3D printer motorcycle parts

3D Printed Motorcycle Parts: Making High-End Custom Parts

In recent years, 3D printing has gained more ground in the automotive industry. This manufacturing technique helps to create prototype parts and add new iterations within a short time. Among the many 3D printing for automotive applications is the creation of 3D printed motorcycle parts.

Making motorcycle parts with 3D printer is now more seamless, thanks to technological advancements. Companies now empower their engineers to create these motorcycle parts with lesser time, effort, and money.

This article discusses the impacts of 3D printing in motorcycle part production. You will also learn the advantages and limitations of 3D printing motorcycle parts. Let’s get right to it!

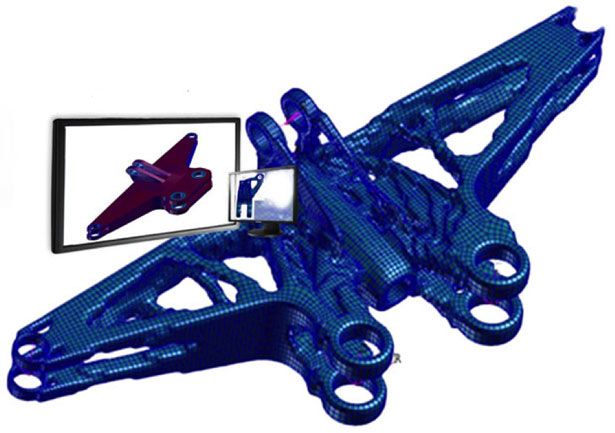

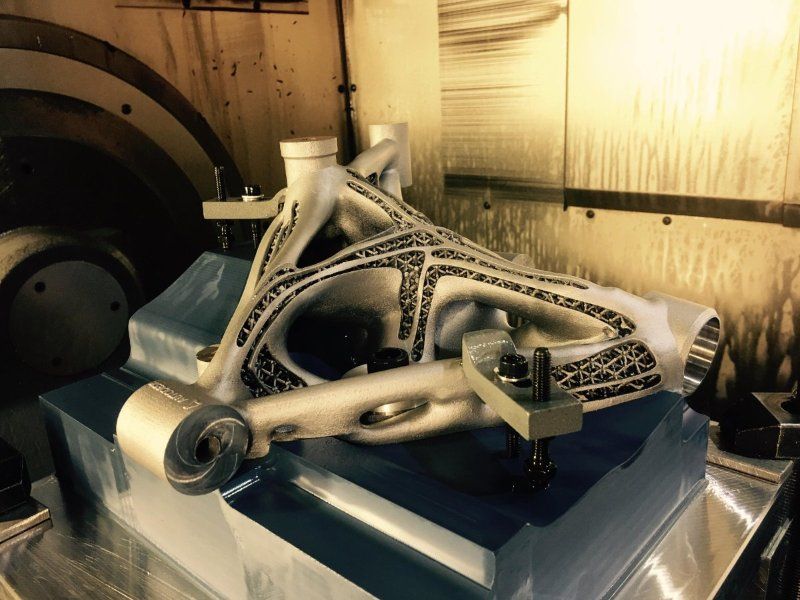

Overview: Development of 3D Printed MotorcycleWhen it comes to rapid prototyping, we aim at low volume productions demanding swift turnarounds. Manufacturing motorcycle parts with complex geometries will require several machining components and tool building.

This can be complicated and may increase costs in the development cycle. Using additive manufacturing (3D printing) eliminates the need for tool building. It creates an opportunity for open-minded designers to generate motorcycle structures with minimal materials.

The critical element driving the adoption of 3D printing in motorcycle industry is the use of electric powertrains. Electric motors generate relatively lower temperatures. There is also a higher impact in terms of weight reduction. Thus, 3D printable polymers are becoming more viable options for several high-end motorcycle parts.

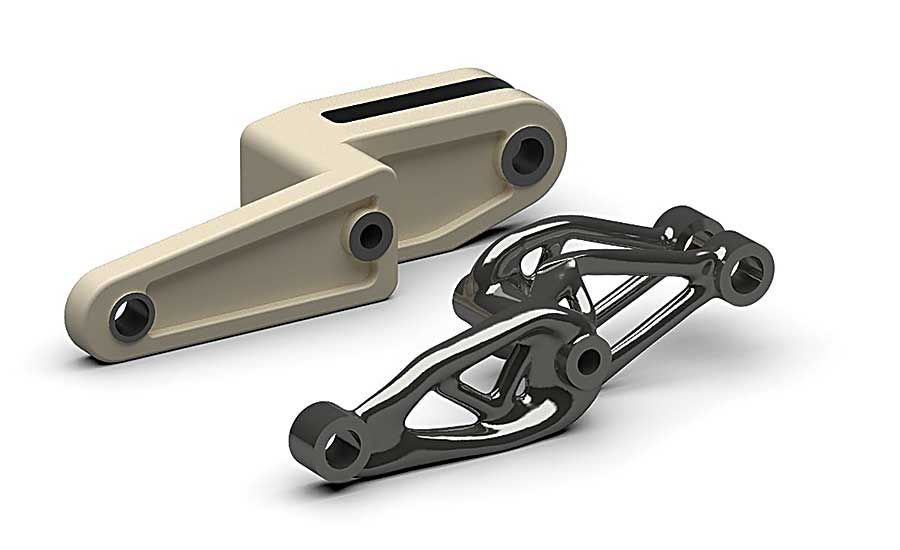

3D printing makes it feasible to create unique, custom motorcycle components like shift levers and linkages. It also allows manufacturers to use available possibilities to expand their creativity. At the same time, you can reduce cycle times and manufacturing costs with 3D-printed motorcycle parts.

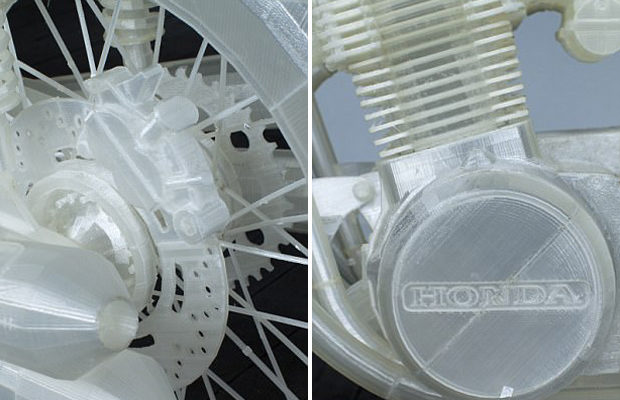

Motorcycle 3D Printing ProcessThe 3D printing process begins with creating a 3D model for the intended motorcycle part. The slicing process follows, converting the 3D model into machine sequences. Material choice is another important of making motorcycle 3d printed parts. 3D printing allows you to produce some prototypes using relatively inexpensive materials.

The slicing process follows, converting the 3D model into machine sequences. Material choice is another important of making motorcycle 3d printed parts. 3D printing allows you to produce some prototypes using relatively inexpensive materials.

Consequently, you can use the initial prototypes to ensure they perfectly fit your motorcycle. If the 3D printed motorcycle parts do not fit in, you have the chance to adjust your 3D model. In many cases, you can use different materials for different motorcycle parts.

Furthermore, 3D printing for motorcycle parts supports surface finishing. Machinists can trim the parts to remove any stray structures attached during printing. Other techniques can also be used to smoothen the part surface. As a result, the surface is suitable for paint application and retention.

Your 3D printed motorcycle is ready for coupling and testing after the finishing stage. Several companies now use different types of 3D printing techniques in making motorcycle parts and making motorcycles from scratch. Moreover, 3D printing is the way to go, enabling the high customization levels that come with motorcycle development.

Moreover, 3D printing is the way to go, enabling the high customization levels that come with motorcycle development.

Making motorcycle parts with 3D printer is highly plausible. 3D printing a motorcycle from the ground up is also gaining popularity in the manufacturing industry.

Some of the common motorcycle 3D printed parts include the following:

Small Bore Motorcycle PartsPLA filaments help in the manufacturing of small-bore motorcycle prototypes. Consequently, you can have material savings of up to 90%. These parts are also usually accurate to CAD drawings. Examples of such components include castings and forgings, fasteners, gears, pull locks, etc.

Quick Replacement PartsThese include parts that require frequent changing to maintain the bike’s performance. Examples are brake pads, driveshafts, bike chains, motorbike saddle, handlebar, pedal, etc.

This manufacturing technology also helps to create motorcycle engine 3D model and other accessories. These include assembly crankcase, camshaft, valve, piston ring, water tank fan, exhaust, and more.

Control System PartsThe 3D printed motorcycle parts under this category include the gearbox, wheel bearings, handlebar, pull lock, steering column, and other related parts.

3D Printed Motorcycle HelmetBesides the actual body parts of the motorcycle, 3D printing also help create a helmet for your bike. So, you have everything you need in one go.

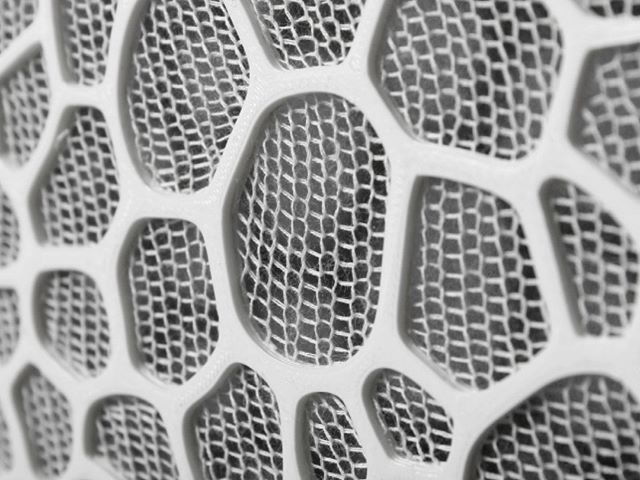

Professionally designed 3D printed motorcycle helmets will ensure proven safety for wearers. Manufacturers often test these helmets for effectiveness in terms of shell deflection and shock absorption.

3D printing helps to create well-designed helmets that ensure objects bounce off at safe angles. Furthermore, 3D printing ensures proper shock absorption if the impact is heavy. Manufacturers use patented impact protection systems so that the outer shell can absorb enough shock. This way, the inner layer of the helmet rotates to deflect the remainder of the impact.

Furthermore, 3D printing ensures proper shock absorption if the impact is heavy. Manufacturers use patented impact protection systems so that the outer shell can absorb enough shock. This way, the inner layer of the helmet rotates to deflect the remainder of the impact.

3D printing is a fantastic manufacturing process, but why is it an excellent option for motorcycle parts? Additive manufacturing allows manufacturers to speed up their creative process from the design stage to eventual manufacturing. In addition, it enables faster iterations and design refinements. The usual design limitations that come with traditional manufacturing processes are easily overcome.

Let’s look at some advantages of 3D printing for crafting your motorcycle parts.

Reduced CostThis is perhaps the most impressive benefit of using 3D printing technology in motorcycle part development. It can significantly reduce the cost of prototyping. In several cases, 3D printed motorcycle parts come at a fraction of the usual cost from other manufacturing processes. This way, you can pursue your motorcycle development with limited budget.

It can significantly reduce the cost of prototyping. In several cases, 3D printed motorcycle parts come at a fraction of the usual cost from other manufacturing processes. This way, you can pursue your motorcycle development with limited budget.

Ordinarily, it would table between 2 to 3 weeks to manufacture a complex motorcycle part like the suspension or frame. However, 3D printing greatly speeds up the development process. Making motorcycle parts with 3d printer will take only about 5 to 8 hours, regardless of the complexity. This means that you can increase your production volume with this technique.

Furthermore, you can make rapid changes during the development stage. You may find the need to tweak designs to meet unique requirements. The traditional manufacturing process would take too much time. However, 3D printing can speed up your motorcycle part development while allowing you to make multiple changes within a short time.

Creating complicated shapes with CNC millers and laser cutting machines can be challenging. There is usually the need to be careful with edges to prevent errors during production. Therefore, most motorcycle parts made with these processes have similar features.

However, motorcycle 3D printed parts often come with unique concepts. Additive manufacturing gives designers the freedom of creativity. You can incorporate sharp edges into your design. In addition, you can also test ideas before mass production. This empowers you to personalize your motorbike parts at minimal costs.

Efficiency and Accuracy3D printing technology is an effective process for creating complex bike parts. Handcrafted motorcycle parts may not be compatible with the bike. This creates additional workloads on the part of the manufacturer. However, 3D printers often ensure up to 99% of the design to save you from the stress of back-and-forth changes.

Many motorcycle parts manufacturers currently use CNC milling and laser cutting for mass production. These processes require machinists to carve out patterns from a block of material. As a result, excess material waste comes from the carved pattern, often not useful for other parts.

On the other hand, 3D printing uses filaments as your project requires. Thus, you can reduce waste created to the barest minimum. Furthermore, ABS material and PLA filaments are usually less expensive than block materials used in subtractive manufacturing.

Challenges of Using 3D Printing for Motorcycle PartsWhile there are several benefits of 3D printing for motorcycle parts, this technology comes with some challenges, primarily when used for large-scale motorcycle parts. These hiccups include:

- Equipment cost

- Software development expertise and capabilities

- The difference in production techniques between materials and models

- Post-processing needs

3D printing applications in the automotive industry are now becoming more popular. The use of additive technologies now helps to reduce costs and production time. RapidDirect helps you make sense of 3D implementation in motorcycle part production. Our specialists now give life to your motorcycle ideas, creating custom 3D printed motorcycle parts and components.

The use of additive technologies now helps to reduce costs and production time. RapidDirect helps you make sense of 3D implementation in motorcycle part production. Our specialists now give life to your motorcycle ideas, creating custom 3D printed motorcycle parts and components.

The nature of our work allows us to emphasize low-volume parts production especially. Therefore, we are able to prepare parts according to your requirements. Asides from creating low-volume motorbike prototypes, we also help modify your motorcycle to give it a unique character. This creative freedom gives you a personalization advantage.

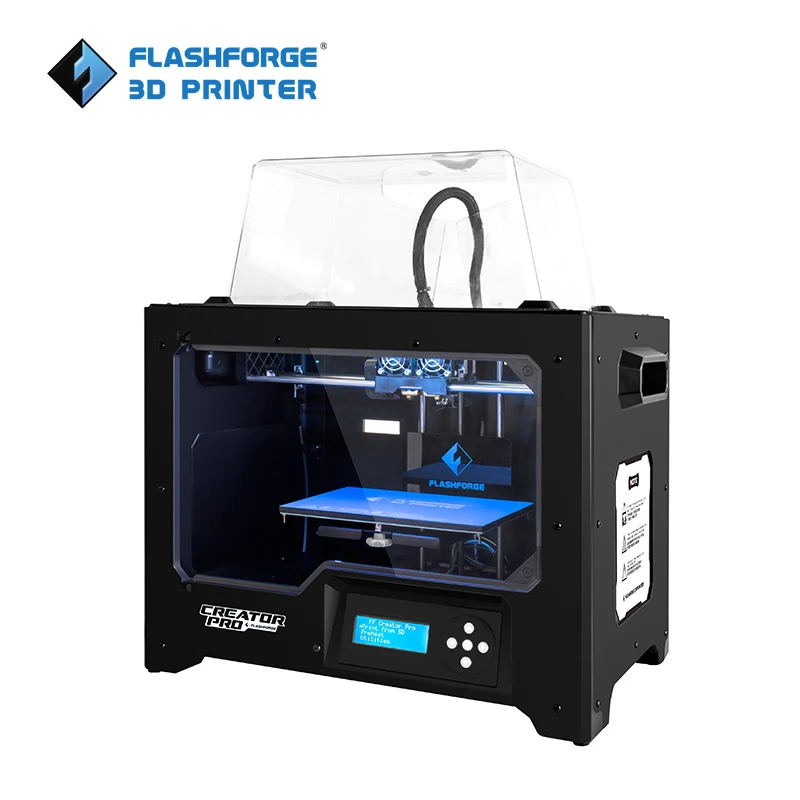

A great benefit of choosing us is that we can help you save manufacturing costs and reduce lead times with our top-notch 3D printing services. At RapidDirect, we used high-quality 3D printers from the design stage to production. You can also tweak your designs and ensure that you have the best end results. Upload your CAD files today, and let’s make your 3D printed motorcycle design come true!

Upload your design of your custom motorcycle parts

FAQsWhat Are the Best Materials for Motorcycle Parts?

Steel and aluminum are the best and the most common materials used for motorcycle parts. These materials have excellent strength-to-weight ratios, making them suitable for this application. Moreover, it is easy to form them into various shapes. However, recent developments have made PLA and ABS filaments useful for 3D printed motorcycle parts.

These materials have excellent strength-to-weight ratios, making them suitable for this application. Moreover, it is easy to form them into various shapes. However, recent developments have made PLA and ABS filaments useful for 3D printed motorcycle parts.

Can You 3D Print a Motorcycle Engine?

At the moment, it is only possible to create a motorcycle engine 3D model. Only a few components of the engine can actually be 3D printed. However, the use of electric motors in recently developed bikes makes 3D printable polymers more suitable for several motorcycle engines.

Which Custom Bike Parts Can You 3D Print?

The additive manufacturing technology is now advanced, enabling the manufacture of several bike parts. These components include small bore motorcycle parts, handlebars, gearboxes, motorbike saddles, wheel bearings, a 3D printed motorcycle helmet, and more.

3D printed motorcycle parts for time and cost savings

BORN Motor Co. is switching from components made using traditional processes to end-use 3D printed motorcyle parts, and is saving €2,000 per modified motorcycle in doing so.

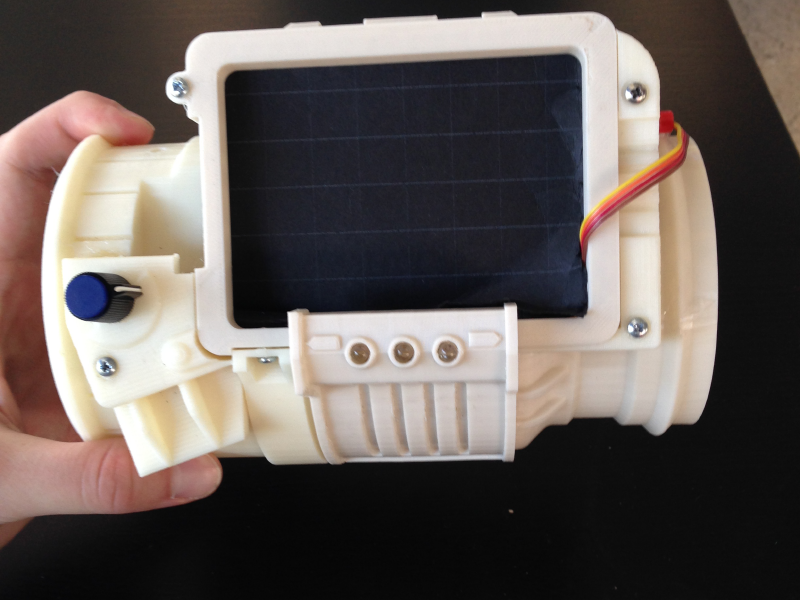

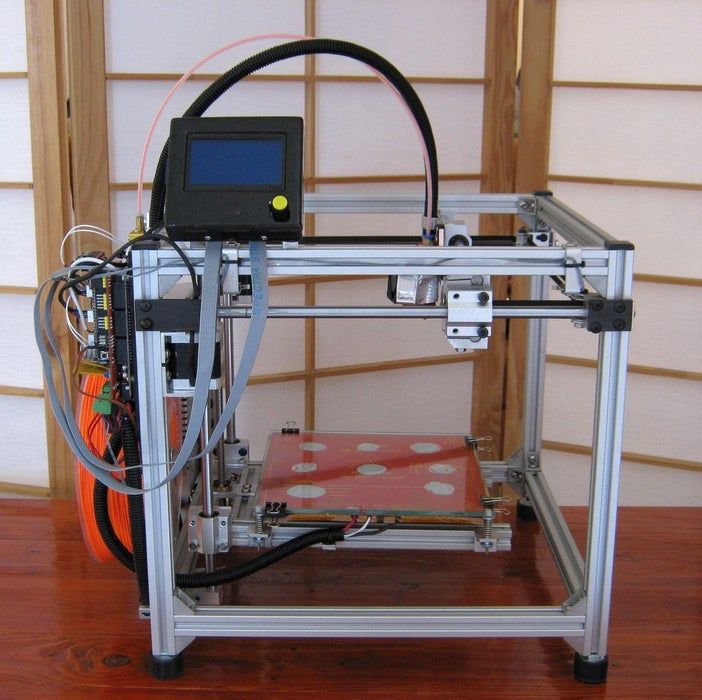

Traditional processes can be time-consuming, expensive for short runs of production, and can limit the design freedom of engineers. The automotive company BORN Motor Co. has decided to break free from the chains of tradition and make the BCN3D Sigma a part of their daily workflow. This decision has empowered its engineers to create more complex parts with a fraction of the previous effort, time, and money.

The challenge

The company, based in Calella, Barcelona, produces high-quality deconstructed motorcycles. BORN also designs limited editions and upgrade kits for motorcycles and, as an industrial design studio, collaborates with several motorcycle manufacturers in aspects of aesthetic design.

Of course, this means that exclusivity and originality are distinctive features for the BORN products. Its design and activities are all purposeful and meaningful, and a lot of inspiration is taken from the team and the individuals they surround themselves with.

In order to follow through with this concept of individualization and uniqueness, BORN has been using traditional manufacturing technologies, such as laser cutting and CNC milling, and creating custom pieces by hand.

However, both of these options are time-consuming and expensive for short runs of production. In addition, such technologies limit the design freedom and the creation of complex, custom pieces.

BORN contemplated investing in injection molds for certain parts, but the low volume production meant that it wasn’t the solution they were looking for.

3D printed motorcycle parts to the rescue3D printing has allowed BORN to speed up its creative process in every stage, from design to testing and manufacture. The team is now capable of faster iteration and of refining designs in a straightforward workflow. They have overcome design limitations imposed on them by the previous manufacturing technologies used.

The team is now capable of faster iteration and of refining designs in a straightforward workflow. They have overcome design limitations imposed on them by the previous manufacturing technologies used.

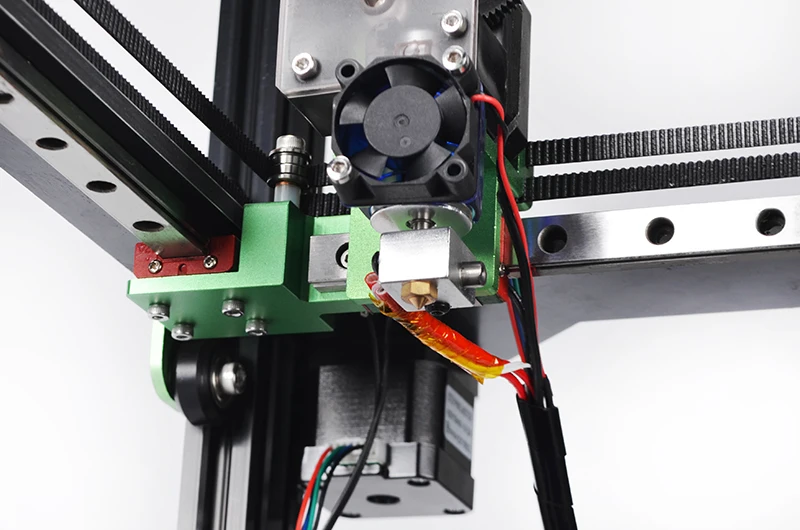

Thanks to the versatility that the BCN3D Sigma 3D printer offers, BORN engineers now are able to fabricate end-use pieces made of different materials, such as Nylon, PET-G, or ABS, for a variety of applications.

Cutting costsRegarding costs, there are several factors to be considered: size, function and geometry all specify which manufacturing technology is ideal for the specific custom part. The following table is based on the modification of a dash housing for a Honda CB25 and portrays the cost efficiency of 3D printing in this case.

| Handcrafted | Machined | 3D Printed | |

| Iterations | 1/part | 2/part | 6/part |

| Costs (labor, materials and service fee) | 1500€/part | 250€/part | 6€/part |

| Lead time | 24h/part | 2-3 weeks | 5-8h/part |

Now that 3D printing is part of the daily life at BORN, the designers are empowered to create more complex parts with a fraction of the previous effort, time and money. While before the staff dedicated a lot of time to handcrafted components, now they can focus on higher added-value parts.

While before the staff dedicated a lot of time to handcrafted components, now they can focus on higher added-value parts.

3D printing for internal or non-aesthetic parts has opened the door to new solutions and design strategies, enriching BORN’s design process and the final outcome, while reducing the time-to-market and overall labor costs.. Are you interested to find out what BCN3D Technologies can do for your business? Contact us, we would love to hear from you!

STL File Motorcycle Parts・3D Printer Design Download・Cults

Cake

3 €

Spare turntable

3 €

Spare car sun visor

3 €

Audi 80 GTE

3 €

spare box

2.50 €

Spare tank

3 €

Spare part

3 €

Spare cover

3 €

The best files for 3D printers in the Tools category

USB Key Holder

Free

Wall Hook

Free

Funnel.

Free

Raspberry Pi B+ Face Case

Free

Multicolor Thread Configuration Disc: MCFCD

Free

OUL BOOKMARK

1,25 €

Deactivated

Cooling system Minimus Hotend

€2.38 -thirty% 1.67 €

Bestsellers in the Tools category

Cooling system Minimus Hotend

€2.38 -thirty% 1.67 €

Armadillo - flexible wire conduit

€1. -thirty% 1.20 €  72

72

SUPERBOX

1,50 €

GEAR AND DRIVE

€9.61 -40% 5.76 €

Ender 3 Briss fang Gen2, red lizard, spider, nf crazy, dragonfly, etc.

€1.80

well designed: Hemera fan duct

2.50 €

Quick Print Ink Bottle Rack (6 sizes)

2.91 €

ENDER 3 S1/PRO SPRITE, V3 AIR DUCT 5015 OR 4020

€2.49 -fifteen% 2. 11 €

11 €

UNIVERSAL BED LEVELING INDICATOR FOR VERY ALL PRINTERS

2,87 €

3D printed wave transmission (harmonic drive)

€4.99

Phone holder

2.49 €

Tool holder for 3D printer V3.0

1.06 €

ENDER 3 S1/PRO SPRITE, HOTEND 4020 OR 5015 FAN PROBE NO Y OFFSET

€1.96 -fifteen% 1.66€

Case for Chill Buddy lighter

0,95 €

telephone ring holder

0,90 €

PET-Machine, make your own plastic bottle filament at home!

50 € -70% 15€

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy. Here are 4 solutions available to everyone:

Here are 4 solutions available to everyone:

-

AD: Disable AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

Can you print a part from a motorcycle?

3D modeling

Follow author

Follow

Don't want

26

It was from this question that I learned that there are quite a lot of plastic parts in motorcycles that break and are difficult or very problematic to get, they are expensive and they need to be transported from abroad.

This was the beginning of my acquaintance with the motor world.

The task was, like last time with the trunk opening handle, to do better than it was.

Outwardly, the details looked 'combat' and. in fact, they are.

Things with modeling went very badly, slowly, because I had never encountered such large-scale details before and I had to create devices for measurements along the way. Of course, the photo with how you had to dodge with rulers and other measuring tools has not been preserved, but based on the results, we can conclude that the accuracy is 'plus or minus the tractor':

But everything bad comes to an end someday, with the second- the third rebuilding of the model and checking the shape of the part and the model, and even begins to look like the truth:

And yes, in addition to the scale, the radiator linings themselves were different, their shape for the right and left sides:

As a result, a third fastener was added, instead of a clip, in the rear parts of the linings, and the printout will be made if necessary.

Conclusion: even if the work is scary, you should definitely take it on, even if they drag on for a long time, because the experience gained after such a job is invaluable.

PS.: Parts are still being prepared for printing, since the parts are complex in shape, it will take about 3 days of continuous printing and there is a high probability of part rejection due to its shape.

But who does not take risks does not do well and beautifully!

Follow the author

Follow

Don't want

26

More interesting articles

grin

Loading

11/13/2022

6918

114

Subscribe to the author

Subscribe

Don't want

Hi all!

As a big (avid) fan of the cartoon "Treasure Island", long ago.