Foodini 3d printer for sale

SHOP | Food Ink.

Interested in our 3D-Printed products? We have partnered with our suppliers to offer you world-leading innovation in technology and design at the best price.

QUOTE 'FOOD INK' FOR FASTER DELIVERY AND SPECIAL DEALS!

FOOD INK 3D-PRINTED FLATWARE 49 EURPRE-ORDER!

– Set contains 3D-Printed Fork, Knife and Spoon

– Food-safe PLA plastic

– High-temperature resistant (handwash-recommended)

– Designed by Polish artist Iwona Lisiecka

– 3D-Printed in Barcelona, Spain, by BCN3D Technologies

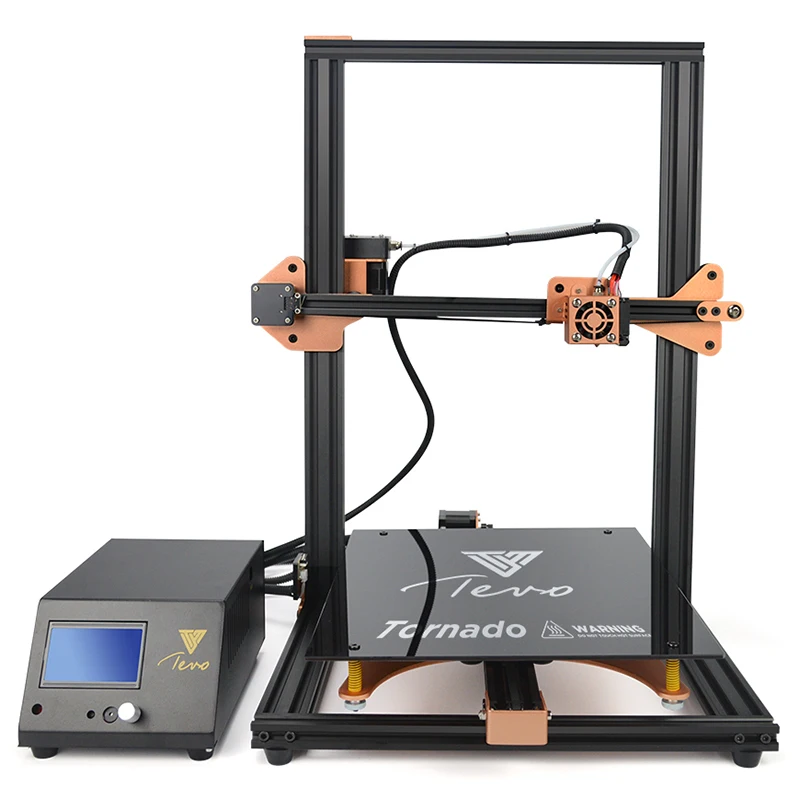

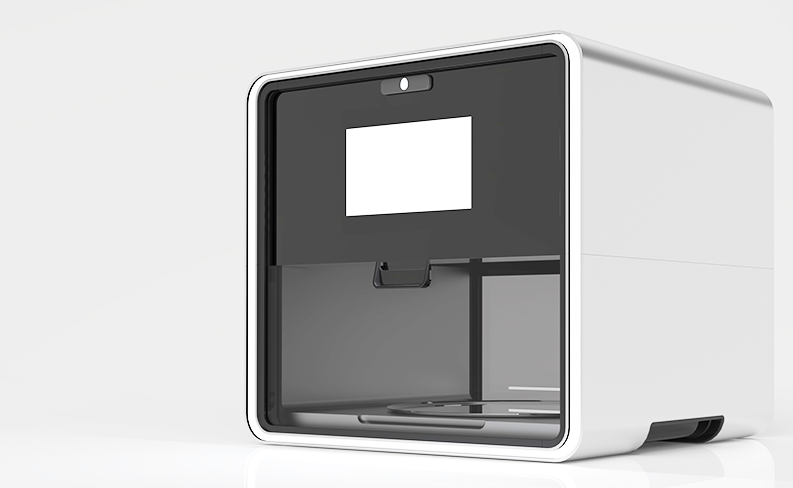

FOODINI BYNATURAL MACHINES

ORDER!

- Foodini is a 3D food printer + IoT (Internet of Things) new-generation kitchen appliance that promotes cooking with fresh, real ingredients.

- Made by Barcelona-based Natural Machines, the pioneer and leader in the 3D food printing category.

- The first 3D printer to print all types of foods from savory to sweet using fresh and real ingredients.

- Foodini ships with empty stainless steel food capsules. This open capsule design means that the consumer prepares and places fresh ingredients in Foodini, having total freedom and control over foods printed and in what form.

- User-friendly touchscreen, internal camera, and connectability to internet and other devices. Start printing immediately from many recipes freely available online– or easily make your own!

- Expands the creative possibilities for chefs by rapidly turning new ideas into unique, stunning and delicious dishes, which are then easy to replicate for multiple guests.

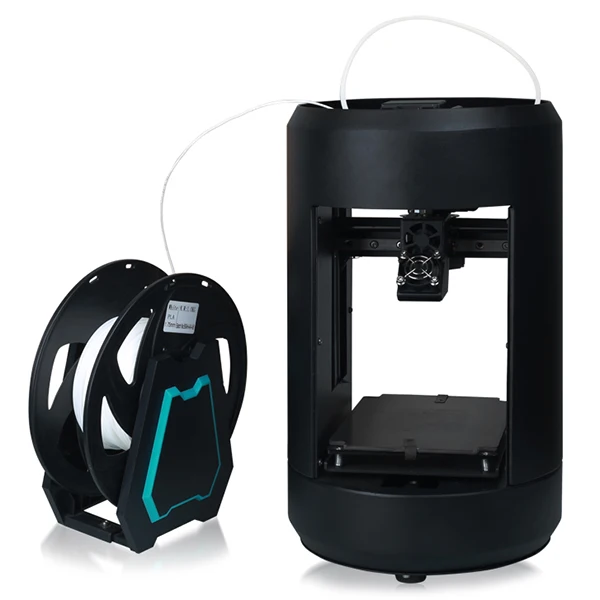

BCN3D TECHNOLOGIES

ORDER!

- The BCN3D Sigma is a professional FFF (Fused Filament Fabrication) 3D printer able to print just about any object you can imagine, and with very high detail.

- Made in Barcelona, Spain, by BCN3D Technologies.

- IDEX (Independent Dual Extruder) system allows it to print without geometric limitations, offering the possibility to combine multiple existing techniques such as multimaterial, multicolor and support printing.

- Materials: Filament diameter 2.85 +/- 0.05 mm. Compatible Materials: PLA, ABS, PVA, HIPS, TPE. Colorfabb co-polyesters 0.4mm nozzle // 0.6mm nozzle. Colorfabb Specials (0.6mm nozzle).

- Software and Electrical Properties: Processing files software: Cura-BCN3D, Slic3r, Simplify3D. Operating systems: Windows, Mac, Linux. Supported files: STL, OBJ, AMF. Input: AC 84-240V, AC 3,6-1,3A, 50-60Hz. Output: 24V DC, 13A. Power consumption: 240W.

- Overall Sigma 3D-Printer dimensions 465mm x 440mm x 680mm (cables included). Shipping package dimensions 550mm x 550mm x 630mm. Shipping package weight 21kg.

- What Is In The Box: 1 x BCN3D Sigma 3D-Printer; 1x Tool Kit; 1x 3DLAC; 1x Quick Start Guide; 2x Colorfila Spool. (Note: 3DLAC not included in shippings to Greece, Ukraine or non-European countries due to air transporation safety regulations.)

- Delivery Time: 24 hours to most countries.

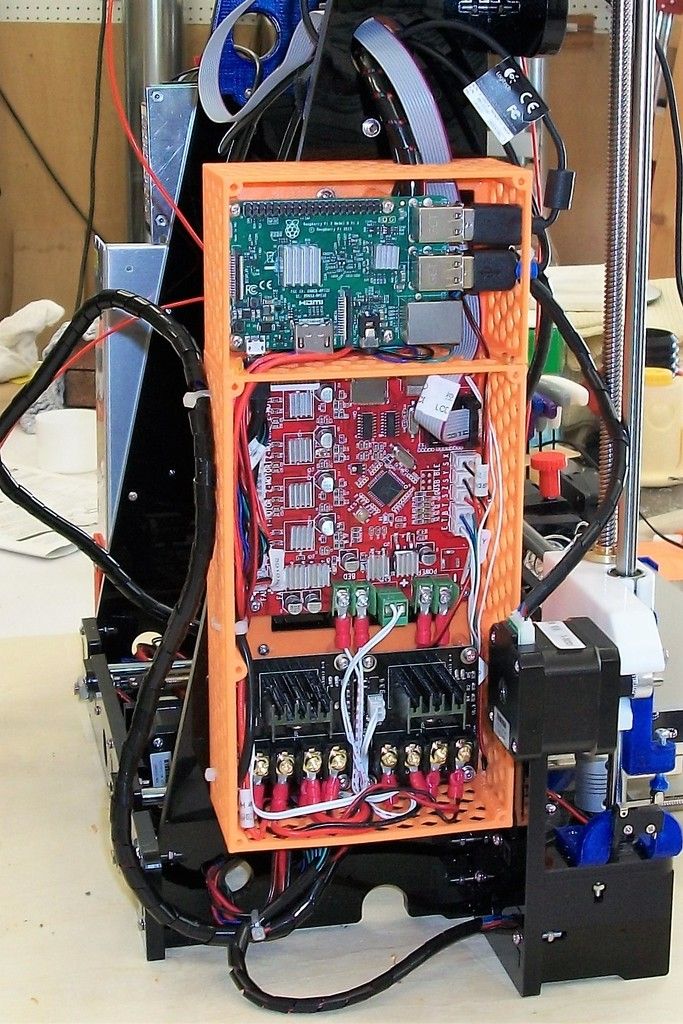

BY WASP

ORDER!

- The ideal 3D-printer: precise and reliable with every material.

- Professional, compact 3D-printer to create objects up to 40 cm height, with a closed room and heated plate.

- DeltaWASP is the new line of clean design 3D-printers. Hot pad, controlled temperature ambience, and amortized bowden guarantee a controlled shrink of the material and better results in the final print.

- Accurate and reliable on all materials with pieces up to 40 cm in height.

- Made in Massa Lombarda, Italy, by WASP.

- Delivery time: 4 weeks.

Foodini Printers in India | Buy Foodini 3D Printers

FOODINI THE 3D FOOD PRINTER

The first smart kitchen appliance that speeds up the process of making food with fresh ingredients: all via a next generation 3D food printer and IoT kitchen appliance.

The Foodini Formula

Foodini is your next-generation kitchen appliance combining technology, food, art and design to help people eat healthier. You can use real, fresh ingredients to make freshly printed meals and snacks at a time. Foodini is an automation kitchen appliance for chefs, hotels, culinary schools, restaurants, labs and food brands.

You can use real, fresh ingredients to make freshly printed meals and snacks at a time. Foodini is an automation kitchen appliance for chefs, hotels, culinary schools, restaurants, labs and food brands.

The premise of all 3D printers is that you become the manufacturer, you are the maker. The same concept applies with Foodini: you become the creator and you control what ingredients go into your foods.

It is an ideal 3D Printer that allows you to present the food the way you want it delivered, perfectly and precisely always

Contact Us Easy to Use 3D Food PrinterFoodini augments and elevates the capabilities of your kitchen right from the centrepiece, the side dish and even the garnish.

Step 1

Prepare the filling using fresh ingredients for your dish.

Step 2

Fill the capsule with the prepared filling.

Step 3

Print the creation and enjoy your meal.

Foodini Materials Specifications - Food-Safe, Food GradeFoodini CreatorFoodini Creator is our easy-to-use print application which comes pre-loaded on Foodini. Use the shape libraries to start designs and recipes, or create them from scratch with Foodini Creator tools.

Stainless Steel CapsulesAll of our capsules are made from 18/8 stainless steel, also known as 304, which is the best food-grade stainless steel.

Interface 7 inch TouchscreenThe Foodini has a built in touchscreen system. Easy to navigate around menus, create designs and print your creations.

Capsule Presses & Other Plastic PartsAny plastic parts used in Foodini are made of PolyCarbonate or PolyPropylene, both of which are food-grade and BPA-free

Silicone Rings & MattsMade of silicone platinum, the highest quality of food-grade and food-safe silicone.

Internet of Things product with all future technology and features built in.

Foodini Materials Specifications - Food-Safe, Food GradeProfessional Kitchens & Restaurants

Take customer experience beyond expectations and create a new sense of belonging with the Foodini 3D Printer. Create wow factors like fascinating food designs, presenting food in extraordinary ways and customizing dishes.

Food Manufacturers & Brands

Foodini is your mini-food manufacturing facility located right in the kitchen. It presents an optimized & sustainable way of providing customized food. This enables creating a direct relationship with customers. Foodini paves the way to delivering personalized products to mass markets

Hospitals & Health Organizations

Many patients suffering from dysphagia or other conditions need consistency-modified diets that might not always be visually appealing. Foodini 3D Printer can improve patients' food intake. With Foodini, one can even track individual nutrients in food

Foodini 3D Printer can improve patients' food intake. With Foodini, one can even track individual nutrients in food

Culinary Schools

Foodini 3D food printer allows students to engage and learn in a fun and interactive way. It is an evolution in the culinary process. Additionally, Foodini can also be used by many research and development companies looking forward to advancing in food and food production

Allows Easy Cleaning & Deep Sanitizing

Simple Operation

Intelligent Connectivity through WiFi

Creative Tools to Create Designs

Multiple Nozzles for Fine to Course Material Extrusion

Beautiful Looks

Dedicated Support Teams

ISO 9001 Certified

Connect With A Foodini Expert

90,000 characteristics, pros and cons of each model 07. 04.2021

04.2021

Content

-

- What is a food 3D printer

- Field of use

- used raw materials

- 9000 9000 9000 9000

- Top 10 Best Food Printers: A List of the Most Current Models

- 1. PancakeBot 2.0

- 2. Wiiboox Sweetin

- 3. Choc Creator V2.0 Plus

- 4. Choc Creator V2.0 Plus Food 3D Printer with Cooling Chamber

- 5. byFlow Focus

- 6. Chefjet Pro

- 7. Foodini

- 8. Mmuse – Chocolate 3D Printer Commercial ArtcakesOT7 .90BOT Printer F5

- 10. ZMorph VX

- What is a food 3D printer

- Selection guide

- Output

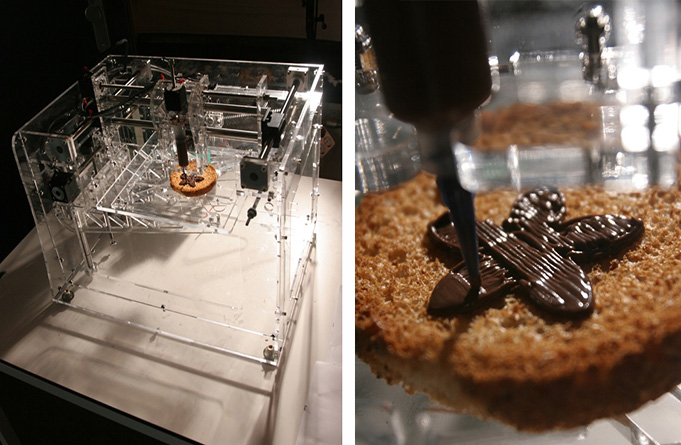

A food printer is a high-tech device that is used to create culinary masterpieces. The decorative design of food products has reached a new level thanks to the use of modern technologies: high-quality and large-format printing is carried out on cakes, waffles, pancakes and even coffee. Here are the top best 3D food printers in different price categories for people who are fond of cooking.

What is a 3D food printer

The main feature of a food 3D printer is the raw materials used: instead of printing ink, the device is filled with edible ingredients. The database stores a large number of different recipes, and in order to print a dish, you just need to select one of them and activate the printing process. The final product is layered on a work surface or on a plate: it can be baked in the oven or sent to the freezer.

Application

Futuristic 3D Printed Sugar Candy

Cookies printed with icing

Chocolate logos of famous companies

Cream Photo Print

Buying a food 3D printer is worth the owners of coffee houses, author's bakeries and private workshops. The finished product has a unique shape and bright appearance. Food printers are often used to create custom wedding cakes, cartoon character cookies, Christmas gingerbread cookies, and so on. The possibilities of a baker who owns such a device are endless: the main thing is to buy quality products.

The possibilities of a baker who owns such a device are endless: the main thing is to buy quality products.

Raw materials used

The following ingredients are used as raw materials:

-

Chocolate without additives and impurities;

-

Mastic;

-

Sugar;

-

Whipped cottage cheese;

-

Vegetable and fruit pastes;

-

Fish and meat pates;

-

Flour;

-

Cheese, etc.

The confectionery pattern is applied to sugar, wafer or shock transfer paper. The first type has a sweetish aftertaste and aroma of vanilla. Due to the snow-white surface, no additional coating is required: the drawings look bright and clear. The wafer paper is made from rice flour and does not have a special taste, due to the light shade, the final drawings look less clear. Shock transfer paper is completely transparent and is suitable for transferring a design to a product (for example, a cake). For the packaging of finished products, food-grade plastic for a 3D printer is used.

For the packaging of finished products, food-grade plastic for a 3D printer is used.

Interesting! Food printers are involved in waste reduction. Unattractive fruit and confectionery leftovers are used in the preparation of printing mixes. This makes it possible to use the means of production more efficiently.

Types of 3D food printers

Cooking enthusiasts can take advantage of the following food printing devices:

-

Food 3D printers are devices that print dishes whose recipes are listed in a database. The final product is layer-by-layer superimposed on the work surface, and the raw material comes from filled cartridges;

-

Confectionery printers are used to transfer images onto specialty paper or to design small confectionery products such as candies. Such printers print an image on pre-prepared paper: rice, wafer or shock transfer;

-

Food plotters transfer the image not to paper, but directly to the finished product.

For example, a plotter is used to transfer an image directly onto a cake.

For example, a plotter is used to transfer an image directly onto a cake.

There are several types of food 3D printers:

-

Extrusion - paint is applied to the surface before the dish is created. The process is controlled by the computer with the loaded image. The system has an extruder that heats the food mixture, and the distribution of raw materials depends on the print head. The raw material is loaded into a syringe placed in the head. This means that in order to combine different shades, you have to periodically stop printing and change the syringe;

-

A carousel-type food 3D printer also has an extruder, but its main feature is the method of feeding raw materials: the containers rotate around the working surface, the supply and dosage of the material used depends on the recipe specified in the program. The storage can contain countless recipes, and operation does not cause difficulties even for an inexperienced user.

Popular brands

Eminent manufacturers offer the best value for money food 3D printer. Quality devices provide accurate printing, high speed, durability, simplicity and ease of use.

Wiibox

This company manufactures 3D printers with high build quality and high productivity. These are universal mechanisms that fill both chocolate paste and mashed potatoes. Numerous positive reviews confirm the high quality of Wiibox products.

byFlow

The Dutch company byFlow specializes in food printing technology. The pursuit of excellence helps the company open up new horizons: the technique prints products from spinach, meat emulsion and other materials. High build quality, ease of use and durability - all these characteristics are applicable to the products of this company.

Choc Edge

Choc Edge is committed to revolutionizing the world of chocolate making. Numerous experiments and focus on consumer feedback help to create more powerful devices that provide the optimal temperature for preparing and storing chocolate figures.

Attention! Printing dishes helps save time on cooking: instead of culinary worries, the user can simply activate the printing process and get on with other things.

Free shipping

Add to compare

Item added to compare Go

| Manufacturer | Choc Edge |

Available on credit. To checkout, add the product to the cart and follow the instructions Go

| Manufacturer | Wiiboox |

Free Shipping

Add to compare

Item added to compare Go

| Manufacturer | Choc Edge |

Top 10 Best Food Printers: List of the Most Current Models

Before you buy a food 3D printer, you need to familiarize yourself with the most popular devices on the world market. The top is based on ratings and customer reviews.

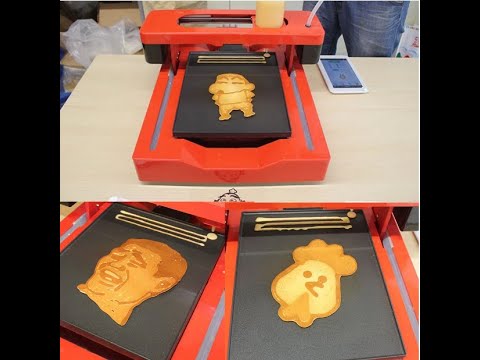

1. PancakeBot 2.0

PancakeBot 2. 0 is easy to use, which means it's suitable for inexperienced users too. Users can choose from suggested designs in the software, or create their own. Used to print pancakes.

0 is easy to use, which means it's suitable for inexperienced users too. Users can choose from suggested designs in the software, or create their own. Used to print pancakes.

Pros:

-

Ease of operation;

-

A wide range of proposed projects;

-

High speed.

Cons:

2. Wiiboox Sweetin

Buying a food printer from Wiiboox is worth not only for confectionery lovers, but also for ordinary chefs: the device prints cakes, cookies and even mashed potatoes. The main raw materials can be meat, cheese, chocolate, jam, mashed potatoes, dough and much more. A convenient touch panel helps to set the desired mode of operation, and a stylish appearance complements the interior of any establishment.

Pros:

-

Versatility: the ability to print not only sweet dishes, but also side dishes;

-

Attractive appearance;

-

High build quality;

-

Convenient control by touch panel.

Cons:

-

High price.

3. Choc Creator V2.0 Plus

When talking about which chocolate 3D printer to buy, it is worth mentioning the numerous advantages of Choc Creator V2.0 Plus. The new model has become more perfect: the developers have worked hard to eliminate the shortcomings of the previous version. The modern model has small dimensions, thanks to which it can be used in any kitchen, and the uniform heating of the syringe ensures high-quality and uninterrupted operation. In practice, the chocolate printer has shown tremendous potential: it prints complex figures from chocolate.

Pros of :

-

Attractive appearance;

-

Uninterrupted work;

-

Durability;

-

The ability to create durable and beautiful chocolate figures.

Cons :

4.

Choc Creator V2.0 Plus 3D food printer with cold chamber

Choc Creator V2.0 Plus 3D food printer with cold chamber

The new version of the Choc Creator V2.0 Plus printer is equipped with cooling chambers by popular demand. Users say that maintaining the optimal temperature in the room to preserve the integrity of chocolate figures is too problematic: therefore, the new device cools the raw materials. The price of a food 3D printer with a cooling system is slightly higher than a classic one, but the high performance of the final product justifies any costs.

Pros of :

-

Availability of a cooling system for finished products;

-

High printing precision;

-

Long service life;

-

Ease of use: You can turn the fans on and off with the side buttons.

Cons :

-

High price.

Attention! Confectionery food 3D printers are often used by artists to create edible masterpieces.

This is a unique technology that helps to unleash the creative potential of the chef.

5. byFlow Focus

Food printer from the Dutch company byFlow, which specializes in 3D printing of food. The compact high-tech device is used for the bakery industry, and the cartridges are suitable for the application of any pasty ingredients.

Pros:

Cons:

6. Chefjet Pro

Buying a ChefJet Pro food printer is a must for people who dream of making bright and stylish sweets. The device is created on the principle of inkjet printing: sugar-containing powder materials are used instead of paints. The final product is made by powder layering. The printer is suitable for combining different shades and creating gradients.

Pros:

-

The ability to create unique flavors;

-

Neat and bright printing;

-

Aesthetic appearance of the device.

Cons:

-

High price.

7. Foodini

The 3D food printer from Foodini works on the principle of a stationary printer, but instead of printing inks, layer-by-layer imposition of edible raw materials is used: dough, cream, chocolate, cream, etc. The device is versatile: the user himself can choose the material, or use ready-made cartridges with products.

Pros:

-

Practicality;

-

High build quality;

-

Attractive appearance;

-

Availability of an online platform with unique recipes.

Cons:

8. Mmuse – Chocolate 3D Printer

The closed MMuse 3D printer is suitable for chocolate printing. Chocolate beans are used as raw materials: they are heated in an extruder and fed to the work surface through the print head.

Pros:

Cons:

9. ZBOT Commercial Art Pancakes Printer F5

ZBOT Commercial Art Pancakes Printer F5 3D Printer

A food printer from Chinese manufacturers is used in the process of making pancakes of various shapes. Ease of operation allows the device to be used by children under adult supervision.

Pros:

-

Ease of operation;

-

High build quality;

-

Affordable cost.

Cons:

10. ZMorph VX

A multifunctional 3D printer capable of printing not only food, but also rubber, ABS plastic, polylactide, PVA, nylon, elastic and metal materials. The product is able to print with chocolate, butter, cookies, icing and other ingredients. In addition, there is a function of engraving and CNC milling.

Pros:

Cons:

-

High price.

Selection guide

The modern market offers a wide range of food printers. Before making a purchase, you need to carefully study the characteristics of each model and build on your own preferences. Experts have created several recommendations for choosing:

-

In case you want to create realistic images for confectionery 3D printing, pay attention to the diameter of the nozzle: the narrower it is, the more accurate the image will be;

-

It is better for people living in regions with a warm climate to purchase chocolate 3D printers with a cooling system: such devices ensure that the figurines are kept at the optimum temperature;

-

The possibility of self-refilling the cartridge is the most practical and economical way to operate the printer;

-

Print speed is an important consideration for restaurant owners. Large batches of dishes must be produced quickly, and for home use this is not a very strict selection criterion.

Output

In the catalog of our online store, you can choose the best food printers from famous brands to create culinary masterpieces. Explore our range, learn about the characteristics of each printer and make great purchases.

#Useful

Expert in the field of additive and subtractive technologies, 3D equipment and CNC machines with over 10 years of experience.

Share

all materials

Guide to 3D Printed Food - a revolution in the kitchen?

Guide to 3D Printed Food - a revolution in the kitchen?

We all remember Replicator, the Star Trek food maker that can turn any molecule into edible food and whole meals. 3D printing of products makes it possible to make dishes from different pastes and materials, so it looks like we are getting closer to the concept of science fiction. However, this time we are not in a sci-fi movie! Just look at the innovations already offered by various manufacturers: ChefJet from 3D Systems, Foodini from Nautral Machines, Chef3D from BeeHex, etc. These are all machines that can produce chocolate, pasta, sugar and even more dishes: the possibilities are practically endless.

These are all machines that can produce chocolate, pasta, sugar and even more dishes: the possibilities are practically endless.

The first results of 3D printing of food, however, were not impressive. The printed objects were made from sugar paste and were often undesirable for consumption. But advances in technology, especially FDM, have helped improve the process so that you can now make chocolate, sweets, or even real food. One of the main advantages is undoubtedly the freedom of design, which is already widely used in other industries. Indeed, the 3D printers are capable of creating very complex shapes that are difficult to achieve with traditional methods. This also applies to 3D food printing. Initially, most of the machines used were modified FDM printers. Today we already have 3D printers specializing in the production of delicious and gourmet food. But what is the future of 3D food printing? Could it revolutionize the way we cook and eat?

The beginning of 3D food printing in space travel

In 2006, NASA began to explore 3D printed food, some have called this project the origin of 3D food printing. In 2013, NASA developed another project, the NASA Food Program with a simple mission: how best to feed a team of astronauts for longer missions? In collaboration with BeeHex, they developed Chef3D, which was able to 3D print pizza. The pizza only had to be put into the oven.

In 2013, NASA developed another project, the NASA Food Program with a simple mission: how best to feed a team of astronauts for longer missions? In collaboration with BeeHex, they developed Chef3D, which was able to 3D print pizza. The pizza only had to be put into the oven.

Overall, 3D printing of space travel food has the goal of making life astronauts more enjoyable and therefore more attractive for longer missions. NASA has already seen some advantages in the new technology. The current space travel food options are boring and unappealing to astronauts, and food printing could make them that much more appealing.

If we look back at our world, we see that there are many opportunities to use technology in the food industry. Many companies have recognized the opportunities and are taking advantage of the 3D print different foods, from sugar and chocolate to pasta and vegetable mixes.

But why 3D print food?

If you can buy the same food from the supermarket or even make it yourself, why invest energy in this new technology?

3D printing is a relatively new technology. It is understandable that few people know about printing products and tend to reject them. We spoke with Lynette Kuchma, CEO and co-founder of Natural Machines (manufacturer of Foodini 3D printers), and that's how she reacted when she was first introduced to the idea of 3D printed food. It has the same appearance as more processed, packaged foods. However, the goal was just the opposite, as Lynette explains: "If you're eating something from food manufacturers, including just about anything packaged in a supermarket, then you're essentially eating 3D printed food." Indeed, the food passes through the machine directly into the mold. However, using 3D printer , you can decide which ingredients you use.

It is understandable that few people know about printing products and tend to reject them. We spoke with Lynette Kuchma, CEO and co-founder of Natural Machines (manufacturer of Foodini 3D printers), and that's how she reacted when she was first introduced to the idea of 3D printed food. It has the same appearance as more processed, packaged foods. However, the goal was just the opposite, as Lynette explains: "If you're eating something from food manufacturers, including just about anything packaged in a supermarket, then you're essentially eating 3D printed food." Indeed, the food passes through the machine directly into the mold. However, using 3D printer , you can decide which ingredients you use.

Lynette also highlights the various possibilities of 3D printing of food products. Young Creative Machines Lab researcher Jonathan Bluetinger also agrees with Lynette's observations. It is true that more innovative products can be created. New tastes can be developed and both consumer health and the environment can benefit from new technologies. The last revolution for food processors was the microwave, and this innovation was made over 70 years ago. It's time for a new one.

New tastes can be developed and both consumer health and the environment can benefit from new technologies. The last revolution for food processors was the microwave, and this innovation was made over 70 years ago. It's time for a new one.

Health Opportunities

In our modern times, we tend to pay a lot of attention to our diets, yet fast food restaurants are becoming more popular, kids are resisting broccoli, and we aren't absorbing all the nutrients we need. Lynette Kuchma thinks this could change once people start printing their own food: "People will be more interested in what they eat again," she explains. She has a 3D printer at her home Foodini and she has had many positive experiences, especially with her children. For example, although her children refuse normal spinach, it is much more attractive in the form of small dinosaurs.

In addition, having your own choice of ingredients allows you to meet special diets. Trends such as veganism, gluten-free and dairy-free are on the rise in today's society. 3D printing can answer these growing trends.

Trends such as veganism, gluten-free and dairy-free are on the rise in today's society. 3D printing can answer these growing trends.

In addition, you can coordinate your devices on 3D printer . Lynette chose the example of her fitness tracker, which displays calorie intake, which in turn feeds the data to the 3D printer to create a customized meal. This data may also be related to insurance companies, but this raises many privacy issues.

Jonathan Blutinger told us about another application that targets people's health. He talked about the use of 3D printed food products in hospitals. First of all, food can be perfectly tailored to the patient's nutritional needs and can lead to a better recovery. Projects such as Biozoon are also helping to ensure that older people don't have a homogeneous porridge in front of them, despite the difficulty they have in chewing. Instead, food can be 3D printed in a more pleasing sequence and improve the lives of many people in nursing homes or hospitals.

However, a young researcher at Columbia University takes it one step further: “The seamless integration of drugs into human nutrition could be more enjoyable. This means not only adapting food to nutritional needs, but also including individual medicines in it.”

Reduce food waste

Additive manufacturing also offers the possibility of using other protein sources. While in the Western world there is a great reluctance to eat insects, in other countries this is quite normal. And rightly so: small insects are valuable protein carriers!

In her project Insects au Gratin, designer Susana Soares pointed out that meat consumption should be reduced. As a substitute, she uses insects, which are generally rejected in the Western world. But insects are more environmentally friendly because they produce less methane and consume less water. With 3D printing of it is still possible to use the inherently non-appetizing protein carrier.