Chefjet 3d dessert printer

The ChefJet 3D Printer Prints Dessert, And Yes, It's Really Good

3D-Printed Food!

LAS VEGAS –- 3D printing is officially delicious.

At the International CES here this week, 3D Systems, a South Carolina-based company, unveiled what it’s billing as “the world’s first and only professional-certified, kitchen-ready 3D food printer.”

It can print sugar, chocolate or candy in pretty much any design imaginable.

To create a sweet, the printer needs water and dry powder ingredients.

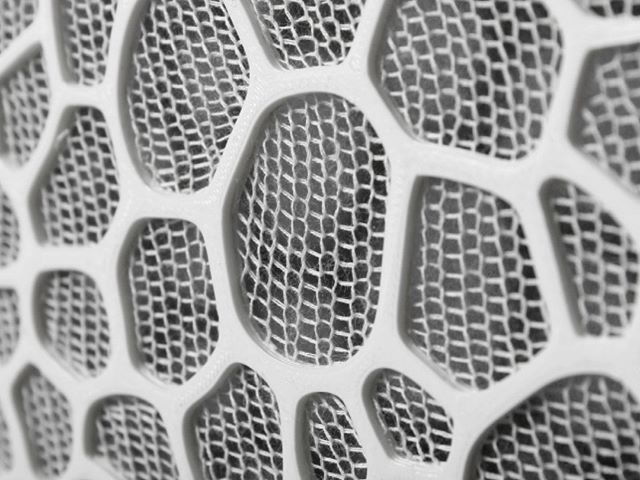

Here’s how it works: A rolling pin-like mechanism first spreads a fine, even layer of powder on the printing surface. An inkjet print head then sprays a narrow stream of water, drawing on the layer of sugar in whatever pattern the owner has pre-programmed. When the water hits the powder, it recrystallizes, so that whatever the water touches hardens.

The process is repeated layer-by-layer, building the treat from the bottom up, printing at the rate of a vertical inch each hour.

Advertisement

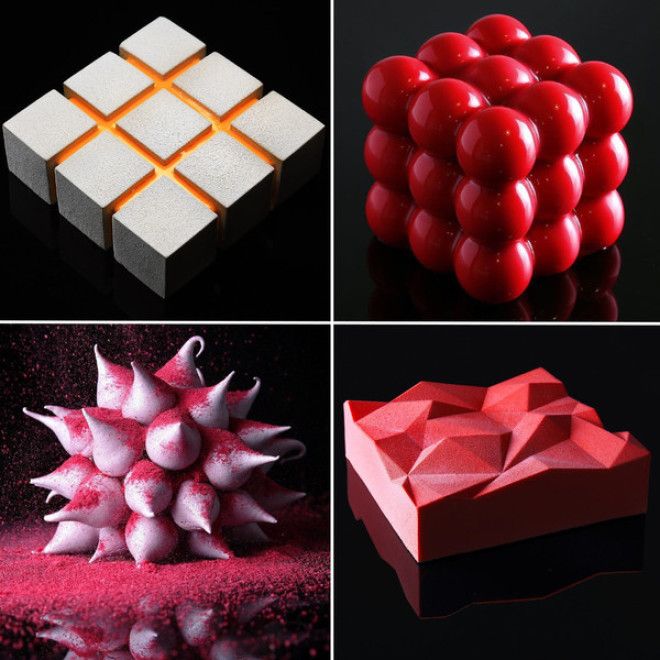

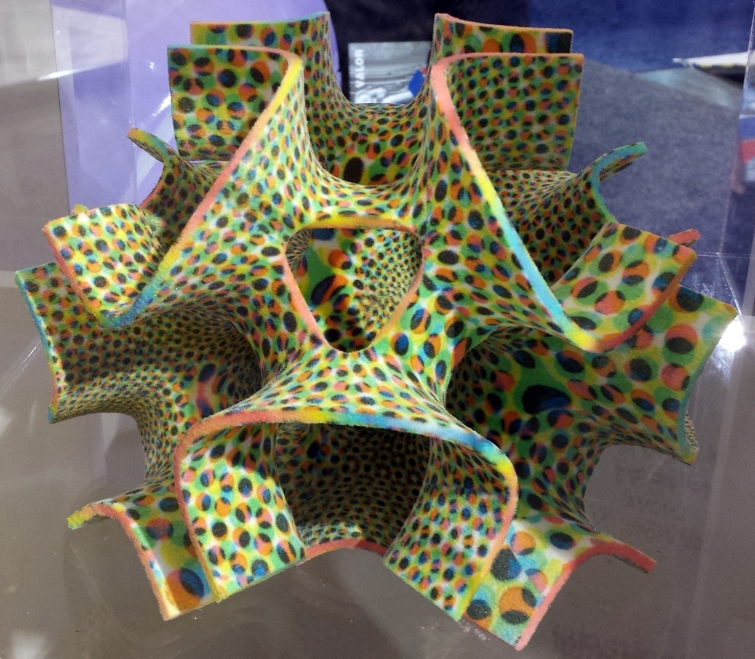

The final result: intricate, detailed confections that twist, turn and sparkle.

The sweets can be used as sculptural toppers on wedding cakes, custom sugar cubes, printed and personalized candies, “and everything in between,” said Liz Von Hasseln, the creative director of food products for 3D Systems.

But don’t expect to buy one of these for your home. The ChefJet, when it’s released sometime in the first half of the year, will start at “under $5,000,” Von Hasseln said. It’s geared toward professional bakers, pastry chefs, restaurateurs and chocolatiers.

A larger version, the ChefJet Pro, can add color to the confections, and will be available for “under $10,000.”

“This is a piece of really professional kitchen equipment,” Von Hasseln said.

Von Hasseln and her husband, Kyle, are both trained architects. In graduate school, according to their website, they wanted to make a unique birthday gift for a friend, so they hacked a 3D printer and tried to print her a cake. The gift ultimately turned out well, and they started a company, The Sugar Lab, to create and design custom confections for events.

The gift ultimately turned out well, and they started a company, The Sugar Lab, to create and design custom confections for events.

Advertisement

3D Systems acquired The Sugar Lab in September, and the Von Hasselns have been working there since, helping develop the ChefJet line.

“This is a whole really new territory for 3D printing,” said Liz Von Hasseln, “and it will allow a whole new community to really engage with the technology that maybe wouldn’t have been able to before, so that’s really exciting.”

And for those wondering: Yes, I got to try a piece of 3D-printed candy -- sour apple flavor -- and it was delicious.

Liz Von Hasseln, left, the creative director of food products for 3D Systems, holds a bowl of printed candy at the International CES on January 9, 2014.

Before You Go

View this post on Instagram

A post shared by Tim Stenovec (@timstenohp) on

Trending

3D Systems ChefJet Printers

There are a number of 3D food printers on the market, promising to print everything from pasta to Nutella. But most simply create shapes from pre-prepared ingredients.

But most simply create shapes from pre-prepared ingredients.

One company, however, has gone a different direction, designing 3D printer that turns sugar into gorgeous geometric confections in your own kitchen.

“They work a lot like making frosting,” Liz von Hasseln, co-inventor of 3D Systems' ChefJet, told Business Insider. “If you’ve ever made frosting and left the bowl overnight in the sink, you’ll know that it gets quite hard and that’s essentially what happens inside the ChefJet Printer.”

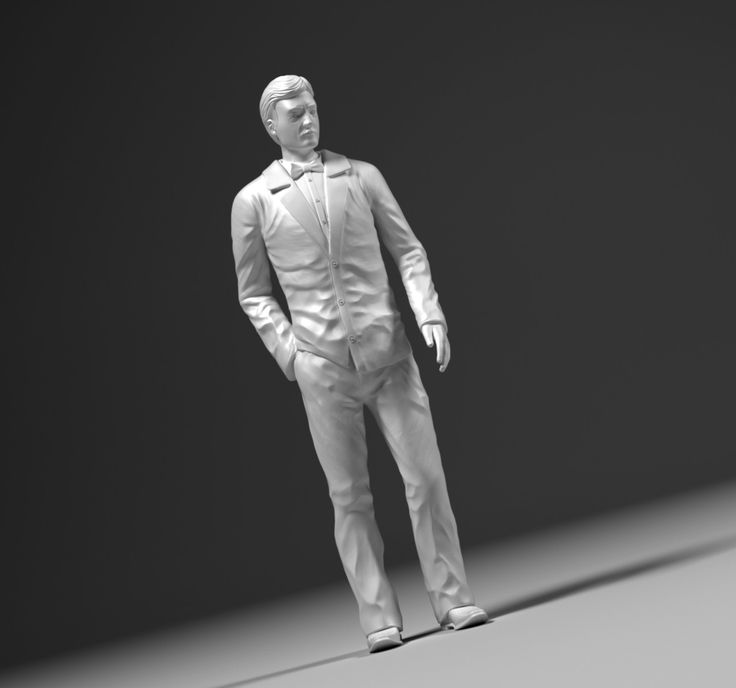

The geometric designs created with a ChefJet printer. Courtesy of 3D Systems The project started when von Hasseln and her husband Kyle, who were graduate students at the Southern California Institute of Architecture, forgot that they were supposed to bake a birthday cake for a friend. Their tiny apartment didn’t have an oven, but they did have the 3D Systems printer they were using for their thesis project.

Their tiny apartment didn’t have an oven, but they did have the 3D Systems printer they were using for their thesis project.

After tweaking the existing technology to print layers of sugar, they printed their friend’s name as a cake topper and a business was born. The von Hasselns quickly realized the potential of their invention and established Sugar Lab, designing and printing 3D candies in flavors like mint, sour cherry, and vanilla.

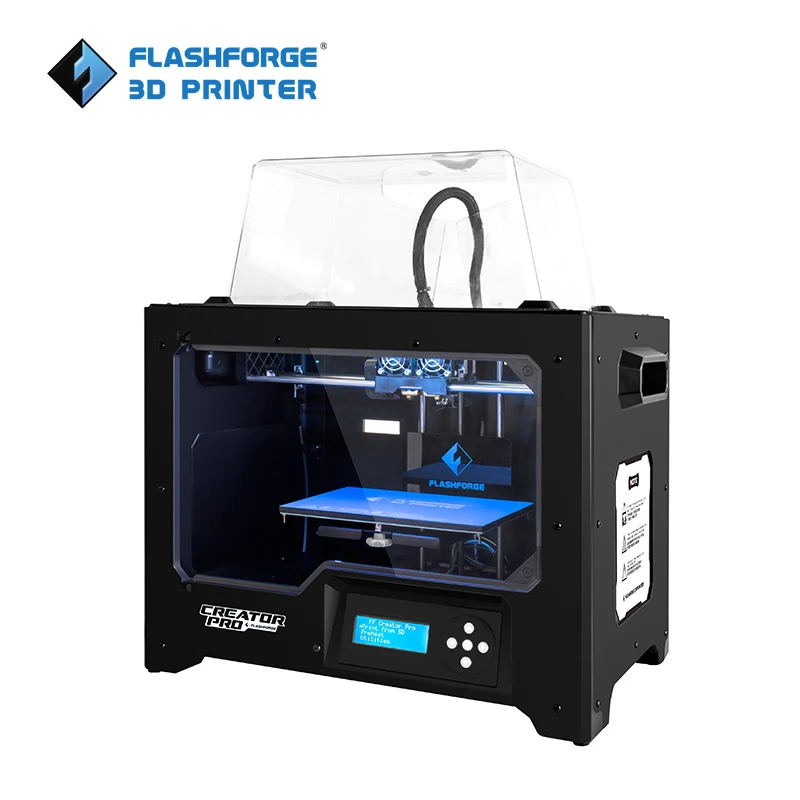

The printer can create 3D candies in a variety of flavors such as mint, sour cherry, and vanilla. Courtesy of 3D Systems Sugar Lab was purchased by 3D Systems last year, and now the von Hasselns are the company's Creative Directors of Food Products. Later this year, they will unveil their sleek ChefJet, which prints in black and white, and slightly larger ChefJet Pro, which can print in color, with prices ranging from $5,000 to $10,000.

Later this year, they will unveil their sleek ChefJet, which prints in black and white, and slightly larger ChefJet Pro, which can print in color, with prices ranging from $5,000 to $10,000.

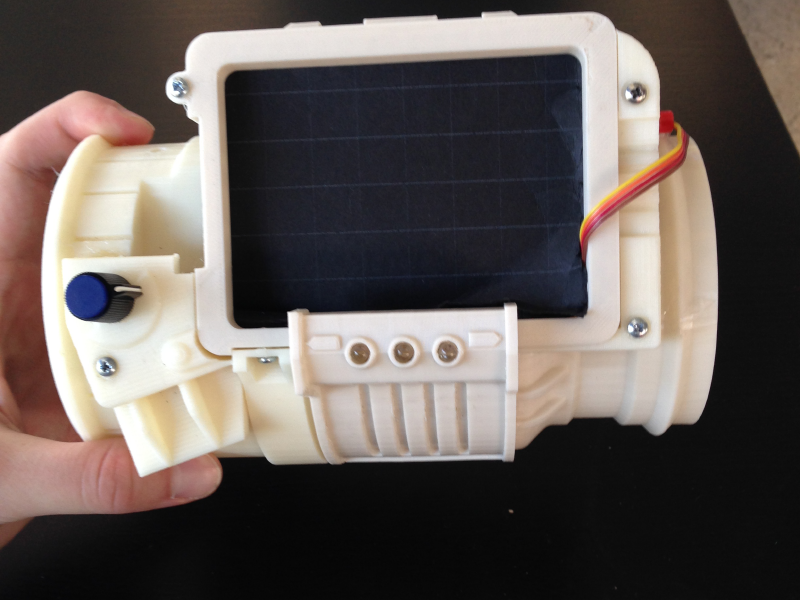

The machines are roughly twice the size of a microwave and look like something one would see on a futuristic cooking show hosted by Spock.

The ChefJet printers can create sugar structures in cocktail glasses for mixologists. Courtesy of 3D Systems And the possibilities with sugar have gone far beyond the candies Sugar Lab originally printed. “We’ve done everything from drink sweeteners to complicated toppers for elaborate wedding cakes," von Hasseln said. "We even did a cake stand for a wedding cake. When you 3D print the frosting, it becomes a structural component of the dessert other than just an embellishment.”

"We even did a cake stand for a wedding cake. When you 3D print the frosting, it becomes a structural component of the dessert other than just an embellishment.”

The end results are gorgeous, geometric creations — especially with the ChefJet Pro, which can make such exact color designs that the end product resemble expensive china.

The technology is still limited to sugar, but the ChefJet and ChefJet Pro come with a sort of “digital cookbook” that’s organized by food types. If you’re working on a wedding cake, there’s a cake section. If you’d like to make sugar cubes or candy, there’s a section for that, too.

If you’d like to make sugar cubes or candy, there’s a section for that, too.

“We want to enable people to be able to create beautiful, customized things that they can print on the ChefJet without having to learn 3D dimensional digital modeling from scratch,” von Hasseln said. “We’re working hard to make sure they’re very user friendly and intuitive right off the bat.”

But don’t expect to run out and buy a ChefJet or ChefJet Pro anytime soon. In its current iteration, ChefJet is meant for the professional market, to be used alongside other industrial kitchen equipment by pastry chefs, molecular gastronomists, and mixologists.

“We are looking at the ChefJet printer as a professional-grade machine,” von Hasseln said. “The ChefJet and ChefJet Pro are really the only printers on the market that are appropriate for that level. They’ll be the first kitchen-certified 3D printers, meaning they’ll be used in commercial, professional settings. No other 3D printers have done that.”

In other words, this is not the next microwave — yet. But as the science continues to evolve, von Hasseln does see additional practical uses for her invention.

“We think that sugar is a great place to start 3D printing food,” Liz said. “But beyond sweets, we see tons of potential for other edible substrates. We’re really excited to continue to experiment with starches, spices, or even proteins down the line. And even further down the road, we see potential for things like personalized nutrition and pharmaceuticals."

“We’re at the very beginning of 3D printing,” she added. “This is a very exciting time.”

Courtesy of 3D SystemsChefJet confectionery 3D printers - the end of the era of sugar cubes

Archive

ChefJet and ChefJet Pro printers.

In fact, the original installation was independently designed by architects Kyle and Liz von Hasseln. The sweet couple met at school, and then entered the experimental architectural institute SCI-Arc, whose educational program includes studying the possibilities of architectural application of high-tech production methods, including additive. It was there that the newlyweds hit upon the idea of building a 3D printer for printing sugar in order to prepare cakes for friends on their birthdays. In 2013, the young family founded their own company, The Sugar Lab, and soon attracted the attention of industrial giant 3D Systems, who bought and improved an innovative design of a confectionery 3D printer.

In fact, the original installation was independently designed by architects Kyle and Liz von Hasseln. The sweet couple met at school, and then entered the experimental architectural institute SCI-Arc, whose educational program includes studying the possibilities of architectural application of high-tech production methods, including additive. It was there that the newlyweds hit upon the idea of building a 3D printer for printing sugar in order to prepare cakes for friends on their birthdays. In 2013, the young family founded their own company, The Sugar Lab, and soon attracted the attention of industrial giant 3D Systems, who bought and improved an innovative design of a confectionery 3D printer. ChefJet Confectionery 3D Printer

The manufacturing process is based on the 3D inkjet technology that is widespread in the world of 3D printers: a granulated sweet mixture is applied in a thin layer, and then selectively "glued" with water fed through the nozzle of the working head. The head moves in two dimensions, following the contours of the digital model layer. Then a new layer of material is applied and the process is repeated to build the next layer of the model. Food additives and dyes allow you to achieve different flavors and colors.

The head moves in two dimensions, following the contours of the digital model layer. Then a new layer of material is applied and the process is repeated to build the next layer of the model. Food additives and dyes allow you to achieve different flavors and colors.

Sugar Cubes - Yesterday

The basic version of the ChefJet allows you to print one-color candy and frosting in chocolate, vanilla, mint, apple or cherry flavors. The dimensions of the 3D printer are large for a home appliance, but compact enough for a desktop installation. On the other hand, the size of the working area inspires respect, reaching 205x205x150mm. This is enough to decorate a small cake.

ChefJet Pro allows for a wide variety of colors and flavors

The ChefJet Pro Professional model takes the idea further, allowing you to print multi-color models and mix or layer flavors. The working volume was increased to 255x355x205mm, although the dimensions of the device itself also increased slightly.

Interestingly, the developers did not stop at powdered sugar as the most simple and convenient choice of material. ChefJet 3D printers are already capable of printing caramel and even chocolate chips.

A bouquet of roses and chocolates for your beloved is banal. How about a chocolate bouquet?

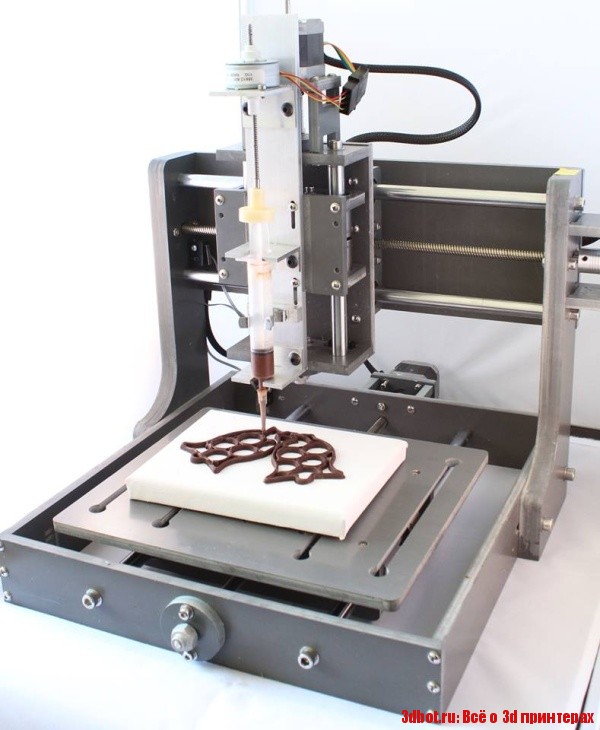

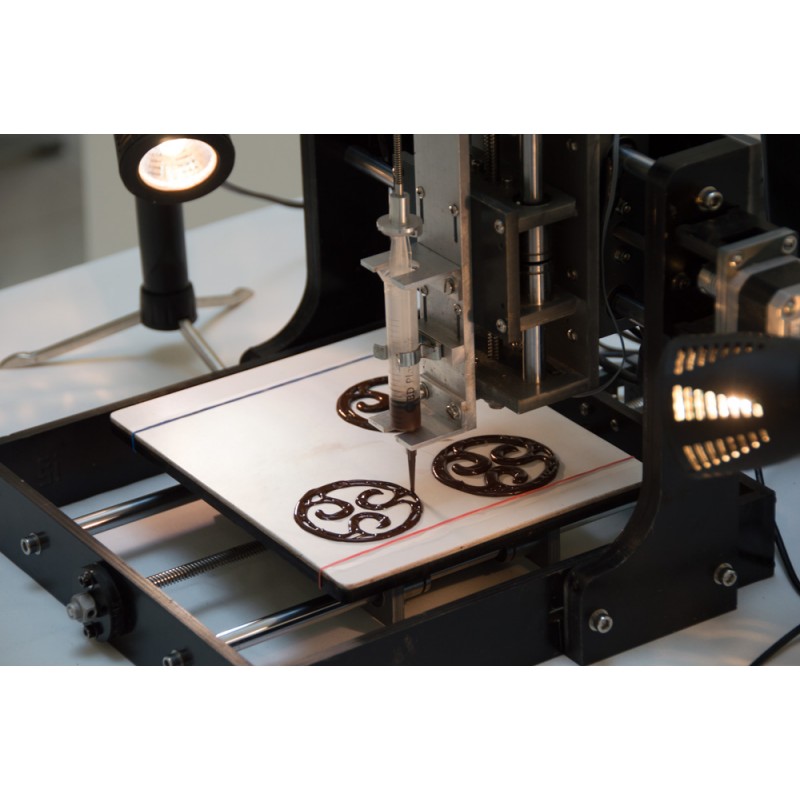

This flexibility comes from a conscious choice of 3D printing method. There have been attempts to print with chocolate before, but in previous cases, developers have tried to adapt the common fusing technology known as FDM or FFF. As a rule, problems with the extrusion of thick melted chocolate invariably lead to the maximum simplification of the design - up to the use of syringes as extruders and cartridges, which requires frequent replacement of "print heads" for filling with consumables. While projects such as Choc Creator have made significant headway and are even looking to commercialize successfully, inkjet adaptation seems to be at least an equally worthy choice when working with confectionery materials.

As expected, the use of additive manufacturing technology allows you to create confectionery products of exceptionally high geometric complexity, inaccessible using traditional methods. It is even possible to create edible rattles - hollow sweets, with freely moving fillings of different tastes.

Scary? But delicious!

Since the device is designed for chefs and pastry chefs, not professional 3D designers, 3D Systems intends to bundle ChefJet 3D printers with specialized ChefJet software and The Digital Cookbook (“Digital Cookbook”). The software should facilitate the use of devices by users unfamiliar with CAD, while still allowing the creation of exceptionally complex 3D designs. As an example, 3D Systems cites the ability to print bride and groom figurines for wedding cakes. It is to be expected that 3D Systems' Cubify website will feature an assortment of ChefJet-compatible digital models.

A candy inside a candy of different flavors

The only fly in the ointment in this barrel of honey is the cost of the devices, which is too high for an ordinary sweet tooth. The basic monochrome version of the ChefJet is tentatively priced at $5,000, while the more capable Professional ChefJet Pro is $10,000. If the demand for such devices is large enough, we can expect a significant reduction in cost as production increases. In the meantime, ChefJet devices are waiting for use in confectioneries, bakeries and coffee shops.

The basic monochrome version of the ChefJet is tentatively priced at $5,000, while the more capable Professional ChefJet Pro is $10,000. If the demand for such devices is large enough, we can expect a significant reduction in cost as production increases. In the meantime, ChefJet devices are waiting for use in confectioneries, bakeries and coffee shops.

The appearance of ChefJet and ChefJet Pro 3D printers in free sale is planned for the second half of 2014.

Follow author

Follow

Don't want

1

More interesting articles

four

Subscribe to the author

Subscribe

Don't want

One of the most promising and least developed areas of 3D printing is bioprinting. Whole a...

Read more

four

Subscribe to the author

Subscribe

Don't want

The progress of 3D printing in recent years has gained such a rapid speed that we will soon stop.![]() ..

..

Read more

3

Subscribe to the author

Subscribe

Don't want

Not so long ago we talked about an interesting engineering and architectural project that is directly related to...

Read more

90,000 characteristics, pros and cons of each model07.04.2021

Content

-

- What is a food 3D printer

- Scope 9014

- Popular Manufacturers

- Top 10 Best Food Printers: Hottest Model List

- 1. PancakeBot 2.0

- 2. Wiiboox Sweetin

- 3. Choc Creator V2.0 Plus

- 4. Choc Creator V2.0 Plus 3D Food Printer with Cold Chamber

- 5. byFlow Focus

- 6. Chefjet Pro

- 7. Foodini

- – Chocolate Musemuse 3D Printer

- 9.

ZBOT Commercial Art Pancakes Printer F5

- 10. ZMorph VX

- Selection Guide

- Output

- What is a food 3D printer

A food printer is a high-tech device that is used to create culinary masterpieces. The decorative design of food products has reached a new level thanks to the use of modern technologies: high-quality and large-format printing is carried out on cakes, waffles, pancakes and even coffee. Here are the top best 3D food printers in different price categories for people who are fond of cooking.

What is a 3D food printer

The main feature of a food 3D printer is the raw materials used: instead of printing ink, the device is filled with edible ingredients. The database stores a large number of different recipes, and in order to print a dish, you just need to select one of them and activate the printing process. The final product is layered on a work surface or on a plate: it can be baked in the oven or sent to the freezer.

Application

Futuristic 3D Printed Sugar Candy

Cookies printed with glaze

Chocolate logos of famous companies

Cream Photo Print

Buying a food 3D printer is worth the owners of coffee houses, author's bakeries and private workshops. The finished product has a unique shape and bright appearance. Food printers are often used to create custom wedding cakes, cartoon character cookies, Christmas gingerbread cookies, and so on. The possibilities of a baker who owns such a device are endless: the main thing is to buy quality products.

Raw materials used

The following ingredients are used as raw materials:

-

Chocolate without additives and impurities;

-

Mastic;

-

Sugar;

-

Whipped cottage cheese;

-

Vegetable and fruit pastes;

-

Fish and meat pates;

-

Flour;

-

Cheese, etc.

The confectionery pattern is applied to sugar, wafer or shock transfer paper. The first type has a sweetish aftertaste and aroma of vanilla. Due to the snow-white surface, no additional coating is required: the drawings look bright and clear. The wafer paper is made from rice flour and does not have a special taste, due to the light shade, the final drawings look less clear. Shock transfer paper is completely transparent and is suitable for transferring a design to a product (for example, a cake). For the packaging of finished products, food-grade plastic for a 3D printer is used.

Interesting! Food printers are involved in waste reduction. Unattractive fruit and confectionery leftovers are used in the preparation of printing mixes. This makes it possible to use the means of production more efficiently.

Types of 3D food printers

Cooking enthusiasts can take advantage of the following food printing devices:

-

Food 3D printers are devices that print dishes whose recipes are listed in a database.

The final product is layer-by-layer superimposed on the work surface, and the raw material comes from filled cartridges;

The final product is layer-by-layer superimposed on the work surface, and the raw material comes from filled cartridges; -

Confectionery printers are used to transfer images onto specialty paper or to design small confectionery products such as candies. Such printers print an image on pre-prepared paper: rice, wafer or shock transfer;

-

Food plotters transfer the image not to paper, but directly to the finished product. For example, a plotter is used to transfer an image directly onto a cake.

There are several types of food 3D printers:

-

Extrusion - paint is applied to the surface before the dish is created. The process is controlled by the computer with the loaded image. The system has an extruder that heats the food mixture, and the distribution of raw materials depends on the print head. The raw material is loaded into a syringe placed in the head. This means that in order to combine different shades, you have to periodically stop printing and change the syringe;

-

A carousel-type food 3D printer also has an extruder, but its main feature is the method of feeding raw materials: the containers rotate around the working surface, the supply and dosage of the material used depends on the recipe specified in the program.

The storage can contain countless recipes, and operation does not cause difficulties even for an inexperienced user.

The storage can contain countless recipes, and operation does not cause difficulties even for an inexperienced user.

Popular brands

Eminent manufacturers offer the best value for money food 3D printer. Quality devices provide accurate printing, high speed, durability, simplicity and ease of use.

Wiibox

This company manufactures 3D printers with high build quality and high productivity. These are universal mechanisms that fill both chocolate paste and mashed potatoes. Numerous positive reviews confirm the high quality of Wiibox products.

byFlow

The Dutch company byFlow specializes in food printing technology. The pursuit of excellence helps the company open up new horizons: the technique prints products from spinach, meat emulsion and other materials. High build quality, ease of use and durability - all these characteristics are applicable to the products of this company.

Choc Edge

Choc Edge is committed to revolutionizing the world of chocolate making. Numerous experiments and focus on consumer feedback help to create more powerful devices that provide the optimal temperature for preparing and storing chocolate figures.

Numerous experiments and focus on consumer feedback help to create more powerful devices that provide the optimal temperature for preparing and storing chocolate figures.

Attention! Printing dishes helps save time on cooking: instead of culinary worries, the user can simply activate the printing process and get on with other things.

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Choc Edge |

Available on credit. To checkout, add the product to the cart and follow the instructions Go

| Manufacturer | Wiiboox |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Choc Edge |

Top 10 Best Food Printers: A List of the Most Current Models

Before you buy a food 3D printer, you need to familiarize yourself with the most popular devices on the world market. The top is based on ratings and customer reviews.

The top is based on ratings and customer reviews.

1. PancakeBot 2.0

PancakeBot 2.0 is easy to use, which means it's suitable for inexperienced users too. Users can choose from suggested designs in the software, or create their own. Used to print pancakes.

Pros:

-

Ease of operation;

-

A wide range of proposed projects;

-

High speed.

Cons:

2. Wiiboox Sweetin

Buying a food printer from Wiiboox is worth not only for confectionery lovers, but also for ordinary chefs: the device prints cakes, cookies and even mashed potatoes. The main raw materials can be meat, cheese, chocolate, jam, mashed potatoes, dough and much more. A convenient touch panel helps to set the desired mode of operation, and a stylish appearance complements the interior of any establishment.

Pros:

-

Versatility: the ability to print not only sweet dishes, but also side dishes;

-

Attractive appearance;

-

High build quality;

-

Convenient control by touch panel.

Cons:

-

High price.

3. Choc Creator V2.0 Plus

When talking about which chocolate 3D printer to buy, it is worth mentioning the numerous advantages of Choc Creator V2.0 Plus. The new model has become more perfect: the developers have worked hard to eliminate the shortcomings of the previous version. The modern model has small dimensions, thanks to which it can be used in any kitchen, and the uniform heating of the syringe ensures high-quality and uninterrupted operation. In practice, the chocolate printer has shown tremendous potential: it prints complex figures from chocolate.

Pros of :

-

Attractive appearance;

-

Uninterrupted work;

-

Durability;

-

The ability to create durable and beautiful chocolate figures.

Cons :

4.

Food 3D printer Choc Creator V2.0 Plus with cold chamber

Food 3D printer Choc Creator V2.0 Plus with cold chamber

The new version of the Choc Creator V2.0 Plus printer is equipped with cooling chambers by popular demand. Users say that maintaining the optimal temperature in the room to preserve the integrity of chocolate figures is too problematic: therefore, the new device cools the raw materials. The price of a food 3D printer with a cooling system is slightly higher than a classic one, but the high performance of the final product justifies any costs.

Pros of :

-

Availability of a cooling system for finished products;

-

High printing precision;

-

Long service life;

-

Ease of use: You can turn the fans on and off with the side buttons.

Cons :

-

High price.

Attention! Confectionery food 3D printers are often used by artists to create edible masterpieces.

This is a unique technology that helps to unleash the creative potential of the chef.

5. byFlow Focus

Food printer from the Dutch company byFlow, which specializes in 3D printing of food. The compact high-tech device is used for the bakery industry, and the cartridges are suitable for the application of any pasty ingredients.

Pros:

Cons:

6. Chefjet Pro

Buying a ChefJet Pro food printer is a must for people who dream of making bright and stylish sweets. The device is created on the principle of inkjet printing: sugar-containing powder materials are used instead of paints. The final product is made by powder layering. The printer is suitable for combining different shades and creating gradients.

Pros:

-

The ability to create unique flavors;

-

Neat and bright printing;

-

Aesthetic appearance of the device.

Cons:

-

High price.

7. Foodini

The 3D food printer from Foodini works on the principle of a stationary printer, but instead of printing inks, layer-by-layer imposition of edible raw materials is used: dough, cream, chocolate, cream, etc. The device is versatile: the user himself can choose the material, or use ready-made cartridges with products.

Pros:

-

Practicality;

-

High build quality;

-

Attractive appearance;

-

Availability of an online platform with unique recipes.

Cons:

8. Mmuse – Chocolate 3D Printer

The closed MMuse 3D printer is suitable for chocolate printing. Chocolate beans are used as raw materials: they are heated in an extruder and fed to the work surface through the print head.

Pros:

Cons:

9. ZBOT Commercial Art Pancakes Printer F5

ZBOT Commercial Art Pancakes Printer F5 3D Printer

A food printer from Chinese manufacturers is used in the process of making pancakes of various shapes. Ease of operation allows the device to be used by children under adult supervision.

Pros:

-

Ease of operation;

-

High build quality;

-

Affordable cost.

Cons:

10. ZMorph VX

A multifunctional 3D printer capable of printing not only food, but also rubber, ABS plastic, polylactide, PVA, nylon, elastic and metal materials. The product is able to print with chocolate, butter, cookies, icing and other ingredients. In addition, there is a function of engraving and CNC milling.

Pros:

Cons:

-

High price.

Selection guide

The modern market offers a wide range of food printers. Before making a purchase, you need to carefully study the characteristics of each model and build on your own preferences. Experts have created several recommendations for choosing:

-

In case you want to create realistic images for confectionery 3D printing, pay attention to the diameter of the nozzle: the narrower it is, the more accurate the image will be;

-

It is better for people living in regions with a warm climate to purchase chocolate 3D printers with a cooling system: such devices ensure that the figurines are kept at the optimum temperature;

-

The possibility of self-refilling the cartridge is the most practical and economical way to operate the printer;

-

Print speed is an important consideration for restaurant owners. Large batches of dishes must be produced quickly, and for home use this is not a very strict selection criterion.