3D print in houston

3D Printing Service for Houston, Texas

CapabilitiesCustom Online 3D Printing ServiceTexasHouston

High Quality Houston, Texas 3D Printing | 60+ Materials Available

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Guaranteed Quality

We back every part we ship with the Xometry Quality Guarantee. Our number one job at Xometry is making your custom parts to your specifications.

Your Houston, Texas 3D Printing Service: 3D Prototypes and Production Parts

A Global Leader in Industrial-Grade 3D Printing

Xometry is an industry-leading 3D printing service. Whether you need prototypes or production parts, we can make them for you in as fast as a day. We are your one-stop-shop for accurate, precise custom 3D printed parts at a low cost. Upload your 3D CAD file to get a quote and lead time within seconds. We use the latest additive manufacturing processes to build affordable functional prototypes & end-use parts in over 60 metals and plastics.

We offer eight high-quality 3D printing processes including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, polyjet, Carbon DLS, binder jet metal, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more.

Houston 3D Printing - Industries and Applications

3D printing, a form of additive manufacturing, is a tremendous manufacturing asset to businesses and organizations in Houston, Texas. If you're looking to better understand how 3D printing could add value to your project or industry, Xometry can assist you with your goals.

According to Thomasnet. com®'s 2022 sourcing data, the top six most popular manufacturing industries in Houston are Chemicals, Education, Transportation and Logistics, General Manufacturing, Metals, and Energy and Utilities. Here's how 3D printing can support local manufacturing in Houston in some of these popular sectors:

com®'s 2022 sourcing data, the top six most popular manufacturing industries in Houston are Chemicals, Education, Transportation and Logistics, General Manufacturing, Metals, and Energy and Utilities. Here's how 3D printing can support local manufacturing in Houston in some of these popular sectors:

- Chemicals: 3D printers can produce necessary complex multi-component chemical equipment within a laboratory, expediting chemical research and making it an invaluable resource for research and development in the chemical industry. Additive manufacturing also allows engineers to make custom sampling, holding, and compounding laboratory equipment and prototypes. Though only a fraction of the materials that are commonly used in conventional component manufacturing can be used for 3D printing, this avenue is being thoroughly explored.

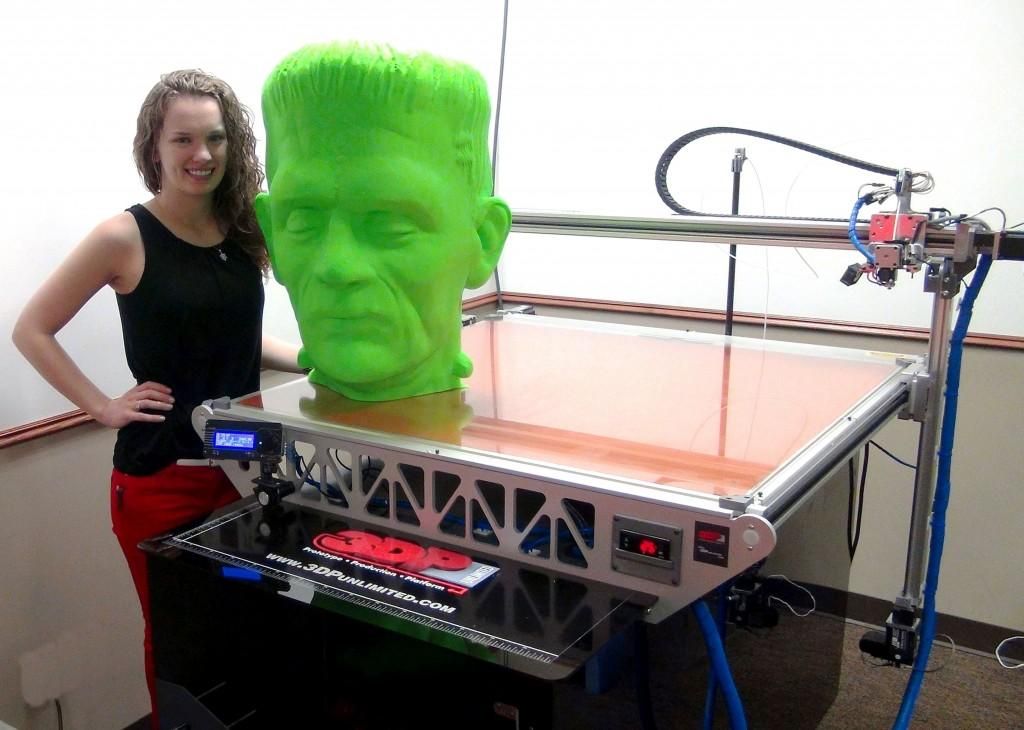

- Education: 3D printing technologies play an increasingly important role in STEM education.

With greater access to CAD, 3D printers in education enable educators to teach students how to create tangible products and tools with a very low barrier to entry. Scientific concepts and deep theoretical constructs can be taught more efficiently with accurate physical 3D printed prototypes to hand. Integrated into classroom environments from elementary school to university, 3D printers are not only a useful hands-on learning tool for students but also a powerful research resource for teachers.

With greater access to CAD, 3D printers in education enable educators to teach students how to create tangible products and tools with a very low barrier to entry. Scientific concepts and deep theoretical constructs can be taught more efficiently with accurate physical 3D printed prototypes to hand. Integrated into classroom environments from elementary school to university, 3D printers are not only a useful hands-on learning tool for students but also a powerful research resource for teachers. - General manufacturing: Considered a necessary utility tool that the majority of manufacturing companies are employing, 3D printing is a low-cost and invaluable manufacturing solution used in many avenues, from parts of the production line and making jigs and fixtures to creating custom tooling for laser marking. It also allows for rapid prototyping to test design concepts ahead of production runs, thus reducing risk and eliminating costly design flaws. Top automotive companies are eager to leverage this technology, i.

e., BMW, which uses Xometry for custom assembly of purpose-designed soft-touch handheld jigs. One case study showed that these improved-quality, lighter-weight, 3D printed products not only reduce fatigue but they also reduce scrap rate, too. Additive manufacturing is also starting to become a substitute process for injection molding, particularly for low-volume projects that require complex tooling from plastic or metal. As 3D printing creates parts directly from the CAD model one layer at a time, it offers cost advantages by eliminating the upfront expenses of creating tooling or molds, such as with die casting, injection molding, or CNC machining.

e., BMW, which uses Xometry for custom assembly of purpose-designed soft-touch handheld jigs. One case study showed that these improved-quality, lighter-weight, 3D printed products not only reduce fatigue but they also reduce scrap rate, too. Additive manufacturing is also starting to become a substitute process for injection molding, particularly for low-volume projects that require complex tooling from plastic or metal. As 3D printing creates parts directly from the CAD model one layer at a time, it offers cost advantages by eliminating the upfront expenses of creating tooling or molds, such as with die casting, injection molding, or CNC machining. - Metals (raw, formed, fabricated): Though most commonly associated with plastic, 3D printing is seeing a rapid rise in the use of metal and the creation of tools to form metal in areas like sheet fabrication, rigid tooling, and even powder metallurgy. In metal injection molding and die casting processes, rigid tooling using extremely tough yet ductile maraging steel is being created with additive manufacturing without the need for a CNC machine.

Even jewelers are digitally creating custom 3D printed prototypes using a master wax pattern. With the ability to create custom products that can be ordered to have the exact features and even bend desired, 3D printing is being used more and more in the metals industry.

Even jewelers are digitally creating custom 3D printed prototypes using a master wax pattern. With the ability to create custom products that can be ordered to have the exact features and even bend desired, 3D printing is being used more and more in the metals industry. - Energy and utilities: Thanks to its quick turnaround time compared to traditional tooling, 3D printing is also being explored for energy and utilities. Parts which are typically cast can be directly printed out of metal or a high-performance polymer substitute quickly and in fewer numbers. There are also many opportunities for large-format industrial printing in the fields of renewable energy and oil & gas. Bespoke, hard-to-transport parts such as metal tubular designs for drilling with internal features to cater to camera monitoring, circuit boards, and sensors can be 3D printed. In these industries, additive manufacturing is more than just engineering a machine component; with the ability to create state-of-the-art groundbreaking mechanisms with endless capabilities, 3D printing can significantly transform and modernize these sectors.

The additive manufacturing and material market is rampantly growing and is estimated to reach US$61.1 Billion by the year 2027. With the technology being so prolific, providing endless options, and the opportunity to greatly add to and advance your business, let Xometry cater to all your industrial-grade 3D printing needs.

Xometry's High Quality 3D Printing Services

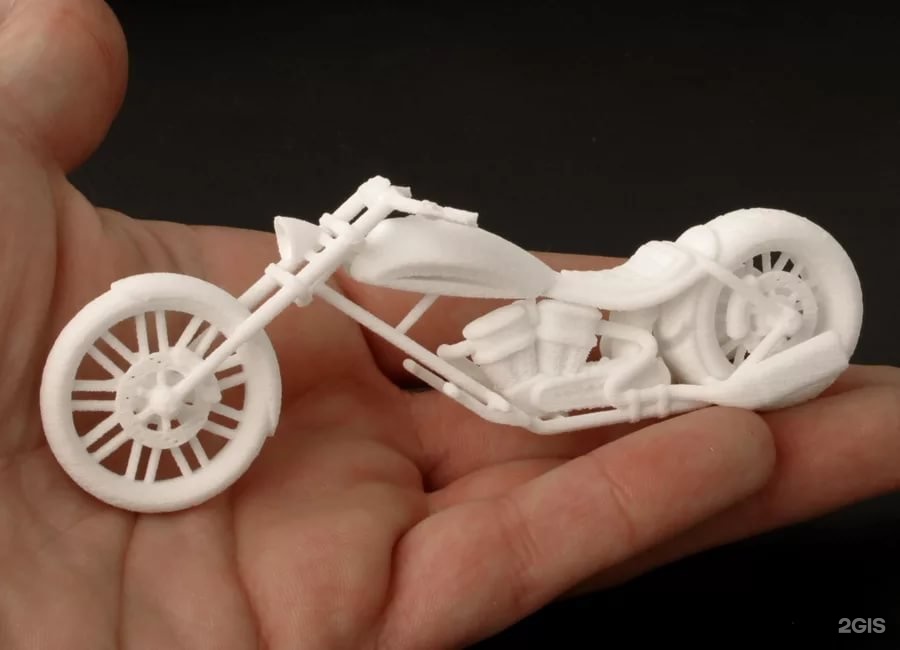

Selective Laser Sintering (SLS)

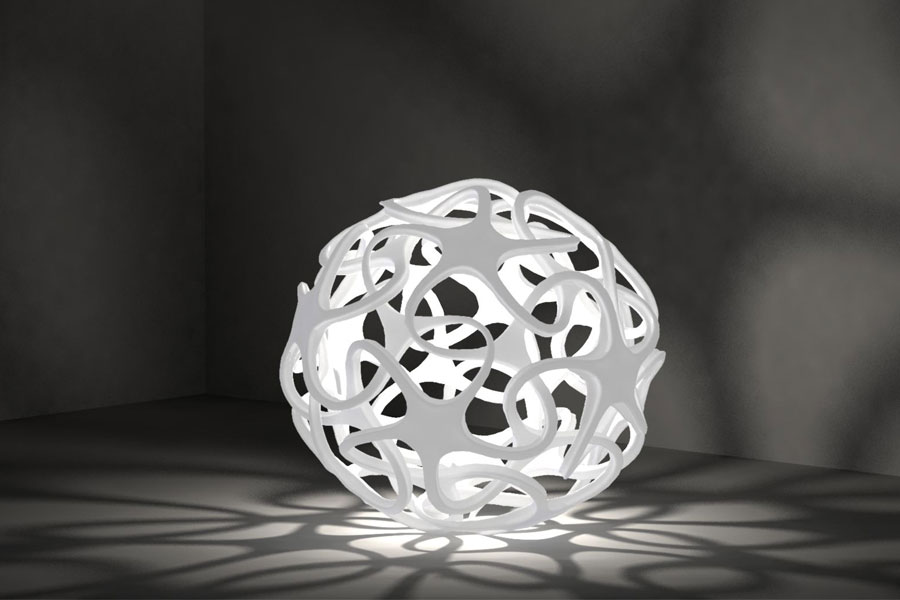

Selective Laser Sintering (SLS) is a powerful 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

An additive manufacturing layer technology, SLS involves the use of a high power laser (for example, a carbon dioxide laser) to fuse small particles of plastic powders into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

Download the SLS Design Guide.

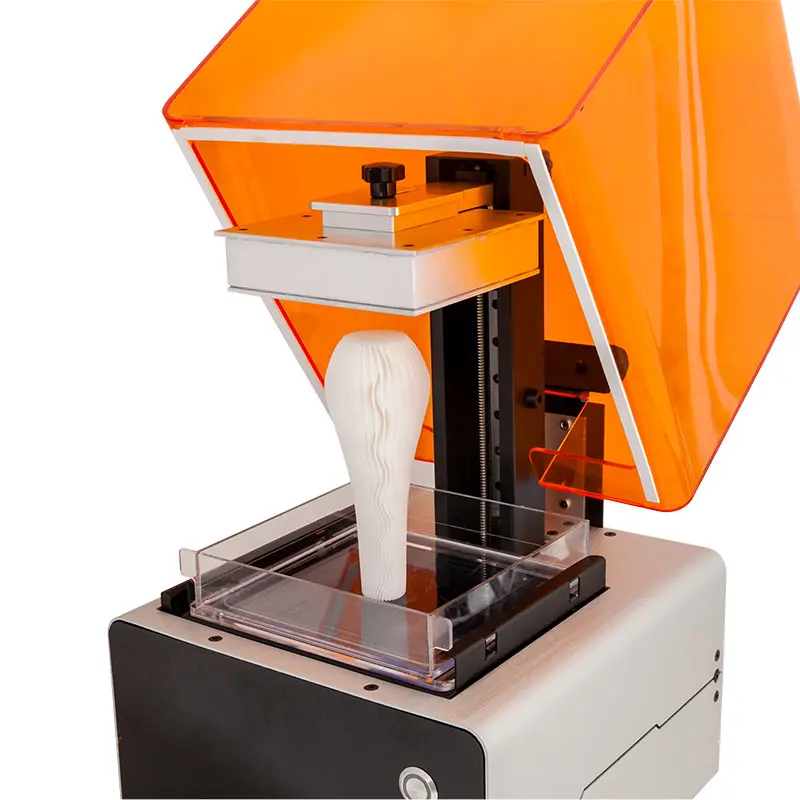

Stereolithography (SLA)

Stereolithography (SLA) is a robust 3D printing technology that produces extremely accurate and high-resolution parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

SLA is an additive manufacturing process that focuses an ultraviolet (UV) light on a vat of photopolymer resin. It offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes. SLA 3D printing is a highly-versatile platform for making custom parts in prototype and production settings; often acting as a stand-in for injection-molded plastic parts.

Xometry offers both standard and high-resolution options for fine detail parts, and can also print larger sized parts and products, with some materials offering up to a 58" inch build area. In addition, Xometry's manufacturing partner network allows us to offer a larger variety of materials than other 3D printing companies - we offer a wide range of both Accura and Somos brand materials.

In addition, Xometry's manufacturing partner network allows us to offer a larger variety of materials than other 3D printing companies - we offer a wide range of both Accura and Somos brand materials.

Download the SLA Design Guide.

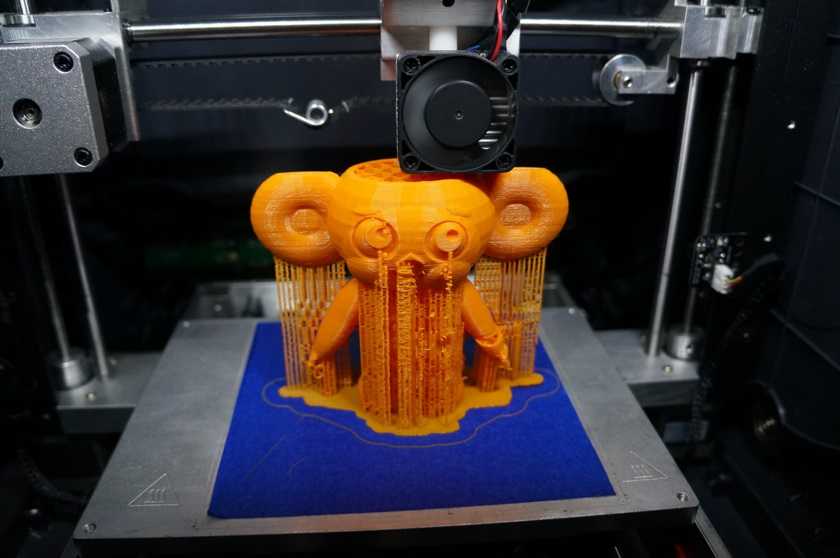

Fused Deposition Modeling (FDM)

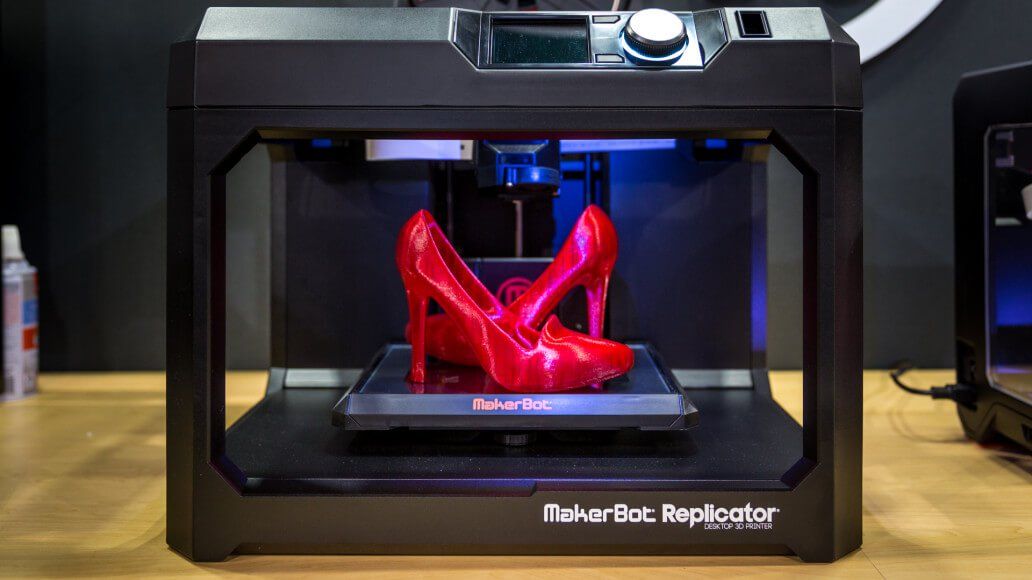

Fused Deposition Modeling (FDM) is a 3D printing technology widely known for its speed, accuracy, and competitive cost. A machine precisely extrudes melted plastic filament to create a part. Parts are very rigid, especially compared to Selective Laser Sintering (SLS), which makes them a great fit for projects with a rigidity requirement. Xometry's FDM solution offers large build volumes up to 24″ x 36″ x 36″, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate to Ultem.

Download the FDM Design Guide.

HP Multi Jet Fusion (HP MJF)

HP Multi Jet Fusion is a new 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping. Since the process uses well-established 2D printing ink-jetting, it has remarkably fast layer times compared to other powder bed fusion technologies.

Since the process uses well-established 2D printing ink-jetting, it has remarkably fast layer times compared to other powder bed fusion technologies.

Download the HP Multi Jet Fusion Design Guide.

PolyJet 3D (PJ3D)

PolyJet 3D is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV curable resin onto a build tray in a process that is somewhat similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. It also supports a wide variety of build materials including rigid and rubber-like plastics. Xometry's PolyJet solution has a maximum build envelope of 19.3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

Download the PolyJet 3D Design Guide.

Direct Metal Laser Sintering (DMLS)

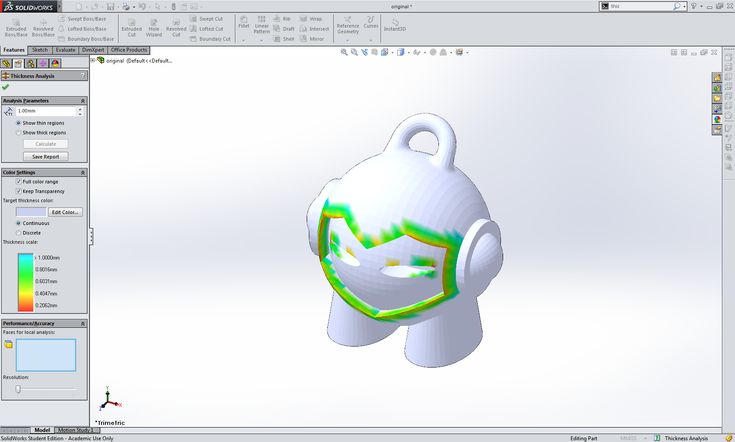

Direct Metal Laser Sintering (DMLS) is an 3D metal printing technology that builds prototype and production metal parts from a CAD file using a laser to selectively fuse a fine metal powder in either stainless steel or aluminum materials. A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

Our DMLS metal 3D printing service typically offers build volumes up to 250 x 250 x 325 mm, but we may be able to accommodate larger part volumes upon request in the quote. (See our Manufacturing Standards for more details) A good first step is to find out the cost of the parts you need using DMLS and compare them to other 3D printing processes and CNC machining.

Download the DMLS Design Guide.

Carbon DLS™

Carbon DLS™ uses digital light projection, oxygen-permeable optics, and programmable liquid resins to produce products with end-use durability, resolution and surface finish. This 3D printing technology is called Digital Light Synthesis™, or DLS for short. Another legacy term for the process is Continuous Liquid Interface Production (CLIP). Along with Carbon’s custom liquid resins, DLS unlocks new business opportunities and product designs previously impossible, including mass customization and on-demand inventory of end-use products.

Carbon bridges, and sometimes substitutes, for processes like Urethane Casting and Injection Molding service production, because the materials are urethane-based or epoxy-based, giving excellent mechanical properties. There are even elastomer and silicone resins that outperform most additive manufactured rubber-like materials.

The typical build area is 7.4” x 4.6” x 12.8”. Parts with dimensions exceeding 4” x 4” x 6” will require manual review.

Download the Carbon DLS Design Guide.

Metal Binder Jetting

With binder jetting, an inkjet print head quickly deposits a bonding agent onto a thin layer of powdered particles -- either metal, sand, ceramics or composites. This process is repeated, layer-by-layer, using a map from a digital design file, until the object is complete. Binder jetting is offered through our Digital RFQ Marketplace through Xometry's partnership with ExOne.

Download the Binder Jetting Design Guide.

Ready to start making custom 3D printed parts?

3D Printing Services for Houston, TX

Back

-

Materials

Materials by Service

Injection MoldingCNC Machining3D PrintingSheet Metal

Materials by Type

PlasticsMetalsElastomers

Related Links

Customer Supplied ResinsColors

Definitive Guide to

CNC MachiningOur downloadable guide offers tips on optimizing your design for machining, tolerances and threading considerations, choosing the right material for your parts, and much more.

Download

-

Resources

Design Tips Toolkits Guides and Trend Reports Case Studies Design Aids Webinars and Trade Shows

Blog Videos FAQs Educators and Students Glossary

Industries Medical Aerospace Automotive Consumer Electronics Industrial Equipment

-

About Us

Who We Are Why Protolabs? Factories x Network Digital Quoting Platform Research and Development Cool Idea Award Sustainability and Social Impact

Careers Investors Locations Press Procurement Partnerships

Contact Us

Proto Labs, Inc.

5540 Pioneer Creek Dr.

Maple Plain, MN 55359

United StatesP: 877.479.3680

F: 763.479.2679

E: [email protected]Digital Factories x

Partner NetworkOur digital factories produce low-volume parts in days while our digital network of manufacturing partners powered by Hubs unlocks advanced capabilities and volume pricing at higher quantities.

Learn More

Get a QuoteSign In

CERTIFICATIONS

ISO 9001:2015 | AS9100D | ITAR Registered

Our 3D Printing Processes

From rapid prototyping to end-use production and plastics to metals, our 3D printing service offers a broad range of capabilities that will meet your project requirements.

Metal 3D Printing

LEARN MORE

Multi Jet Fusion (MJF)

LEARN MORE

Stereolithography (SLA)

LEARN MORE

PolyJet

LEARN MORE

Selective Laser Sintering (SLS)

LEARN MORE

Carbon DLS

LEARN MORE

Compare 3D Printing Technologies

Examine 3D Printing Materials by Technology

Metal 3D Printing (DMLS)

- Aluminum (AlSi10Mg)

- Cobalt Chrome

- Copper (CuNi2SiCr)

- Inconel 718

- Stainless Steel (17-4PH and 316L)

- Titanium (Ti 6-4)

Stereolithography (SLA)

ABS-Like

- ABS-Like Gray (Accura Xtreme Gray)

- MicroFine™ (Gray and Green)

- ABS-Like Translucent/Clear (WaterShed XC 11122)

- ABS-Like Black (RenShape SL7820)

- ABS-Like White (Accura Xtreme White 200)

PC-Like

- PC-Like Translucent/Clear (Accura 60)

- PC-Like Advanced High Temp (Accura 5530)

- Ceramic-Like Advanced HighTemp (PerFORM)

PP-Like

- PP-Like Translucent White (Somos 9120)

Selective Laser Sintering (SLS)

- PA 12 White (PA 650)

- PA 11 Black (PA 850)

- PA 12 40% Glass-filled (PA 614-GS)

- PA 12 Mineral-filled (Duraform HST)

Multi Jet Fusion

- PA 12 Nylon Black

- PA 12 40% Glass-Filled Black

PolyJet

- Digital Clear/Translucent

- Digital Black

- Digital White

Carbon DLS

- Carbon RPU 70

- Carbon FPU 50

If you have any issues getting your guide, click here to download.

3D Printing Surface Finish Guide

Get this quick reference guide to explore your surface finish options across our six 3D printing technologies.

United States of AmericaAfghanistanÅland IslandsAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBolivia, Plurinational State ofBonaire, Sint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape VerdeCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongoCongo, the Democratic Republic of theCook IslandsCosta RicaCôte d'IvoireCroatiaCubaCuraçaoCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland Islands (Malvinas)Faroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly See (Vatican City State)HondurasHong KongHungaryIcelandIndiaIndonesiaIran, Islamic Republic ofIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea, Democratic People's Republic ofKorea, Republic ofKuwaitKyrgyzstanLao People's Democratic RepublicLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacaoMacedonia, the Former Yugoslav Republic ofMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesia, Federated States ofMoldova, Republic ofMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorthern Mariana IslandsNorwayOmanPakistanPalauPalestine, State ofPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarRéunionRomaniaRussian FederationRwandaSaint BarthélemySaint Helena, Ascension and Tristan da CunhaSaint Kitts and NevisSaint LuciaSaint Martin (French part)Saint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint Maarten (Dutch part)SlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth SudanSpainSri LankaSudanSuriNameSvalbard and Jan MayenSwazilandSwedenSwitzerlandSyrian Arab RepublicTaiwan, Province of ChinaTajikistanTanzania, United Republic ofThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUgandaUkraineUnited Arab EmiratesUnited KingdomUnited States Minor Outlying IslandsUruguayUzbekistanVanuatuVenezuela, Bolivarian Republic ofViet NamVirgin Islands, BritishVirgin Islands, U. S.Wallis and FutunaWestern SaharaYemenZambiaZimbabwe

S.Wallis and FutunaWestern SaharaYemenZambiaZimbabwe

I agree to receive email messages containing service updates and Design Tips from Protolabs and its affiliates

Why Choose Protolabs for 3D Printing in Houston?

Get design feedback from our experienced engineering team that has helped thousands of customers bring their products to market with quality 3D-printed parts. We will also work with you to determine optimal part orientation based on your application's requirements.

Across our six 3D printing technologies, we use a range of commercial-grade thermoset resins, and thermoplastic and metal powders to 3D print parts that are suitable for various part applications and industries.

If required for your parts, we offer a variety of post-process options such as heat treating, secondary machining, plating, painting, and dyeing to further enhance mechanical properties and cosmetics.

LEARN MORE

Our industry-leading tolerances and surface finish quality stems from a dedicated process engineering and quality team for each 3D printing technology. We also offer a proprietary material called Microfine™, which can build features as small as 0.0025 in.

We also offer a proprietary material called Microfine™, which can build features as small as 0.0025 in.

SEE MICROFINE DETAILS

Our facility is home to more than 120 3D printing machines that produce metal and plastic parts. This means we'll always have capacity when you need parts fast.

Consultative Quoting

Wide Material Selection

Precision and Repeatability

Unmatched Scale

Custom Finishing for 3D-Printed Parts

Looking to boost the strength, clarity, or appearance of your 3D-printed parts? Choose from microfluidic and micro-resolution materials, metal plating, secondary machining, and custom finishes like painting, clear coating, and decaling.

VIEW FINISHING OPTIONS

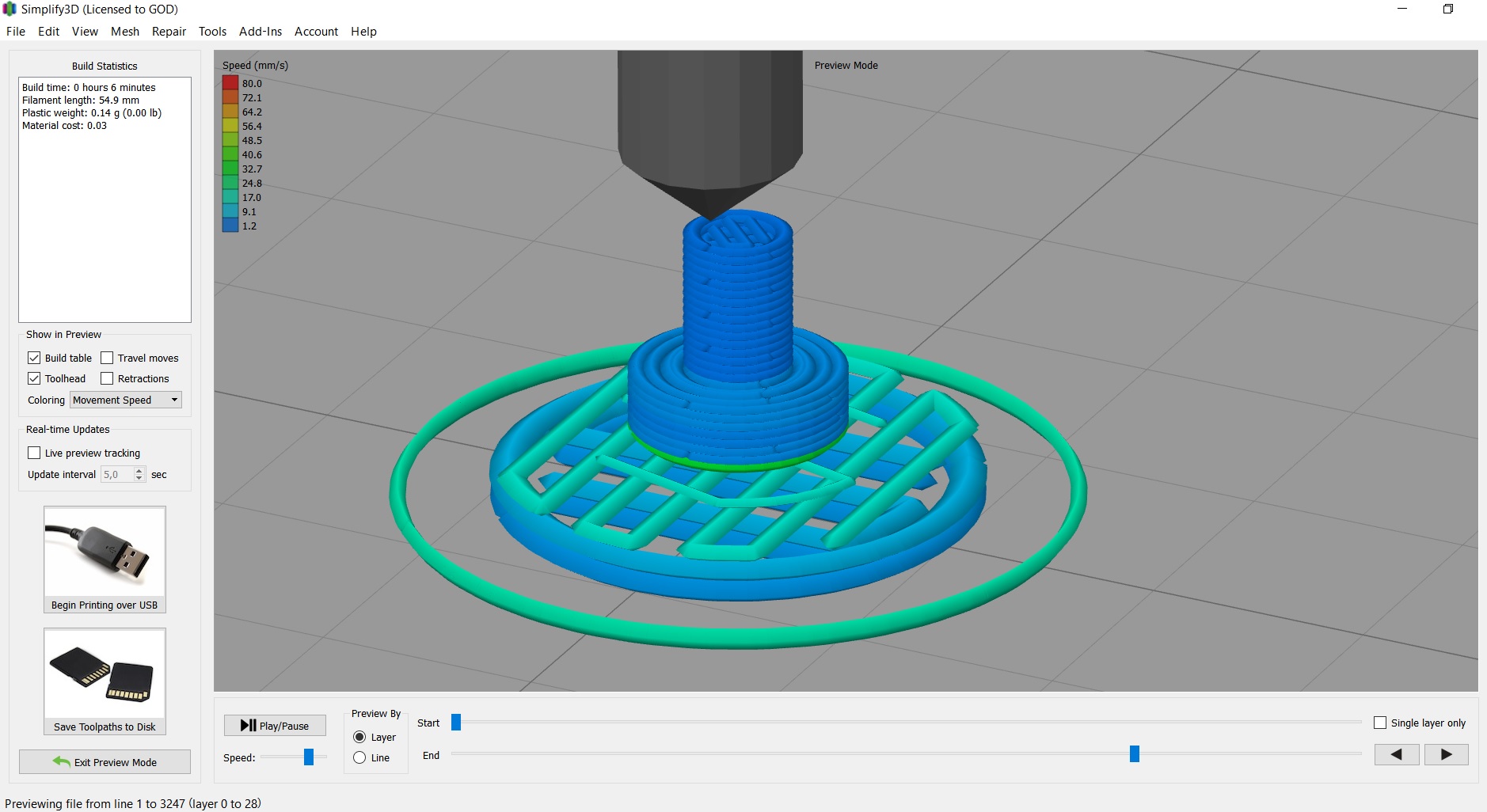

What's in Your Instant 3D Printing Quote?

Once you upload a 3D CAD file you'll get an instant quote on your 3D printing design. See real-time cost implications based on your choice of 3D printing material and resolution level.

GET INSTANT QUOTE VIEW SAMPLE QUOTE

3D Printing Resources

Designing for Direct Metal Laser Sintering

Direct metal laser sintering (DMLS) produces complex, durable, lightweight metal parts. Depending on the design, DMLS can be a reliable way to manufacture metal parts.

Read Design Tip

3D Printing Micro Features with Stereolithography’s MicroFine Material

MicroFine is an ABS-like stereolithography (SLA) material specifically designed to 3D print parts with features as fine as 0.0025 in.

Read Blog

3D Printing Materials: Select the Right Plastic or Metal for Your 3D-Printed Part

Explore material properties available for plastic and metal 3D printing processes

Read Guide

Selecting a Material for Stereolithography (SLA) 3D Printing

Compare materials for stereolithography with one another and with injection-molded plastics.

Read Design Tip

90,000 Hanna begins construction of "the first 3D printed high-rise building in the United States."Ithaca, New York-based design studio Hannah has begun work on Cores, a building in Houston that it says will be the first 3D printed multi-story structure to be completed in the United States.

The hybrid structure is built from 3D printed concrete combined with a timber frame and is designed as a multi-storey single family home.

Hana designed a 3D printed high-rise building in Houston.

With 4,000 square feet (371 square meters) of living space, the home must be scalable and compatible with typical timber frame structures.

“The project showcases the power of 3D printing technology, mass customization and design solutions that integrate traditional building methods,” Hanna said.

The house will combine 3D printed concrete with a wooden frame.

“Through a hybrid construction method that combines concrete 3D printing with timber framing, this approach allows for the strategic use of two material systems and aims to expand the applicability of 3D printing in the US, where framing is one of the most common construction methods. Hanna said.

Hanna said.

Hanna's concept includes a series of printed "cores" that contain stairwells and functional spaces for the structure.

Portal printer creates stairwells and functional spaces from concrete.

These space cores will then be connected with a timber frame to complete the structure.

The team worked with the US subsidiary of the German 3D construction company PERI 3D Construction, as well as the engineering firm CIVE, to design a house using a COBOD BOD2 portal printer and printable concrete for the building.

A closed cell foam system was used to insulate the house.

Concrete is at the heart of the building

The cores have been designed to be modular and the designers hope that this concept will be applied to further multi-family and mixed-use construction in the future.

“The project also highlights the exciting potential of designing custom-made architectural components to meet the needs of homeowners and facilitate building system integration,” Hanna said.

"These design efforts aim to increase the impact, applicability, sustainability, and cost-effectiveness of 3D printing for future US residential and multi-family buildings."

According to Hanna, the structure will take 220 hours to print, and the studio will move the printer to three different locations during the process to accommodate the linear section.

Renderings of the completed project show a raw sandwich concrete façade with metal panels and windows arranged according to the print gradient.

In the past few years, the development of 3D printed houses has become more and more common.

Last year, Logan Architecture and construction company ICON completed the first 3D printed homes for sale in the United States.

Printable concrete was used to create the structure.

According to ICON, 3D printed houses can provide good protection against natural disasters through sustainable materials and modular construction methods.

While concrete is commonly used for printing, firms have also experimented with using materials such as soil for design.

Hannah was founded by Lesley Locke and Sasha Zivkovic, associate professors at the Cornell School of Architecture.

The studio previously designed a cabin in New York using a 3D printed base and beetle reclaimed ash wood.

Photo taken by Anthony Wu.

Tags:

Architecture

Giant printer prints US's first two-story house

New technologies

third

Time to read: 2 minute(s)

The machine pours a special concrete mixture, regardless of the weather, time of day and under the control of a few staff, a giant printer prints a house of 370 square meters .

3D printing has been (or is being tried to be) used in construction for over 10 years. But the technology began to receive active development in the US market only in the last couple of years, said Leslie Locke, the architect and designer of the project. Several similar houses have already been built or are currently under development.

Several similar houses have already been built or are currently under development.

Leslie Locke is the co-founder of design firm Hannah. Her team aims to take the technology to the next level, 3D printing apartment buildings.

"The Houston project is a step towards printing apartment buildings because it's a fairly large single-family home," she said.

The three bedroom home is the result of almost two years of collaboration between Hannah, Peri 3D Construction of Germany and Cive ( an engineering and construction company in Houston ).

Proponents of the technology say 3D printing could solve a range of building problems, including labor shortages and the ability to build prefabricated buildings (like in a disaster area).

The Houston home project allows the team to explore the possibilities of an industrial printer to understand how the technology can be optimized both economically and technically.

Hikmat Zerbe, Head of Structural Design Department Cive:

In the future, 3D construction should become easier and cheaper to compete with other building technologies.

“This is a case study. We study the capabilities of the machine, we study the reaction of the material under various weather conditions. We are learning to optimize print speed,” added Zerbe.

When this project is completed, we should have a comprehensive idea of how to proceed in the future.

After the start of construction in July, the printing process is only half completed, he said.

According to Hikmat Zerbe, once the technology of 3D printing is improved, the printed houses will not only compete with conventional ones, but will be able to start replacing them.

In terms of design, Lok sees an opportunity one day to offer custom designs on a massive scale, without excessive design and labor costs.

The printer prints both unique and standard projects equally well, which opens up a huge space for creativity.

Learn more