3D surface scanners

Best 3D Scanner - The Top 10 3D Scanners for 2023 [Reviews]

Much like a regular scanner, laser scanning 3D uses various methods to analyze a physical object and then relay that data to a computer to create digital 3D models. The 3D digitizer process might be automatic or users might need to complete the model to their requirements by using software. The aim is usually to get an accurate model to the right standard and format, ready for 3D printing, for virtual reality applications or other purposes.

Such scanners are used in many professional industries, but with advances in home 3D printing, there are now also a good variety of home options. They are sometimes called portable 3D scanners or handheld scanners if they’re designed as such. These allow you to easily scan small to medium-sized objects for 3D printing.

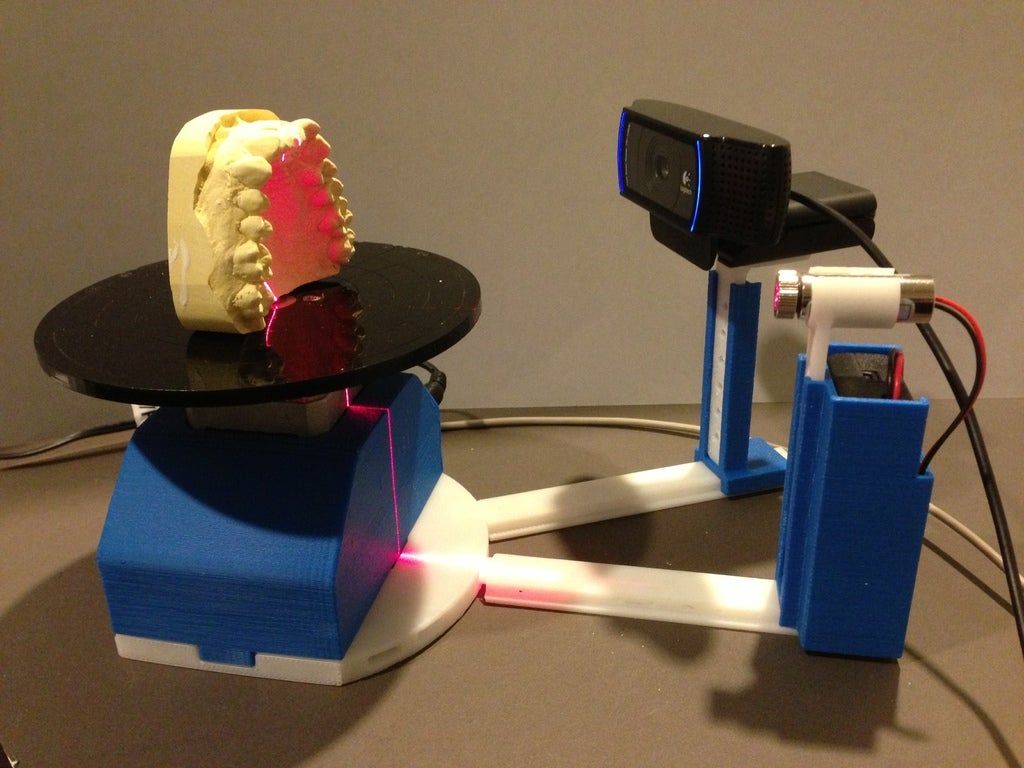

Some come completely assembled while others, like 3D printers themselves, you’ll have to put them together by yourself. The benefit for those that are good with that type of thing is it reduces the price and allows for easier upgrades and modifications.

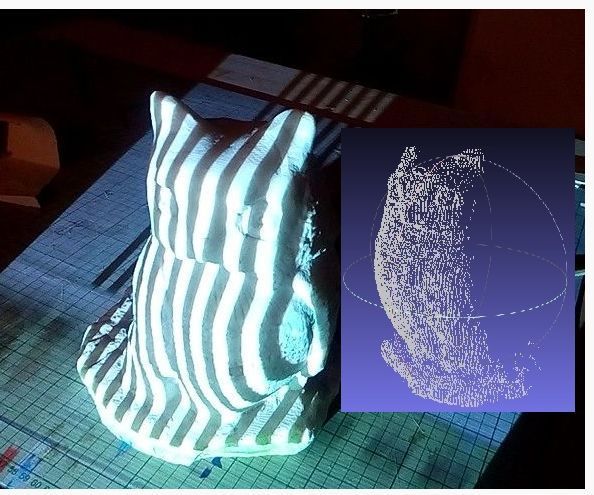

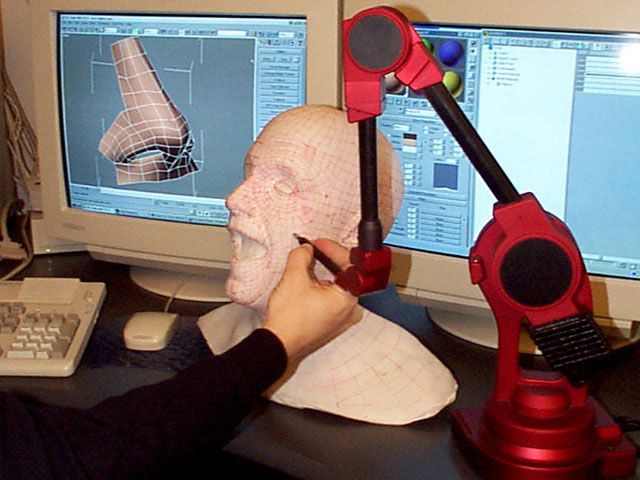

Scanning is typically done using laser triangulation or various forms of structured light to surround the object and measure its 3D dimensions or ‘geometry’. High-quality 3D scanner camera lenses also capture the color and surface texture of the object. Using accompanying or third-party software, the model can then be scaled up or down, or completely modified.

It’s never been easier to scan 3D objects!

How Do 3D Scanners Work?So, how do you scan 3D objects into a computer? Whether it’s on an industrial scale, at a small business, or on a desk at home, 3D scanners all share similar characteristics in the way they work.

The majority use laser and/or white light technology and cameras. The physical object is placed in a bed, tray, or suitable location. Electromagnetic light bounces off the object, measuring its circumference, full dimensions, and all its finer details.

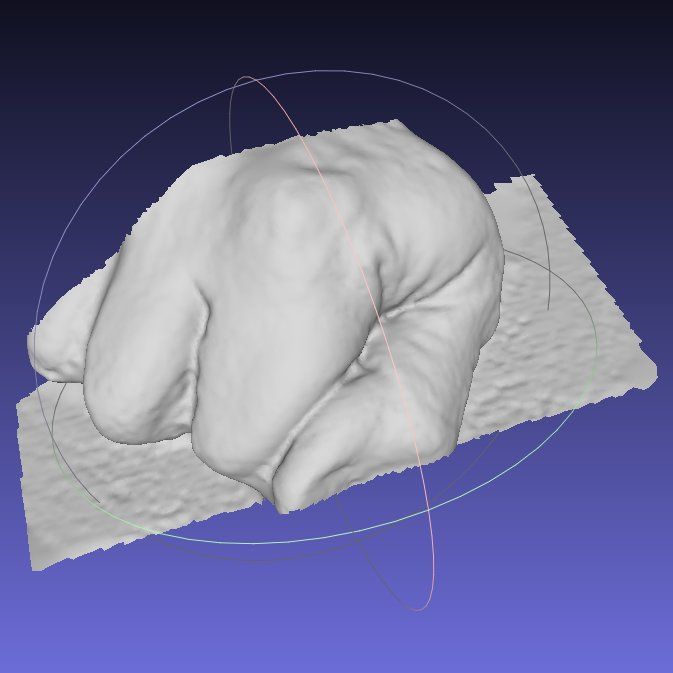

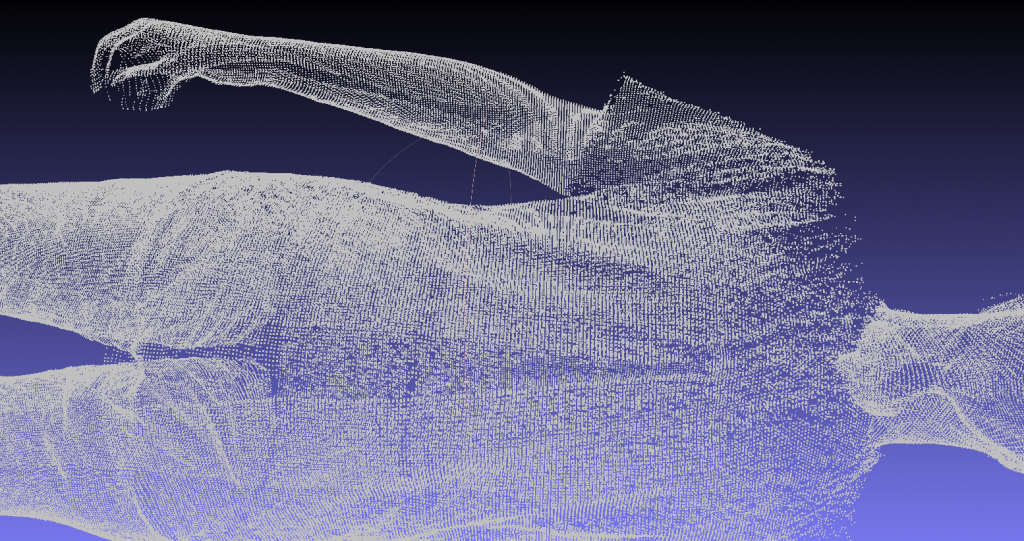

Depending on the scanner it may use multiple light sources, cameras, and other tech to aid this process. The collected data is called a point cloud, which refers to the number of points captured by the laser.

The more points collected the more accurate the scan. A high-resolution scanner can capture hundreds of thousands of points in seconds and reach millions overall. The whole process only takes a few minutes.

While the light tends to be a measure of the object’s geometry, HD cameras tend to capture the surface detail and color.

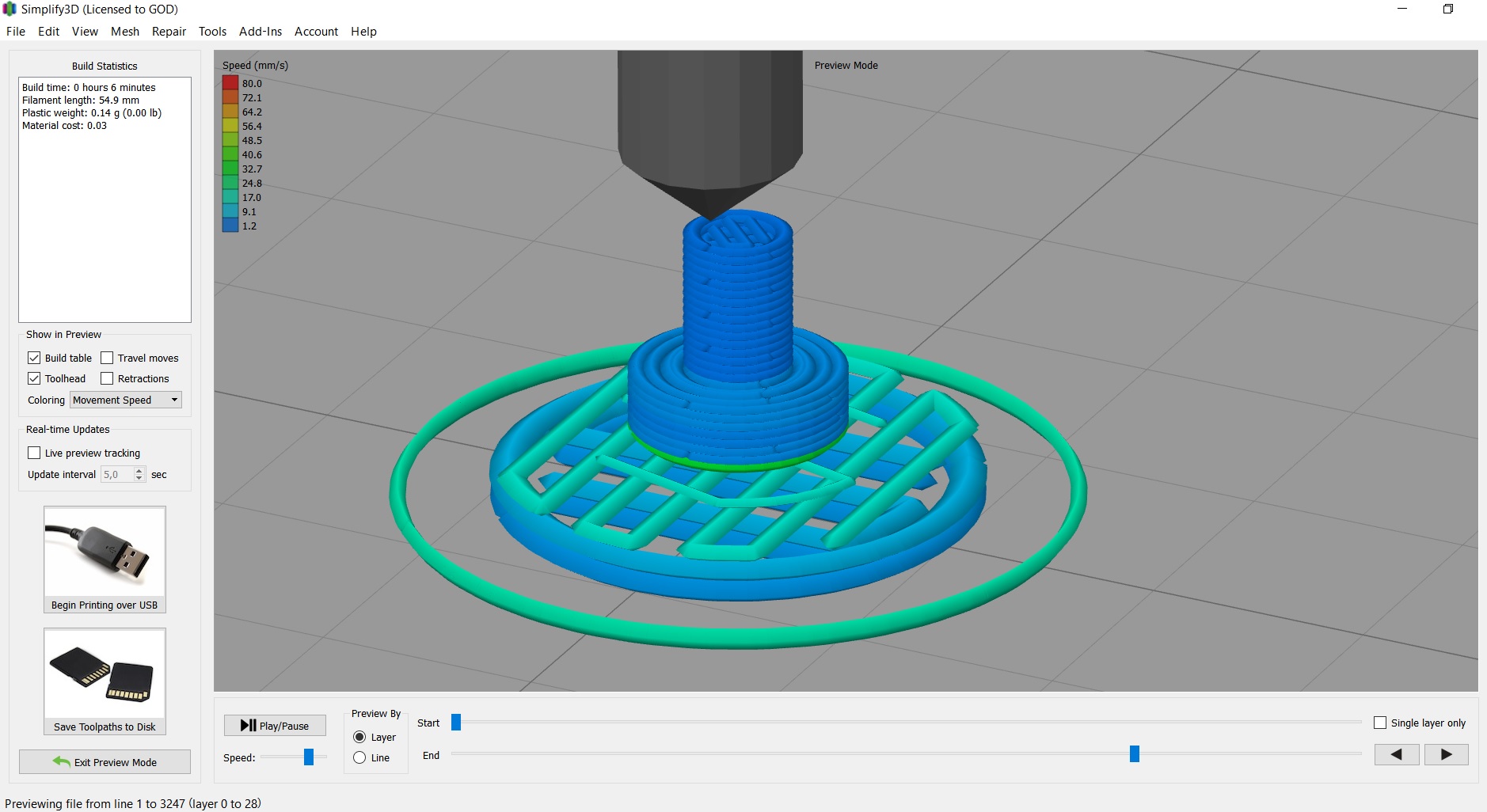

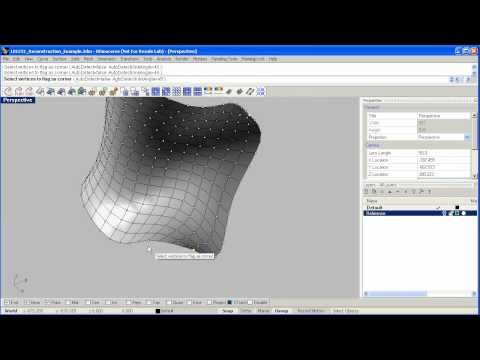

The data recorded can then be fed into a computer-aided design program or similar software for inspection and manipulation. E.g. if you’re planning to use it for 3D printing, the model might need scaling up or down, hollowing, have added support structures, be re-colored or have brightness/contrast changes, etc.

There are, of course, different types of 3D scanner and scanning technology. So, let’s take a closer look at each one:

So, let’s take a closer look at each one:

There are several 3D scanner types. Before making your decision check out the section below:

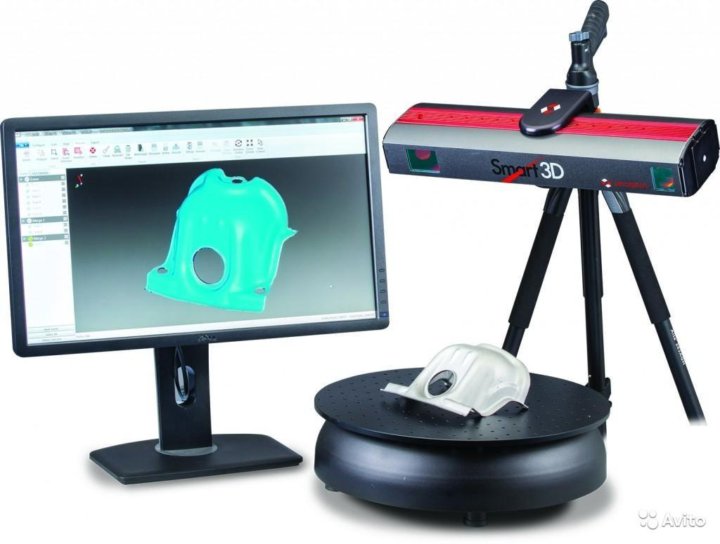

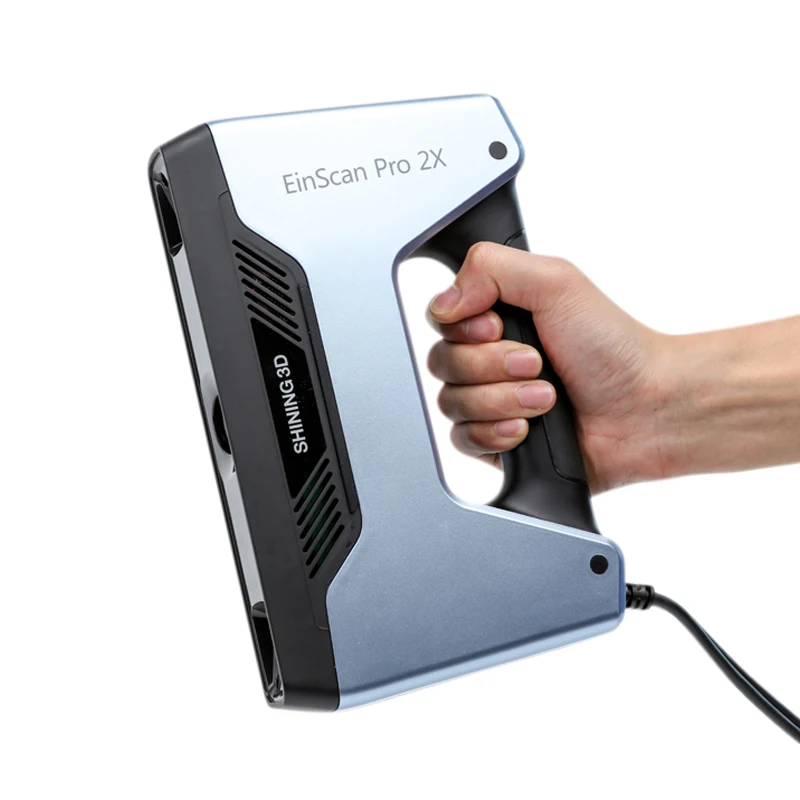

Handheld vs StationaryHandheld and stationary 3D scanners often use the same technology and can overlap in their functions. The difference lies mainly in the design.

A handheld scanner has a grip and lets the user move around the object themselves to capture it at every angle.

A stationary scanner has to be positioned in front of the object, which is typically placed on a rotating plate and captures it as it spins 360 degrees. The user may have to reposition the object several times to capture every angle.

Newer designs are becoming smaller and more easily portable.

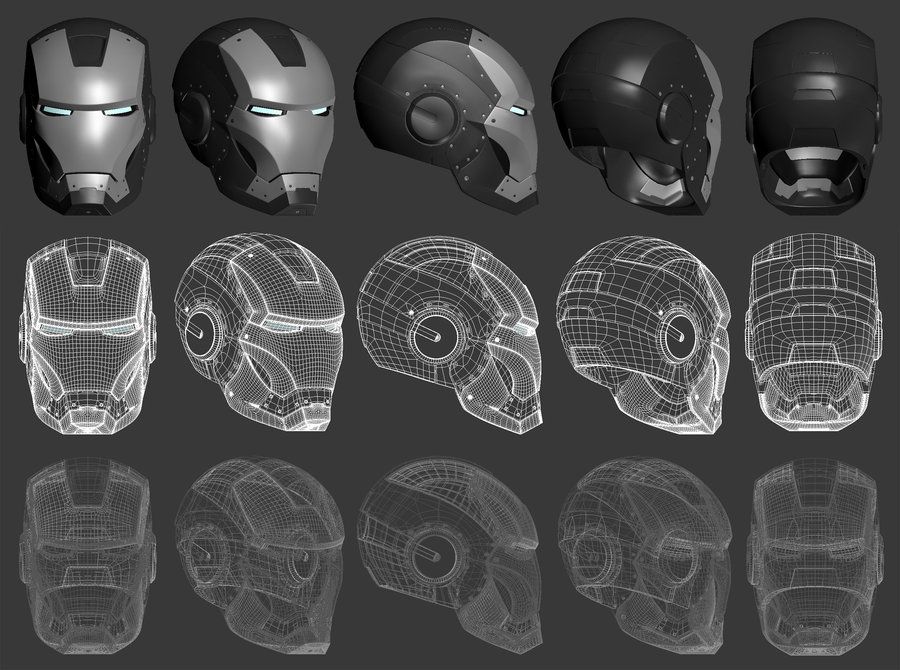

Laser TriangulationThe most common technology used in 3D scanning is laser trigonometric triangulation. It records millions of different points on the surface of the object to build an accurate overall polygon mesh. These are common in handheld options and industrial-grade scanner machines. They can also work long-range and for laser-tracking objects.

It records millions of different points on the surface of the object to build an accurate overall polygon mesh. These are common in handheld options and industrial-grade scanner machines. They can also work long-range and for laser-tracking objects.

Similar and often used interchangeably with laser triangulation, structured light or ‘white light’ projects itself in a grid-like pattern over an object. It can then measure the structure of that grid as it applies to the object by using sensors/3D scanner cameras and triangulation.

Long RangeLonger range scanners use phase shift or pulse technology that can capture millions of points while rotating 360 degrees with the aid of mirrors. This is more commonly used to scan large objects like cars or buildings.

They might also use ‘time of flight’ technology that measures the distance of an object in relation to the speed of light and the time it takes for it to return to a sensor.

This is less relevant for everyday 3D scanning and printing.

3D Scanning ApplicationsThere are many different applications for 3D laser scanning - from those for 3D printing at home, to prototyping, industrial scale medical supply production and even architecture.

Hobbyist 3D printingCheaper 3D scanners are typically used by home users for scanning simple objects and 3D printing them for fun.

MedicalThe medical field and dentistry commonly use 3D scanning to create implants and aids to serve their patients’ needs. For example, scanning people’s feet with a high-quality 3D scanner allows for the creation of orthotics (shoe inserts). It is also used in the creation of prosthetics.

Virtual EngineeringIndustrial 3D scanners are used both in the creation and quality control of cars, planes, and even aerospace. It ensures existing parts are as accurate as their original models and that new viable parts are made.

From the home computer desk to the manufacturing floor, 3D scanning allows users to reverse engineer or copy existing objects. Saved models also allow for the reconstruction of damaged objects.

Virtual RealityFrom creating realistic 3D worlds to the people that occupy them, 3D scanning devices are integral to the growing virtual reality industry. This ranges from AAA video games, virtual cinematography, and computer-generated imagery (CGI), to virtual tours and office meetings. It is also a side industry to motion capture.

ForensicsCSI has come a long way. Forensic experts nowadays don’t just have to rely on memory, photos, and evidence of a crime scene. They can capture the entire location in a full 3D model for closer inspection and for running through different scenarios.

Archeology and ArchivingFrom museums to libraries, 3D scanning is being used to log and preserve everything from artifacts to digitizing books. This also gives experts and the public remote access.

This also gives experts and the public remote access.

3D scanning can also help architects map the areas they will be designing their buildings in, take inspiration from existing architecture, and aid in building miniatures/prototypes.

What Should I Know Before Buying a 3D Scanner?Before you buy a 3D scanner, there are several things to consider:

- your budget

- what you’ll actually be using it for

- it’s speed and accuracy

- the device’s other features.

3D laser scanner price ranges vary greatly. On the cheaper end, you may be able to pick one up for home for just shy of $300, like the XYZprinting 3D Scanner 1.0 A. However, if you want the highest overall quality and the ability to scan small and large objects. Or, if you’re a professional and need a 3D part scanner in a field like medical implants or automotive parts, you’re looking at anywhere between $3,000 and $35,000.

Typically, it’s best to look for 3D scanners for sale online where you can find the best selection and prices.

3D PrintingWhile a dual 3D printer scanner combo is rare, if you want to scan models for 3D printing, you will need to make sure it has good accuracy and resolution. The software also must be able to export to a usable format. You will need to check your 3D printer and its own software to see what file types it accepts and then choose your scanner accordingly.

Fortunately, almost all of our 3D scanner reviews include devices that can export in common file types like OBJ and STL.

It’s typically only the more expensive scanners that are good for other applications, like VR, full-body scanning, architecture, and engineering.

Handheld vs StationaryWe already explained the difference, but basically, a handheld scanner is mobile, while the stationary one will require you to move and adjust the object. Neither is necessarily better than the other, it’s all down to your needs.

Neither is necessarily better than the other, it’s all down to your needs.

How fast is the scanner? Do you have a lot of spare time or require the job to be done as fast as possible? All 3D scanners will take a few minutes to complete, while many scanning complex objects in high resolution can talk half an hour or longer.

Accuracy and ResolutionAccuracy refers to how close to the object being scanned your digitized model will be, measured in millimeters. Therefore, the smaller the better. The term resolution may be used interchangeably with accuracy or refer to the resolution of any cameras being used as part of the scanning process.

Generally, the lower the millimeter, the better. Other factors also play a role in overall quality, such as lighting conditions, color, and depth.

Object Size and SpaceSome types of 3D scanners excel at scanning small objects while others are better at medium to large. Others are all-rounders. Before buying a scanner, you should decide the general size of the items you will be scanning.

Others are all-rounders. Before buying a scanner, you should decide the general size of the items you will be scanning.

You will also need to make room for the scanner. Although all the products on our list are small and relatively portable, stationary scanners at least need a table to work from. Likewise, there will be a minimum and maximum distance the scanner must be in relation to the object being scanned.

You’ll need more room when scanning larger objects in full.

Connected DevicesAll 3D scanners need to be connected to a computer or device to help monitor the process and for saving the digital model. This is usually done via a USB or HDMI cable. You will need to check that your computer or laptop meets the minimum requirements for the scanning and modeling software. Also, make sure that you have a tablet to make real-time monitoring easier.

SoftwareYour device will either come with its own software or a popular third-party program to aid the process and to help touch-up the model once it’s scanned. Different 3D printing software is better suited to different skill levels. Some programs have a lot of features for experienced users and others do most of the basic tasks automatically. Check our 3D scanner reviews to see the software each device comes with and how advanced and easy to use it is.

Different 3D printing software is better suited to different skill levels. Some programs have a lot of features for experienced users and others do most of the basic tasks automatically. Check our 3D scanner reviews to see the software each device comes with and how advanced and easy to use it is.

Best 3D scanner 2023 - Expert selections for every need

What is the best 3D scanner?

Many different types of 3D scanners exist, from desktop 3D scanners to handheld 3D scanners and advanced metrology systems. 3D scanners serve an extremely wide range of applications, from reverse engineering to 3D body scanning or even forensic investigations.

However, given the low number of reliable 3D scanner reviews, it can be challenging to find the best 3D scanner. It can also be complex to know what kind of 3D scanner to get based on your application. A $2,000 3D scanner won’t be sufficient for part inspection, and a $60,000 3D scanner would be overkill if you don’t need the precision.

With that in mind, our goal is to offer an overview of the best 3D scanners in different categories. We broke down our best 3D scanner picks into actionable selections:

- Professional: A mix of the best desktop and handheld options for professionals

- Affordable: Entry-level 3D scanners for makers with prices starting at around $400

- Metrology: High-precision 3D scanners for demanding use cases

- Handheld: Portative devices that can access hard-to-reach places

- SLAM and iMMS: Mobile laser 3D scanners for BIM and other large-scale applications

- TLS: Terrestrial LiDAR scanners

- Dental (desktop): Stationary 3D scanners for the dental labs

- Jewelry: Closed, high-precision 3D scanners for jewelers

- 3D body scanners: Booths and handheld color 3D scanners

Note that there can be some overlap between categories. For example, some handheld 3D scanners are precise enough for metrology or can capture colors and work for 3D body scanning.

Tip: Use the table of contents to the top left of your screen to easily navigate between our selections.

We also run through different 3D scanning applications (reverse engineering, 3D inspection, architecture, etc.) and provide concise explanations of the various 3D scanning technologies that exist.

Professional 3D scanner selection

This category groups some of the best professional 3D scanners. Our selection spans a wide price spectrum and includes both desktop scanners and handheld 3D scanners. These 3D scanners can cover most professional use cases.

| Brand | Product | Accuracy | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| SCANTECH (HANGZHOU) CO., LTD This brand is a certified partner from our network. | iReal 2E | 0.1 mm0.003937 in | China | $ 3,9803 980 €3,299 £536,377 ¥ | Quote |

| Shining 3D This brand is a certified partner from our network. | EinScan H | 0.05 mm0.001969 in | China | $ 4,9994 999 €4,144 £673,705 ¥ | Contact |

| Shining 3D This brand is a certified partner from our network. | EinScan HX This product has been reviewed by our team. | 0.04 mm0.001575 in | China | $ 12,00012 000 €9,947 £1,617,216 ¥ | Quote |

| Medit | Solutionix C500 | 0.01 mm0.000394 in | South Korea | $ 40,00036 500 €33,156 £5,390,720 ¥ | Quote |

| Creaform | HandySCAN BLACK Elite This product has been reviewed by our team. | 0.025 mm0.000984 in | Canada | $ 65,00057 000 €53,879 £8,759,920 ¥ | Quote |

| GOM | ATOS Q This product has been reviewed by our team. | – | Germany | upon request | Quote |

| GOM | GOM Scan 1 This product has been reviewed by our team. | – | Germany | upon request | Quote |

| SCANTECH (HANGZHOU) CO., LTD This brand is a certified partner from our network. | SIMSCAN This product has been reviewed by our team. | 0.02 mm0.000787 in | China | upon request | Quote |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Brand | Product | Technology | Category | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|---|

SCANTECH (HANGZHOU) CO. , LTD , LTD This brand is a certified partner from our network. | iReal 2E | Structured light | Mobile > Handheld | China | $ 3,9803 980 €3,299 £536,377 ¥ | Get a quote |

| Shining 3D This brand is a certified partner from our network. | EinScan H | Hybrid | Mobile > Handheld | China | $ 4,9994 999 €4,144 £673,705 ¥ | Contact manufacturer |

| Shining 3D This brand is a certified partner from our network. | EinScan HX This product has been reviewed by our team. | Structured light | Mobile > Handheld | China | $ 12,00012 000 €9,947 £1,617,216 ¥ | Get a quote |

| Medit | Solutionix C500 | Structured light | Stationary > Desktop | South Korea | $ 40,00036 500 €33,156 £5,390,720 ¥ | Get a quote |

| Creaform | HandySCAN BLACK Elite This product has been reviewed by our team. | Laser triangulation | Mobile > Handheld | Canada | $ 65,00057 000 €53,879 £8,759,920 ¥ | Get a quote |

| GOM | ATOS Q This product has been reviewed by our team. | Structured light | Stationary > Industrial | Germany | upon request | Get a quote |

| GOM | GOM Scan 1 This product has been reviewed by our team. | Structured light | Stationary > Desktop | Germany | upon request | Get a quote |

| SCANTECH (HANGZHOU) CO., LTD This brand is a certified partner from our network. | SIMSCAN This product has been reviewed by our team. | Laser triangulation | Mobile > Handheld | China | upon request | Get a quote |

Overview of the best professional 3D scanners

The iReal 2E is another versatile 3D scanning option in the entry-level price range. It uses VCEL structured light to capture medium- to large-sized objects. Like infrared light, VCEL light is invisible to the human eye and is therefore also particularly adapted to face and body 3D scanning.

It uses VCEL structured light to capture medium- to large-sized objects. Like infrared light, VCEL light is invisible to the human eye and is therefore also particularly adapted to face and body 3D scanning.

Scantech has reported diverse use cases for the iReal 2E 3D scanner, namely in forensic investigations, healthcare, and even culture preservation. In the latter, Scantech’s customer 3D scanned a woman performing different Tai Chi movements– an interesting and uncommon application!

Contact manufacturer Get a quote Add to comparison

The EinScan H was launched alongside the EinScan HX in September 2020. It uses a combination of structured LED light and infrared light, with a built-in color camera for texture acquisition.

This 3D scanner can therefore serve a range of applications involving color capture, with uses in retail, art preservation, healthcare, and more. Furthermore, its infrared light is eye-safe and won’t blind users during a face or body scan.

Shining 3D’s versatile EinScan H is a great entry-level deal for most basic use cases, and its software is getting more intuitive by the update.

Contact manufacturer Get a quote Add to comparison

The EinScan HX features hybrid technology: it has both structured LED light and laser triangulation capabilities, an industry-first from Shining 3D. Each technology is accessible through a specific mode that the user chooses at the beginning of a 3D scanning process.

After reviewing the HX, we found that it is a powerful and versatile product, capable of 3D scanning parts of various properties (sizes, colors, textures). It has a nice and sturdy finish and is easy to manipulate. In addition, the little weight it has is very well distributed to offer an ergonomic balance.

In this price range and at this level of performance, the EinScan HX is unrivaled.

Read the full review: Shining 3D EinScan HX review

Contact manufacturer Get a quote Add to comparison

The SIMSCAN is extremely lightweight for a handheld 3D scanner, weighing only 570 grams. It’s also very compact– the absolute smallest in its class– with dimensions of 203 x 80 x 44 millimeters. Scantech earned a Red Dot Design Award in 2021 for the SIMSCAN’s disruptive design.

Scantech earned a Red Dot Design Award in 2021 for the SIMSCAN’s disruptive design.

After using the SIMSCAN to 3D scan various types of parts, we can confirm it’s an excellent product that feels, looks, and works great. With a price of around €25,000, the SIMSCAN’s price-to-performance is outstanding. The only blemish lies in the software, but it receives updates regularly and you can export your scans to your preferred suite.

Read the full review: Scantech SIMSCAN review

Contact manufacturer Get a quote Add to comparison

The BLACK Elite tops out Creaform’s flagship HandySCAN range, which we have reviewed several times over the years. It delivers a powerful performance that reminds us of the Metrascan 750, but without all the hurdles (complex setup, number of parts and accessories, and large footprint).

Creaform’s HandySCAN BLACK Elite boasts a clean, robust finish. Everything exudes quality and rigor, the attention to detail is similar to the feeling that Apple products give off. It’s no wonder this scanner received a Red Dot Design Award (2019).

It’s no wonder this scanner received a Red Dot Design Award (2019).

Read the full review: HandySCAN BLACK Elite review

Contact manufacturer Get a quote Add to comparison

With a starting price of around €20,000, the GOM Scan 1 is GOM’s most entry-level, metrology-grade solution. We visited GOM’s Benelux HQ to review the scanner in early 2022, and were not disappointed.

The offer? GOM quality and performance at an affordable price. It is on par with high-end metrology 3D scanners and is quite fast at 6,000,000 points per scan. The GOM Scan 1 also benefits from the same, powerful GOM Inspect software as its more premium counterparts.

It is a small, lightweight, and precise machine packed with very serious capabilities.

Read the full review: GOM Scan 1 review

Contact manufacturer Get a quote Add to comparison

The ATOS Q is part of GOM’s ATOS lineup, a range of industrial-grade optical metrology solutions. It is aimed at industrial users looking for a powerful and flexible metrology solution at a reasonable price.

One of the ATOS Q’s key selling points is the fact that it can be easily moved along an assembly line or from one site to another. It can’t be qualified as “portable”, but is without a doubt “transportable”.

The scanner also offers a lot of flexibility in part type and size thanks to its multiple lenses and is able to acquire difficult surfaces thanks to its blue light equalizer.

Read the full review: GOM ATOS Q review

Contact manufacturer Get a quote Add to comparison

Solutionix is part of the larger, South-Korean Medit group, and is known for its high-precision dental 3D scanners. Their C500 is able to scan larger objects while benefitting from the same, excellent precision and resolution. Its automatic turntable not only turns but also tilts, providing very thorough scans.

While the Solutionix C500 is sensitive to dark and shiny surfaces, it offers very clean data and high resolution when such surfaces are matted with special spray (like AESUB). The C500 comes with four different sets of lenses for varying fields of view, resolution, and accuracy. Its smallest lens set gives an accuracy of 10 microns and a resolution of just 28 microns (point-to-point distance).

Its smallest lens set gives an accuracy of 10 microns and a resolution of just 28 microns (point-to-point distance).

The C500 is particularly adapted to small parts, but can be mounted onto a tripod for the occasional large scan.

Contact manufacturer Get a quote Add to comparison

Affordable 3D scanners for makers

This selection includes some of the best affordable 3D scanners for makers.

| Brand | Product | Accuracy | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| Scan Dimension | SOL | – | Denmark | $ 599564 €497 £80,726 ¥ | Contact |

| Revopoint | POP 2 | 0.1 mm0.003937 in | China | $ 699658 €579 £94,203 ¥ | Contact |

| Creality | CR-SCAN 1 | 0. 1 mm0.003937 in 1 mm0.003937 in | China | $ 700700 €580 £94,338 ¥ | Contact |

| Matter and Form | Scanner V2 | 0.1 mm0.003937 in | United States | $ 749705 €621 £100,941 ¥ | Contact |

| Shining 3D This brand is a certified partner from our network. | EinScan-SE (Elite) | 0.1 mm0.003937 in | China | $ 1,1991 129 €994 £161,587 ¥ | Contact |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Brand | Product | Technology | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| Scan Dimension | SOL | Laser triangulation | Denmark | $ 599564 €497 £80,726 ¥ | Contact manufacturer |

| Revopoint | POP 2 | Structured light | China | $ 699658 €579 £94,203 ¥ | Contact manufacturer |

| Creality | CR-SCAN 1 | Structured light | China | $ 700700 €580 £94,338 ¥ | Contact manufacturer |

| Matter and Form | Scanner V2 | Laser triangulation | United States | $ 749705 €621 £100,941 ¥ | Contact manufacturer |

| Shining 3D This brand is a certified partner from our network. | EinScan-SE (Elite) | Structured light | China | $ 1,1991 129 €994 £161,587 ¥ | Contact manufacturer |

Overview of the best affordable 3D scanner options

Revopoint launched the POP 2 towards the end of 2021 after a successful Kickstarter campaign with the original POP. We reviewed the original POP shortly before this release, and it seems that some of the quacks (mainly software-related) we encountered have since been worked out. Their new software features a calibration process and a new “Wi-Fi host” mode.

The POP 2 is an interesting option for makers or beginners looking to learn more about 3D scanning. We wouldn’t particularly recommend it for professional use cases, though it can get the job done if you don’t need high resolution.

The Revopoint POP 2 can be used on a small tripod or as a handheld device, and is able to capture colors.

Contact manufacturer Add to comparison

The EinScan-SE is a powerful entry-level desktop 3D scanner designed to capture small- to medium-sized objects in 3D. Launched back in 2017, it’s still relevant today as an affordable, professional-grade option.

Launched back in 2017, it’s still relevant today as an affordable, professional-grade option.

It is based on white structured light technology and offers two 3D capture modes: Fixed Scan and Auto Scan (with a rotating table). The Shining 3D EinScan-SE is a versatile and fast 3D scanner, suitable for a wide range of applications and designed with 3D printing applications in mind.

Contact manufacturer Add to comparison

This affordable desktop 3D scanner is geared towards hobbyists and tech enthusiasts. The SOL 3D scanner is equipped with an automatic turntable to complement its hybrid 3D scanning technology (a combination of structured light and laser triangulation).

Scan Dimension notes that this 3D scanner is easy to use, thanks to a simplified app that lets users avoid complex calibration and software manipulation.

Contact manufacturer Add to comparison

The CR-SCAN 1 is another 3D scanner under $1,000. It can be used on a tripod as well as in handheld mode. According to Creality, the use of markers is unnecessary thanks to their AI-based alignment algorithm.

According to Creality, the use of markers is unnecessary thanks to their AI-based alignment algorithm.

Contact manufacturer Add to comparison

Matter and Form has been producing affordable desktop 3D scanners since 2014. The 3D Scanner V2 (a.k.a. MFS1V2) is, as its naming suggests, the second version of their flagship product, the Matter and Form MFS1V1 3D scanner.

It boasts a great price-to-performance ratio and is able to quickly scan 3D objects while displaying results in real time. Matter and Form also manufactures the Bevel dongle for use with 3D scanning smartphone apps.

Contact manufacturer Add to comparison

Metrology 3D scanner selection

3D metrology is the process of acquiring highly accurate physical 3D measurements of an object. The result is a digital 3D model that users can analyze or retro-engineer.

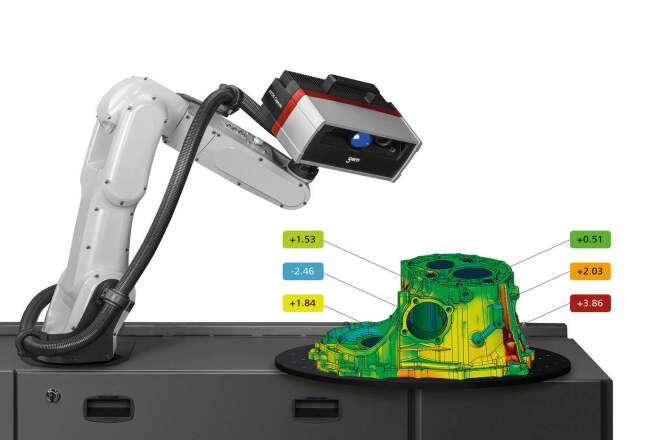

Take quality inspection, for example. Professionals can compare the 3D scan to a reference CAD model to make sure the object respects established norms and standards. 3D metrology helps ensure product quality while saving time and, thus, lowering costs.

3D metrology helps ensure product quality while saving time and, thus, lowering costs.

Handheld 3D scanner selection

Handheld 3D scanners have been gaining a lot of popularity over the past few years. They offer various benefits over other types of 3D scanners:

- Ability to access hard-to-reach places

- Relative ease of use

- Portability

Their versatility makes them suitable for a wide range of industries, including automobile, aerospace, engineering, and design, and some can even be used for 3D body scanning.

SLAM 3D scanner selection

SLAM (Simultaneous Localization and Mapping) technology allows a device to position itself and navigate through a given space based on its surroundings. Sometimes called CML (Concurrent Mapping and Localization), it was initially developed for robots and autonomous appliances.

In 3D scanning (mobile mapping), SLAM algorithms combine and use the sets of data collected from one or more sources to track the scanner’s position, all while building up an accurate, complete 3D point cloud of the surrounding environment.

SLAM-based 3D scanners can work in extremely remote locations where GPS or GNSS signals are unavailable, and make it easy to quickly 3D scan large areas like building sites and underground caves.

TLS (Terrestrial Laser Scanner) selection

Terrestrial laser scanning (TLS) is a form of 3D scanning in which tripod-mounted laser scanners are used to capture large objects and environments. The technique is widely used in construction, surveying, forestry, and other disciplines.

Also known as long-range laser scanning, TLS involves deploying a scanner in a static location, whereas other laser scanners may be handheld or mounted to vehicles to capture data from a greater number of vantage points. TLS produces more accurate scans than mobile scanning — at the expense of speed and simplicity.

These 3D scanners are often generically called LiDAR scanners, though terrestrial scanners aren’t the only type of scanner to use the technology.

Desktop dental 3D scanner selection

Bit by bit, dentists are beginning to replace traditional methods with digital dentistry. This involves the use of digital capture, digital design, and digital production technologies to improve the speed, accuracy, and profitability of dental practice.

A key part of digital dentistry is the use of 3D scanners, which capture 3D shapes using a combination of cameras and light projection before transferring the result to a computer.

Desktop dental 3D scanners capture dental models or impressions (negative imprints of a patient’s teeth and gums) and are usually used in a laboratory setting.

Jewelry 3D scanner selection

A popular use of 3D scanning technology is jewelry 3D scanning. This is the process of 3D scanning jewelry, precious metals, and gemstones with the goal of creating a digital copy of the original object. The digital twin can be used for many purposes, such as repairing or duplicating a valuable item.

3D scanners have been adopted as a supplementary tool by traditional jewelers, but the technology has also allowed newcomers to enter the field, many of which have combined 3D scanning with jewelry 3D printing.

Most jewelry 3D scanners are enclosed or partly enclosed desktop machines that offer ideal lighting conditions. Desktop jewelry 3D scanners almost always feature an automatic turntable, or auto-rotating table, on which the piece of jewelry is placed to be scanned.

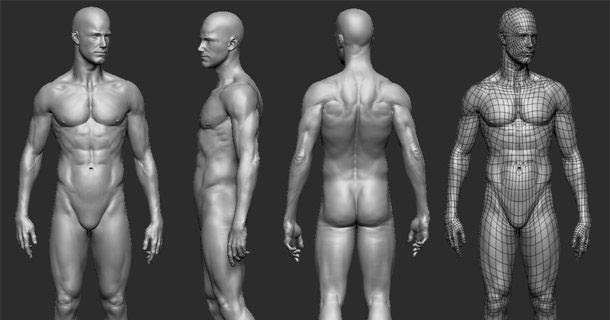

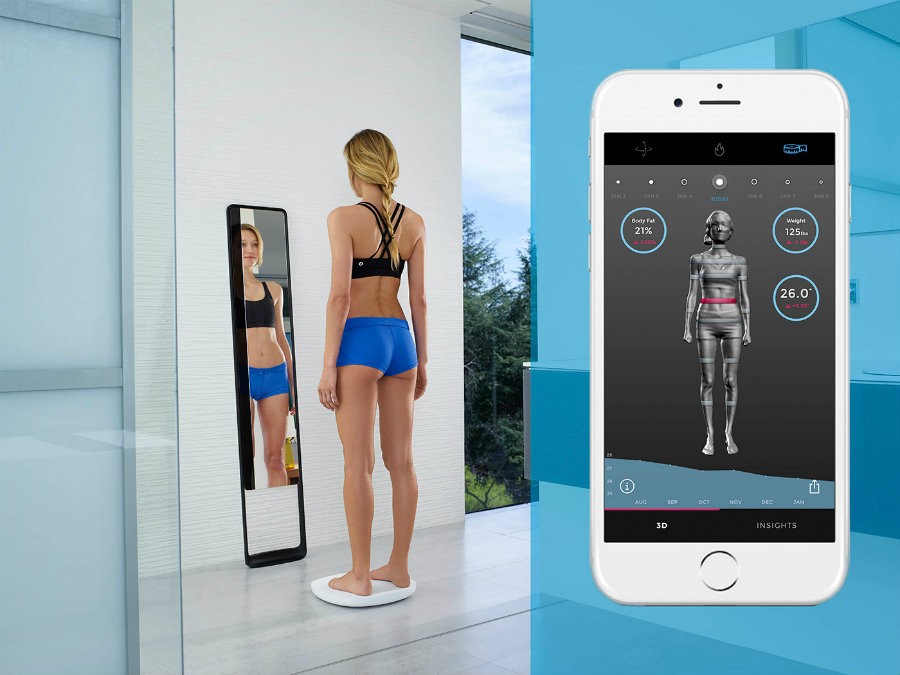

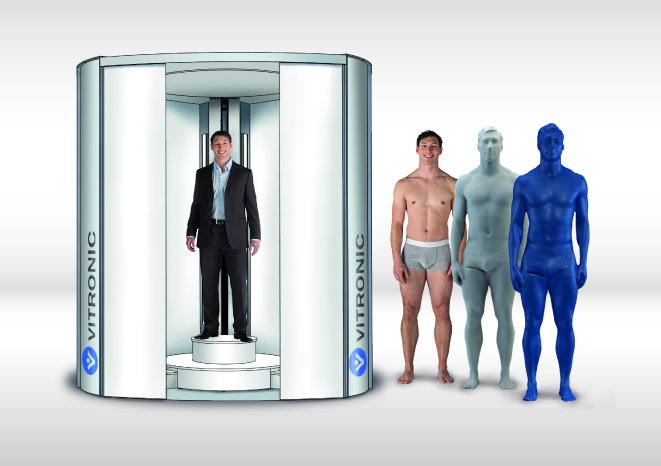

3D body scanner selection

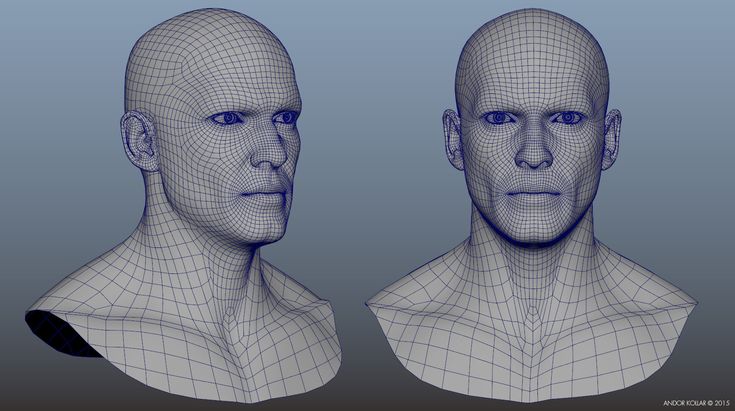

3D body scanners are designed to capture your full body in 3D. The result is a 3D model (or 3D avatar) of your exact body shape with accurate data such as body measurements, posture analysis, textures, …

Originally developed for the fashion industry as fast and accurate 3D measurement solutions, 3D body scanners are now used in various other fields such as healthcare, 3D figurines and 3D photos, fitness, and entertainment.

To obtain a full-body 3D scan, the customer or patient holds a pose for a few seconds, which is the time it takes for the 3D scanner to capture images from all angles. The 3D software then reconstructs the final 3D model of the body by “stitching” all of the images together, generating a highly detailed 3D model. Models can have colors and textures depending on the type of body scanner.

Which 3D scanner is the best for me?

3D scanning can be used in a large variety of fields. For every application, the features necessary to generate a great 3D model are different. The 3D scanner must be chosen according to your desired use and results.

What the best 3D scanner is for you will depend on many factors, detailed below.

3D scanning field of application

The first thing to take into consideration is the field in which the 3D scanner will be used. It could be for example:

Professional use

- Small objects: dentists, jewelers, and other professionals can use 3D scanning to capture small pieces.

- Big objects: professionals such as architects and archeologists might need to 3D scan large objects such as statues, archeological fields, or buildings.

- 3D body scanning is increasingly used in various professional fields such as healthcare and 3D figurines.

Personal use

- Occasional scanning: A person might need to use 3D scanning on rare occasions or maybe just one time.

- 3D scanning on a regular basis: You can use 3D scanning for various things from making personalized objects to making a replica of yourself, friends, or family members.

Type of 3D scanned object

Dimensions and distance of the object (scan area and scanning range)

The “best 3D scanner” will depend on the dimensions and the distance of the objects you wish to 3D scan. A desktop 3D scanner can’t 3D scan a 2-meter-tall statue, and a handheld 3D scanner might not be the best option to 3D scan a very small and precise piece.

Surface of the object

Not every 3D scanner is able to capture colors. For color capture, you need a scanner with photogrammetry.

It can also be challenging to capture objects with black, shiny, or reflective surfaces. However, as 3D scanning OEMs fine-tune their technology and hardware, such surfaces are becoming less and less of a challenge. For cases where it is a challenge, it is always possible to use a white mattifying spray.

Desired resolution

Not all 3D scanners offer the same level of resolution. Therefore, depending on the quality you need, some 3D scanner models are more adapted than others. Reverse engineering requires high resolution and precision, for example.

Desktop 3D scanners

Desktop 3D scanners can be ideal for both professionals and hobbyists that need to scan small parts. They tend to be more accurate since you aren’t holding and moving the 3D scanner around yourself.

Also, many desktop 3D scanners come with (or at least optionally) an automatic turntable, which makes it much easier to get clean 3D scans.

Handheld 3D scanners

Handheld 3D scanners, a.k.a. portable 3D scanners, are versatile and can 3D scan small to very large objects. They also enable users to 3D scan hard-to-reach places. The precision and the ability to capture color and texture will depend on the 3D scanner model.

3D body scanners3D body scanners have applications in numerous fields.

- Professionals: professionals might want to 3D scan a person to make a 3D figurine, prepare for a surgical intervention, follow-up on a pregnancy or skin conditions, etc.

- Individuals: 3D body scanners can help with fitness goals and personal shape. These 3D scanners usually can’t capture color and texture but offer a high resolution.

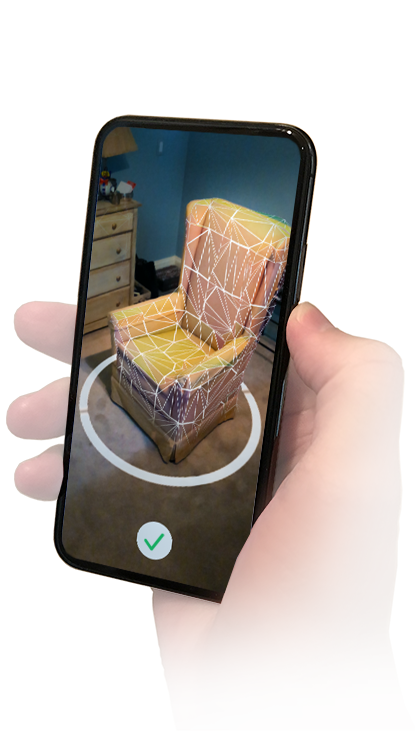

3D scanning mobile apps

3D scanning mobile apps are ideal for occasional users that are not willing to or are unable to invest in a 3D scanner.![]() They are not as precise as most 3D scanners, but mobile apps are a great way to get familiar with 3D scanning.

They are not as precise as most 3D scanners, but mobile apps are a great way to get familiar with 3D scanning.

3D scanner price

3D scanner prices can range from just several hundred dollars to over $100,000.

Desktop 3D scanner price

Desktop 3D scanner prices vary a lot from one model to another. It can start at a few hundred dollars and can top out at around $50,000 for the more advanced 3D scanners. More industrial-grade, robot-mountable scanners can cost double.

Handheld 3D scanner price

The handheld 3D scanner price range is very wide. A professional handheld 3D scanner can start at around $5,000 and can reach up to over $70,000 for very high-end and advanced 3D scanners.

There are plenty of great entry-level options for a couple of thousand dollars. Mid-range handheld 3D scanners tend to cost between $10,000 and $30,000.

Industrial 3D scanner price

Industrial 3D scanners generally offer more cutting-edge features and higher precision. Hence, their prices can be pretty high, ranging from $10,000 for the simplest ones to more than $100,000 for the most evolved ones.

Hence, their prices can be pretty high, ranging from $10,000 for the simplest ones to more than $100,000 for the most evolved ones.

3D scanning applications

There are many reasons to buy a 3D scanner, for various industries and applications.

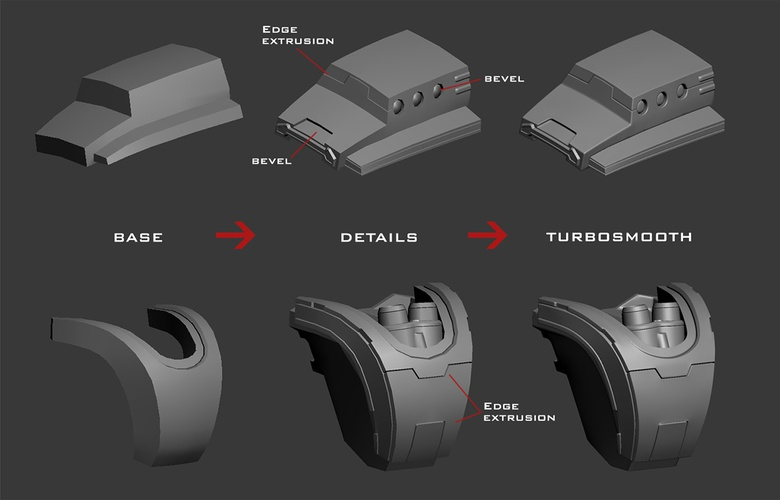

Reverse engineering

Reverse engineering, also known as retro-engineering, is the process of extracting information from an object or process and studying it. 3D scanners can be used to capture all the parts of a disassembled object to create a 3D model. The user will then be able to digitally study it in 3D afterward.

Jewelry

Jewelers are starting to use 3D printing and 3D scanning to build casts in order to create amazing jewels. Read more on our 3D printing and 3D scanning for jewelry page.

Dental

Dentists and dental labs are using 3D printing to build and create various dental appliances. Find more information on our 3D printing and 3D scanning for the dental industry.

Medical

3D scanners are very versatile and are used in many different ways in healthcare, from making prosthetics to studying a person’s posture. Find more information in our guide to 3D scanning and 3D printing for the medical industry.

A dental 3D scan by Pierre-Antoine.Metrology/inspection

Industries need to make sure their factories are producing perfect products that are perfectly in line with the products’ reference dimensions. 3D scanners enable professionals to efficiently measure potential discrepancies.

Figurines and 3D selfies

3D portraits or mini-me’s are increasingly popular. To make one, you scan yourself in 3D and 3D print your mini lookalike. To learn more about the subject, you can visit our 3D printed figurines, 3D selfies, and 3D portraits page.

Architecture

Architects can use 3D scanning to capture an area, building, or habitation and present it in a more efficient way to their clients. Find more information on our 3D scanning and 3D printing for architects page.

Find more information on our 3D scanning and 3D printing for architects page.

Archeology and museums

Archaeologists, museum curators, and researchers are starting to use 3D scanning to get a better view and capture ancient pieces. To read more about this topic, you can visit our 3D printing and 3D scanning in archeology and cultural preservation page.

A dot cloud of Notre Dame. Source: engadgetOverview of 3D scanning technologies

Photogrammetry

Photogrammetry consists of taking measurements from photographs to recover the exact positions of surface points.

The principle of photogrammetry is to analyze several photographs of a static subject, taken from different viewpoints, and to automatically detect pixels corresponding to the same physical point.

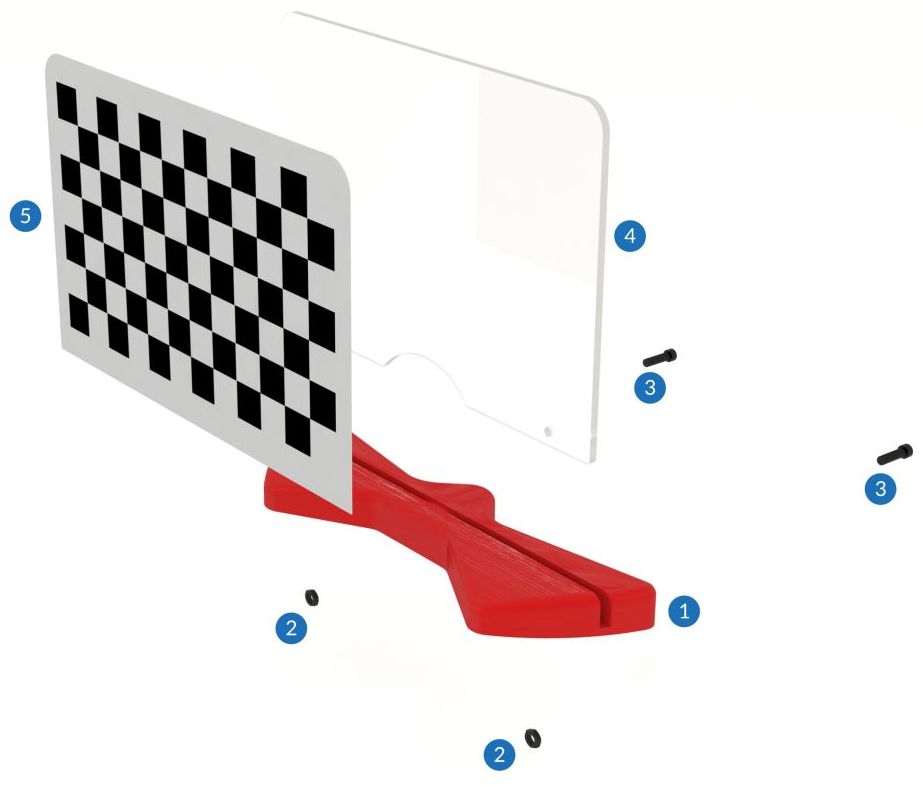

Photogrammetry enables scanners to capture an object’s color (a.k.a. texture). This technology also often serves to detect positioning markers (sticky targets placed on or around the object to help the scanner precisely align scans together).

Structured light

3D scanners using structured light project a series of linear light patterns onto an object.

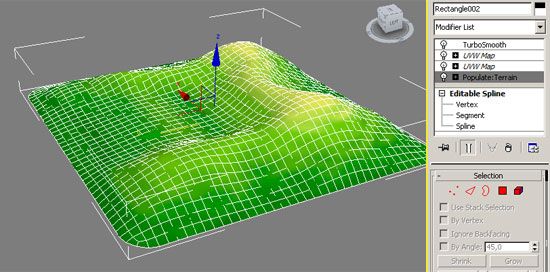

The system is then able to examine the deformations of each line and to calculate the distance between the 3D scanner and the object’s surface. With this data, the software is able to build an accurate 3D model of the object.

Structured light 3D scanning technology. Source: Depth BiomecanicsTriangulation

A 3D scanner using triangulation technology will project a laser beam on the object’s surface and measure the deformation of the laser ray (similar to structured light, but with one or more lasers).

3D scanning laser triangulation technology. Source: NeoMetrixContact

Contact 3D scanners probe the subject via physical touch. A touch probe moves along an object’s surface to record 3D information.

For more precise and detailed explanations, you can visit our 3D scanning technologies page.

FAQ

What is the most accurate 3D scanner?

The most accurate 3D scanners are metrology 3D scanners, which generally offer an accuracy of around 20 microns.

Is a 3D scanner worth it?

This is entirely up to how much you will be using your 3D scanner. We can however say that 3D scanning is an impressive technology that does help save a lot of time for product design, reverse engineering, part inspection, and many other use cases.

How much does a good 3D scanner cost?

Again, the definition of “good” is quite subjective in 3D scanning. Some of the best 3D scanners we have reviewed cost between $10,000 and $30,000. But a $5,000 3D scanner can do “good” if its specs meet your requirements.

Is 3D scanning expensive?

Not only is 3D scanning hardware generally expensive, but so are the necessary, professional software solutions. Sometimes, it’s a one-time fee for a permanent license; other times, a monthly or yearly subscription is the only way to access a software suite. And to run such software, you will likely require a powerful, monster of a PC with a lot of RAM and a high-end graphics card. You may also need to buy a tripod or turntable if they aren’t included in your 3D scanner package. All of this can quickly amount to several thousand dollars.

Sometimes, it’s a one-time fee for a permanent license; other times, a monthly or yearly subscription is the only way to access a software suite. And to run such software, you will likely require a powerful, monster of a PC with a lot of RAM and a high-end graphics card. You may also need to buy a tripod or turntable if they aren’t included in your 3D scanner package. All of this can quickly amount to several thousand dollars.

Day-to-day 3D scanning expenses can include cans of mattifying spray and rolls of adhesive markers if you need them. Other than that, aside from potential software subscriptions, there are no extra hidden costs.

scopes and overview of models / Sudo Null IT News

3D laser scanning - creating a digital model of a physical body using a laser beam. The technology is non-contact, works at close and long distances, eliminates damage to objects during scanning. The principle of operation of 3D laser scanners: a directed laser beam is reflected from the surface of an object, forming a cloud of points. Each point has its own coordinates in space. The software identifies them and creates a finished 3D digital model based on this data.

Each point has its own coordinates in space. The software identifies them and creates a finished 3D digital model based on this data.

From the overview you will find out where laser scanning is used and what equipment is used to solve related problems.

Purpose of laser scanners

Source: newequipment.com

Compared to traditional measurement methods, laser scanners have an important advantage - they can digitize objects with complex surfaces and work in hard-to-reach places for humans. The main areas of application of devices are input and output quality control in production, inspection of working devices in order to prevent and eliminate defects, reverse engineering and other areas.

Construction, renovation and renovation of objects

Source: ellisdon.com

During the preparation of the building design, it is necessary to evaluate the features of the site and the cost of the forthcoming works. With the help of 3D laser scanners, a landscape model is created, on the basis of which further work is carried out. During the construction process, intermediate control of the geometry of future buildings is required: walls, corners, openings, etc. Laser scanning copes with this task more accurately and faster than conventional measuring technologies.

With the help of 3D laser scanners, a landscape model is created, on the basis of which further work is carried out. During the construction process, intermediate control of the geometry of future buildings is required: walls, corners, openings, etc. Laser scanning copes with this task more accurately and faster than conventional measuring technologies.

The basis for an exterior or interior renovation is often an accurate digital model, on the basis of which changes and additions to the current interior or exterior are planned. Laser scanners are also indispensable in this area.

Road networks and transport

Source: autodesk.com

Laser scanning is becoming an integral part of the planning and creation of urban and suburban road networks, tunnels, pedestrian sections, railways, ports. The technology is used to assess the current state of coatings, plan and estimate the cost of repairs, to obtain models of perennial structures, such as bridges. The equipment is involved in the design, manufacture, repair and tuning of cars, air transport and ships.

The equipment is involved in the design, manufacture, repair and tuning of cars, air transport and ships.

Public utilities

Source: 3dscanner.es

With the help of 3D laser scanners, it became possible to quickly digitize and document engineering communications. Scanning significantly saves time during maintenance and reconstruction. The devices work remotely, minimizing the risks of people when working in adverse conditions and in hard-to-reach areas.

Oilfield installations

Source: ramboll.com

Oil production complexes located in the water require constant monitoring of work processes. Objects are regularly exposed to adverse and changeable environmental influences: winds of different strengths and directions, currents, temperature changes, etc. 3D laser scanning is becoming an integral part of the inspection of oil production installations. The equipment allows you to quickly identify and fix deformations and other damage, control wear, calculate the timing of scheduled maintenance, and prevent accidents.

The equipment allows you to quickly identify and fix deformations and other damage, control wear, calculate the timing of scheduled maintenance, and prevent accidents.

Forensic examination

Source: faro.com

Photographs and manual measurements in investigative processes and forensic examinations are being replaced by 3D laser scanning. The devices create three-dimensional models of scenes of incidents with accurate fixation of the location of objects and the distances between them. The data is used in the process of pre-trial and litigation.

Other applications

Source: news.microsoft.com

3D laser scanners facilitate and optimize workflows in the following areas:

- In cartography and geodesy - when creating terrain plans, maps, geographic information systems (GIS).

- In archeology - in the restoration and preservation of ancient artifacts.

- In paleontology, to create missing parts of excavated skeletons.

- In medicine, including plastic surgery and dentistry.

Overview of models and manufacturers

FARO Focus

Source: ifworlddesignguide.com

FARO is one of the popular manufacturers of laser scanning devices. The new Focus3D S-series instruments stand out from other scanners in lightness and compact size, as well as the ability to work in bright sunlight and keep in touch with the location using GPS.

The FOCUS 3D S 150 scanner works at a distance of up to one hundred and fifty meters, with an accuracy of up to ±2000 microns at a maximum distance. The device is used in design, architecture and construction, for digitizing equipment and other objects.

You can learn more about this model on the website.

Source: youtube.com

Focus3D S 350 scans with the same accuracy as the previous device, but the distance to the measurement object is increased to 0. 35 km. The device is designed for outdoor use.

35 km. The device is designed for outdoor use.

Source: kkgeosystem.blogspot.com

SHINING 3D

Source: shining3d.com

FreeScan is a line of well-known Chinese manufacturer of digital equipment SHINING 3D. These are universal laser handheld 3D scanners FreeScan X5 (X5+), FreeScan X7 (X7+) weighing up to 1 kg, with an excellent set of professional features.

Basic parameters:

Specifications

Creaform

Source: foundry-planet.com

Creaform's SCAN 3D range is characterized by high scanning quality combined with ease of use. Portable laser scanners HandySCAN 3D, MetraSCAN 3D have a clear interface, do not require special skills and complex user training.

Instrument features:

ScanTech

Handheld range

Source: cmmxyz. com

com

The HandHeld Prince series uses blue and red laser beams to scan large and small objects with high accuracy. Scanners can operate in bright sunlight and low light conditions. Due to its compact size, high speed and detail, the equipment is widely used in reverse engineering, quality inspection, digitization of museum, archaeological and other objects.

Key features:

Composite series

Source: twitter.com

In addition to the dual scan mode, the KSCAN20 is equipped with a photogrammetry system, thanks to which the working area of the device is 2.5 m * 3 m with an accuracy of 35 µm / m.

Blue and red lasers provide high-speed scanning of up to 650,000 measurements per second with a resolution of 0.01 mm.

Key Features:

3D Laser Scanner Applications

Reduce construction costs and time with FARO Focus

Source: autodesk. com

com

US construction company Gilbane invested $60,000 in a FARO Focus-S 350 laser scanner, software, and employee training. At first glance, the amount seems too large for a small-scale firm. But, after the calculations, the company's management came to the conclusion that the investment will pay off in the shortest possible time.

According to Gilbane's director of 3D design, John Tocci Jr., after introducing the expensive new technology, the company began to use the equipment even in areas where it was not originally planned. The specialists managed to save $30,000 for one hour of Focus-S 350 and Autodesk Revit software.

Source: autodesk.com

Building a digital model of air ducts and other systems made it possible to avoid errors during the installation of physical objects, which could take several weeks. The use of FARO Focus in the assembly of plumbing, electrical and mechanical installations helped to optimize costs at all stages of work

Case “Modernization of the building of the University of Miami”

Source: elevar. com

com

At the time of the start of work, the architects had drawings made 85 years ago, and a little more than 4.5 thousand square meters of the old building. Using a 3D laser scanner, Gilbane digitized the training areas in one day. Modernization of load-bearing structures, as well as the main utility systems: plumbing, electrical and ventilation, was based on data obtained from scanning.

Quality Inspection with ScanTech

Source: 3d-scantech.com

The advantage of metal stamping over forging and casting is the lower weight and thickness of the resulting parts. The use of molds gives high accuracy and maximum compliance of the obtained parts with the specified characteristics, but does not completely exclude deviations and deformations. Which, in turn, can lead to difficulties in assembling finished products and reducing product quality. Therefore, constant quality inspection is a necessary part of production.

Having understood the problems of the manufacturer, ScanTech experts proposed to check the quality of stamped parts using the PRINCE laser scanner. The ability to switch blue and red laser modes allowed the device to combine the functionality of traditional portable and metrological 3D scanners. The mode of operation with an active beam of a red laser provides fast digitization of objects. In the case of increased requirements for accuracy and detail, turn on the blue laser beam mode.

The photo shows the stages of work:

1. Installing markers - takes about two minutes.

Source: 3d-scantech.com

2. Digitizing a part takes about three minutes.

Source: 3d-scantech.com

Source: 3d-scantech.com

3. Deviation detection - lasts 3 minutes.

Source: 3d-scantech.com

The digital model shows the parameters and deviations, allows you to correct errors at the design stage. The case clearly shows that the process required a minimum of time and effort.

The case clearly shows that the process required a minimum of time and effort.

Using FARO 3D scanners on Justin Timberlake's world tour

Source: disguise.one

Timberlake's "Man of the Woods" program features scenery brought to life on stage. First, the ScanLAB team digitized a number of corners of the forest in the US state of Oregon. Laser projectors then directed images over the auditorium and stage, painting amazing pictures of the Portland landscape on translucent canvases suspended in the air.

Source: faro.com

Two Faro Focus X 330 laser scanners, Faro Scene 6.2 software were used to prepare visual effects. In total it took 40 digital copies and 1 working day in the concert hall.

Source: www.esa.int

Considering the limited preparation time, the large surface areas for displaying the image and the corresponding need for high image resolution, creating visual effects in a short time without using the chosen technology was impossible.

Selection guide for 3D laser scanners

In the review, we introduced you to the equipment of market leaders with an excellent reputation. All the devices described have high performance, so we recommend that you pay attention to these devices for use in various fields:

FARO Focus: Focus3D S350, Focus 3D S150.

Creaform: MetraSCAN 350 (350 Elite), MetraSCAN 750 (750 Elite), HandySCAN Black (Black Elite).

SHINING 3D: FreeScan X5 (X5+), FreeScan X7 (X7+).

ScanTech: KSCAN20, PRINCE 775, PRINCE 335.

Results

Source: 3d-scantech.com

The cases discussed clearly prove that the use of 3D laser scanning optimizes workflows in many areas. The range of tasks solved with the help of 3D laser scanners is constantly expanding.

Buy a professional 3D laser scanner in Top 3D Shop — experienced specialists will help you choose the most suitable equipment, software for your business, and offer a project to modernize production.

technologies, types, how 3D devices work

Many digital engineering strategies for the future of development, manufacturing, quality control, and product release start with 3D scanning. 3D scanners work with advanced technologies and specialized software to create a tool that allows you to achieve revolutionary results. For those still working with power tools and traditional coordinate measuring machine (CMM) technology, 3D scanners serve as an easy gateway to advanced manufacturing and engineering strategies.

Read below to learn more about how 3D scanners work and what this technology can do, so you can start enjoying its benefits now.

What are 3D scanners?

A 3D scanner works by capturing data from the surface of a physical object to describe its shape in an accurate digital 3D format. Unlike CMM measurement data, high quality 3D scan data is used for more than just inspection and dimensional analysis. The data obtained by non-contact measurement allows faster and more accessible digital analysis and inspection using a visual, in-depth method of examination.

3D scanners are also used to replicate parts in reverse engineering, check the fit, shape and function of components in remote locations, and check CAD models of 3D printed parts. 3D printers can use 3D scan data to create physical objects.

What is 3D scanning?

3D scanning is the process of collecting data about the surface of an object in digital format to determine its shape, allowing users to either reproduce the part by reverse engineering or verify it by dimensional analysis.

To do this, operators use scanners that use lasers, light or sensors to determine the surface of the scanned object and assign data points to this surface. These data points will eventually recreate the . Depending on the type of laser, light, or sensor used, the level of detail and scanning performance may vary.

3D Scanning Technologies

Photogrammetry

Originating from photography, photogrammetry is an incredibly useful technology in various fields. This technology allows you to take multiple images taken at different positions and triangulate points on those images to determine their location in 3D space.

For example, cartographers use this technology when compiling maps. When it comes to hard-to-reach places like mountains, surveyors can use photogrammetry to take measurements.

Many modern technologies use photogrammetry, and the quality of the images is the main factor determining accuracy. If the images are poor quality, there will be holes in the grid. The more images you can get, the higher the scan accuracy will be.

Shining 3D offers a solution - DigiMetric Photogrammetric System.

Read also DigiMetric case study “Scanning with a Digimetric Photogrammetric System and a FreeScan Handheld 3D Laser Scanner”

Structured Light

This technology is created by applying geometric patterns to an object while simultaneously capturing an image with a camera. In this case, the camera registers the deviation of the image.

Based on this template offset, all existing points can be located. It is necessary to conduct many scans from different positions, and then merge them until the mesh is 100% complete. Computer programs automatically combine all images to form a complete grid.

3D laser scanning method

3D laser scanning data acquisition

3D laser scanning process

The object to be laser scanned is placed on the scanner platform. Specialized software directs the laser probe over the surface of the object. A laser probe projects a line of laser light onto the surface, and 2 sensor cameras continuously record the change in distance and shape of the laser line in three dimensions (XYZ) as it passes along the object.

Acquired data

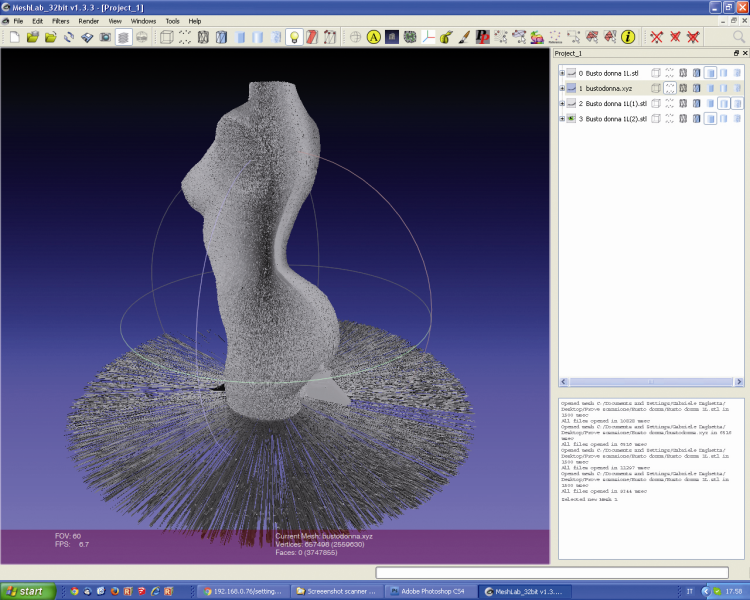

The shape of an object is displayed as millions of dots, called “point clouds”, on a computer monitor as the laser moves around, capturing the entire shape of the object's surface. The process is very fast and laser scanning is more accurate than infrared.

Point cloud data for inspection

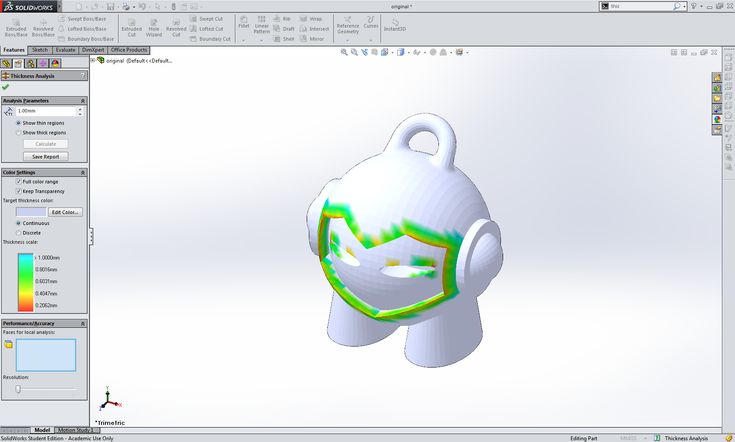

If the data is to be used for inspection, the scanned object can be compared with the designer's nominal CAD data. The result of this comparison is provided as a “color map deviation report” in PDF format, which clearly describes the differences between scanned data and CAD data.

Reverse engineering CAD model

Laser scanning is the fastest, most accurate and automated way to obtain digital 3D data for reverse engineering. Again, with the help of specialized software, point cloud data is used to create a 3D CAD model of the geometry of the part.

The CAD model can accurately reproduce the scanned object, or the object can be modified in the CAD model to correct imperfections.

Types of 3D scanners

Active scanners emit some radiation or light. The scanner detects the reflection to collect information about the object. Let's take a look at the active views of 3D scanners below.

3D Laser Scanners

3D Laser Scanners use a process called trigonometric triangulation to accurately display a 3D shape as millions of dots. Laser scanners work by projecting a laser line or lines onto an object and then capturing its reflection using one or more sensors.

The sensors are located at a known distance from the laser source. Accurate point measurements can be made by calculating the angle of reflection of the laser light.

Laser scanners are very popular and come in many designs. These include handheld, manipulator-based, CMM-based handheld devices, long-range trackers, and long-range single-point trackers.

Benefits of 3D laser scanners:

- Ability to scan complex surfaces such as shiny or dark surfaces.

- Less sensitive to changes in lighting conditions and ambient light.

- More accurate data, available for inspection.

Learn about FreeScan UE 3D laser scanner features, features, features and benefits.

An example of using FreeScan UE and photogrammetry can be found on our blog page - Large Part 3D Inspection.

As well as the article The rebirth of historic motorsport icons.

Projected or structured light 3D scanners

Historically known as “white light” 3D scanners, most structured light 3D scanners today use blue or white LED projected light. These 3D scanners project a pattern of light onto an object, consisting of stripes, blocks, or other shapes. A 3D scanner has one or more sensors that look at the edges of these patterns or structural shapes to determine the object's 3D shape.

Using the same trigonometric triangulation method as in laser scanners, so the distance from the sensors to the light source is known. Structured light scanners can be mounted on a tripod or hand held.

Benefits of Structured Light 3D Scanners:

- Very fast scan times of only 2 seconds per scan.

- Versatility - multiple lenses for scanning small and large parts in one system.

- Portability - handheld systems are highly mobile.

- Eye friendly for 3D scanning of people and animals.

- Color 3D scans available.

- Various price ranges from inexpensive to expensive depending on resolution and accuracy.

An excellent solution of 3D scanners with structured light, are models:

- Einscan HX

- manual 3D scanner Einscan H.

Examples of scanning using 3D 3D scanners Einscan:

- HTTPS: // www.shining3d.ru/blog/perfectly-equipped-for-emergency-with-the-einscan-hx/

- https://www.shining3d.ru/blog/at-the-intersection-of-craftsmanship-and- technology-einscan-h-and-fusion-360-in-traditional-boat-building/.

Coordinate Measuring Machine (CMM)

Coordinate Measuring Machine (CMM) is mainly used for parts inspection. The machine can be controlled manually or through autonomous control by software and computers. Measurements are determined by attaching a sensor to the machine. The sensor usually has a small ball at the end of a shaft of known diameter. The CMM is then programmed to make contact with the part. When the machine senses contact with the probe tip, a value in XYZ space is measured. The most common type of CMM is the bridge type, which has 3 x, y, and z axes. The attached sensor system can be rotated to provide an additional 3 xyz axes, giving a total of 6 degrees of freedom (DOF).

For very precise measurement of parts down to a few microns, CMMs are usually installed in a controlled room.

The room includes a reinforced floor, controlled humidity and temperature, and isolation from vibration and other forces that may affect accuracy.

In addition, most CMMs have a large granite table surface that is perfectly flat. Details are fixed on a granite table in such a way as to exclude their movement during the measurement process.

Advantages of CMM:

- One of the most accurate way to measure an object

- With the appropriate machine, both small and large parts can be measured

- There are industry standards and certifications for measurement and software

Solutions provided by Shining 3D – FreeScan Trak CIM Portable Wireless Scanning System.