3D printing skills

10 Key Skills for Industrial 3D Printing

With such a disruptive innovation as 3D printing, sector growth has happened much more quickly than the education offering for the workforce. To become Additive Manufacturing (AM) experts, employees need to re-skill or up-skill into new roles.

Industrial 3D printing offers companies immense potential in the development of new applications. The knowledge needed ranges from basic understanding of the technology to selecting components for production, as well as design and engineering, to scaling and validating production.

We at Additive Minds Academy have made it our mission to enable people and organizations worldwide to use the potential of industrial 3D printing for responsible manufacturing.

First, those interested in additive manufacturing need a comprehensive overview of the stages of the process chain and the different technologies.

These are the unique skills required along the additive manufacturing process chain

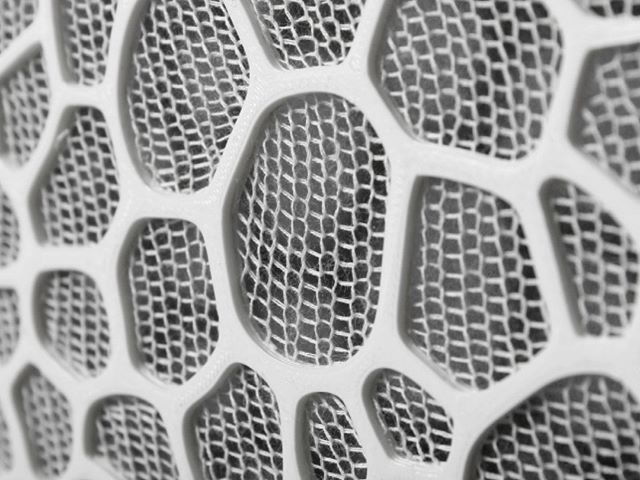

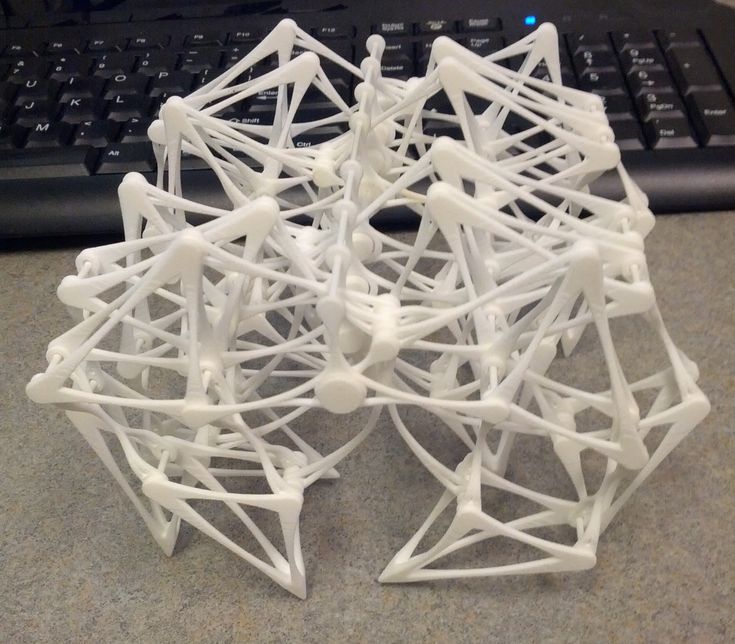

Design is one of the most important parts of the additive manufacturing process chain. Without good design, every other stage is unpredictable. An educated and creative designer can greatly contribute to decreasing the consumption of powder, reducing build time, and lowering the overall cost-per-part, making them a vital part of the team. Designing 3D printed parts for real world use requires an in-depth knowledge of methodologies and guidelines and the possibilities and limitations in 3D printing, and how to apply this knowledge to design viable yet innovative parts.

To create a great application, you need to master both systems and software. To select the right quality part parameters for each case, you need knowlegde about process parameters such as Up-Skin, Core, Down-skin, overlapping and contours.

Proper part screening and selection are highly important. You need the skill set to decide, which part fits best economically and technically to grant AM success and profitability."

Each material has its unique properties and will behave differently in the process. Therefore, you need material specific parameter editor training to understand the values and the implications for data preparation. Furthermore, you will need to dig deeper into the exposure settings for hatch, contour and edge.

At the same time, you need to study the attributes of different materials and decide which material is best for which job. It is important to know which materials shrink or warp when processed and by learning about the qualities of our most common material types, you will gain a deeper understanding of the data preparation stage and its importance.

Understanding the data preparation process will enable you to optimize job preparation and reduce failed builds, contributing to build. You need to know how to design successful support structures, how to choose appropriate materials and how to select the most beneficial parameters for each part type.

You need to know how to design successful support structures, how to choose appropriate materials and how to select the most beneficial parameters for each part type.

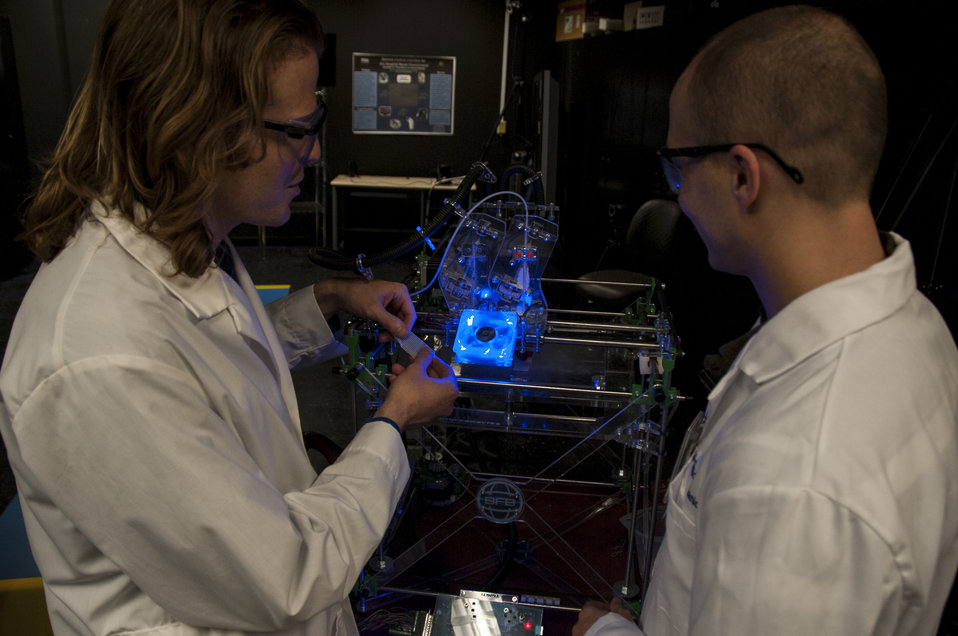

Before you can operate a system, you need intensive training on the safe and efficient operation of the machine itself and its peripherals. This includes the handling of the processing software, the set-up, job start and observation of the process and knowledge of the post-processing procedures as well as machine cleaning and maintenance.

Additive manufacturing is not only about designing and preparing your project for 3D printing. A distinguishing professional feature is the level of post-processing skills needed to make realistic and accurate model representations. Therefore, you need to know about different methods and technology to postprocess parts and be able to apply approaches of powder removal, cutting of parts from the platform as well as support removal and surface finishing methods.

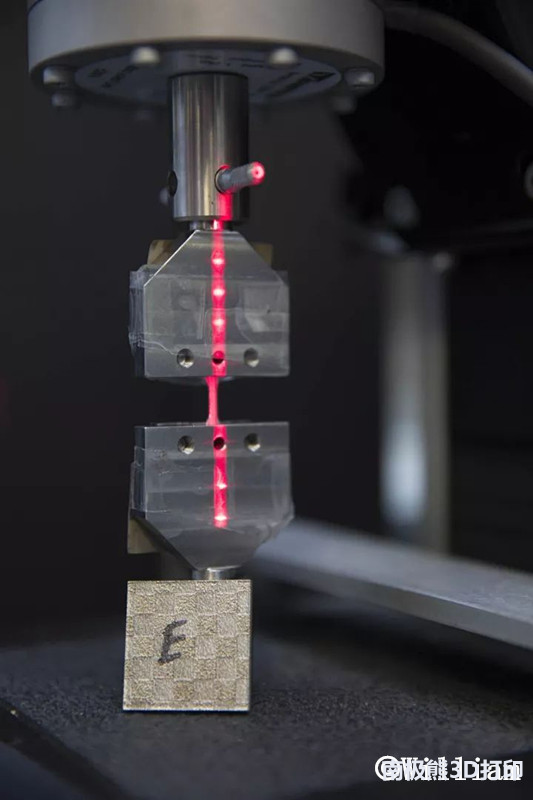

Recognize the definition of quality within the 3D printing industry and how to measure it during each stage of the process. You need to learn about quality criteria such as dimensional accuracy, tensile strength, hardness, density, and electrical conductivity.

Finally, you need to learn how to properly carry out a business case analysis. This will be the moment to integrate your knowledge of the entire process chain. Get to know the impact of key cost levers and how to reduce overall cost-per-part. You need to understand both the quantitative and qualitative side of the different types of business models and how to explain these to the many different stakeholders involved.

Before you start serial production, you should simulate your production using a digital twin. As a result, you can forecast the throughput and output of your production site based on the machine park equipment, operator shifts, machine maintenance procedures, etc.

Since the entire process chain from procurement to production is digitally synchronized and all machines are connected and communicate via IIoT platforms, you can easily align your production with local demands while significantly reducing transportation and storage costs. By distributed manufacturing, we mean globally distributed small and flexible production centers that produce where the customers are and where the demand arises.

These are the unique skills required along the additive manufacturing process chain

Whether you're a professional seeking further development, or a business and innovation leader seeking new talent to take advantage of the technical advancements, you need to get your workforce trained for these skills.

Additive Minds Academy has developed a comprehensive online training program to optimize onboarding processes and accelerate the knowledge buildup at the forefront of innovation. The portfolio consists of online courses and e-learnings for all levels of expertise making Additive Manufacturing knowledge available anytime, anywhere.

The portfolio consists of online courses and e-learnings for all levels of expertise making Additive Manufacturing knowledge available anytime, anywhere.

Find the right training now

Contact me on LinkedIn

back to the blog articles

What Are the Essential Skills for a Career in 3D Printing?

3D Insider is ad supported and earns money from clicks, commissions from sales, and other ways.

3D printing has often been described as the future of manufacturing. While it may not outright the more traditional manufacturing techniques, there is no doubt that 3D printing has earned its place in a more modern industry that emphasizes flexibility and customization.

This also means that there is a growing demand for professionals who are well-versed in 3D printing technology. This could potentially be a very lucrative career in the coming years. If you’re interested in creating a career focused on 3D printing, then here are some skills you may want to develop.

Machine Operation

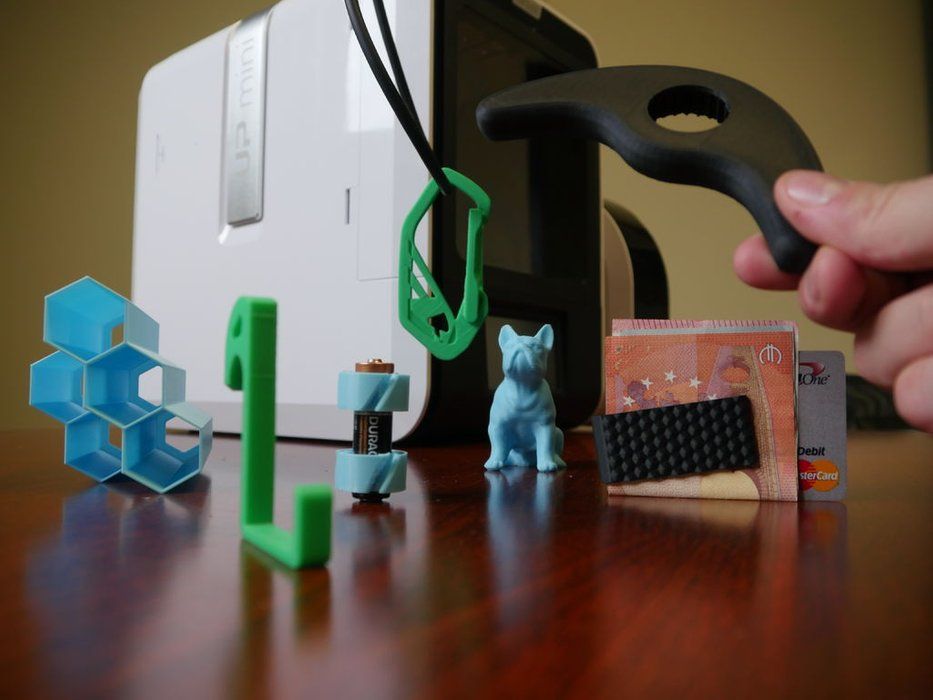

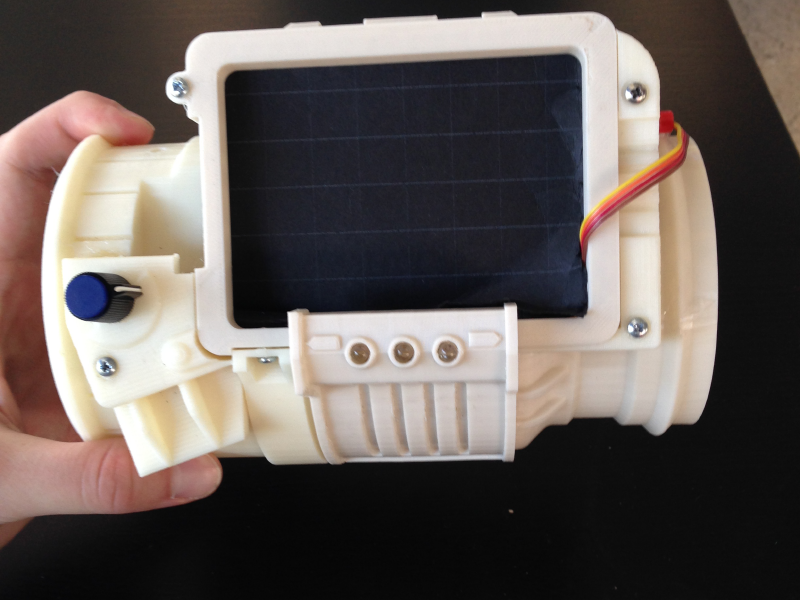

The most basic requirement for working around 3D printing is being able to operate them in a manner that is safe and efficient, both for the users and the machine. This includes being able to work with a variety of different 3D printing technologies, printing parameters, and materials. Extensive hands-on experience is crucial in developing this skill, ideally augmented with some formal training.

Take note that operating a 3D printer does not just mean being able to handle the hardware. Since 3D printing is a highly automated process, understanding the slicer software and the 3D printer firmware is equally as important.

Maintenance and cleaning are some of the other main responsibilities of a 3D printing machine operator. This is crucial in ensuring that the 3D printer works as expected and does not cause any significant disruptions in the workflow. If something does go wrong, it is beneficial for the machine operator to be able to do basic troubleshooting and repairs. This means having a deep understanding of how the 3D printer and all its components work together to achieve your manufacturing objectives.

This means having a deep understanding of how the 3D printer and all its components work together to achieve your manufacturing objectives.

CAD Modeling and 3D Design

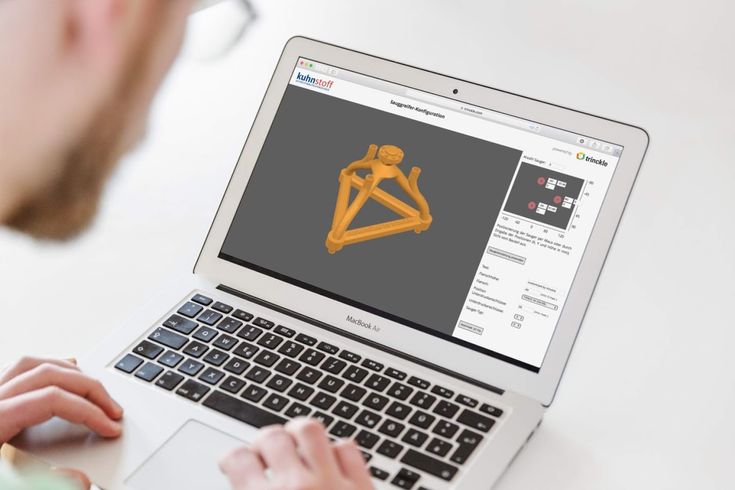

All 3D printed products start from digital 3D models. While casual and hobby 3D printing can get by with downloaded 3D models, businesses and professionals will need to come up with models that are original and serve their client’s needs. This is where a 3D modeler or designer comes in.

3D modelers are responsible for receiving the ideas for 3D printed products and turning them into digital models. This could be for engineered parts that require precise measurements or more creative products such as action figures or ornaments. In any case, being a successful 3D modeler or designer requires having expertise in using 3D design tools and programs.

One of the main advantages of 3D printing is the speed at which ideas can turn into physical products. The 3D designer plays a central role in this process. They must be able to accommodate design ideas and this may involve integrating design changes that result from client input or collaboration with other stakeholders.

They must be able to accommodate design ideas and this may involve integrating design changes that result from client input or collaboration with other stakeholders.

As mass-produced 3D-printed products become more common, there will continue to be a growing demand for 3D modelers. If there is a single skill that could make entry into the 3D printing industry easier, then it is likely the ability to make bespoke 3D models from scratch.

Post-Processing and Surface Finishing

3D printed products are rarely considered finished products when they come out fresh off the 3D printer. Regardless of 3D printing technology, there is significant work needed to post-process these products to bring them to a professional level of quality.

There is a range of different post-processing techniques used in 3D printing. This can include sanding, powder removal, cutting off parts and pieces, polishing, annealing, or UV treatment. There is not a single method that can apply to all 3D printing applications.

Although not technically demanding, taking over the post-processing of 3D printed products requires expertise in handling tools. Post-processing is one of the steps in the 3D printing workflow that is still done mostly manually. This means that you will need to be comfortable working with your hands while maintaining both quality and productivity.

Materials Science and Engineering

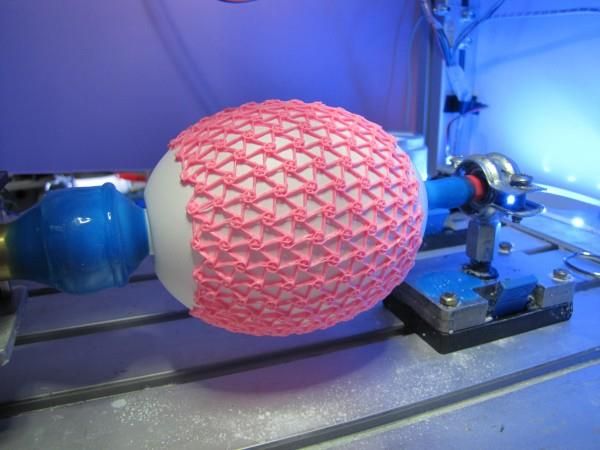

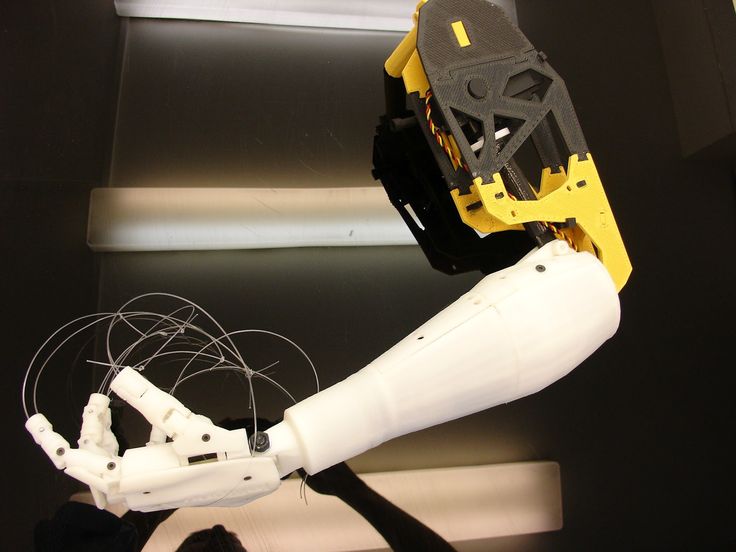

The use of different materials is at the forefront of innovations in 3D printing. Resin and other plastics have become incredibly common, especially in hobbyist circles. The use of different types of metals has also become a standard for professional applications, especially in engineering and machine parts. However, there is no shortage of ideas for more innovative materials for 3D printing.

Many 3D printing companies around the world have dabbled in using more sustainable materials. Examples include wood, clay, plant material, or recycled plastic. These are all attempts to make 3D printing more environment-friendly and palatable to the modern market.

On other fronts, some companies and research institutions have been able to use very unconventional materials for 3D printing. For instance, a research team at MIT has been working on developing a machine that can 3D print glass. If this becomes feasible at a commercial scale, 3D printed glass can revolutionize the jewelry and ornaments industry.

3D printing food is also one of the more persistent areas of interest. Chocolate 3D printers have existed for a while now, so have 3D printers that can make fancy candies by directly extruding sugar. 3D printers that can make entire meals have been a pipe dream for a long while now and are a topic that seems to be revived every few years.

Developing new materials for 3D printing requires a blend of creativity and technical expertise. Someone with this proficiency is also better equipped to select a material based on the requirements of the intended application. Does the material shrink or contract when subjected to extreme temperatures? What is its maximum tensile strength and yield strength?

Product and Business Development

If you’re really creative, you can come up with ideas on how 3D printed products can be profitable. A little bit of technical skill is useful for this type of job, but what matters more is having a mindset of innovation and entrepreneurship.

A little bit of technical skill is useful for this type of job, but what matters more is having a mindset of innovation and entrepreneurship.

Product development is essentially coming up with ideas for new products that cater to an existing market. Conversely, it can also pertain to coming up with a completely new product and creating a market that did not exist previously.

In this sense, a 3D printing business is just like any other business. To grow a client or customer base, there has to be someone constantly looking for opportunities. If you sell directly to consumers, this can be as simple as coming up with new products based on popular trends.

Higher-end 3D printing companies may benefit from offering their services to specific industries such as healthcare and manufacturing. There can also be opportunities to provide training or education in institutions, especially now that 3D printing and rapid prototyping are being considered some of the newest professional skills.

Patent Laws

If your company makes your own designs, then you should take steps to protect your intellectual property. This can also work the other way, as similar designs can make any 3D printing company vulnerable to allegations of intellectual property theft. The legal landscape of 3D printing is still very messy right now, so companies need to have an expert on patent laws, intellectual property ownership, licensing, and scope of rights.

Of course, legal knowledge is not nearly enough if you plan to have a career in 3D printing. Knowing the fundamentals of 3D design and 3D printing are still needed to implement IP protection mechanisms. Lawyers will be more equipped to provide counsel for 3D printing companies if they can learn about the more technical side of the business.

Final thoughts

3D printing has become a lot more popular in the past years, but it is yet to break out as a mainstream industry. If you’re looking for new career opportunities or skills to develop, then you should really consider learning about 3D printing. This is still a relatively young industry that can offer lots of opportunities.

This is still a relatively young industry that can offer lots of opportunities.

You don’t need to be an expert in 3D printing to have a career in this industry. You can be well-versed in patent laws or product development and still be considered an essential part of any 3D printing company. However, it certainly helps to dip your toes into the technology a bit.

Warning; 3D printers should never be left unattended. They can pose a firesafety hazard.

Seven reasons to use 3D printing technology in education

The development of modern technologies does not bypass educational institutions. Ceiling projectors in the 1930s, pocket calculators in the 1970s, personal computers in the 2000s, technology has always been used to engage students and prepare students for postgraduate realities.

The era has come when 3D printing will completely change the idea of classrooms and laboratories. Advances in 3D printing have made the technology more convenient and accessible, helping to increase its popularity in educational circles.

Workers in almost any scientific discipline have the opportunity to use 3D printing as part of the educational process, both in classic face-to-face seminars and in online classes. The thoughtful integration of this technology into educational spaces will enable educators to improve academic performance by developing student analytical and critical thinking skills.

In this article, we explore seven benefits of using 3D printing technology using Formlabs 3D printers to create a real interactive learning environment, unleash creativity, prepare students for combat, and more.

Seven reasons for introducing 3D printing technology into the educational process:

- 1. Creation of an interactive learning environment;

- 2. Development of creativity and innovation;

- 3. Improved perception of the real world;

- 4. Preparation for postgraduate practice;

- 5. Involvement in digital processes;

- 6. Development of problem-solving skills;

- 7.

Development of design thinking.

Development of design thinking.

Creating an interactive learning environment

Students enjoy immersing themselves in the learning process if the learning environment makes them participants in this process. Material presented through slides can at best only arouse interest and hold attention for a short time. 3D printing technology makes learning dynamic by encouraging students to develop critical thinking skills while designing models. Interactive sessions allow you to explore advanced topics in more depth while developing practical skills such as decision making and problem solving. In addition, 3D printing is accessible to students with different perceptions of the material, which means that kinesthetic and visual learners will equally experience all the benefits of this approach to learning.

For example, 3D printing is a part of almost all engineering courses. Students learn 3D printing technology for product development and prototyping, creating functional assemblies and mechanisms, etc. Practicing engineers work on a similar principle. This means that students are given the opportunity, through hands-on experience, to understand what the real job of an engineer is.

Practicing engineers work on a similar principle. This means that students are given the opportunity, through hands-on experience, to understand what the real job of an engineer is.

Stereolithography (SLA) 3D printing is ideal for custom designs such as anatomy for biology or other medical subjects.

3D printing can be introduced into the educational process not only in engineering areas. In the field of teaching, there are many opportunities for using 3D printing: biology students can print anatomical models of organs, future chemists can study the structure of molecules from their 3D models, graphic designers can create 3D versions of their creative works, historians can recreate historical artifacts, architects - print 3D models of building designs.

Despite the spread of distance learning, the opportunity to gain practical skills has been preserved thanks to technology. A case in point was the case of Michael Silver, professor of architecture at the University of Kentucky College of Design and Architecture, who prints and mails models of buildings his students have been working on. Having physical models of objects helps students analyze their own concepts and ideas. As a result, despite the remote format of classes, 3D printing made it possible to maintain the important principle of “immersion in the process”.

Having physical models of objects helps students analyze their own concepts and ideas. As a result, despite the remote format of classes, 3D printing made it possible to maintain the important principle of “immersion in the process”.

Developing creativity and innovation

Creativity, often underestimated, is nevertheless a critical skill for any successful student. It affects the ability to generate new ideas and develop innovative solutions. 3D printing technology is entirely based on creative skills, encouraging students to find solutions to problems through 3D printing, design models using computer-aided design (CAD) programs, and work on optimizing the printing process. In addition to this, students can color the finished models, further revealing their creative potential.

3D stereolithography (SLA) printed finished products feature smooth surfaces, incredible detail and ease of painting.

At the University of Massachusetts Lowell, Professor Yoko Oda uses 3D printing to improve his curriculum in 3D design, sculpture, 3D modeling and animation. One of the latest significant developments in the world of sculpture is the use of virtual reality (VR) technology in combination with 3D printing. VR is breaking down the boundaries of 3D design, allowing professional artists and students to create their own 3D artwork using software such as Oculus Medium. Professor Yoko's students can create a 3D object in virtual reality in 30 minutes and then print the finished work on a 3D printer. 3D printing opens up new possibilities for innovation in the creative world.

One of the latest significant developments in the world of sculpture is the use of virtual reality (VR) technology in combination with 3D printing. VR is breaking down the boundaries of 3D design, allowing professional artists and students to create their own 3D artwork using software such as Oculus Medium. Professor Yoko's students can create a 3D object in virtual reality in 30 minutes and then print the finished work on a 3D printer. 3D printing opens up new possibilities for innovation in the creative world.

Improving the perception of the real world

Institutes of higher education are required to prepare their students for "real life" in the profession outside the institution. Therefore, it is extremely important for future specialists to understand how to apply the acquired skills in their work. “It is better to see once than hear a hundred times” - this is exactly where 3D printing can help!

Dental students from Turkey practice dental nerve removal on 3D specimens.

Pre-made 3D objects can also be part of anatomy teaching. At the University of Canakkale Onsekiz Mart in Canakkale, Turkey, 3D printing of dental models has made it possible to teach dentistry remotely.

“The Formlabs Form 3B printer is a great machine with a large print platform that can make 80 molars in 9 hours. The finished models are characterized by a high degree of detail and accuracy of the originals, which made it possible to use the models as demonstration samples,” says Mr. Yosunchyr.

3D printing of organs, cells and other elements of biology and medicine uses polymers specially developed for the healthcare industry, such as Elastic Resin or BioMed Clear Resin. For students of medical specialties, 3D printing technology makes it possible to train operations on finished models. Thus, the high degree of detail of printed objects allows teams of surgeons to plan complex operations.

Postgraduate training

3D printing skills are valued by employers. This technology is used not only in the engineering and manufacturing fields. 3D printing affects many professional areas, from the entertainment industry to jewelry making. According to the report of the research company, the volume of the global 3D printing market in 2019. amounted to 11.58 billion dollars. In addition, the market is projected to grow at a CAGR of more than 14% between 2020 and 2027. In 2018, about 1.4 million 3D printers were shipped worldwide. This figure is expected to reach 8 million units by 2027.

This technology is used not only in the engineering and manufacturing fields. 3D printing affects many professional areas, from the entertainment industry to jewelry making. According to the report of the research company, the volume of the global 3D printing market in 2019. amounted to 11.58 billion dollars. In addition, the market is projected to grow at a CAGR of more than 14% between 2020 and 2027. In 2018, about 1.4 million 3D printers were shipped worldwide. This figure is expected to reach 8 million units by 2027.

Such a strong growth in the introduction of 3D printers into work processes determines the increase in demand for 3D design skills among graphic design students. 3D printing would not be possible without designers creating models. With the increasing demand for custom-made products, custom design is becoming more relevant than ever. Research and development activities also involve the possession of skills and knowledge about 3D printing. The production of consumer goods requires intensive analytics. 3D printing technology will allow professionals to identify opportunities to reduce costs and improve process performance in their project. The creation of models is also in demand in the field of biology, ranging from the manufacture of three-dimensional sculptural elements to the design of organ models. 3D printing is highly relevant for architecture and construction professionals as they rely heavily on the development of "prototypes".

3D printing technology will allow professionals to identify opportunities to reduce costs and improve process performance in their project. The creation of models is also in demand in the field of biology, ranging from the manufacture of three-dimensional sculptural elements to the design of organ models. 3D printing is highly relevant for architecture and construction professionals as they rely heavily on the development of "prototypes".

Students who have knowledge of 3D printing are more prepared for their future jobs. By mastering 3D printing as part of their studies, students develop creativity, which will allow them to easily cope with professional duties in the future.

Digital Engagement

In today's digital world, students need to be able to effectively use the available technological opportunities. Often, modern technologies are perceived as a negative factor that distracts from the educational process, however, with their correct application, students will be able to interact more productively with the outside world. At the same time, there is no need to be limited to a specific specialization, since technological modernization has affected many areas of professional activity: from fine arts to factory production. Incorporating the study of 3D printing technology into the curriculum will allow students to better navigate digital workflows. The concept of 3D printing encompasses more than just the knowledge of a 3D printer. During the training, students comprehensively study this phenomenon, analyzing all the processes completely, from designing a model in a CAD program to post-processing of the finished product.

At the same time, there is no need to be limited to a specific specialization, since technological modernization has affected many areas of professional activity: from fine arts to factory production. Incorporating the study of 3D printing technology into the curriculum will allow students to better navigate digital workflows. The concept of 3D printing encompasses more than just the knowledge of a 3D printer. During the training, students comprehensively study this phenomenon, analyzing all the processes completely, from designing a model in a CAD program to post-processing of the finished product.

For example, you can study photogrammetry, i.e. a scientific and technical discipline that deals with determining the size and other characteristics of objects from their photographic images. Several photographs of an object, building or person taken from different positions are used as the basis for measurements. Then, using automatic algorithms, the images are transferred to a 3D model.

Developing Problem Solving Skills

3D printing technology can handle real-world problems. So, a solution was found to the shortage of personal protective equipment (PPE) and medical supplies for sampling during the COVID-19 coronavirus pandemic. Similarly, it is possible to build work within the classroom. 3D printing will undoubtedly be an incentive to develop problem solving skills in students. At the initial stage of working on their 3D printing project, the author needs to answer the following questions:

- What will the 3D object I print be used for?

- What should you pay attention to when creating a model, choosing materials, processing a finished object?

- How to organize the 3D printing process in such a way that it is most efficient and productive?

These are just some of the questions that need to be answered early in the project. Problems like these require a critical approach. Students will have the opportunity to go from an abstract idea to a real three-dimensional object by analyzing how these concepts relate to each other. By working on prototyping, students will be able to assess how close their project will be to the intended goal, without focusing only on its functionality. 3D printing allows you to solve problems using a logical systems approach, further developing creative thinking.

By working on prototyping, students will be able to assess how close their project will be to the intended goal, without focusing only on its functionality. 3D printing allows you to solve problems using a logical systems approach, further developing creative thinking.

Development of design thinking

Design thinking is more than just a buzzword. This phenomenon is defined as “an iterative process in which we seek to understand the user, disprove assumptions, rethink the problem in order to find non-obvious alternative solutions.” Design thinking is not a fast-paced trend, but a truly effective approach that is already being adopted by major brands such as Apple and Google. How is 3D printing related to design thinking?

Collaboration and interaction is a key principle of the design thinking methodology. 3D printing opens up opportunities for collaborative creative experimentation among students in group projects. Working on a common 3D printing project, its participants adopt each other's vision and work style. Iteration is another key to design thinking. 3D printing allows students to upgrade their designs based on the results of previous versions and the feedback gathered.

Iteration is another key to design thinking. 3D printing allows students to upgrade their designs based on the results of previous versions and the feedback gathered.

Conclusion

3D printing is a multidisciplinary technology that allows you to develop a wide variety of skills. Any science education program, no matter the level of difficulty, complemented by the study of 3D printing can become much more fun and applied, as well as contribute to higher learning outcomes. Exciting imagination and revealing the secrets of the implementation of their own ideas, 3D printing technology is a full-fledged element of modern education.

FDM 3D printing guide for beginners. Understanding Basic Terms

Getting started with 3D printers doesn't have to be intimidating. We have created this simple 3D printing guide for beginners to help all beginners understand the basic terms.

3D printing is a very general term. The media, especially mainstream marketing, portray 3D printing as the magical technology of the future, capable of reproducing complex objects.

But this approach makes it difficult to understand what 3D printing is from a technical point of view.

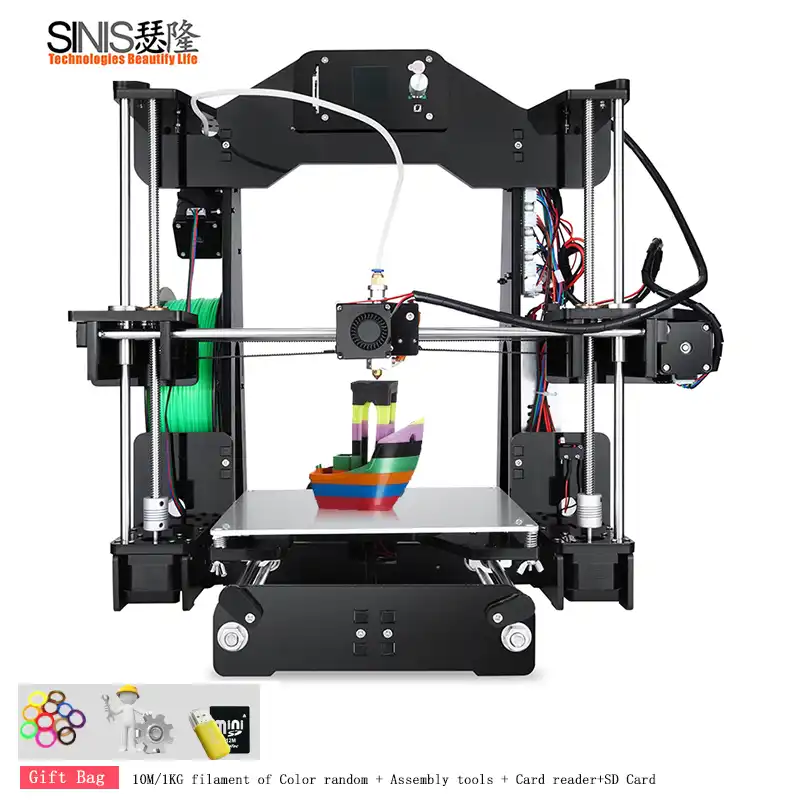

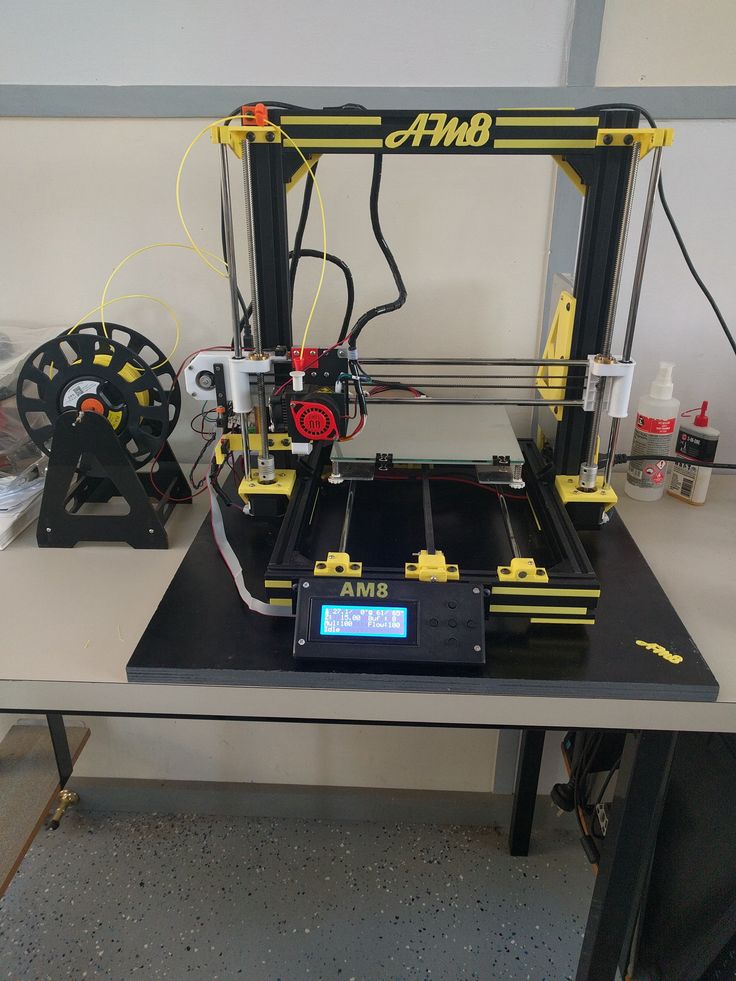

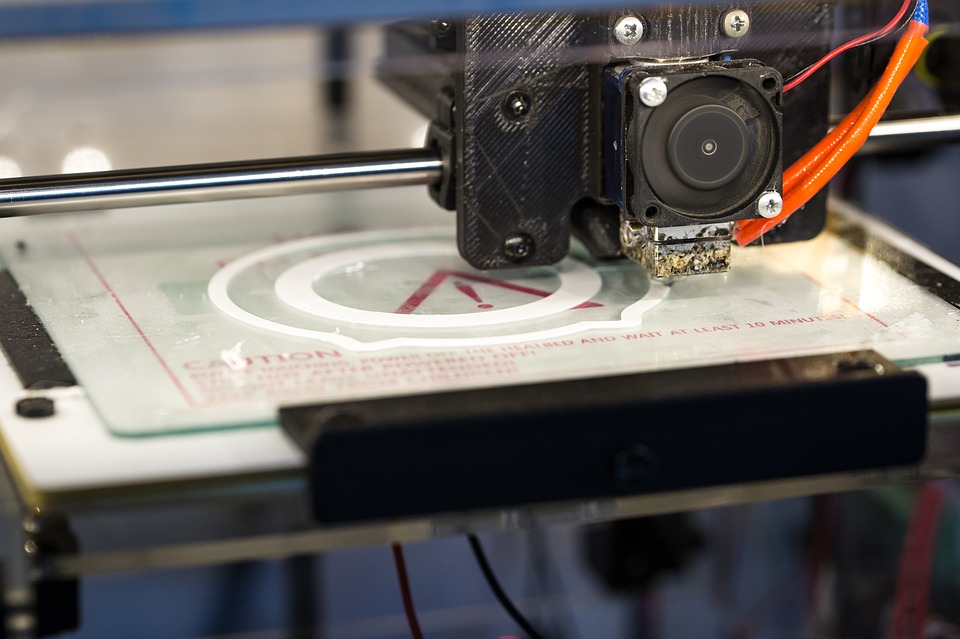

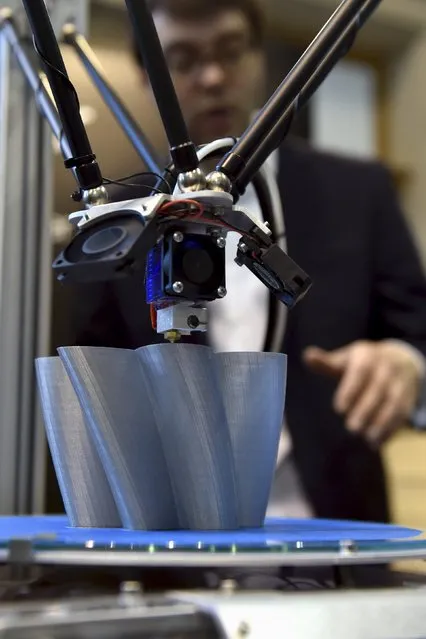

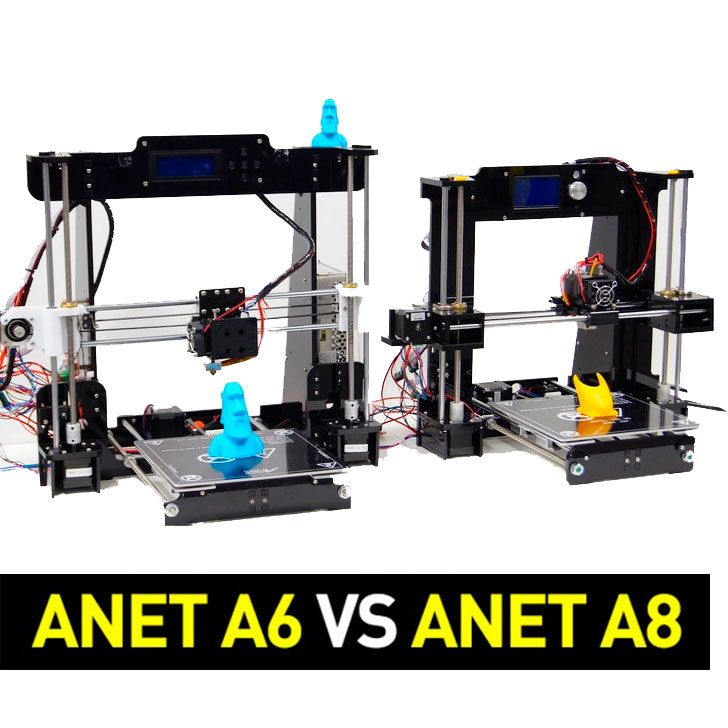

In reality, there are many different 3D printing technologies, but the most common for beginners is layer-by-layer modeling (FDM or FFF), which is the focus of this article.

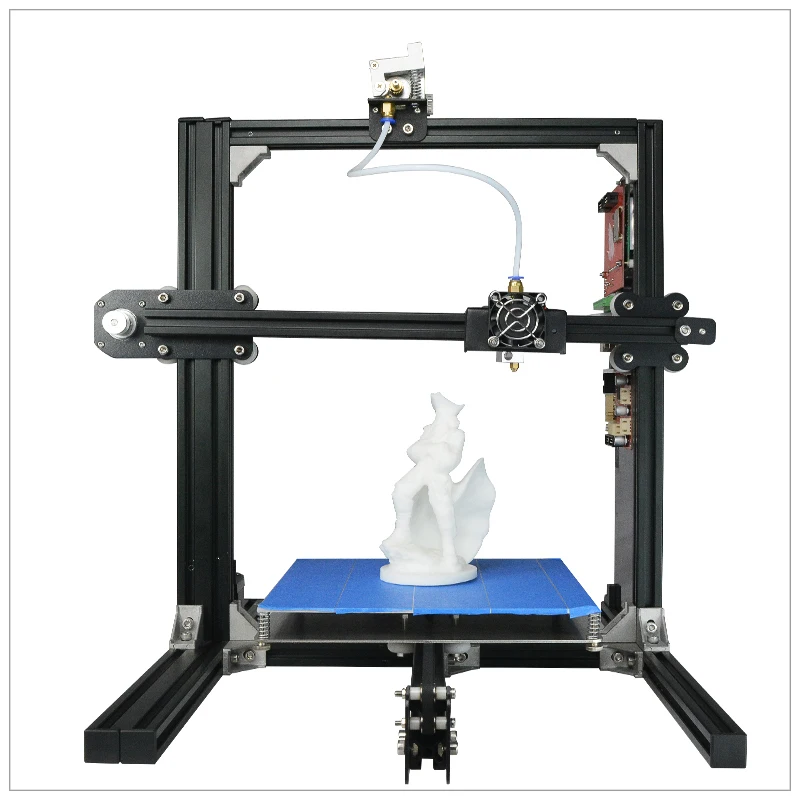

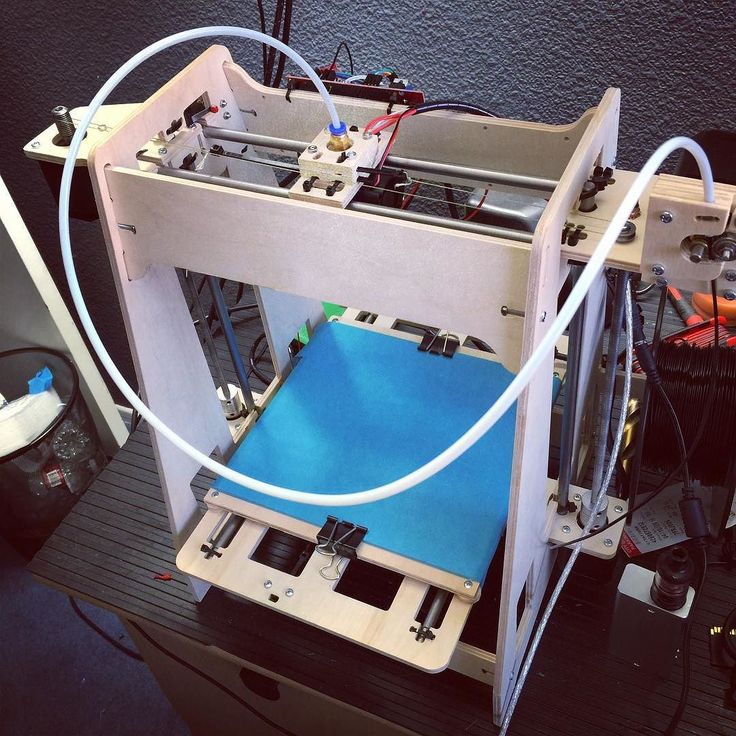

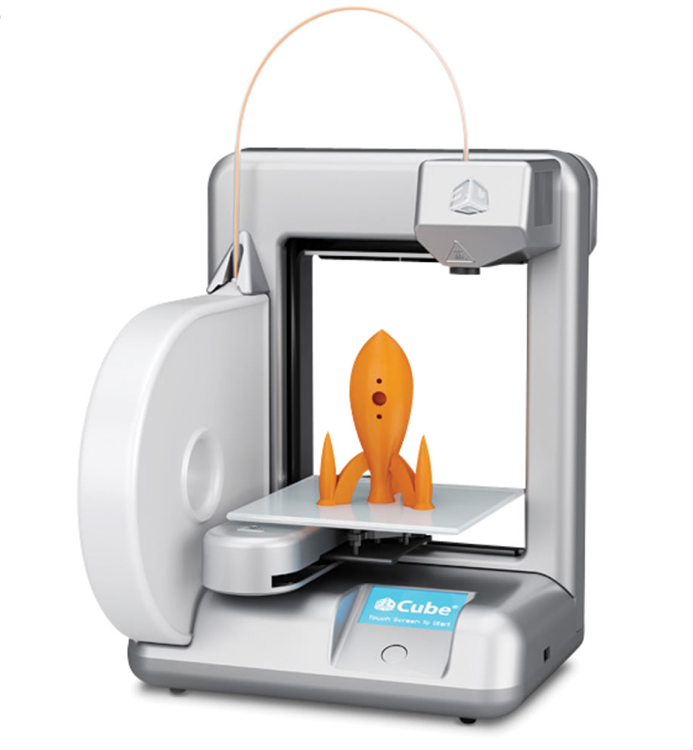

Ender 3 V2 is one of the most popular hobbyist 3D printers.

FDM prints parts using thermoplastic, which is basically a filament of material that can melt, cool, and solidify. Details are built by stacking layers on top of each other.

This technology was created because people needed a way to quickly prototype parts. Even today, rapid prototyping is one of the biggest advantages of FDM and 3D printing in general. Not surprisingly, 3D printing is also gradually becoming a powerful manufacturing solution.

Before we get into the details of how FDM works, there is one more thing worth mentioning. If you have done some research on FDM, you may have noticed that some sources use the term "FFF" instead of FDM when referring to the technology. This is because FDM is a term originally patented by Stratasys and FFF is a non-proprietary generic abbreviation. Remember, this is the same technology, only the names are different. Today, most people use the term FDM.

This is because FDM is a term originally patented by Stratasys and FFF is a non-proprietary generic abbreviation. Remember, this is the same technology, only the names are different. Today, most people use the term FDM.

FDM 3D printing. How it works?

- 3D printer control interface

- 3D printing plastic (filament)

- Extruder

- Hotend (hot end)

- Fan (cooler)

- Print platform (table)

- 3D printing

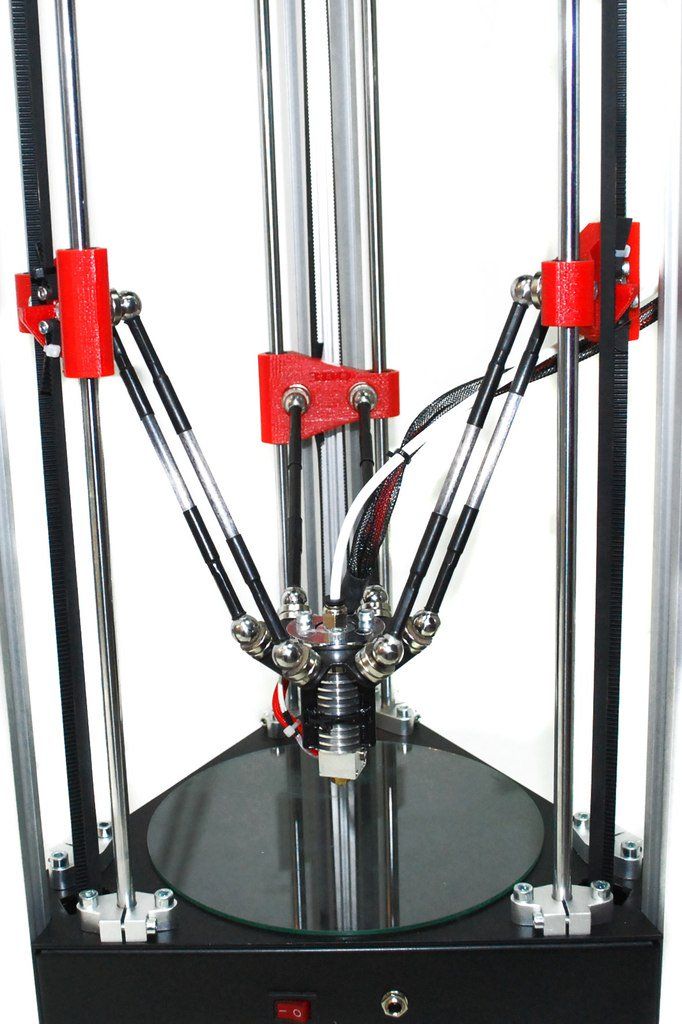

The easiest way to understand how FDM works is to study the details of an FDM 3D printer. However, before we get into the specifics, it's worth mentioning that most 3D printers can move in three axes: X, Y, and Z. The X and Y axes are responsible for moving left, right, forward, and backward, while the Z is responsible for vertical movement.

Now let's look at the main components of a 3D printer:

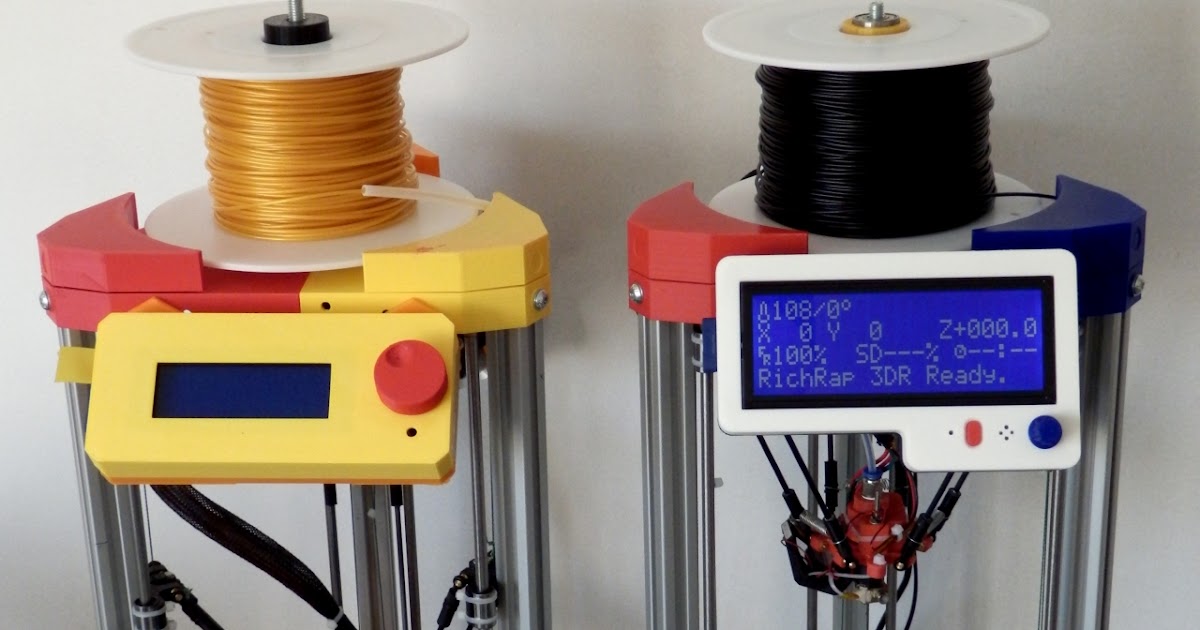

Control interface : Some modern 3D printers have a touch screen that is used to control the 3D printer. On older printers, a simple LCD with physical scrolling and a click wheel may be present instead of a touch interface. Depending on the model, an SD card slot and a USB port may also be present.

On older printers, a simple LCD with physical scrolling and a click wheel may be present instead of a touch interface. Depending on the model, an SD card slot and a USB port may also be present.

Print Bed : The bed or table of a 3D printer is essentially the surface on which parts are made. Platforms are most often made with heating to improve the adhesion of the part, but more on that later.

Extruder(s) : The extruder is the component responsible for melting and progressively depositing the plastic filament to build the model.

The extruder actually consists of two subcomponents: hot and cold. The hot end or hot end contains a heater and nozzle that actually melts the filament, while the cold end consists of a motor, drive gears and other small components that push the filament into the hot end to melt.

There is a heatsink and a fan between the hot and cold ends because it is necessary that the cold end stays cold to avoid jamming.

In addition to the heatsink fan, there is usually at least one other fan designed to cool the molten filament after it exits the extruder - this is commonly referred to as the parts cooling fan.

Print head : one or more extruders are installed on the print head (standard 3D printers have one extruder). At the top of the print head is a tube that feeds filament into the print head.

How a 3D printer prints.

The process starts when you send the 3D model file to the printer. After starting a print job, the nozzle starts to heat up. When the nozzle reaches the temperature required to melt the filament, the extruder draws the filament into the hot end in preparation for deposition modeling.

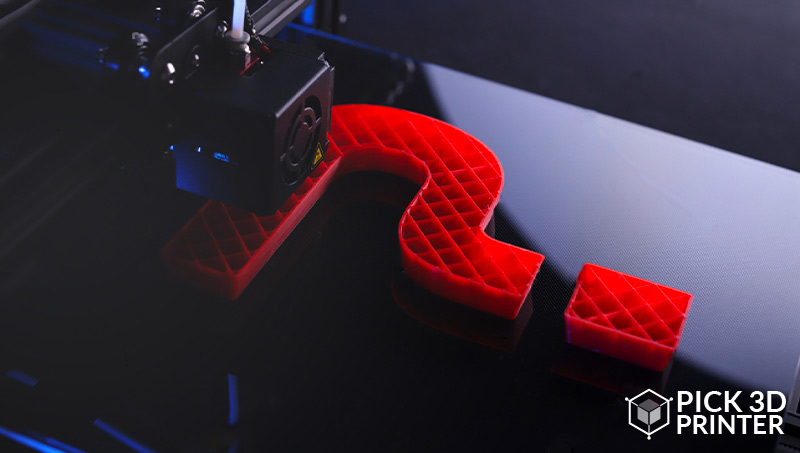

The printer is now ready to 3D print the part. The print head descends onto the build surface (platform) and begins to fuse the filament, which cools and solidifies shortly after exiting the nozzle thanks to the part cooling fans.

Plastic is applied one layer at a time, and after one layer is completed, the printhead moves up the Z-axis a short distance and the process is repeated until the part is completed.

Create, download and purchase 3D models.

Naturally, if you want to 3D print a part, you must have a 3D model of that part. 3D models are created using 3D modeling software commonly referred to as CAD (computer-aided design) software. Here are some examples of popular 3D modeling software:

- Autodesk's Fusion 360 (Free for non-commercial use)

- Blender (free of charge)

- ZBrush (paid, but free trial available)

However, most 3D printing beginners do not have the skills required to use such software. If so, don't worry because there are other solutions.

First, there are simpler CAD software options like Tinkercad, a program that almost anyone can use without any prior experience. This is an online application developed by Autodesk, one of the leading developers of CAD software.

Downloading files

With so many people having access to 3D printers in recent years, several sites have become repositories for 3D models.

Here are some of the most popular:

- Thingiverse (free)

- MyMiniFactory (many free, some paid)

- Cults3D (free and paid)

- CGTrader (some free and most paid)

- PrusaPrinters (all free)

So anyone can get their hands on a model without any modeling skills.

Model preparation.

3D models must be prepared for 3D printing using special software that translates the model into machine instructions. This is done using slicing software, also called a slicer. 3D models are imported into a slicer, which then actually "cuts" the model into layers. The resulting files consist of a G-code, which is essentially a long list of instructions that a 3D printer follows to build a model.

G-code is the "language" of 3D printers and CNC machines. These files contain important parameters needed to create a model, such as print speed and temperature, wall thickness, infill percentage, layer height, and many others. In other words, 3D printing is impossible without G-code files!

In other words, 3D printing is impossible without G-code files!

Supports (support structures)

Another of the main functions of the slicer is the generation of support structures (supports). In particular, supports are needed for parts with attachments.

9The 0002 Slicer allows you to choose where to place the supports and how tight you want them to be. Some slicers even offer users the ability to select different types of support structures for easier removal or strength.Printer preparation.

Before you start printing on a 3D printer, there are a few mandatory steps to take:

Plastic loading: The extruder must be ready to extrude the filament before printing begins. The loading process begins with heating the hot end to the melt temperature, and then the filament is directly loaded into the heated extruder.

Platform Leveling: In order for the printer to successfully print an object, the table must be as level as possible.

Depending on the printer, platform calibration can be performed manually, semi-automatically or automatically.

Platform leveling is very important because, for example, if the nozzle is too far from the table, the first and most important layer will not adhere to the surface, resulting in you not being able to print your object.

Materials for FDM 3D printing.

As we already mentioned, FDM 3D printers use spools of plastic as part material. Filament is basically a thermoplastic specifically designed to melt and cool while maintaining its structural integrity.

3D printing filaments usually come in two diameters: 1.75mm and 3mm (or 2.85mm). Most 3D printers use 1.75 diameter plastic, which is why the variety of types and shades of 1.75 filament significantly exceeds 2.85.

We recommend that before you buy a 3D printer, be sure to clarify which filament it works with.

Converting the extruder from 2.85 to 1.75 is possible, but requires fiddling, time and additional accessories.

One of the best things about FDM 3D printers is that they can handle a wide range of plastics.

Here are just a few of the different types that are used in FDM 3D printing:

Standard:

- PLA

- ABS

- PETG

Engineering:

- Flexible (TPU, TPE)

- Nylon

- With additives (wood, metal, etc.)

- Polycarbonate (PC)

For supports:

- HIPS

- PVA

Among other things, FDM filament is one of the cheapest materials used in the world of 3D printing.

Post-processing of printed products.

Post-processing is the final steps you must take to complete your object.

Below we have listed some of the post-processing steps for a 3D printed part. You don't necessarily need to complete each of these steps.

Most often, post-processing is completed at the stage of removal of supports.

Support Removal : After printing, the support structures are mechanically removed by simply breaking them off. As a result, you can see marks left on the surface of the part.

As a result, you can see marks left on the surface of the part.

If you have bought a 3D printer with two extruders, you can use special soluble plastics to print supports. In this case, you just need to place the object in water if you printed with PLA+PVA or in limonene if you printed with ABS+HIPS.

Sanding : Your part may have imperfections (for example, after removing supports). In this case, grinding comes into play. Light sanding of 3D printed parts can make the surface smoother.

Coloring : You will often print in one color. To add more colors, details or protection, you can paint your model!

Polishing or Smoothing : Epoxy is one way to smooth the surface of a printed part. For ABS, an acetone steam bath is often used. Under the influence of acetone vapors, ABS begins to dissolve and, if this process is stopped in time, you will get a smooth and glossy part.

Gluing : If you want to print a large 3D model that won't fit in your printer's build chamber, you can print the part in two or more parts and then glue them together.

Common 3D printer problems.

Let's discuss some of the most common problems beginners may encounter when using a 3D printer.

Warp : This problem occurs due to temperature differences during the 3D printing process. 3D Print Delamination - 5 Tips and Tricks to Avoid Delamination.

Plastic bleed (snot) : Thin extra filaments of plastic on your model may be caused by incorrect temperature or retraction settings. Some types of plastic, such as PETG, are more prone to free flow from the nozzle.

Nozzle Clog : Nozzle clogging is one of the most annoying problems of FDM 3D printers.

If you hear a strange printhead sound and no plastic comes out of the nozzle, the nozzle may be clogged. This can be caused, for example, by poor filament quality or incorrect temperature settings.

Layer Offset : This problem can be caused by vibrations and wobbles in your printer, insufficient X and Y belt tension, or excessively high print speeds.