3D printing organs company

Top 10 3D bioprinting startups

Updated: October 23, 2022 |

3D bioprinting is the process of generating spatially-controlled cell patterns using 3D printing technologies, where cell function and viability are preserved within the printed construct.

1

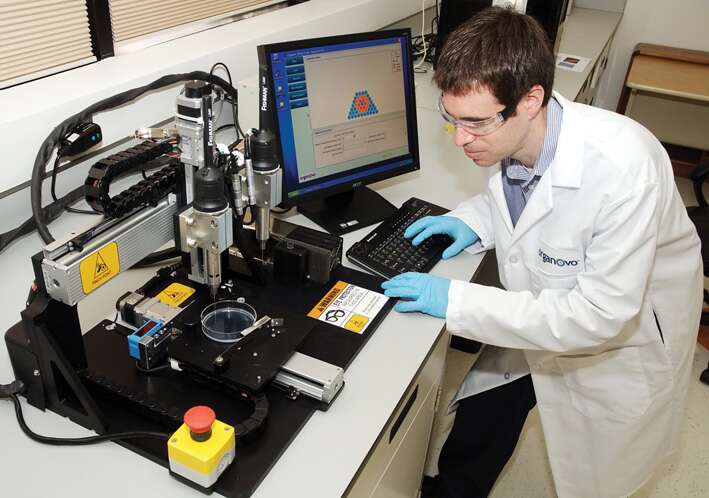

Organovo

Country: USA | Funding: $112.3M

At Organovo, we design and create functional human tissues using our proprietary three-dimensional bioprinting technology. Our goal is to build living human tissues that are proven to function like native tissues. With reproducible 3D tissues that accurately represent human biology, we are enabling ground-breaking therapies by:

2

Prellis Biologics

Country: USA | Funding: $64.9M

Prellis employs holographic tissue printing technology with rapid fully human antibody discovery, in vitro human disease and ADME/Tox models

3

Cyfuse Biomedical

Country: Japan | Funding: $29. 8M

We contribute to significant advances in medical treatments through our revolutionary 3D tissue-engineering technology. We successfully developed the BIO 3D PRINTER, Regenova. It is a state-of-the-art robotic system that enables fully automated fabrication of three-dimensional artificial tissues/organs from living cells.

4

Aspect Biosystems

Country: Canada | Funding: $24M

Aspect Biosystems is an award-winning biotechnology company specializing in 3D bioprinting and tissue engineering. We bring together a multi-talented team of individuals to develop cutting-edge custom human tissue technology for use in the life sciences.

5

Pandorum Technologies

Country: India | Funding: $14M

Pandorum Technologies is a biotechnology startup with a distinct synergy of life science and engineering competences focused on tissue engineering. The company uses its proprietary technology platforms to design and manufacture functional, three-dimensional living human tissues; intended for medical research, therapeutic and other applications.

6

Regenovo Biotechnology

Country: China

Chinese company, founded in 2013. Commercializing bioprinter “Regenovo” for “making biomaterials, organs and tissues” for regenerative medicine.

7

regenHU

Country: Switzerland | Funding: $701K

RegenHU is an innovative biomedical company that acts as a biosystem architect exploiting new biomanufacturing solutions in order to respond to the emerging challenges facing the biomedical industry.

8

MedPrin

Country: China

MedPrin is a high-tech enterprise co-founded by outstanding biomedicine scientists in September 2008, specialized in R & D, production and sales of regenerative medicine materials and regenerative implantable medical devices. MEDPRIN aims to become global leader in the field of implantable medical devices, relying on amazing capacity to provide excellent products for the patients worldwide based on biological 3D printing technology and nano-bionics technology

9

Allevi

Country: USA | Funding: $4. 7M

7M

Allevi offers bioprinters that enable users to experiment with any biomaterial, work with any cell line, and print in any geometry.

10

Nanofiber Solutions

Country: USA | Funding: $4.6M

Nanofiber Solutions designs and manufactures novel three-dimensional (3D) nanofiber scaffolds. Our platform technology mimics the extracellular matrix found within the body, providing a realistic environment for for all types of cells whether in the body or on a lab bench.

Ad

Advertise your startup

11

TeVido Biodevices

Country: USA | Funding: $3.7M

TeVido BioDevices uses the innovative process of 3D bio-printing of living human cells for use as implants or grafts targeting use in reconstructive surgery and wound care. TeVido will change the way reconstructive surgery is approached, starting by improving options for breast cancer survivors but expanding capability to others who suffer disfigurement and long to improve their self-esteem.

12

Kwambio

Country: Ukraine | Funding: $3.1M

Kwambio is an additive manufacturing company and a developer of unique products with implementations in a variety of fields including medicine

13

3D Bioprinting Solutions

Country: Russia

Russia’s leading bioprinting firm, 3D Bioprinting Solutions aims to 3D print multiple human organs. The company now has an incredibly ambitious timeline in which they seek to develop a 3D printed kidney. Their machine utilizes stem cells taken from a patient via their fat cells which are then mixed with hydrogels before being printed layer-by-layer. When the hydrogel dissolves, only the cells remain, forming tissue.

14

Precise Bio

Country: Israel

Precise Bio develops and commercializes 4D bio-fabricated functional tissues and organs that can save lives and improve its quality. It combines world-class tissue-engineering and transplantation experience with best-in-class bio-printing, to create a scalable bio-fabrication platform, that can overcome current industry challenges and make complex human organs available for transplantation.

15

Brinter

Country: Finland | Funding: €1.2M

Brinter provides comprehensive 3D bioprinting solutions and services for pharmaceutical, biotechnological and cosmetic industries, universities, and research facilities.

16

Regemat 3D

Country: Spain | Funding: $1.1M

REGEMAT3D, a biotech company pioneer in the use of 3D printing for regenerative therapies.

17

Advanced Solutions Life Sciences

Country: USA

Advanced Solutions Life Sciences provides solutions for living organisms, molecular biology, and biotechnology.

18

Longe Medikal

Country: Malaysia | Funding: $255K

Lönge Medikal is a medical device company focusing on accessory device to revolutionise minimally-invasive medical procedures. It developed high-fidelity patient specific medical models using medical-grade fabrication processes with 3D printing technology.

19

Next Big Innovation Labs

Country: India

Next Big Innovation Labs is a 3D Bioprinting Company. Our Vision is to create Organs within a Laboratory using the disruptive technology of 3D Bioprinting. Our team, with expertise in 3D Printing, Biotechnology and Pharmaceuticals, endeavours to create a paradigm shift in Pharmaceutical, Cosmetic and Clinical research and development by building robust Bio-automation Hardware and Biotechnology products and by Partnering with Pioneers in these fields.

Our Vision is to create Organs within a Laboratory using the disruptive technology of 3D Bioprinting. Our team, with expertise in 3D Printing, Biotechnology and Pharmaceuticals, endeavours to create a paradigm shift in Pharmaceutical, Cosmetic and Clinical research and development by building robust Bio-automation Hardware and Biotechnology products and by Partnering with Pioneers in these fields.

20

FoldInk

Country: Armenia

FoldInk is focused on the development of 3D Bioprinting technologies, that allows researchers to print human living organs and tissues. Biofabricated tissues are used in pharmacological researches and development of costemtics and pharmaceutical products.

21

ROKIT Healthcare

Country: South Korea

ROKIT HEALTHCARE is a leading regenerative medicine biotechnology company. We are committed to pioneering medical treatments based on the principles of 3D bioprinting and autologous stem cell use to regenerate and restore functions of human tissues and organs.

22

Life SI

Country: Argentina

Life SI enables 3D printing with biological, biocompatible and other materials.

Eight 3D Bioprinting Companies for Medical Solutions

In the United States, nearly 107,000 people are on waitlists for organ transplants. The problem is even bigger worldwide, with millions of people waiting to get their hands on an organ. The trouble is that there’s only so many organs to go around. While China is filling in the tremendous demand with its $1 billion organ black market, and Iran is selling organs legally, the rest of the world is looking for a less shady more sustainable option. 3D bioprinting organs has often been touted as the holy grail for facing these supply challenges.

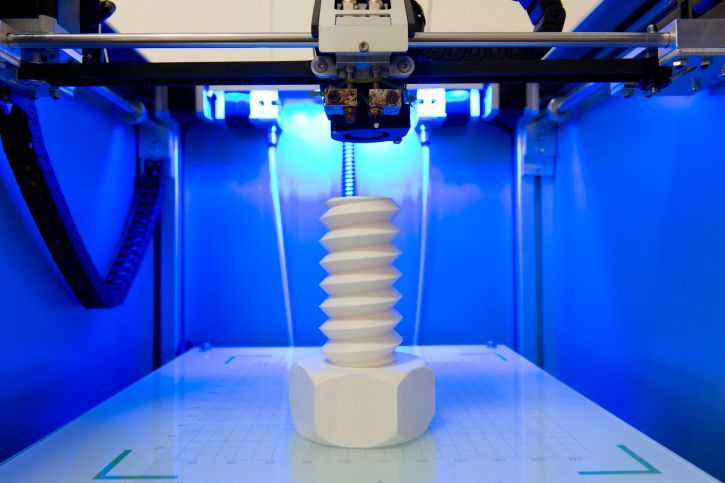

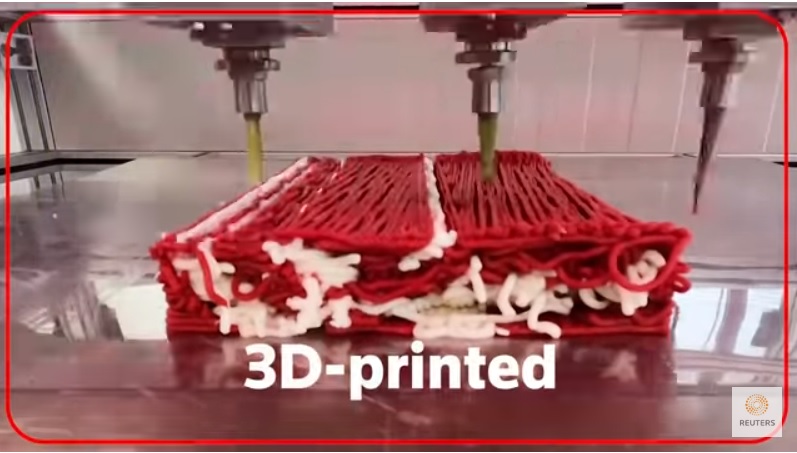

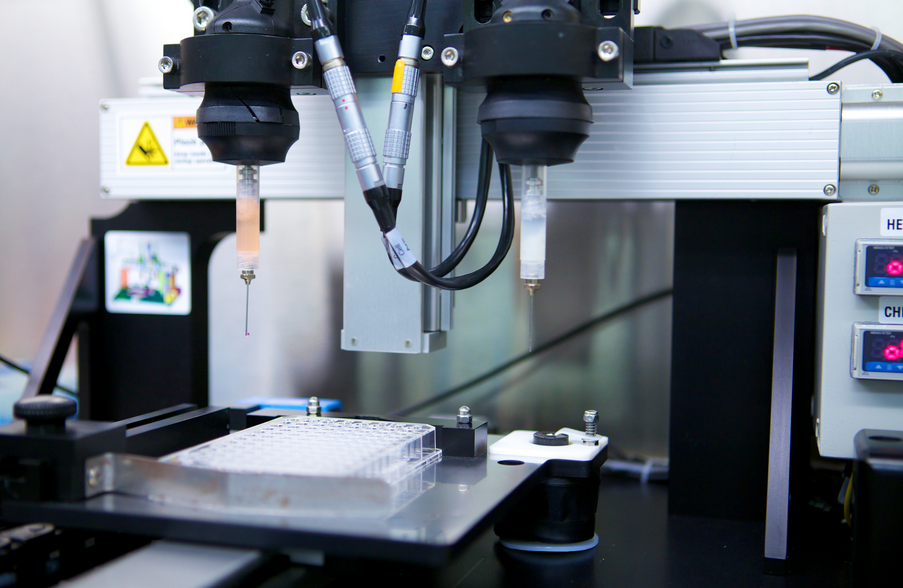

In a similar manner to how traditional 3D printing works, 3D bioprinting involves layering patient-derived stem cells one-by-one in a biocompatible material to construct an organ-like structure. The stem cells are programmed to differentiate into the specific cell types by the scaffolding material, usually collagen or a synthetic plastic that mimics collagen, creating a hybrid composite that can be transplanted into a patient. The two keys to this technology are the bioprinter, which extrudes the material into a 3D form from a computer-generated model, and the bioink, which is the mixture of cells, scaffolding, and nutrients that makes up the 3D-bioprinted organ.

The two keys to this technology are the bioprinter, which extrudes the material into a 3D form from a computer-generated model, and the bioink, which is the mixture of cells, scaffolding, and nutrients that makes up the 3D-bioprinted organ.

One of the first biotech companies to commercialize bioink was CELLINK (CLNK-B.ST). Founded in 2016, this Swedish company has been a leading player in the bioprinting space by providing the tools and materials for the entire workflow of 3D bioprinting. That means it’s been selling branded bioinks, bioprinters, biomaterials, consumables, sanitizing wipes, toilet paper. You name it, CELLINK’s got it. We own a little chunk of CELLINK and recently gave a play-by-play on how to get a piece of the action.

Here’s another eight 3D bioprinting companies that are making sure our aging population has a tailor-made set of replacement organs for the next couple of decades, so they can use up all their hard-earned retirement savings.

3D Bioprinting Companies for Bioink and Biomaterials

Israeli-based CollPlant (CLGN) was founded in 1981 and now sports a market cap of $205 million. One of CollPlant’s signature ingredients and products is its human Type 1 collagen, called rhCollagen, produced in genetically engineered tobacco plants. The company uses this clinical-grade collagen as part of the scaffolding of its bioprinting technology and bioink.

Feels just like the real thing. Credit: CollPlantBecause rhCollagen is actually derived from the human genetic code, it exhibits better properties and lower risk of immune rejection compared to other collagens. That makes up part of its successful secret sauce for biocompatible bioinks, dermal fillers, and 3D-printed breast implants. We’re confident that many of the cast members in The Real Housewives of Orange County are now sporting CollPlant in one form or another. (It’s a stock we took a closer look at days later.)

Based in the Windy City, Dimension Inx is a bioprinting startup founded in 2017 that’s grabbed a total of $3. 2 million in funding through a Seed round from a group of life science venture capital firms back in 2020. The company is designing biomaterials that mimic the microenvironment of the human body so that the body can use the materials as a scaffold to heal itself.

2 million in funding through a Seed round from a group of life science venture capital firms back in 2020. The company is designing biomaterials that mimic the microenvironment of the human body so that the body can use the materials as a scaffold to heal itself.

In layman’s terms, a surgeon can cut up a patient and shove in one of Dimension Inx 3D printed fake bones, made from medical-grade ceramic or metal, and pray to the medical gods that the patient’s body doesn’t reject it. The hope is that the body starts to grow around the implant. The first commercial application of Dimension Inx’s biomaterials is implants for facial reconstruction of patients with physical trauma, dental malformations, and defects from aging. The Kardashians might be ready for a nice set of Dimension Inx hardware in the next couple of years.

3D Bioprinting Companies for Tissue and Organ Transplants

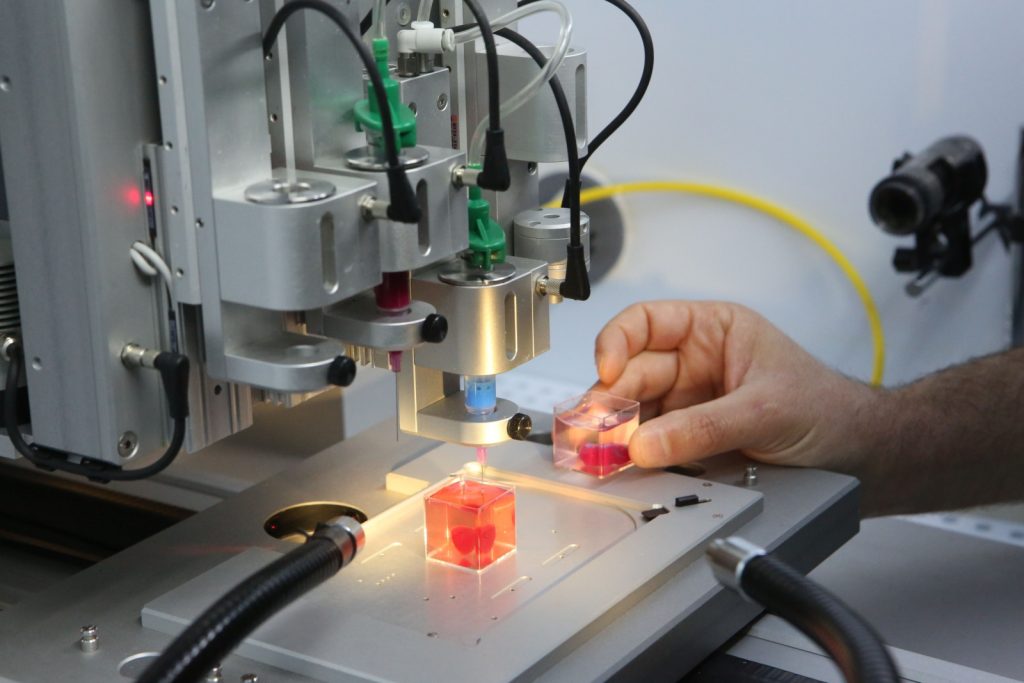

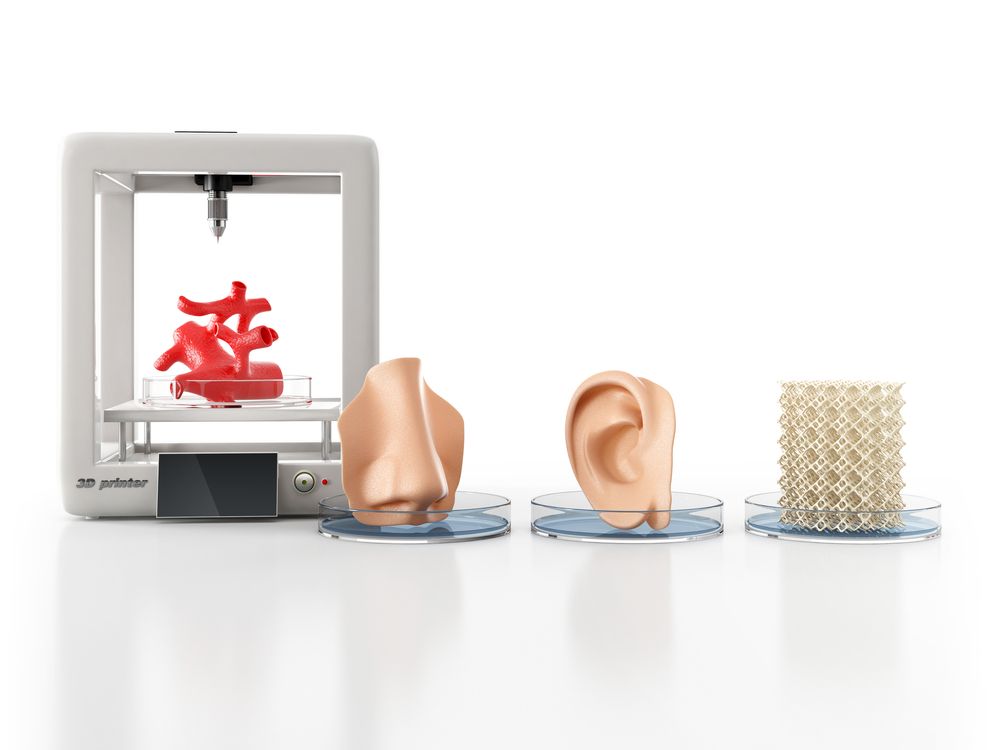

Founded in 2014, 3DBio is headquartered in The Big Apple and has brought in a total of $28. 5 million to focus on designing personalized living tissue implants for patients. 3DBio has a suite of proprietary processes and biomaterials used to ensure its manufactured tissues and organs meet FDA requirements. The company’s technology starts with its GMPrint bioprinter, a current Good Manufacturing Practice (cGMP) technology that uses aseptic workflows to make sure that next artificial heart doesn’t start growing fluffy mold once it gets sewn into a patient’s chest. 3DBio also has its own therapeutic-grade bioink, ColVivo, which is a collagen-based biomaterial used to construct scaffolding during bioprinting.

5 million to focus on designing personalized living tissue implants for patients. 3DBio has a suite of proprietary processes and biomaterials used to ensure its manufactured tissues and organs meet FDA requirements. The company’s technology starts with its GMPrint bioprinter, a current Good Manufacturing Practice (cGMP) technology that uses aseptic workflows to make sure that next artificial heart doesn’t start growing fluffy mold once it gets sewn into a patient’s chest. 3DBio also has its own therapeutic-grade bioink, ColVivo, which is a collagen-based biomaterial used to construct scaffolding during bioprinting.

The company is working on four tissue and organ products to treat four different diseases and congenital medical conditions. These include 3D-bioprinted ears for underdeveloped ears, noses for nasal defects, and tissues for herniated or degenerative disks. These are all in the pre-clinical stage. We can’t wait for 3DBio to start working on another collagen-rich organ that men around the world are looking to extend.

These are all in the pre-clinical stage. We can’t wait for 3DBio to start working on another collagen-rich organ that men around the world are looking to extend.

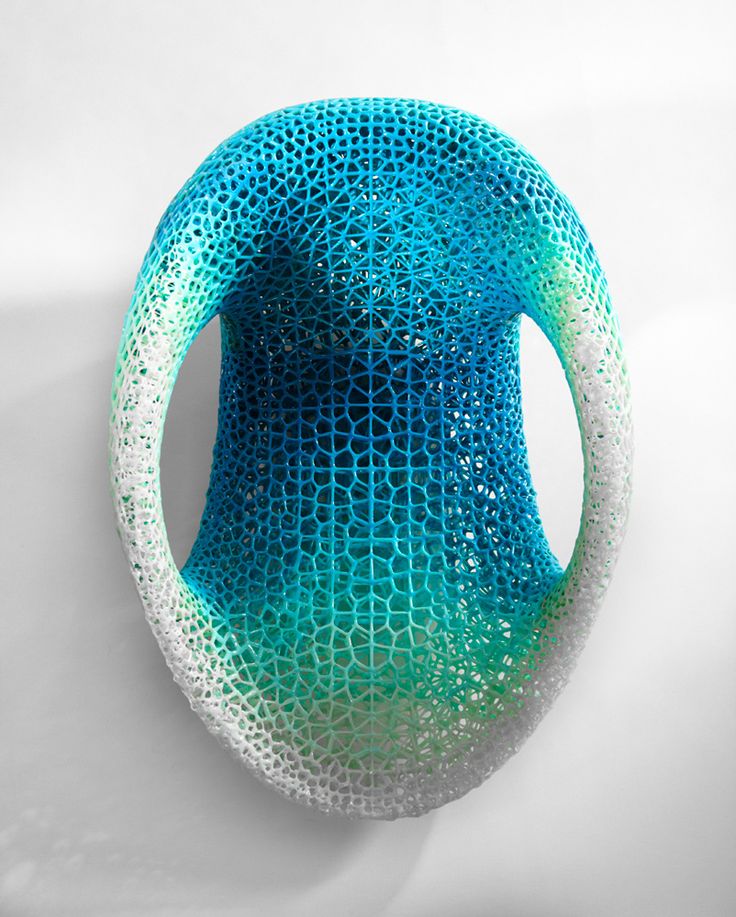

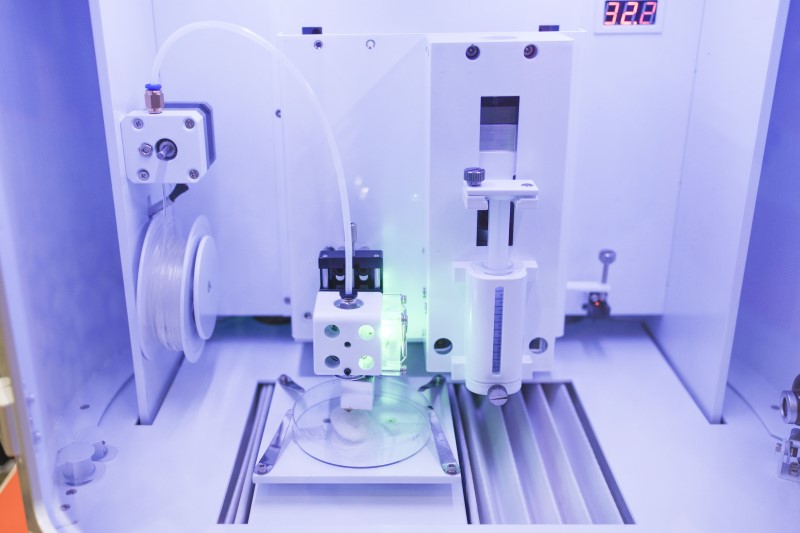

Representing the Lone Star State is Volumetric, a biofabrication company that was founded in 2018 and has added $2 million to its coffers after a series of Seed rounds that closed in 2020. Notable investors include tech accelerator Y Combinator and the Methuselah Foundation, a life-extension non-profit. Volumetric partnered with CELLINK to design its market-ready signature Lumen X Bioprinter, a nice piece of hardware that combines microfluidics, lab-on-a-chip, and living tissue all in one.

3D bioprinted materials for those outrageous raves in the desert. Credit: VolumetricThe bioprinter constructs 3D models of tissues and organs using biocompatible photoinks, which are specialized inks that harden into a hydrogel when exposed to UV light. We’re not sure what all that technical mumbo jumbo means, but the bioprinter was featured in two research publications in 2020 so that must mean something good.

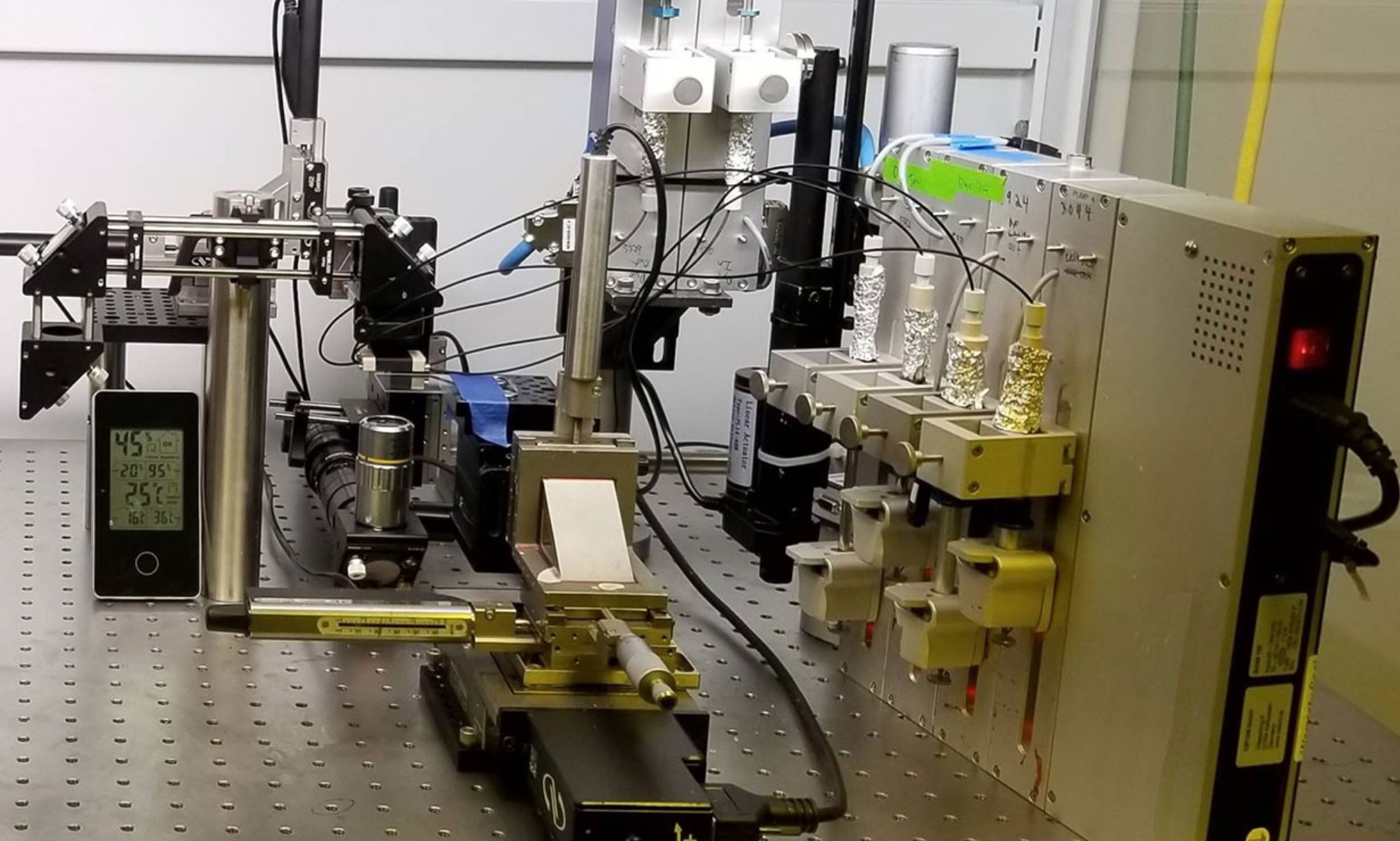

Founded in 2018, Finnish startup Brinter is piecing together a modular 3D bioprinter for the medical market after raising $1.45 million in June 2021. The company has plans to build out tissue and organs for transplants but is currently focusing on bioprinting scaffolding to direct the differentiation of stem cells harvested directly from patients. The module design of its bioprinter allows clients to switch out dispensing tools and integrate third-party tools so applications can be customized for specific needs.

Modular 3D Bioprinter. Credit: BrinterBrinter wants to get its fingers in a lot of pots, with commercial applications of its bioprinter for basic research, drug and toxicity screening, tissue models for cancer research, and eventually, bioprinted tissues and organs. The company is also touting that its bioprinter can be used to design personalized drugs, where multiple pharmaceuticals can be printed into a composite matrix as a single pill. No more late-night searches on those microdosing forums for that perfect cocktail of psychedelics.

3D Bioprinting Companies for Clinical Research

Founded in 2016, San Francisco-based Prellis Biologics is a bioprinting startup that’s building human tissues for drug development, and eventually working to design human organs for transplantation. We covered Prellis Biologics back in 2019 as part of our regenerative medicine company recap. The company has since pulled in $10.6 million after a Convertible Note agreement that closed on April 2020, with the likes of Khosla Ventures and IndieBio at the investment table. Prellis Biologics is working together with CELLINK on Holograph X, a high-resolution bioprinter that can match the detail of microcapillaries and other fine-resolution biostructures. We’re waiting for the day surgeons start secretly etching their names into patients’ organs with these bad boys.

The technology can print fine biological details such as neural connections between astrocytes. Credit: Prellis BiologicsThe company is touting its Externalized Immune System (EXIS) platform as a clinical solution to the problem of researching immunity. By pulling out immune cells from healthy donors, the platform can bioprint organ-like lymph nodes and stress them with an antigen from a virus, bacteria, or other pathogens, to produce antibodies. According to Prellis Biologics, the process allows researchers and biomedical companies to discover human-grade therapeutic antibodies in less than three weeks, versus 9 to 12 months in animal models. AbCellera, take note.

By pulling out immune cells from healthy donors, the platform can bioprint organ-like lymph nodes and stress them with an antigen from a virus, bacteria, or other pathogens, to produce antibodies. According to Prellis Biologics, the process allows researchers and biomedical companies to discover human-grade therapeutic antibodies in less than three weeks, versus 9 to 12 months in animal models. AbCellera, take note.

Oakland-based Frontier Bio was founded in 2018 to manufacture tissue and has brought in $825k after a Seed round that closed in 2020. The company is focused on building blood vessels, nerves, and muscle tissues for good ol’ fashion research and development, as the first commercial application. The game plan is to eventually develop those tissues into implants for unmet clinical needs.

Credit: Frontier BioWe’re thinking Frontier Bio wants to biomanufacture patient-specific blood vessels for coronary artery bypass surgery, for those of us who visit McDonald’s one too many times. Frontier Bio’s current clients include UC Berkeley and the Mayo Clinic.

Frontier Bio’s current clients include UC Berkeley and the Mayo Clinic.

Bulgarian 3D bioprinting firm Printivo came into existence in 2016 and has since raised $363k after a Pre-Seed round that ended in 2020. The startup is putting its attention on bone tissue, especially on its complex micro-architecture that requires highly precise cell layering. Since bone is rather complicated, containing four different cell types all interacting with one another, a 3D-bioprinted bone-mimic can model the complexity of human tissue inside a human.

The EVE Bioprinter. Credit: PrintivoThe company is providing these bone tissue grafts to pharmaceutical companies so they can be used for more accurate drug testing in pre-clinical research. This strategy is slightly better than shoving untested pharmaceuticals into the drinking water of lab rats.

Conclusion

There are now more than 100 bioprinting companies around the globe, each of which is providing tools, materials, services, and applications for the emerging field of tissue and organ engineering. But experts agree that we’re still 10 to 15 years away from constructing more complicated, fully functional human organs for high-need transplants.

But experts agree that we’re still 10 to 15 years away from constructing more complicated, fully functional human organs for high-need transplants.

While the power to design personalized tissue and organs could allow parents to one day build the perfect child that can get into the Ivy Leagues on an athletics scholarship, right now the technology is still limited to providing biomaterials for basic research and breast implants for former beauty queens.

Tech investing is extremely risky. Minimize your risk with our stock research, investment tools, and portfolios, and find out which tech stocks you should avoid. Become a Nanalyze Premium member and find out today!

all about printing organs on a 3D printer

Printing organs on a 3D printer or bioprinting is a promising technology for growing healthy and living organs to replace damaged or missing ones. In addition to a 3D printer, bioprinting requires a model of an organ, patient cell material, and an environment where the organ will remain until implantation.

Printed organs are better than prostheses and transplanted body parts. Their capabilities are identical to native ones and they are not rejected by the immune system if they are created from the patient's DNA. Bioprinting will reduce the time to obtain the desired organ and save the lives of patients who need an immediate transplant.

Printing organs on a 3D printer has already been successfully tested on animals. Scientists at Northwestern University implanted artificial ovaries in sterilized mice and they gave birth to healthy mice. In the Chinese company Sichuan Revotek, rhesus monkeys have been implanted with blood vessels grown from the material of the same monkeys.

From human body parts, only internal tissues and skin are printed so far. Reduced but working copies of ears and noses are created. The first printing of human organs is expected by 2030.

How bioprinting works

Research groups or companies are developing different bioprinting concepts:

- Wireframe.

The growth of living cells on an inorganic base, which disappears with the development of natural connections between cells. The main difficulty is to find a material that is as elastic or rigid as the organ being replaced. It must degrade quickly so as not to interfere with the strengthening of the extracellular matrix and dissolve without leaving toxic compounds. Hydrogel, titanium, gelatin, synthetic and biopolymers are suitable for wireframe printing.

The growth of living cells on an inorganic base, which disappears with the development of natural connections between cells. The main difficulty is to find a material that is as elastic or rigid as the organ being replaced. It must degrade quickly so as not to interfere with the strengthening of the extracellular matrix and dissolve without leaving toxic compounds. Hydrogel, titanium, gelatin, synthetic and biopolymers are suitable for wireframe printing.

- Frameless. Application of prepared cells on a hydrogel base. While the cells are in the printer, they are cooled and are in thin hydrogel spheroids. When printing, the temperature rises to 36.6°C, the spheroids scatter, and the cells gradually form their own natural framework - the cellular matrix. This printing is less common than wireframe printing - it appeared later and is more difficult to reproduce.

- Mimicry. The technology of the future, involves the creation of complete copies of organs at once.

For it, bioprinting is being developed at the molecular level and in-depth studies of the nature of cells are being carried out.

For it, bioprinting is being developed at the molecular level and in-depth studies of the nature of cells are being carried out.

Methods for 3D printing of organs

Inkjet. The first devices for bioprinting were inkjet, conventional printers also use this method. They store biological material in cartridges that are sprayed onto a hydrogel substrate like paint on paper. Disadvantages - inaccurate droplet ejection and blockage of the spray nozzle with possible death of cellular material. Inkjet printing of organs on a printer is not suitable for viscous materials because they are not atomized. The scope is limited to the restoration of bone, cartilage, muscles and skin. Advantages - low cost and mass reproducibility.

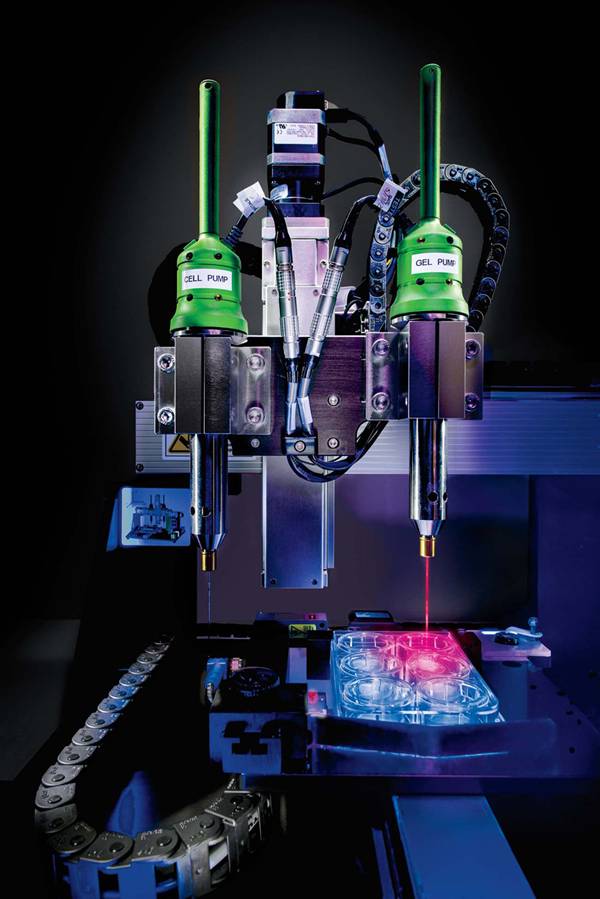

Microextrusion. This method is used in inorganic 3D printing. For printing, a pneumatic supply of material is used in a movable extruder head, which stacks the cells. The more heads, the more accurate and faster the printer. Disadvantages - the denser the cells fit, the less they survive. With a comparable stacking density, more cells die from microextrusion printing than from inkjet printing. Advantages - suitable for 3D printing of high-density organs, fine-tuning of the material supply due to pressure regulation.

Disadvantages - the denser the cells fit, the less they survive. With a comparable stacking density, more cells die from microextrusion printing than from inkjet printing. Advantages - suitable for 3D printing of high-density organs, fine-tuning of the material supply due to pressure regulation.

Laser. Common in industry but used in bioprinting. A laser is used to heat glass with a liquid cell substrate. At the beam concentration point, excess pressure is created, which pushes the cells to the desired area of the substrate. A reflective element is placed between the beam and the glass with biomaterial, which reduces the power of the beam. Disadvantages - increased metal content in the cells from the evaporation of the reflective element. Price. Advantages - controlled up to individual cells, laying of biomaterial.

Who offers 3D printing of organs

Bioprinting companies that offer 3D printing of organs or sell bioprinters:

- Organovo - San Diego, USA.

Prints and sells liver tissue " exVive3D" to pharmaceutical companies. In 2009, Organovo, together with the Austrian Invetech, launched the first mass-produced bioprinter, Novogen.

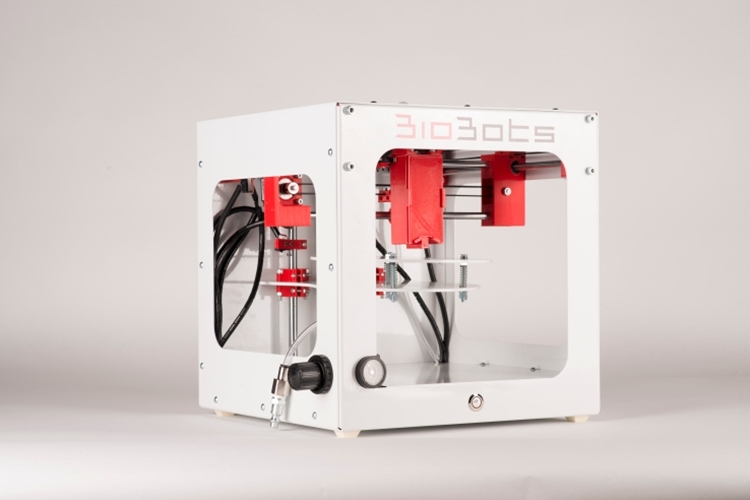

Prints and sells liver tissue " exVive3D" to pharmaceutical companies. In 2009, Organovo, together with the Austrian Invetech, launched the first mass-produced bioprinter, Novogen. - BioBots is a startup that presented a cheap commercial bioprinter at TechCrunch 2013. Today, the Biobot 1 model is available for purchase, Biobot 2 is still in development, but already presented on the company's website.

- 3D Bioprinting Solutions - Russia , Moscow. Focused on frameless printing, has developed its FABION 3D printer and is working on its own organoprinting technology

- Cyfuse Biomedical - Tokyo, Japan. They developed the Regenovo bioprinter, which was used to print skin and successfully grew 2-mm vessels.

How much does a 3D bioprinter cost

The average cost of a bioprinter is a quarter of a million dollars, but budget models are available for up to $10,000. Most printers available for purchase are extrusion type and work with frame printing.

Most printers available for purchase are extrusion type and work with frame printing.

- 3D Bioplotter - $200,000 Envision TEC, Germany.

- Novogen MMX - $250.00. Organovo, USA.

- Biobot 1 - $10,000. Biobots, USA.

- 3DDiscovery - $200,000. RegenHU & Biofactory, Switzerland.

- BioAssemblyBot - $160,000 Advanced Solutions, The Netherlands.

Supporting a patient with life support devices costs about $75,000 per year. In 10 years, the patient will spend $1 million. The printer costs $200,000 and the operation costs about the same. Considering how much it costs to print organs, the operation using 3D bioprinting is reduced by 50%.

The Future of Bioprinting

3D bioprinting has gone from concept to working and commercially successful technology. So far, the main clients of bioprinting companies are large pharmaceutical corporations. They speed up drug testing by testing them directly on printed human tissues.

Expensive bioprinters won't be in city clinics in 5 years, but some patients are already recovering thanks to 3D printing. The jaw of an 83-year-old woman from Belgium was struck by osteomyelitis. The restoration was more expensive and would have taken longer than the removal of the diseased jaw and the implantation of a printed new one. A team of doctors led by Professor Jules Poukan performed the operation and the woman was able to speak immediately after the operation. The development of bioprinting will lead to medical practices where it is easier to remove an injured limb and grow a new one than to treat injuries that are now treated without amputation.

Medicine of the distant future minimizes mechanical intervention in the body. The scalpel will remain in the past - a swarm of nanorobots will print organs immediately inside the body. In 2018, a full-fledged printing of a human organ on a printer is planned - the kidneys. Then the bronchi, arteries and heart will be printed. But even clinical trials on humans are about 10 years away, and mass 3D printing of human organs and body parts will come even later.

But even clinical trials on humans are about 10 years away, and mass 3D printing of human organs and body parts will come even later.

In addition to doctors, bioprinting is attractive to cosmetologists and plastic surgeons. The desire to remain young and beautiful, and not the treatment of rare and complex diseases, will make 3D printing of human organs mass. Perhaps the people of the future will change organs and appearance as easily as smartphones.

When will we be able to print new organs on a 3D printer? In China alone, there are 1.5 million people on the waiting list, in the United States - 113 thousand, of which, on average, 20 people die a day without waiting for a donor. A new kidney - the most demanded organ - has to wait from three to five years. This problem can be solved by printing the necessary organs on special 3D printers.

True, not earlier than in the next ten years.

Bioprinting technology: how and why organs are printed today?

(Video: RBC)

The principle is about the same as in conventional 3D printing: we get a three-dimensional object on a special printer.

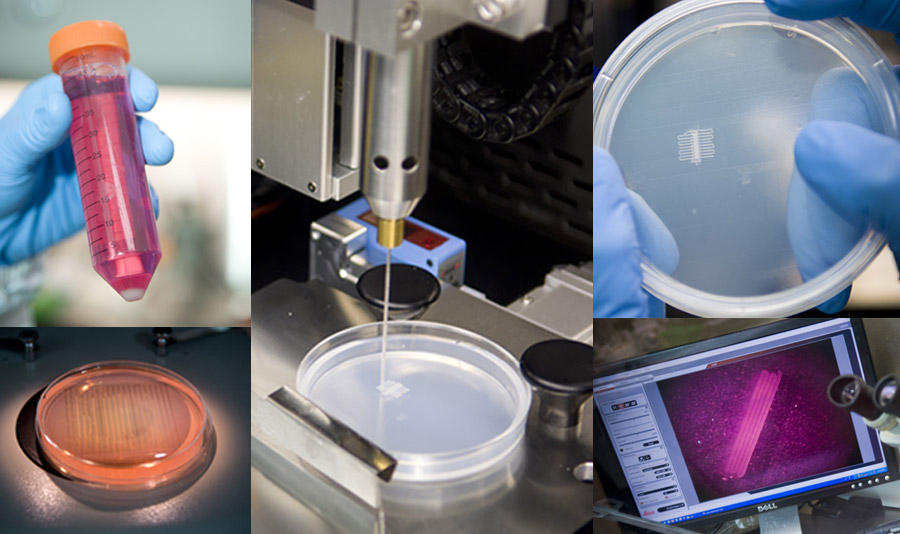

The first stage is preprinting : first, a digital model of the future organ or tissue is created. For this, images obtained on MRI or CT are used.

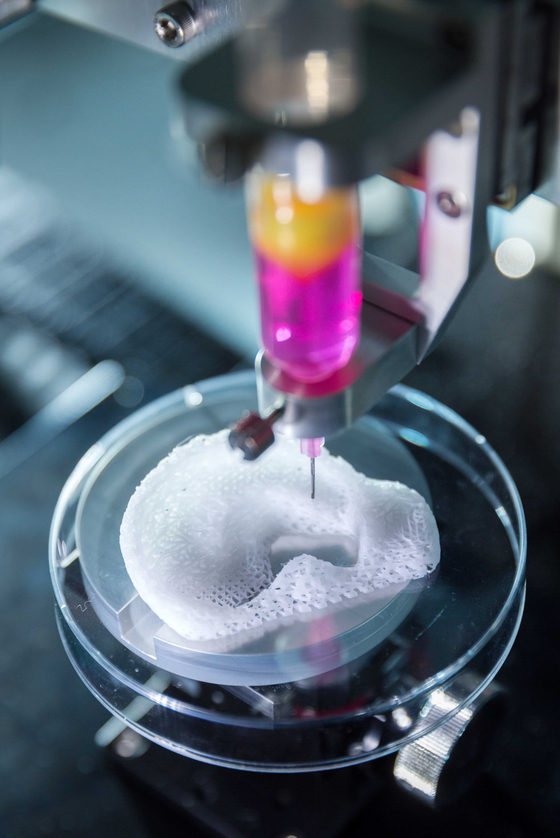

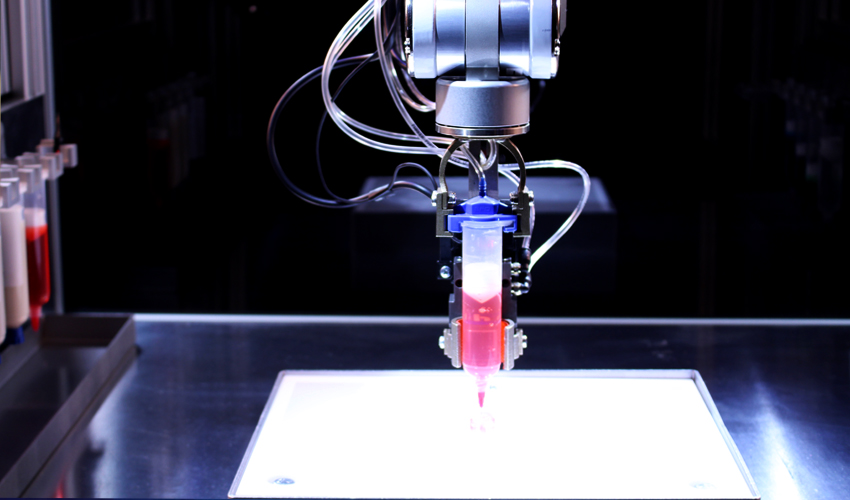

Then they print, layer by layer - this technology is called additive. Only instead of a conventional 3D printer, there is a special bioprinter, and instead of ink, there are biomaterials. These can be human stem cells, which in the body perform the role of any cells; porcine collagen protein or seaweed-based cell material.

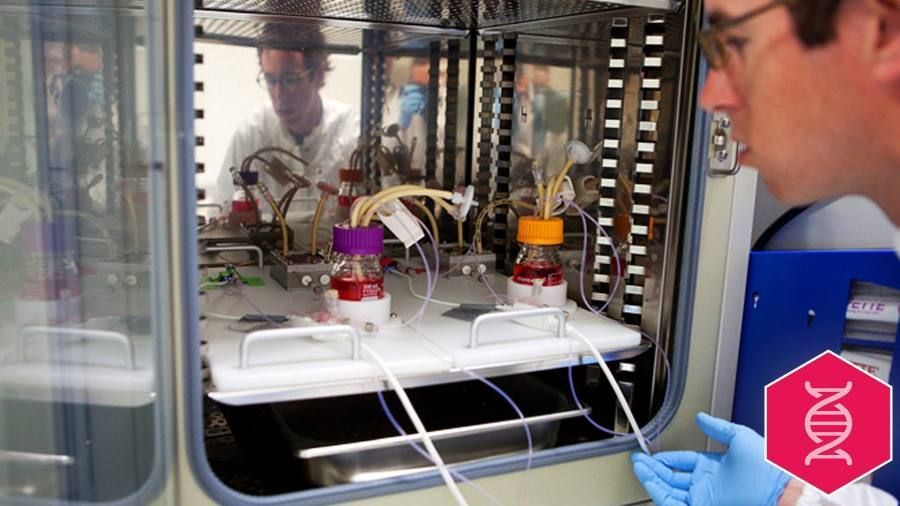

If the cells are alive, they are biopsied and prepared in a bioreactor until they multiply by division to the desired number. During printing, the bioprinter polymerizes the cellular structure - that is, binds it with the help of ultraviolet light, heating or cooling. Cell layers are connected using a hydrogel - organic or artificial.

The resulting structure is then placed in a biological environment where it "ripens" before transplanting. This is the longest stage: it can last several weeks. During this time, the structure stabilizes, and the cells are ready to perform their functions.

During this time, the structure stabilizes, and the cells are ready to perform their functions.

Then the organ is transplanted and they monitor how it takes root.

Bioprinting: how living organs are printed on a 3D printer

(Video: RBC)

In addition to conventional additive bioprinters, there are other bioprinters. Some of them print collagen directly on an open wound: this way you can quickly build up new skin even in the field. In this case, the ripening (post-printing) step is skipped.

There are also printers that print in outer space, in zero gravity. In the future, they can be used on the ISS:

There are more than 100 companies worldwide that produce 3D bioprinters. 39% of them are in the USA, 35% are in Europe (of which more than half are in France and Germany), 17% are in Asia, 5% are in Latin America.

In Russia, bioprinters are produced by 3D Bioprinting Solutions, which is also engaged in research in the field of bioprinting.

The cheapest and most compact bioprinter — Tissue Scribe by American 3D Cultures, costs from $1.5 thousand

In second place - Australian Rastrum from Inventia for $5,000.

Aether Bioprinter from the USA can be bought from $9,000. biosystems.

3D Bioplotters from the German EnvisionTEC cost from $100,000, and the Russian FABION (3D Bioprinting Solutions) is even more expensive.

Finally, the most expensive bioprinters — more than $200,000 — are NovoGen MMX from Organovo (USA) and NGB-R from Poietis (France).

In addition to the cost of the printer, the printing process itself is an additional 15-20% of the cost of the entire project. It will cost even more to obtain the necessary cell material.

So far, the most successful experience has been the transplantation of cartilage tissue - the very ears of Chinese children.

Small artificial cell bones are printed on a printer and then coated with a layer. They are planned to be transplanted instead of a broken or damaged area, after which they completely regenerate in three months. In the future, they want to use the technology for spinal injuries.

They are planned to be transplanted instead of a broken or damaged area, after which they completely regenerate in three months. In the future, they want to use the technology for spinal injuries.

The most promising direction is 3D printing of leather. Already in five years they promise that this can be done directly on a person, over or instead of the damaged area. Skin and other tissues are being printed from cells from cancer patients to test various therapies.

More complex organs, such as kidneys or hearts, have so far only been printed as prototypes or transplanted into mice, not humans.

In order for the organs to take root and function well in the human body, they take the patient's cells, and then they divide until there are enough of them for printing. There are entire institutes that create cell lines for bioprinting. But the problem is that cells have a division limit, after which they are no longer usable. Therefore, it is possible to print a model of the heart, but not life-size - that is, it is not suitable for transplantation into a person.