3D printing mechanical hands

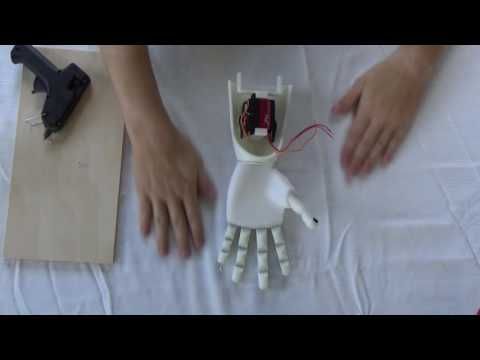

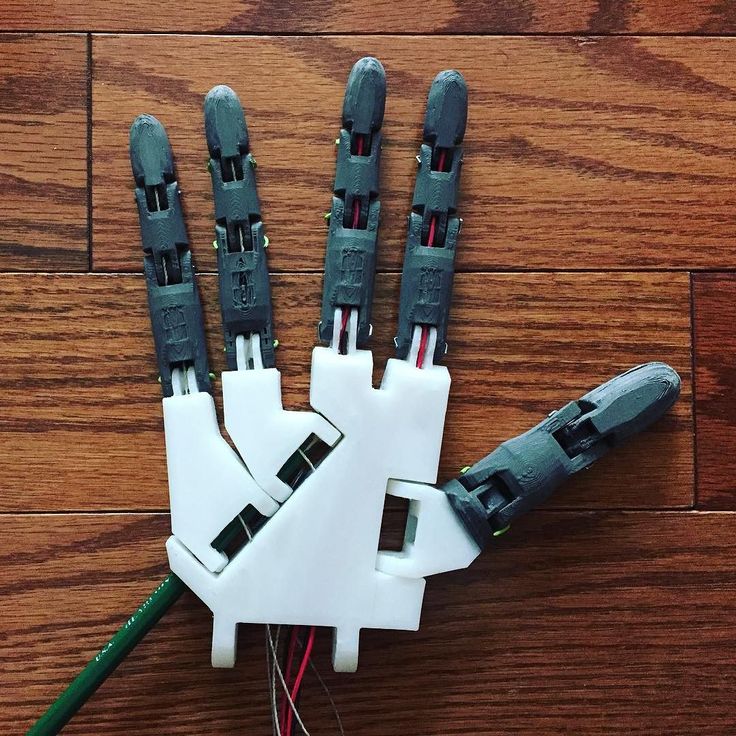

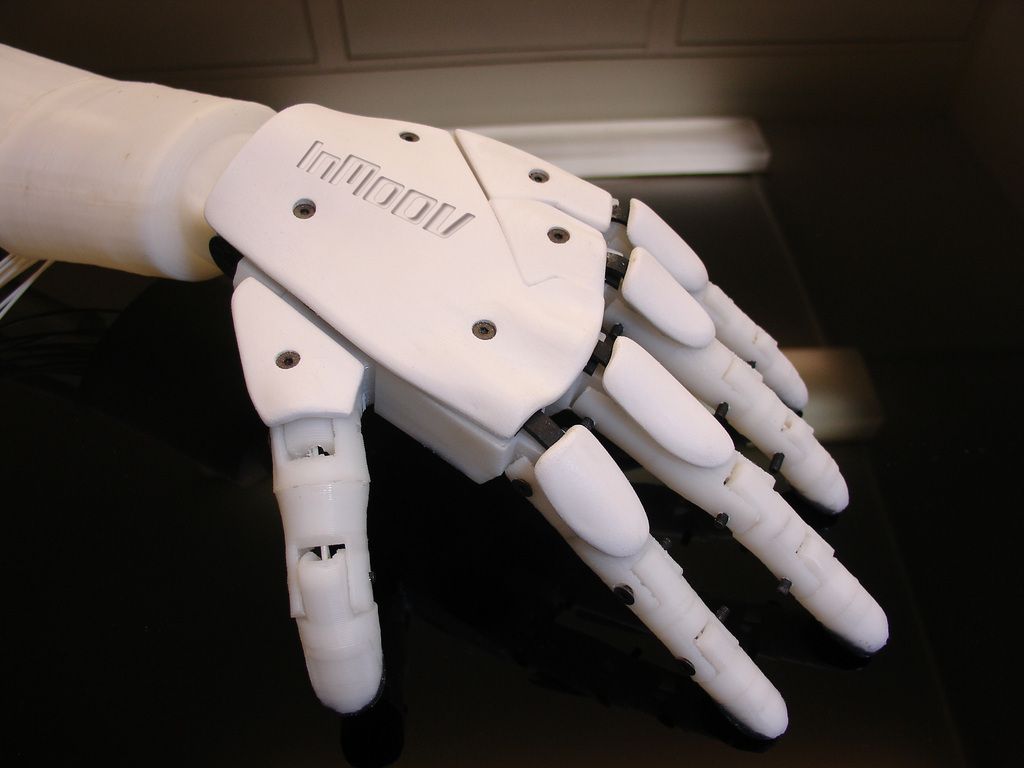

BUILD A HAND – Enabling The Future

Find the files and assembly instructions you need to build a hand!

The e-NABLE community has developed a collection of different 3D-printable assistive devices that are free for download and fabrication by anybody who would like to learn more about the designs or fabricate a device for somebody in need.

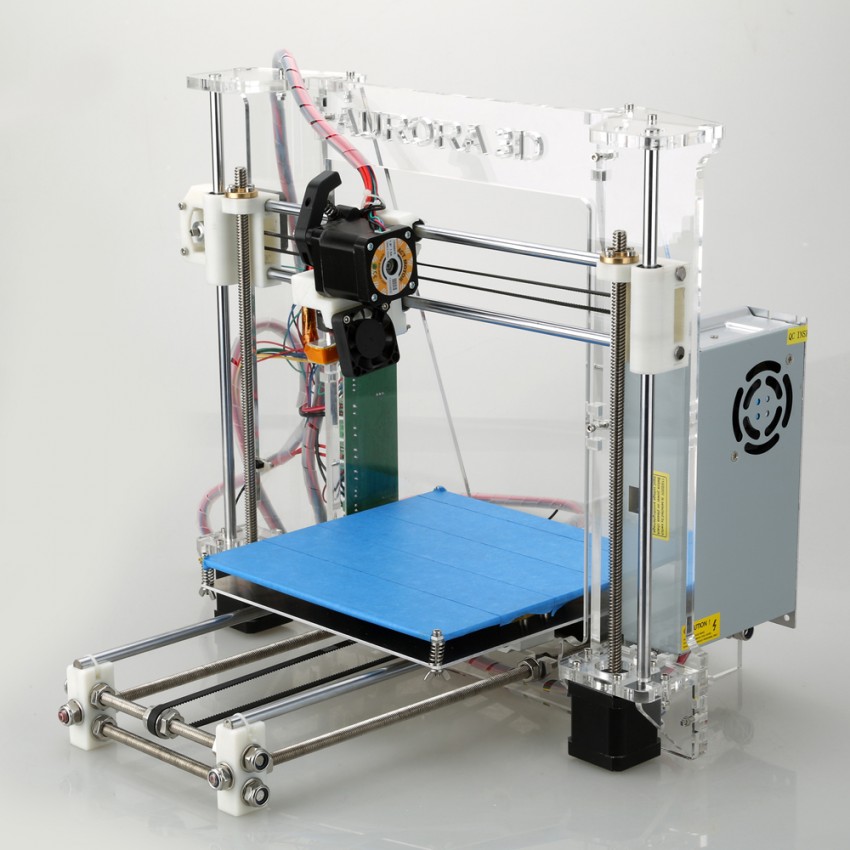

If you are interested in building your own 3D printed upper limb device and have access to a 3D printer, here is the information you will need to get started:

- Decide which kind of device is recommended for the limb different person in need.

Visit our Which Design page to see what your options are and choose from the designs that are currently available and recommended for those types of limb differences. Please note, that the e-NABLE Community does not currently have designs for above elbow limb differences, so the recipient or user must have a functional wrist or elbow to make these devices function properly. - Make sure to take photographs correctly to ensure a proper fit. Watch the tutorial video to learn how to take images that will help you get the measurements you need to create a device that will fit properly.

- Refer to the e-NABLE Device Sizing page to learn how to properly size an e-NABLE device.

- Check out our e-NABLE Devices page for tutorials, assembly kits and other helpful information!

If you have any questions along the way, feel free to ask our volunteers by posting a message in the forum.

If you would like to make your own device but do not have access to a 3D printer, check our our e-NABLE Chapters page, which includes a searchable map of e-NABLE Chapters. This map includes many libraries and makerspaces that may have 3D printers available for public use. You can also check this Google Map for libraries with 3D printers available.

Please note: It is very important that you work with your physician, occupational therapist, physical therapist or prosthetist when using a 3D printed open-source e-NABLE device.

ACCEPTANCE

By accepting any design, plan, component or assembly related to the so called “e-NABLE Hand” , I understand and agree that any such information or material furnished by any individual associated with the design team is furnished as is without representation or warranties of any kind, express or implied, and is intended to be a gift for the sole purpose of evaluating various design iterations, ideas and modifications. I understand that such improvements are intended to benefit individuals having specific disabilities and are not intended, and shall not be used, for commercial use. I further understand and agree that any individual associated with e-NABLE organization shall not be liable for any injuries or damages resulting from the use of any of the materials related to the e-NABLE hand.

Like this:

Like Loading...

South Africa's 3D Printed Mechanical 'Tenim Hand' Allows for Individual Finger Control - 3DPrint.com

Let’s be real: I love 3D printed fun things as much as the next person–I have two 3D printed dragons on my desk as I write–but the best part of my workday here at 3DPrint. com is reading and writing about the ways this incredible technology is being used to help people the world over. Medical advances using 3D technology are making huge strides forward, and it’s no exaggeration to say the tech is truly taking the world by storm.

com is reading and writing about the ways this incredible technology is being used to help people the world over. Medical advances using 3D technology are making huge strides forward, and it’s no exaggeration to say the tech is truly taking the world by storm.

We may be most familiar, when it comes to 3D printed prostheses, with organizations like e-NABLE here in the US, but similar contributions toward reliable, realistically shaped, functional prosthetic devices are being designed and produced the world over. I’m in Cleveland, Ohio; one of the farthest places in the world from me is Cape Town, South Africa (noted especially since I couldn’t attend my sister’s wedding there six months ago–it’s far). And that is exactly where another impressive design for a 3D printed prosthetic hand has been patented.

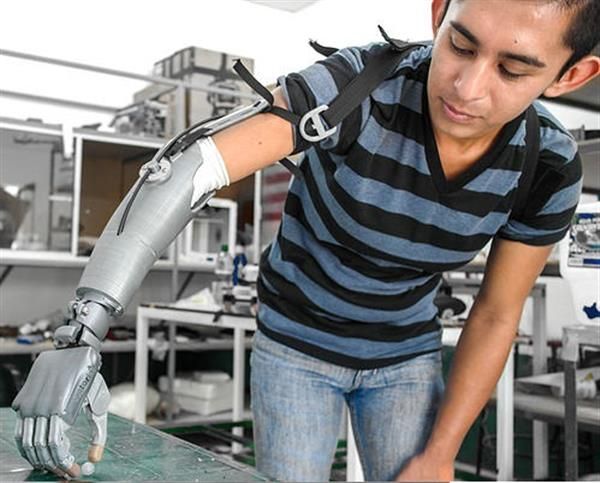

A duo from the University of Cape Town (UCT), working in conjunction with the Centre for Rapid Prototyping and Manufacturing at the Central University of Technology (CUT) in Bloemfontein, has made waves lately through the development of a mechanically operated prosthetic that has already proven to be award-winning and impressively affordable.

“I wanted to address amputees in the low-income bracket; to create a hand that doesn’t cost a fortune, but that works similarly to a real hand,” said Dr. George Vicatos. “Because the alternative for this income group is a hook, or a non–functional hand.”

Dr Vicatos (center) and Tenim (right) receiving their Cutting Edge award October 10, Popular Mechanics FutureTech 2014 event

Dr. George Vicatos was Popular Mechanics‘ South African Inventor of the Year in 2011. This past October, Dr. Vicatos and his MSc student Severin Tenim were presented with the Cutting Edge award for the design and development of their new low-cost prosthetic hand–the Tenim Hand–at the Popular Mechanics FutureTech event, held in Cape Town.

“Because locally designed and produced products cost far less than imported equivalents and are delivered faster to the surgeons and hence to the patients, the lower cost is passed on directly to the patient.

They’re also more affordable to medical aids,” said Dr. Vicatos of the Tenim Hand.

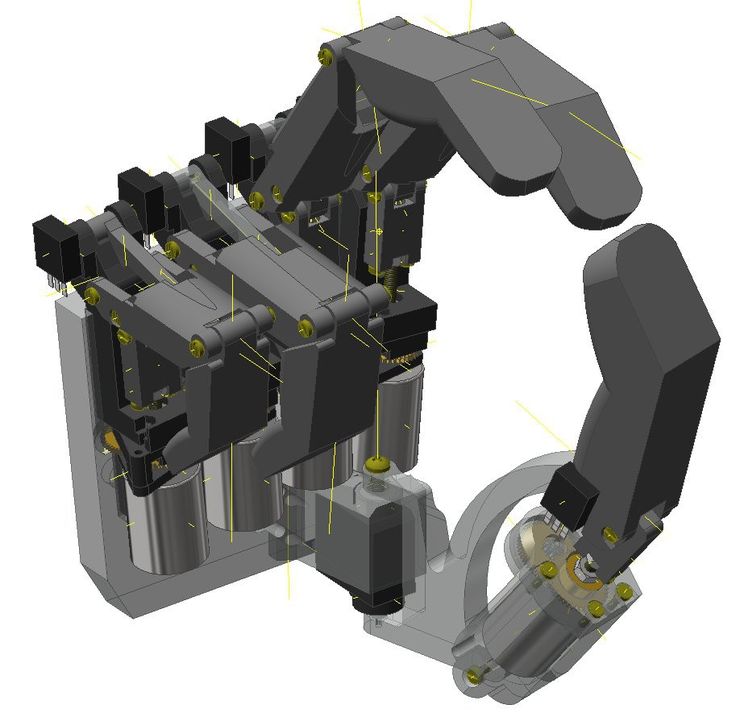

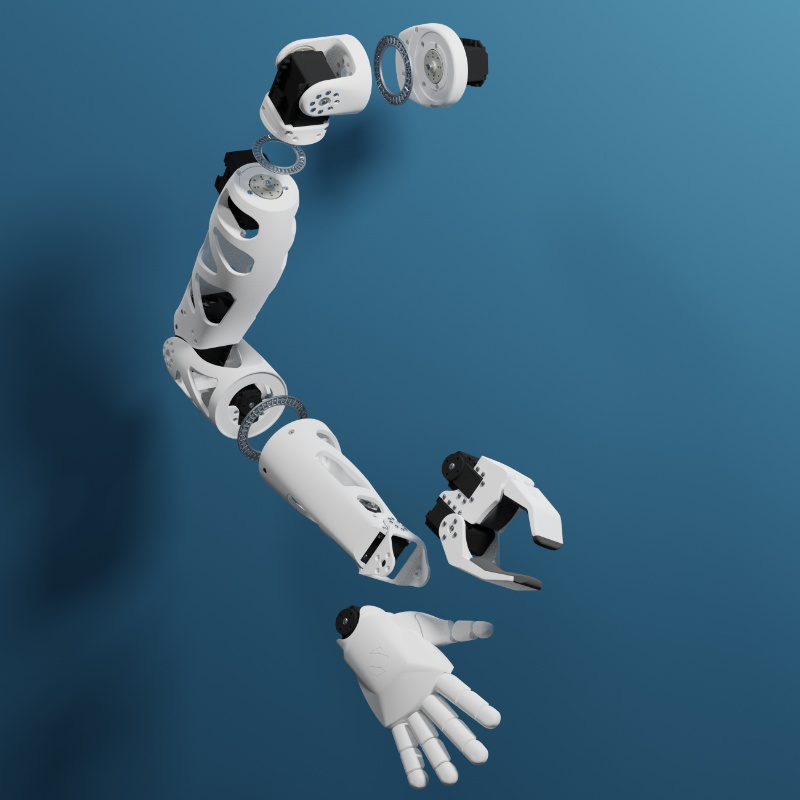

Dr. Vicatos and Tenim designed the hand to be accessible to the medical community and the patients it serves. Designed for either right- or left-upper limb amputees, the hand is a “mechanical prosthetic” that utilizes a metal cord to control the fingers and thumb’s grip and release functionality. It is able to be positioned open or partially or fully closed. A provisional patent was filed in July 2014 in the UK.

“The hand has a metal cord at the wrist that is either released or pulled in a direction parallel to the fingers. By pulling the cord, the fingers will grip until the hand is closed. The cord works together with a knob, adjacent to the fifth metacarpal (little finger). When the knob is manually rotated or pushed the fingers become locked in position. The thumb is attached by a swivel to rotate and move either towards or away from the fingers,” reads the hand’s technical description.

The cords are attached to a harness, worn across the back, with the shoulder’s movements controlling the pull function. Each individual finger is able to be moved separately from the others, rather than closing or opening the entire hand at once. “There is no other mechanically operated device that is as close to the anatomical function of the hand as this,” said Dr. Vicatos.

Once the design was set, Dr. Vicatos and Tenim sent the files to UCT for 3D printing, then assembled it upon receipt back at UCT.

As UCT project engineer Johan Els explained the build process, 3D printing was utilized to create a “sacrificial part” from polystyrene, which was then covered with a ceramic slurry. The polystyrene was melted out, leaving the ceramic part as a mold in which to pour nylon.

The hand design is not yet finalized, but is clearly on its way to becoming part of the options available to South African amputees.

“The younger generation doesn’t want the ‘glove’ look, or a hand that’s trying to look real when it’s fake,” says Dr.

Vicatos. “They want to enhance the fact that they have something artificial – and the mechanics inside this are quite beautiful, so there will be an option to have a transparent window that shows them off.”

What do you think of the Tenim Hand? Does this design stand out to you compared to other prosthetic designs? Let us know your thoughts in the Tenim Prosthetic Hand forum thread over at 3DPB.com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printed hand • 3d printed prosthetic hands • Centre for Rapid Prototyping and Manufacturing at the Central University of Technology • FutureTech • Popular Mechanics • prostheses • prosthetic hand • prosthetic hands • south africa • Tenim Hand • University of Cape Town

Please enable JavaScript to view the comments powered by Disqus.

3D printed soft mechanical hand responds to human handshake (+ video)

3D technologies

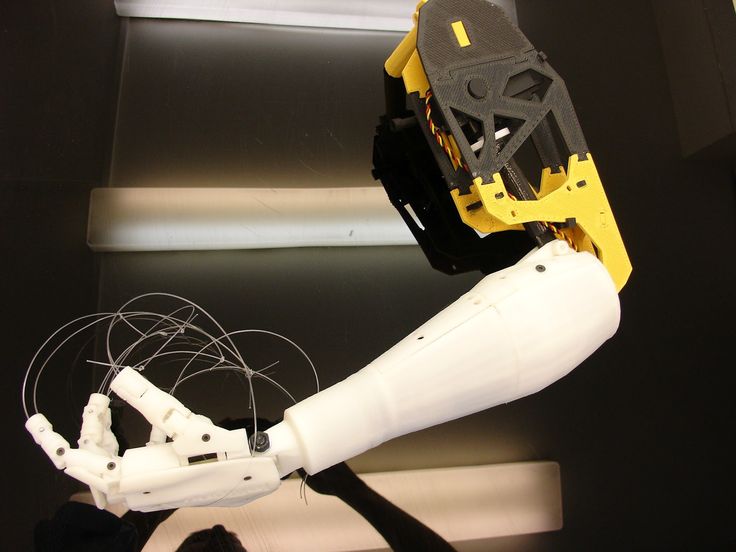

Delft University of Technology graduate Rob Scharf has created a soft mechanical arm designed to interact with humans as a research project on "soft robots". The hand he created is made of soft, semi-flexible material and is able to shake people's hands in response to squeezing.

“Robots are popping up in every area of our lives, so it's becoming extremely interesting and important to look at robotics from a design perspective. Most robots in existence today are relatively rigid machines that move in unnatural ways. Through the use of soft materials, it is possible to make robots that will show a different perspective of human interaction,” explains Scharf.

The mechanical arm works by a complex system of small air chambers built into the palm. When someone takes a hand and squeezes it, the cameras fire like bellows, and the movement of air causes the robot to shake the person's hand in response as tightly as the force applied. For example, if someone shakes hands tightly, the robot will squeeze the human hand with the same force. In turn, in response to a less firm handshake, the robot will also make less effort.

For example, if someone shakes hands tightly, the robot will squeeze the human hand with the same force. In turn, in response to a less firm handshake, the robot will also make less effort.

In developing the mechanical arm, Scharf observed natural biological systems, including the complex musculature of humans and the structure of an elephant's trunk. Typical animal musculature works when two opposing groups of muscles stretch against each other, becoming rigid and controlling a limb, organ or skeleton, setting them in motion. However, the design of the mechanical arm uses chambers of air instead of muscles – they become harder under the influence of applied force. The wrist can rotate, which makes the handshake more natural and interactive. In addition, pneumatic systems are located in the fingers of the device, which allow you to control each finger individually.

“The handshake is used as a metaphor to show how technology can be used to improve human-robot interaction. This development can be used, for example, in orthopedics, the creation of prostheses, robotic nurses and mechanisms that are used in research and industrial purposes,” comments Scharf. The developer also posted a video showing the mechanical arm in action.

This development can be used, for example, in orthopedics, the creation of prostheses, robotic nurses and mechanisms that are used in research and industrial purposes,” comments Scharf. The developer also posted a video showing the mechanical arm in action.

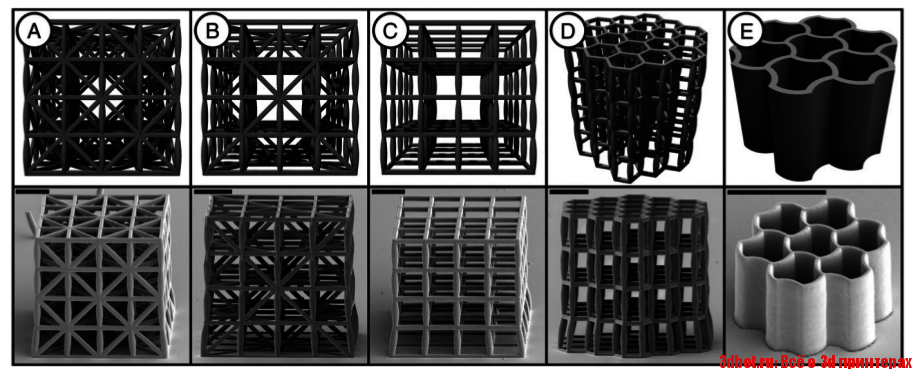

In order to print the complex internal structure of the robot as a whole, Scharf used SLS, selective laser sintering technology. When fused, the powdered material becomes flexible and resembles polyurethane in its properties. Scharf's soft robot was showcased as part of Mind The Step at Design Week 2015 in the Netherlands in October, where visitors were given the opportunity to experience the robot in person.

The development is still largely a prototype, but Scharf has already begun building the first full-fledged product using this technology. These are custom-made, 3D-printed gloves that will allow stroke patients to learn how to hold objects again. Undoubtedly, the development can be applied to the creation of other products, such as prostheses and bionic limbs. Perhaps in the future, such soft robots will help in examining patients or caring for paralyzed and people with limited mobility.

Undoubtedly, the development can be applied to the creation of other products, such as prostheses and bionic limbs. Perhaps in the future, such soft robots will help in examining patients or caring for paralyzed and people with limited mobility.

Tags: 3D Printer, 3D Technology, Soft Robots

Cyberpunk Giant Mechanical Arms 3D File・Template to Download and 3D Print・Cults

Attack on Titan 3DMG ODM Gear + Swords (3D BUNDLE)

45.16 €

Sandevistan 3D model STL (for 3D printing)

17.12 €

Attack on Titan 3DMG Functional Titan Swords

26.98 €

Halo inspired ODST Helmet - (3D MODEL - STL)

34.18 €

Universal Cosplay Hand Armor Gauntlet

13.35 €

Halo Infinite inspired Sniper Rifle Toy - (3D MODEL - STL)

22.83 €

Halo inspired MK IV helmet - (3D MODEL - STL)

22. 51 €

51 €

Halo 3 Inspired Security Helmet (3D MODEL - STL)

20.55 €

Best 3D Printer Files in the Gadget Category

Spiral capsule

2.03 €

Printed Twist Targets

Free

KAMAZ-63968 Typhoon-K MRAP

14 €

DIY Arduino Lamp

Free

TOOTHBRUSH AUTOMATIC HOLDER

2,39 €

Free Hugs

0.83 €

Modular desk organizer

2.50 €

Mini Quadcopter fpv Racer 120mm micro FC lumenier racing F4 Brushless 1103 10.000kv 2S

Free

Bestsellers in the Gadget category

Zhiromat

3.04 €

Double Text Illusion App

3. 68 €

68 €

Karambit keychain spinner tiktok keyrambit NO BEARING

€1.73 -fifteen% 1.47 €

Fantastic business card application

3.68 €

Keychain "Fussy Cauldron" - Halloween

1.89 €

Case for PIXEL 7 (two designs)

0.94 €

Working steam engine, printed on site, fully assembled, no supports

3.34 €

AR-15 LOWER MULTI-CAL. REINFORCED CONSTRUCTION

8,50 €

Dice box with mechanical rotating top

4 €

Gato fantasma / creepy cat

3.30 €

WALL KEY HOLDER - EYE (FULL COLLECTION)

1.88 €

Halloween Pumpkin Keychain

1.