorative models when it is not possible to use alcohol to wash the final product.

Print Technology: DLP/LCD/LED

UV wavelength: 395~420nm

Shore hardness: 75D

Color palette: white, transparent, black, gray

Volume: 0.5 kg, 1 kg

Han Solo in transparent Wanhao Water washable

Test model of transparent Wanhao Water washable

Test patterns in different colors Wanhao Water washable

Engineering

Previously, photopolymer printers were mainly used for making master models and products with high accuracy. Now they face a wider range of tasks. It is much more convenient to make a ready-made, functional model right away. For this, engineering photopolymer resins with improved characteristics have been developed. Depending on the application required, they can be harder, heat resistant and durable than standard resins.

Reinforced

These are polymers with improved characteristics - for example, high heat resistance or impact strength. They can be used to produce functional prototypes, engineering models, etc.

Phrozen TR250-LV

The Phrozen TR250-LV has been specifically designed to meet engineering challenges. In addition to high strength and hardness, the resin has increased heat resistance and can withstand heating up to 150 degrees.

The Phrozen TR250-LV is suitable for the production of models for subsequent thermoforming or products that require increased heat resistance.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 79D

Tensile strength 25 MPa

Izod impact strength: 6.31 kJ/m2

Color palette: gray

Volume: 1 kg

Jaw Layout

Orc Bust

Phrozen ABS-like

This resin is similar in characteristics to ABS plastic, familiar to many from FDM printing. There is a white color in the palette, this allows, if necessary, to easily paint the finished product.

Phrozen ABS-like is suitable for printing functional models and prototypes.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 79D

Izod Impact Strength: 2.32 kJ/m2

Color palette: gray, white

Volume: 1 kg

Skull Model

Weapons for miniature figures

1/4 mask

Phrozen Rock-Black Stiff

When creating Rock-Black Stiff, emphasis was placed on strength, wear resistance and heat resistance (up to 97 degrees). Models are strong and slightly flexible to withstand shock loads.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 81D

Elongation at break: 4%

Izod impact strength: 2. 68 kJ/m2

Color palette: black

Volume: 1 kg

Elf bust

Bust printed in Phrozen Rock-Black Stiff

Phrozen Nylon Green Tough

Photopolymer is an analogue of nylon. Nylon is a very strong and wear-resistant material, familiar to many from FDM printing. Products are very durable and resistant to stress. Finished models printed in Nylon Green Tough can be folded.

Suitable for the manufacture of finished products or functional prototypes.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 68D

Elongation at break: 130%

Tensile strength: 19MPa

Izod impact strength: 23.79 kJ/m2

Color palette: green

Volume: 1 kg

Phrozen Nylon Green Tough Vase

Test model

Spectacle frame

Phrozen TR300 Ultra-High Temp

TR300 Ultra-High Temp allows you to quickly produce durable, shock and heat resistant products (up to 160 degrees). The photopolymer compares favorably with its competitors by its short exposure time (on 3D printers of the Phrozen Sonic series, 1.3 seconds per layer).

Phrozen TR300 is suitable for the manufacture of heat-resistant and durable products. For example, it can be a model for subsequent thermoforming or manufacturing an industrial layout.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 80D

Tensile strength: 32MPa

Izod impact strength: 8 kJ/m2

Elongation at break: 2%

Color palette: gray

Volume: 1 kg

Phrozen Onyx Rigid Pro410

The main properties of models made from Onyx Rigid Pro410 are amazing detailing and durability. The resin was developed in partnership with Henkel and is intended primarily for home workshops.

Photopolymer is perfect for models with an abundance of small details that need high detail. Or for engineering/functional models where high accuracy and strength are important.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Color Palette: Black

Volume: 1 kg

Tablet stand

Fruit bowl

Wall mounted spice holder

Wall hanger

Flexible

Products made from such resins will look like silicone or rubber. Such photopolymers make it possible to obtain flexible and durable functional products resistant to tearing.

Phrozen Biege Flex

This is a resin designed for products that need to be strong and slightly flexible. Phrozen Biege Flex is suitable for functional models that need some flexibility.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 65D

Tensile strength: 40 MPa

Modulus of elasticity: 192 MPa

Color palette: beige

Volume: 0. 5 kg

Bust of Harley Quinn

Miniature from Phrozen Biege Flex

Functional carabiner

HARZ Labs Industrial Flex

By its properties, finished products from HARZ Labs Industrial Flex resemble polyurethane. Products from it are elastic and very durable.

HARZ Labs Industrial Flex is suitable for the manufacture of gaskets or any other model where softness and tensile strength are important.

Industrial Flex can be used as an additive for other HARZ Labs resins. This allows you to increase the flexibility and strength of the finished model. Depending on the resin ratio, different degrees of flexibility can be achieved in the finished product.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 63D

Shrinkage: 0.5%

Elongation at break: 103%

Tensile strength: 13 N/mm2

Color palette: transparent

Volume: 0. 5kg 1kg

Various gaskets printed from HARZ Labs Industrial Flex

ESUN Flex

Flexible and durable material with good wear resistance. Good tear resistance and accuracy make ESUN Flex suitable for engineering models.

For example, products that must be strong and flexible at the same time. These can be engineering prototypes or functional models.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 85-90 A

Shrinkage: 6.9%

Elongation at break: 100-150%

Bending strength: 77 Mpa

Tensile strength: 390-320 kN-m

Color palette: transparent yellow

Volume: 0.5 kg

Test model from ESUN Flex

Dental resins

From the very beginning of its existence, photopolymer printers have taken the place of indispensable assistants in the dental industry, therefore, in the assortment of many companies that manufacture photopolymer resins, there are materials intended for use by dentists.

Special photopolymers

These are special polymers that are focused on solving specific problems. No one forbids using them for other than their intended purpose, but they fully reveal their potential precisely in the task for which they were created.

Harz Labs Dental Soft

Dental Soft was created as a material to simulate gums in demonstration models. The finished print is pink in color and has high strength and chemical resistance. Despite its flexibility, the finished model will be resistant to deformation. Harz Labs Dental Soft is certified for medical use.

The material is suitable for gum printing or other medical applications.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 87-90D

Shrinkage: <0.5%

Elongation at break: 68%

Tensile strength: 1.2 N/mm2

Color palette: pink

Volume: 0.5 kg, 1 kg

Gums from Harz Labs Dental Soft

Gums from Harz Labs Dental Soft

NextDent Gingiva Mask

Another gum simulation resin from NextDent. Gingiva Mask is a flexible and durable resin that blends beautifully with model material.

The resin is suitable for various models in the dental industry.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 60 - 75 A

Elongation at break: 40 - 60%

Color palette: pink

Volume: 1 kg

Gingiva made from NextDent Gingiva Mask

Part of the gum made from NextDent Gingiva Mask

Jaw Demo with NextDent Gingiva Mask Inserts

Harz Labs Dental Clear

Products from this resin are durable and hard. The main feature is the resin is transparent, without turbidity and yellowness. Harz Labs Dental Clear is certified for medical use.

This photopolymer is suitable for the manufacture of surgical templates, demonstration models and even aligners.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 90-92D

Elongation at break: 4-6%

Shrinkage: less than 0.5%

Color palette: transparent

Volume: 0.5 kg, 1 kg

Jaw Demo Model

Piece of jaw printed from Harz Labs Dental Clear

Dental Yellow Clear

Very similar in its properties to Harz Labs Dental Clear - just as strong and hard. The only difference is that the color of the resin is not crystal clear, but yellow. The resin is certified for use in medicine.

Dental Yellow Clear is suitable for making aligners or demonstration models.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 90-92D

Elongation at break: 4-6%

Shrinkage: less than 0.5%

Color palette: transparent yellow

Volume: 0. 5 kg, 1 kg

Gingiva pad made of Dental Yellow Clear

Jaw models

Dental Yellow Clear Demonstration Product

Burnout

In addition to specialized resins in dentistry, low-ash burnable or smelted materials are needed for direct casting.

Before casting, be sure to read the instructions from the manufacturer. Each resin has its own burnout cycle in order to obtain a good casting quality.

ESUN Castable Dental

ESUN Castable is designed for direct casting in dentistry. Finished products are smooth and hard. When burning, the ash content is practically absent.

High precision allows ESUN Castable to be used for crowns, bridges and other castings.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 80D

Elongation at break: 11-20%

Bending strength: 49-58 Mpa

Impact strength according to Izod: 44 - 49 J/m

Color palette: green

Volume: 1 kg

Crowns printed from ES

ESUN Castable jaw

Example of printed and molded model

Phrozen Wax-like Dental Green

Wax-like Dental Green is a waxy resin with low shrinkage and zero ash content. Due to the low shrinkage, the finished products are very accurate, and the matte surface will help to see even small imperfections.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Color palette: green

Volume: 0.5 kg

Ring made from Phrozen Wax-like Dental Green

HARZ Labs Dental Cast Cherry

HARZ Labs Dental Cast Cherry was developed for direct casting of dental products. With the correct burnout cycle, it is possible to achieve almost zero ash content. The photopolymer is certified for medical use.

Dental Cast Cherry is suitable for casting metal or ceramic crowns and bridges.

The manufacturer recommends the use of phosphate-based phytomass, because they can be used at high temperatures, which are required for high-quality burning of the model.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 40-50D

Shrinkage: less than 1%

Color palette: red

Volume: 1 kg

Crown models printed with Dental Cast Cherry

Cast crowns

NextDent Cast

It is an easy-to-burn-out resin with zero ash content. Designed for the manufacture of burn-out dental models.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 80-90D:

Color palette: red

Volume: 1 kg

Crowns made from NextDent Cast

Demo Model

DETAX Freeprint cast UV

High precision resin designed for fast manufacturing of dental products. Finished products can be used for direct casting. DETAX Freeprint cast UV burns out ashless even with large casting volumes. For molding, it is recommended to use phosphate-based masses.

Print Technology: DLP/LCD/LED

UV wavelength: 378-388 nm

Color palette: red

Volume: 1 kg

Overlay made of DETAX Freeprint cast UV

Crowns made from DETAX Freeprint cast UV

Burnout resins

In addition to dentistry, 3D printers have firmly established themselves in the jewelry industry. 3D printing allows you to create complex products much faster than classical methods (manual wax cutting, CNC machine). Burnt-out resins were created especially for jewelers.

ESUN Castable for jewelers

Photopolymer specially designed for printing and casting small models with high detail. Products from ESUN Castable are smooth, and almost zero ash content makes it easy to get the desired product in the metal.

The resin is suitable for printing jewelry - rings, pendants, earrings and for other burn-out models, in which accuracy and perfect surface quality are important.

Print Technology: DLP/LCD/LED

UV wavelength: 395-405nm

Shore hardness: 60 D

Color palette: yellow, green

Volume: 1 kg

Ring printed from ESUN Castable

Ring from ESUN Castable

Phrozen Wax-like Castable Violet

Waxy polymer with low shrinkage and zero ash content. Products made of Phrozen Wax-like Castable Violet have a nice matte surface, which will show the slightest imperfections.

Wax-like Castable is suitable for making any castable models.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Color palette: purple

Volume: 0.5 kg

Ring printed in Wax-like Castable and finished casting

Wax-like Castable Openwork Rings and Precast Castings

Wax-like Castable pendant and finished product

HARZ Labs Jewelry J-Cast

This is a photopolymer designed for the manufacture of burn-out models for subsequent casting in metal. High precision, low shrinkage (less than 1%) and low ash content (less than 0.1%) make it possible to print even very small products without distortion.

HARZ Labs Jewelry J-Cast is suitable for printing jewelry. Due to its high thermoplasticity, the photopolymer can be burned out over a wide temperature range. The result is a product with a smooth surface.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shrinkage: less than 1%

Color palette: blue

Volume: 1 kg

Ring molded with a model made from HARZ Labs Jewelry J-Cast

Totals

A wide variety of photopolymer materials make it possible to make a 3D printer an almost universal tool for the production of products of various directions. 3D printing not only helps to shorten the production chain in large enterprises, but also becomes an indispensable tool for small home workshops.

When working with photopolymer resins, do not forget about safety precautions.

-

Try to print in a well-ventilated area.

-

Read the information about the resin on the manufacturer's website, important nuances may be indicated there. For example, some resins cannot be immersed in isopropyl alcohol for a long time.

Choosing a liquid photopolymer for a 3D printer. Classification of materials for SLA/DLP 3D printing.

Contents:

- Introduction

- SLA Overview

- SLA standard resins

- Standard photopolymer resin - Standard

- Clear Photopolymer Resin - Clear

- Engineering photopolymer resins

- Rigid photopolymer resin - Tough (like ABS)

- Durable photopolymer resin - Durable (PP-like)

- Heat resistant photopolymer resin - Heat resistant

- Rubber-like photopolymer resin - Rubber-like (Elastic)

- Ceramic photopolymer resin - Ceramic filled (Hard)

- How to choose the right resin for your application

- Dental and medical SLA resins

- Medical Device Photopolymer Resin - Custom Medical Appliances (Class I Biocompatibility)

- Dental Long Term Biocompatible Resin (Class IIa Biocompatible)

- Class I biocompatibility vs Class IIa biocompatibility

- Cast SLA resins

- Cast resin for jewelry making

- Generalized rules

Hello everyone, Friends! With you 3DTool!

This article compares photopolymer resins using Formlabs SLA 3D printing products – standard standard

Catalog of photopolymer 3D printers

Photopolymers from FormLabs

Detailed review of the Formlabs Form 3 3D printer

Introduction

The stereolithography prints plastic parts with high resolution, good fine detail, and a smooth surface. Due to the variety of photopolymer resins available for SLA, this technology is used in many different industries:

-

"Standard" photopolymers are used for prototyping

-

Engineering photopolymers have certain mechanical and thermal properties

-

Dental and medical photopolymers have biocompatibility certificates.

-

Cast photopolymers have a zero ash content after burning.

SLA 3D printing resin overview

SLA uses a laser to cure a liquid photopolymer resin. This process is called photopolymerization. Various combinations of polymers and other additives that are part of the resin allow you to get different material properties.

The main advantages and limitations that are common to all resins in SLA 3D printing are:

Benefits:

Weaknesses:

Base Resins for SLA

Post-Processing SLA/DLP 3D Printing Article

Standard photopolymer resin - Standard

Standard resins produce parts with high stiffness, detail and a smooth surface. The low cost of resins, from $250 per liter, makes them ideal for prototypes.

The color of the resin also affects its properties. For example, in FormLabs products, gray resin is suitable for models with fine details, and white resin for parts that require the smoothest possible surface.

Benefits of using Standard resins:

Cons Standard:

Also included in the class of "Standard" photopolymer resins from FormLabs is the Color KIT - a set of special dyes and "Color Base" photopolymer resin for mixing and obtaining a variety of color solutions. This eliminates the need for painting parts after 3D printing.

FormLabs Engineering Photopolymer Resins

Engineering resins have a range of properties for injection molded plastics.

All engineering resins require additional UV curing, such as using the Form Cure, to achieve their maximum properties.

Tough photopolymer resin - Tough (similar to ABS)

Tough resin was developed for models that need to withstand high loads and be durable.

This material produces strong, shatter-resistant parts and functional prototypes such as snap-on housings.

Pros:

Cons:

Ideal for: functional prototypes, mechanical parts

Durable photopolymer resin - Durable

Durable resin is a wear-resistant and flexible material with mechanical properties similar to polypropylene.

Durable photopolymer produces models with a smooth glossy surface and high resistance to deformation.

Durable Resin is ideal for:

- Bushings and bearings;

- Various functional compounds

Pros:

Cons:

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

-

Low heat distortion temperature

-

Low flexural strength (lower than hard resin)

Ideal for: functional prototypes.

Refractory Photopolymer Resin - Formlabs High Temp Resin

The heat resistant resin is ideal for parts that require high temperature resistance and operate at high temperatures.

Formlabs High Temp Resin provides the highest melting point (HDT): 238°C at 0.45 MPa.

The resin should be used to print detailed, accurate prototypes with high heat resistance.

Pros:

Cons:

Flexible Resin

Rubber-like resin allows flexible parts to be made. This material has a low tensile strength and high elongation at break and is well suited for parts that will be bent or compressed.

It can also be used to add ergonomic features to multi-material assemblies such as: dies, wearable prototypes, handles, pads and grips.

Pros:

-

High flexibility (high elongation at break)

-

Low hardness (simulates 80A durometer rubber)

-

High impact resistance

Cons:

-

Doesn't have all the properties of real rubber

-

Requires extensive support structures

-

Material properties deteriorate over time as the part is exposed to ultraviolet radiation (sunlight)

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

Ideal for flexible prototyping.

Ceramic photopolymer resin - Rigid Resin

This resin is reinforced with glass, which provides very high rigidity and a polished surface. The polymer is very resistant to deformation and is excellent for 3D printing thin elements.

Ideal for: molds and tooling, jigs, manifolds, retainers, electrical and automotive fixture housings

Thermal management components printed with SLA ceramic (hard) resin. Image credit: Formlabs

How to choose the right resin for your application

The table below shows the main mechanical properties of photopolymers for SLA:

Source: Formlabs

Standard resin ( standart ) has high tensile strength but is very brittle (very low elongation at break) so it is not suitable for functional parts. The ability to create a good part surface makes it ideal for visual prototypes and art models.

durable ( durable ) resin has the highest impact strength and elongation at break of any other SLA material. Best suited for prototyping parts with moving parts and latches. It lacks, however, the strength of thermoplastic 3D printing materials such as SLA nylon.

tough ( tough ) resin is a compromise between the material properties of tough and standard resin. It has a high tensile strength, so it is best suited for rigid parts that require high hardness.

heat resistant resin ( heat resistant ) can withstand temperatures above 200 o C, but has poor impact strength and is even more brittle than standard resin.

ceramic ( ceramic reinforce ) resin has the highest tensile strength and flexural modulus, but is brittle (poor elongation at break and toughness). This resin is preferred for thin wall parts that require increased rigidity.

The graphs below compare the mechanical properties of the most common SLA materials visually:

Comparison chart for elongation at break and toughness for common SLA printing specifications and standard media. Image courtesy of Formlabs.

Stress-strain curves for conventional SLA technologies and standard materials. Image credit: Formlabs

Comparative chart of material properties of various technical resins. Image credit: Formlabs.

Dental and medical resins

Photopolymer resin for medical devices - Custom Medical Class 1 biocompatible resins can be used to make medical equipment such as surgical guides. Parts printed on this resin can be steam sterilized in an autoclave for direct use in the operating room.

Pros:

Cons:

- Moderate wear and tear resistance

Ideal for: Surgical aids and appliances

Dental Long Term Biocompatible Resin - Dental Long Term (Class 2A biocompatible)

1347

These resins are specially formulated for long term dental fixtures. Class 2A biocompatible resins can come into contact with the human body for up to a year.

High resistance to breakage and wear make this resin ideal for making rigid cotter pins or retainers.

Pros:

Cons:

-

High price

Ideal for: durable dental instruments, fracture and wear resistant medical parts, rigid cotter pins, retainers

What is the difference between class 1 and class 2a biocompatibility?

Class 1 biocompatibility rules apply to materials that are allowed to be used for:

-

non-invasive devices that come into contact with intact skin

-

devices for temporary use or short-term use in the mouth or ear canal or in the nasal cavity

-

reusable surgical instruments

Class 2a biocompatibility rules apply to materials that are allowed to be used for:

-

devices that come into contact with bodily fluids or open wounds

-

devices used to introduce substances into or remove substances from the human body

-

invasive short-term devices such as invasive surgical items

-

long-term implantable devices placed in the teeth

Photopolymer resins in SLA 3D printing for jewelers

Jewelry resins

This material allows you to print models with fine details and a smooth surface without leaving ash or residue after burning.