3D printing repair

How Do I Get My 3d Printer Fixed? – Home 3d Prints

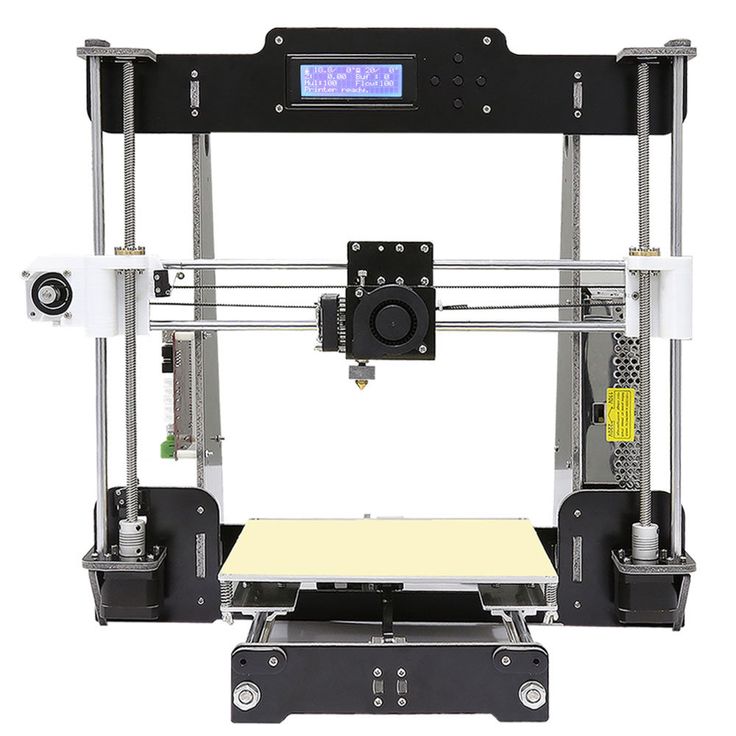

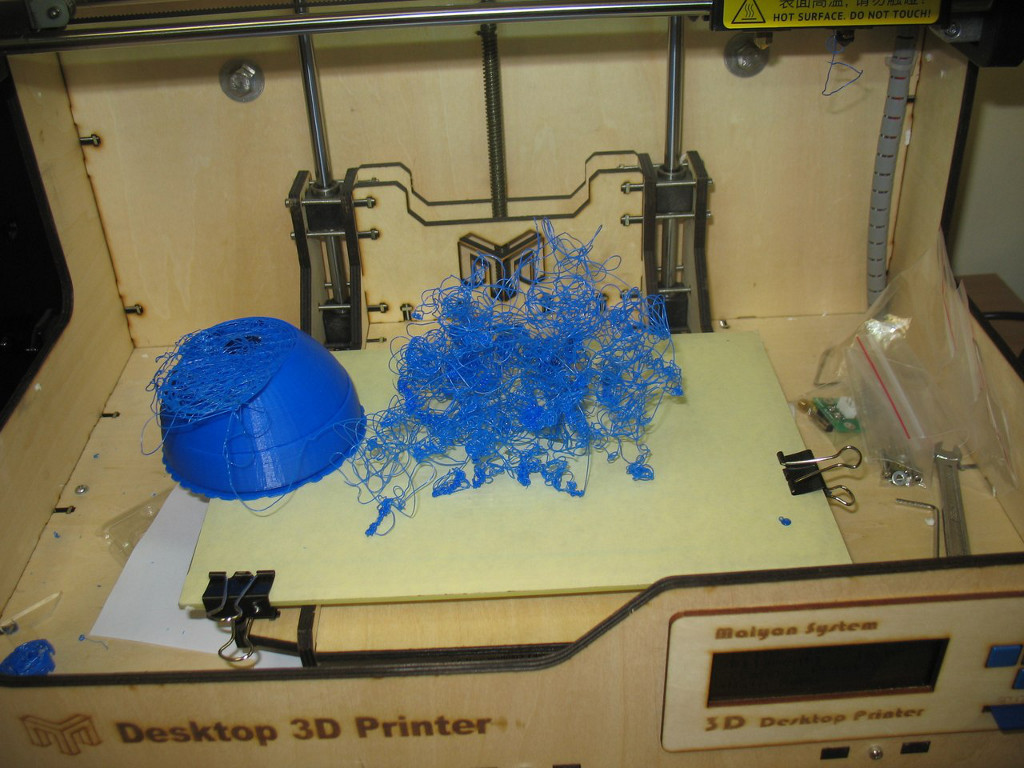

A friend of mine finally decided to purchase a 3d printer. He didn’t go cheap. He wanted quality. He picked up a Prusa I3 Mk3 printer kit. From his research, it looked like a great printer with a large print volume and stellar reviews. I helped him assemble it. It took us 10 hours to assemble it. When we turned it on, we were greeted with a satisfying, happy control screen! We had done it! Next came print bed leveling, and we utterly failed here. We had no clue what we were doing. We needed help.

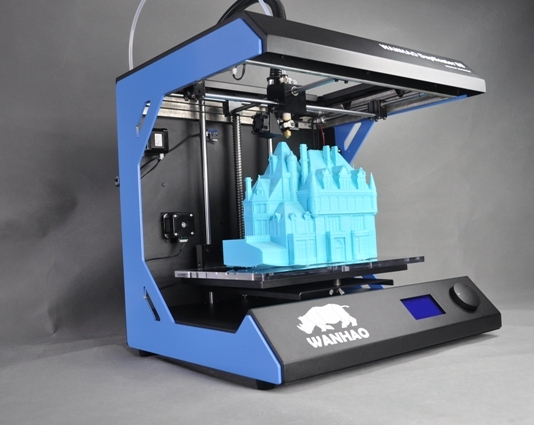

Flexion Single Extruder Kit3d printers are complex machines that can require servicing and repair. If you do not have the skills, knowledge or tools, then using a paid repair service may be the best option. The services are generally very well versed in the issues and know how to fix what they find. They are fast and many of the services allow you to ship them the printer to repair, and then ship it back after repair.

The Prusa I3 Mk3 comes stock with an automatic bed leveling system. This was failing because we had not assembled the hot end correctly, and it hung too low below the housing. We didn’t know that.

Depending on the printer that you purchase, you may find that the manufacturer’s website may have troubleshooting tips. With Prusa, we contacted their chat support, and within a few minutes, we were chatting with a gentleman from the company. We went through some testing with him, and he asked us to take some photos with our phone and upload them to him.

The photos showed the problem. He could see that we had incorrectly assembled the machine. He showed us where in the instruction book what steps to redo, and we could repair the faulty assembly and get on our way. We profusely thanked him for his help, but after the long assembly and the stress of it all, we felt that we could use some help.

3d Printer Repair ServicesThere aren’t that many 3d repair services out there. I think the reason is that 3d printing is relatively new, and there isn’t a demand for them yet. I don’t think (but haven’t verified) that you can take your 3d printer to Best Buy’s Geek Squad for some help. Maybe you can, but having been a technician for them many years back, I know that they’re not cheap and likely they’ll ship it out for repair rather than fix it themselves.

I think the reason is that 3d printing is relatively new, and there isn’t a demand for them yet. I don’t think (but haven’t verified) that you can take your 3d printer to Best Buy’s Geek Squad for some help. Maybe you can, but having been a technician for them many years back, I know that they’re not cheap and likely they’ll ship it out for repair rather than fix it themselves.

We decided to search for a repair service. We’re in the Southwest of the United States, and the first service on our Google.Com search was LA 3d Printer Repair. Surprisingly enough, they’re based in Los Angeles, California. We gave them a call, and the gentleman that answered the call (one of the owners of the service) helped us out. He was extremely helpful. He walked us through the troubleshooting, and agreed with the Prusa chat representative, that we had assembled it incorrectly.

He was willing to stay on the call and walk us through the disassembly, fix and reassembly if we wanted, all for no charge. That was fantastic, and if we weren’t exhausted, we would have taken him up on it. Instead, we convinced him that we would like to send it in for repair. He agreed, and charged a flat fee to repair it, check to ensure that it functioned correctly (so we didn’t get it back and find another thing wrong), and upgrade it to the Prusa I3 Mk3S standard. It was more money, but we felt it was a good option.

That was fantastic, and if we weren’t exhausted, we would have taken him up on it. Instead, we convinced him that we would like to send it in for repair. He agreed, and charged a flat fee to repair it, check to ensure that it functioned correctly (so we didn’t get it back and find another thing wrong), and upgrade it to the Prusa I3 Mk3S standard. It was more money, but we felt it was a good option.

Off the printer went to Los Angeles, and two weeks later, it arrived back, very well packaged. My buddy hasn’t looked back. He ran the auto bed leveling, and started his first print. He’s printed over 30 models since, and all have succeeded. We raised a toast to the LA 3d Printer Repair guys for their excellent service!

- LA 3d Printer Repair: https://la3dpr.com/

There are other 3d printer repair services across the world. In the US, another recommended service is in North Dakota. Check out these guys for similar service on your 3d printer:

- Fargo 3d Printer Repair: https://www.

fargo3dpr.com/

fargo3dpr.com/

C

an You Repair Your 3d Printer Yourself?You can absolutely fix many of the problems that you experience with 3d printers yourself. They’re really not that complicated, from the mechanical point of view. Electronically (or code-wise) they’re much more complicated. But to fix moving parts that aren’t moving or not moving correctly, you can certainly do it yourself.

Take a look at IFixIt 3d Printer Repair Guides and Tools: https://www.ifixit.com/Device/3D_Printer. They have a limited number of printers that they cover, but they cover most “types” of printer. The concepts are likely the same, though, so could be useful, even if you own a printer that isn’t in their list. Find something close and see if what they’re suggesting could work for your printer.

I have an M3D Micro, which is one of the guides that IFixIt does cover. It has both a disassembly guide and several replacement guides. Each of the guides is both well written and illustrated. I found it clear in the instructions that I followed (to replace the small cooling fan).

I found it clear in the instructions that I followed (to replace the small cooling fan).

They also offer a range of specialty precision tools that can come in handy for not only your current repair, but any moving forward. I picked up their Apple-specific Torx drivers a while back for repairing a MacBook, and was impressed by the quality. Most 3d printers, though, come with at least the necessary hex keys necessary to disassemble and work on the printer. That’s the norm now, but I got no tools when I originally purchased the M3D Micro. Still, likely a good set of hex keys and small needle-nosed pliers and some small screw drivers will be enough.

YouTube.Com – Your Source For Every RepairI contend that there is nothing you can’t learn on YouTube.Com. Someone has done what you want to do before you do and has likely filmed it or at least filmed talking about it. That’s certainly true for repairs of 3d printers and fixing issues that come up with 3d printing.

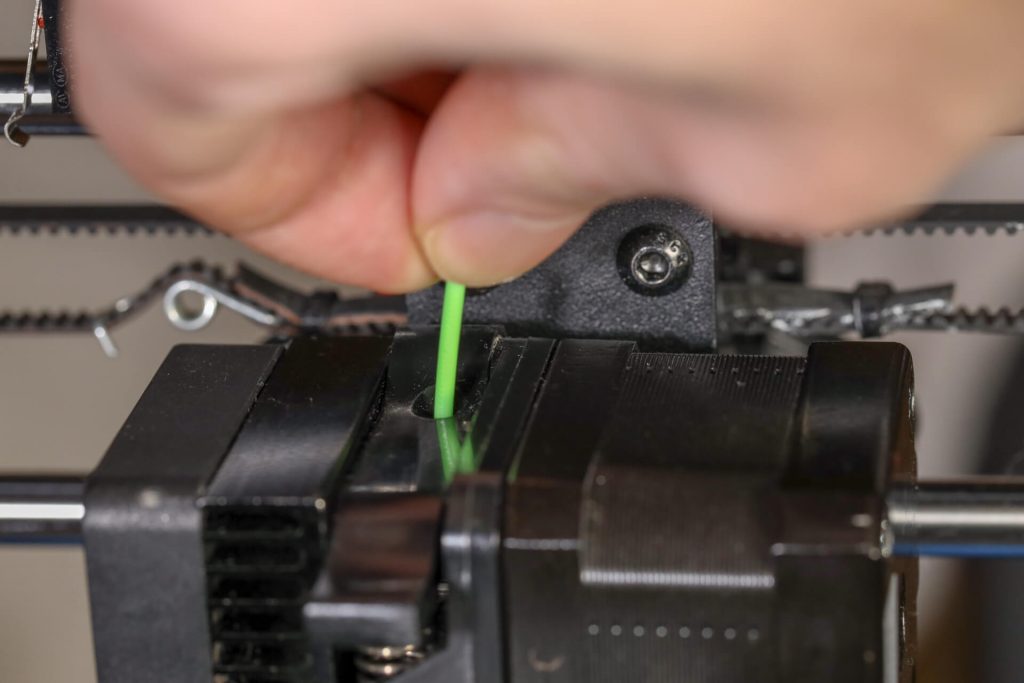

Simply search for what you need, either on Google.Com or YouTube.Com. I am a visual learner, so this helps me dramatically. I learned how to replace the Bowden tube, the hot end extruder nozzle and the hot end insulation on my Ender 3 this way. I had no idea how to do any of that before I watched several videos. Armed with that knowledge, the process was far simpler.

It’s easy to get sucked into watching yet another YouTube video, though. Remember, you’re a maker and a doer. Get the information that you need and go get it done!

Related QuestionsHow do I stop my 3d printer from moving?

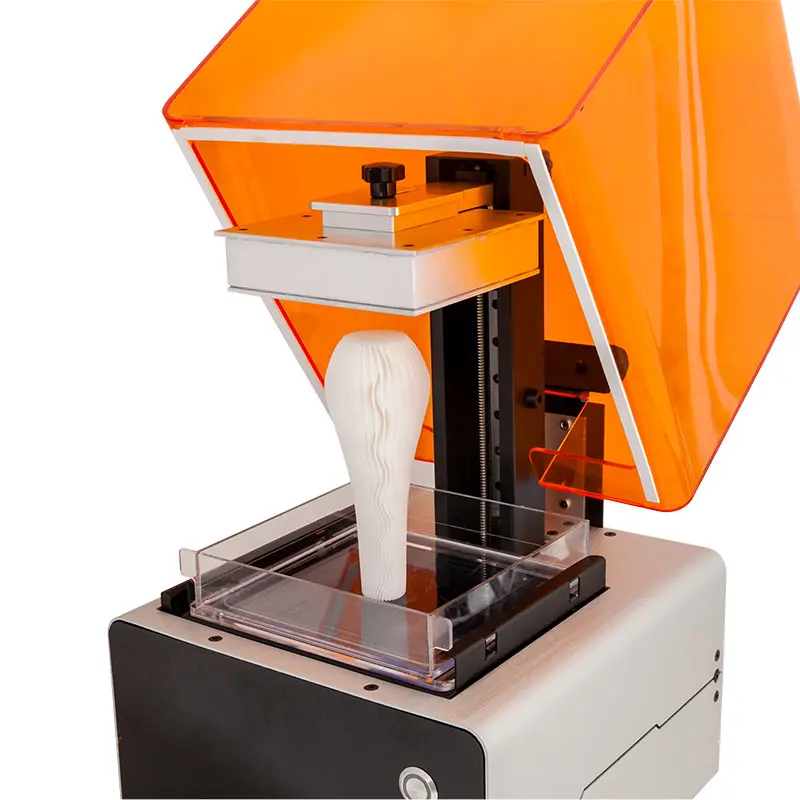

Your printer shouldn’t be moving around when you print. If you’re using a DLP resin printer, the only moving part goes up and down, and very slowly. For an FDM filament printer, if you are printing too fast, the print head on the X-Y plane flies around and can jerk the printer with the inertia of the movement. Don’t print so fast. Slow down the print speed (in mm per second) and your printer should stop moving and your quality will go up.

Why does my 3d print shift?

The most likely explanation for a shift in an FDM filament printer job is due to one of the cables getting caught during printing. If this happens, the printer’s extruder or its bed are not where the printer thinks they are. The printer will continue to print, but now the print is printing offset from the lower layers. To fix this, ensure that the cables are tied so that they cannot get caught or snagged. Many printers have 3d printed add-ons that you can use to guide the cables to ensure that they do not get caught. Search Thingiverse.Com for these items.

Tweet

Which Places Fix & Repair 3D Printers? Repair Costs – 3D Printerly

For people that are having issues with their 3D printer and just can’t manage to fix it, they wonder which places can fix and repair 3D printers, as well as the costs. This article will answer some of these key questions and provide information to get you more up-to-date with repairs.

Keep on reading to learn more.

Which Places Fix 3D Printers? Repair Services

1. LA 3D Printer Repair

LA 3D Printer Repair service providers are based in Los Angeles, California, United States. They have a team with experience in troubleshooting, and fixing issues in almost all brands and models of 3D printers.

They offer support where a dedicated operator will listen to the issue you are having with a 3D printer and will guide you to fix it at home.

They also offer shipping services which means that you can send your 3D printer to them, then they will fix it and will ship it back to you along with the necessary documentation to make things easier for you. Just go to their website, reach out to them, and drop the details about your 3D printer.

A user shared his experience with LA 3D printers repair stating that they gave them a call and an operator helped them out. The operator guided them to troubleshoot the issues and tell them that they made some mistakes while assembling the 3D printer.

The operator offered to stay on the call and help them assemble the Prusa 3D printer from the beginning and surprisingly all without charging a single penny.

However, they sent the printer so that LA 3D Printer Repair can fix all issues by themselves, and they charged a flat fee while upgrading the printer to a standard Prusa i3 Mk3S.

2. Makerspace Community

Makerspace is a great option if you can find a group or even a single person in your hometown or the city. Just message them and seek permission to take your 3D printer to them and they will help you out as much as they can.

If they help you without charging anything, it is recommended to compensate them with a pack of soda or at least coffee.

One user recommended searching “Makerspace Near Me” on Google or looking for a local Makerspace community center and if someone is willing to help, you are good to go.

Another user suggested contacting Charlotte Makerspace as they can help out. Even if they aren’t near you, they will have access to a network that may refer you to good repair service.

Even if they aren’t near you, they will have access to a network that may refer you to good repair service.

One guy said that he has a good experience with maker spaces as there are a lot of people who do 3D printing around Freeside Atlanta.

3. Hackerspace

Hackerspace is a community page where various people have enrolled themselves on the list. You can contact a person who is near you and ask for help.

https://www.reddit.com/r/3Dprinting/comments/edtpng/is_there_a_3d_printer_repair_business_totally/

4. Prusa Research/Prusa World Map

You can take a look at the PrusaPrinters World Map as there will be orange markers that indicate a person or an expert that is willing to help in different aspects of Prusa 3D printing issues. Even if you use a 3D printer other than Prusa, you should give it a try as they know about other 3D printers as well.

One user also suggested visiting the Reddit Prusa3D forum, uploading each issue in separate posts, adding photos, and explaining the problem. There will be people willing to guide you through repairs.

There will be people willing to guide you through repairs.

In a nutshell, there are quite a few 3D printer repair services in the world.

In some cases, users recommend that you sell your 3D printer if there are significant problems since the expenses of delivery, repair may not be worth the cost. There should be some kind of electronics place that may have experience fixing 3D printers, so I’d recommend looking for something local.

Another user said that you should fix your 3D printers by yourself because of costs.

Let’s say you have a broken stepper motor that needs replacement. The motor itself will cost you about $15 but the repairing cost might be around $30 which means that you have already spent almost 1/4th the price of an entry-level 3D printer.

He recommended the following resources to seek help in case you have a faulty 3D printer.

- Simplify3D Support

- Teaching Tech (YouTube Channel)

- Thomas Sanladerer (YouTube Channel)

How Much Do 3D Printers Repair Cost?

It varies from region to region but a service provider can charge about $30 for the diagnosis of 3D printers while the repairing fee is around $35 per hour, on average. The cost of replacing parts and equipment and shipping charges will also be added to the final bill.

The cost of replacing parts and equipment and shipping charges will also be added to the final bill.

It depends on the service provider as well. For example, MakerTree 3D Printer Repair charges average prices while the LA 3D Printer Repair is quite expensive as their cost are:

- $150 to Tune Up Stock 3D Printer

- $175 to Tune Up Modified/Upgraded 3D Printer

- $250 for Assembling Prusa Mk3S+

- $100 for Assembling Prusa Mini

- They will also charge $25-$100 more in a few situations such as if your 3D printer has multiple extruders or you have a 3D printer with a big volume.

These prices are really expensive compared to the price of the 3D printer itself. In many cases, it will be cheaper to learn how to fix the problem with some online help with tutorials, or to find a local electronics store that has some experience with 3D printers.

Does Geek Squad Repair 3D Printers?

Geek Squad does repair 3D printers and it was one of the first to provide 3D printer repair services. They have a physical center in some places where you can bring your 3D printer for repair. You can also schedule an appointment through online means for diagnosis on the same day, then repair afterwards by experts.

They have a physical center in some places where you can bring your 3D printer for repair. You can also schedule an appointment through online means for diagnosis on the same day, then repair afterwards by experts.

One user mentioned that you should go for some other repair service provider instead of Geek Squad as they can be too costly and some of their centers just send the 3D printers to some other repair service provider instead of fixing it by themselves.

It’s a good idea to read customer reviews before you delivery your 3D printer to any repair center.

Repair of ski equipment using 3D printing

Application

work. In connection with all the restrictions imposed due to the sanctions, transport and logistics schemes and trade between the countries were disrupted. Therefore, some products became impossible to buy, while delivery times for others greatly increased. Winter came very quickly, and in order to get to the ski equipment rental season in time, my friends asked me to provide repair services using 3D printing.

Why 3D printing, because it:

1. Fast;

2. Quality;

3. Reliable;

4. Cheap.

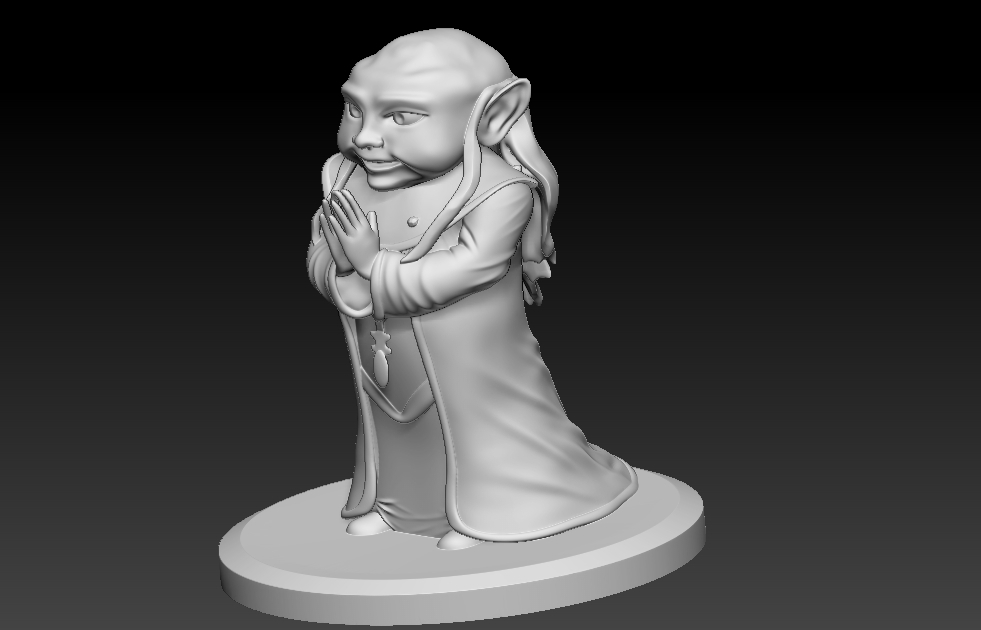

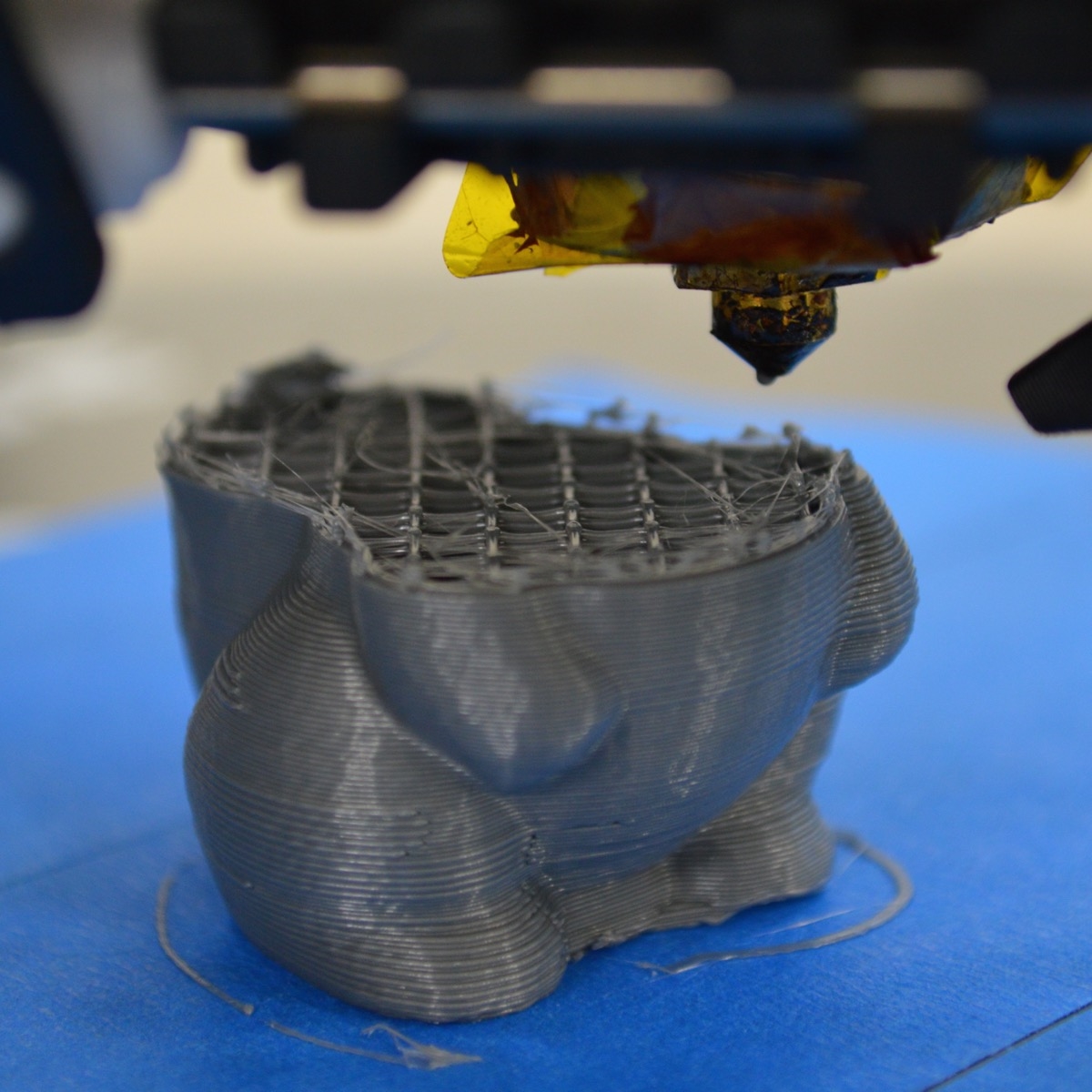

The hardest part was 3D modeling the damaged plastic parts and fitting them to the equipment. Some 3D models were found on the Internet, some were developed from scratch using the Compass 3D program.

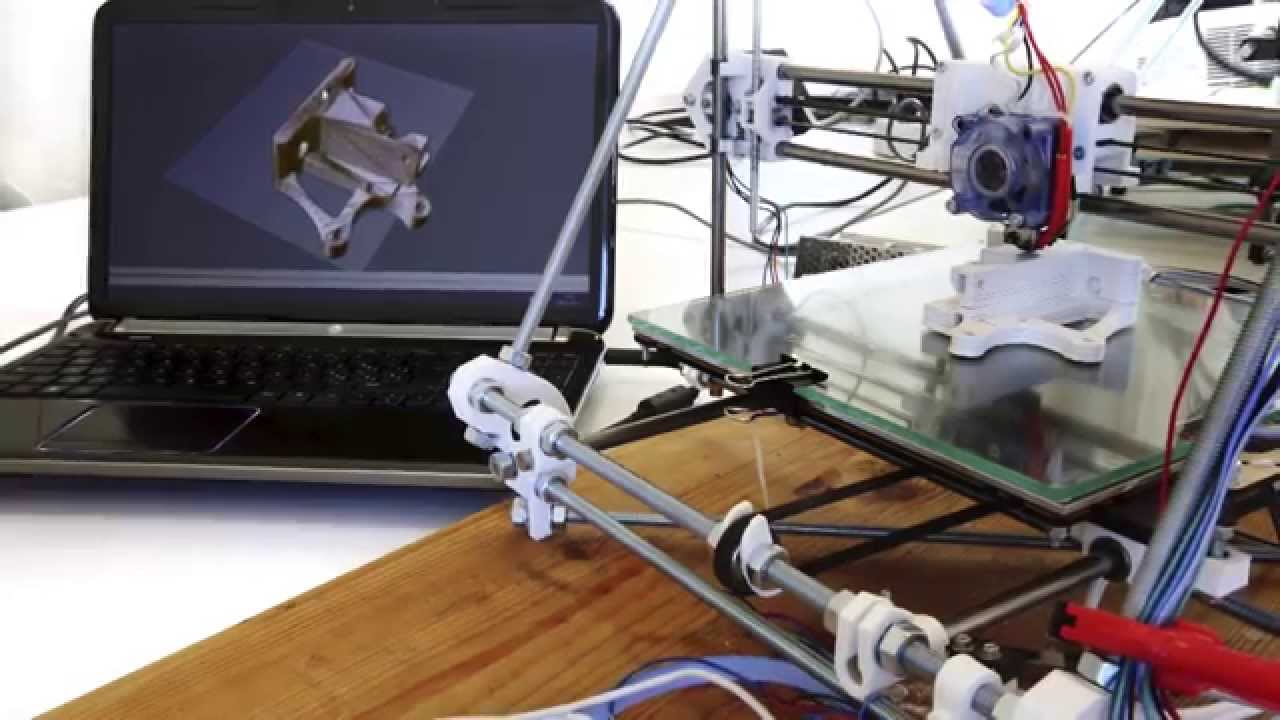

Printed on the proven Flying Bear Ghost 5.

This Chinese printer is quite reliable. Of the modifications, quiet drivers and LED illumination of the working area are installed on it. The speed of high-quality printing is certainly not high, but it copes with its tasks. I can say one thing about this printer, it does not need additional modifications. And if you want to redo it, then you need to redo everything and it turns out that it is easier to buy a new and ready-made printer.

The material for printing was mainly PETg plastic from the company FILAMENTARNO with a diameter of 1.75 mm.

Let me explain the choice of this particular plastic for use in 3D printing:

1. Printed at home, so non-toxic plastic is used for printing;

Printed at home, so non-toxic plastic is used for printing;

2. Easy to print with PETg plastic, it does not require special agents for adhesion to the printer table, adheres well to the printer's ultrabase, does not shrink when cooled, the part does not deform;

3. Plastic quality from FILAMENTARNO. I got it as a gift, I have not worked with it before, but in my opinion the details are very high quality.

Ski equipment needs to be repaired from time to time due to missing or damaged components. First, I’ll tell you what repairs were made, and then, using the example of one part, I’ll tell you about the process.

Ski poles have been made with plastic handles and feet that have been damaged or lost during use. But here the work was not significant. Basically, ski boots needed serious repairs.

Plastic soles and heels of boots often wear out, especially in older models, and it is not possible to find a replacement. This is where 3D printing comes in.

Repair work can be divided into 3 stages:

1. 3D modeling of the part;

2. Printing a part on a 3D printer

3. Finishing and fitting.

I will consider the whole process using the example of old ski boots made in Italy. To create a 3d model, I needed a damaged part and the boot itself, a compasses and a program for 3d modeling. I used Compass 3D as a program. Of course, I did not create an exact copy, but an analogue adapted for printing on a 3D printer and not inferior in functionality to the native part.

The next step is to prepare for printing. Using the CURA slicer, I choose the optimal parameters for printing and the location of the part on the printer table. We send the generated file for printing.

The part was printed on a Flying Bear Ghost 5 printer using FILAMENTARNO plastic.

After printing, I remove all supports and try on the finished heel to the boot. Of course, during the manufacturing process, not all parts fit perfectly, and some had to be redone several times. But thanks to the efforts made, the skiing season can be called successfully opened. Clients are satisfied, the costs cost 3 kopecks, the work was completed on time.

But thanks to the efforts made, the skiing season can be called successfully opened. Clients are satisfied, the costs cost 3 kopecks, the work was completed on time.

3d model of the heel for these shoes is posted in the profile. Thank you all

Repair of plastic products using 3D printing

Repair of plastic products on a 3D printer

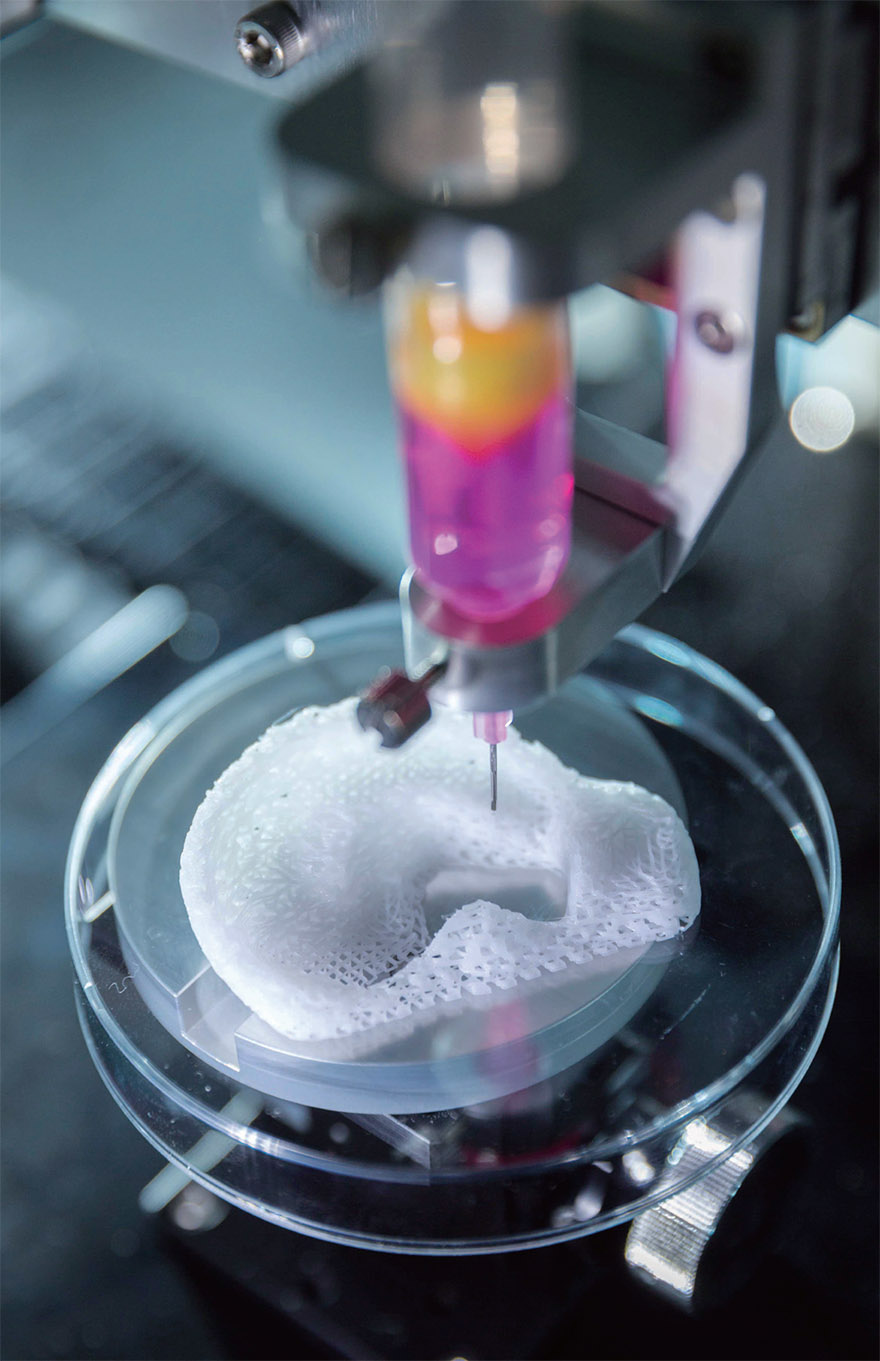

the Bureau. Repairing plastic products on a 3D printer is a simple and convenient process that does not require a significant investment of time or money. So, to restore plastic parts, you only need their 3D model, which you can easily make yourself.

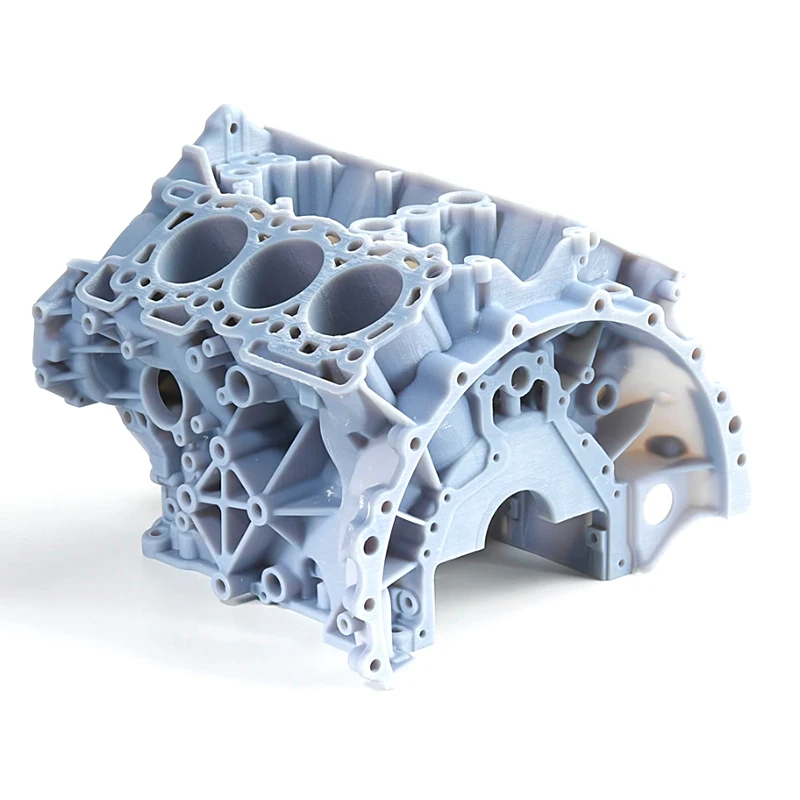

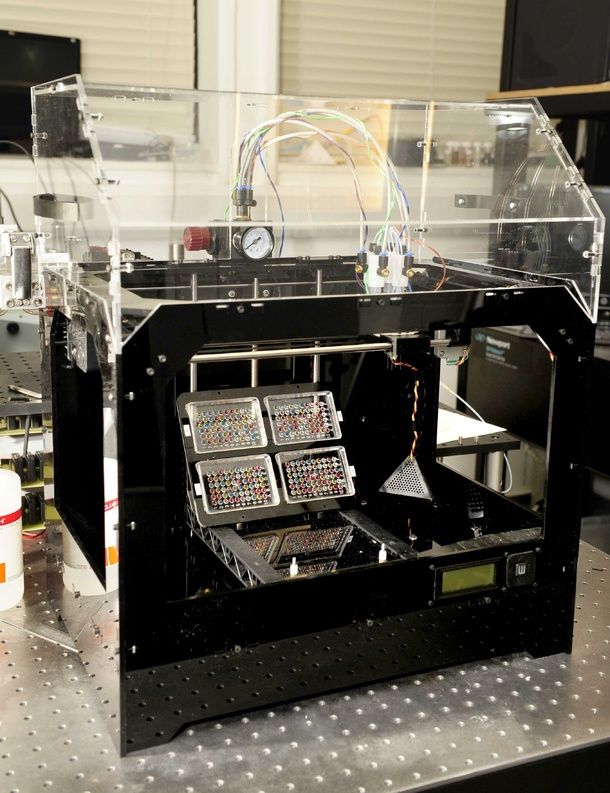

And if it is still possible to argue about the profitability of household repairs using 3D printing, then the benefits of 3D printers for service centers cannot be underestimated. In the case of repair shops, where the number of orders for the restoration of damaged products is very high, the use of 3D printing is quite justified. Particularly in demand is the repair of plastic products, which are difficult to find in free sale.

3D printing in service centers

Recently, more and more repair shops are switching to using 3D printing in their practice, and there are a number of good reasons for this:

- First, 3D printing is fast. It will take you from several hours to several days to reproduce one product using 3D printing (depending on the complexity and dimensions of the model). This is an extremely important feature when it comes to restoring exclusive parts, or in the face of burning deadlines;

- Secondly, there is a huge variety of plastic for 3D printers. Absolutely any parts are subject to damage and wear, and here the key factor is the properties of 3D plastic, from which you need to reproduce an identical part. With 3D printing, repairing flexible, durable, or chemical resistant parts will not be a problem for you;

- Thirdly, you can print anything you want. Absolutely everything, and even more. Modern 3D printing techniques allow the production of components of extremely complex structure.

And add to this also various plastics, and the needs of any service center will be satisfied;

And add to this also various plastics, and the needs of any service center will be satisfied; - Fourthly, the repair of plastic products by this method is financially beneficial. Here again it is worth remembering rare and exclusive components that are difficult to find on sale. And also about original parts from the manufacturer, which will cost a tidy sum. With a 3D printer and basic 3D modeling skills, all the cards are in your hands - you can become a manufacturer of unique components yourself.

Repair 3D printers

Benefits 3D printing is good, you say. But what kind of products can be repaired using a 3D printer? The answer will be obvious, honest - absolutely any! Anything made of plastic can be 3D printed with little effort. Here are some examples of how 3D printer plastic repair can be applied: