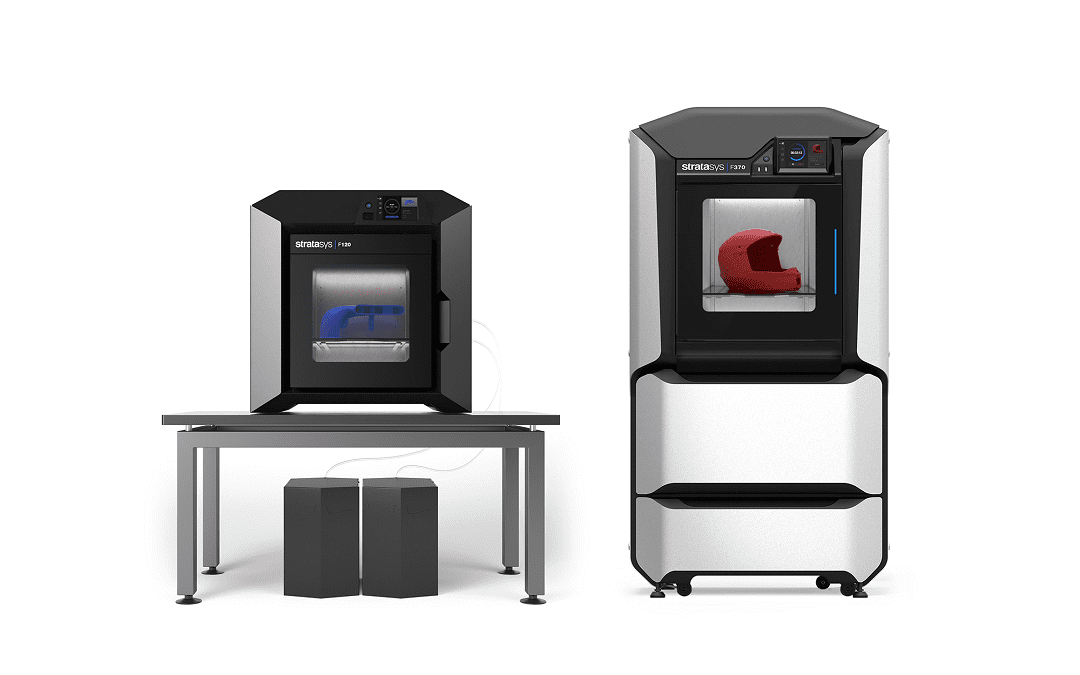

Stratasys f270 3d printer

Page not found – Objective3D

Skip to contentSeminar: How to implement Additive Manufacturing Successfully | 27th October, Perth.

Search

It looks like nothing was found at this location.

Objective3D is a leading provider of Additive Manufacturing (AM) solutions in Australia and New Zealand. They offer a range technology solution for thermoplastic and photopolymer from Stratasys, ceramics from Lithoz, and metal from GE Additive, as well as Artec 3D Scanners and Materialise AM Software. Supported by the Stratasys Direct Manufacturing Global Network, Objective3D also offers manufacturing on-demand services and is ISO 9001 certified.

Contact Us

Head Office: 33-35 Yazaki Way, Carrum Downs, VIC 3201, Australia

AU Phone: +613 9785 2333

NZ Phone: +649 801 0380

Email: enquiries@objective3d. com.au

I want to

Go to back top

I need

I want to learn about

© 2022 Objective3D, Inc. All Rights Reserved. Designed and Developed by

Facebook Twitter Youtube Linkedin-in Envelope

Go to back top

Filter 3D Scanners

Sort By

Industry

Aerospace

Architecture

Automotive

Consumer Products

Dental

Education

Entertainment

Medical

Support Object Size

Very Small

Small

Medium

Large

Accuracy Up To

0. 01mm - 0.09mm

01mm - 0.09mm

0.1mm - 0.4mm

Resolution Up To

0.01mm - 0.09mm

0.1mm - 0.4mm

0.5mm - 0.9mm

Scanner Type

Desktop

Handheld

Tetherless

Long Range

Filter Used 3D Printers

Sort By

Industry

Aerospace

Automotive

Application

Clear Aligner Moulds

Crowns and Bridges

Design and Packaging

Implantology

Jigs & fixtures

Manufacturing

Medical Device Development

Orthodontics

Pre-Surgical Planning

Production Parts

Prototyping

Removables

Surgical Guides and Tooling

Tooling

Training and Education

Technology

Digital Light Processing (DLP)

Fused Deposition Modelling (FDM)

Lithography Ceramic Manufacturing

Metal LaserCusing

Polyjet

Selective Absorption Fusion (SAF)

Material

Ceramics

Metal

Photopolymers

Thermoplastics

Carbon Fibre

More

Printer Size

Large Size Production

Large Team Solution

Mass Production

Professional Entry Solution

Filter 3D Printers

Sort By

Industry

Aerospace

Automotive

Commercial Products

Consumer Goods

Dental

Education

Medical

Application

Clear Aligner Moulds

Crowns and Bridges

Design and Packaging

Implantology

Jigs & fixtures

Manufacturing

Medical Device Development

Orthodontics

Pre-Surgical Planning

Production Parts

Prototyping

Removables

Surgical Guides and Tooling

Tooling

Training and Education

Technology

Digital Light Processing (DLP)

Fused Deposition Modelling (FDM)

Lithography Ceramic Manufacturing

Metal LaserCusing

Polyjet

Selective Absorption Fusion (SAF)

Material

Ceramics

Metal

Photopolymers

Thermoplastics

Carbon Fibre

More

Printer Size

Large Size Production

Large Team Solution

Mass Production

Professional Entry Solution

"*" indicates required fields

Full Name*

Company*

Post Code*

State*

Telephone / Mobile No. *

*

Country*

Select CountryAustraliaNew Zealand

Business Email*

Industry

Select IndustryAerospace and SpaceArts and EntertainmentArchitectureAutomotiveCommercial ProductsConstructions and EngineeringConsumer ElectronicsConsumer GoodsDefenceDentalEducationEngineering Consulting ServiceGovernmentIndustrial Design AgencyIndustrial EquipmentJewelryMarineMedical Hospitals and Patient CareMedical Device or EquipmentMiningOil and EnergyToysTransportationOther

Product You're Interested

Your Budget $

Message

Name

This field is for validation purposes and should be left unchanged.

Stratasys F370CR Composite Ready FDM 3D Printer

SEE CURRENT 3D PRINTING PROMOTIONS

A Composite Ready Industrial FDM 3D Printer

800-688-3234

high strength composite printing The Stratasys F370CR allows you to meet deadlines and stay on budget, with high strength composite printing.

- Equipped with hardened components to operate with composite materials

- Print carbon fiber-reinforced materials like ABS-CF10 and Nylon CF10

- Ideal for workholding fixtures, soft jaws, and component parts

with composite 3D printing - Print parts in a fraction of the time and cost

it takes to machine a metal equivalent.

Explore your Options. Get pricing on a Stratasys F370CR

unmatched uptime

F123CR printers are built on the same platform as the proven F123 Series, with a verified 99%- uptime and a 99%-dimensional repeatability performance

Simple setup, and GO

You don’t need special training to operate F123CR printers. Job setup simply involves importing the part’s CAD file using GrabCAD Print™ software and initiating the print.

Job setup simply involves importing the part’s CAD file using GrabCAD Print™ software and initiating the print.

Open materials

The open material platform enhances versatility by allowing you to expand your application space with new materials you develop or ones developed by Stratasys and third party partners.

Support

Stratasys invented FDM Technology, and has been perfecting it for over 30 years. GoEngineer's Stratasys technicians and application engineers know how to maximize your printer

investment.

-

ABS-CF10

- Potential Applications:

– Tooling

– Jigs and fixtures

– Production and assembly

– Drill guides -

ABS-CF10 Combines standard ABS material with 10% carbon fiber by weight .

This makes for a 50% stiffer than standard ABS 3D printing material and 15% stronger than standard ABS 3D printing materials.

This makes for a 50% stiffer than standard ABS 3D printing material and 15% stronger than standard ABS 3D printing materials. - Learn More >

-

ABS-ESD7

- Potential Applications:

– End-use components

– Electronic products

– Industrial equipment

– Jigs & fixtures

-

ABS-ESD7 standard FDM thermoplastic works with soluble support technology, so support removal is hands-free and complex parts require no extra effort.

- Learn More >

-

ABS-M30

- Potential Applications:

– Conceptual models

– Functional prototypes

– Manufacturing tools

– Production parts -

ABS-M30 FDM material enables you to prototype quickly and efficiently.

This strong, familiar material lets you explore more ideas, test frequently, work iteratively – and ultimately take better products to market faster.

This strong, familiar material lets you explore more ideas, test frequently, work iteratively – and ultimately take better products to market faster.

- Learn More >

-

ASA

- Potential Applications:

– Conceptual models

– Functional prototypes

– Manufacturing tools

– Production parts -

Mechanical strength and UV stability make ASA a great choice for functional prototyping. Ease of use makes it a top pick for iterative design. Outstanding aesthetics and ten fade-resistant colors make it an all-around favorite, even for end-use parts.

Learn More >

-

Diran

- Potential Applications:

– Tooling

– Jigs & fixtures -

Displaying functional properties of chemical resistance, high-impact strength, and a low coefficient of friction this material is well-suited for jigs and fixturing applications where non-marring robust tooling is desired.

Learn More >

-

FDM TPU 92A

- Potential Applications:

– Hoses, tubes, air ducts

– Protective covers & seals

– Vibration dampeners

– Prototype and end-use parts -

Thermoplastic polyurethanes otherwise known as TPU’s are flexible elastomers found in products that require a soft touch, shock absorption, or a comforting grip. They are commonly co-molded or over-molded onto ABS and Polycarbonate substrates in sunglasses and phone/tablet cases.

- Learn More >

-

Nylon CF10

- Potential Applications:

–Metal forming dies

– Press brakes

– End effectors

– Alignment and assembly fixtures -

3D printing with carbon fiber material lets you build strong, stiff, lightweight tools and parts.

FDM Nylon CF10 combines nylon and carbon fibers to achieve a high flexural strength and stiffness-to-weight ratio.

FDM Nylon CF10 combines nylon and carbon fibers to achieve a high flexural strength and stiffness-to-weight ratio. - Learn More >

-

pc-abs

- Potential Applications:

– Conceptual models

– Functional prototypes

– Manufacturing tools

– Production parts -

For functional prototyping, tooling, and low-volume manufacturing that requires superior impact strength, FDM Technology works with PC-ABS thermoplastic. PC-ABS also exhibits excellent feature definition and surface finish.

Learn More >

Request More Information about Materials for the Stratasys F370 CR 3D Printer

System Size and Weight

- 1626 x 864 x 711 mm (64 x 34 x 28 in.

)

) - 227 kg (500 lbs.)

BUILD ENVELOPE

- 355 x 254 x 355 mm (14 x 10 x 14 in.)

MATERIALS

- ABS-CF10, ABS-M30, ABS ESD7, ASA, Diran, FDM Nylon-CF10, FDM TPU 92A, PC-ABS, QSR Support material, (*Diran requires SUP4000B support material)

MATERIAL DELIVERY

- 4 material spool bays, 2 for model, 2 for support located in a drawer on the front of the unit

ACHIEVABLE ACCURACY

- Parts are produced within an accuracy of +/- .200 mm (.008 in), or +/- .002 mm/mm

(.002 in/in), whichever is greater

SOFTWARE

Operator Attendance

- Limited attendance for job start and stop required

OPERATING CONDITIONS

- Operating temperature: 15 – 30 ºC (59 – 86 ºF), Humidity: 30 – 70% RH

- Storage temperature: 0 – 35 ºC (32 – 95 ºF), Humidity: 20 – 90% RH

POWER REQUIREMENTS

- 100-132V/15A or 200–240V/7A.

50/60 Hz

50/60 Hz

operating System

- Windows 10 (64 bit only) and Window 11 with a minimum of 4GB RAM

(8GB or more recommended)

Regulatory Compliance

- CE (low-voltage and EMC directive), FCC, EAC, cTUVus, FCC, KC, RoHs, WEEE, Reach, RCM

Wireless Network Connectivity

- Wired: TCP/IP protocols at 100 Mbps minimum 100 base T, Ethernet protocol, RJ45 connector

- Wireless-ready: IEEE 802.11n, g, or b; Authentication: WPA2-PSK, 802.1x EAP Encryption:

CCMP, TKIP

Request More Information on the Stratasys F370CR 3D Printer Specifications

GrabCAD Print

Professional 3D Printing Made Easy and Accessible

GrabCAD Print is the most complete solution for Stratasys 3D printers on the planet. The intuitive, easy-to-use software allows for simplified preparation, scheduling, monitoring, and reporting of print jobs. With the ability to read and understand CAD files natively, GrabCAD Print offers an efficient workflow that streamlines job management in shared office and model shop environments.

The intuitive, easy-to-use software allows for simplified preparation, scheduling, monitoring, and reporting of print jobs. With the ability to read and understand CAD files natively, GrabCAD Print offers an efficient workflow that streamlines job management in shared office and model shop environments.

LEARN MORE

INSIGHT SOFTWARE

OPTIMIZE BUILD OUTPUT FOR 3D PRINTING

(ONLY AVAILABLE ON F370)

Insight software prepares your CAD program’s STL output for 3D manufacturing on a Fortus machine by automatically slicing and generating support structures and material extrusion paths. For maximum control, users can manually edit parameters that determine the look, strength, and precision of parts as well as the speed and material use of the FDM process.

For maximum control, users can manually edit parameters that determine the look, strength, and precision of parts as well as the speed and material use of the FDM process.

- Optimize build orientation for maximum strength and smoothest surface finish

- Customize supports for fast, easy removal and best use of materials

- Program pauses into the build for any reason, such as to embed hardware or circuitry

- Manipulate tool paths for advanced control over part properties

Included with Insight is Control Center. This sophisticated software application communicates with user workstations and Fortus systems, to manage jobs and monitor production status. Design, engineering, and manufacturing teams can network and share 3D manufacturing capacity to maximize efficiency and throughput.

This sophisticated software application communicates with user workstations and Fortus systems, to manage jobs and monitor production status. Design, engineering, and manufacturing teams can network and share 3D manufacturing capacity to maximize efficiency and throughput.

*Compatible with GrabCAD Print for use with job reports, scheduling, and remote monitoring.

Request More Information on Insight 3D Printing Software

F-SERIES

View the Entire F-Series office friendly addditive manufacturing product line available from Stratasys. F-Seriesl 3D Printers

3D Printing Services

AWARD WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

LEARN MORE

ADDITIVE MANUFACTURING TRAINING

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

LEARN MORE

3D Print and Part Design

No matter your size, quantity or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing and Part Design Services to help your organization produce the best parts and prototypes available on the market.![]()

LEARN MORE

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

Online Store

FREE SOLIDWORKS Tools

Enjoy this collection of small ‘macros’ that were tailored to help our customers. These free SOLIDWORKS tools are for you to use, review, and modify. SOLIDWORKS Automation Tools

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet, SL, or Metal 3D printers. 3D Printing Services

3D Printing Services

3D printing services on Stratasys Connex3 Objet260

Intrasoft JSC offers 3D printing services on Stratasys F270 and Stratasys Connex3 Objet260

3D printer Stratasys Connex3 Objet260 prototype. For parts that require a wide range of mechanical, optical or thermal properties (for example, multi-layer casting, the production of transparent covers, flexible joints or heat-resistant surfaces).

The Objet260 Connex3 professional resin 3D printer can use a wide range of materials in a single job to create realistic prototypes without the need for unnecessary assembly and post-processing.

Applications Objet260 Connex3

- Instrumentation - for making molds using inserts with complex internal cooling channels;

- Architecture and design - to quickly create accurate and visual models, layouts and compositions;

- Industry (aerospace, defense, automotive industry) - modeling and high-precision prototyping of various samples, parts, improvement of drawings, innovative developments;

- Advertising, marketing - creation of mockups, three-dimensional models, samples of commercial products;

- Education - the creation of test, educational and training products that most accurately repeat the physical and geometric properties of real objects.

Objet260 Connex3 3D Printer Features

Print technology:

PolyJet Matrix Layer-by-layer deposition of photopolymer materials, with the possibility of simultaneous use of two modeling materials with different properties.

Supported materials

3D base materials:

Vero family color opaque materials:

- VeroGray (RGD850) 90)

- VeroBlue (RGD840) (blue)

- VeroBlackPlus (RGD875) (black)

- VeroCyan (blue)

- VeroMagenta (Purple)

- VeroYellow (yellow)

- VeroBlack (black)

- VeroWhitePlus (white)

- Vero PureWhite, a brilliant white 20% brighter than VeroWhitePlus and half as transparent

Digital Materials:

- Hundreds of composite materials can be made on the fly, including:

- Bright mixed colors of rigid and opaque material

- Translucent color shades

- Elastic materials in various Shore hardnesses

- Digital ABS materials for durability, including blends with rubber

- High temperature resistant polypropylene materials

Construction area size (maximum model size): 255 × 252 × 200 mm

T layer thickness: 16. 30 µm

30 µm

Axis resolution: X-axis: 600 dpi (42 µm) ; Y-axis: 600 dpi (42 µm) ; Z-axis: 1600 dpi (16 µm).

Accuracy: 20-85 µm for parts up to 50 mm; up to 200 µm for full-size models (only for solid materials, depending on geometric parameters, axes parameters and model orientation).

Print modes:

High Speed - speed up to 20 mm/h, layer thickness 30 µm, work with one material,

High Quality (high quality) - layer thickness 16 µm, speed up to 12 mm/h, work with one material,

Digital Material (DM) (composite material) - production of models from a mixture of 2 materials, layer thickness 30 microns.

Software

Supported file formats: STL, SLC and objDF File

Learn more and calculate the cost: +7 812 363-14-09, [email protected]

Also see 3D printing services and samples of finished products on the Stratasys F270 printer

-Printers for printing with plastic

Supplier of 3D equipment since 2010

3D@globatek. ruwhatsApp to order a call

ruwhatsApp to order a call +7 495 646-15-338 800 333-12-82

3D-scanners 3D-printer-printering services of

On company clients of the clientele-prosquitudic. 9Blog

Contacts

filters

filters

Plastic

Material

-

Plastic

28

-

Photopolymer

9000 -

Composite powder

2

-

Sand

4

Manufacturer

-

03DLAM

09 0

-

Total Z

7

-

UnionTech

0

-

Intamsys

3

-

Farsoon

0

-

Stratasys

7

-

3D Systems

0

-

BIGREP

3

-

SLM Solutions

0

-

FlashForge

1

-

STEREETECH

Price on request

Up to 6 months

Read moreTotal-Z AnyForm 500 PRO

- Technology: FDM

- Production: Russia

- Chamber: 500×500×500 C

- layer thickness: from 0.

05 mm

05 mm - Support: Soluble

Price for

to 6 months

more mmPrice for

to 6 months

Read moreTotal-Z AnyForm 950 Pro

- Technology: FDM

- Production: Russia

- Came 650×950 mm

- Extruder temperature: up to 500°C

- Heated chamber: yes

Price on request

Up to 6 months

Learn moreTotal-Z AnyForm 1200 PRO

9004 Technology0043Price for

to 6 months

moreTotal-Z ANYFORM 1000 LPRO

- Technology: FDM / FGF

- Chamber: 1200×650×1200 mm

- Extruder temperature: up to 500°C

- Heated chamber: yes

Learn more 90 Price on request

0009 Total-Z G5- Technology: FDM

- Chamber: 300×300×300 mm

- Layer thickness: 0.

05 mm

05 mm - Extruder temperature: up to 450°C

Read more

Intamsys Funmat HT

- Technology: FDM

- Camera: 260x260x260 mm

- layer thickness: 0.05 mm

- Country: China

Price on request

4-6 weeks 410

- Technology: FDM

- Camera: 305x305x406 mm

- layer thickness: 0.05 mm

- Country: China

Price on request

4-6 weeks

Intamsys Funmat 9000ht 9004 FDM

Price on request

4-6 weeks

MoreStereotech Made in RF 9000

- Technology: 5dtech

- Material: plastic

- Camera: 330x330x250 mm

- layer thickness: 0.01-0.2 mm

Price on request

4-6 weeks

Read more Stereotech 530 Fiber

- Technology: 5dtech

- Material: plastic

- Camera: 330x330x250 mm

- layer thickness: 0.

Learn more