3D print selling

14 Things to 3D Print and Sell in 2022 – Clever Creations

Thinking about starting a 3D printing business? Want to try to sell 3D printed items on the side? You may be wondering where to start.

There are several ways to make money with a 3D printer, for example, you can open an online shop to sell 3D printed items, or offer print-on-demand 3D printing services.

In this article, we’ll cover how and where you can sell 3D printed items. We’ll also show cool (and profitable) ideas for things to 3D print and sell, and explain what you need to know before you turn your passion for the hobby into a business.

What to keep in mind when selling 3D prints

Selling 3D printed items can be a lucrative business. However, you need to consider a few things before opening your shop and taking your first orders.

Profit margins

Before setting a price for your 3D prints, you should calculate your costs and margins. This isn’t unique to 3D printing, since all business owners need to know if their product will make a profit.

You need to consider all costs associated with 3D printing the item and selling it. This includes the 3D printer cost, but also the print materials, shipping supplies, 3D printer power usage, seller platform fees, and wages for your time. The more thorough you are, the more accurate the results of your calculations will be.

Copyright

The issue of copyright when selling 3D prints is twofold. If you are printing and selling a 3D model created by someone else, you must follow the designer’s license. If the designer has listed the model as non-commercial, you cannot sell it. If you still choose to do so, they can take legal action against you or your business for infringing on their copyright.

Another layer of the copyright issue is that you cannot sell prints of copyright or trademarked material. This is true even if the model has a commercial license. For example, Bulbasaur is a trademarked and copyrighted character of Nintendo. Thus, you can’t sell Bulbasaur planters even if the 3D model has a public domain license.

Where to sell 3D prints

You can sell your 3D prints using many different channels. Live events like craft fairs, festivals, and trade shows are a great way to garner in-person sales. Consignment shops and displays in local businesses can give your 3D prints a brick-and-mortar presence without the overhead.

Online eCommerce platforms are by far the easiest and most widespread sales channels to use. You can start your own website and sell directly from there or use an existing marketplace.

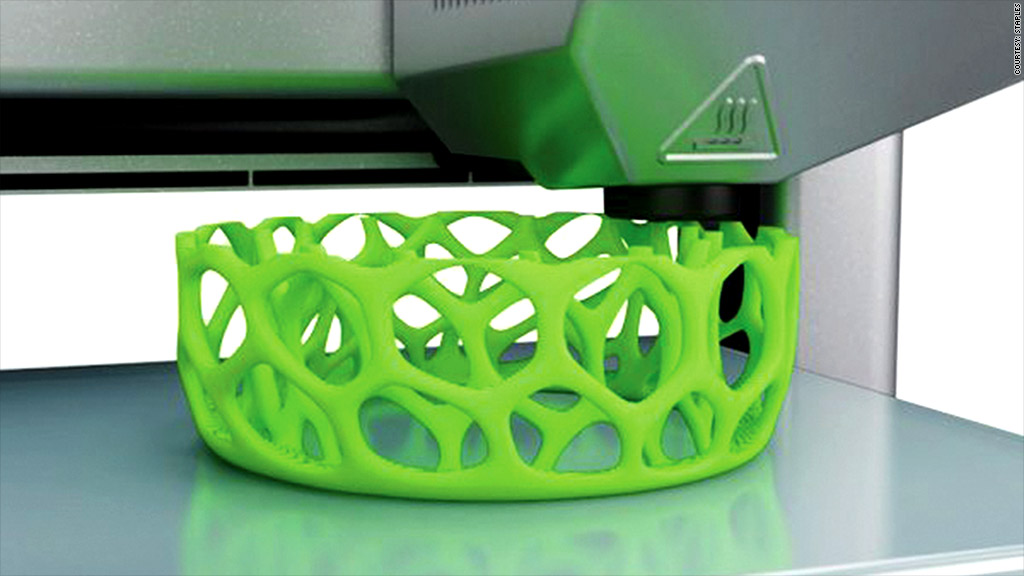

Image: crosslink via MyMiniFactory

3D printed vases are a hit on almost any platformThe latter option is much easier for beginners who don’t know much about online retail. By using existing marketplaces, you can leverage their existing audience and make money with a 3D printer in no time.

Etsy

The online marketplace Etsy focuses on handmade, vintage, and handmade supply products. They charge a $0.20 listing fee per item every four months (or until it sells and is relisted). They also take a percentage of the sales revenue when an item sells.

They also take a percentage of the sales revenue when an item sells.

Many 3D printing shops have been very successful in selling items like planters, cookie cutters, and toys on the Etsy platform. Aside from those, there are plenty of other things to 3D print and sell on the platform.

Recommended:

The 5 Best 3D Printers for Making Cookie Cutters

Amazon

The Amazon marketplace is the largest eCommerce platform available. Amazon integrates third-party sellers into their warehouse system. An independent 3D printing shop using the platform can send their prints to the nearest warehouse and Amazon would process them and ship them out as they sell.

eBay

More dated than most of the other platforms on this list, eBay never quite left its days as an auction site behind. It has at least integrated the ‘Buy It Now’ functions that allow it to work more like an eCommerce platform.

New sellers get free listings to get started, then pay a flat fee per listing and a percentage of their revenue.

eBay shouldn’t be your main eCommerce platform for making money with your 3D printing business. However, it works well as a supplement to the other services we’ve listed.

Fiverr

Starting as a place to pay people to do menial tasks for $5, Fiverr has grown into a labor outsourcing giant. They are now competing with the likes of Upwork, Freelancer, and so on.

Fiverr’s system pays you for your labor, so you are not listing your product. You are listing your ability to 3D print cool 3D prints for other users.

Best 3D Printed Items That Sell

1. Miniatures (D&D, Warhammer, etc.)

Image: BaconuCrazy via MyMiniFactory

One of the best things to print and sell with your 3D printer is miniatures for tabletop games like D&D and Warhammer.

These figurines are small and highly detailed. This means that if you want to make money by 3D printing miniatures, you are best off with a resin 3D printer. On the other hand, larger terrain pieces are best suited for traditional fused deposition modeling (FDM) 3D printers.

Recommended:

Resin vs Filament 3D Printers: What’s the Difference?

Part of the appeal of miniatures is that they are customizable. They are sold unpainted (similar to some model kits) so the buyer can decorate and paint the miniatures as they see fit. This is excellent news for anyone looking to make money printing by selling 3D printed miniatures. No painting means there is less need for post-processing work.

3D printed miniatures are well-liked among consumers, as customers can buy miniatures that aren’t available to them through traditional manufacturing companies.

Consumers also enjoy commissioning customized minis. These figurines are often original characters in their campaigns or stories. If you have the level of skill needed to model and/or sculpt these personalized minis, that can be a significant upcharge for your 3D printing business.

If you want to go this route, you might want to check out our article on the best 3D printers for miniatures.

2. Cosplay items (helmets, armor, props, etc.)

Image: TieKai via MyMiniFactory

Cosplay items are one of the most labor-intensive options on the list of things to 3D print and make money with. Taking hours or days from start to finish, making cosplay costumes and props to sell is not for the faint of heart. These items (especially 3D printed armor sets and 3D printed helmets) are large parts that take hours to print and post-process.

Most users expect their cosplay items to be finished and painted to a professional level when they buy them. This takes a great deal of time and effort on your part as the seller. The upside to this is that you can charge a premium price for these items to make up for the extra time spent 3D printing and assembling them. Customers are often willing to pay well for these items.

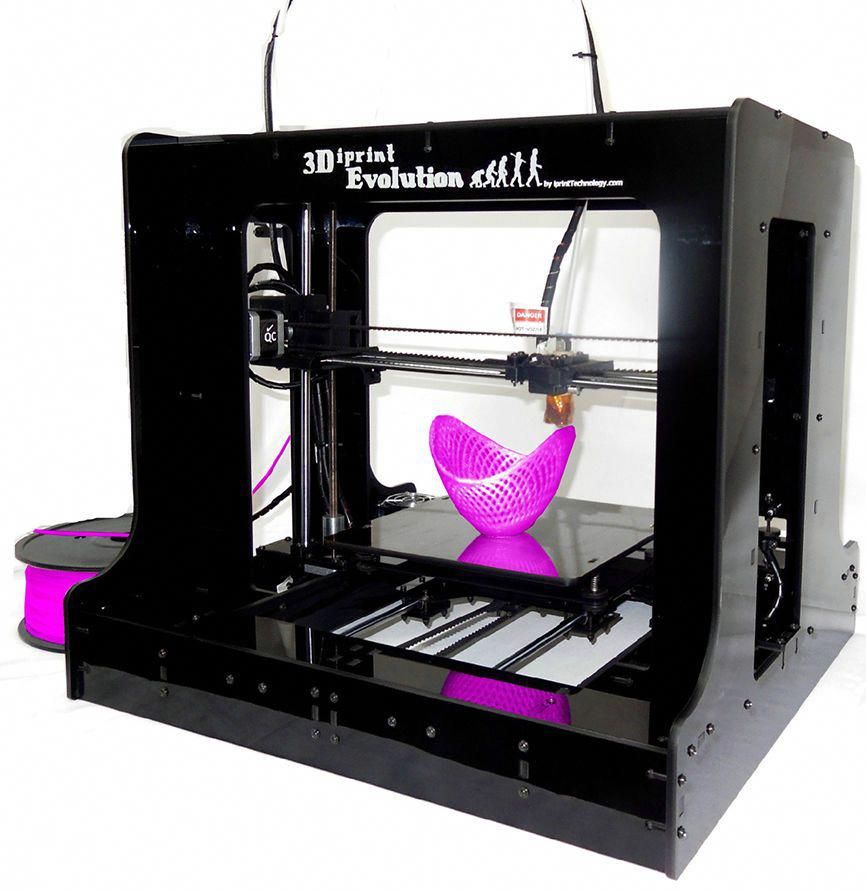

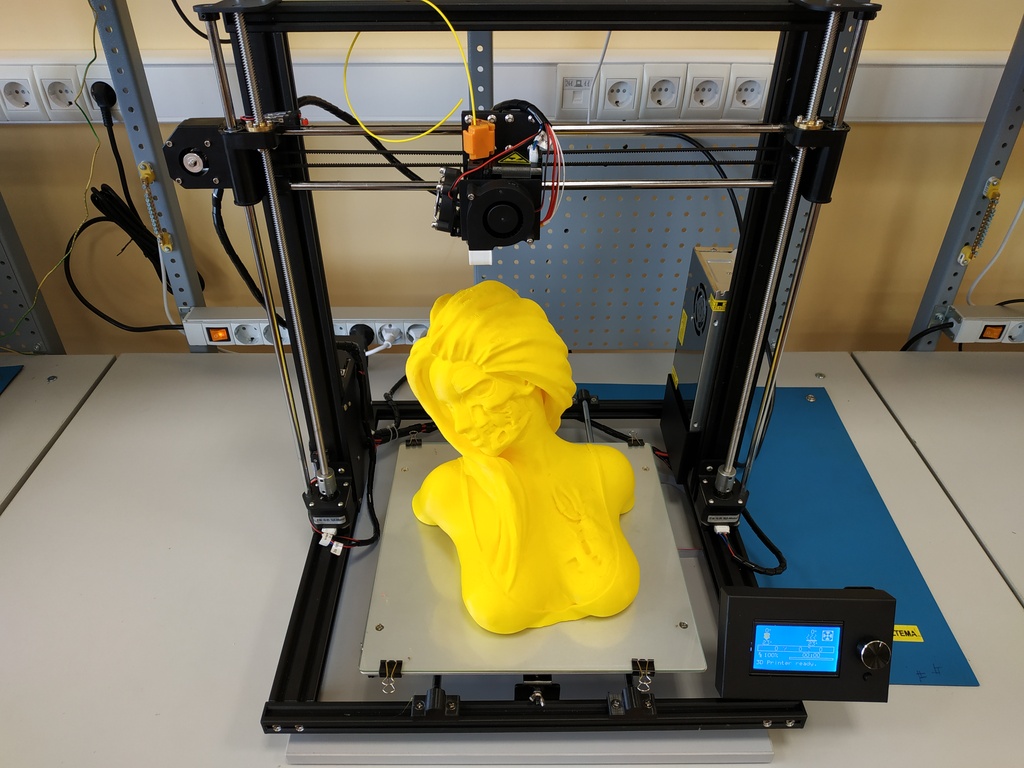

If you want to make money 3D printing and selling cosplay items, it is a good idea to use a 3D printer with a large build volume. That way, you won’t need to spend time splitting parts to fit the build plate and gluing them together when the printing is complete.

Use a large 3D printer for cosplay, and you can simply 3D print full-size pieces in one go.

3. Jewelry

Image: Muttonheid via MyMiniFactory

The jewelry market is a high mark-up market with excellent profitability if approached correctly. Its main problem is that it is oversaturated with artisans and hobbyists. Your designs and marketing both need to be unique and strategic in this space. Otherwise, it is impossible to have any visibility on most of the eCommerce platforms mentioned in this article.

Since jewelry pieces tend to be small, you need negligible amounts of raw material to print each piece. This keeps production costs low and makes it possible to create many at once. Like miniatures, jewelry requires a high level of detail. For the highest-quality pieces, you will need a 4K resin printer or higher (6K/8K).

Recommended:

The 8 Best 4K+ Resin 3D Printers

FDM 3D printers are not entirely ineffective for jewelry making. They can still print forms for silicone molding material. Then use those molds with things like polymer or precious metal clays, resins, low-temperature metals, and other castable materials.

Then use those molds with things like polymer or precious metal clays, resins, low-temperature metals, and other castable materials.

3D printed mold forms need to be smooth and non-porous before molding. You’ll need to sand, fill, or use other extensive post-processing work to achieve the right look.

If you can keep the cost low and produce (customized) jewelry that you promote effectively (e.g. through social media), you will have a good chance at creating a successful 3D printing business in the jewelry niche.

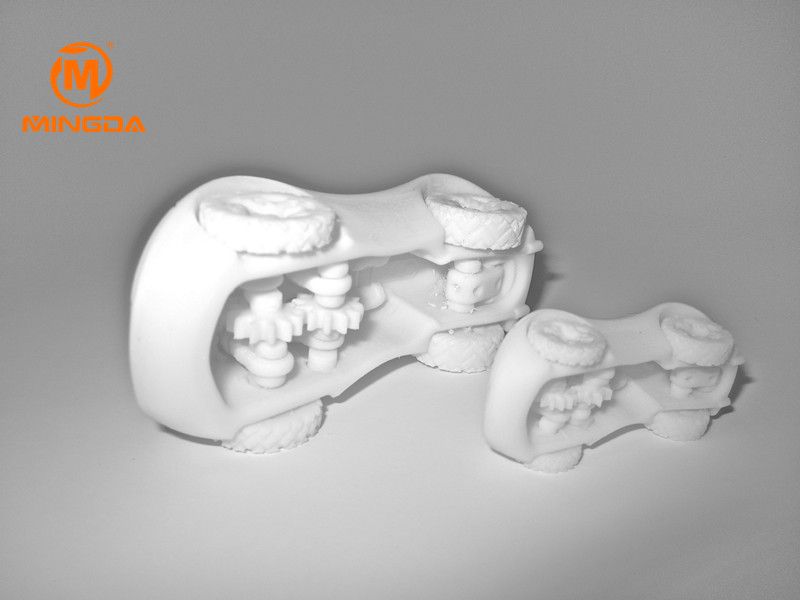

4. Toys

Image: animm07 via MyMiniFactory

3D printed toys are a great option to sell. However, you need to be cautious about regulations on children’s products when choosing to manufacture them with your 3D printer. Some countries require certification to make and sell certain items. This mainly pertains to products for babies and very young children. The guidelines vary from country to country.

Fidget toys and articulated creatures geared towards older kids and adults run a much lower risk of liability and are quite popular. These items are even more memorable when printed from something like color changing, glow in the dark, or filled (Woodfill, Copperfill) PLA filament.

These items are even more memorable when printed from something like color changing, glow in the dark, or filled (Woodfill, Copperfill) PLA filament.

Recommended:

The 8 Best 3D Printers for Kids

Most toys are quick and efficient to make. They print easily on a traditional FDM 3D printer and don’t require much post-processing. Plus there are plenty of cool toy ideas out there that you can 3D print.

5. Nerf gun accessories

Image: GoKidd via MyMiniFactory

Customized or unique Nerf gun accessories and gun bodies are a popular niche in the 3D printing community. They also have quite a demanding retail market.

Items like sights, dart holders, extra clips for discontinued products, larger magazines, and improved barrels are all popular Nerf-related 3D prints. They are easy to create on most 3D printers and fit well with the other ideas of things to 3D print and sell.

It is also not uncommon for Nerf-enthusiasts to want custom guns that the company has not or will not make. Sometimes this means turning a cosplay prop into a functioning dart gun. Other times it means making a gun body that is not commercially available.

Sometimes this means turning a cosplay prop into a functioning dart gun. Other times it means making a gun body that is not commercially available.

Cosplay prop and customized Nerf gun designs are great designs to sell. They have high markup potential and popularity. You can have a profitable business in this niche as long as you don’t overstep trademark rules.

The name Nerf is technically protected under trademark laws. It can help to use generic terms like dart gun, foam dart weapon, etc. in place of the brand in your product listings. This makes sure you don’t gain the attention of any corporate lawyers. They do periodic intellectual property sweeps on popular eCommerce platforms.

Accessories have a lower profit margin than 3D printing full Nerf guns. However, most users don’t care if their dart holders or magazines are not sanded smooth, so they are a quick and easy way to make money with a 3D printer.

6. Architecture models

Image: Format3D via MyMiniFactory

Architectural models are a difficult 3D printing project. They often recreate both the interior and exterior design of a building. They are usually printed in pieces so that the roof and separate levels can be removed for easy access to all the interior elements. Because of their complexity, they can be sold at a high markup and are a great option to 3D print and sell.

They often recreate both the interior and exterior design of a building. They are usually printed in pieces so that the roof and separate levels can be removed for easy access to all the interior elements. Because of their complexity, they can be sold at a high markup and are a great option to 3D print and sell.

Architectural prints can be used for prototyping/visualization, education, play, and decoration. Selling house models as a dollhouse toy or a recreation of a famous building for education or decoration purposes is a great way to market them to consumers.

Some architectural and engineering firms like to have tangible models of their designs. This is helpful for prototyping, sales meetings, and even for troubleshooting the design. Aligning yourself with local companies looking for this 3D printing service could be a beneficial opportunity.

7. Figurines and statues

Image: philippeb66 via MyMiniFactory

Figurines and statues are yet another group of 3D printed products that sell exceptionally well. Many of the figurine and statue 3D models that are available online are of copyrighted content. Things such as characters from video games, movies, or tv shows. These are not particularly helpful resources for making commercial items.

Many of the figurine and statue 3D models that are available online are of copyrighted content. Things such as characters from video games, movies, or tv shows. These are not particularly helpful resources for making commercial items.

Yet, there are still plenty of options for unbranded designs either through ready-made models or customized ones that you design yourself. Animals, mythological creatures, etc. are all popular designs to 3D print and sell without fear of copyright infringement.

Custom figurines of either customers or their pets are another option to diversify your product offerings. This does require an advanced skill level for 3D modeling and/or sculpting. If you aren’t there yet, keep it as an option for the future. In the meantime, you are welcome to look at our recommendations for free 3D modeling software.

8. Phone cases

Image: Malex via MyMiniFactory

Phone cases are a large market, and 3D printed versions are no exception. There are countless possibilities for making and selling phone cases with your 3D printer. You can print basic stretch cases using a flexible filament like TPU, or decorative hard cases made from PLA or ABS.

You can print basic stretch cases using a flexible filament like TPU, or decorative hard cases made from PLA or ABS.

Recommended:

The 10 Best PLA Filaments for 3D Printing

Basic cases are inexpensive and readily available to the consumer from most stores and online retailers. If you want to sell cases, it’s best to use unique or customized models.

The most eye-catching 3D printed options emphasize the technical capabilities of 3D printing. The geared iPhone case is a great example.

A large difficulty with 3D printing a phone case to sell is that there are so many different phone models available and they update constantly. As such, you may find it difficult to source consistent phone case models. You may also realize your designs are becoming quickly outdated if you model them yourself.

The best solution to the variability of phone case compatibility is to start out 3D printing and selling cases for only a handful of different phone models. From there, you could make the decision to scale up or down as needed.

9. Self-watering planters

Image: diegopvp via MyMiniFactory

Planters in general are a hot seller in the 3D printing world, but self-watering planters are even more popular. They are hard to find in stores, making them a fantastic item to add to your business’ offerings.

Self-watering planters are typically designed in two parts: the planter and a water reservoir.

Since both pieces are in contact with water, they need to be watertight in order to not leak. Typical 3D prints have microscopic gaps between each layer. Water can seep through these layers and onto whatever surface the print is sitting on. A clear, non-toxic sealant is a great solution for this problem and gives customers a much better experience with their planter.

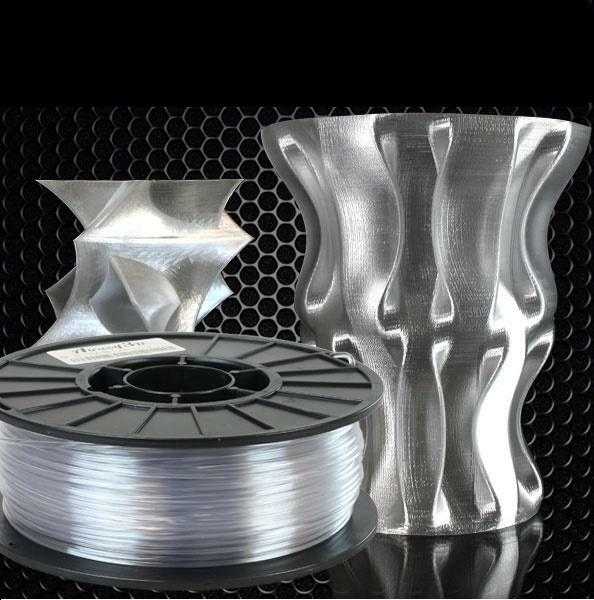

10. Designer vases

Image: didierklein via MyMiniFactory

3D printed vases are another home décor product capable of generating a large number of sales. With the exotic shapes that can be created in CAD and made on a 3D printer, the end results are far more modern and sophisticated than vases that are commercially available.

Like the planters mentioned above, vases need a sealant to make them watertight. They are quick and easy to make and can be 3D printed as one continuous spiral. The continuous print lines that this creates improve the speed and quality of the print job.

Items like vases can be printed on either FDM or resin 3D printers (if the print bed size is not an issue for the latter). Extruder-driven ceramic and clay 3D printers are also an excellent option if you are lucky enough to have access to one.

Regardless of the type of 3D printer you use, vases are an excellent choice for making money with a 3D printer.

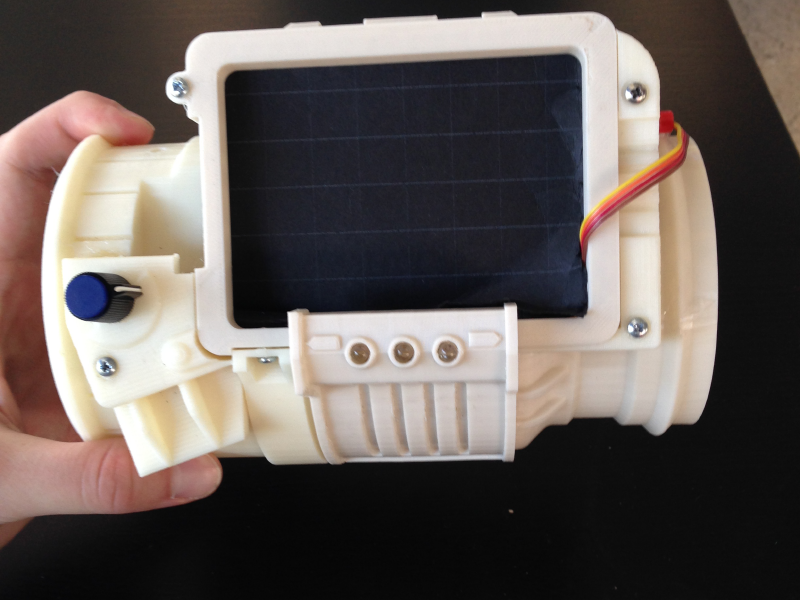

11. Raspberry Pi cases

Image: Laza via MyMiniFactory

Raspberry Pi boards are a common component in homemade electronics projects. Pi boards are inexpensive single-board computers that are suitable for many projects. For example, they can control smart home equipment, act as a controller for other projects, power a video game emulator console, or run as an underpowered but functional DIY computer.

Since Raspberry Pi’s are so small, it is easy to print cases and enclosures for them. The cases not only protect their components but also make them look more functional and professional. Selling the cases to interested tinkerers has sales potential by itself. If you happen to be handy with electronics, you could also sell fully assembled Raspberry Pi projects.

12. Eyeglasses frames

Image: Sacha_Zacaropoulos via Thingiverse

3D printed eyeglass frames have risen in popularity over the years. Several major eyewear companies have started selling FDM-produced 3D printed eyeglass frames. These products are usually made from WoodFill and other specialty filaments.

Even so, consumers are also flocking to smaller businesses that can design a new pair of frames. Sometimes they want new frames designed for their existing lenses if their store-bought frames break. Other times, they want to transfer blue light or sunglass lenses to a new pair of 3D printed frames for comfort or aesthetic reasons.

We don’t recommend using PLA or other low-temp filaments on this project. If the person wearing them spends enough time outside on a hot day, the frames could soften and warp from the heat. ABS and Nylon are safer filament choices, as they have a higher glass transition temperature (i.e. they melt at higher temperatures).

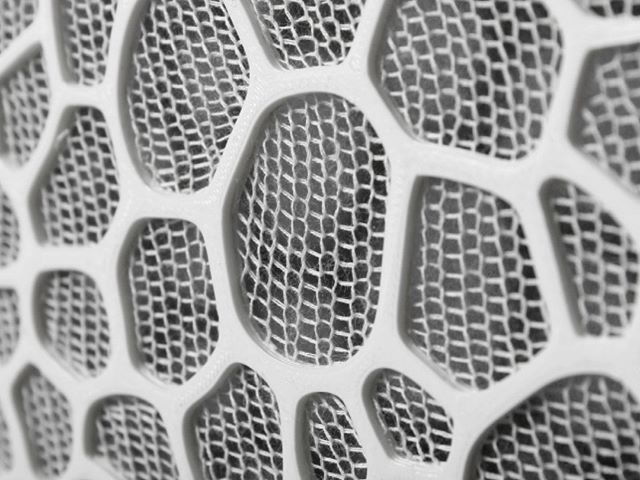

13. Lamps

Image: Frank Cheung via MyMiniFactory

You can make a variety of different types of lamps on a 3D printer. They are popular choices when it comes to making and selling 3D printed items. Home décor is a thriving market. When you can offer something unique for their living space, design-minded consumers take notice.

Lamps (especially pendant lights) most often require a 3D printer with a medium to large build volume. Because of their shape and texture, most designs don’t fare well when split and glued back together. Seams also change the way light passes through the filament, so they may be noticeable once the light is on.

14. Landmarks

Image: ShakeandB1ake via MyMiniFactory

Landmark models and statues recreate well-known buildings, places, statues, and other monuments. They vary from highly-detailed architectural models of famous buildings to sites like Stonehenge. They don’t usually come apart as architectural models do.

These models are popular sellers with tabletop gamers. They are sometimes used in tabletop campaigns and world or story-building exercises. They also make excellent educational tools and are great additions to the modern classroom.

Frequently asked questions

What are the most popular 3D printed items?

Cosplay props, planters, and miniatures are some of the biggest sellers. The popularity depends on which platform you are selling on. For example, on Etsy, the main customer base is looking for pretty, trendy things. Beautiful planters, jewelry, and the like will be most popular.

The best way to learn what is selling on your platform is to do a little research. Find the shops with the best sales numbers, see what their bestsellers are. Use that as an estimate of which categories and niches are most popular. It will be much easier to make money with a 3D printer by finding the niche that works best for you and to fill it with unique products.

Find the shops with the best sales numbers, see what their bestsellers are. Use that as an estimate of which categories and niches are most popular. It will be much easier to make money with a 3D printer by finding the niche that works best for you and to fill it with unique products.

Is it legal to 3D print and sell?

It is perfectly legal to sell your 3D prints. Issues rarely arise if you follow licenses of the models you download and you don’t sell trademarked goods. There are some extra considerations for certain groups of products. For example, you sometimes need special certification to make or sell items directed at young kids or babies.

Certifications vary from country to country, so research the limitations and laws of your country to find out more.

The easiest way to avoid liability is to design your own models to 3D print and sell. Creating your own models avoids the complications of using other people’s intellectual property.

Image: TobiasKuijper via MyMiniFactory

Designing your own 3D models is a good way to avoid copyright issues when selling 3D printsIs selling 3D prints profitable?

Depending on what you make and how you market it, selling your 3D prints can be a very profitable way to make money online. To get the best results from selling 3D printed items, you need to do thorough market research.

To get the best results from selling 3D printed items, you need to do thorough market research.

You should look at what items are selling, where they are selling, and what you can do to stand out.

Do people buy 3D printed objects?

They sure do! As awareness of 3D printing technology increases, more people understand it is an easy way to get their hands on custom or unique items.

Be sure you are very clear in your descriptions about what material the item is made from. It is common to see customers confuse 3D printed items with wood in their reviews.

Conclusion

That’s everything you need to know about selling your 3D printed items. Do you sell your prints? What’s the most difficult part of running a 3D printing business? Let us know in the comments below!

The 7 Best 3D Printers for Miniatures (2022) – Clever Creations

What to keep in mind when buying a 3D printer for miniatures?

Now that we’ve looked at some of the best 3D printers for miniatures, it is also important to go evaluate the features that are important. In this section, we will go over the major things that you need to consider when getting a 3D printer specifically for miniatures. This will help you set your priorities and select the printer that best suits your needs.

In this section, we will go over the major things that you need to consider when getting a 3D printer specifically for miniatures. This will help you set your priorities and select the printer that best suits your needs.

What kind of miniatures do you want to 3D print?

Non-minis (terrains, props, scenery)

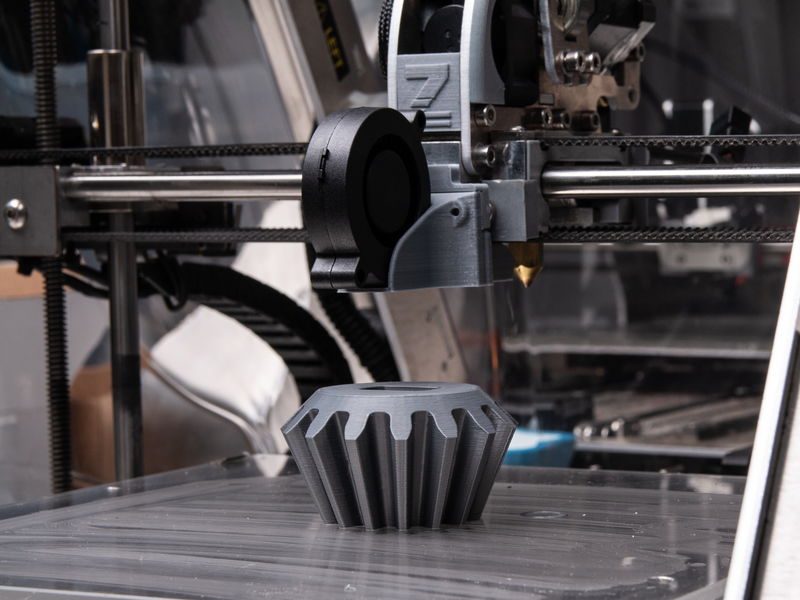

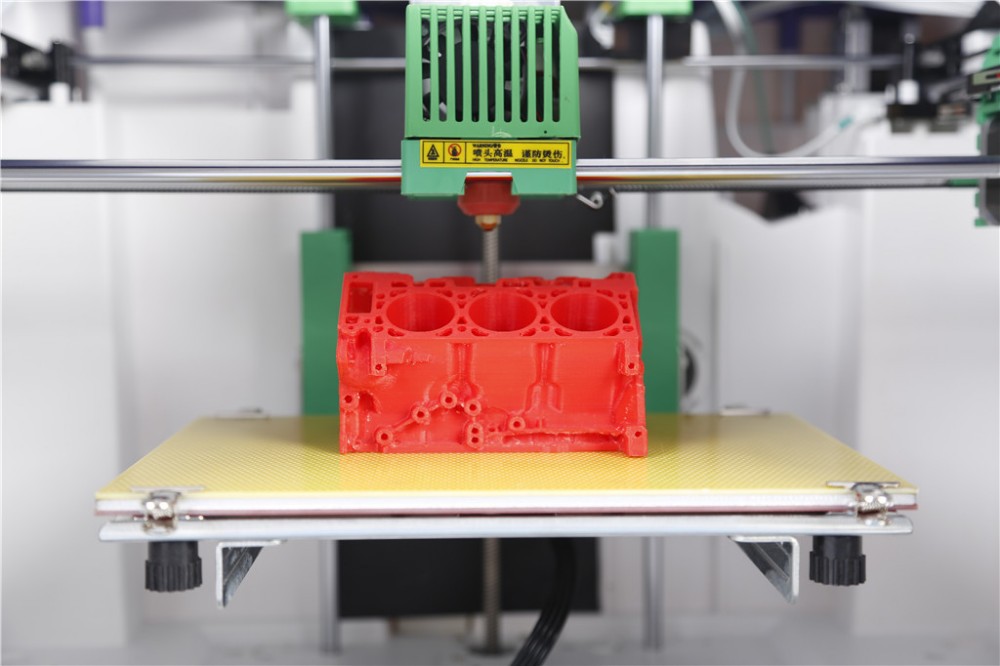

Games like Warhammer and D&D can have an elaborate terrain setup. Since these terrain prints are usually of larger sizes, it makes sense to print them with an FDM 3D printer. The large build volume and cheaper material costs are great for printing terrains and other props. FDM printers also allow you to use the prints right away, as they barely need any post-processing.

Miniatures & figurines

You can commonly find D&D minis in two different sizes. A tabletop version of 54 mm or a mini version of 28 mm.

If you can fine tune your FDM 3D printer, you can very well print the 28mm minis with it. However, you might have to sacrifice finer details and surface finish. Because of this, a resin 3D printer is a better choice for these sizes of miniatures.

Because of this, a resin 3D printer is a better choice for these sizes of miniatures.

Image: IUsedToBeABaker via Reddit

A collection of resin-printed minisThe 54 mm versions consist mostly of figurines and action figures. They can be printed on both FDM & resin 3D printers without sacrificing a lot of detail.

Keep in mind that figurines of this size can quickly get expensive with resin printers. So, if quality is not a pressing issue, a finely tuned FDM 3D printer can give you similar results at considerably lower 3D printing costs.

Bed size

A bigger build platform has its own set of merits and drawbacks. Looking at resin 3D printers, a bigger build platform gives a number of drawbacks. Most notably a bigger resin reservoir, a bigger machine size, and higher peeling forces.

On the other hand, a bigger build plate lets you print more objects at once. This is beneficial when you’re 3D printing a lot of minis in batches, for example.

Image: GomeowCreations via YouTube

The bigger the bed, the more you can print at onceIf you really need to print a lot of minis at once or want to print taller miniatures, the Elegoo Saturn and Anycubic Photon Mono X are a good choice.

If you’re going to be printing a lot of single, small-sized minis, and don’t wish to spend too much money on resin, then you’re better off with smaller 3D printers such as the Elegoo Mars 2 or Phrozen Sonic Mini 4K.

Layer thickness

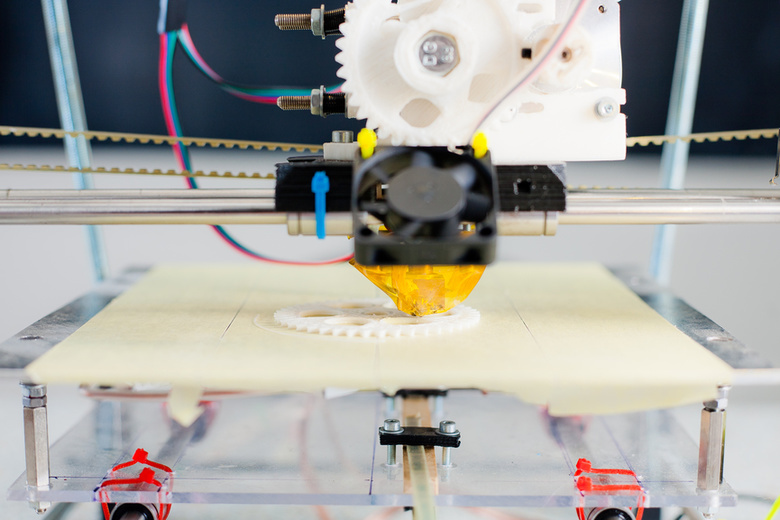

Layer thickness dictates the level of surface finish your 3D printed mini will have. The smaller the layer height, the better the surface finish. An SLA 3D printer like the Form 3 can give you a layer height of just 25 microns or 0.025mm. While with DLP 3D printers, you can still get a respectable layer height of just 50 microns or 0.50mm.

With FDM 3D printers, the layer height of the model depends on the size of the extrusion nozzle. Usually, you can go as low as 100 microns or 0. 1 mm. To achieve this layer height on an FDM 3D printer, you do need to do quite a bit of fine-tuning.

1 mm. To achieve this layer height on an FDM 3D printer, you do need to do quite a bit of fine-tuning.

Image: CaptainSpicyBeard via Reddit

25 microns (left) vs 100 microns (right) –You also need to keep in mind that the lower the layer height, the more time the 3D printing takes. A lower layer height for minis makes sense, but for terrains and other props it is best to use a higher layer thickness. This will save you time and decreases the chances of print failure because of lengthy 3D printing times.

XY resolution

Just as layer thickness refers to the Z-axis resolution and the vertical plane, XY resolution is measured on a horizontal plane. In the case of SLA 3D printers, it is the spot size of the laser. With DLP 3D printers, it is the individual pixel size of the screen.

Normally, the lower the XY resolution, the better the quality of the 3D printed object will be. A very low XY resolution allows the 3D printer to produce even the finest of details. The end result is a 3D print with better quality. Most resin 3D printers have an XY resolution of 50 microns. This is enough to reproduce fine details of the 3D models you are working with.

The end result is a 3D print with better quality. Most resin 3D printers have an XY resolution of 50 microns. This is enough to reproduce fine details of the 3D models you are working with.

Material

The choice of material plays a key element in any 3D printing application. In comparison with FDM 3D printing, the cost of resin 3D printing material is on the higher side. You are also limited to the resins that are compatible with your specific resin 3D printer.

Overall, there are still plenty of material options when working with resin. You can even special resins with which you can cast your own metal figurines.

In FDM 3D printing, the most commonly used materials are PLA, ABS and PETG. PLA filament is easy to 3D print, but difficult to post-process. While ABS is difficult to 3D print, you can smoothen it out using an Acetone bath, for example, and get a great surface finish. All of these materials are cheaply available and you can expect good prints once you have the 3D printing settings dialed down perfectly.

Recommended:

The 10 Best PLA Filaments for 3D Printing

Resin vs filament for miniatures

Choosing between resin vs filament (FDM) 3D printers comes down to your specific needs. There are a few factors that are of particular importance.

Size

FDM 3D printers are available in larger sizes than their resin counterparts. If you’re someone who wants to 3D print larger objects, an FDM 3D printer makes more sense than a resin 3D printer.

Quality

The quality of parts produced on a resin 3D printer will always be superior to any FDM 3D printer. You get a smooth surface finish, higher quality of details, and the part looks as good as an injection molded component.

However, this does not mean that FDM 3D printed minis are worse. If you take the time and effort to finely tune your FDM 3D prints, you can still get some very high-quality minis from your FDM 3D printer.

Material

As discussed earlier, resin material is more expensive than FDM filaments. Aside from an increased cost in the 3D prints, any print failures also lead to higher losses. You’re also limited by the choice and colors of resin materials.

Aside from an increased cost in the 3D prints, any print failures also lead to higher losses. You’re also limited by the choice and colors of resin materials.

In the case of FDM, you have a variety of materials available and can easily get them anywhere in the world.

Operation

Resin 3D printers are messy machines. You need to carefully handle the resin and be sure to print in a well-ventilated area. After printing, you need to wash and cure the 3D printed part with a UV curing station. This requires an extra set of machines and increases lead times.

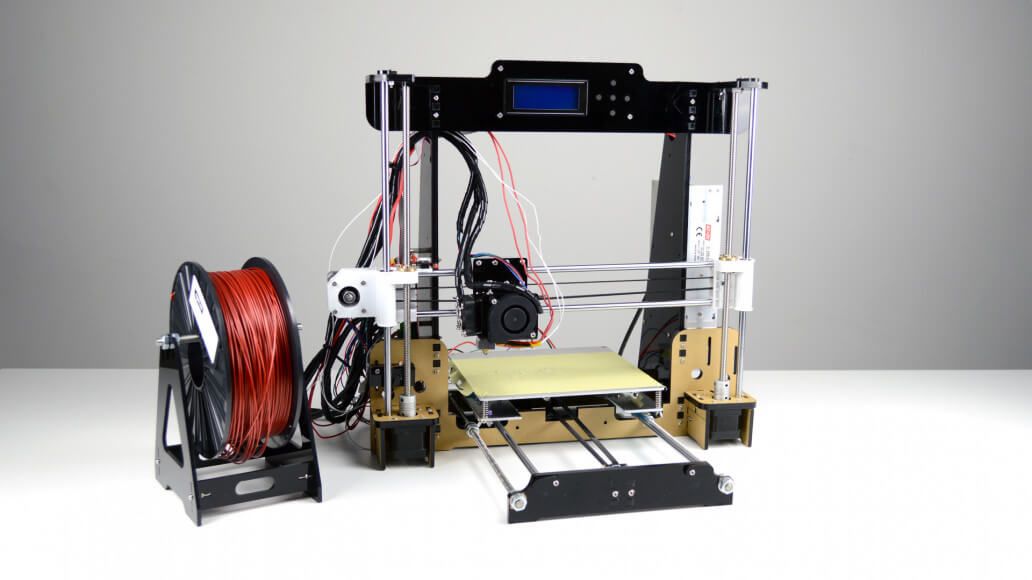

FDM 3D printers are easy to operate and very beginner-friendly. There are relatively few risks involved in their operation. You can use them safely around children and in classrooms. FDM 3D printer parts are also widely available and replaceable without too many complications.

Recommended:

The 8 Best 3D Printers for Kids

Cost

A big decision factor is the total cost. There is a lot more to consider than just the retail price of the printer.

If your goal is to sell D&D minis, you must add operation costs, labor costs, overheads, failure costs, and material costs all to your calculations. That said, if you’re going to be printing minis consistently and in high volumes, you will still quickly break even on the costs of a resin printer.

From that perspective, a resin 3D printer is definitely costlier than an FDM alternative. When comparing these two, it is important to compare their cost vs quality and evaluate for yourself which is more important to you.

FAQ

What printer resolution do you need for miniatures?

In resin 3D printers, 50 microns of XY resolution gives a pretty good surface finish while capturing all the details of the model. However, for the highest quality, you are best off getting a 4K/6K/8K resin printer. These offer much higher resolutions and capture all fine details of the 3D models.

Recommended:

The 8 Best 4K+ Resin 3D Printers

For FDM printers, 0. 2 mm (200 microns) layer height provides a good balance between speed and quality. Needless to say, this does not offer the same amount of detail as a resin print.

2 mm (200 microns) layer height provides a good balance between speed and quality. Needless to say, this does not offer the same amount of detail as a resin print.

How long does it take to 3D print a miniature?

The printing time of a miniature depends on various parameters. You can print a miniature in as little as 3-4 hours or as long as 1-2 days. The layer height and the exposure time play a critical role.

In resin 3D printing, the total time required to print multiple minis at the same time is dependent only on their height, and not their number.

With FDM, as the number of minis increases, the time required to them increases proportionately. Also, on an FDM 3D printer, you might need to slow down the printing speed to achieve maximum quality.

How much does it cost to 3D print a miniature?

There is no one fixed price that we can say it costs to 3D print a miniature. You have to take into account the cost of the materials, 3D printer, STL files, post-processing, etc. Though, an FDM 3D printed mini would cost you much less than a similar resin 3D printed component.

Though, an FDM 3D printed mini would cost you much less than a similar resin 3D printed component.

Here is a good Reddit thread that goes into detail about this topic.

Where to download miniatures to 3D print?

There are a lot of websites from which you can download miniatures. Some of the popular ones are Thingiverse, MyMiniFactory, CGTrader, Cults3D, Sketchfab, and Gambody.

Desktop 3D printers for the home

Anet Anycubic Creality3D CreatBot Dremel Elegoo Felix FlashForge FLSUN Flying Bear Formlabs IBRIDGER imprinta MakerBot Peopoly Phrozen PICASO 3D QIDI Raise3D Tiertime Ultimaker Uniz Voxelab wanhao XYZPrinting ZENIT Zortrax

Availability

In stock

Manufacturer

Phrozen Raise3D Creality wanhao FlashForge

PICASO 3D Anycubic Formlabs Tiertime Flyingbear QIDI Uniz CreatBot Dremel DigiLab Felix Zortrax XYZprinting Ultimaker imprinta Elegoo MakerBot Anet FLSUN iBridger Peopoly snapmaker Voltera Voxelab ZENIT

Delivery

Assembled printer Assembly kit

Application

Architecture For large objects For beginners The medicine Education

Orthopedics Production prototyping Reverse engineering Advertising, exhibitions Sculpture Dentistry Hobby jewelry

Print technology

DLP/LCD/SLA FDM/FFF LFS

Thread diameter

1. 75 mm 2.85 mm 3.00 mm

75 mm 2.85 mm 3.00 mm

Material type

ABS PLA PETG Photopolymers Flex

Nylon (Nylon) ASA Carbon HIPS PC PEEK PP TPU other Metal (Ultrafuse 316L, Ultrafuse 17-4PH)

Number of extruders (print heads)

Heating table

Yes Not

Wi-Fi or other wireless network

Yes Not

Country of origin

China Russia USA Taiwan Hong Kong

Netherlands Poland

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220 x 220 x 250 mm |

| Number of extruders (print heads) | 1 |

Add to compare

Product added to compare Go

| Manufacturer | Flyingbear |

| Construction area size | 255x210x210 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Construction area size | 102x57x165 mm |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Construction area size | 197 x 122 x 245 mm (5. 9 l) 9 l) |

| Chamber volume | 5.9 l |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

| Construction area size | 134x75x130 mm |

| Country of origin | Taiwan |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Construction area size | 197 x 122 x 245 mm (print volume 5.9 l) |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

| Construction area size | 165x72x180 mm |

| Country of origin | Taiwan |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 198 × 123 × 210 mm |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Flash Forge |

| On order/Transit | Goods on the way |

| Construction area size | 200*200*250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | QIDI |

| On order/Transit | Goods in transit |

| Construction area size | 270 x 200 x 200 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to Compare

Product added to comparison Go

| Manufacturer | Phrozen |

| Construction area size | 200x125x220 mm |

| Country of origin | Taiwan |

Add to compare

Product added to compare Go

| Manufacturer | Flyingbear |

| Construction area size | 325*325*350 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Wanhao|

| Construction area size | 500x500x500 mm |

| Number of extruders (print heads) | 2 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| On order/Transit | Goods in transit |

| Construction area size | 192 x 120 x 200 mm |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

| Construction area size | 218 x 123 x 235 mm |

| Country of origin | Taiwan |

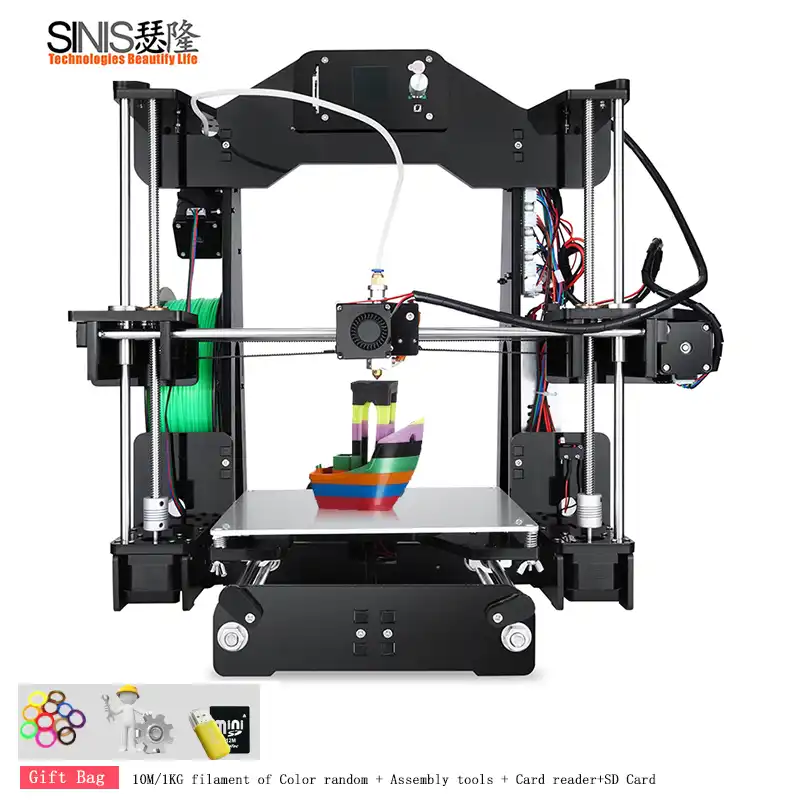

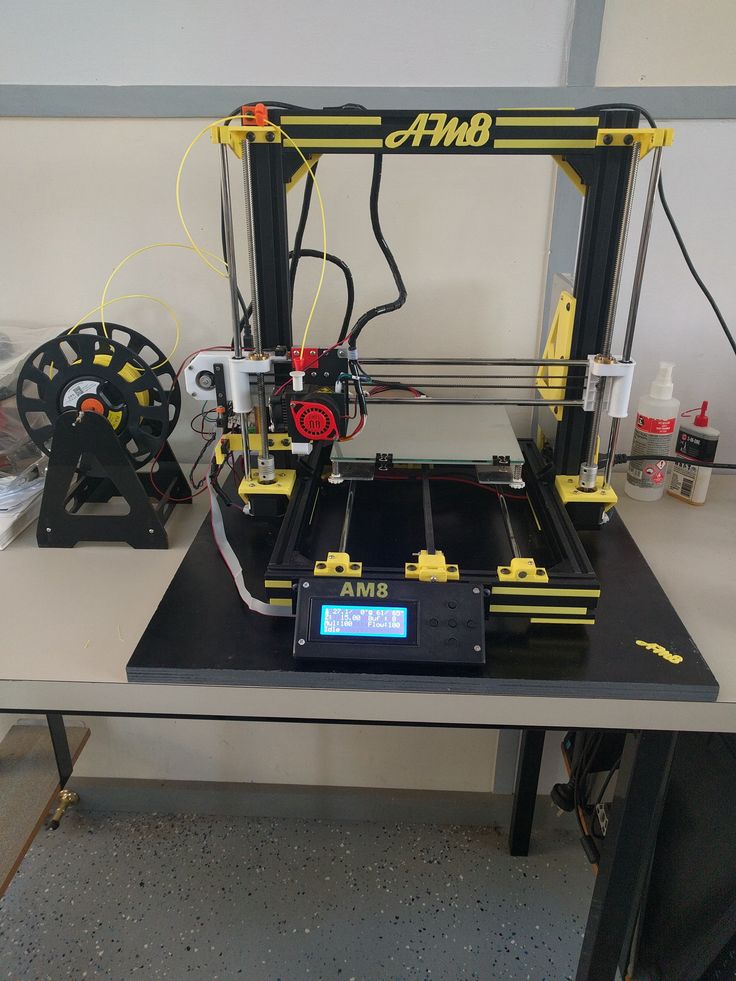

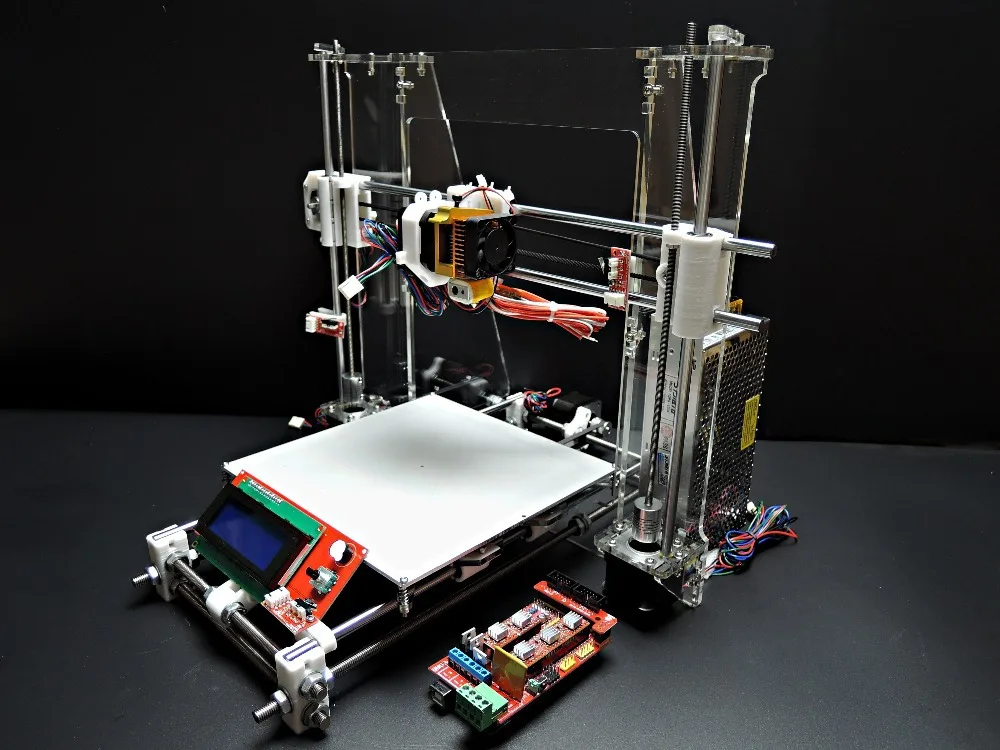

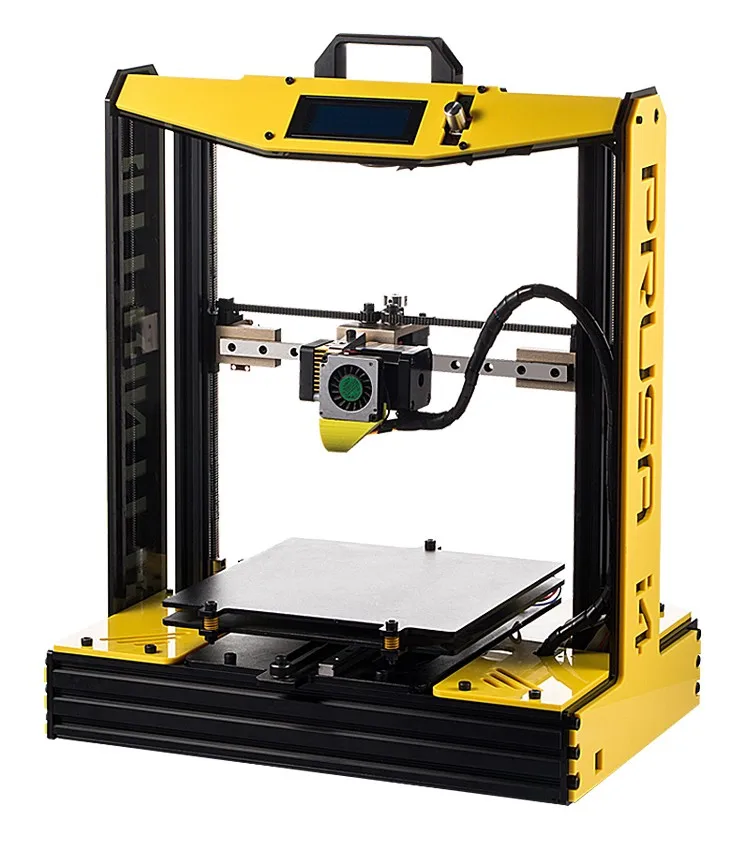

3D printing is one of the most promising areas of technological development in the 21st century. Having gone a long way from bulky and heavy boxes to compact desktop devices, 3D printers have ceased to be something inaccessible to a wide range of users. The era of mass additive manufacturing has already arrived, and every home can now house a real desktop factory.

Having gone a long way from bulky and heavy boxes to compact desktop devices, 3D printers have ceased to be something inaccessible to a wide range of users. The era of mass additive manufacturing has already arrived, and every home can now house a real desktop factory.

You can buy a 3D printer capable of printing small models and prototyping of medium complexity today at the price of an entry-level laptop. The price of PLA or ABS plastic, which acts as a consumable, also no longer seems exorbitant. In a word, if you have long dreamed of getting to know the world of 3D printing and joining the ranks of makers, the right moment has come!

To save you time and make it easier to select equipment, we have collected in one section all desktop 3D printers optimized for home and office use. These are the real "workhorses" with the perfect balance of functionality, quality and price. Even a beginner can understand the settings, mount and calibrate a 3D printer, and as he gains experience, he will be able to print more and more complex three-dimensional models.

3D Printing in the category "Technique and Electronics"

Photopolymer resin Anycubic Basic

in a warehouse in Cherkasy

Delivery in Ukraine

UAH

Buy

3D Prints and Materials_3DSTUFF 9000 Polymaker, 1.75 mm, 0.75 kg

in warehouse

Delivery in Ukraine

1 890 UAH

1 795.50 UAH

Pro3d.com.ua 9000 , 0.75 kg greens 9Ol000

Delivery in Ukraine

1 890 UAH

1 795.50 UAH

Buy

Pro3d.com.ua

Plastic Polysmooth Polymaker, 1.75 mm, 0.75 kg of Zhovtiya

in warehouse

Complex0003

1 890 UAH

1 795.50 UAH

Buy

Pro3d.com.ua

Polysmooth Polymaker, 0.75 kg Orangeviy

at the warehouse

Delivery in Ukraine

9000 1 89 GRN1 795.50 UAH

Buy

Pro3d. com.ua

com.ua

Photopolymer resin Anycubic (UV Resin) Basic Transparent, 1

in a warehouse in Cherkasy

Delivery

1 450 GRN

Buy

Buy

Buy

Buy

003

3D printers and materials_3DSTUFF

Photopolymer resin Anycubic (UV Resin) Basic Green translucent, 1,

In a warehouse in Cherkasy

Delivery in Ukraine

UAH

3D PROPERPEMER resin PLEXIWIRE resin basic rigid gray

In a warehouse in Kyiv

Delivery in Ukraine

881 UAH

Buy

3D printers and materials_3DStuff 9Ol000

N/A

312 UAH

View

3Dplast - manufacturer of plastic for 3D printing

HIPS plastic 3Dplast filament for 3D printer 1.75 mm 0.75 kg yellow

Inaccessible

312 UAH

Watch

3DPLAST - manufacturer of plastic for 3D Press

HIPS (UPS) Plastic 3DPLAST PLASTER 1. 75 mm 0.75 kg Red

75 mm 0.75 kg Red

HIPS plastic 3Dplast filament for 3D printer 1.75 mm 0.75 kg blue

Unavailable

312 UAH

Watch

3DPLAST - Plastic manufacturer 3D print

HIPS (UPS) Plastic 3DPLAST FILAST FILASTER 1.75 mm 0.75 kg black

Non -access PLA Brown 1.75mm BOZE

Delivery across Ukraine

410 UAH

Buy

Boze 3D

PLA plastic BOZE Blue 1.75mm

Delivery across Ukraine

410 UAH

Buy

Boze 3D

PLA yellow-orange 1.75mm BOZE

Delivery in Ukraine

410 UAH

Buy

9000 BOZE 3D 9000 PLA White 1.75mm Boze 9000 410 UAHBuy

Boze 3D

PLA Green 1.75mm Boze

Delivery in Ukraine

410 UAH

Buy

Boze 3D

002 Delivery in Ukraine

260 UAH

Buy

"3DFilament" - Vobron plastic up to 3D Printeri

PLA Filament Plastic Plastic Pochatok Filament 1.