3D print glass filament

FibreX™ Nylon+GF30 3D Filament | Glass Fiber Reinforced

ON SALE

$47.00 – $185.00

4 interest-free payments with Learn More

FibreX™ PA6+GF30 glass fiber reinforced nylon copolymer is an engineering-grade material that has excellent mechanical and thermal properties [HDT of 170°C] while offering ease of printing in a wide array of desktop printers. This material is a must-have when printing functional prototypes and production parts.

[yith_wcwl_add_to_wishlist]

SKU: Select options above Brand: FibreX™ Categories: Glass Fiber Nylon, Glass Fiber Filaments, Nylon Family

- Description

- Reviews

- Questions & Support

FibreX™ Nylon+GF30 30% Glass Fiber Reinforced Nylon

Our Nylon+GF30 glass fiber reinforced Nylon 6 Copolymer (PA6) is nothing less than an industrial-grade beast! Formulated to be exceptionally stiff and strong, all without being brittle. Polyamides (PA) are the work horse of the plastics industry the world over thanks to their excellent mechanical, chemical, and thermal resistance. The addition of heavy glass fiber reinforcement takes it to the next level.

Gearbox HT2™ 3D Printer: Print industrial-grade parts using our PA6+GF30 and more with the new Gearbox™ HT2 High-Temp 3D Printer.

Print Recommendations

Extruder Temp

260-280°C

Bed Temp

60-75°C

Heated Chamber

Not required

Nozzle Specs

0.4mm diameter minimum

Hardened Steel Nozzle

Bed Adhesion

Magigoo Bed Prep

Layer Height

0. 25mm or higher

25mm or higher

Drying Specs

90°C for 4 hours

Supports

X1 USM Water Soluble Support

Benefits of Nylon+GF30 Include:

- Printable on practically any 3D printer with a heated bed

- Ideal for structural engineering-grade applications

- Exceptionally stiff and strong, without being brittle

- Excellent chemical resistance makes it suitable for automotive and industrial applications

- Resists fuels, lubricants, heat, and mechanical loading

- High thermal properties keep it strong up to 170°C in use, depending on printing and mechanical loads applied

- Glass fiber reinforcement improves dimensional stability, reduces shrinkage, lift, and warp

- Very strong layer bonding

Filament Specifications:

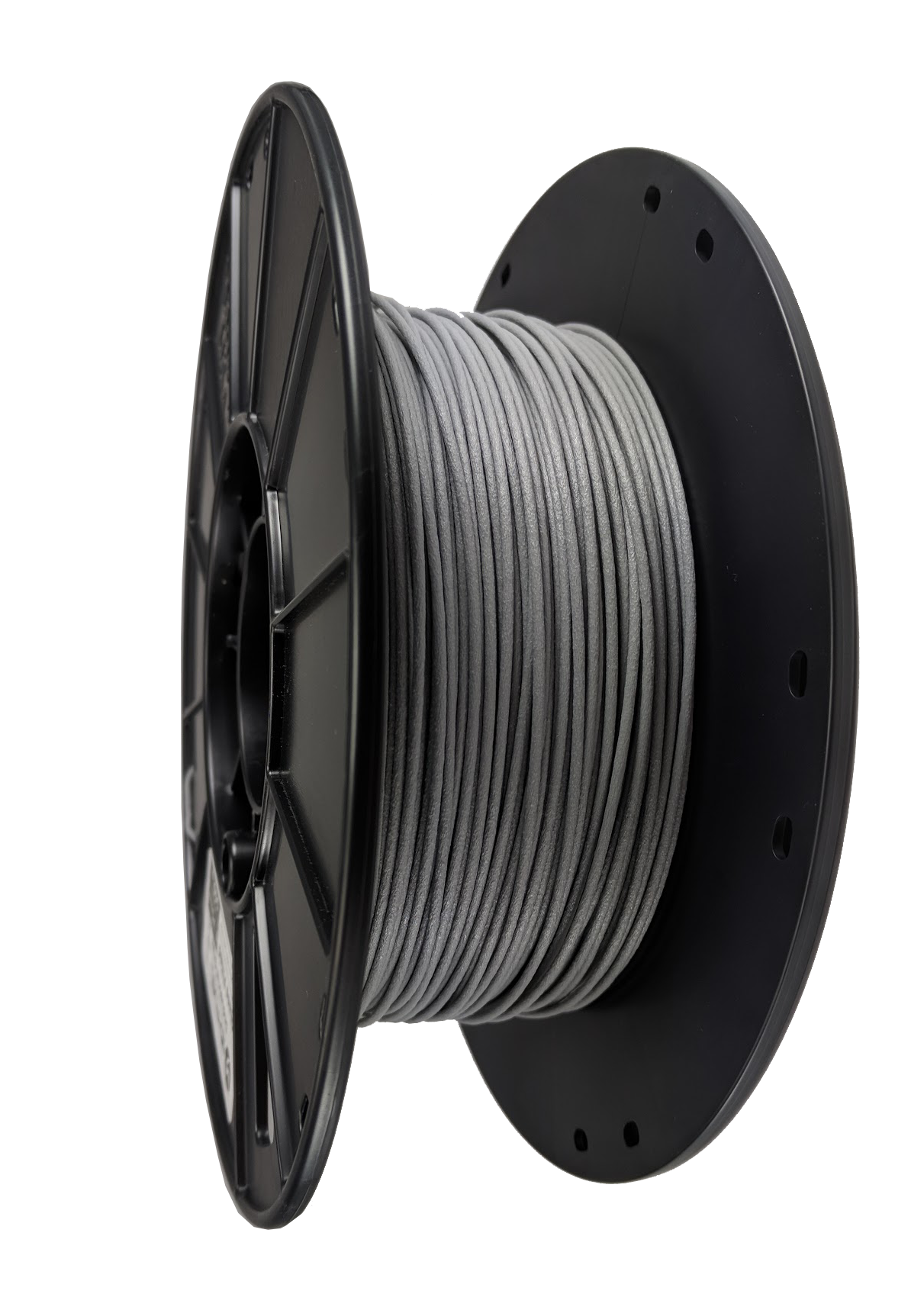

1.75mm and 2.85mm +/- 0.05mm in diameter

Recommended Print Settings:

- Extruder: 260-280°C

- Bed Temp: 60-75°C

- Nozzle: We currently recommend a hardened steel nozzle with a minimum diameter of 0.

4mm

4mm - Other: Ideal layer height is 60% of nozzle diameter. We do not recommend printing layers smaller than 0.25mm with glass fiber reinforced filaments

- Bed Prep: Magigoo Bed Prep or 3DXTECH Polyimide Tape gives us the best results

- Heated Chamber: Not required, but a 30-80°C chamber does improve layer bonding and finished part mechanical properties

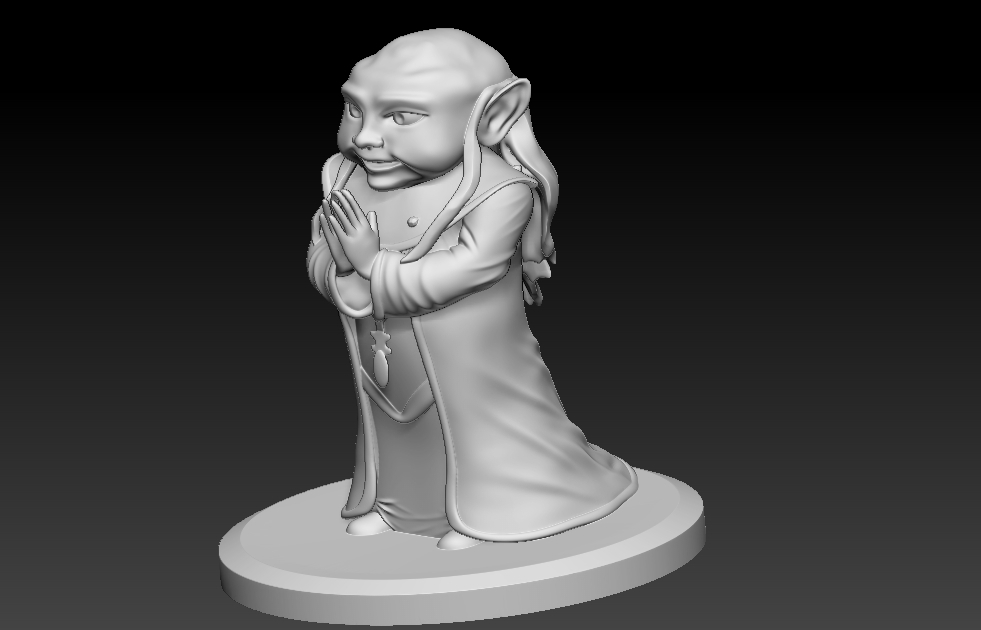

- Supports: AquaTek™ water soluble X1 USM Universal Support Material works ideal for complex parts.

- Drying Instructions: 90°C for 4 hours.

What Is It?

Fibers made of glass reinforced into the polymer during manufacturing and aligned along the axis of filament.

This, along with their physical makeup, give this material enormous strength and mechanical properties.

What Does It Do?

Glass fiber reinforcement gives material a lot of desirable properties:

- High strength

- High stiffness

- High chemical resistance

- Low thermal expansion

How Does It Work?

Reinforcing plastic with glass fibers produces a 3D printing filament which exhibits the best properties of both fiberglass and the plastic of choice.

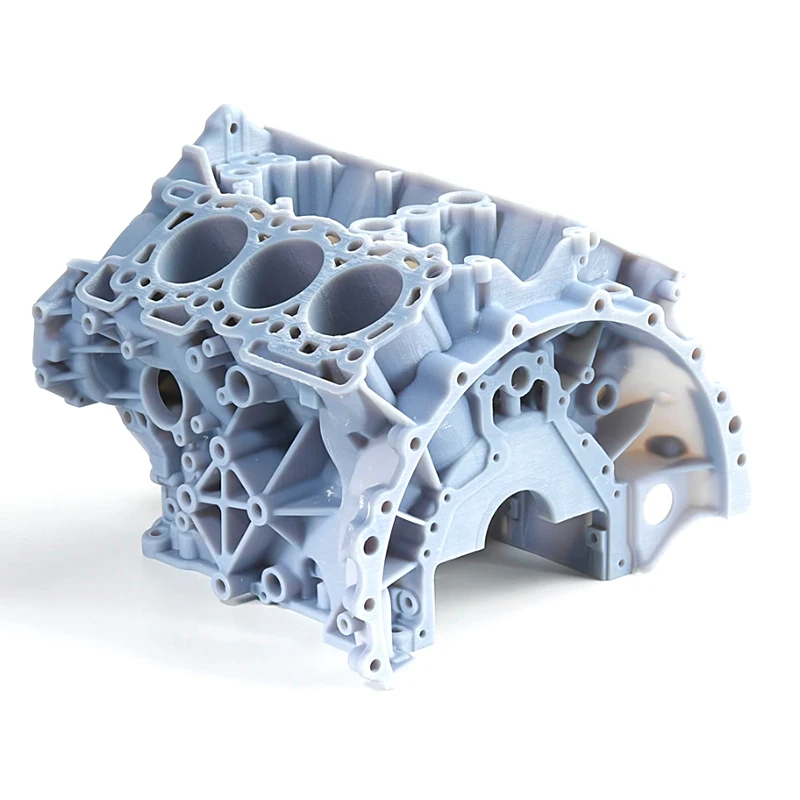

What Is It Good For?

Ideal for any applications which require strength and rigidity.

For these reasons, glass fiber reinforced filament is very popular in automotive, mechanical, civil engineering, and research industries.

What Is It?

Fibers made of glass reinforced into the polymer during manufacturing and aligned along the axis of filament.

This, along with their physical makeup, give this material enormous strength and mechanical properties.

What Does It Do?

Glass fiber reinforcement gives material a lot of desirable properties:

- High strength

- High stiffness

- High chemical resistance

- Low thermal expansion

How Does It Work?

Reinforcing plastic with glass fibers produces a 3D printing filament which exhibits the best properties of both fiberglass and the plastic of choice.

What Is It Good For?

Ideal for any applications which require strength and rigidity.

For these reasons, glass fiber reinforced filament is very popular in automotive, mechanical, civil engineering, and research industries.

Abrasive Material

This material is particularly abrasive among 3D printing filaments. Users may find standard brass nozzles are chewed through very quickly compared to standard wear and tear. When worn through, the nozzle diameter will widen inconsistently and the printer will experience extrusion issues.

Because of this, it's strongly recommended this material be printed through a hardened steel nozzle rather than a softer metal. Hardened steel nozzles can often be inexpensive and easily installed depending on your printer manufacturer's instructions.

Questions?

Send us a message and we'll reach out as soon as we can!

Please enable JavaScript in your browser to complete this form.Name *

Business / Organization

Email *

Phone

What can we help you with? *

Newsletter Signup

- Sign me up for the 3DXTECH newsletter

Glass 3D Printing Filaments: A Complete Guide

Glass 3D printing filaments are a handy way of adding strength to your models, and can be made safely and easily using many desktop 3D printers. Hobbyists and professionals alike will find their 3D printing endeavors vastly improved by using these filaments.

Hobbyists and professionals alike will find their 3D printing endeavors vastly improved by using these filaments.

In this article, we will take you through two of the most popular glass 3D printing filaments, glass PLA and NylonG, their advantages and disadvantages, and some innovative ways in which glass is being implemented in the 3D printing industry.

- For a guide to every filament, also check out our complete 3D printer filament guide.

Part 1: Glass 3D Printing Filaments Printing Parameters

The main way in which glass is incorporated into these 3D printing filaments is through making composite filaments with tiny fragments of glass fibers within. These ‘composite’ filaments, encompassing not only glass infused filaments but also carbon fiber, are vastly stronger than their pure plastic counterparts.

The inclusion of other materials such as glass in these filaments improves strength and reduces susceptibility to bending and breaking. This means that the parts produced have far greater tensile strengths and are much more durable.

Glass filaments also have a number of benefits that make the 3D printing process much easier as well. They have a much lower potential for warping than other plastics, meaning less special attention is needed during the cooling process. They also do not produce the same odors or toxic gasses that other plastic filaments do.

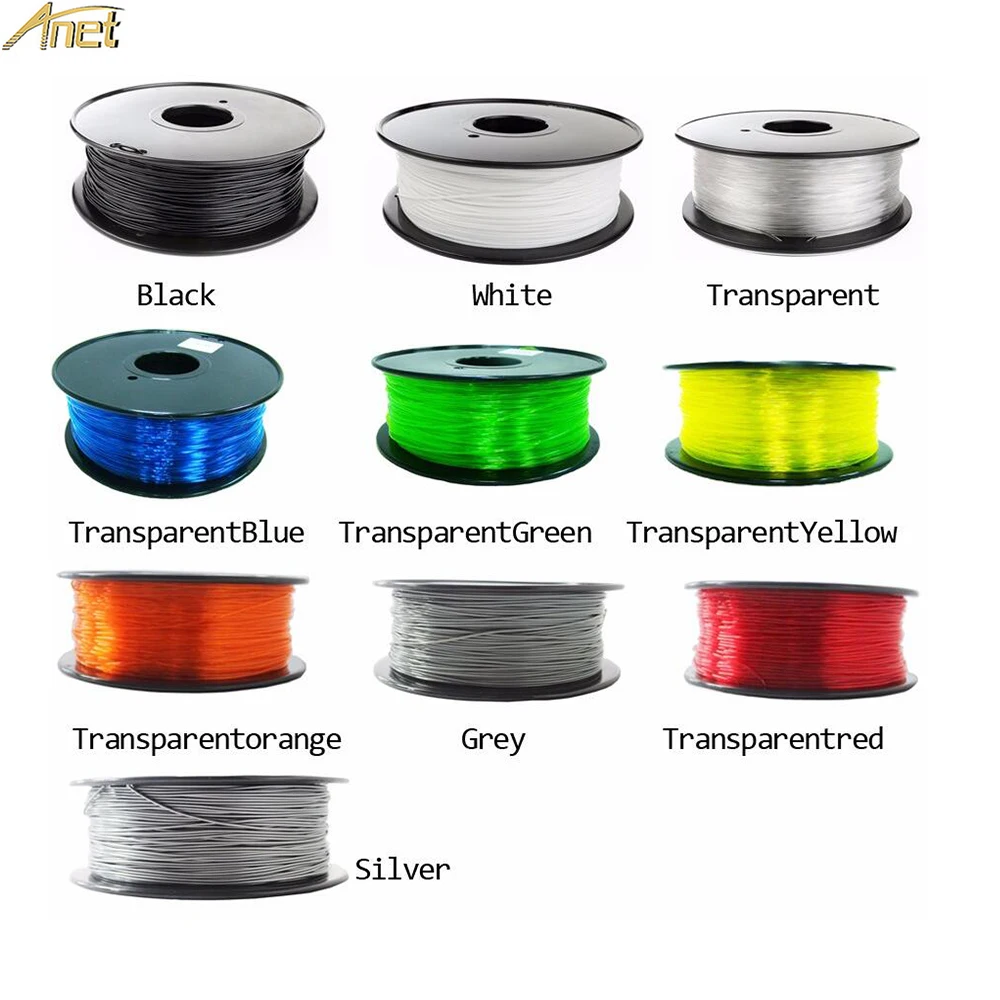

There are two particular glass-infused filaments that are noteworthy as they have become increasingly prevalent in the last few years.

Glass-Infused PLA

- Printing Temperature: 180°C-220°C

- Bed Temperature: 40°C (Optional)

Polylactic Acid (PLA) is a favorite material among many beginners in 3D printing as it is much easier to print than many other plastics. Its 180°C extruder temperature is far lower than ABS or PP.

It is a stiff, brittle plastic used for prototypes, ornaments and cosmetic accessories, helped to no end by the wide array of colors that it comes in. PLA is also biodegradable, making it among the most environmentally friendly plastic filaments.

The addition of glass into PLA filaments helps to remove these shortcomings, and makes PLA a much more well-rounded and versatile material. Composite glass-infused PLA is 1.5x stronger and impact resistant, and also twice as flexible than standard PLA.

This means it is more durable than Acrylonitrile Styrene Acrylate (ASA), a popular plastic in outdoor applications, yet nearly as flexible as pure nylon, giving it an unforeseen range of improvements that broaden the material’s capabilities.

This makes PLA ideally suited for exterior fittings and outdoor tools, and can be printed much easier than other comparably strong materials.

NylonG

- Printing Temperature: 260°C-280°C

- Bed Temperature: 60°C-75°C

Similarly to PLA, the infusion of glass fibers into nylon has maintained what makes it unique and useful, but helped to correct some of its deficiencies.

Pure nylon is among the most flexible 3D printing filaments on the market, making it useful in producing products such as cable ties, fishing lines, and various forms of clothing where flexibility and durability are key. It is also extremely resistant to wearing down, meaning harder variations of nylon are used for things like skateboard wheels.

It is also extremely resistant to wearing down, meaning harder variations of nylon are used for things like skateboard wheels.

- If you are interested in printing flexible filaments, we also have a guide to 3D printing TPU filaments.

However, nylon 3D printing does have a number of flaws and potential pitfalls. It requires expert care as it is very prone to warping and disfiguring if cooled too fast. The filament itself is also very hygroscopic, so the filament must be kept in an airtight container or it will deteriorate, printing weaker parts with bubbly imperfections.

- We have another article on Nylon carbon fiber composites.

After production, it must also be properly dried to avoid serious printing defects and for this reason, nylon is extremely unsuitable for moist or humid environments.

NylonG removed many of these concerns. Without losing any flexibility, the glass gives the nylon filament extra structure and makes it much stronger. This increased density also gives the added benefit of making the filament less absorbent, and reduces the possibility of moisture damage.

This increased density also gives the added benefit of making the filament less absorbent, and reduces the possibility of moisture damage.

Also, similar to the benefits of glass-infused PLA, NylonG warps less during printing, simplifying the printing process and making the material much more accessible to hobbyists and professionals alike.

Part 2: How Much Do Glass 3D Printing Filaments Cost?

Glass 3D printing filaments are naturally slightly more expensive than their pure polymer counterparts. Glass PLA filaments start around $68 per kilogram, with NylonG starting at a much pricier $100 per kilogram.

Where to buy Glass filaments

We recommend the following glass filament selections:

- Glass filament selection of both standard and professional composites on Matterhackers here

- NylonG selection on Matterhackers

Part 3: Best Practices for Glass Filled Filaments

Use a Hardened Steel Nozzle

Glass 3D printing filaments are packed with tiny, almost microscopic fragments of glass. These are guaranteed to rub against your extruder nozzle as they are deposited, wearing away softer brass nozzles that ship with standard affordable 3D printers.

These are guaranteed to rub against your extruder nozzle as they are deposited, wearing away softer brass nozzles that ship with standard affordable 3D printers.

For this reason, upgrading to a steel nozzle rather than using a standard brass nozzle will save the time from constantly switching these worn down nozzles out. Hardened steel nozzles hold up better against the abrasive fibers within glass filament. This will greatly increase the longevity of your setup.

Start Heat Higher

It is best to start your heat high when 3D printing using glass-infused composites. While it is definitely possible to print at lower temperatures, especially with PLA, the glass fibers can do real damage if any clogs occur.

It’s best to avoid this by starting high and guaranteeing a good flow, and then lowering the temperature on later attempts until you find your optimum level.

Use a Raft

This is mainly for printing at lower temperatures, but using a raft is the best way to make certain of the best adhesion for your part. Starting off with a base of material and printing on top of that will give you enough of a foundation to make the best part possible.

Starting off with a base of material and printing on top of that will give you enough of a foundation to make the best part possible.

If you notice that separating the part from the raft after printing is difficult, you can adjust the raft-model spacing setting to reduce this.

Part 4: Advantages and Disadvantages of Glass 3D Printing Filaments

Advantages of glass 3D printing filaments

Stronger Parts

The rigid structure that the addition of glass provides makes these filaments much stronger than their pure alternatives and makes them competitive with some of the strongest plastics on the 3D printing market.

They have higher tensile strengths and higher levels of impact resistance, and, despite being biodegradable, are among the most durable plastic filaments money can buy.

Overall Easier to Print

There are a number of other aspects that make these filaments easier to print than other polymers, and even more than their pure alternatives. The addition of glass makes them less prone to warping and thereby reduces the amount of special care needed to print effectively.

The addition of glass makes them less prone to warping and thereby reduces the amount of special care needed to print effectively.

On top of this, they produce less odor and harmful fumes, require no special extruder, and PLA does not even need a heated bed.

Disadvantages of glass 3D printer filaments

More Expensive

In exchange for added strength and durability, your wallet is going to have to do some heavy lifting. Both glass-infused PLA and NylonG are more than double the price of their pure polymer counterparts.

For this reason, these filaments are not ones to try out unless you have money to burn. If you are a beginner, you may fall into the traps that anyone could with any filament. The pure forms of these plastics, especially PLA, are much cheaper and give you the room to experiment with if you are on a tighter budget.

However, for professionals and industrial prototypers, engineers, and for a variety of other industrial applications, these improved material characteristics more than justify the investment.

Part 5: Alternate Methods of Glass 3D Printing

Aside from using polymer filaments, researchers have been experimenting for years with ways to 3D print using pure glass. However, despite successes, there are huge limitations. Traditional glass manufacturing requires extraordinarily high temperatures, upwards of 1500°C.

When first experimenting with 3D printing glass, manufacturers tried two different techniques. Firstly, they attempted to use deposition printing with molten glass.

However, this had significant drawbacks with the need for prolonged heating at high temperatures, as well as similarly heat-resistant equipment that did not previously exist in the 3D printing industry.

Elsewhere, experiments were conducted involving using powdered ceramic which could be deposited at room temperature, and sintered with a high-powered laser, similar to Direct Metal Laser Sintering (DMLS). Yet this reduced the capacity for complex designs for small intricate parts.

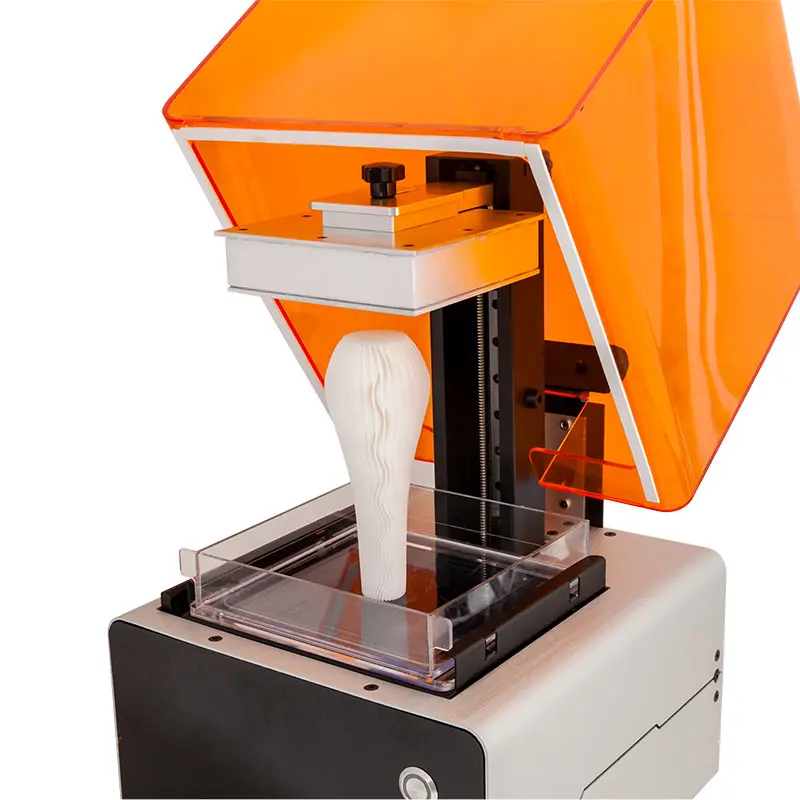

A new and slightly more accessible technique has been developed by researchers at Swiss institute ETH Zurich. Their process is very similar to stereolithography, among the first 3D printing techniques, and uses resin, containing plastic and a mixture of molecules used in the traditional manufacturing of glass.

Once deposited, the resin is irradiated with ultraviolet light to harden. The finished product is then heated, first to 600°C to burn away the polymer, and then to 1000°C to form the remaining ceramic structures into glass.

While the heating process significantly shrinks the glass model, the remaining part is crystal clear and highly detailed. Naturally, this is solely an industrial-level process, but successful products are able to maintain an extraordinarily high level of complexity, with intricate edges and designs.

Like traditional glass products, they are still very brittle and will crack and shatter under moderate stress. Due to the shrinkage issues, it is also not possible to print large designs. However, with this small but significant first step, the glass 3D printing industry is well on its way to major development.

However, with this small but significant first step, the glass 3D printing industry is well on its way to major development.

While completely impractical for home printing, new techniques could give glass a new lease of life in the manufacturing industry, with applications in industries ranging from jewelry to aerospace to communications.

What we do see now though is glass 3D printing filaments are becoming a fixture of in-home 3D printing, and taking the first steps towards wider adoption of glass in the industry.

Related articles:

- Ender 3 glass bed – best upgrades

- 3D printed glasses – a feature story

3D printing with glass will change the process of glass production

Amazing 3D printing with glass

3D printing technology is developing so rapidly that it is sometimes difficult to imagine what else scientists can surprise us with. However, the field of research is very extensive and it is difficult to find an area that it would not affect, providing developers with a lot of opportunities to implement a variety of ideas. Just yesterday, we reported on the receipt by British researchers of a patent for a 3D printing technique with silicone, and today we are in a hurry to share no less exciting news: scientists from the Massachusetts Institute of Technology (MIT) have developed a 3D printer that prints with glass. 3D glass printing is an extremely promising process that scientists have high hopes for.

Just yesterday, we reported on the receipt by British researchers of a patent for a 3D printing technique with silicone, and today we are in a hurry to share no less exciting news: scientists from the Massachusetts Institute of Technology (MIT) have developed a 3D printer that prints with glass. 3D glass printing is an extremely promising process that scientists have high hopes for.

Glass 3D Printer

In his recent interview with Sculpteo, an international 3D printing service, Dr. Pierre-Thomas Bruhn shared some of the latest advances in working with molten glass. Together with Neri Oksman, assistant professor of arts and sciences, he began to study the properties of this material. The doctor hopes to reveal all its features for further use in the development of a unique 3D glass printer. The team was well aware that in the event of a successful outcome of the experiment, they would be able to completely change the technology for manufacturing glass products.

3D glass printing is of great interest not only from an industrial point of view. Dr. Brun is also interested in the scientific side of the issue. “My daily research is about mathematics that moves the world around. I'm interested in everything from rings of honey falling on toast to a self-similar solution that describes the process of blood cell clotting,” says Brune. “But I have focused on the study of the dynamics of fluids and flexible bodies, with particular attention to non-linear effects, which I study by combining data from tables, precise measurements and theories. I try to select the best of these tools to rationalize the physics behind such systems.”

3D Printing Glass

The 3D printing glass that Dr. is studying is brought to a middle state between resilience and toughness. This is done because in a 3D printer it is necessary to maintain a strictly defined temperature in order to produce a quality product. It is well known in certain circles that the result that the development team is committed to was previously almost impossible to achieve.

In their research, the scientists also needed the help of MIT's Glass Lab, as their secondary goal was to create hardware to efficiently feed molten glass. The developers named their project G3DP (Glass 3D Printing). Its highlight is the possibility of using it both for industrial purposes and for creating amazing pieces of art - glass forms are so enchanting with their beauty.

In general, the team developed a new equipment consisting of two sections. The upper one functions as a furnace, melting glass at temperatures above 1000°C. The lower one is made in the form of a conventional extruder that supplies glass, which then cools and hardens. As stated in their latest work “Additive Manufacturing of Optically Transparent Glass”, in addition to temperature, the technology allows you to control the viscosity of the glass, the flow rate and the height of the layer of the created product.

Features of 3D printed glass

3D printed products exhibit good layer adhesion along with satisfactory transparency. The researchers say the new 3D printer will be capable of producing high-quality glass parts featuring high detail, transparency, and various aesthetic and mechanical settings. Unique 3D-printed products from such a sought-after material can be implemented in various scales and functional areas, including object and architectural design. The peculiarities of this glass 3D printing technology are that it is at the intersection of design, engineering, science and art, representing a rather multifaceted invention.

The researchers say the new 3D printer will be capable of producing high-quality glass parts featuring high detail, transparency, and various aesthetic and mechanical settings. Unique 3D-printed products from such a sought-after material can be implemented in various scales and functional areas, including object and architectural design. The peculiarities of this glass 3D printing technology are that it is at the intersection of design, engineering, science and art, representing a rather multifaceted invention.

All products created with the new 3D printer, and the printer itself, will be on display at the Cooper-Hewitt Museum this year. Like many other fields, the glass industry is poised to be completely transformed by 3D printing technology. The development team believes that their project will allow them to take a fresh look at the process of manufacturing glass products and enjoy the new hardware capabilities of production. And, having estimated results of work, it is difficult to disagree with them.

Back to main page

Techno Print 3D Company

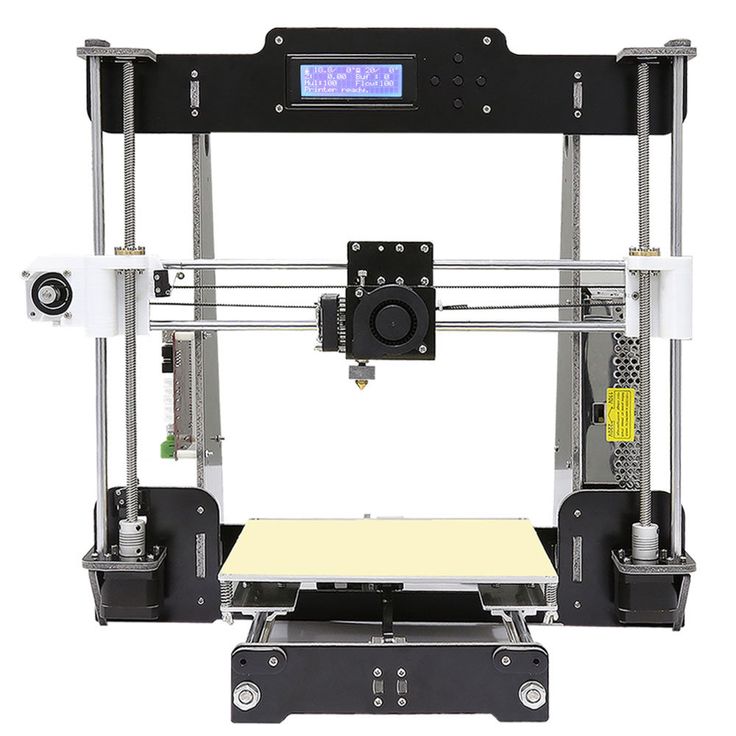

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

Known for its daVinci line of desktop 3D printers, XYZprinting is bringing five new devices to the professional and industrial environment.