Bacterial nanobionics via 3d printing

Bacterial Nanobionics via 3D Printing

. 2018 Dec 12;18(12):7448-7456.

doi: 10.1021/acs.nanolett.8b02642. Epub 2018 Nov 7.

Sudeep Joshi 1 , Ellexis Cook 1 , Manu S Mannoor 1

Affiliations

Affiliation

- 1 Neuro-Bionics and Neuro-Electric Medicine Laboratory, Department of Mechanical Engineering , Stevens Institute of Technology , Hoboken , New Jersey 07030 , United States.

- PMID: 30403141

- DOI: 10.

1021/acs.nanolett.8b02642

Sudeep Joshi et al. Nano Lett. .

. 2018 Dec 12;18(12):7448-7456.

doi: 10.1021/acs.nanolett.8b02642. Epub 2018 Nov 7.

Authors

Sudeep Joshi 1 , Ellexis Cook 1 , Manu S Mannoor 1

Affiliation

- 1 Neuro-Bionics and Neuro-Electric Medicine Laboratory, Department of Mechanical Engineering , Stevens Institute of Technology , Hoboken , New Jersey 07030 , United States.

- PMID: 30403141

- DOI: 10.

1021/acs.nanolett.8b02642

1021/acs.nanolett.8b02642

Abstract

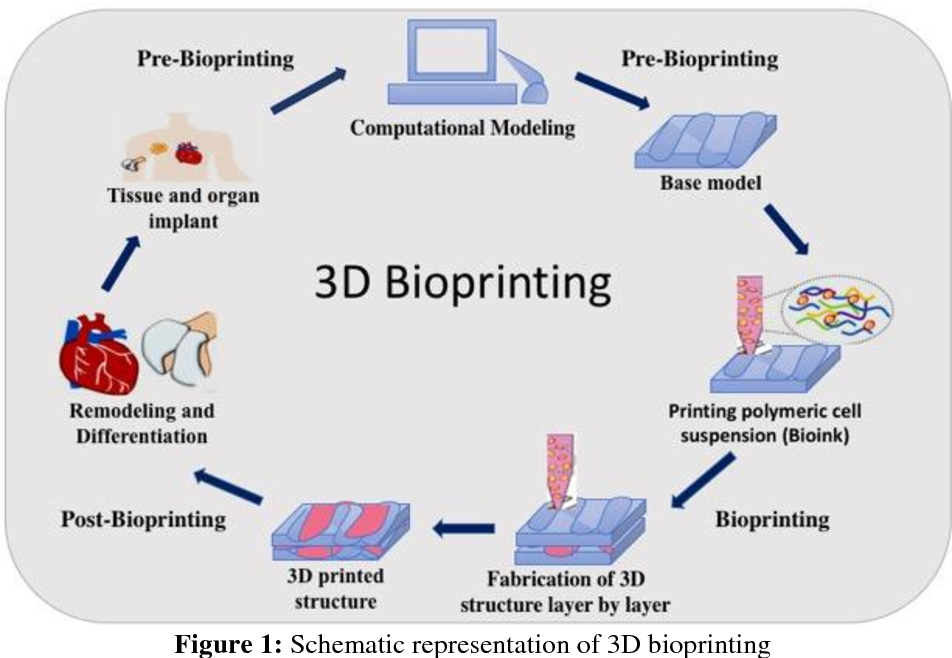

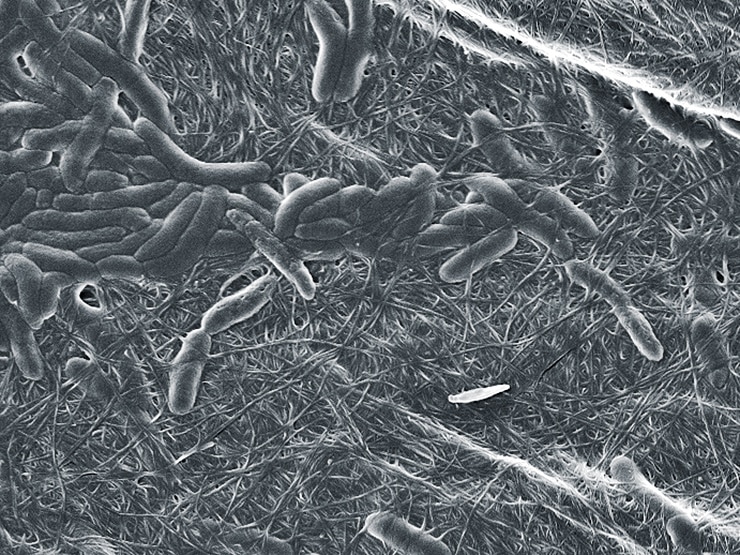

Investigating the multidimensional integration between different microbiological kingdoms possesses potential toward engineering next-generation bionic architectures. Bacterial and fungal kingdom exhibits mutual symbiosis that can offer advanced functionalities to these bionic architectures. Moreover, functional nanomaterials can serve as probing agents for accessing newer information from microbial organisms due to their dimensional similarities. In this article, a bionic mushroom was created by intertwining cyanobacterial cells with graphene nanoribbons (GNRs) onto the umbrella-shaped pileus of mushroom for photosynthetic bioelectricity generation. These seamlessly merged GNRs function as agents for mediating extracellular electron transport from cyanobacteria resulting in photocurrent generation. Additionally, three-dimensional (3D) printing technique was used to assemble cyanobacterial cells in anisotropic, densely packed geometry resulting in adequate cell-population density for efficient collective behavior. These 3D printed cyanobacterial colonies resulted in comparatively higher photocurrent (almost 8-fold increase) than isotropically casted cyanobacteria of similar seeding density. An insight of the proposed integration between cyanobacteria and mushroom derives remarkable advantage that arises from symbiotic relationship, termed here as engineered bionic symbiosis. Existence of this engineered bionic symbiosis was confirmed by UV-visible spectroscopy and standard plate counting method. Taken together, the present study augments scientific understanding of multidimensional integration between the living biological microworld and functional abiotic nanomaterials to establish newer dimensionalities toward advancement of bacterial nanobionics.

These 3D printed cyanobacterial colonies resulted in comparatively higher photocurrent (almost 8-fold increase) than isotropically casted cyanobacteria of similar seeding density. An insight of the proposed integration between cyanobacteria and mushroom derives remarkable advantage that arises from symbiotic relationship, termed here as engineered bionic symbiosis. Existence of this engineered bionic symbiosis was confirmed by UV-visible spectroscopy and standard plate counting method. Taken together, the present study augments scientific understanding of multidimensional integration between the living biological microworld and functional abiotic nanomaterials to establish newer dimensionalities toward advancement of bacterial nanobionics.

Keywords: Additive manufacturing; bionic symbiosis; cyanobacteria; graphene nanoribbons; mushroom; photosynthetic bioelectricity.

Similar articles

-

3D Bioprinting of Cyanobacteria for Solar-driven Bioelectricity Generation in Resource-limited Environments.

Liu L, Gao Y, Lee S, Choi S. Liu L, et al. Annu Int Conf IEEE Eng Med Biol Soc. 2018 Jul;2018:5329-5332. doi: 10.1109/EMBC.2018.8513490. Annu Int Conf IEEE Eng Med Biol Soc. 2018. PMID: 30441540

-

Bionic 3D printed corals.

Wangpraseurt D, You S, Azam F, Jacucci G, Gaidarenko O, Hildebrand M, Kühl M, Smith AG, Davey MP, Smith A, Deheyn DD, Chen S, Vignolini S. Wangpraseurt D, et al. Nat Commun. 2020 Apr 9;11(1):1748. doi: 10.1038/s41467-020-15486-4. Nat Commun. 2020. PMID: 32273516 Free PMC article.

-

3D Printed Bionic Nanodevices.

Kong YL, Gupta MK, Johnson BN, McAlpine MC. Kong YL, et al. Nano Today. 2016 Jun;11(3):330-350. doi: 10.1016/j.nantod.2016.04.007. Epub 2016 Apr 29. Nano Today.

2016. PMID: 27617026 Free PMC article.

2016. PMID: 27617026 Free PMC article. -

Biological photovoltaics: intra- and extra-cellular electron transport by cyanobacteria.

Bradley RW, Bombelli P, Rowden SJ, Howe CJ. Bradley RW, et al. Biochem Soc Trans. 2012 Dec 1;40(6):1302-7. doi: 10.1042/BST20120118. Biochem Soc Trans. 2012. PMID: 23176472 Review.

-

Photosynthetic Microbial Fuel Cells.

Laureanti JA, Jones AK. Laureanti JA, et al. Adv Biochem Eng Biotechnol. 2016;158:159-175. doi: 10.1007/10_2016_48. Adv Biochem Eng Biotechnol. 2016. PMID: 28070595 Review.

See all similar articles

Cited by

-

Design and biofabrication of bacterial living materials with robust and multiplexed biosensing capabilities.

Usai F, Loi G, Scocozza F, Bellato M, Castagliuolo I, Conti M, Pasotti L. Usai F, et al. Mater Today Bio. 2022 Dec 24;18:100526. doi: 10.1016/j.mtbio.2022.100526. eCollection 2023 Feb. Mater Today Bio. 2022. PMID: 36632629 Free PMC article.

-

Harnessing photosynthesis to produce electricity using cyanobacteria, green algae, seaweeds and plants.

Shlosberg Y, Schuster G, Adir N. Shlosberg Y, et al. Front Plant Sci. 2022 Jul 27;13:955843. doi: 10.3389/fpls.2022.955843. eCollection 2022. Front Plant Sci. 2022. PMID: 35968083 Free PMC article. Review.

-

Additive Manufacturing of Micro-Electro-Mechanical Systems (MEMS).

De Pasquale G. De Pasquale G. Micromachines (Basel). 2021 Nov 8;12(11):1374.

doi: 10.3390/mi12111374. Micromachines (Basel). 2021. PMID: 34832786 Free PMC article. Review.

doi: 10.3390/mi12111374. Micromachines (Basel). 2021. PMID: 34832786 Free PMC article. Review. -

Programmable microbial ink for 3D printing of living materials produced from genetically engineered protein nanofibers.

Duraj-Thatte AM, Manjula-Basavanna A, Rutledge J, Xia J, Hassan S, Sourlis A, Rubio AG, Lesha A, Zenkl M, Kan A, Weitz DA, Zhang YS, Joshi NS. Duraj-Thatte AM, et al. Nat Commun. 2021 Nov 23;12(1):6600. doi: 10.1038/s41467-021-26791-x. Nat Commun. 2021. PMID: 34815411 Free PMC article.

-

From Shape to Function: The Next Step in Bioprinting.

Levato R, Jungst T, Scheuring RG, Blunk T, Groll J, Malda J. Levato R, et al. Adv Mater. 2020 Mar;32(12):e1906423. doi: 10.1002/adma.201906423. Epub 2020 Feb 11.

Adv Mater. 2020. PMID: 32045053 Free PMC article. Review.

Adv Mater. 2020. PMID: 32045053 Free PMC article. Review.

See all "Cited by" articles

Publication types

MeSH terms

Bacterial Nanobionics via 3D Printing.

- DOI:10.1021/acs.nanolett.8b02642

- Corpus ID: 206749165

@article{Joshi2018BacterialNV, title={Bacterial Nanobionics via 3D Printing.}, author={Sudeep Joshi and Ellexis Cook and Manu Sebastian Mannoor}, journal={Nano letters}, year={2018}, volume={18 12}, pages={ 7448-7456 } }- Sudeep Joshi, Ellexis Cook, M. S. Mannoor

- Published 7 November 2018

- Biology, Engineering

- Nano letters

Investigating the multidimensional integration between different microbiological kingdoms possesses potential toward engineering next-generation bionic architectures. Bacterial and fungal kingdom exhibits mutual symbiosis that can offer advanced functionalities to these bionic architectures. Moreover, functional nanomaterials can serve as probing agents for accessing newer information from microbial organisms due to their dimensional similarities. In this article, a bionic mushroom was created…

View on PubMed

doi.org

Programmable microbial ink for 3D printing of living materials produced from genetically engineered protein nanofibers

- Anna M. Duraj-Thatte, Avinash Manjula-Basavanna, N. Joshi

Biology, Engineering

bioRxiv

- 2021

An extrudable microbial ink is produced entirely from genetically engineered microbial cells, programmed to perform a bottom-up, hierarchical self-assembly of protein monomers into nanofibers, and further into nan ofiber networks that comprise extrudables hydrogels.

Phenotypically Complex Living Materials Containing Engineered Cyanobacteria

- Debika Datta, Elliot L.

Weiss, J. Pokorski

Biology, Engineering

bioRxiv

- 2023

By integrating genetically engineered stimuli-responsive cyanobacteria in patterned volumetric 3D-printed designs, the potential of programmable photosynthetic biocomposite materials capable of producing functional outputs including, but not limited to, bioremediation is demonstrated.

Design and biofabrication of bacterial living materials with robust and multiplexed biosensing capabilities

Bacterial biofilms as platforms engineered for diverse applications.

- Zhong Li, Xinyu Wang, Fuhui Wang

Biology, Engineering

Biotechnology advances

- 2022

Biomimetic 3D living materials powered by microorganisms.

- D. Wangpraseurt, Shangting You, Yazhi Sun, Shaochen Chen

Biology, Engineering

Trends in biotechnology

- 2022

aNew trends in biotechnological applications of photosynthetic microorganisms.

3D Bioprinting: The Emergence of Programmable Biodesign

- S. Correia Carreira, R. Begum, A. Perriman

Biology, Engineering

Advanced healthcare materials

- 2019

The current state‐of‐the‐art in the field of bioprinting is discussed, with a special emphasis on recent hardware developments, biopprinting for regenerative medicine, and late‐breaking nontraditional topics.

Engineered living biomaterials

- Aleixandre Rodrigo-Navarro, S. Sankaran, M. Dalby, A. del Campo, M. Salmerón-Sánchez

Biology, Engineering

Nature Reviews Materials

- 2021

Biomaterials have evolved from inert materials that lack interaction with the body to biologically active, instructive materials that host and provide signals to surrounding cells and tissues and, thus, can be designed as active and response biomaterials.

From Shape to Function: The Next Step in Bioprinting

- R.

Levato, Tomasz Jungst, Ruben G Scheuring, T. Blunk, J. Groll, J. Malda

Engineering, Biology

Advanced materials

- 2020

The recent material and technological advances since the introduction of the biofabrication window are briefly summarized, i.e., approaches how to generate shape, to then focus the discussion on how to acquire the biological function within this context.

Three-dimensional bioprinting: A cutting-edge tool for designing and fabricating engineered living materials.

SHOWING 1-10 OF 45 REFERENCES

SORT BYRelevanceMost Influenced PapersRecency

3D printing of microscopic bacterial communities

A microscopic three-dimensional printing strategy that enables multiple populations of bacteria to be organized within essentially any 3D geometry, including adjacent, nested, and free-floating colonies is described.

3D printing of bacteria into functional complex materials

- Manuel Schaffner, P.

A. Rühs, F. Coulter, S. Kilcher, A. Studart

Materials Science, Biology

Science Advances

- 2017

3D printing of bacteria-laden hydrogels enables the digital fabrication of complex functional materials displaying spatially specific compositions, geometry, and properties not accessed by standard technologies can be assembled from bottom up for new biotechnological and biomedical applications.

A Straightforward Approach for 3D Bacterial Printing

This methodology combines the capability of bacteria to form new materials with the reproducibility and tailored approach of 3D printing systems to enable a sustainable approach for the production of numerous new materials.

3D Printed Bionic Ears

- M. S. Mannoor, Ziwen Jiang, Michael C. McAlpine

Materials Science

Nano letters

- 2013

A bionic ear is generated via 3D printing of a cell-seeded hydrogel matrix in the precise anatomic geometry of a human ear, along with an intertwined conducting polymer consisting of infused silver nanoparticles, which enables readout of inductively-coupled signals from cochlea-shaped electrodes.

Enhanced photo-bioelectrochemical energy conversion by genetically engineered cyanobacteria.

- N. Sekar, Rachit Jain, Yajun Yan, R. Ramasamy

Engineering, Biology

Biotechnology and bioengineering

- 2016

The engineered cyanobacterium Synechococcus elongatus PCC 7942 was genetically engineered to express a non-native redox protein called outer membrane cytochrome S (OmcS) resulting in approximately ninefold higher photocurrent generation on the anode of a PBEC than the corresponding wild-type cyanobacteria.

Biomimetic 4D printing.

- A. Gladman, Elisabetta A. Matsumoto, R. Nuzzo, L. Mahadevan, J. Lewis

Biology

Nature materials

- 2016

Shape-morphing systems can be found in many areas, including smart textiles, autonomous robotics, biomedical devices, drug delivery and tissue engineering. The natural analogues of such systems are…

Photocurrent generation by immobilized cyanobacteria via direct electron transport in photo-bioelectrochemical cells.

The electricity generation capability was significantly enhanced and the power densities achieved in this work are the highest among 'non-engineered' cyanobacteria based electrochemical systems reported to date.

Light-Dependent Electrogenic Activity of Cyanobacteria

- John M. Pisciotta, Y. Zou, I. Baskakov

Physics

PloS one

- 2010

It is shown that diverse genera of cyanobacteria including biofilm-forming and pelagic strains have a conserved light-dependent electrogenic activity, i.e. the ability to transfer electrons to their surroundings in response to illumination, which illustrates that cyanobacterial electrogensic activity is an important microbiological conduit of solar energy into the biosphere.

Nitroaromatic detection and infrared communication from wild-type plants using plant nanobionics.

Living spinach plants can be engineered to serve as self-powered pre-concentrators and autosamplers of analytes in ambient groundwater and as infrared communication platforms that can send information to a smartphone.

Mechanistic studies of intracellular delivery of proteins by cell-penetrating peptides in cyanobacteria

- B. Liu, Yue-Wern Huang, Han-Jung Lee

Biology

BMC Microbiology

- 2012

It is demonstrated that cyanobacteria use classical endocytosis and macropinocytotic to internalize exogenous GFP and CPP/GFP proteins, respectively, and the CPP-mediated delivery system is not toxic to cyanob bacteria, and can be used to investigate biological processes at the cellular level in this species.

Bacterial "ink" for 3D printer | Nauka i Zhizn

With the help of three-dimensional printing of bacteria, it is possible to quickly create a variety of chemical sensors and even microcircuits for a "cellular computer".

Hand with 3D printed bacterial tree; the three parts of the figure correspond to three different genetic modifications of the bacteria. (Photo: MIT. )

In the printed tree of bacteria, the three parts of the pattern reacted to each substance. (Photo: MIT.)

‹

›

View full size

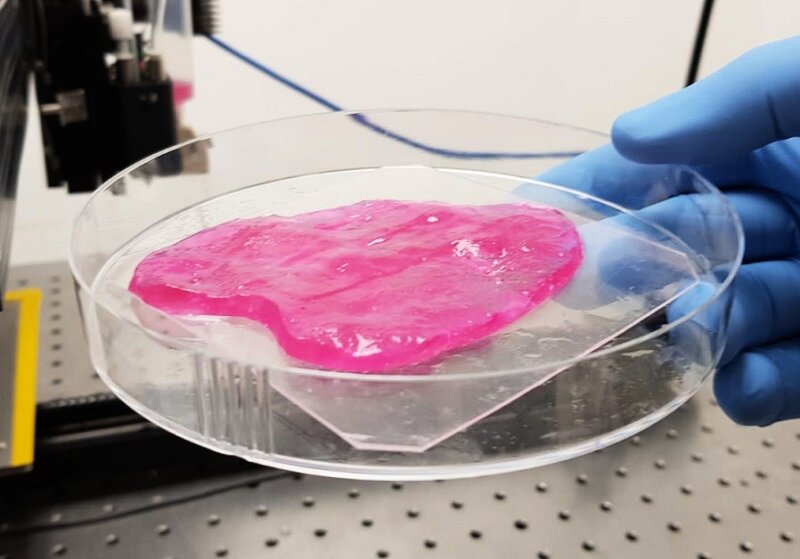

3D printing technology allows the use of a variety of substances as "ink". Indeed, in recent years, everything has been loaded into 3D printers, ranging from ingenious thermo- and light-sensitive polymers, from which objects are made that change shape when temperature or light changes, and up to proteins, from which semi-synthetic organs are created. (We once wrote about one such organ - it was the ovary, the protein framework for which was created precisely with the help of a 3D printer.)

Moreover, from time to time, researchers try to print something directly from living cells. But so far, cell printing has not advanced far, for the simple reason that our cells, which are protected from the external environment by only a two-layer lipid membrane, do not withstand the conditions of the method and die.

But what if we take not human and animal cells, but bacteria? After all, in addition to the membrane, they also have a fairly powerful cell wall, and in general, bacteria are not as sensitive to extreme influences as eukaryotic cells, so it is quite possible that they will easily survive a 3D printer.

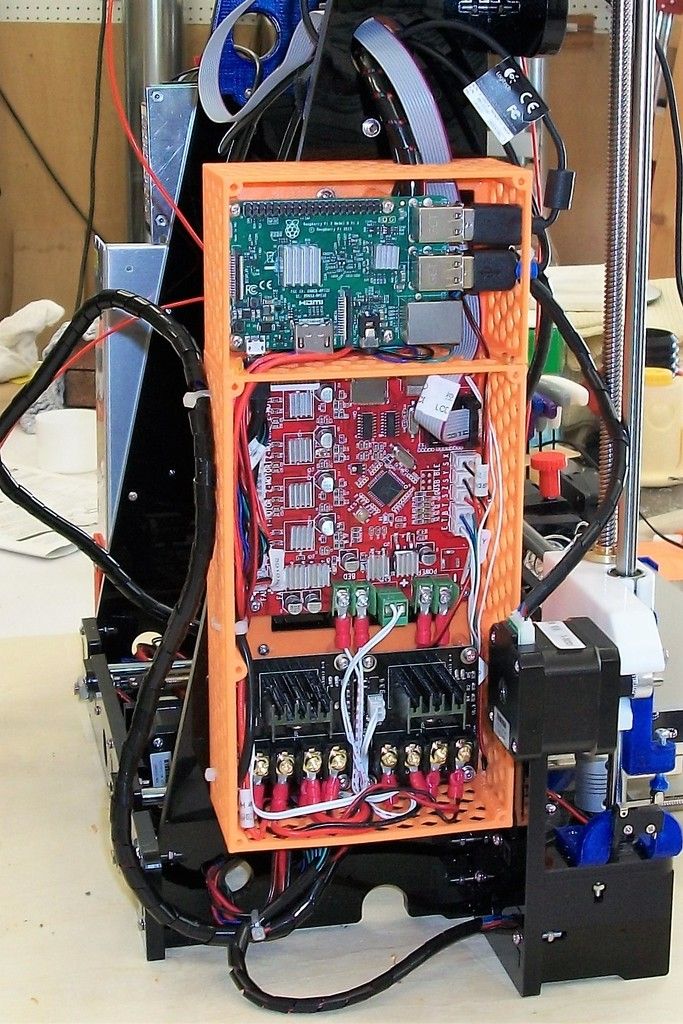

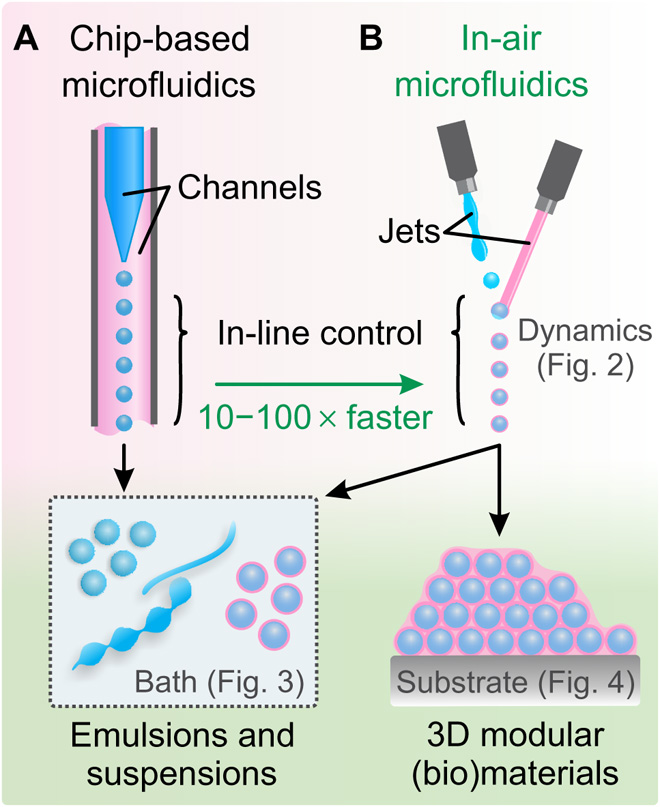

To print with bacteria, they need to find an environment in which they could live, being applied to the surface. In the bacterial "ink" created by Xuanhe Zhao ( Xuanhe Zhao ) and his colleagues at the Massachusetts Institute of Technology, a hydrogel based on pluronic acid was used as a carrier for bacteria: such a hydrogel retains water with nutrients, allowing cells to live and function, and is quite suitable for 3D printer.

Before the experiment, the bacteria underwent genetic modification, which made them sensitive to a particular substance: if the desired substance appeared in the medium, the bacteria synthesized a fluorescent protein. Then, using a 3D printer, a tree-like pattern was printed on a special elastic material, consisting of three types of bacteria that react to three different substances (it is clear that the printer allows you to mix and alternate the “ink” as we please). The resulting pattern was glued to a human hand, which had previously been moistened with a solution with three types of signal molecules - and as a result, the pattern on the hand began to glow: different bacteria each felt their own substance and made a fluorescent protein in response.

An article in Advanced Materials states that bacterial "3D ink" allows printing at very high resolutions of up to 30 micrometers, which in turn is suggestive of bacterial microcircuits, in which groups of bacteria perform logical operations, similar to microcircuits. in computer.

We have already written about the bacterial calculator. Its essence is that bacteria process certain chemical signals, which can be combined according to the rules of logical operators AND, OR, etc. In the case of a bacterial microcircuit, bacteria can transmit signals to other bacteria, which, depending on the combination of signals, will formulate a response. Such a microcircuit may well analyze the complex chemical conditions of the environment, taking into account combinations of different substances, temperature, etc. (Some of these microcircuits were printed by the authors of the work themselves.)

But even if we do not think about “cellular computers” yet, then in a simple form, bacterial “printouts” can play a big role in biotechnology and medicine. Since genetic engineering methods make it possible to "tune" bacteria to a variety of compounds, one can imagine how many different chemical sensors can be made quite quickly using 3D printing, in addition, they can be used to make smart drugs that would release drugs at a strictly defined time and under strictly defined conditions.

Why mass-produced 3D printing is still not a trend

Photo: asharkyu / Shutterstock, Chris McGrath / Getty Images

The production of goods with individual characteristics is one of the trends in the consumer market. However, personification has not yet become a popular phenomenon. Is this idea promising for business development?

When the problem of shortage of personal protective equipment (PPE) for doctors became acute, the owners of 3D printers united in the volunteer movement #3Dfor doctors. They began to print adapters, which made it possible to connect diving masks with virus-bacterial filters. Manufacturers were able to quickly develop and release adapters in various configurations for popular types of masks found in stores, quickly covered burning needs and saved many lives - and then began to make full-fledged protective masks and shields.

Adapters for masks - example of a customized product (made to order. - RBC Trends ), that is, adapted to different types of masks. How quickly manufacturers were able to design and release a new product with unique characteristics demonstrates the main advantages of 3D printing.

3D printing allows you to create products based on the preferences or personal characteristics of the buyer - personalized goods. This idea arose in the early 2000s, but so far, contrary to forecasts and the rapid development of additive technologies, has not become a mass phenomenon.

Personalization challenges

Since 2012, Nike and Adidas have been experimenting with 3D printing in the production of sneakers. The goal is to create sports shoes in the presence of the buyer according to the individual characteristics of his foot. For example, Adidas announced in 2015 that a consumer could walk into a store, spend a couple of minutes on the treadmill, and immediately receive a printed pair of running shoes that take into account the contours of the foot and pressure points while running. At the same time, Nike announced the possibility of printing shoes directly at the customer's home. To do this, you just need to download the file with the parameters of the sneakers and the characteristics of the foot from the corporation's website to your home 3D printer.

However, by 2020, these opportunities remained unrealized. In practice, everything turned out to be more difficult.

The point is the high cost of such products: the consumer is not ready to pay for customized sneakers many times more expensive when you can choose the right model from thousands of more affordable options.

Customization does not take root among automakers either. For example, in 2017, BMW launched the MINI Yours Customized service, which allows you to customize a new or previously purchased MINI car using decorative elements printed on a 3D printer. For example, it was possible to order individual side body inserts, trim parts, LED door sills and LED door projectors. However, the service is currently unavailable.

Where personification has taken root

So far, 3D printing is most actively used in medicine, where it is vital to take into account the individual characteristics of a person. First of all, the technology is useful in orthopedics and dentistry for the manufacture of prostheses and implants. Customization is especially in demand in the production of prosthetic limbs. With the help of 3D scanning, the parameters of the patient are determined, a digital model of the prosthesis is created, which is printed on a 3D printer. In this case, you can create a unique design of the artificial limb. For example, they produce children's prostheses stylized as favorite movie characters.

Another area where 3D printing is being used to customize products is in the jewelry and fashion jewelry industry. There are enterprises that produce mass products using 3D printing, for example, the American brands LACE, Nervous System and others. Customization is carried out, first of all, by small studios and workshops offering exclusive jewelry. They print digital models created according to customer sketches or cast them from precious materials using 3D printed molds.

Economics of innovation Living hand: who creates bionic prostheses in Russia

As for the majority of goods, the price works here in 99% of cases. Especially when the share of online sales is growing. You type in Google "buy a fountain pen is the cheapest" - and no matter where you are, you buy this fountain pen cheaper. This is where mass production wins.

You can think of many products that could be customized. But you need to be clear about who you will sell them to. Are there enough people willing to overpay for customization to keep your business alive? “In your calculations, you need to take into account real consumer demand, and not the desire to make money on hype,” says Vlasov. “The conclusion is simple: personalized production is possible when it will give approximately the same price as mass production. ”

Denis Alekseev, Head of R&D and Production at JSC ROBBO (educational robotics, Skolkovo resident), is confident that personalized production will become a popular trend of the future. But in order to attract the mass consumer to this segment, it is necessary to overcome a number of technical and organizational issues. For the end user, the process of ordering a customized product should be as simple as possible: with a few steps, order what he wants, while receiving the finished product quickly and conveniently. The cost of individual products may be higher, but this increase must be of value to the customer.

Main disadvantages of 3D printing:

-

low production rate;

-

often low quality products;

-

high cost of the product when trying to mass production.

How to reduce the cost of a customized product?

The cost of the finished product primarily depends on the materials for 3D printing. One way to cut costs is to produce consumables yourself.

Another option to reduce the cost of consumables is possible with the development of additive technologies and the development of new printing materials.

The main question is: who will buy it?

Entrepreneurs who will find the answer to the question: who will buy them will be able to develop the production of personalized goods? Businesses that already operate in a particular market and feel the needs of their audience can feel the demand. It is almost impossible to guess - you need to be sure of the demand.

Artur Gerasimov notes that small-scale production is promising for business development using additive technologies. One of the areas of work of his company Innovax is the production of parts and mechanisms by order of industrial enterprises from the automotive industry, instrument making, and the aerospace industry.